Abstract

This study reports the extraction of U(VI) using poly(vinyl chloride)-based polymer inclusion membrane (PIM), possessing the extractant alamine336 and the plasticizer Polyoxyethylene alkyl ether (POE). The effects of transport parameters such as alamine336 and POE concentration in the PIM composition, uranium and sulfuric acid concentration in the feed phase, and the receiving phase type and concentration were discussed. Under the optimum conditions, 91.02 ± 2% of uranium was transported through the PIM. The prepared PIM showed excellent selectivity for U(VI) from the sulfuric acid leach solution. The stability of the PIM was found to be acceptable for 5 days.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Liquid membrane (LM) technique is an efficient and simple separation method that can compete with conventional solvent extraction techniques (Aguilar and Cortina 2008). Some advantages of this method compared with the solvent extraction are simultaneous extraction and receiving at one stage, low consumption of extractant, possible complete transfer of solute because of non-equilibrium mass transfer. In comparison with the solvent extraction method, formation of the third phase, phase entrainment, and flooding can be avoided in liquid membrane technique. However, the significant disadvantage of the liquid membrane is the low stability, which should be considered before any large-scale applications (Kislik 2010; Mahanty et al. 2015).

Polymer inclusion membranes (PIMs) are similar to the supported liquid membranes (SLMs) where an extractant is entrapped within a polymer matrix, usually with adding a plasticizer to modify the chemical species solubility within the membrane (Almeida et al. 2012; St John et al. 2012). In the PIM technique, the loosing of the carrier from the base polymer into the aqueous phases is very low and can alleviate the stability issues of LMs (Mahanty et al. 2016). So, in this investigation, the separation of uranium from sulfuric acid media was studied using the PIM system.

Liquid membrane techniques have been used for the separation of uranium by many investigators (Mohapatra et al. 2006; El Sayed 2003; Shamsipur et al. 2010; Davarkhah et al. 2013; Biswas et al. 2013; Elsayed et al. 2013). However, there are not many studies on the separation of uranium using PIMs. Matsuoka et al. (1980) reported the transport of uranium using a PIM containing TBP (three butyl phosphate) as an extractant. However, because of the high water solubility of TBP, the PIM has not enough stability for practical application. Bayou et al. used cellulose triacetate (CTA) PIM, including trioctylphosphine oxide (TOPO) as an extractant and 2-nitrophenyl octyl ether (NPOE) as a plasticizer for investigating the transport of uranium and molybdenum ions. They compared the transport properties of this PIM with an SLM and showed that the uranium and molybdenum transport efficiency was high using the PIM system. However, they were not able to extract uranium completely (Bayou et al. 2010). St John et al. used some commercial extractants for uranium separation from sulfate media using a PIM system. They showed that the PIM with compositions 40% (m/m) di-(2-ethylhexyl)phosphoric acid (D2EHPA) and 60% (m/m) poly(vinyl chloride) (PVC) had superior ability to separate U(VI) (St John et al. 2010). In another work, they showed that uranium transport across a PIM containing 35% D2EHPA, 10% NPOE and 55% PVC in comparison with a PIM consisting of 45% D2EHPA and 55% PVC, was only a little faster. So, the use of PIM without an expensive plasticizer was preferred (St John et al. 2012). Mahanty et al. (2016) demonstrated actinides separation from acidic feed solutions using a (CTA)-based PIM composed of C-pivot tripodal diglycolamide (T-DGA) as a carrier and NPOE as a plasticizer. They also used a branched diglycolamide as an extractant for this purpose (Mahanty et al. 2015).

