Abstract

In this paper, gluten proteins in fermented dough were taken as the research object, and the variations in their physicochemical properties after storage at subfreezing (-9 °C, -12 °C) and − 18 °C were compared. The soluble protein concentration (beginning: 20.77 mg/g; end of storage: 14.21 mg/g at -9 °C, 11.88 mg/g at -12 °C, 9.38 mg/g at -18 °C), water holding capacity (beginning: 5.13%; end of storage: 3.28% at -9 °C, 3.02% at -12 °C, 3.77% at -18 °C), emulsifying capacity (beginning: 50%; end of storage: 47% at -9 °C, 45% at -12 °C, 46% at -18 °C), foaming capacity, and foaming stability of gluten protein decreased as storage time increased at different temperatures. Wheat gluten protein showed an increasing trend in oil holding capacity and emulsifying stability. There was no significant variation in wheat gluten protein quality between the subfreezing storage group and the − 18 °C storage. The sulfhydryl disulfide bond and SDS-PAGE results showed that storage temperature had no significant effect on oxidative denaturation and subunit content of gluten protein. In brief, subfreezing storage can effectively maintain the quality of gluten protein close to -18 ℃.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Frozen dough refers to semi-finished products processed by freezing technology in order to facilitate storage and transportation during production, that is, refrigerate the semi-finished product, thaw it when used, and then carry out the rest of the production process [1]. During long-term transport storage, freezing and thawing, frozen dough undergoes a series of temperature variations, which can induce ice crystal growth and recrystallization [2]. Recrystallization during frozen storage can cause mechanical damage to dough tissue, destroying the gluten protein network structure, and when storage duration is extended, the structure and composition of dough protein shrink and break [3]. The physicochemical characteristics of starch in frozen dough did not change substantially with storage duration, showing that low temperature freezing had little influence on starch’s freeze-thaw stability [4]. Wheat gluten protein is an important part of frozen flour products in addition to raw starch and water [5]. In order to understand the mechanism of physical and chemical changes of flour products during frozen storage, it is necessary to analyze the changes of wheat gluten protein. Wheat gluten protein components are linked together by various chemical linkages, which not only form a high strength network structure but also offer the dough adhesiveness and flexibility [6]. Wheat gluten protein has an important influence on the processing and production of frozen dough and frozen flour products, and the product’s ultimate edible value is also connected to its quality [7]. Guadarrama-Lezama et al. [8] discovered that the viscoelasticity and network structure of wheat gluten protein influenced dough water absorption and adhesion. Tang and Liu [9] found that the molecular weight of wheat gluten protein was substantially linked with dough physical changes. High molecular weight glutenin subunits are thought to be the primary components determining dough rheological characteristics [10].

During storage at -18 °C, the recrystallization of water will not only damage the gluten protein structure in the dough, but also decrease the water holding capacity and gas holding capacity of the dough [11, 12]. Subfreezing refers to the freezing of free water and some uneasy flowing water used by microbial reproduction in food, and the combined water is not frozen. The process is straightforward, simple to control, and simple to use in industrial production. Previous studies discovered that subfreezing storage (-9 °C, -12 °C) and − 18 °C storage had no influence on dough quality or sensory features [13, 14].

The aim of this study was to investigate the effects of different storage temperatures (-9℃, -12℃, -18℃) on the physicochemical and functional properties of gluten protein, so as to provide a theoretical basis for further optimizing the frozen storage process in frozen flour products.

Materials and methods

Materials

Wheat flour (all-purpose flour) was provided by Yihai Kerry Group Co., Ltd., Henan, China. The chemical composition of flour: protein 12.8%; lipid 1.6%; wet gluten 32.43%; moisture 10.07%; sedimentation value 36.76 ml; ash 0.55%. Highly active dry yeast was provided by Angel Yeast Co., LTD., Hubei, China.

