Abstract

Solid-state fermentation (SSF) is a bioconversion process for turning cheap agro-industrial materials to added-value products. For enrichment of agro-industrial materials with arachidonic acid (ARA; C20:4 n-6), SSF process of Mortierella sp. was developed by optimizing cultivation medium and parameters. The results showed that the fungal cultivation on the medium with optimal ratio of selected agricultural materials provided the fermented mass containing high ARA proportion of total fatty acid. Inclusion of the optimal medium with suitable amount of spent mushroom substrate, which was used as an internal support, significantly promoted the ARA production yield. Using the predicted quadratic model generated by Box–Behnken design, the maximal ARA production yield was achieved, thereby the fermentation parameter set for ARA production was experimentally validated using the developed medium formula. Of variables studied, the culture temperature and initial moisture content were important for the ARA production. The developed SSF process would provide a prospect for larger scale production of ARA by this fungal strain.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agro-industrial residues are inexhaustibly generated from various agriculture and food industries. Some of them, such as wheat bran, soybean meal and spent malt grain, have long been exploited as feed ingredients. Recently, there is considerable attention in increasing nutritional value of such residues for boosting animal health. Bioconversion of feed ingredients by fungal fermentation is a promising approach for sustainable production of added-value products. Of them, the fermented product enriched with arachidonic acid (ARA, 5,8,11,14-cis-eicosatetraenoic acid), which is an essential fatty acid in n-6 series, is of particular interest due to its biologically active function. This 20-carbon polyunsaturated fatty acid (20C-PUFA) is a precursor for synthesis of certain eicosanoid, series-2 prostaglandin (Bell and Sargent 2003; Ricciotti and FitzGerald, 2011). In addition to application in infant formula, the 20C-PUFA has been proven to benefit for aquacultures. There is evidence, showing that the inclusion of ARA oils into fish feeds led to enhance growth, development and survival of freshwater and marine fish species (Bessonart et al. 1999; Castell et al. 1994).

Mortierella spp. belonging to Zygomycete fungi are promising producers for ARA (Castell et al. 1994; Kendrick and Ratledge 1992; Rayaroth et al. 2017). One of microbial process platforms for ARA production is solid-state fermentation (SSF), which offers several advantages over the counter part of submerged fermentation, such as utilization of low-priced agro-industrial substrates, simple operation mode and cost-effectiveness (Certik et al. 2012; Lio and Wang, 2012; Soccol et al. 2017). Moreover, the decrease of anti-nutrient compounds in agro-industrial substrates was also derived as a result of enzyme catalytic function during fungal growth. However, the ability in ARA production of this fungal group is strain-dependent, and thus special effort has been made to screen the potential strains from natural habitats (Aki et al. 2001; Zhu et al. 2004). A variety of agro-industrial materials with nutritional diversity have been exploited for ARA production through fungal SSF (Jang et al. 2000). Supplementations of basic solid substrates with spent malt grain and plant oils as an internal support and fatty acid precursors, respectively, have been postulated to be efficient approaches for enhancing PUFA production yield (Certik et al. 2013). In addition to the nutrient composition and physical structure of substrates, optimization of cultivation parameters is also a crucial step in enrichment of the tailored-made oils in the fermented products (Asadi et al. 2015). However, the techno-economic feasibility and scalability of the 20C-PUFA production process should be taken into account.

Spent mushroom substrate (SMS) is a by-product derived from mushroom production after the completion of harvest. Even though SMS has low value, it contains some nutrients and organic matter with beneficial effects on animal health (Medina et al. 2009; Paredes et al. 2009; Zhu et al. 2012). Therefore, it is becoming challenge to explore new applications of such renewable resource. This work aimed to develop SSF process for ARA production by Mortierella sp. BCC40632, which is an ARA over-producing strain, using a combinatorial strategy. The medium composition for SSF was optimized by combining the suitable type of agricultural substrates with optimal ratio. In addition, SMS was also included into the optimized medium for investigating its effect on ARA production. Statistically experimental design was employed for assessing significant variables and fine-tuned optimizing the ARA production yield of Mortierella sp.