So far, many high-molecular-weight amines have been used for extraction of uranium from the ore leached with sulfuric acid (Boirie 1958; Sato 1963; Kumar et al. 2010). Also, the price and extraction efficiency of these amines have been assessed. On the other hand, an amine extractant breaks down to nitrogen and oxygen; so, its disposition is easier in comparison with organophosphate extractants (Ohashi et al. 2014). However, the use of these amines as the carrier in the membrane systems is restricted (Babcock et al. 1980). One of the most efficient commercial amines for the extraction of uranium from the leaching solution is alamine336. However, despite the extensive use of alamine336 in the field of solvent extraction (Kumar et al. 2010; Nasab 2014; Quinn et al. 2013; Kim et al. 2012; Ramadevi et al. 2012) and liquid membrane (Wongkaew et al. 2014; He et al. 2000), the use of alamine336 in the PIM system for the extraction of uranium has not been reported yet in the literature. The only unsuccessful report in this regard relates to St John et al. (2010) research group that could not prepare PIMs containing alamine336 with sufficient transparency and flexibility, and also reasonably resistant to mechanical stress to extract uranium from 0.1-M H2SO4. Therefore, in this study, the PIM containing alamine336 as an extractant was prepared and the transport of uranium through that was investigated for the first time. Various parameters such as extractant and plasticizer concentration in the membrane, sulfuric acid concentration in the feed phase, receiving agent type and concentration, and uranium concentration in the feed phase have been investigated. The selectivity and stability of the prepared PIM were also checked.

Experimental

Reagents

Tri-octyl/decyl amine (alamine336) (NetSun Co., China), poly(vinyl chloride) with high molecular weight (Merck), and tetrahydrofuran (THF) (HPLC grade, Merck) were all used as received. Polyoxyethylene alkyl ether (POE) with three polar oxyethylene groups and an alkyl chain length of 12 was prepared from Kimyagaran Emrooz Co. (Iran). Uranyl acetate dehydrate, H2SO4, (NH4)2CO3, Na2CO3, HNO3, H2SO4, HCl, NaNO3, NaF, NH4Cl, and NaHCO3 were purchased from Merck.

Apparatus

The pH value of aqueous solutions was measured using a pH meter (Sartorius).

The concentrations of U(VI) ions in aqueous phases were measured using Inductivity Coupled Plasma-Atomic Emission Spectrometry (ICP-AES, Optima 7300 DV, America).

An INSIZE digital micrometer was used for measuring the PIM thickness.

The characterization of the PIM was studied using the FT-IR spectrometer (Brukere Model).

Membrane preparation

In a glass beaker, specified amounts of PVC, POE, and alamine336 were mixed with 10 mL of THF. Throughout this paper, the amount of PIM compositions was reported in weight percent. The glass beaker was put on a magnetic stirrer for 2 h to have a uniform solution of all ingredients. Afterward, the mixture was transferred into a flat bottom petri dish to evaporate the THF and forming the PIM film. To reduce the evaporation rate of THF and have a uniform PIM film, the petri dish was covered with a perforated aluminum sheet. After 24 h, the content of the petri dish was immersed in cold water to remove the resulting polymer film. The prepared PIM had an oily surface that shows there is a little bonding capacity between the PVC and alamine336. So, to increase the hydrogen bonding capacity of alamine336, it was protonated with 0.1 mol/L sulfuric acid. To determine the thickness of the prepared PIM, the thicknesses of several points of that were averaged. A circular segment of the PIM with a diameter of 57 mm was cut and placed in a permeation cell. The effective diameter of the PIM was 47 mm. All experiments were repeated three times.

Transport studies

A glass cell comprised of two compartments for the feed and receiving solutions was used to study the transport properties of the prepared PIM. For this purpose, the prepared PIM was clamped between these two compartments. Both compartments were stirred with a magnetic stirrer at 600 rpm. The extraction and back-extraction rate and the average back-extraction flux (Jav) were revealed by monitoring U(VI) concentration in the aqueous phases by Eqs. (1)–(3).

where CU,0 is the primary U(VI) concentration in the feed solution. CU,f, and CU,r, are the concentrations of U(VI) in the feed and receiving solutions at time t, respectively. V is the receiving phase volume, and A is the PIM effective surface area, respectively.

