Abstract

In this study, a new sample preparation strategy termed ultrasonic-assisted dispersive magnetic ionic liquid/magnetic solid wire microextraction (UA-DMIL/MSW-ME) has been developed for simultaneous determination of fifteen nitrotoluene compounds (NTCs) in the soil and water samples. The extraction was performed by dispersing a magnetic ionic liquid (MIL) into the sample solution using ultrasonic irradiation. After completing the extraction, by stopping the sonication, a neodymium wire (NW) was placed inside the sample solution allowing the MIL containing the pre-concentrated analytes to cover the surface of NW with a thin layer due to the magnetic forces. Afterward, the MIL-coated NW was subjected to a homemade syringe and directly injected into a gas chromatography–mass spectrometry (GC–MS) instrument for thermal desorption of analytes; then, quantitative measurements were taken. The central composite design was applied to explore some parameters influencing the extraction efficiency. Ultimately, under the optimized conditions, the proposed method was successfully implemented to analyze NTCs in the real samples (coastal and forestal soils, river water, and industrial wastewater) and acceptable results were obtained. The resultant calibration curves were linear over the concentration range of 0.07–80 μg/L (R2 > 0.993). The estimated limits of detection and quantification were lower than 0.07 μg/L, and the enrichment factors were between 3538 and 3817. The wire-to-wire and single-wire reproducibility values were found to be lower than 5.8% (n = 6). The intra- and inter-day repeatability varied below 5.5% (n = 6), and the relative recoveries were calculated between 91–110 and 89–108% for soil and water samples, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrotoluene compounds (NTCs) include a group of highly toxic ecological contaminants that are capable of persisting in environment (Ebrahimzadeh et al. 2009; Mohsen et al. 2014). This group of compounds is classified among the explosive materials that enter the environment via activities of military facilities and ammunition factories. Moreover, these compounds are used in several industrial and chemical manufacturing applications (Ebrahimzadeh et al. 2007). Therefore, the probability of NTCs migrating into aqueous systems has been increased by the discharging industrial wastewater into rivers and ground waters, and the dumping of ammunition in marine supplies (Costa dos Reis et al. 2017; Lordel-Madeleine et al. 2013). Nitrotoluenes are very important in both environmental and forensic science (Cortada et al. 2011; Gaurav et al. 2009). Hence, pre-concentration and determination of slight amounts of these compounds are significant from two aspects: First, the development of detection systems and measurement of explosives to prevent illegal activities and, second, reduction in the concerns about human health risk through elimination of these compounds from the living environment and aqueous systems (Fernández et al. 2014; Roushani and Shahdost-fard 2018; Şener et al. 2017).

Sample preparation has probably been the focus of researches during many years in the environmental analytical chemistry area because analytical apparatuses cannot deal with complex samples directly (Safavi et al. 2018). Therefore, developing rapid, highly sensitive, simple, low-cost, and green sample pre-treatment methods has been favored in analytical chemistry. The objective of this step is to refine and concentrate desired analytes from intricate matrices (Shahraki et al. 2018). Yet, customary techniques such as liquid–liquid extraction (LLE) and solid-phase extraction (SPE) might have involved some drawbacks (Es’haghi et al. 2011; Sarafraz-Yazdi and Amiri 2010). In the previous decades, researchers have tried to develop novel miniaturized and economical sample preparation methods (Es’haghi et al. 2010; Farrokhzadeh and Razmi 2018; Guerra et al. 2017). Among microextraction methods presently developed, magnetic-based approaches (Nazari et al. 2016; Yamini and Safari 2018) have been favored because of the magnetic features of the extractant that let their easy and quick recovery through an external magnetic field (Lu et al. 2018). In recent years, the development of magnetic ionic liquids (MILs) paved the way for a new wave of researches to create innovative devices and develop products and analytical processes (Clark et al. 2016; Fernández et al. 2018; Trujillo-Rodríguez et al. 2016; Zhang et al. 2015). These products integrate the general features of ionic liquids (ILs) with magnetic features linked to the incorporation of a paramagnetic component in the cation or anion of the IL structure (Del Sesto et al. 2008; Krieger et al. 2010), such as a strong response to the magnet (Santos et al. 2014a). Besides, MILs have some of exclusive physicochemical features of ILs, such as low vapor pressure at room temperature, ecologically friendly behavior, and impressive solvation capabilities for both polar and nonpolar compounds (Sintra et al. 2017; Zhang et al. 2015). Lately, (Benedé et al. 2018; Chisvert et al. 2017) developed a hybrid microextraction method using a MIL as the extractant. The procedure is based on the dispersion of a paramagnetic extractant (a MIL in this particular case) in the sample solution by a neodymium-core magnetic stir bar at high stirring rates during extraction process and subsequent analysis of magnetically retrieved extractant on the surface of stir bar using thermo-desorption system joined to a GC–MS instrument. In this study, a thin neodymium wire (NW) was replaced with the neodymium core and ultrasonic agitation was used instead of magnetic stirring. Hence, by applying a simple homemade syringe and a reproducible fragment of the neodymium string (as a separate magnetic needle), the procedure was further miniaturized and its carryover effects were completely eliminated. Moreover, the thermo-desorption system was totally removed using a smart strategy based on the invention of an efficient device. After extraction, the NW was withdrawn by a plastic forceps and put into the needle of a homemade syringe and then inserted into the GC–MS injector for desorption and analysis. The key originality of this work is to develop an effective analytical technique for trace determination of fifteen NTCs in the real soil and water samples by applying a smart strategy based on a homemade device. A multivariate investigation with a minimum number of trials was employed for optimizing and evaluating the effect of each variable factor, as well as their interactions, on the relative peak area of target analytes to that of the internal standard (I.S) using the central composite design (CCD).

Experimental

Chemicals and standard solutions

Target analytes including 2-nitrotoluene (2-NT), 3-nitrotoluene (3-NT), 4-nitrotoluene (4-NT), 2,6-dinitrotoluene (2,6-DNT), 2,4-dinitrotoluene (2,4-DNT), 3,5-dinitrotoluene (3,5-DNT), 2,5-dinitrotoluene (2,5-DNT), 2,3-dinitrotoluene (2,3-DNT), 3,4-dinitrotoluene (3,4-DNT), 2,4,6-trinitrotoluene (2,4,6-TNT), 2,4,5-trinitrotoluene (2,4,5-TNT) and 3,4,5-trinitrotoluene (3,4,5-TNT), 2,3,4-trinitrotoluene (2,3,4-TNT), 2,3,5-trinitrotoluene (2,3,5-TNT), 2,3,6-trinitrotoluene (2,3,6-TNT), and nitrobenzene (NB) as I.S were kindly donated by Zarrin Shahr ammunition industries (Esfahan, Iran) and used as standards. Table S1 in “Electronic Supplementary Material” shows the chemical structure and relevant information of target analytes. Ultra-pure deionized water was used in all experiments for preparation of aqueous solutions and was obtained from Ghazi Company (Tabriz, Iran).