Experimental

Microorganism

Mortierella sp. strain BCC40632, which has been deposited in BIOTEC Culture Collection (BCC), was subjected for SSF. It was maintained on potato dextrose agar (PDA) slant at 4 °C and regularly transferred every 2 months.

Inoculum preparation

The fungal cells grown on PDA medium at 30 °C for 7 days were used for inoculum preparation. A primary inoculum was prepared in 250-mL baffle flask containing 50 mL of semi-synthetic medium, which one liter consisted of 40.0 g glucose, 5.0 g yeast extract, 2.4 g KH2PO4, 0.5 g MgSO4.7H2O, 0.1 g CaCl2.7H2O, 0.2 g NH4Cl, 10 mg MnSO4.H2O, 0.5 mg CuSO4.5H2O, 15 mg FeCl3.6H2O and 7.5 mg ZnSO4.7H2O. The culture was grown at 30 °C with shaking at 250 rpm for 3 days. For preparation of the secondary inoculum, 7–13% (v/v) of the active mycelial cells were transferred into 500-mL baffle flask containing 100 mL of the semi-synthetic medium and cultivated at the condition as described above. Then, the mycelial suspension was used as an inoculum for SSF.

SSF by Mortierella sp. using agricultural and agro-industrial materials

SSF was carried out in a 250-mL Erlenmeyer flask containing 20 g of substrate. For screening of suitable substrate for ARA production, various agricultural and agro-industrial materials, including corn (CO), defatted soybean meal (DFSB), full-fat soybean (FSB), polished rice (PR) and rice bran (RB) were individually used as basal substrates. Furthermore, the agricultural material (RB), which provided the highest ARA content, were selected as a substrate base for optimizing the composition of seven solid media (Mix 1–Mix 7), as shown in Table 1. The spent mushroom substrate derived from oyster mushroom cultivation was chosen as an internal support. The SMS, which consisted of 36.42% carbohydrate, 2.21% total nitrogen and 0.06% fat (w/w), was prepared by mechanical grinding to derive the particle size of about 1.0–1.5 mm. The ground SMS was added into the culture medium at different amounts (10–50%, w/w). For some experiments (Mix 6 and Mix 7), polished rice and full-fat soybean were also included to investigate the effect of mixed agricultural substrates on ARA production. Full-fat soybean contained high content of lipids, which consisted of high levels of oleic acid (C18:1 n-9) and linoleic acid (C18:2 n-6). Fatty acid profile and total fatty acid content of all substrates used in this work are provided in Supplementary 1. In addition, effect of supplementation of plant oils, including rice bran oil, soybean oil and sunflower oil, with different amounts (1, 3 and 5% w/w) on ARA production was investigated.

In experiments of medium optimization, 10% (v/w) of mycelial suspension were added into individual substrates and mixed thoroughly. The initial moisture content of all substrates was adjusted to 70%. The cultures were incubated at 30°C, gently shaken every day, and then harvested at different fermentation periods (3, 6 and 9 days). All the experiments were performed in triplicates, and the values are expressed as means ± SD. Statistical Program for Social Sciences (SPPS) software version 11.5 (SPSS software products, USA) was used for statistical analysis of data. One-way analysis of variance (ANOVA) was used to compare the mean values using Tukey test. Data with p values ≤ 0.05 were considered statistically significant.

Design of experiment

For maximizing the ARA production yield, Box–Behnken design (BBD) (Box and Behnken 1960) and response surface methodology (RSM) were used to generate a mathematical correlation between three independent variables on ARA production of Mortierella sp. The variables studied were initial moisture content of substrate (X1), culture temperature (X2) and inoculum size (X3). Each variable was tested at three levels, high (+), middle (0), and low (− 1), as shown in Table 2. Accordingly, the BBD of experiment consisted of 18 runs (Table 3), in which the optimized substrate mixture (Mix 7) was employed. Before fungal inoculation, the initial moisture contents of the medium were adjusted to the set points (50–70%), regarding to the optimal range as previously reported (Jang et al. 2000). The amounts of mycelial suspension were varied (7, 10 and 13%, v/w), and the temperature variables were 25–30 °C, which the values were considerable concern for operating costs, including culture volume and chilling processes, respectively.