The separation factor (SF) was calculated as in Eq. 4:

where CU is the U(VI) concentration, and CX is the other ions concentration in the sulfuric acid leach solution. Subscripts r and f represent the receiving phase and the feed phase, respectively. All experiments were conducted at ambient temperature (25 °C).

Results and discussion

Influence of alamine336 content in the PIM

As mentioned above, to increase the hydrogen bonding capacity of alamine336, it was protonated with 0.1 mol/L sulfuric acid before use for preparing a PIM. The results in Fig. 1 show that the PIM containing protonated alamine336 is transparent and without oily surface. To see the effect of alamine336 content on the uranium transport, various amounts of that were used in the PIM composition according to Table 1. As revealed in Fig. 2, U(VI) was not transported in the absence of alamine336. By adding alamine336 to the PIM composition, the flux of U(VI) grew considerably as the alamine336 content was enhanced to 40 wt%. In these conditions, the presence of numerous extracted species at the interface of the feed and membrane rises the transport of U(VI) across the PIM (St John et al. 2012). The mechanistic description of U(VI) transport with alamine336 was explained in Sect. 3.6. Further increase in the amount of alamine336 led to a PIM with an oily surface and weak mechanical resistance, and hence it was difficult to handle the membrane for transport experiments. So, the high content of the alamine336 (above 40 wt%) was not investigated.

Influence of plasticizer content in the PIM

The use of plasticizers in the PIM structure often modifies the membrane plasticity and softness that provides conditions for easy transport of metal ions through that (Mahanty et al. 2016). The influence of plasticizer content was studied using PIMs, including the different amounts of POE (Table 2). The obtained results in Fig. 2 show there is no transport of U(VI) through the PIM without any plasticizer. After that, increasing the plasticizer content up to 23.21 wt% increases PIM permeability significantly. Because, the presence of POE in the PIM structure improves the movements of extractant and extracted species (Yildiz et al. 2016). After that, there is no change in transport efficiency with increasing plasticizer amount. So, 23.21 wt% POE was chosen as the optimal content in subsequent experiments.

Influence of sulfuric acid concentration in the feed phase

The effect of sulfuric acid concentration in the feed phase on U(VI) flux was investigated in the range of 0.01–1.0 mol/L. As shown in Fig. 3, the maximum flux was obtained for 0.1 mol/L sulfuric acid. Kumar et al. (2010) observed this trend for the solvent extraction of uranium using alamine336. Based on the results obtained from solvent extraction studies in the literature (TRÉMILLON 1965), the maximum flux in the presence of 0.1 mol/L sulfuric acid can be attributed to the conversion of alamine336 (R3N) in the membrane phase into favorable amine sulfate species according to the following reaction,

Transport of U(VI) across (40 wt% Alamine336/23.21 wt% POE/36.78 wt% PVC) PIMs with different concentrations of sulfuric acid in the feed phase (feed phase: 1.0 × 10−4 mol/L U(VI); receiving phase: 0.5 mol/L (NH4)2CO3) and with different concentrations of ammonium carbonate in the receiving phase (feed phase: 1.0 × 10−4 mol/L U(VI) in 0.1 mol/L H2SO4)

and subsequently, the extraction of uranium U(VI) according to the following reaction,

The drastic decline in the flux of U(VI) for concentrations higher than 0.1 mol/L sulfuric acid can also be described by conversion of alamine336 (R3N) in the membrane phase into unfavorable amine bisulfate species as follows:

which leads to undesirable extraction of U(VI) into the PIM as Eq. 8 shows,

Influence of receiving agent type and concentration

Experiments were also made to study the effect of the receiving agent type in the internal phase. For this purpose, ten different receiving agents, NaF, H2O, NaHCO3, Na2CO3, NH4Cl, (NH4)2CO3, H2SO4, HNO3, HCl and NaNO3 with the same concentration of 0.5 mol/L were used. Figure 4 shows that, under the same experimental conditions, the flux of uranyl ions into the receiving phase decreases in the order (NH4)2CO3 > NaHCO3 > NaF > Na2CO3 > NH4Cl > H2SO4 > NaNO3 > HCl > H2O > HNO3. Thus, ammonium carbonate is the most efficient agent in receiving uranium from PIM containing alamine336. The results also showed that the basic agents play their roles as a receiving phase better than the acidic and neutral agents for the back-extraction of uranium. Thus, to the best of our knowledge, the most efficient mechanism for the recovery of uranium from the membrane is to neutralize the protonated amine in the structure of ion-associated complex at the interface of membrane and receiving phase, thereby the uranyl ion is abandoned into the receiving phase. Obviously, this mechanism depends on the pH and the alkaline solutions as a stripper facilitate its occurrence.

The effect of the variation of ammonium carbonate concentration in the receiving phase was also studied; the results in Fig. 3 show that with an increase in ammonium carbonate concentration higher than 0.5 mol/L, the flux of U(VI) diminishes. Thus, a solution of 0.5 mol/L ammonium carbonate could be used as the most suitable receiving phase.

Influence of U(VI) concentration in the feed phase

The variation of flux with the U(VI) concentration in the feed solution was studied in the range of 1.0 × 10−4 to 8.33 × 10−4 mol/L. The obtained results in Fig. 5 show that the U(VI) concentration has a significant effect on the transport of U(VI) through a (40 wt% alamine336/23.21 wt% POE/36.78 wt% PVC) PIM. According to Eq. 6, the stoichiometric ratio of U(VI) to alamine336 is 1:4. For the studied range of uranium concentration, the mole ratio of U(VI) to alamine336 is between 1:5 and 1:40. As the mole ratio of U(VI) to alamine336 is always more than the stoichiometric ratio, increasing the U(VI) concentration in the feed solution leads to increasing the U(VI) flux (St John et al. 2012). In other words, in this region, the transport is mainly determined by the uranyl ions diffusion through the boundary layer in the feed phase and the reaction of uranyl ions and alamine336 molecules (Wijers et al. 1988).

Extraction and receiving mechanism of U(VI) at the PIM interfaces

There are various species of dissolved uranyl ions in the sulfuric acid medium such as UO22+, UO2SO4, UO2(SO4)2−2 and UO2(SO4)4−3 whose concentration is a function of the free sulfate concentration in the solution. In 0.1 mol/L sulfuric acid solution, the concentration of free sulfate is almost 0.032 mol/L (Brubaker Jr 1957). Considering the latter concentration of the free sulfate, and according to the calculations of Boirie (1958), the dominant species of uranyl ion in the solution is UO2SO4. On the other hand, based on the solvent extraction studies in 0.1 mol/L sulfuric acid medium, alamine336 (R3N) at the feed side interface forms the neutral species of (R3NH)2SO4 by accepting protons. Thus, at the mentioned level of sulfuric acid concentration, uranyl ions are essentially extracted as the ion-associated complex of (R3NH)4UO2(SO4)3 (Boirie 1958). Therefore, at the feed–membrane interface, the main reaction can be written as follows:

The reaction at the membrane–receiving phase interface and in the presence of 0.5 mol/L ammonium carbonate is as follows:

The transport of uranyl ions is coupled with the co-transport flow of the constituent ions of sulfuric acid, i.e., sulfate and proton ions. This transport mechanism of the uranyl sulfate as a predominant species of uranium in the feed phase across a PIM is schematically described in Fig. 6.

Membrane surface characterization

The surface characterization of the prepared PIM was studied using the FT-IR technique. The FT-IR spectrum of the PVC powder, POE, the PIM including PVC + POE and the PIM including PVC + POE + alamine336, is shown in Fig. 7. Figure 7a shows the characteristic vibrational C–H, C–Cl, and CH2 bands of the PVC at 1431, 2916, and 619/cm, respectively. As shown in Fig. 7c, two peaks of C–O and O–H bands appear at 1118 and 3442, respectively, because of adding POE plasticizer to PVC. However, in comparison to the FT-IR spectrum of the pure POE (Fig. 7b), the O–H band has low peak intensity. This demonstrated that the POE plasticizer and PVC were banded together by O–H groups (Zaheri and Ghassabzadeh 2017).

