Abstract

Nowadays, environmental problems such as petroleum resources exhaustion, pollution and global warming are in ceaseless aggravation. Consequently, vegetable oil becomes one of the most important resources due to its cheapness, easily availability and environmental regeneration. In this study, a series of sustainable polyurethanes based on epoxy soybean oil modified by different contents of 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane [DDSQ(Me)OH] have been prepared. Polyol prepared with epoxy soybean oil has effectively replaced the petroleum-based polyol and the DDSQ(Me)OH performed as chain extender together with 1,4-butanediol (BDO). The structure of DDSQ(Me)OH was verified by 1H NMR and MALDI–TOF–MS. The structure and properties of sustainable polyurethanes were characterized by FTIR, DSC, TGA, SEM, tensile test and static contact angle. TGA demonstrated that hybrid polyurethanes were thermally stable due to the covalent incorporation of DDSQ(Me)OH in polymer main chain, the 5% weight loss temperatures (Td5) of hybrid polyurethane can be 21 °C higher than pure PU. DSC revealed the improved glass transition temperature (Tg) of polyurethanes, and the Tg can be 12.4 °C improved compared with pure polyurethane. SEM showed that the aggregation of DDSQ(Me)OH has dispersed homogeneously in the hybrid polyurethanes matrix. The results of the static contact angle revealed that with the increase of DDSQ(Me)OH content, the surface hydrophobicity has been enhanced significantly, and the static contact angle of water for hybrid polyurethanes can be up to about 110.2°.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Combined the light weight, good toughness and easy shaping of polymers with high strength and fine thermal stability of inorganic materials, organic–inorganic hybrid materials may create new properties for materials through synergy (Wang et al. 2014; Liu and Jeng 2013). Polyhedral oligomeric silsesquioxanes (POSS) is a class of silicon compound with three-dimensional skeleton structure. POSS can be used as modifier for polymers due to its good thermal stability, chemical stability and homogeneous dispersion in the polymers by nanoscale (Wang et al. 2011). A great deal of papers focused on POSS-containing organic–inorganic composites was reported during past years (Gnanasekaran et al. 2013; Musto et al. 2012). POSS can be functionalized with monoactive group, diactive groups or multiactive groups through many ways; among those, Top-Cap reaction is the most common method to prepare the monofunctional POSS. Monofunctional POSS with –OH, –COOH, –NH2, –NCO has already been synthesised (Feher and Weller 1990; Feher and Wyndham 1998; Lichtenhan et al. 1993, 1995). Without changing the organic polymer main chain, POSS cages act as pendent side groups or end groups in the hybrid composites. Multifunctional POSS was usually prepared by the functionalizing of phenylsilsesquioxane and the hydrosilation reaction,it can connect with the polymer by the form of stellate intersection point structure (Ledin et al. 2014; Zhang et al. 2013). Multifunctional POSS-containing hybrids such as polyimide (Huang et al. 2003), polybenzoxazines (Huang and Kuo 2010), poly(ethylene imine) (Zeng et al. 2008), polymethyl methacrylate and polyurethane have been reported (Liu and Zheng 2005; Liu et al. 2006).

For the past few years, the double-decker silsesquioxane, which can be used to prepare linear POSS-containing hybrids with POSS in the main chains for some special applications, has become a research hotspot. Moore et al. (2018) reported that bis-phenylethynyl polyhedral oligomeric silsesquioxane (bis-PE-POSS) compounds were synthesized and thermally cured yielding crosslinked materials. Żak et al. (2014) presented a methodology that opens up a possibility to obtain a new class of trans-unsaturated (oligo)polymers with a silsesquioxyl-silylene spacer. On the basis of the results they obtained, new, promising materials with interesting optoelectronic and thermal properties may be developed in the future. To my knowledge, a few researches have been reported on efficient synthesis of difunctional POSS macromers until this moment. Nevertheless, there still remains a lot of spaces for further investigation on the synthesis and properties of POSS-containing copolymers with covalent bond by the use of double-decker POSS. Hoque and Kawakami (2016) has synthesized polysilsesquioxanes with end functional double-decker silsesquioxanes (DDSQ). According to the results, compared with polysilsesquioxane containing methyl end capped DDSQ, polysilsesquioxane containing iso-butyl end capped DDSQ showed better solubility. Wei et al. (2013) synthesized organic–inorganic polyurethanes with polyhedral oligomeric silsesquioxane (POSS) in the main chains. The properties such as thermal stability and surface hydrophobicity have been significantly improved by the incorporation of DDSQ. In the previous work of Huang et al. (2016a, b, 2017) environmentally friendly polyurethane was synthesized by vegetable oil and modified by double-decker silsesquioxane (DDSQ); it was pointed out that with the DDSQ in the main chain, the glass transition temperatures (Tg), the thermomechanical properties, and the hydrophobicity were significantly improved.