Multiple regression analysis is explained by the following quadratic model equation:

where Y is the predicted respond. β0 is intercept. β1, β2 and β3 are the linear coefficients, whereas β11, β22 and β33 are the squared coefficients, and thus β12, β13 and β23 are the interaction coefficients. The coefficients of the model, ANOVA for the experimental data, optimal parameters, and generation of response surface plot were calculated and plot using Design-Expert® Software Version 11.0 (Stat-Ease Inc., MN, USA). As a consequence, experimental validation of the quadratic model was performed. Using the Mix 7 medium with optimized initial moisture content (60%) and inoculum size (10%, v/w), the fungal fermentation at lower temperature (20 °C) was also conducted.

Fatty acid analysis

The fermented mass was harvested and dried at 60 °C to obtain a constant weight, and then subjected for fatty acid analysis. Fatty acid methyl ester (FAME) was prepared using the method modified from the previous report (Lepage and Roy 1984), and then analyzed using gas chromatography (GC-7890B; Agilent Technologies; USA) equipped with a flame ionization detector and an HP-88 capillary column (100 m × 250 μm × 0.2 μm, Agilent Technologies, USA). The injector and detector temperatures were maintained at 240 °C, and oven temperature was programmed from 140 to 240 °C with an increasing rate of 4 °C/min. Fatty acids were identified by comparing their retention times with FAME standards (Sigma, St. Louis, MO). Amounts of fatty acids were calculated from their chromatography peak areas using heneicosanoic acid (C21:0) as an internal standard.

Results and discussion

Evaluation of agro-industrial and agricultural materials for ARA production by SSF

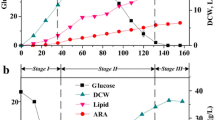

Fatty acid analysis showed that the nutritionally important 20C-PUFA (ARA), which is a predominant fatty acid of Mortierella cells (Dyal and Narine 2005), was detected in all cultures of Mortierella sp. BCC40632, but it was absent in substrates, indicating that the fungus was able to grow on all agro-industrial and agricultural substrates tested. At 30 °C cultivation, there were significant differences in ARA contents and proportions among the cultures using various substrates (p < 0.05). With the exception of the rice bran culture, the maximal ARA contents in fermented mass were found in the Mortierella cultures grown for 6 days, which a range of 2–10 mg ARA/g dry fermented mass was obtained (Fig. 1).

Solid-state fermentation of Mortierella sp. BCC40632 using 20 g of individual corn (CO), defatted soybean (DFSB), full-fat soybean (FSB), polished rice (PR) and rice bran (RB) as sole substrates. The ARA proportion in total fatty acid a, ARA content of fermented mass b, and total fatty acid content in fermented mass c of Mortierella cultures are illustrated. Diagonal, black and white bars indicate the cultures grown at 30 °C for 3, 6 and 9 days, respectively

Interestingly, the highest ARA proportion (75.8 ± 2.2% of TFA) was obtained in the 6th-day polished rice culture (Fig. 1a). Although the rice bran cultures contained lower ARA proportions in TFA as compared to the polished cultures, the highest ARA content (about 30 mg/g dry fermented mass) was observed in the rice bran cultures grown for 6 and 9 days (Fig. 1b). However, TFA contents in the rice bran culture decreased when prolonged cultivations (Fig. 1c), that might be explained by the fungal growth using the oils in rice bran as a carbon source. Possibly, the fatty acids constituted in rice bran might be transformed to ARA by the fungal cells as the sharp increase of ARA content, and the decrease of oleic acid and linoleic acid contents in the 6th-day fermented mass, when compared with rice bran substrate. Taken together, rice bran was the most effective substrate in terms of high ARA content in fermented mass followed by full-fat soybean and polished rice, which are in agreement with the previous reports for PUFA production by fungal fermentation (Jangbua et al. 2009; Oliveira et al. 2011). It has been reported that rice bran was the best suitable substrate for ARA production by Mortierella alpina ATCC 32222 when cultivated at lower temperature (20 °C) for 8 days (Jang et al. 2000). Notably, corn and defatted soybean were poor substrates for ARA production by Mortierella sp. BCC40632. In addition to the nitrogen source, the high amounts of lipids (TFA) rich in oleic acid (C18:1 n-9) and linoleic acid (C18:2 n-6) in the nutrient-enriched rice bran and full-fat soybean (Supplementary 1) might be used as precursors for ARA biosynthesis of Mortierella cells.