The FT-IR spectrum of the PIM containing PVC + POE + alamine336 in Fig. 7d reveals the additional bands at 1253 and 1454/cm that relate to the C–N and CH2 groups of alamine336 extractants. In this case, it also can be seen that the O–H band of POE has low peak intensity. This indicated that alamine336, PVC, and POE were bonded via O–H groups and this connection is strong. This is evidence of a significant increase in the uranium flux through the membrane in the presence of alamin336.

Selectivity of PIM

To study the selectivity of the synthesized membrane, in the course of a competitive transport experiment from the feed phase containing sulfuric acid leach solution, the percentage of the metal ions U(VI), Al3+, Ca2+, Mg2+, Mn2+, Fe3+ released in the receiving phase under optimum conditions was determined. The achieved results (Table 3) show a high selectivity of the PIM including alamine336 towards uranium ions and also a high efficiency for uranium recovery in this competitive experiment.

The kinetic of uranium transport across the PIM

Under the achieved optimum conditions, the concentration variation of uranium in the feed, membrane, and receiving phases versus time is shown in Fig. 8a. The kinetic of the transport of uranium across the PIM was described as a first-order reaction,

where k and t are the rate constant and time of transport, respectively.

To determine k value, the variation of ln(CU,f/CU,0) vs. time is plotted in Fig. 8b. There was a linear relationship between ln(CU,f/CU,0) and time, which was confirmed by the high value of R2. The k value was calculated to be 6 × 10−5/s. Jin et al. (1989), Kozlowski and Walkowiak (2002) also concluded the first-order reaction for metal ions.

The performance of the PIM system containing (40 wt% alamine336, 23.21 wt% POE and 36.78 wt% PVC) was compared in terms of permeability, stability, and U(VI)/Fe3+ separation factor with other PIM systems in Table 4. Since the experimental conditions of the used PIM systems by other investigators are different, instead of flux, the permeability was used to evaluate their transport properties by the following equation,

The results show that the prepared PIM in this study has exclusive transport properties and long-term stability. It is also evident that the prepared PIM has the highest separation factor towards uranium ions and Fe3+ ions.

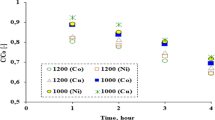

Stability of PIM

The stability of the selected PIM was studied by conducting five consecutive cycles of extraction and back-extraction under the same experimental conditions. Each cycle of these five experiments was run with new feed and receiving solutions. The results in Table 5 show that the extraction and back-extraction efficiency was over 90.00% in the five cycles of experiments. The slight decline in the extraction efficiency may be related to the transporting the extractant into the aqueous solutions (Kaya et al. 2013). However, the PIM technique, due to enfolding an extractant within a polymer structure, is very persistent to the loss of the extractant in comparison with liquid membrane and solvent extraction methods.

Conclusion

The separation of U(VI) from a sulfuric solution was performed using a PVC-based PIM, including protonated alamine336 extractant and POE plasticizer.

The obtained results revealed that the transport of U(VI) through the prepared PIM is affected by the amounts of the extractant and plasticizer in the PIM composition, the sulfuric acid concentration in the feed phase, and the receiving phase concentration. Under the assessed optimum conditions (PIM consisting of (40 wt% alamine336, 23.21 wt% POE and 36.78 wt% PVC), 0.1 mol/L sulfuric acid in the feed solution and 0.5 mol/L ammonium carbonate as a receiving solution), the acceptable performance with average flux value as 1.82 × 10−7 mol/m2 s and very high selectivity value as 7307 for U(VI)/Fe3+ was achieved for the prepared PIM.