Polyurethane (PU) is a class of functional polymer material with excellent performance, which is widely applied in aerospace, transport, architecture, electronic product and other fields. Traditional PU is usually prepared by petroleum-based polyol and isocyanate. However, during the using of petroleum-based polyol and isocyanate, the environmental problem such as resource exhaustion, pollution and global warming will be aggravated. Recently, vegetable oil has become an important resource to develop the sustainable polyurethane due to its cheapness, easily availability and environmental regeneration. A kind of vegetable oil-based non-isocyanate polyurethane has attracted increasing attention. Recently, many researches on the non-isocyanate PU production have been reported. Büttner et al. (2017) prepared a catalytic system and then used to produce eight carbonated fatty acid methyl esters and even four carbonated vegetable oils in excellent isolated yields. Those products combine biological and chemical CO2 fixation that can be used in the area of sustainable PU. Sawpan (2018) comprehensively reviewed recent developments in the preparation of renewable resource-based polyols and isocyanates for producing polyurethanes and applications. Pérez-Sena et al. (2018) optimized the production of methyl oleate, epoxidized methyl oleate and carbonated methyl oleate first and then built a kinetic model for the aminolysis of cyclic-carbonate by diamine. It was found that the reactions of aminolysis and amidation were low exothermic reactions. To develop the application of vegetable oil in polymer materials, a series of effective measures can be taken to functionalize the vegetable oil, for instance, epoxidation followed by ring opening (Leveneur et al. 2014), thiol-ene reaction (Lluch et al. 2010), transesterification (Garbark and Benecke 2011), hydroformylation and ozonolysis (Kandanarachchi et al. 2002; Petrović et al. 2013) are representative examples of such reactions. Sustainable polymers can be prepared by the reaction between vegetable oil-based polyols and diisocyanates. Nevertheless, vegetable oil-based polyurethane was obsessed by low rigidity, thermal stability, and strength, which limited its application in the field of polymer; so many researches have been done to solve this problem. Sheng et al. (2015) prepared a series of sustainable polyurethanes which introduced different content of cyclic polysilanol as a chain extender to replace 1,4-butanediol (BDO). Oaten and Choudhury (2005) and Turri and Levi (2005a, b) have investigated on the surface properties of linear polyurethanes modified with monofunctional POSS macromers, and found that with the presence of POSS, the surface free energy of the materials significantly reduced and the surface hydrophobicity of the materials improved. There already have some sustainable polyurethanes be developed for the industrialized production. The Huntsman Corporation has had the JEFFADD™ B650 series of polyols through vegetable oil, which were used to produce polyurethanes (Zhao et al. 2011). Malaysian Maskimi company has the capacity to produce 600,000 tons of palm oil-based polyol annually, and its production of palm oil-based polyol is mainly used in polyurethane rigid foam (Zhang et al. 2012).

In this research, to prepare a new sustainable hybrid nanocomposites, soybean oil-based polyol was first synthesised, and 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane was also prepared and then added as modifier. This route not only makes contribution to the global environmental problems but also overcomes the shortcoming of pure vegetable oil-based polyurethanes. Meanwhile, the thermal properties, mechanical properties, the surface properties and morphology of these hybrid polyurethanes were also discussed. The results of this paper can provide some insight and scientific data for vegetable oil-based hybrid polyurethanes.

Experimental

Materials

Epoxy soybean oil (ESO) with 6.1% epoxy value was obtained from Hairma Chemical (GZ) Ltd., China. Phenyltrimethoxysilane (98%) was purchased from Chengdu Xiya Reagent Co. and used without further purification. Isophorone diisocyanate (IPDI) was obtained from Wuxi East Grace Electronic Material Technology Co., Ltd. The NCO content of IPDI is 37.81% as calculated. Other reagents such as tetrahydrofuran (THF) need to be refluxed above metal sodium, and then distilled and stored in the presence of 4°A molecular sieves. Besides, other reagents in this experiment were also purchased from Shanghai Reagent Co., China and used as received.