Preparation of gluten protein

Fermented dough was prepared according to the method of Meng et al. [13], and the wheat gluten protein was extracted by the method of Day et al. [15]. 100 g flour, 1% yeast, 50% ultrapure water and 1% white granulated sugar (based on the weight of flour) were put into the dough mixing machine (DL-C03, Dongling Electric Co., Ltd., Guangdong, China), stirred for 8 min, and then fermented for 40 min at a humidity of 80% and a temperature of 37 °C. Let the dough stand in ultrapure water for 30 min and then rinse it with water to extract gluten protein.

The prepared wheat gluten protein (360 g) was divided into spheres with diameter of 2 cm and wrapped with preservative film. These samples were divided into three groups and quick-frozen at -32 °C in a cryogenic incubator (HYC-TH-80DH, Dongguan Hongjin Testing Instrument Co., Ltd., Dongguan, China) to central temperatures of -9 °C, -12 °C and − 18 °C, respectively, then transferred into other cryogenic incubators with the same temperature. Samples at -9 °C were stored for 0, 30, 60, 75, 90, 120, 150 d, samples at -12 °C and − 18 °C were stored for 0, 30, 60, 90, 120, 150, 180 d. The sample was taken out, dried by vacuum freeze dryer (LGJ-18, Beijing Songyuan Huaxing Scientific Instruments Co., Ltd.), then crushed and passed 80 mesh sieve. Gluten protein extracted from fresh dough as control group (CK). The samples stored at -9 °C storage for 75 d were used to determine the glutenin subunits.

Soluble protein content

Bradford [16] method was used for determination.

Water holding capacity and oil holding capacity

0.10 g of sample was weighed and put into a centrifuge tube. 2 g of distilled water was added into the cenetrfuge tube and stirred for 30 min on a magnetic stirrer (ZNCL-B, Henan Aibot Technology Development Co. LTD, China). The solution was centrifuged at 3000r /min for 10 min in a refrigerated centrifuge (Multifuge XIR, Thermo, USA). Then poured out supernatant and recorded total mass of centrifuge tube and precipitate [17].

The oil holding capacity was measured according to the methods of Liu et al. [18] with some modification. Weigh 0.50 g sample and place it in a centrifuge tube. Record the total mass of the sample and the centrifuge tube. Added 5 mL soybean oil into the centrifuge tube, stirred evenly, and centrifuged it at 2200 r/min for 25 min. Then poured out supernatant and recorded total mass of centrifuge tube and precipitate.

Emulsifying ability and emulsifying stability

A gluten protein suspension was obtained by placing 0.2 g of gluten protein into 100 ml of distilled water and stirring thoroughly. 20 mL of soybean oil was mixed with 20 mL of gluten protein suspension. Then the emulsifying ability and emulsifying stability of samples was determined according to the method described by Wang et al. [19]. The mixed solution was stirred for 1 min in a high-speed shearing dispersing emulsifier (Shanghai Fluke Fluid Machinery Manufacturing Co., Ltd.) (10,000 r/min). The emulsion obtained was transferred to two 10 mL centrifuge tubes, respectively. One of them was centrifuged in a centrifuge (3000 r/min) for 10 min to record the volume of the emulsion layer. Samples that measure emulsifying stability were bathed at 50 °C for 30 min, then the centrifuge tube was removed and cooled to room temperature. Finally, the centrifuge (3000 r/min) was centrifuged for 10 min, and the volume of the emulsion layer at this time was recorded.

Foaming capacity and foaming stability

0.5 g gluten protein was placed in 100 mL distilled water and stirring thoroughly. The foaming capacity and foaming stability of the gluten protein were determined according to the method of Chen et al. [20]. The mixed solution was stirred for 1 min in a high-speed shearing dispersing emulsifier (10,000 r/min). The solution was immediately poured into a 250 mL measuring cylinder and the total volume of the foam was read out quickly. After the foam was left standing at room temperature for 30 min, the total volume of the foam and the liquid was recorded.