Investigating the effect of receiving agent type on uranium transport through PIM showed that the basic agents act as a better receiving phase than the acidic and neutral agents for the back extraction of uranium.

The prepared PIM showed long-term stability for five consecutive extractions of uranium.

According to high selectivity, stability, and a few use of alamine336 in the prepared PIM, it is an eco-friendly and affordable process for selective extraction of uranium from the sulfuric acid leach solution.

References

Aguilar M, Cortina JL (2008) Solvent extraction and liquid membranes: fundamentals and applications in new materials. CRC Press, Boca Raton

Almeida MI, Cattrall RW, Kolev SD (2012) Recent trends in extraction and transport of metal ions using polymer inclusion membranes (PIMs). J Membr Sci 415–416:9–23

Babcock WC, Baker RW, Lachapelle ED, Smith KL (1980) Coupled transport membranes II: the mechanism of uranium transport with a tertiary amine. J Membr Sci 7(1):71–87

Bayou N, Arous O, Amara M, Kerdjoudj H (2010) Elaboration and characterisation of a plasticized cellulose triacetate membrane containing trioctylphosphine oxyde (TOPO): application to the transport of uranium and molybdenum ions. C R Chim 13:1370–1376

Biswas S, Pathak PN, Roya SB (2013) Kinetic modeling of uranium permeation across a supported liquid membrane employing dinonyl phenyl phosphoric acid (DNPPA) as the carrier. J Ind Eng Chem 19:547–553

Bloch R, Finkelstein A, Kedem O, Vofsi D (1967) Metal-ion separations by dialysis through solvent membranes. Ind Eng Chem Process Des Dev 6:231–237

Boirie Ch (1958) Extraction of uranyl sulfate with amines. Bull Soc Chim Fr 8–9:1088–1093

Brubaker CH Jr (1957) Textbook errors: XIII The nature of ionic and molecular species in sulfuric acid. J. Chem. Educ. 34(7):325

Davarkhah R, Khanramaki F, Asgari M, Salimi B, Ashtari P, Shamsipur M (2013) Kinetic studies on the extraction of uranium(VI) from phosphoric acid medium by bulk liquid membrane containing di-2-ethylhexyl phosphoric acid. J Radioanal Nucl Chem 298:125–132

El Sayed MS (2003) Uranium extraction from gattar sulfate leach liquor using aliquat-336 in a liquid emulsion membrane process. Hydrometallurgy 68:51–56

Elsayed HM, Fouad EA, El-Hazek NMT, Khoniem AK (2013) Uranium extraction enhancement form phosphoric acid by emulsion liquid membrane. J Radioanal Nucl Chem 298:1763–1775

He D, Ma M, Zhao Zh (2000) Transport of cadmium ions through a liquid membrane containing amine extractants as carriers. J Membr Sci 169:53–59

Jin M, Michel FC Jr, Noble RD (1989) Kinetics of copper extraction using (anti)-2-hydroxy-5-nonylbenzophenone oxime. Ind Eng Chem Res 28:193–198

Kaya A, Alpoguz HK, Yilmaz A (2013) Application of Cr(VI) transport through the polymer inclusion membrane with a new synthesized calix[4]arene derivative. Ind Eng Chem Res 52:5428–5436

Kim CJ, Kumar JR, Kim JS, Lee JY, Yoon HS (2012) Solvent extraction studies on uranium using amine based extractants and recovery from low grade ore leach liquors. J Braz Chem Soc 23:1254–1264

Kislik VS (2010) Liquid membranes: principles & application in chemical separations & wastewater treatment, 1st edn. Elsevier, The Netherlands

Kozlowski CA, Walkowiak W (2002) Removal of chromium(VI) from aqueous solutions by polymer inclusion membranes. Water Res 36:4870–4876

Kumar JR, Kim JS, Lee JY, Yoon HS (2010) Solvent extraction of uranium(VI) and separation of vanadium(V) from sulfate solutions using Alamine 336. J Radioanal Nucl Chem 285:301–308