To synthesize trihexyl(tetradecyl)phosphonium tretrachlorocobalt ([P6,6,6,14]+2[CoCl4]2−), trihexyl(tetradecyl)phosphonium tretrachloroferrate ([P6,6,6,14]+[FeCl4]−), trihexyl(tetradecyl)phosphonium tretrachloromanganese ([P6,6,6,14]+2[MnCl4]2−) and trihexyl(tetradecyl) phosphonium hexachlorogadolinium ([P6,6,6,14]+3[GdCl6]3−) MILs, the reagents trihexyl(tetradecyl)phosphonium chloride, cobalt (II) chloride, iron (III) chloride, manganese (II) chloride, and gadolinium (III) chloride hexahydrate were purchased from Sigma-Aldrich (Louis, USA) and used with no refinement. All other reagents and solvents were analytical grade and obtained from Merck (Darmstadt, Germany) and, unless otherwise stated, they were applied with no extra drying or purification.

The stock standard solution of desired NTCs was prepared in the mixture of methanol and acetonitrile (1:1) at a concentration of 1000 mg/L. Working solutions were prepared by proper dilution of the stock solution in deionized water and kept in the dark at 4°C.

Instrumentation

All analyses were carried out on an Agilent 7890 N gas chromatograph coupled to a 5975C single quadrupole inert mass selective detector (Agilent Technologies, California, USA). The separation of extracted compounds was carried out on an HP-5 MS capillary column (30 m × 0.25 mm i.d., and 0.25 μm film thickness) containing 5% phenyl-methylpolysiloxane phase (Agilent Technologies, California, USA). Helium (99.999%, Allentown, Pennsylvania, USA) was employed as carrier gas at a constant flow rate of 2 mL/min (with the overall output pressure of 50 psi), and it was further purified by passing through a gas purifier (Hewlett Packard, California, USA) containing a molecular sieve (with pore diameter of 5 angstrom) and an oxygen-adsorbing gas purifier. The column oven was initially held at 80°C for 1 min, and the temperature was then increased to 230°C at a rate of 15°C/min and held for 4 min (total run time of 15 min for one analysis). The injection port was electronically adjusted to 200°C and operated in splitless mode with the purge flow closed for 5 min by applying a commercial liner packed with ultra-inert glass wool. The MS conditions were operated as follows: ion source temperature 230°C; transfer line (auxiliary) temperature 230°C; MS analyzer (quadrupole) temperature 150°C; electron multiplier automatically adjusted at − 1100 V; the MS was operated in electron impact ionization mode at 70 eV energy. To achieve the highest possible sensitivity, the analytes’ quantification was performed at the selected ion monitoring (SIM) acquisition mode. The MS system was regularly adjusted in SIM mode, and each NTC was quantified based on relative peak area by applying one target and six qualifier ions. The ions were chosen considering abundance compared to the risk of matrix interferences, and the SIM dwell time was 100 ms. Complete SIM parameters (characteristic and quantitative ions) and retention times for all NTCs are listed in Table S1. Agilent Chemstation (E.02) software was used for instrumental operations, chromatographic data acquisition, and peak integration processing under the Windows 7 operating system (Microsoft).

An ultrasonic processor (UP50H, 50 W, 30 kHz) with a titanium cylindrical sonotrode (7 mm o.d.; 80 mm length) from Dr. Hielscher (Teltow, Germany) was applied as the sonic probe for the sonication of sample solutions for avoiding that MIL remains in the vial inhibiting dispersion.

The NW (0.45 mm diameter × 2 cm length) from Azar-Electrode (Urmia, West Azerbaijan, Iran) was used as magnetic retriever of MIL.

A homemade syringe (GC injection device) with a magnetic hollow tip (as a fiber holder, 0.75 mm o.d.) was made in cooperation with Azar-Electrode (see Fig. S1 in the supplementary file).

Synthesis of MILs

[P6,6,6,14]+2[CoCl4]2−, [P6,6,6,14]+[FeCl4]−, [P6,6,6,14]+2[MnCl4]2− and [P6,6,6,14]+3[GdCl6]3− MILs were prepared according to the previous technique (Del Sesto et al. 2008; Santos et al. 2014b). In brief, cobalt (II) chloride (11.45 g, 0.5 equiv.), iron (III) chloride (26.02 g, 1 equiv.), manganese (II) chloride (26.02 g, 0.5 equiv.), and gadolinium (III) chloride hexahydrate (11.92 g, 0.3 equiv.) were added to a solution of [P6,6,6,14] (50 g, 0.096 mol) in dichloromethane and stirring was applied to the solution at room temperature for 24 h. Subsequently, two layers were formed, and the aqueous phase was discarded. The organic phase was dehydrated over MgSO4 and filtered. Stirring was applied to MIL under vacuum (< 1 mmHg) at 60°C overnight to remove the solvent. Ultimately, [P6,6,6,14]+2[CoCl4]2−, [P6,6,6,14]+[FeCl4]−, [P6,6,6,14]+2[MnCl4]2−, and [P6,6,6,14]+3[GdCl6]3− were obtained as blue, brown, green, and colorless viscous oils, in the respective order.

Sample preparation

River and industrial wastewater samples

The industrial wastewater sample was taken from a canal stream carrying water discharged from the neighboring factories mostly pesticides and polymer industries in Shiraz Industrial Park (Fars, Iran), and river water sample was taken from the Sepidrood River (Gilan Province, Iran) in September 2018. Both samples were collected and transported to laboratory using Pyrex brown glass containers.

Since industrial wastewaters contain high concentration of dispersed solids, the samples were preliminarily filtered with a 0.2-μm membrane filter (Chromafil® syringe filters, Xtra CA-20/25) from Macherey–Nagel (Düren, Germany). River water samples were put directly to analysis without any purification or dilution. Both samples were spiked at the suitable concentration and kept in the dark at 4°C until study.

Forestal and coastal soil samples

Coastal soil samples were collected from the Caspian Sea at local seashore near Rudsar beach (Gilan Province, Iran), and forestal soil samples were collected from the Golestan Forest (Golestan Province, Iran). Both samples were taken between 0 and 50 cm deep on the ground in different areas (5 kg of each sample).