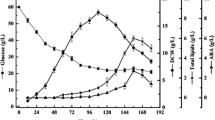

Enhanced ARA production by mixing suitable substrates

Regarding to the result of substrate screening, three agricultural materials, including full-fat soybean, rice bran and polished rice, were selected for further improvement of ARA production of Mortierella sp. by either mixing equal amount of each substrate or optimizing SMS amount (Table 1). Using the substrate mixtures (Mix 1–Mix 7), TFA contents of all cultures continually decreased along the fermentation period (Fig. 2), which might be a result of lipid degradation by the fungal cells, possibly for cell growth. Similar finding has been reported for SSF of other filamentous fungi using rice bran substrate (Oliveira et al. 2011; Oduguwa et al. 2008). It is noteworthy that the ARA contents in the cultures using the substrate mixtures increased and reached the maximum levels at 9th-day cultivation, corresponding to the induced ARA proportions (Fig. 2), which were not similar to the cultures grown on single substrate as aforementioned (Fig. 1). Obviously, the ARA content of the culture grown on the substrate mixture of rice bran and 10% (w/w) SMS (Mix 1) significantly increased (51.67% increase) when compared with the culture using rice bran as a sole substrate (p < 0.05). When combined with higher amount of SMS (20–50% w/w) into the medium, the ARA content did not increase as compared with the rice bran culture containing 10% SMS, which might be explained by insufficient nutrient for cell growth and ARA production as a consequence of reduced amount of rice bran in the medium. Probably, the combination with low amount of SMS (10% w/w) could sufficiently enhance either oxygen transfer or mycelial penetration into substrates as a result of the physical structure of SMS, which was a relatively porous material. Actually, fatty acid desaturation is oxygen-dependent reaction (Laoteng et al. 2011), and thus oxygen molecule is required for ARA biosynthesis. This finding is coincided with the previous report using spent malt grain as an internal support for gamma-linolenic acid production (Jangbua et al. 2009). Besides, SMS derived from oyster mushroom cultivation also consisted of some metal ions (Ashrafi et al. 2014; Lou et al. 2017), which might positively affect the ARA production of Mortierella sp. as previously described (Laoteng et al. 2011).

Solid-state fermentation of Mortierella sp. BCC40632 using substrate mixtures (Mix 1–Mix 7, see Table 1). The ARA proportion in total fatty acid a, ARA content of fermented mass b, and total fatty acid content in fermented mass c of Mortierella cultures are illustrated. Diagonal, black and white bars indicate the cultures grown for 3, 6 and 9 days, respectively

Combining rice bran with polished rice and full-fat soybean (1:1:1) in the Mix 6 culture markedly enhanced both ARA content and proportion in TFA when compared with those of the culture using rich bran as a sole substrate (Figs. 1, 2). Expectedly, slight increase of ARA content was also obtained by adding 10% SMS into the culture (Mix 7). These findings suggest that equal amounts of the three agricultural substrates might provide optimal C:N ratio for the 20C-PUFA production.