Sulfhydryl and disulfide bond

-

Ye et al. [21] and Jo et al. [22] methods were used to combine the sulfhydryl groups and disulfide bonds of wheat gluten proteins. The 15 mg sample was dissolved and mixed with 1 mL Tris-Gly buffer, then 4.7 g guanidine hydrochloride was added, and the buffer was diluted to 10 mL. When the sulfhydryl group was determined, 1 mL of the solution was added with 4 mL of urea-guanidine hydrochloride solution and 0.05 mL of Ellman ‘s reagent to measure the absorbance at 412 nm. When the disulfide bond was determined, 1 mL solution was taken, 0.05 mLmercaptan and 4 mL urea-guanidine hydrochloride solution were added. After shaking, the solution was placed at 25°C for 1 h, 10 mL 12% trichloroacetic acid was added, and the solution was kept at 25°C for 1 h. The solution was centrifuged at 3 000 r/min for 10 min, and the precipitate was washed twice with 5 mL 12% trichloroacetic acid. The precipitate was dissolved in 10 mL 8 mol /L urea, 0.04 mL Ellman ‘s reagent was added, and the light absorption value was measured at 412 nm in the dark.

SDS polyacrylamide gel electrophoresis (SDS-PAGE)

SDS-PAGE was modified by Yu et al. [11] and Wang et al. [23]. Due to the excessive samples in the frozen storage process, the representative samples at the beginning, middle and end of storage (0 d, 75 d and 150d samples stored at -9 °C, 90 d and 180 d samples stored at -12 °C, 90 d and 180 d samples stored at -18 °C) were selected for observation. 1 g wheat gluten protein sample was mixed with 20 mL Tris-HCl (pH = 6.8), stirred thoroughly, extracted (25 °C, 2 h ), centrifuged (4000 r/min, 20 min). 0.4 mL supernatant and the sample buffer were mixed in a micro centrifuge tube. The centrifuge tube was heated in boiling water for 5 min and cooled to room temperature. The gel consists of 5% stacking gel and 20% separating gel. Dye with Coomassie brilliant blue R-250.

Statistical analyses

The test data were analyzed by Origin 9.0 and SPSS 16.0. Each sample was measured in parallel to three groups, and the experimental results were represented by mean ± standard deviation. ANOVA was used for significance analysis, and the significance level (P) was 0.05.

Results and discussion

Soluble protein content

Because wheat gluten protein contains high non-polar amino acids and glutamine side chain, it is easy to form hydrophobic action and hydrogen bond. The low solubility of gluten protein is due to the high content of non-polar amino acids in the amino acid composition of gluten protein, which is easy to produce hydrophobic interaction. Some amino acid side chains are easy to interact with to form hydrogen bonds. When dissolving gluten protein, it is necessary to destroy both hydrophobic interaction and hydrogen bond [16, 24]. Figure 1 shows that the soluble protein content was negatively correlated with storage time. This is because frozen storage makes the network structure of wheat gluten protein constantly formed and destroyed by growing ice crystals [25], resulting in the weakening of secondary bonds of wheat gluten and the exposure of internal hydrophobic groups to the aqueous phase [26], so the soluble protein content of wheat gluten protein gradually decreases. The soluble protein content in the control group (CK) was 20.77%, which was similar to the experimental results of Yong et al. [27]. At the conclusion of the prolonged storage, the soluble protein content of gluten proteins in subfreezing storage (-9 °C, -12 °C) were 14.21%, 11.88%, and that of -18 °C was 9.38%, which decreased by 31.56%, 42.8% and 54.8% respectively compared with the CK. The content of soluble protein (-9 was 14.21%, -12 was 11.88%) storage at subfreezing temperatures was higher than that storage at -18 °C (9.38%). Therefore, storage at -9 °C and − 12 °C is conducive to delaying the decline of soluble protein content of gluten protein.

Water and oil holding capacity

The water holding capacity of proteins is related not only to the presence of hydrophilic and hydrophobic groups, but also to the physical interception capacity of the protein gel network [28]. Figure 2a depicts the steady decline in water holding capacity as storage time increased. The development and recrystallization of ice crystals damages the network structure of gluten protein during storage. In addition, the change of wheat gluten conformation causes the exposure of hydrophobic groups, which weakens the binding ability of wheat gluten to water molecules, and finally leads to the decline of water holding capacity of wheat gluten [4]. At the end of the storage, the water holding capacity of gluten protein under subfreezing temperatures and − 18 °C was 3.28%, 3.02% and 3.77%, respectively. At 150 days of storage, there was no significant difference in water holding capacity of gluten proteins between subfreezing (-9 °C, -12 °C) and − 18 °C storage, but the difference was significant at 90 d and 120 d of storage.