Prior to application, soils were homogenized, sieved (1-mm mesh), and air-dried at room temperature. 1 g of soil was weighed in a 15-mL falcon test tube and spiked at the favorite concentration. After adding a portion of 10 mL MeOH and ACN (1:1) to the intended test tube, handshaking was applied to the sample vigorously for 2 min. Then, the leaching process was assisted by an ultrasonic bath with a frequency of 40 kHz (SONICA 2200 S3, Milano, Italy) for 1 h. Afterward, 21 ml deionized water was applied to dilute the sonicated sample, which was filtered through a 0.20-μm Chromafil® Xtra CA-20/25 filter. Ultimately, the samples were taken in brown flasks and kept in the dark at 4°C until study.

The extraction of non-spiked samples was also carried out in parallel to examine the presence of analytes in the blank samples.

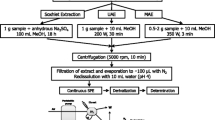

Extraction procedure

The ionic strength of deionized water or previously prepared real samples (see section Sample preparation) spiked with NTCs (50 μg/L for water samples and 50 ng/g for soil samples) and I.S (100 μg/L for water samples and 100 ng/g for soil samples) was adjusted to an appropriate amount (NaCl, 2.4% (w/v)). A 31-mL aliquot of aforementioned solution was introduced in a 50-mL glass vial. Then, 8 μL of [P6,6,6,14]+3[GdCl6]3− MIL was added to the sample and the solution was sonicated inside a water bath (with a temperature of 29°C) for 1 min. Consequently, after inserting the titanium cylindrical sonotrode directly into the solution, the mixture was thoroughly homogenized to form a cloudy state. Once the extraction was finished, the ultrasonic processor was stopped, and then, a 2-cm NW (0.45 mm diameter) was placed inside the vial. Subsequently, [P6,6,6,14]+3[GdCl6]3− (7 ± 1 μL) containing target analytes was collected onto the surface of NW due to its magnetic capability. Then, a plastic forceps was applied to remove [P6,6,6,14]+3[GdCl6]3−-coated NW, which was put into the homemade syringe for performing GC–MS analysis (Fig. 1).

Schematic image of the UA-DMIL/MSW-ME procedure extraction procedure by dispersion of [P6,6,6,14]+3[GdCl6]3− MIL in the sample solution using the ultrasonic irradiation (a); magnetic retrieval of [P6,6,6,14]+3[GdCl6]3− MIL containing target NTCs by Introducing a NW into the sample solution (top view) (b); installation of MIL-coated NW on the syringe tip using a plastic forceps (c) assembled syringe and close image of NW along with oily droplets of MIL on its surface (d); protecting the MIL-coated NW by pulling it into the casing hollow needle using plunger (e); injecting the syringe into a GC–MS analysis system. The numbers (1–6) indicate the order of steps in the proposed method

Data handling and statistical processing

Chemometrics methodology based on experimental design enables simultaneous investigation of the variable experimental factors, reducing analysis time and materials consumption. This tactic is more efficient than customary optimization method based on the variation in one factor at a time (Fernández et al. 2016). To optimize the parameters affecting the new procedure termed ultrasonic-assisted dispersive magnetic ionic liquid/magnetic solid wire microextraction (UA-DMIL/MSW-ME), response surface methodology (RSM) was employed using Stat-Ease Design-Expert (trial version 7.0.0) software (Stat-Ease Inc., Minneapolis, Minnesota, USA). The most common design in RSM is CCD, which is used to fit the results with quadratic (second-order) polynomial models. This statistical optimization strategy was first proposed by Box and Wilson and combines two-level full or fractional factorial points, axial points, and one or more central points at the center of the experimental domain which have been replicated to calculate an accurate and independent estimation of the pure experimental error (Ranjbari and Hadjmohammadi 2015). In this study, the CCD was selected as the most appropriate experimental design, because this tactic is very powerful to explain the second-order interactions. In other words, the CCD can introduce five levels of variations for one factor by applying the axial points which are situated at the certain distances from the center of the experimental region. Hence, the parameters are capable of fitting to a quadratic equation (to investigate the linear effects of parameters along with the interactions between parameters) through the proper determination of axial and central points by considering the rotatability and orthogonality of the design.

Results and discussion

Generally, it is difficult to determine the NTCs in real samples directly because of their low concentrations and coexisting interferences (Babaee and Beiraghi 2010; Lordel et al. 2010). Thus, a refinement and/or pre-concentration process is needed before analysis. Herein, the new UA-DMIL/MSW-ME technique was developed for the extraction and pre-concentration of fifteen NTCs from natural soil and water samples. To achieve the optimum conditions, types of MIL (non-numerical factor) were primarily studied using traditional (one variable at a time) methodology. Moreover, the desorption parameters of GC (desorption time and temperature) were individually studied to evaluate the chromatographic responses of each NTC.

Preliminary experiments

The results of preliminary experiments revealed that the pH of sample solution did not affect the extraction efficiency significantly (see Fig. S2) since the NTCs are not all ionizable compounds in aqueous solution (Guan et al. 2007). Therefore, the extraction was carried out in neutral solution.

Based on the preliminary tests, it was found that the maximum amount of MIL which can be attached onto the surface of the NW is about 14 ± 2 μL due to its limited surface area. Hence, the MIL volume above 14 μL was not examined. Larger wires were not used in order to not outstrip the dimension limitations of the homemade syringe and GC inlet. Besides, the similar supplementary experiments indicated that in the absence of MIL, the NW has no adsorption performance for target NTCs which are hydrophobic compounds.

