Abstract

This study investigated the optimum extraction conditions of bioactive compounds from roselle (Hibiscus sabdariffa), the effect of the air inlet temperatures of spray drying on the final product, and variations in the volatile compounds during converting the plant extracts into soluble powder forms. The extraction was conducted at 54°C for 120min to obtain extracts with superior total phenolic content (TPC) (2032.71mg GAE/100g), total anthocyanin content (TAC) (995.37mg Dp-3-sam/100g), DPPH radical scavenging activity (9.48g sample/g DPPH), and ABTS radical scavenging activity (3326.15mg TEAC/100g). The powder forms of the extracts were produced at air inlet temperatures of 165 and 200°C by spray drying and the process was confirmed by FTIR spectroscopy. An increment in air inlet temperature improved the microencapsulation yield (MY) (76.53% for 165°C and 80.83% for 200°C) but adversely affected the solubility (96.86% for 165°C and 90.22% for 200°C). The HPLC results showed that anthocyanins tended to degrade in powders produced at higher temperatures. No interaction was detected between process temperatures and antioxidant properties (p > 0.05). However, there were remarkable changes in the concentration of volatile compounds during the process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Roselle (Hibiscus sabdariffa) is a medicinal plant that belongs to the Malvaceae family. The different parts of roselle including seeds, leaves, fruits, roots, and calyces are used both to prepare foodstuff and for medicinal purposes [1]. Although its many parts are rich in valuable nutrients and bioactive phytochemicals [2], roselle is famous for its calyces due to its health-promoting effects and attractive red color. Roselle calyces contain an appreciable concentration of bioactive compounds such as phenolic acids, anthocyanins, flavonoids, and polysaccharides that are known to possess multiple biological activities like antioxidant, hypocholesterolemic, antihypertensive, antimicrobial, anti-inflammatory, antidiabetic, and anticarcinogenic properties [2,3,4]. Among these bioactive compounds with health-promoting effects, anthocyanins are also responsible for the characteristic color of roselle calyx [5]. In the food industry, roselle calyx has been used in the production of jams, jellies, sauces, wine, fermented drinks, and syrups [2,3,4,5], among others. Besides, it is commonly consumed in herbal infusion form by steeping in cold or hot water due to traditional knowledge on the health benefits resulting from its bioactive compounds [6].

There are several options for consumers to prepare tea or herbal infusions such as loose tea, teabag, and instant tea. The use of tea bags and instant tea is considered a time-saving alternative for the preparation of herbal tea. Instant tea has several advantages on teabag beyond being a time-saving alternative. Instant tea does not require a brewing process and does not generate any waste [7]. Instant tea is a relatively new product in the market. It is a powder form of soluble solids of respective plant material. The production process of instant tea involves brewing, concentration (if necessary), and drying steps [8].

All production steps are important to produce instant tea powder of the desired quality. Brewing is the first step in the instant tea production process and the extraction of bioactive and volatile compounds is performed in this step. The presence and concentration of bioactive compounds in the herbal infusion can be influenced by the brewing conditions of the herbal material. The use of medicinal and aromatic plants is limited because of different reasons including not knowing the exact steeping time/procedure for the plant of interest, and unwillingness to be involved in the preparation of the final solution as it might be too cumbersome to transform the plant into the drinkable form [9], and probability of microbial contamination to the extracts [10]. There is no standard brewing condition for the preparation of infusions from herbal materials. Depending on the characteristics of the herbal material and targeting bioactive compounds, the brewing conditions are specific to the herbal material [7]. Recently, the effect of brewing conditions on the total soluble solids, total phenolic content, and antioxidant capacity of roselle tea was evaluated by Nguyen and Chuyen [11]. However, the effect of brewing conditions on anthocyanin content, distinctive compounds in roselle tea, remains unknown.

Another step is drying. The conversion of liquid extracts into powder form can be accomplished by any drying method including spray-, freeze-, and vacuum-drying [8], but spray-drying is a more economical and flexible process for industrial production. Spray drying of herbal infusion can be performed with or without a carrier agent/drying aids in instant tea production. The use of carrier agents such as proteins and polysaccharides provides a positive effect on the physical and reconstitution characteristics of the final powder as well as the protection of volatile and non-volatile compounds. However, when it comes to instant tea production, the solubility of the drying aid to be used is of great importance. Therefore, maltodextrin with high solubility is frequently preferred as a drying aid in instant tea powder production [12]. Several studies have been conducted to produce high-quality powder from roselle extracts and infusions using spray drying and different drying aids [13,14,15,16,17]. However, these studies have commonly focused on the phenolic content, anthocyanin content, antioxidant capacity, and color properties of roselle powders. The knowledge about the volatile compounds of spray-dried roselle powders is still scarce and, to the best of our knowledge, only one study has tackled this issue in the literature. In that study, the effect of spray drying at different temperatures without any coating material of the 30% ethanol extract of fresh roselle calyces on the volatile components was investigated by Gonzalez-Palomares et al. [18]. The authors reported the significant effect of spray drying temperatures on volatile compounds.