Synthesis of 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane [DDSQ(Me)OH]

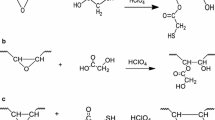

The structure and synthetic route to sodium salt of double-decker phenylsilsesquioxane [DDSQ(ONa)] was shown in Scheme 1. The specific synthesis methods were used by following method reported by Seino et al. (2006) with a slight modification. Sodium hydroxide (3.2 g, 0.08 mol) was dissolved in deionized water (2.5 g, 0.14 mol) to obtain a solution, then phenyltrimethoxysilane (24 g, 0.12 mol) was added drop wisely, and then 2-propanol (120 mL) was also added to the mixed solution at room temperature for about 15 min under nitrogen atmosphere. The reaction mixture was heated to 90 °C and refluxed for about 4 h, then the solution was cooled to room temperature, and maintained stirring for about 15 h. After filtration, the precipitate was washed for three times with 2-propanol and dried at 70 °C for 5 h in vacuum oven to obtain the white powder.

The synthetic route to DDSQ(Me)OH was shown in Scheme 1. The synthesis was according to the method reported by Hoque et al. (2009) with a slight modification. DDSQ(ONa) (4 g, 3.45 mmol), THF (40 mL), and TEA (1.04 g, 10.37 mmol) were placed in a two-neck 100-mL flask equipped with a reflux condenser, and the reaction was carried out in a dry nitrogen stream. Methyltrichlorosilane (2.0 g, 13.33 mmol) was added dropwise to the system with a syringe at room temperature and the system was kept stirring for 12 h by means of a magnetic stirrer. Then water (17.3 mL) was added to the reaction mixture under ice bath, and the system was maintained stirring for 30 min to hydrolyze excess trichlorosilane, and to dissolve sodium chloride formed during the reaction. Toluene (80 mL) was used to extract soluble products, and separate the organic layer, which was washed repeatedly with deionized water until it became neutral. Then organic layer was dried with anhydrous sodium sulfate, and precipitation of less soluble products would exhibit when the volume of toluene was reduced to around 20 mL. The precipitate was filtered off after the solution was kept at 0 °C for overnight. Then the clear filtrate was dried on a rotary evaporator to obtain DDSQ(Me)OH as white solid.

Preparation of soybean oil-based polyurethane

To synthesize sustainable polyurethane, first, as feedstock, ESO need to be converted into polyol. In this method, tetrafluoroboric acid was used as catalyst, 2-propanol was used as solvent, epoxy groups were opened with methanol according to method in the literature reported by Petrovic (2008). Then, a pale yellow viscous SBO polyol with the OH number of 185 mg KOH/g was obtained. A standard two-step prepolymer method was used to synthesize polyurethanes and a typical synthetic procedure was as follows: SBO polyol (4 g, 13.16 mmol OH), EtAc (20 mL), stannous octoate (100 μL), and IPDI (2.07 mL) were charged into a flask equipped with magnetic stirrer, condenser and nitrogen bubbler. The pre-polymerization was performed at 80 °C for 2 h under a high pure nitrogen atmosphere with vigorous stirring. According to ASTM D5155-96, the isocyanate (NCO) content was determined. The excess NCO content was obtained, thus the corresponding content of 1,4-butanediol (BDO) was calculated. Then the certain content of BDO, as chain extender, was added to the reaction mixture. Then keep the mixture stirring for another 2 h at 80 °C. Finally, the resultant mixture was poured into a Teflon plate to evaporate the solvent under atmospheric conditions and then cured at 50 °C for 24 h.

Preparation of soybean oil-based hybrid polyurethanes with DDSQ(Me)OH as modifier

The synthesis of hybrid polyurethanes was according to the formation shown in Table 1. At the first stage, the hybrid polyurethanes were prepared similarly to the pure polyurethane. After the isocyanate (NCO) content of the prepolymer was measured, different content of DDSQ(Me)OH (see Table 1) and stoichiometric amount of chain extender 1,4-butanediol (BDO) were obtained based on calculation and were added to the reaction mixture, the reaction was performed at 80 °C for another 2 h. Then the products were poured into the Teflon plate to evaporate the solvent and cured at 50 °C for 24 h after that. Finally, a series of hybrid polyurethanes modified with DDSQ(Me)OH were successfully synthesized.