A similar fashion was also observed in all cultures supplemented with individual plant oils (sunflower, rice bran and soybean oils), in which ARA contents induced with the increase of plant oil concentrations (Fig. 3). However, the supplementation with plant oils with different concentrations did not significantly promote the ARA production when compared with the Mix 7 culture without oil supplementation, except for the culture added with 5% sunflower oil (53.3 ± 3.6 mg/g of ARA in fermented mass). It has been reported that sunflower oil cake was the best substrate for ARA production of M. alpina as its constituents of 85% unsaturated fatty acids, including oleic acid and linoleic acid (Ghobadi et al. 2011; Jacobs et al. 2010). Nevertheless, the ARA proportions in TFA of all cultures supplemented with plant oils were lower than that of the Mix 7 culture without plant oil addition. These results indicated that the ARA production yield depended on not only the plant oils type, but also concentration of the supplemented oils. The inconsistency of plant oil supplementation on ARA synthesis of Mortierella fungi has been documented that exogenous lipids repressed de novo fatty acid synthesis, but had no effect on fatty acid desaturation and elongation (Wynn and Ratledge 2000). Considering cost structure of the production process, particularly in the medium cost, the oil supplementation would be not practical. Hence, the Mix 7 medium was the best substrate for ARA production in terms of high ARA proportion and content that might be come from both optimum nutrient composition and physical structure of the substrate mixture. Due to the scrupulous and dense properties of moisten rice bran, the optimized Mix 7 medium may offer a solution in ARA production of the filamentous fungus at larger scale.

ARA proportion in total fatty acid a, ARA content of fermented mass b and total fatty acid content in fermented mass c of Mortierella cultures supplemented with different amounts (1, 3 and 5%, w/w) of plant oils, including rice bran oil (RBO), soybean oil (SBO) and sunflower oil (SFO). Diagonal, black and white bars indicate the cultures grown for 3, 6 and 9 days, respectively. The Mix 7 culture without oil supplementation was used as a control

Optimization of fermentation parameters using Box–Behnken design

Three independent variables, including initial moisture content of the medium, culture temperature and inoculum size, which are important for fungal SSF, were chosen to investigate their interactions on the dependent response of ARA production yield. The experimental results (actual values) and predicted values of ARA production yield are shown in Table 3. The multiple correlation coefficients (R2) of the model was 0.940, indicating the model strength, which permits description of the response (Babu and Satyanarayana 1995; Jatinder et al. 2006; Malaiwong et al. 2016). In addition, the ANOVA result revealed that X2, X 21 , and X 22 were highly significant variables for the ARA production (p < 0.05), as shown in Table 4.

For ARA production of Mortierella sp., a significant linear effect was influenced by culture temperature (p = 0.000), and the quadratic effects were exerted by both culture temperature (p = 0.000) and initial moisture content (p = 0.000). The optimal values of individual variables are presented by three-dimensional response surface plots (Fig. 4), which were generated to correlate the variables interaction with the ARA production yield.

Of the variables studied, temperature had the greatest impact on the ARA production, whereas the 20C-PUFA yield was not significantly affected by varying the inoculum sizes. The decrease of the culture temperature led to increase the ARA production yield, and the maximum ARA level was found in the culture grown at 25 °C, which was the lowest temperature tested by BBD due to concerning the cost of chilling process for further application at larger scale. It has been reported for submerged fermentation process that low culture temperature favored the production of PUFAs by increasing the degree of fatty acid unsaturation in Mortierella spp. (Sakuradani et al. 2005).

As shown in Fig. 4, the modulate level of initial moisture content in the medium (60%) was sufficient for the enhanced ARA production. Jang and Yang (2008) indicated that optimal initial moisture content of rice bran for production of linoleic acid and ARA was about 75%. In fact, the optimized moisture content is crucial due to its impact on physical–chemical properties of solid substrate that affects the overall productivity (Ganesan et al. 2008). It has been documented that high moisture content of culture medium led to a risk of bacterial contamination, and reduction of substrate porosity affecting oxygen transfer during SSF (Babu and Satyanarayana 1995; Bastos et al. 2016; Lekha and Lonsane 1994). As a result, the optimal SSF condition for ARA production of this fungal species could be identified, which were 25 °C culture temperature, 57% initial moisture content and 10% (v/w) inoculum. Under such condition, the predicted maximum yield of ARA production was 46.57 mg/g dry fermented mass. Previously, Certik et al. (2008) investigated the effect of cereal substrates on ARA production by M. alpina CCF185, which ARA production of 42.3 mg/g dry fermented mass was obtained when using the optimal ratio of wheat bran and spent malt grains (3:1). Similarly, Stredansky et al. (2000) improved the ARA production of Pythium ultimum MUCL 16164 by mixing barley and spent malt grains with linseed oils.