Protein damage exposes hydrophobic bonds and increases its oil holding capacity [29]. The oil holding capacity of wheat gluten protein increased constantly during the cryopreservation procedure, as shown in Fig. 2b. This is due to the fact that freezing changes the ice crystal within the wheat gluten protein, which in turn changes the protein’s structure and exposes more hydrophobic groups, so the oil holding capacity of wheat gluten protein increases [30]. Gluten proteins stored at subfreezing temperatures (-9 °C, -12 °C) and − 18 °C at the conclusion of the storage period had oil holding capacities of 2.6, 3.2, and 3.1, respectively. Varying storage techniques showed different effects on the oil holding capacity of proteins. Oil holding capacity of wheat gluten was significantly larger than that of CK during subfreezing storage and − 18 °C storage, however there was no significant difference in oil holding capacity between − 12 °C and − 18 °C at the later storage stage (p > 0.05). This demonstrates that the effect of subfreezing storage on enhancing the oil holding capacity of gluten protein is comparable to that of usual − 18 °C commercial freezing storage, and the sample quality remains higher.

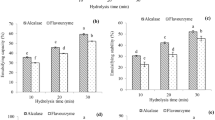

Emulsifying capacity and emulsion stability

Emulsifying capacity and emulsion stability are important indexes for maintaining protein properties, which are affected by many factors [31]. Foaming stability is affected by the rheological properties of protein film. As can be seen from Fig. 3, the emulsifying stability and ability of wheat gluten displayed the opposite pattern as storage time increased, demonstrating a decrease and upward trend, respectively. The amount of soluble protein in the wheat gluten protein in Fig. 1 is constantly reduced, making it difficult for the protein to diffuse to the oil/water interface and reducing emulsification. Furthermore, the interaction between the wheat gluten protein-water phase and the wheat gluten protein-oil phase influences the stability of the emulsion layer. Because of the change in protein conformation, the interaction between the two phases was strengthened, resulting in a more stable emulsion layer [32]. At the end of storage, the emulsifying capacity and emulsion stability of the subfreezing storage groups were not significantly different from those of the − 18 °C storage group (p > 0.05). This experiment demonstrated that subfreezing could effectively inhibit the decrease of gluten protein’s emulsifying capacity and provide a storage effect comparable to freezing at -18 °C.

Foaming capacity and foaming stability

The foaming capacity of proteins is primarily influenced by soluble protein content, molecular flexibility and other factors [33]. Foaming stability is affected by the rheological properties of protein film. It can be seen from Fig. 4 that the foaming capacity and foaming stability of wheat gluten decreased continuously as storage time increased. During storage, wheat gluten protein aggregates and denatures gradually during storage due to the formation of ice crystals [34], reducing not only the flexibility and soluble protein content of wheat gluten protein, but also causing a conformational change in wheat gluten protein. As a result of the wheat gluten protein failing to fully unfold at the air/water interface, foamability suffers. The decrease in foaming stability is due to a decrease in protein-water interaction caused by the exposed of hydrophobic groups in protein [35]. Through the study of this experiment, it was found that there was no significant difference in foaming ability and foaming stability at the end of storage between subfreezing storage (end of storage at -9 °C is 150d, end of storage at -12 °C is 180d) and − 18 °C storage (end of storage at -12 °C is 180d), and the storage effect was similar.