Characterizations

1H (400 MHz) NMR spectra were obtained on A Bruker Instruments (model Avance 400, Germany), and CDCl3 was used as solvent. For MALDI–TOF–MS analysis, the matrix 2,5-dihydroxybenzoic acid, dissolved in THF (50 mg/mL) were mixed with 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane solution (0.1 mg/mL in 1:1 v/v ratio). The ATR-FTIR spectra were obtained from Nicolet 6700 infrared spectrometer. All spectra were measured between 4000 and 500 cm−1 with averaging 32 scans at a resolution of 4 cm−1. The morphology of all the hybrid polyurethanes were observed by scanning electron microscopy (S-4800, Hitachi), all the samples were fractured with liquid nitrogen and coated with gold prior to the test. The thermodynamic properties of the hybrid polyurethanes were measured by differential scanning calorimetry (DSC-8000) and thermogravimetric analysis (TGA/1100SF), respectively. The thermogravimetric analysis (TGA) was conducted from 30 °C to 800 ramped at 20 °C/min with a nitrogen flow rate of 50 mL/min. For DSC analysis, samples (5–10 mg) underwent a temperature range from − 30 to 150 °C at a nitrogen flow rate of 20 mL/min. The mechanical properties were measured according to ASTM D 882-97 on a tensile tester model with 10 mm/min extension rate and the gauge length was 4 mm, and five specimens were used for each sample. The surface hydrophobicity of the hybrid polyurethanes was carried out on a DCA-315 static contact angles, and ultrapure water was chosen as probe liquids at room temperature. All samples were tested at three different positions and the results were expressed as mean value.

Results and discussion

Synthesis

Synthesis of 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane [DDSQ(Me)OH]

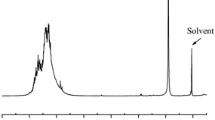

3,13-Dimethyhydroxysilyl double-decker phenylsilsesquioxane [DDSQ(Me)OH] was prepared via the reaction between DDSQ(ONa) and methyltrichlorosilane. To further confirm the successful synthesis of DDSQ(Me)OH, 1H NMR and MALDI–TOF–MS were utilized to characterize the formation. In the 1H NMR shown in Fig. 1, the signals of resonance assignable to the protons of –CH3, Si–OH bond and phenyl groups were detected at 0.38, 1.63 ppm and 7–8 ppm, respectively. The ratio of integral intensity for these signals of resonance was measured to be 3:1:20, which was in good accordance with the value calculated based on the structural formula. For further confirmation, the as-prepared 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane[DDSQ(Me)OH] was subjected to MALDI–TOF–MS to measure its molecular weight and the mass spectrum is presented in Fig. 2. It can be seen that the DDSQ(Me)OH possessed a molecular weight of M = 1184.057 (viz. 1207.057-23), which was assignable to the value calculated according to the structural formula (see Scheme 1). The results of 1H NMR and MALDI–TOF–MS indicate that 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane [DDSQ(Me)OH] was successfully obtained.

Synthesis of sustainable polyurethane and hybrid polyurethanes

Before the polyurethanes were prepared, the SBO polyol was first prepared. ATR-FTIR was taken to identify the chemical structure of the ESO and SBO polyol as shown in Fig. 3. That can be clearly seen by the absorption at 823 cm−1 for the expoxy group in ESO has disappeared in SBO polyol, showing no epoxy group was present in the SBO polyol. Instead, there was an absorption peak around 3427 cm−1 for the –OH group was formed. The results of the IR spectra indicate that the SBO polyol was successfully synthesized. Hybrid polyurethanes were synthesized by two steps: first, the prepolymer was prepared by the reaction between SBO polyol and IPDI, then different molar ratios of the DDSQ(Me)OH and BDO were added as chain extenders of the reaction. Thus, a series of hybrid polyurethane has a content of DDSQ(Me)OH up to 12.26 wt%. The IR spectra of pure polyurethane and hybrid polyurethane are shown in Fig. 4. All polyurethanes exhibited peaks around 3340 cm−1, which belonged to the characteristic absorption peaks of –NH–. The peaks around 1680 cm−1 and 1520 cm−1 belonged to the bending vibration peaks of amide and telescopic vibration peaks of C=O, respectively. The absorption peak around 1100 cm−1 belonged to the stretching vibration of Si–O–Si groups. Unfortunately, the overlap between the aliphatic ether and Si–O–Si groups in the hybrid polyurethanes, led to small difference in the IR spectra (Liu and Zheng 2005).