Validation of the optimal condition for ARA production

Validation of the quadratic model and regression equation was conducted using the condition closed to the optimal levels of three variables (60% initial moisture content, 25 °C culture temperature and 10% (v/w) inoculums size). Based on the model, the predicted ARA content and proportion were 45.80 mg/g dry fermented mass and 48.2% of TFA, respectively. The experimental result showed that 46.72 ± 2.54 mg/g dry fermented mass of ARA was obtained in the 9th-day culture of Mortierella sp., which was unquestionably fitted with the predicted value, indicating the respectable model for maximizing the ARA production of this fungal strain. Remarkably, the high ARA proportion (49.50 ± 3.23% of TFA) was also found, which is very close to the predicted value (Supplementary 2). Nevertheless, the ARA production at lower temperature (20 °C) was also investigated using the optimized initial moisture content and inoculums size, yielding 21.6 ± 2.3% ARA/TFA and 20.34 ± 1.54 mg/g ARA in fermented mass of the 9th-day culture. Although the ARA production at the low temperature increased when prolonged cultivation for 12 days (33.5 ± 1.1% ARA/TFA and 36.67 ± 2.12 mg/g ARA in fermented mass), the production yield remained lower than the cultures grown at 25 °C for 9 days. Taken together, the fermented product rich in ARA was obtained, in which ARA was the highest proportion in total lipid. However, the ARA-enriched mass should be further assessed for animal trials, particularly in terms of nutrition properties and feed formulation that would bring a perspective for its application as feed ingredient or feed supplement.

Conclusions

The optimized medium consisting of the mixture of agro-industrial materials substantially attributed the ARA production of Mortierella sp. BCC40632. Improvement of the ARA production yield was also achieved by optimizing the fermentation parameters using BBD. The quadratic model markedly points to the impact of culture temperature and moisture content on the ARA production. This is the first report to demonstrate the application of SMS as an internal support for enhancing ARA production that would be applicable to the production process at larger scale.

Abbreviations

- ARA:

-

Arachidonic acid

- SSF:

-

Solid-state fermentation

- SMS:

-

Spent mushroom substrate

- TFA:

-

Total fatty acid

- PUFA:

-

Polyunsaturated fatty acid

- FAME:

-

Fatty acid methyl ester

References

Aki T, Nagahata Y, Ishihara K, Tanaka Y, Morinaga T, Higashiyama K, Akimoto K, Fujikawa S, Kawamoto S, Shigeta S, Ono K, Suzuki O (2001) Production of arachidonic acid by filamentous fungus, Mortierella alliacea strain YN-15. J Am Oil Chem Soc 78:599–604

Asadi SZ, Khosravi-Darani K, Nikoopour H, Bakhoda H (2015) Evaluation of the effect of process variables on the fatty acid profile of single cell oil produced by Mortierella using solid-state fermentation. Crit Rev Biotechnol 35:94–102. https://doi.org/10.3109/07388551.2013.804805

Ashrafi R, Mian MH, Rahman MM, Jahiruddin M (2014) Recycling of spent mushroom substrate for the production of oyster mushroom. Res Biotechnol 5:13–21

Babu KR, Satyanarayana T (1995) α-Amylase production by thermophilic Bacillus coagulans in solid-state fermentation. Process Biochem 30:305–309

Bastos RG, Motta FL, Santana MHA (2016) Oxygen transfer in the solid-state cultivation of D. monoceras on polyurethane foam as an inert support. Brazil Chem Eng 33:793–799

Bell JG, Sargent JR (2003) Arachidonic acid in aquaculture feeds: current status and future opportunities. Aquaculture 218:491–499. https://doi.org/10.1016/S0044-8486(02)00370-8

Bessonart M, Izquierdo MS, Salhi M, Hernandez-Cruz CM, Gonzalez MM, Fernandez-Palacios H (1999) Effect of dietary arachidonic acid levels on growth and fatty acid composition of gilthead sea bream (Sparusaurata L.) larvae. Aquaculture 179:265–275. https://doi.org/10.1016/S0044-8486(99)00164-7

Box GEP, Behnken DW (1960) Some new three level design for the study of quantitative variables. Tech nom 2:455–475