Content of sulfhydryl and disulfide bonds

Sulfhydryl and disulfide bonds help proteins maintain their tertiary structure by maintaining structural stability and functionality [36]. The oxidation degree of protein can be expressed by the content of sulfhydryl and disulfide bond. Figure 5 shows that the content of the sulfhydryl group in the sample is about 2–3 times that of the disulfide bonds, which is similar to the results of Fan et al. [37]. And as storage time increased, the sulfhydryl content and disulfide bond concentration of gluten proteins at different storage temperatures showed opposing patterns, gradually increasing and gradually decreasing. The reason for this change was caused by the exchange of sulfhydryl group and disulfide bond in wheat gluten protein during freezing storage, and the increase in sulfhydryl group content was caused by disulfide bond transformation [38]. The continuous oxidation of wheat gluten protein weakens the gluten strength over time. Ice crystal damage to the network structure may be causing the deterioration of gluten protein quality. The contents of disulfide bonds and sulfhydryl groups in gluten stored at -12 °C did not differ significantly from storage at -18 °C. At the storage end point, the amount of sulfhydryl in subfreezing storage (-9 °C, -12 °C) was not significantly different from storage at -18 °C. These findings suggest that different storage methods have different effects on the oxidative denaturation of proteins. In the subfreezing storage group, the degree of protein oxidation was similar to the traditional − 18 °C commercial storage effect, and the quality of gluten protein was maintained well.

SDS-PAGE

It can be seen from Fig. 6 that wheat gluten protein moves on the electrophoresis map according to the different molecular weight of its subunit, which is mainly divided into three regions: high molecular weight band (molecular weight of 43,000 Da and above), medium molecular weight band (22,000–43,000 Da; Contains 22,000 Da) and low molecular weight bands (below 20,100 Da). By comparing the protein bands in Fig. 6, it was found that the number and relative mobility of protein bands did not change much in the samples of subfreezing (-9 °C, -12 °C) and frozen storage (-18 °C). This conclusion was consistent with the findings of Wang et al. [34] that the content of each subunit of gluten and gliadin remained basically unchanged under the condition of constant temperature frozen storage, and there was no covalent aggregation behavior of each subunit of gliadin. It is consistent with the results of Ribotta et al. [39] that freezing storage time has a certain effect on the gluten subunits. Because some low molecular weight glutenin subunits (B-type) and high molecular weight glutenin subunits had been significantly depolymerized during dough production [40], the number of glutenin subunits decreases significantly.

Conclusion

The soluble protein concentration, water holding capacity, emulsifying capacity, foaming capacity, and foaming stability of wheat gluten decreased with the increase of storage time at different storage temperatures. Oil holding capacity and emulsion stability showed an increasing trend. The sulfhydryl concentration in gluten protein increased over time at different storage temperatures, while the disulfide bond content gradually decreased. Storage temperature had different effects on oxidative denaturation of gluten protein, and the lower protein oxidative degree was showed in subfreezing storage group. SDS-PAGE results reflected that there is no difference in the subunits of gluten protein between subfreezing temperature storage and common frozen storage (-18 °C). In short, there was no significant difference in protein properties between the subfreezing temperature storage and traditional frozen storage ( -18 °C), that is, subfreezing storage (-9 °C, -12 °C) has a similar storage effect to -18 °C storage, and it is an energy saving method of frozen storage.

Data availability

All data generated or analysed during this study are included in this published article.

References

S. Ma, L. Li, X. Wang, X. Zheng, K. Bian, Q. Bao, Effect of mechanically damaged starch from wheat flour on the quality of frozen dough and steamed bread. Food Chem. 202, 120–124 (2016). DOI:https://doi.org/10.1016/j.foodchem.2016.01.075

B. Zhang, J.O. Omedi, J. Zheng, W. Huang, T. Gao, Exopolysaccharides in sourdough fermented by weissella confusa qs813 protected protein matrix and quality of frozen gluten-red bean dough during freeze-thaw cycles. Food Biosci. 43, 101180 (2021). DOI:https://doi.org/10.1016/j.fbio.2021.101180

J.O. Omedi, W.N. Huang, B.L. Zhang, B. Li, J.X. Zheng, Advances in present-day frozen dough technology and its improver and novel biotech ingredients development trends-A review. Cereal Chem. 96(1), 34–56 (2019). DOI:https://doi.org/10.1002/cche.10122

E.F.J. Esselink, H. van Aalst, M. Maliepaard, J.P.M. van Duynhoven, Long-term Storage Effect in Frozen Dough by Spectroscopy and Microscopy. Cereal Chem. 80(4), 396–403 (2003). DOI:https://doi.org/10.1094/cchem.2003.80.4.396