Thermal decomposition behaviour

Thermogravimetric analysis (TGA) was applied to evaluate the thermal stability of the pure and hybrid polyurethanes in a nitrogen atmosphere between 30 and 800 °C. As the TGA results shown in Fig. 5, all hybrid polyurethanes displayed similar degradation profiles with the pure polyurethane, indicating that the incorporation of DDSQ(Me)OH did not significantly alter the degradation mechanism. For the convenience of comparison, we define Td5 as the onset of decomposition temperature, where the samples attained 5% weight loss. The polyurethanes undergo a two-step thermal deposition process, and the decomposition of urethane bonds took place at above 200 °C first. Obviously, the 5% weight loss temperatures (Td5) were significantly enhanced, with 4.46 wt% DDSQ(Me)OH content, and the Td5 is 291 °C (see Table 2), almost 21 °C higher than pure polyurethane. However, beyond 4.46 wt%, with the increasing content of DDSQ(Me)OH, the Td5 showed a downtrend. Two possible factors could contribute to this phenomenon: one is that the incorporation of DDSQ(Me)OH into the main chain of polyurethane, and the movement and scission of molecular chains were significantly retarded, thus improved the Td5. The other one is that the aggregation of DDSQ(Me)OH became more and more serious when DDSQ(Me)OH content is over 4.46 wt%, which could reduce the overall effectiveness in inhibiting chain scission. These two opposite factors determined the change of the Td5. Afterwards, the second decomposition process occurred at about 340 °C belonged to the chain scission of SBO oil (Morent et al. 2011; Gu et al. 2012). In addition, the decomposition rates of the hybrid polyurethanes during the second decomposition process were slower, due to the curves became flatter above 350 °C with high DDSQ(Me)OH content. At high temperature, the silicon dioxide from the oxidation of DDSQ(Me)OH would be wrapped in the surface so that the release of gaseous products from segmental decomposition was suppressed. This significantly improved the thermal insulation and the flame resistance of the material (Vaia and Maguire 2007).

DSC analysis

The differential scanning calorimetry (DSC) was applied to measure the glass transition temperatures (Tg) of the hybrid polyurethanes. The Tg (the midpoint of the stepwise decrease of the heat flow trace observed during heating) values are listed in Table 2 and Tg curves are shown in Fig. 6. It was indicated that the Tg of the hybrid polyurethanes increased to the maximum and then decreased with the increasing of the DDSQ(Me)OH content. With 4.46 wt% DDSQ(Me)OH content, Tg reached the maximum of 65.8 °C (12.4 °C improved compared with pure polyurethane). There are two opposite factors contributed to this phenomenon. At low DDSQ(Me)OH content, the DDSQ(Me)OH cages in the polyurethane main chains could restrict the motion of chains and hinder the chain slide, thus improved the Tg. However, high DDSQ(Me)OH content led to serious aggregation. And the aggregation particles acted as lubricant in the molecular chains, thus improved chain sliding and cause the decrease of the Tg. Both of these two factors act on the Tg change of hybrid polyurethanes.

Mechanical properties of hybrid polyurethanes

The mechanical properties of hybrid polyurethanes were investigated as the curves of elongation at break and tensile strength are shown in Fig. 7. It showed that the tensile strength of pure polyurethanes is 6.2 MPa, but with the addition of DDSQ(Me)OH, the tensile strength increased obviously. When the content of DDSQ(Me)OH was up to 4.46 wt%, the tensile strength of hybrid polyurethane was 12.3 MPa. It is probably due to the increment of the polymer’s crosslinking density with the chemical introduction of DDSQ(Me)OH and nano-reinforcement from the DDSQ(Me)OH cages. Nevertheless, when the DDSQ(Me)OH content exceeded 4.46 wt%, the tensile strength decreased. The aggregation of DDSQ(Me)OH and over-crosslinking led to the mechanical impairment and then caused this change. The incorporation of DDSQ(Me)OH did not make significant effects on the elongation at break.

Morphology

Scanning electron microscopy (SEM) was applied to detect the change in the surface morphology caused by the DDSQ(Me)OH content. Figure 8 exhibits a series of polyurethanes with different DDSQ(Me)OH contents. It showed that the morphology of hybrid polyurethane displayed relatively smooth structure at low DDSQ(Me)OH content, whereas as the DDSQ(Me)OH content increased, due to the hydrophobicity of benzene ring, the hydroxyls hung on the open face of the DDSQ(Me)OH cage would be the only direction of the nano-cages interacted with the matrix. As a result, the dispersed particles gradually seeped into the organic matrix and small particles gradually aggregated into larger ones. In addition, the material morphology would be changed due to the inclusion of DDSQ(Me)OH.