Selection of the MIL type

The first step in the optimization procedure was choosing a suitable MIL as the extractant. The physicochemical properties of MIL control the emulsion conditions and consequently the extraction efficiency. The primary necessities of an adequate MIL for the extraction technique are water immiscibility, high extraction ability of target compounds, and desirable capability to form a stable two-phase system in the presence of an intense agitation when it is introduced to an aqueous solution. In addition, it must be relatively nonvolatile to prevent potential solvent loss during extraction (Yang et al. 2016). Most importantly, it should be magnetic enough to be retrieved by a magnet (Benedé et al. 2018). In addition, the MIL ought to have some essential conditions, such as low level of toxicity and having no interferences with the peaks of analytes during direct injection into the chromatographic system (Chisvert et al. 2017; Clark et al. 2016). The injection port of GC works mostly at high temperatures; hence, the MIL should have high boiling point and thermal stability. Thus, by considering these factors, four MILs with different magnetic susceptibilities including [P6,6,6,14]+2[CoCl4]2−, [P6,6,6,14]+[FeCl4]−, [P6,6,6,14]+2[MnCl4]2−, and [P6,6,6,14]+3[GdCl6]3− were investigated for the extraction of target NTCs. As shown in Fig. 2, the relative peak area of NTCs indicates that [P6,6,6,14]+3[GdCl6]3− achieved the best extraction efficiencies, and it had no interferences with target peaks in the obtained chromatograms. Moreover, MILs are capable of electrostatic forces (through dipole–dipole interactions with nitro groups of NTCs) (Mattarozzi et al. 2011) and van der Waals interactions with NTCs (Zarei et al. 2018) concurrently. Besides, functionalizing MILs with long aliphatic chains for imparting hydrophobic character paves the way for their usage in aqueous systems for effective extraction and pre-concentration of lipophilic organics (Deng et al. 2011). Furthermore, when combining the [P6,6,6,14]+ cation with anions comprising different metal components (in this case, Co (II), Fe(III), Gd(III) and Mn(II)), MILs with a wide range of magnetic susceptibilities were generated (Del Sesto et al. 2008). Those products that contain Fe(III) and Mn(II) had similar magnetic susceptibilities (4.29 and 4.23 emu K/mol, respectively), while Co (II)-based MIL showed lower susceptibility values (2.10 emu K/mol). Noticeably, higher magnetic susceptibilities were observed for [P6,6,6,14]+3[GdCl6]3− (6.51 emu K/mol), which is the expected outcome of trivalent-ion lanthanide metal in comparison with transition metals. The incorporation of Gd ion into MIL offers the advantage of a metal ion that has a significantly greater effective magnetic moment (μeff) than any known transition metal (Clark et al. 2016; Mallick et al. 2008). So, in the case of [P6,6,6,14]+3[GdCl6]3−, the retrieval of MIL containing extracted NTCs from sample solution onto the surface of NW is more efficient than three other MILs. Therefore, [P6,6,6,14]+3[GdCl6]3− was selected as the most appropriate MIL for the subsequent studies.

Effect of the MIL type on the relative peak area of target NTCs after UA-DMIL/MSW-ME. Extraction conditions sample solution, 30 mL deionized water spiked with 50 μg/L of each NTC and 100 μg/L of I.S; extraction temperature, 25°C; the volume of extractant (four kinds of MIL), 10 μL; extraction time, 4 min; without salt addition and pH adjustment. Desorption conditions 200°C for 5 min. The error bars indicate the standard deviation of the mean relative peak area correspond to three replicate experiments

Optimization of the desorption parameters in GC injector

The influence of desorption temperature was explored in the range from 180 to 230°C for 5 min. Higher temperatures were not examined to prevent [P6,6,6,14]+3[GdCl6]3− MIL from going into the GC apparatus and damaging the column because of the restricted thermal stability of this MIL (Del Sesto et al. 2005). The analytical response (relative peak area) was significantly enhanced for all target NTCs as desorption temperature raised up to 200°C, and it was reduced as the desorption temperature elevated from 200 to 230°C (see Fig. S3). The likely reason for these findings is that NTCs are not by nature thermally stable and could be decomposed during desorption process (Guan et al. 2007). Thus, the desorption temperature of 200°C was set as the optimum value.

In order to investigate the influence of desorption time, various desorption times were examined to confirm the total desorption of analytes, 1, 3, 5, 7 and 10 min. An evident increase among the signals obtained could be seen between 1 and 5 min (see Fig. S4). It was revealed that 5 min desorption time (at 200°C) was enough and no carryover was detected. After 5 min, desorption time did not contribute to any improvement in the relative peak area of target analytes. Blank tests showed that no NTCs remained on the NW after 5 min desorption. Therefore, 5 min desorption time and 200°C desorption temperature were set as the optimum conditions for further tests.

In order to evaluate the carryover effects of [P6,6,6,14]+3[GdCl6]3− MIL, the same MIL-coated NW was exposed to a second desorption in the GC inlet and the measured relative amounts of analytes detected in the two steps were compared to each other. The results demonstrated that no analyte carryover was detected in the second analysis. The possible reason is that the MIL covers the NW with an ultra-thin layer due to its slight amounts. Since the extractant has no analyte carryover after desorption of NTCs in the GC inlet, it can be deduced that the MIL attached onto the NW surface could be reused in the subsequent experiments owning to the lack of background contamination. However, the reusability of [P6,6,6,14]+33[GdCl6]3− MIL is limited in comparison with solid-phase extractants due to its very minor dissolution in the aqueous samples. In order to recover the [P6,6,6,14]+3[GdCl6]3− MIL, the MIL-coated NW was soaked in an appropriate solvent (e.g., methanol, acetonitrile, acetone and ethanol) and sonicated for 5 min to elute the extractant from the NW surface, and then, the solvent was removed under vacuum.

Multivariate optimization

The most effective parameters on the performance of UA-DMIL/MSW-ME method, including sample volume, salt amount, extraction temperature, MIL quantity, and extraction time, were studied at five levels using the CCD. Since these analytes have a similar tendency to differ in relative peak area, sum of relative peak area (SRPA) of considered NTCs was applied to investigate the effect of five variables to attain a compromise between the responses of all NTCs. According to a five-variable CCD, totally 32 experimental runs (26 experiments plus six replications at the central point) were carried out in a randomized mode to reduce the influence of unknown (uncontrollable) variables that might show bias. The values of relative peak area (obtained from each NTC) in three replicate experiments were averaged for each run, and SRPA of fifteen NTCs was assumed as the GC–MS responses for evaluating the extraction effectiveness of target analytes. Table S2 represents the main variables, their symbols, levels, and design matrix as well as the response of each experiment. The experimental domain for each factor was defined by considering the preliminary experiments and operative limits. The results of the experimental data were fitted to a second-order model with multiple regressions, and the following polynomial equation was generated including quadratic effects, linear effects, and interaction effects of variables in terms of coded values:

where R is the SRPA for NTCs as a function of sample volume (A), salt amount (B), extraction temperature (C), MIL quantity (D), and extraction time (E). To assess the fitness, the significance of each variable, and interaction terms of this quadratic polynomial model, the obtained data were analyzed by analysis of variance (ANOVA). The quality of equation that has been written as a model was shown by the determination coefficient (R2) of the regression equation. R2 is an estimation of the fraction of overall variation in the data based on the model (as a measure of the global fit of the model) that should be at least 0.80 for an admissible agreement between the experimental data and predicted model (Ranjbari and Hadjmohammadi 2015). The obtained R2 (0.992) shows an acceptable fit of the quadratic model with a high capability for variation in response (see Fig. S5). The ANOVA summary revealed that the model was significant, with an F-value of 70.52 and p value less than 0.0001. A p value less than 0.05 in the ANOVA table (Table S3) shows the statistical significance of an effect at 95% confidence level; therefore, the lack-of-fit (LOF) p value of 0.2306 suggests that the LOF in this model is insignificantly linked to the pure error. A large F-value and small p value for each term in the model indicate the term’s significant effect on the extraction performance (Yang et al. 2016).