L. Lu, Z. Yang, X.N. Guo, J.J. Xing, K.X. Zhu, Effect of NaHCO3 and freeze–thaw cycles on frozen dough: from water state, gluten polymerization and microstructure. Food Chem. 358, 129869 (2021). DOI:https://doi.org/10.1016/j.foodchem.2021.129869

J. Zhan, S. Ma, X. Wang, L. Li, X. Zheng, Effect of baked wheat germ on gluten protein network in steamed bread dough. Int. J. Food Sci. Tech. 54, 2839–2846 (2019). DOI:https://doi.org/10.1111/ijfs.14200

L. Lu, J.J. Xing, Z. Yang, X.N. Guo, K.X. Zhu, Influence of ε-poly-l-lysine treated yeast on gluten polymerization and freeze–thaw tolerance of frozen dough. Food Chem. 343, 128440 (2021). DOI:https://doi.org/10.1016/j.foodchem.2020.128440

A.Y. Guadarrama-Lezama, H. Carrillo-Navas, E.J. Vernon-Carter, J. Alvarez-Ramirez, Rheological and thermal properties of dough and textural and microstructural features of bread obtained from nixtamalized corn/wheat flour blends. J. Cereal Sci. 69, 158–165 (2016). DOI:https://doi.org/10.1016/j.jcs.2016.03.011

X. Tang, J. Liu, A Comparative Study of partial replacement of wheat flour with whey and soy protein on Rheological Properties of Dough and Cookie Quality. J. Food Quality 2017, 1–10 (2017). DOI:https://doi.org/10.1155/2017/2618020

S. Li, Y. Liu, J. Tong, L. Yu, M. Ding, Z. Zhang, A. Rehman, M. Majzoobi, X. Wang, X. Gao, A comparative study of partial replacement of wheat flour with whey and soy protein on Rheological Properties of Dough and Cookie Quality. Food Res. Int. 130, 108914 (2019). DOI:https://doi.org/10.1016/j.foodres.2019.108914

W. Yu, D. Xu, H. Zhang, L. Guo, T. Hong, W. Zhang, Y. Jin, X. Xu, Effect of pigskin gelatin on baking, structural and thermal properties of frozen dough: comprehensive studies on alteration of gluten network. Food Hydrocolloid 102, 105591 (2020). DOI:https://doi.org/10.1016/j.foodhyd.2019.105591

M. Zou, R. Yang, Z. Gu, P. Wang, Heat-triggered polymerization of frozen gluten: the micro-morphology and thermal characteristic study. J. Cereal Sci. 87, 185–193 (2019). DOI:https://doi.org/10.1016/j.jcs.2019.03.020

K.X. Meng, H.Y. Gao, J. Zeng, G.L. Li, T.C. Su, Effect of subfreezing storage on the quality and shelf life of frozen fermented dough. J. Food Process. Pres. 45(3), e15249 (2021). DOI:https://doi.org/10.1111/jfpp.15249

Y.F. Dai, H.Y. Gao, J. Zeng, Y.F. Liu, Y.Q. Qin, M.Y. Wang, Effect of subfreezing storage on the qualities of dough and bread containing pea protein. J. Sci. Food Agr 35318659 (2022). DOI:https://doi.org/10.1002/jsfa.11891

L. Day, M. Augustin, R.J. Pearce, I.L. Batey, C.W. Wrigley, Enhancement of gluten quality combined with reduced lipid content through a new salt-washing process. J. Food Eng. 95(2), 365–372 (2009). DOI:https://doi.org/10.1016/j.jfoodeng.2009.05.018

M.M. Bradford, A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72, 248–254 (1976). doi:https://doi.org/10.1006/abio.1976.9999

S. Benelhadj, A. Gharsallaoui, P. Degraeve, H. Attia, D. Ghorbel, Effect of pH on the functional properties of Arthrospira (Spirulina) platensis protein isolate. Food Chem. 194, 1056–1063 (2016). DOI:https://doi.org/10.1016/j.foodchem.2015.08.133