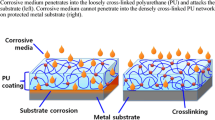

Surface hydrophobicity

The surface hydrophobicity of hybrid polyurethanes was investigated by the contact angle (CA) measurement using water. The results are summed up in Table 3 and Fig. 9. Pure polyurethane was hydrophilic, and its static contact angle of water was about 85.7°. When 1.48 wt% of DDSQ(Me)OH was incorporated, the contact angle of water was about 92.2°, which means the hybrid polyurethane turned into hydrophobic. What’s more, the contact angles of water for hybrid polyurethanes were significantly increased with the addition of DDSQ(Me)OH. With 12.26 wt% of the DDSQ(Me)OH, the static contact angle of water for hybrid polyurethanes was up to about 110.2°, the surface hydrophobicity received a remarkable improvement, which was supposed to have more strong water-proof property than unmodified polyurethane films. And it has a potential to be developed in coatings after further improvement.

Conclusions

In this work, 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane and soybean oil-based polyol were successfully synthesized according to the results of IR, 1H NMR and MALDI–TOF–MS analysis. Consequently, a series of sustainable polyurethanes were prepared and modified by different contents of DDSQ(Me)OH in the main chain. The thermodynamic performance, mechanical properties, morphology and surface hydrophobicity of the hybrid polyurethanes were analyzed through several characterization techniques. TGA indicated that the stability of the hybrid polyurethanes was improved especially at high temperature. The DSC revealed that the glass transition temperature (Tg) of the modified materials were also enhanced. In terms of tensile test, under certain content of DDSQ(Me)OH, the mechanical properties were improved obviously. SEM suggested that the DDSQ(Me)OH was dispersed homogeneously in the polymer matrix at low content, while the serious aggregation was triggered at high content. Overall, due to the aggregation of DDSQ(Me)OH at high content, the thermal stability and mechanical properties got the best improvement at 4.46 wt% DDSQ(Me)OH content. While DDSQ(Me)OH is the derivatives of organosilicon compound, which is known for low free energy. As the static contact angle displayed, with the increase of DDSQ(Me)OH incorporation content, the hydrophobicity of the hybrid polyurethanes was significantly improved, that means the aggregation of DDSQ(Me)OH at high content had very little effect on the hydrophobicity property. In sum, current work was confirmed that the introduction of DDSQ(Me)OH in the polyurethane main chain improved the polymer quantities in different ways, which is expected to reduce the use of petroleum-based material for the development of polyurethanes.

References

Büttner H, Steinbauer J, Wulf C, Dindaroglu M, Schmalz HG, Werner T (2017) Organocatalyzed synthesis of oleochemical carbonates from CO2 and renewables. Chemsuschem 10:1076–1079. https://doi.org/10.1002/cssc.201601163

Feher FJ, Weller KJ (1990) Polyhedral aluminosilsesquioxanes as models for aluminosilicates: unique synthesis of anionic aluminum/silicon/oxygen frameworks. Organometallics 9:2638–2640

Feher FJ, Wyndham KD (1998) Amine and ester-substituted silsesquioxanes: synthesis, characterization and use as a core for starburst dendrimer. Chem Commun 3:323–324. https://doi.org/10.1039/A707140J

Garbark DB, Benecke HR (2011) Solvent-less preparation of polyols by ozonlysis. US patent, 0269978, 3 Nov 2011

Gnanasekaran D, Walter PA, Reddy B (2013) Influence of moieties on morphology, thermal, and dielectric properties in polyamide–polyhedral oligomeric silsesquioxanes nanocomposites. Polym Eng Sci 53:1637–1644. https://doi.org/10.1002/pen.23427

Gu R, Konar S, Sain M (2012) Preparation and characterization of sustainable polyurethane foams from soybean oils. J Am Oil Chem Soc 89:2103–2111. https://doi.org/10.1007/s11746-012-2109-8

Hoque MA, Kawakami Y (2016) Synthesis of polysilsesquioxanes with double-decker silsesquioxane repeating units. J Sci Res 8:217–227. https://doi.org/10.3329/jsr.v8i2.26791

Hoque MA, Kakihana Y, Shinke S, Kawakami Y (2009) Polysiloxanes with periodically distributed isomeric double-decker silsesquioxane in the main chain. Macromolecules 42:3309–3315. https://doi.org/10.1021/ma900124x

Huang KW, Kuo SW (2010) High-performance polybenzoxazine nanocomposites containing multifunctional POSS cores presenting vinyl-terminated benzoxazine groups. Macromol Chem Phys 211:2301–2311. https://doi.org/10.1002/macp.201000362

Huang J, He C, Xiao Y, Mya KY, Dai J, Siow YP (2003) Polyimide/POSS nanocomposites: interfacial interaction, thermal properties and mechanical properties. Polymer 44:4491–4499. https://doi.org/10.1016/S0032-3861(03)00434-8