As Table S3 shows, it was verified that the parameters of A, B, C, and D had significant linear effects on the response. The interactive effects of AB, AD, AE, BC, BD, CD, and DE were also significant. The values of SRPA were mapped versus different combinations of two experimental variables in 3D response surface plots (using trial version of Stat-Ease Design-Expert 7.0.0 software) for visualizing the curvatures of interactions between the five examined variables and the relevance between the responses and experimental levels of factors (Fig. 3a–g). In line with Fig. 3a–c, the SRPA reached to the maximum when the sample volume was about at the 31 mL. Based on the preliminary experiments, when the sample volume was more than 35 mL, the observed decrease in the response is most possibly due to the intense dispersion of [P6,6,6,14]+3[GdCl6]3− in the solution, which prevents its complete retrieval onto the surface of NW. Besides, for the sample volumes less than 15 mL, the droplet size of [P6,6,6,14]+3[GdCl6]3− was large and these phenomena exhibited a detrimental effect on the extraction efficiency. According to Figs. 3a, d and e, the maximum responses were obtained at a salt amount of 2.4% (w/v). The extraction efficiency was boosted with increasing salt concentration up to 2.4%, and then, it was reduced with further increasing the salt concentration. The results can be probably explained by the two concurrently occurring processes. At the beginning, the salting-out effect was involved significantly, but by increasing the salt concentration, salt ions were able to interact with polar sections of analytes and there was a possibility to participate in electrostatic interactions making the polar molecules to precipitate (Hatami et al. 2013). This process could block the analytes to be extracted into the [P6,6,6,14]+3[GdCl6]3−. Based on Figs. 3d and f, the maximum SRPAs were achieved at an extraction temperature of 29°C, because mass transfer rates of analytes were improved with increasing sample temperature up to 29°C. Temperature is a controlling parameter for dispersing extractant in the solution, facilitating the migration of NTCs into the [P6,6,6,14]+3[GdCl6]3−. Higher temperatures (more than 29°C) had a significant negative effect on the SRPA, due to the further dissolution of [P6,6,6,14]+3[GdCl6]3− in the solution, and also a decrease in distribution coefficients of target analytes (because of an increase in the solubility of NTCs which decreases the migration rates). The tortuous surfaces in Fig. 3b, e–g indicate that the extractant quantity has the largest influence on the SRPA and a negative effect upon the extraction. These absolute maximums were obtained when [P6,6,6,14]+3[GdCl6]3− volume was about at 8 μL. By increasing its quantity, the SRPAs were decreased due to the further dilution of NTCs in the extractant phase. The volumes of [P6,6,6,14]+3[GdCl6]3− less than 6 μL were not tested owning to lack of extractant phase. However, the extractant quantity should be as small as possible to achieve the highest SRPA and minimize the contamination of environment; also it must be sufficient that efficient recovery for NTCs is obtainable in subsequent analysis. According to Fig. 3c, g, the SRPA reached to the maximum in all intervals. Thus, prolonging the extraction time would only extend the overall extraction time. As indicated in Table S3, the extraction time has no significant linear effect on the response (p value = 0.5214) and this extraction method is time independent. It was revealed that after the dispersion of [P6,6,6,14]+3[GdCl6]3− in the solution by ultrasonic irradiation, the surface area between the fine droplets of [P6,6,6,14]+3[GdCl6]3− and sample solution is infinitely and essentially large; thus, the analyte transfer from aqueous phase to [P6,6,6,14]+3[GdCl6]3− is fast. The optimal extraction was carried out within 1 min, while longer extraction times did not enhance SRPA or only somewhat improved it. Ultimately, according to the response surface plots and desirability functions, the optimal extraction conditions for UA-DMIL/MSW-ME method were fixed at 31 mL sample volume, 2.4% (w/v) NaCl concentration, 29°C extraction temperature, 8 μL of [P6,6,6,14]+3[GdCl6]3−, and 1 min extraction time.

Response surface plots of SRPA versus sample volume—ionic strength (a); sample volume—[P6,6,6,14]+3[GdCl6]3− MIL volume (b); sample volume—extraction time (c); ionic strength—extraction temperature (d); ionic strength—[P6,6,6,14]+3[GdCl6]3− MIL volume (e); extraction temperature—[P6,6,6,14]+3[GdCl6]3− MIL volume (f); [P6,6,6,14]+3[GdCl6]3− MIL volume—extraction time (g)

Quantitative analysis and method validation

For evaluating the analytical performance of the UA-DMIL/MSW-ME method, the figures of merit, including the coefficient of determination (R2), dynamic linear ranges (DLRs), limits of detection (LODs) and quantification (LOQs), enrichment factors (EFs), and relative standard deviations (RSDs), were investigated under the optimum conditions to determine NTCs (Table 1). The linearity was evaluated in pure water by nine concentration levels in the range of 0.01–100 μg/L for each analyte and 100 μg/L of I.S. For each concentration, six replicate extractions were performed with determination. The peaks’ area of each analyte were corrected versus I.S (Aa/Ai, where Aa is the peak area of desired NTCs and Ai is that of the I.S), and the calibration curves were drawn by plotting the average corrected areas as a function of the standard concentrations. Wide DLRs with the coefficient of determination higher than 0.993, were obtained for all target analytes. The LOD (3Sb/m) and LOQ (10Sb/m) values of target analytes (where m is the slope of calibration graph after pre-concentration and Sb is the standard deviation of blank) were calculated in the range of 0.003–0.021 μg/L and 0.009–0.070 μg/L, respectively. The EFs, which were defined as the ratio of final concentration of NTCs in the [P6,6,6,14]+3[GdCl6]3− (7 ± 1 μL), collected on the NW surface, to their concentration in the original solution, were calculated in the range of 3538–3817. The method repeatability was expressed as RSD for each analyte and assessed through the analysis of six consecutive replicates of aqueous standards containing the desired NTCs at three different concentrations (0.5, 5, and 50 μg/L of target NTCs and 100 μg/L of I.S) in the same day (intraday) and six different days (inter-day). The RSD values were found to be in the range of 4.03–4.90% and 4.60–5.50% for intra- and inter-day assays, in the respective order (Table 1). Moreover, the method reproducibility was represented as RSD for each analyte and assessed through the analysis of six consecutive replicates of aqueous standards containing the desired NTCs at three different concentrations (0.5, 5, and 50 μg/L of target NTCs and 100 μg/L of I.S) by the same wire (single wire) and six different wires (wire to wire). The RSD values obtained from each analyte proved that the application of NW was reproducible. The results are summarized in Table 1.