Castell JD, Bell JG, Tocher DR, Sargent JR (1994) Effects of purified diets containing different combinations of arachidonic and docosahexaenoic acid on survival, growth and fatty acid composition of juvenile turbot (Scophthalmus maximus). Aquaculture 128:315–333. https://doi.org/10.1016/0044-8486(94)90320-4

Certik M, Adamechova Z, Hanusova V, Breierova E (2008) Biotechnology as a useful tool for nutritional improvement of cereal-based materials enriched with polyunsaturated fatty acids and pigments. Acta Agron Hung 56:377–384. https://doi.org/10.1556/AAgr.56.2008.4.1

Certik M, Adamechova Z, Laoteng K (2012) Microbial production of gamma-linolenic acid: Submerged versus solid-state fermentations. Food Sci Biotechnol 21:921–926. https://doi.org/10.1007/s10068-012-0121-2

Certik M, Adamechova Z, Guothova L (2013) Simultaneous enrichment of cereals with polyunsaturated fatty acids and pigments by fungal solid state fermentations. J Biotechnol 168:130–134. https://doi.org/10.1016/j.jbiotec.2013.03.016

Dyal SD, Narine SS (2005) Implications for the use of Mortierella fungi in the industrial production of essential fatty acids. Food Res Int 38:445–467

Ganesan V, Muthukumarappan K, Rosentrater KA (2008) Effect of moisture content and soluble level on the physical, chemical, and flow properties of distillers dried grains with solubles (DDGS). Cereal Chem 85:464–470

Ghobadi Z, Esfahani ZH, Azizi MH (2011) Determination of effective variables on arachidonic acid production by Mortierella alpina CBS 754.68 in solid-state fermentation using plackett-burman screening design. World Acad Sci Eng Tech 58:678–680

Jacobs A, Botha A, Reddy JK, Van Zyl WH (2010) Sunflower press cake as a substrate for eicosapentaenoic acid production by representative of the genus Mortierella. Bioresour Technol 5:1232–1243

Jang HD, Lin YY, Yang SS (2000) Polyunsaturated fatty acid production with Mortierella alpina by solid substrate fermentation. Bot bull Acade Sci 41:41–48

Jang HD, Yang SS (2008) Polyunsaturated fatty acids production with a solid-state column reactor. Bioresour Technol 99:6181–6190. https://doi.org/10.1016/j.biortech.2007.12.024

Jangbua P, Laoteng K, Kitsubun P, Nopharatana M, Tongta A (2009) Gamma-linolenic acid production of Mucor rouxii by solid-state fermentation using agricultural by-products. Lett Appl Microbiol 49:91–97

Jatinder K, Chadha BS, Saini HS (2006) Optimization of culture conditions for production of cellulases and xylanases by Scytalidium thermophilum using response surface methodology. World J Microbiol Biotechnol 22:169–176. https://doi.org/10.1007/s11274-005-9015-2

Kendrick A, Ratledge C (1992) Lipids of selected molds grown for production of n-3 and n-6 polyunsaturated fatty acids. Lipids 27:15–20

Laoteng K, Certik M, Cheevadhanark S (2011) Mechanisms controlling lipid accumulation and polyunsaturated fatty acid synthesis in oleaginous fungi. Chem Pap 66:97–103. https://doi.org/10.2478/s11696-010-0099-2

Lekha PK, Lonsane BK (1994) Comparative titres, location and properties of tannin acyl hydrolase produced by Aspergillus niger PKL 104 in solid-state, liquid surface and submerged fermentations. Process Biochem 29:497–503. https://doi.org/10.1016/0032-9592(94)85019-4

Lepage G, Roy CC (1984) Improved recovery of fatty acid through direct transesterification without prior extraction or purification. J Lipid Res 25:1391–1396

Lio J, Wang T (2012) Solid-state fermentation of soybean and corn processing coproducts for potential feed improvement. Agric Food Chem 60:7702–7709

Lou Z, Sun Y, Zhou X, Baig SA, Hu B, Xu X (2017) Composition variability of spent mushroom substrates during continuous cultivation, composting process and their effects on mineral nitrogen transformation in soil. Geoderm 307:30–37. https://doi.org/10.1016/j.geoderma.2017.07.033