Y. Liu, L. Zhang, Y. Li, Y. Yang, F. Yang, S. Wang, The functional properties and structural characteristics of deamidated and succinylated wheat gluten. Int. J. Biol. Macromol. 109, 417–423 (2018). DOI:https://doi.org/10.1016/j.ijbiomac.2017.11.175

L. Wang, B. Zhang, J. Xiao, Q. Huang, C. Li, X. Fu, Physicochemical, functional, and biological properties of water-soluble polysaccharides from Rosa roxburghii Tratt fruit. Food Chem. 249, 127–135 (2018). DOI:https://doi.org/10.1016/j.foodchem.2018.01.011

G. Chen, C. Fang, X.X. Chen, Z. Wang, M. Liu, J. Kan, High-pressure ultrasonic-assisted extraction of polysaccharides from Mentha haplocalyx: structure, functional and biological activities. Ind. Crop Prod. 130, 273–284 (2019). doi:https://doi.org/10.1016/j.indcrop.2018.12.086

L. Ye, Y. Liao, W.Z. Sun, M. Zhao, Effect of protein oxidation on the stability of peanut beverage. CyTA-J Food 13(1), 49–55 (2015). DOI:https://doi.org/10.1080/19476337.2014.910556

B.H. Jo, T.Y. Park, T.Y. Park, Y.J. Yeon, Y.J. Yoo, H.J. Cha, Engineering de novo disulfide bond in bacterial alpha-type carbonic anhydrase for thermostable carbon sequestration. Sci. Rep-UK 6, 29322 (2016). DOI:https://doi.org/10.1038/srep29322

F. Wang, J. Zeng, H. Gao, S. Sukmanov, Effects of different physical technology on compositions and characteristics of bean dregs. Innov. Food Sci. Emerg. 73, 102789 (2021). DOI:https://doi.org/10.1016/j.ifset.2021.102789

H.H. Zhang, Q. Li, I.P. Claver, K.X. Zhu, W. Peng, H.M. Zhou, Effect of cysteine on structural, rheological properties and solubility of wheat gluten by enzymatic hydrolysis. Int. J. Food Sci. Tech. 45(10), 2155–2161 (2010). DOI:https://doi.org/10.1111/j.1365-2621.2010.02384.x

V.O. Selomulyo, W. Zhou, Frozen bread dough: Effects of freezing storage and dough improvers. J. Cereal Sci. 45(1), 1–17 (2007). DOI:https://doi.org/10.1016/j.jcs.2006.10.003

E. Yalçın, S. Çelik, Solubility properties of barley flour, protein isolates and hydrolysates. Food Chem. 104(4), 1641–1647 (2007). DOI:https://doi.org/10.1016/j.foodchem.2007.03.029

Y.H. Yong, S. Yamaguchi, Y. Matsumura, Effects of Enzymatic Deamidation by protein-glutaminase on structure and functional Properties of Wheat Gluten. J. Agr Food Chem. 54(16), 6034–6040 (2006). doi:https://doi.org/10.1021/jf060344u

C. Wu, W. Ma, Y. Chen, W.B. Navicha, D. Wu, M. Du, The water holding capacity and storage modulus of chemical cross-linked soy protein gels directly related to aggregates size. LWT-Food Sci. Technol. 103, 125–130 (2019). doi:https://doi.org/10.1016/j.lwt.2018.12.064

H. Zhang, G. Chen, M. Liu, X. Mei, Q. Yu, J. Kan, Effects of multi-frequency ultrasound on physicochemical properties, structural characteristics of gluten protein and the quality of noodle. Ultrason. Sonochem 67, 105135 (2020). DOI:https://doi.org/10.1016/j.ultsonch.2020.105135

J. Prakash, G. Ramanatham, Effect of stabilisation treatment of rice bran on functional properties of protein concentrates. J. Sci. Food Agr 67(2), 181–187 (1995). DOI:https://doi.org/10.1002/jsfa.2740670207