The determination of NTCs in soil samples was also carried out by the standard addition method using eight incremental levels of spiked concentrations (10–250 ng/g).

Application of the proposed method for the analysis of real samples

For evaluating the applicability of the proposed method, two natural water (river water and industrial wastewater) and soil (forestal and coastal soil) samples were selected and analyzed under the optimized conditions. Accordingly, 4-NT, 2,6-DNT, 2,4-DNT, 3,5-DNT and 2,3,4-TNT were determined in the non-spiked industrial wastewater samples (17.7–46.5 μg/L). Meanwhile, only 3,4-DNT and 2,4,6-TNT were determined in the non-spiked coastal soil samples (16.6–35.3 ng/g), whereas no NTC was found in the non-spiked forestal soil and river water samples. To investigate the matrix effects, the relative recovery (RR) studies were performed on the real samples. The relative recovery for each species was determined by making a comparison between the amounts of analyte added to the real sample and the concentration left following the procedure. Therefore, the non-spiked (a) and spiked (b) real samples with NTCs (5 and 50 μg/L for water samples; 5 and 50 ng/g for soil samples) were prepared and analyzed with six intra- and inter-day replications by implementing the UA-DMIL/MSW-ME method. I.S was added to the spiked and non-spiked samples at the concentration of 100 μg/L and 100 ng/g for water and soil samples, respectively. The relative recovery and RSD values of target NTCs are listed in Table 2 (water samples) and Table S4 (soil samples). The average results of six intra- and inter-day replications analysis indicated that the obtained relative recovery values ranged from 91 to 110% and 89 to 108% with the RSD values less than 5.9% for soil and water samples, respectively, showing a good accuracy with respect to the intricacy of the matrices investigated. The chromatograms (SIM acquisition mode, Fig. 4) obtained from non-spiked (a) and spiked (b) pure water (1) and industrial wastewater (2) samples, subjected to the proposed method, depict clean separations and good chromatographic behaviors with little sample matrices. Other chromatograms related to the river water and forestal and coastal soil samples are shown in Figs. S6, S7, and S8.

Typical GC–MS chromatograms (SIM acquisition mode) of non-spiked (a) and spiked (b) pure water (1) and industrial wastewater (2) samples (spiking level 50 μg/L of each NTC), subjected to the UA-DMIL/MSW-ME method under optimized conditions. In all cases, 100 μg/L of I.S was added to the samples. Peaks identification 2-NT (a); 3-NT (b); 4-NT (c); 2,6-DNT (d); 2,4-DNT (e); 3,5-DNT (f); 2,5-DNT (g); 2,3-DNT (h); 3,4-DNT (i); 2,4,6-TNT (j); 2,4,5-TNT (k); 3,4,5-TNT (l); 2,3,4-TNT (m); 2,3,5-TNT (n); 2,3,6-TNT (o)

A comparative study between the suggested method and other sample pre-treatment methods in which the same NTCs were determined was performed to assess the suggested method comprehensively (Table 3). As shown, the analytical performance of UA-DMIL/MSW-ME method is generally similar to other reported microextraction methods in the literature.

Conclusion

In the current paper, for the first time, a novel microextraction procedure, namely UA-DMIL/MSW-ME, has been successfully developed for the simultaneous pre-concentration of fifteen NTCs in the soil and water samples followed by GC–MS-SIM determination. A multivariate optimization approach based on CCD was applied for optimizing the parameters affecting the microextraction technique. The proposed method proved to be a highly feasible technique for environmental analysis considering the reduced consumption of extractant, short extraction times, great sensitivity with low LODs, high EFs, desirable precisions and accuracy, little matrix interferences, and good figures of merit compared to other microextraction techniques.

Data availability statement

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Babaee S, Beiraghi A (2010) Micellar extraction and high performance liquid chromatography-ultra violet determination of some explosives in water samples. Anal Chim Acta 662:9–13. https://doi.org/10.1016/j.aca.2009.12.032

Benedé JL, Anderson JL, Chisvert A (2018) Trace determination of volatile polycyclic aromatic hydrocarbons in natural waters by magnetic ionic liquid-based stir bar dispersive liquid microextraction. Talanta 176:253–261. https://doi.org/10.1016/j.talanta.2017.07.091

Chisvert A, Benedé JL, Anderson JL, Pierson SA, Salvador A (2017) Introducing a new and rapid microextraction approach based on magnetic ionic liquids: stir bar dispersive liquid microextraction. Anal Chim Acta 983:130–140. https://doi.org/10.1016/j.aca.2017.06.024

Clark KD, Nacham O, Purslow JA, Pierson SA, Anderson JL (2016) Magnetic ionic liquids in analytical chemistry: a review. Anal Chim Acta 934:9–21. https://doi.org/10.1016/j.aca.2016.06.011

Cortada C, Vidal L, Canals A (2011) Determination of nitroaromatic explosives in water samples by direct ultrasound-assisted dispersive liquid–liquid microextraction followed by gas chromatography–mass spectrometry. Talanta 85:2546–2552. https://doi.org/10.1016/j.talanta.2011.08.011

Costa dos Reis L, Vidal L, Canals A (2017) Graphene oxide/Fe3O4 as sorbent for magnetic solid-phase extraction coupled with liquid chromatography to determine 2,4,6-trinitrotoluene in water samples. Anal Bioanal Chem 409:2665–2674. https://doi.org/10.1007/s00216-017-0211-3

Del Sesto RE, Corley C, Robertson A, Wilkes JS (2005) Tetraalkylphosphonium-based ionic liquids. J Organomet Chem 690:2536–2542. https://doi.org/10.1016/j.jorganchem.2004.09.060

Del Sesto RE et al (2008) Structure and magnetic behavior of transition metal based ionic liquids. Chem Commun. https://doi.org/10.1039/B711189D