Huang J, Jiang P, Li X, Huang Y (2016a) Synthesis and characterization of sustainable polyurethane based on epoxy soybean oil and modified by double-decker silsesquioxane. J Mater Sci 51:2443–2452. https://doi.org/10.1007/s10853-015-9557-0

Huang J, Jiang P, Wen Y, Deng J, He J (2016b) Soy-castor oil based polyurethanes with octaphenylsilsesquioxanetetraol double-decker silsesquioxane in the main chains. RSC Adv 6:69521–69529. https://doi.org/10.1039/C6RA12790H

Huang J, Jiang P, Wen Y, Agus H (2017) Synthesis and properties of castor oil based polyurethanes reinforced with double-decker silsesquioxane. Polym Bull 74:2767–2785. https://doi.org/10.1007/s00289-016-1838-5

Kandanarachchi P, Guo A, Petrovic Z (2002) The hydroformylation of vegetable oils and model compounds by ligand modified rhodium catalysis. Mol Catal A Chem 184:65–71. https://doi.org/10.1016/S1381-1169(01)00420-4

Ledin PA, Tkachenko IM, Xu WN, Choi I, Shevchenko VV, Tsukruk VV (2014) Star-shaped molecules with polyhedral oligomeric silsesquioxane core and azobenzene dye arms. Langmuir 30:8856–8865. https://doi.org/10.1021/la501930e

Leveneur S, Ledoux A, Estel L, Taouk B, Salmi T (2014) Epoxidation of vegetable oils under microwave irradiation. Chem Eng Res Des 92(8):1495–1502. https://doi.org/10.1016/j.cherd.2014.04.010

Lichtenhan JD, Vu NQ, Carter JA, Gilman JW, Feher FJ (1993) Silsesquioxane–siloxane copolymers from polyhedral silsesquioxanes. Macromolecules 26:2141–2142

Lichtenhan JD, Otonari YA, Carr MJ (1995) Linear hybrid polymer building blocks: methacrylate functionalized polyhedral oligomeric silsesquioxane monomers and polymers. Macromolecules 28:8435–8437

Liu HS, Jeng SC (2013) Liquid crystal alignment by polyhedral oligomeric silsesquioxane (POSS)-polyimide nanocomposites. Opt Mater 35:1418–1421. https://doi.org/10.1016/j.optmat.2013.02.011

Liu H, Zheng S (2005) Polyurethane networks nanoreinforced by polyhedral oligomeric silsesquioxane. Macromol Rapid Commun 26:196–200. https://doi.org/10.1002/marc.200400465

Liu Y, Ni Y, Zheng S (2006) Polyurethane networks modified with octa(propylglycidyl ether) polyhedral oligomeric silsesquioxane. Macromol Chem Phys 207:1842–1851. https://doi.org/10.1002/macp.200600241

Lluch C, Ronda JC, Galia M, Lligadas G, Cadiz V (2010) Rapid approach to biobased telechelics through two one-pot thiol-ene click reactions. Biomacromolecules 11:1646–1653. https://doi.org/10.1021/bm100290n

Moore LM, Zavala JJ, Lamb JT, Reams JT, Yandek GR, Guenthner AJ, Haddad TS, Ghiassi KB (2018) Bis-phenylethynyl polyhedral oligomeric silsesquioxanes: new high-temperature, processable thermosetting materials. RSC Adv 8(48):27400–27405. https://doi.org/10.1039/C8RA05954C

Morent R, Geyter ND, Vlierberghe SV, Beaurain A, Dubruel P, Payen E (2011) Influence of operating parameters on plasma polymerization of acrylic acid in a mesh-to-plate dielectric barrier discharge. Prog Org Coat 70:336–341. https://doi.org/10.1016/j.porgcoat.2010.09.031

Musto P, Abbate M, Pannico M, Scarinzi G, Ragosta G (2012) Improving the photo-oxidative stability of epoxy resins by use of functional POSS additives: a spectroscopic, mechanical and morphological study. Polymer 53:5016–5036. https://doi.org/10.1016/j.polymer.2012.08.063

Oaten M, Choudhury NR (2005) Silsesquioxane–urethane hybrid for thin film applications. Macromolecules 38:6392–6401. https://doi.org/10.1021/ma0476543

Pérez-Sena WY, Cai X, Kebir N, Vernières-Hassimi L, Serra C, Salmi T, Leveneur S (2018) Aminolysis of cyclic-carbonate vegetable oils as a non-isocyanate route for the synthesis of polyurethane: a kinetic and thermal study. Chem Eng J 346:271–280. https://doi.org/10.1016/j.cej.2018.04.028