In the light of the information above mentioned, it is clear that more investigation is required related to volatile compounds of roselle calyx, roselle extract, and powder to have a better understanding of the effect of the production process of instant tea powder. In the present study, it was aimed (i) to optimize the brewing condition of roselle, (ii) to evaluate the effects of different spray drying temperatures on physicochemical properties and bioactive compounds of roselle powder, and (iii) to determine the effect on volatile compounds of these processes.

Materials and methods

Plant material and chemicals

Dried calyces of roselle were obtained from a spice seller in the province of Kayseri in Turkey. Approximately 1500g plant was grounded into fine particles with a Waring blender (Staufen, Germany) and then passed through a 30 mesh sieve to obtain uniform particles. The dried and grounded roselle was stored at 4°C in a glass bottle avoiding contact with any light source until further analyses. All chemicals of analytical grade were supplied from Merck (Darmstadt, Germany) unless stated otherwise.

Extraction and spray drying process

Experimental design for bioactive compounds extraction

The response-surface methodology (RSM) was used for the selection of optimum conditions to extract bioactive compounds from roselle. For this, a face-centered central composite design with 2 blocks, 2 factors, and 3 levels, giving a total of 14 experimental points was generated using Design Expert 7.0 (Stat-Ease Inc., Minneapolis, MN) software to investigate the effects of independent variables on the selected responses. Extraction temperature (40–100°C) and extraction time (5-120min) as independent variables were assigned to maximize dependent factors including total phenolic content (TPC), total anthocyanin content (TAC), DPPH radical scavenging activity, and ABTS radical scavenging activity. One hundred mL distilled water was transferred into a bottle containing 5g roselle and the extraction was conducted in a shaking water bath (Nüve St30, Turkey) under the experimental conditions specified in Table1. After performing each extraction condition, the slurry was centrifuged (Hettich-Centrifuge-Universal, Germany) at 5000rpm for 5min, and the roselle extracts were stored at -18°C until further analyses and spray drying process.

Instant soluble powder production

The soluble solid contents of the roselle extracts obtained under optimum extraction conditions were adjusted to 5g/100g by adding water. Five g maltodextrin (13–17 dextrose equivalents) as wall material was mixed with this solution by using a homogenizer (Ultraturrax T18, Staufen, Germany) at 10,000rpm for 5min. This mixture was fed into a lab-scale spray dryer (Buchi B290, Flawil, Switzerland) with an air inlet temperature of 165 and 200°C, aspiration rate of 100%, and feeding rate of 30%. The extracts converted to powder form were stored in hermetic plastic containers without light exposure at 4°C until analyses.

Analyses

Total and surface phenolic content

TPC of samples was determined by a spectrophotometric method using Folin-Ciocalteu’s phenol reagent [19]. Briefly, 0.4 mL diluted extract or diluted powder (microcapsules) solution (5% w/v) were added to a tube containing 0.2 mL Folin-Ciocalteu’s phenol reagent and 1.8 mL distilled water. After the addition of 1.6 mL sodium carbonate solution (7.5%, w/v), this mixture was incubated at room temperature in darkness for 60min. The absorbance of the final solutions was read at 760nm using a spectrophotometer (UV-1800, Shimadzu, Kyoto, Japan). Results were given as mg gallic acid equivalents (GAE) per 100g of sample.

For the determination of surface phenolics, phenolics were extracted from microcapsules by using ethanol instead of distilled water.

Total monomeric anthocyanin content

TAC of the extracts was determined using the pH differential method [20] with slight modification. Firstly, 0.025M potassium chloride at pH 1 and 0.4M sodium acetate at pH 4.5 were prepared, and 4.9 mL of these buffer solutions were mixed separately with 0.1 mL extract. The absorbance of the solutions was measured at 520 and 700nm using a spectrophotometer. Results were calculated using the following equation Eq.(1) and given as mg Delphinidin 3-Sambubioside equivalents per 100g of sample.

Where A: absorbance ((A520 – A700) pH1-(A520 – A700) pH4.5), MW: molecular weight of Delphinidin 3-Sambubioside molecular weight (465.2), DF: dilution factor; MA: molar absorptivity of Delphinidin 3-Sambubioside (27,481).

Antioxidant activity

For DPPH radical scavenging activity, 0.1 mL extract or powder solution (5% w/v) at different concentrations was mixed with 3.9 mL of DPPH (30mg/L). The mixture was incubated at room temperature in the dark for 30min. After the incubation period, the absorbance of the remaining DPPH was measured at λ = 515nm using a spectrophotometer [21]. Results were given as effective concentration (EC50 value: the amount of sample required to scavenge 50% of the DPPH radical) [22].