Q.T. Zhang, Z.C. Tu, H. Xiao, H. Wang, X.Q. Huang, G.X. Liu, C.M. Liu, Y. Shi, L.L. Fan, D.R. Lin, Influence of ultrasonic treatment on the structure and emulsifying properties of peanut protein isolate. Food Bioprod. Process. 92(1), 30–37 (2014). DOI:https://doi.org/10.1016/j.fbp.2013.07.006

R.E. Aluko, O.A. Mofolasayo, B.M. Watts, Emulsifying and Foaming Properties of Commercial Yellow pea (Pisum sativum L.) seed flours. J. Agr Food Chem. 57(20), 9793–9800 (2009). DOI:https://doi.org/10.1021/jf902199x

P. Wang, H. Tao, F. Wu, N. Yang, F. Chen, Z. Jin, X. Xu, Effect of frozen storage on the foaming properties of wheat gliadin. Food Chem. 164, 44–49 (2014). doi:https://doi.org/10.1016/j.foodchem.2014.05.010

P. Wang, H.Y. Chen, B. Mohanad, L. Xu, Y.W. Ning, J. Xu, F.F. Wu, N. Yang, Z.Y. Jin, X.M. Xu, Effect of frozen storage on physico-chemistry of wheat gluten proteins: studies on gluten-, glutenin- and gliadin-rich fractions. Food Hydrocolloid 39, 187–194 (2014). DOI:https://doi.org/10.1016/j.foodhyd.2014.01.009

A. Moro, C. Gatti, N. Delorenzi, Hydrophobicity of whey protein concentrates measured by fluorescence quenching and its relation with surface functional properties. J. Agr Food Chem. 49(10), 4784–4789 (2001). DOI:https://doi.org/10.1021/jf001132e

J. Sun, M. Chen, X. Hou, T. Li, H. Qian, H. Zhang, Y. Li, X. Qi, L. Wang, Effect of phosphate salts on the gluten network structure and quality of wheat noodles. Food Chem. 358, 129895 (2021). DOI:https://doi.org/10.1016/j.foodchem.2021.129895

J.L. Fan, N. Han, H.Q. Chen, Physicochemical and structural properties of wheat gluten/rice starch dough-like model. J. Cereal Sci. 98, 103181 (2021). doi:https://doi.org/10.1016/j.jcs.2021.103181

P. Zhang, T.O. Jondiko, M. Tilley, J.M. Awika, Effect of high molecular weight glutenin subunit composition in common wheat on dough properties and steamed bread quality. J. Sci. Food Agr 94(13), 2801–2806 (2014). DOI:https://doi.org/10.1002/jsfa.6635

P.D. Ribotta, A.E. Leon, M.C. Anon, Effect of freezing and frozen storage of doughs on bread quality. J. Agr Food Chem. 49(2), 913–918 (2001). DOI:https://doi.org/10.1021/jf000905w

V.L. Pietsch, M.A. Emin, H.P. Schuchmann, Process conditions influencing wheat gluten polymerization during high moisture extrusion of meat analog products. J. Food Eng. 198, 28–35 (2017). DOI:https://doi.org/10.1016/j.jfoodeng.2016.10.027

Acknowledgements

This work was financed by the Program of Xinxiang Major Scientific and Technological Project (No. ZD2020003); the Academic Talent Program of Henan Institute of Science and Technology (grant number 205010617006); and Science and Technology Projects in Henan Province (grant number 19A550007).

Author information

Authors and Affiliations

Contributions

Haiyan Gao: Conceptualization, Formal analysis, Investigation, Methodology, Writing - review & editing. Yufen Liu: Conceptualization, Investigation; Methodology, Writing - original draft. Kexin Meng: Conceptualization, Methodology, Writing - original draft. Jie Zeng: Project administration, Methodology, Writing - review & editing. Yueqi Qin: Investigation, Methodology, Data curation. Yunfei Dai: Investigation, Supervision, Methodology.

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and the manuscript is approved by all authors for publication.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, H., Liu, Y., Meng, K. et al. Wheat gluten protein properties from fermented dough storage at subfreezing temperatures. Food Measure 17, 2135–2143 (2023). https://doi.org/10.1007/s11694-022-01775-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01775-7