Mahanty BN, Mohapatra PK, Raut DR, Das DK, Behere PG, Afzal Md (2015) Polymer inclusion membranes containing N, N, N′, N′-tetra(2-ethylhexyl) diglycolamide: uptake isotherm and actinide ion transport studies. Ind Eng Chem Res 54:3237–3246

Mahanty BN, Mohapatra PK, Raut DR, Das DK, Behere PG, Afzal M, Verboom W (2016) Polymer inclusion membrane containing a tripodal diglycolamide ligand: actinide ion uptake and transport studies. Ind Eng Chem Res 55:2202–2209

Matsuoka H, Aizawa M, Suzuki Sh (1980) Uphill transport of uranium across a liquid membrane. J Membr Sci 7:11–19

Mohapatra PK, Lakshmi DS, Mohan D, Manchanda VK (2006) Uranium pertraction across a PTFE flatsheet membrane containing Aliquat 336 as the carrier. Sep Purif Technol 51:24–30

Nasab ME (2014) Solvent extraction separation of uranium(VI) and thorium(IV) with neutral organophosphorus and amine ligands. Fuel 116:595–600

Ohashi Y, Murashita S, Nomura M (2014) Extraction of uranium from solid waste containing uranium and fluorine. Miner Eng 61:32–39

Quinn JE, Wilkins D, Soldenhoff KH (2013) Solvent extraction of uranium from saline leach liquors using DEHPA/Alamine 336 mixed reagent. Hydrometallurgy 134–135:74–79

Ramadevi G, Sreenivas T, Navale AS, Padmanabhan NPH (2012) Solvent extraction of uranium from lean grade acidic sulfate leach liquor with alamine 336 reagent. J Radioanal Nucl Chem 294:13–18

Sato T (1963) The extraction of uranium(VI) from sulphuric acid solutions by tri-N-octylamine. J Inorg Nucl Chem 25:441–446

Shamsipur M, Davarkhah R, Khanchi AR (2010) Facilitated transport of uranium(VI) across a bulk liquid membrane containing thenoyltrifluoroacetone in the presence of crown ethers as synergistic agents. Sep Purif Technol 71:63–69

St John AM, Cattrall RW, Kolev SD (2010) Extraction of uranium(VI) from sulfate solutions using a polymer inclusion membrane containing di-(2-ethylhexyl) phosphoric acid. J Membr Sci 364:354–361

St John AM, Cattrall RW, Kolev SD (2012) Transport and separation of uranium(VI) by a polymer inclusion membrane based on di-(2-ethylhexyl) phosphoric acid. J Membr Sci 409–410:242–250

Trémillon B (1965) Chimie analytique—1 Généralités. Armand Colin, Paris

Wijers MC, Jin M, Wessling M, Strathmann H (1988) Supported liquid membranes modification with sulphonated poly(ether ether ketone): permeability, selectivity and stability. J Membr Sci 147:117–130

Wongkaew K, Leepipatpiboon N, Pancharoen U (2014) State of the art hollow fiber supported liquid membrane on Pd (II) separation from wastewater using alamine 336. Int J Chem Eng Appl 5(4):311–314

Yildiz Y, Manzak A, Tutkun O (2016) Selective extraction of cobalt ions through polymer inclusion membrane containing Aliquat 336 as a carrier. Desalin Water Treat 57:4616–4623

Zaheri P, Ghassabzadeh H (2017) Preparation of polymer inclusion membrane including mixture of D2EHPA and Cyanex272 for the extraction of Eu from nitrate media. Chem Pap 71(9):1623–1631

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zaheri, P., Davarkhah, R. Selective separation of uranium from sulfuric acid media using a polymer inclusion membrane containing alamine336. Chem. Pap. 74, 2573–2581 (2020). https://doi.org/10.1007/s11696-019-01029-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-01029-9