Petrovic ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–115. https://doi.org/10.1080/15583720701834224

Petrović ZS, Wan X, Bilic O, Zlatanic A, Hong J, Javni I, Ionescu M, Milic J, Degruson D (2013) Polyols and polyurethanes from crude algal oil. J Am Oil Chem Soc 90:1073–1078. https://doi.org/10.1007/s11746-013-2245-9

Sawpan MA (2018) Polyurethanes from vegetable oils and applications: a review. J Polym Res 25:184. https://doi.org/10.1007/s10965-018-1578-3

Seino M, Hayakawa T, Ishida Y, Kakimoto MA, Watanabe K, Oikawa H (2006) Hydrosilylation polymerization of double-decker-shaped silsesquioxane having hydrosilane with diynes. Macromolecules 39:3473–3475. https://doi.org/10.1021/ma052631p

Sheng Y, Jiang P, Zhang D, Hua J (2015) Synthesis and characterization of sustainable polyurethane modified by cyclic polysiloxane. J Appl Polym Sci 132:41277. https://doi.org/10.1002/app.41277

Turri S, Levi M (2005a) Structure, dynamic properties, and surface behavior of nanostructured ionomeric polyurethanes from reactive polyhedral oligomeric silsesquioxanes. Macromolecules 38:5569–5574. https://doi.org/10.1021/ma047304g

Turri S, Levi M (2005b) Wettability of polyhedral oligomeric silsesquioxane nanostructured polymer surfaces. Macromol Rapid Commun 26:1233–1236. https://doi.org/10.1002/marc.200500274

Vaia RA, Maguire JF (2007) Polymer nanocomposites with prescribed morphology: going beyond nanoparticle-filled polymers. Chem Mater 19:2736–2751. https://doi.org/10.1021/cm062693+

Wang L, Zhang CY, Zheng SX (2011) Organic–inorganic poly(hydroxyether of bisphenol A) copolymers with double-decker silsesquioxane in the main chains. J Mater Chem 21:19344–19352. https://doi.org/10.1039/C1JM13596A

Wang XB, Chin JM, He CB, Xu J (2014) Highly thermally resistant polyhedral oligomeric silsesquioxanes lubricating oil prepared via a thiol-ene click reaction. Sci Adv Mater 6:1553–1561. https://doi.org/10.1166/sam.2014.1804

Wei K, Wang L, Zheng S (2013) Organic–inorganic polyurethanes with 3,13-dihydroxypropyloctaphenyl double-decker silsesquioxane chain extender. Polym Chem 4:1491–1501. https://doi.org/10.1039/C2PY20930F

Żak P, Dudziec B, Kubicki M, Marciniec B (2014) Silylative coupling versus metathesis—efficient methods for the synthesis of difunctionalized double-decker silsesquioxane derivatives. Chem A Eur J 20(30):9387–9393. https://doi.org/10.1002/chem.201402862

Zeng K, Liu Y, Zheng S (2008) Poly(ethylene imine) hybrids containing polyhedral oligomeric silsesquioxanes: preparation, structure and properties. Eur Polym J 44:3946–3956. https://doi.org/10.1016/j.eurpolymj.2008.07.049

Zhang J, Zhao W, Yu J (2012) Progress in preparation of vegetable oil based polyols and their applications in rigid polyurethane foams. Chem Propellants Polym Mater 10:11–22

Zhang X, Wang C, Fang S, Sun J, Li C, Hu Y (2013) Synthesis and characterization of well-defined star PLLA with a POSS core and their microspheres for controlled release. Colloid Polym Sci 291:789–803. https://doi.org/10.1007/s00396-012-2790-z

Zhao H, Herrington R, Driguez F (2011) Natural oil based autocatalytic polyols. US patent, 20110118432, 19 Mar 2011

Acknowledgements

The authors gratefully acknowledge the support from the Fundamental Research Funds for the Central Universities (JUSRP51623A). The authors also thank International Joint Research Laboratory for Biomass Conversion Technology at Jiangnan University for the support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Wen, Y., Jiang, P., Haryono, A. et al. Synthesis and properties of epoxy soybean oil-based polyurethanes modified by 3,13-dimethyhydroxysilyl double-decker phenylsilsesquioxane. Chem. Pap. 73, 747–756 (2019). https://doi.org/10.1007/s11696-018-0620-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-018-0620-6