Deng N, Li M, Zhao L, Lu C, de Rooy SL, Warner IM (2011) Highly efficient extraction of phenolic compounds by use of magnetic room temperature ionic liquids for environmental remediation. J Hazard Mater 192:1350–1357. https://doi.org/10.1016/j.jhazmat.2011.06.053

Ebrahimzadeh H, Yamini Y, Kamarei F, Shariati S (2007) Homogeneous liquid–liquid extraction of trace amounts of mononitrotoluenes from waste water samples. Anal Chim Acta 594:93–100. https://doi.org/10.1016/j.aca.2007.05.013

Ebrahimzadeh H, Yamini Y, Kamarei F (2009) Optimization of dispersive liquid–liquid microextraction combined with gas chromatography for the analysis of nitroaromatic compounds in water. Talanta 79:1472–1477. https://doi.org/10.1016/j.talanta.2009.06.022

Es’haghi Z, Mohtaji M, Hasanzade-Meidani M, Masrournia M (2010) The measurement of ecstasy in human hair by triple phase directly suspended droplet microextraction prior to HPLC-DAD analysis. J Chromatogr B 878:903–908. https://doi.org/10.1016/j.jchromb.2010.02.015

Es’haghi Z, Sorayaei H, Samadi F, Masrournia M, Bakherad Z (2011) Fabrication of a novel nanocomposite based on sol–gel process for hollow fiber-solid phase microextraction of aflatoxins: B1 and B2, in cereals combined with high performance liquid chromatography–diode array detection. J Chromatogr B 879:3034–3040. https://doi.org/10.1016/j.jchromb.2011.08.042

Farrokhzadeh S, Razmi H (2018) Use of chicken feet yellow membrane as a biosorbent in miniaturized solid phase extraction for determination of polycyclic aromatic hydrocarbons in several real samples. Microchem J 142:403–410. https://doi.org/10.1016/j.microc.2018.06.036

Fernández E, Vidal L, Iniesta J, Metters JP, Banks CE, Canals A (2014) Screen-printed electrode-based electrochemical detector coupled with in situ ionic-liquid-assisted dispersive liquid–liquid microextraction for determination of 2,4,6-trinitrotoluene. Anal Bioanal Chem 406:2197–2204. https://doi.org/10.1007/s00216-013-7415-y

Fernández P, Taboada V, Regenjo M, Morales L, Alvarez I, Carro AM, Lorenzo RA (2016) Optimization of ultrasound assisted dispersive liquid-liquid microextraction of six antidepressants in human plasma using experimental design. J Pharm Biomed Anal 124:189–197. https://doi.org/10.1016/j.jpba.2016.02.041

Fernández E, Vidal L, Canals A (2018) Hydrophilic magnetic ionic liquid for magnetic headspace single-drop microextraction of chlorobenzenes prior to thermal desorption-gas chromatography-mass spectrometry. Anal Bioanal Chem 410:4679–4687. https://doi.org/10.1007/s00216-017-0755-2

Gaurav D, Malik AK, Rai PK (2009) Development of a new SPME–HPLC–UV method for the analysis of nitro explosives on reverse phase amide column and application to analysis of aqueous samples. J Hazard Mater 172:1652–1658. https://doi.org/10.1016/j.jhazmat.2009.08.039

Guan W, Xu F, Liu W, Zhao J, Guan Y (2007) A new poly(phthalazine ether sulfone ketone)-coated fiber for solid-phase microextraction to determine nitroaromatic explosives in aqueous samples. J Chromatogr A 1147:59–65. https://doi.org/10.1016/j.chroma.2007.01.132

Guerra E, Lamas JP, Llompart M, Garcia-Jares C (2017) Determination of oxidative hair dyes using miniaturized extraction techniques and gas chromatography-tandem mass spectrometry. Microchem J 132:308–318. https://doi.org/10.1016/j.microc.2017.02.017

Hatami M, Karimnia E, Farhadi K (2013) Determination of salmeterol in dried blood spot using an ionic liquid based dispersive liquid–liquid microextraction coupled with HPLC. J Pharm Biomed Anal 85:283–287. https://doi.org/10.1016/j.jpba.2013.07.025

Krieger BM, Lee HY, Emge TJ, Wishart JF, Castner EW Jr (2010) Ionic liquids and solids with paramagnetic anions. Phys Chem Chem Phys 12:8919–8925. https://doi.org/10.1039/B920652N

Lasarte-Aragonés G, Lucena R, Cárdenas S, Valcárcel M (2011) Effervescence-assisted dispersive micro-solid phase extraction. J Chromatogr A 1218:9128–9134. https://doi.org/10.1016/j.chroma.2011.10.042

Lordel S, Chapuis-Hugon F, Eudes V, Pichon V (2010) Development of imprinted materials for the selective extraction of nitroaromatic explosives. J Chromatogr A 1217:6674–6680. https://doi.org/10.1016/j.chroma.2010.04.081

Lordel-Madeleine S, Eudes V, Pichon V (2013) Identification of the nitroaromatic explosives in post-blast samples by online solid phase extraction using molecularly imprinted silica sorbent coupled with reversed-phase chromatography. Anal Bioanal Chem 405:5237–5247. https://doi.org/10.1007/s00216-013-6921-2

Lu N, He X, Wang T, Liu S, Hou X (2018) Magnetic solid-phase extraction using MIL-101(Cr)-based composite combined with dispersive liquid-liquid microextraction based on solidification of a floating organic droplet for the determination of pyrethroids in environmental water and tea samples. Microchem J 137:449–455. https://doi.org/10.1016/j.microc.2017.12.009

Mallick B, Balke B, Felser C, Mudring AV (2008) Dysprosium room-temperature ionic liquids with strong luminescence and response to magnetic fields. Angew Chem Int Ed 47:7635–7638. https://doi.org/10.1002/anie.200802390

Mattarozzi M, Bianchi F, Bisceglie F, Careri M, Mangia A, Mori G, Gregori A (2011) Planar solid-phase microextraction-ion mobility spectrometry: a diethoxydiphenylsilane-based coating for the detection of explosives and explosive taggants. Anal Bioanal Chem 399:2741–2746. https://doi.org/10.1007/s00216-010-4472-3

Mohsen Y, Lahlou H, Sanchez J-B, Berger F, Bezverkhyy I, Weber G, Bellat J-P (2014) Development of a micro-analytical prototype for selective trace detection of orthonitrotoluene. Microchem J 114:48–52. https://doi.org/10.1016/j.microc.2013.12.001