Malaiwong N, Yongmanitchai W, Chonudomkul D (2016) Optimization of arachidonic acid production from Mortierella alpina PRAO7-10 by response surface methodology. Agricul Nat Res 50:162–172. https://doi.org/10.1016/j.anres.2016.06.003

Medina E, Paredes C, Perez-Murcia M, Bustamante M, Moral R (2009) Spent mushroom substrates as component of growing media for germination and growth of horticultural. Bioresour Technol 100:4227–4232. https://doi.org/10.1016/j.biortech.2009.03.055

Oduguwa OO, Edema MO, Ayeni AO (2008) Physico-chemical and microbiological analyses of fermented corn cob, rice bran and cowpea husk for use in composite rabbit feed. Bioresour Technol 99:1816–1820

Oliveira MS, Feddern V, Kupski L, Cipolatti EP, Badiale-Furlong E, Almeida L (2011) Changes in lipid, fatty acids and phospholipids composition of whole rice bran after solid-state fungal fermentation. Bioresour Technol 102:8335–8338. https://doi.org/10.1016/j.biortech.2011.06.025

Paredes C, Medina E, Moral R, Perez-Murcia MD, Moreno-Caselles J, Bustamante MA, Cecilia JA (2009) Characterization of the different organic matter fractions of spent mushroom substrate. Commun Soil Sci Plant Anal 40:150–161

Rayaroth AC, Tomar RS, Mishra RK (2017) Arachidonic acid synthesis in Mortierella alpina: origin, evolution and advancements. Proc Nat Acad Sci 87:1053–1066

Ricciotti E, FitzGerald A (2011) Prostaglandins and inflammation. Arterioscler Thromb Vasc Biol 31:986–1000. https://doi.org/10.1161/atvbaha.110.207449

Sakuradani E, Takeno S, Abe T, Shimizu S (2005) Arachidonic acid production of Mortierella alpina: creation of mutants and molecular breeding. In: Cohen Z, Ratledge C (eds) Single cell oil. AOCS press, Champaign, pp 21–35. https://doi.org/10.1016/B978-1-893997-73-8.50006-2

Soccol CR, Costa ESF, Letti LAJ, Karp SG, Woiciechowski AL, Vandenberghe LPS (2017) Recent developments and innovations in solid state fermentation. Biotechnol Res Inn 1:52–71. https://doi.org/10.1016/j.biori.2017.01.002

Stredansky M, Conti E, Salaris A (2000) Production of polyunsaturated fatty acids by Pythium ultimum in solid-state cultivation. Enz Microbial Technol 26:304–307. https://doi.org/10.1016/S0141-0229(99)00146-5

Wynn JP, Ratledge C (2000) Evidence that the rate-limiting step for the biosynthesis of arachidonic acid in Mortierella alpina is at the level of the 18:3–20:3 elongase. Microbiology 146:2325–2331

Zhu H, Sheng K, Yan E, Qiao J, Lv F (2012) Extraction, purification and antibacterial activities of a polysaccharide from spent mushroom substrate. Int J Biol Macromol 50:840–843. https://doi.org/10.1016/j.ijbiomac.2011.11.016

Zhu M, YuLJ Liu Z, Xu HB (2004) Isolating Mortierella alpina strains of high yield of arachidonic acid. Lett Appl Microbiol 39:332–335. https://doi.org/10.1111/j.1472-765X.2004.01581.x

Acknowledgements

This work was funded by Cluster Program Management Office, National Science and Technology Development Agency, Thailand (grant number P-13-50368), and Research Initiative fund of Food Biotechnology Research Unit, BIOTEC (grant number P-17-51646).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Antimanon, S., Chamkhuy, W., Sutthiwattanakul, S. et al. Efficient production of arachidonic acid of Mortierella sp. by solid-state fermentation using combinatorial medium with spent mushroom substrate. Chem. Pap. 72, 2899–2908 (2018). https://doi.org/10.1007/s11696-018-0519-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-018-0519-2