Nazari N, Masrournia M, Es′ haghi Z, Bozorgmehr M (2016) Simultaneous extraction and preconcentration of aniline, phenol, and naphthalene using magnetite–graphene oxide composites before gas chromatography determination. J Sep Sci 39:3046–3053

Ranjbari E, Hadjmohammadi MR (2015) Optimization of magnetic stirring assisted dispersive liquid–liquid microextraction of rhodamine B and rhodamine 6G by response surface methodology: application in water samples, soft drink, and cosmetic products. Talanta 139:216–225. https://doi.org/10.1016/j.talanta.2015.02.051

Rapp-Wright H, McEneff G, Murphy B, Gamble S, Morgan R, Beardah M, Barron L (2017) Suspect screening and quantification of trace organic explosives in wastewater using solid phase extraction and liquid chromatography-high resolution accurate mass spectrometry. J Hazard Mater 329:11–21. https://doi.org/10.1016/j.jhazmat.2017.01.008

Reyes-Gallardo EM, Lasarte-Aragonés G, Lucena R, Cárdenas S, Valcárcel M (2013) Hybridization of commercial polymeric microparticles and magnetic nanoparticles for the dispersive micro-solid phase extraction of nitroaromatic hydrocarbons from water. J Chromatogr A 1271:50–55. https://doi.org/10.1016/j.chroma.2012.11.040

Roushani M, Shahdost-fard F (2018) A glassy carbon electrode with electrodeposited silver nanoparticles for aptamer based voltammetric determination of trinitrotoluene using riboflavin as a redox probe. Microchim Acta 185:558. https://doi.org/10.1007/s00604-018-3098-6

Safavi A, Ahmadi R, Ramezani AM (2018) Vortex-assisted liquid-liquid microextraction based on hydrophobic deep eutectic solvent for determination of malondialdehyde and formaldehyde by HPLC-UV approach. Microchem J 143:166–174. https://doi.org/10.1016/j.microc.2018.07.036

Santos E, Albo J, Irabien A (2014a) Magnetic ionic liquids: synthesis, properties and applications. RSC Adv 4:40008–40018. https://doi.org/10.1039/C4RA05156D

Santos E, Albo J, Rosatella A, Afonso CA, Irabien Á (2014b) Synthesis and characterization of magnetic ionic liquids (MILs) for CO2 separation. J Chem Technol Biotechnol 89:866–871. https://doi.org/10.1002/jctb.4323

Sarafraz-Yazdi A, Amiri A (2010) Liquid-phase microextraction. Trends Anal Chem 29:1–14. https://doi.org/10.1016/j.trac.2009.10.003

Şener H, Anilanmert B, Cengiz S (2017) A fast method for monitoring of organic explosives in soil: a gas temperature gradient approach in LC–APCI/MS/MS. Chem Pap 71:971–979. https://doi.org/10.1007/s11696-016-0042-2

Shahraki S, Ahmar H, Nejati-Yazdinejad M (2018) Electrochemical determination of nitrazepam by switchable solvent based liquid-liquid microextraction combined with differential pulse voltammetry. Microchem J 142:229–235. https://doi.org/10.1016/j.microc.2018.07.003

Sintra TE et al (2017) Ecotoxicological evaluation of magnetic ionic liquids. Ecotoxicol Environ Saf 143:315–321. https://doi.org/10.1016/j.ecoenv.2017.05.034

Sobhi HR, Kashtiaray A, Farahani H, Javaheri M, Ganjali MR (2010) Quantitation of mononitrotoluenes in aquatic environment using dispersive liquid–liquid microextraction followed by gas chromatography–flame ionization detection. J Hazard Mater 175:279–283. https://doi.org/10.1016/j.jhazmat.2009.09.161

Trujillo-Rodríguez MJ, Nacham O, Clark KD, Pino V, Anderson JL, Ayala JH, Afonso AM (2016) Magnetic ionic liquids as non-conventional extraction solvents for the determination of polycyclic aromatic hydrocarbons. Anal Chim Acta 934:106–113. https://doi.org/10.1016/j.aca.2016.06.014

Yamini Y, Safari M (2018) Modified magnetic nanoparticles with catechol as a selective sorbent for magnetic solid phase extraction of ultra-trace amounts of heavy metals in water and fruit samples followed by flow injection ICP-OES. Microchem J 143:503–511. https://doi.org/10.1016/j.microc.2018.08.018

Yang M et al (2016) Use of magnetic effervescent tablet-assisted ionic liquid dispersive liquid–liquid microextraction to extract fungicides from environmental waters with the aid of experimental design methodology. Anal Chim Acta 906:118–127. https://doi.org/10.1016/j.aca.2015.12.019

Zarei AR, Nedaei M, Ghorbanian SA (2017) Application of deep eutectic solvent based magnetic colloidal gel for dispersive solid phase extraction of ultra-trace amounts of some nitroaromatic compounds in water samples. J Mol Liq 246:58–65. https://doi.org/10.1016/j.molliq.2017.09.039

Zarei AR, Nedaei M, Ghorbanian SA (2018) Ferrofluid of magnetic clay and menthol based deep eutectic solvent: application in directly suspended droplet microextraction for enrichment of some emerging contaminant explosives in water and soil samples. J Chromatogr A 1553:32–42. https://doi.org/10.1016/j.chroma.2018.04.023

Zhang C, Ingram IC, Hantao LW, Anderson JL (2015) Identifying important structural features of ionic liquid stationary phases for the selective separation of nonpolar analytes by comprehensive two-dimensional gas chromatography. J Chromatogr A 1386:89–97. https://doi.org/10.1016/j.chroma.2015.01.074

Zhang W et al (2016) Tetraazacalix[2]arence[2]triazine coated Fe3O4/SiO2 magnetic nanoparticles for simultaneous dispersive solid phase extraction and determination of trace multitarget analytes. Anal Chem 88:10523–10532. https://doi.org/10.1021/acs.analchem.6b02583

Acknowledgement

The authors thank the Research Council of Islamic Azad University of Mashhad for providing the service of instrumental analysis and laboratory facilities. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no known conflicts of interest related to this publication, and this work has not received any significant financial support to influence its outcome.

Ethical approval

This article does not contain any studies with human participants or animals.

Informed consent

Informed consent is not applicable in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ismailzadeh, A., Masrournia, M., Es’haghi, Z. et al. An environmentally friendly sample pre-treatment method based on magnetic ionic liquids for trace determination of nitrotoluene compounds in soil and water samples by gas chromatography–mass spectrometry using response surface methodology. Chem. Pap. 74, 2929–2943 (2020). https://doi.org/10.1007/s11696-020-01131-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-020-01131-3