ABTS radical scavenging activity was determined according to the method of Re et al. [23] with some modifications. Firstly, 0.192g ABTS was mixed with 5 mL 12.25 mM potassium persulfate in a 25 mL flask, and then distilled water was added up to the relevant part of this flask. The stock solution was left in the dark for 16h. The absorbance of this solution was adjusted to 0.700 ± 0.005 at λ = 734nm by using 0.2M sodium phosphate buffer (pH = 7.4). Twenty µL diluted extract or diluted powder solution (5% w/v) in different concentrations was mixed with 2 mL of ABTS•+ solution. After an incubation period of 6min, the absorbance was measured at λ = 734nm using a spectrophotometer. The results were given as mg Trolox equivalents antioxidant capacity (TEAC) per g or 100g of sample.

The antioxidant activity analysis of samples based on the β-carotene bleaching test was carried out using the method of Singh et al. [24]. For preparing the β-carotene solution, the mixture of 20mg linoleic acid, 200mg Tween 40, and 2mg β-carotene was dissolved in 1 mL chloroform in a vial. The vial was exposed to nitrogen gas for evaporation of chloroform and then 10 mL distilled water was added into this vial. Four mL β-carotene solution was added into the test tube containing 0.2 mL extracts or powders solution (5% w/v) at different concentrations. Distilled water rather than the samples for the preparation of control was used, and the blank was prepared without β-carotene. The absorbance was measured at λ = 734nm using a spectrophotometer at 0min and after incubation in the water bath at 50°C for 90min. The antioxidant activity was calculated according to the following equation Eq.(2).

Where \({A}_{0}\) = initial absorbance of the sample, \({A}_{90}\) = absorbance of the sample after 90min, \({A}_{c0}\) = initial absorbance of the control, \({A}_{c90}\) = absorbance of the control after 90min.

FTIR analysis

The samples were placed in the relevant part of an FTIR spectrophotometer (Shimadzu Corporation, Japan) for determining their specific chemical formations. The spectrum scan was conducted with a 1cm− 1 resolution between 4000 and 400cm− 1 wavelengths at room temperature [25].

Microencapsulation yield and microencapsulation efficiency

The microencapsulation yield (MY) and microencapsulation efficiency (MEE) were calculated according to the following equations Eqs.(3, 4) [26].

where \({Phenolic}_{surface}\)is the uncoated phenolic content of powders and \({Phenolic}_{total}\) is the total phenolic content of powders.

Physicochemical analysis

Dry matter content, water activity, solubility, Carr index, and color analyses were carried out according to Cam et al. [22].

SEM analysis

The powders coated with palladium were placed in the corresponding part of the scanning electron microscope (SEM) (ZEISS, Germany) and the surface morphology was analyzed under high vacuum conditions at 30kV with the magnification of x1000 [27].

Anthocyanin analysis by HPLC

The HPLC analysis was adapted from a previous study for the quantification of anthocyanins [28]. The samples were analyzed for their anthocyanin by using an HPLC (Shimadzu, Kyoto, Japan) equipped with 2 LC-20ADXR pumps, a SIL-20ACXR auto-sampler, and an SPD-M20A photodiode array detector (DAD). Chromatographic separations were conducted by using a Brisa LC2 C18 column (150mm × 4.6mm, 5μm, Teknokroma, Barcelona, Spain) at 45°C using a mixture of acetonitrile-water-formic acid (1:9:0.1, v/v) (mobile phase A) and acetonitrile (mobile phase B) at the flow rate of 0.5 mL/min. The ratio of mobile phase A to mobile phase B in the gradient condition was 95:5 from 0 to 20min, 80:20 from 20 to 25min, 60:40 from 25 to 30min, back to the initial conditions from 30 to 35min. The injection volume of samples and detection absorbance was 5 µL and 520nm, respectively. Quantification was done by using mg cyanidin-3-O-glucoside and mg Cyanidin 3-O-rutinoside standards.

Volatile compounds by GC-MS

The volatile compound analysis was carried out according to the method of Salum and Erbay [29] after some modifications.

Before GC-MS analysis, 9 mL extract or powder solution was added into a 20 mL screw cap equipped with PTFE/silicone septa. On the other hand, roselle without any treatment (0.5g) was sliced and mixed with 9 mL deionized water in the vials.

Extract and powders were analyzed in terms of volatile compounds by using a GC-MS coupled to an automatic injection module (7890B, Agilent Tech., Santa Clara, USA; 5977A MSD, Agilent Tech., Santa Clara, USA; GC Injector 80, Agilent Tech., Santa Clara, USA). The headspace solid-phase microextraction (SPME) technique was conducted with Divinylbenzene/Carboxen/Polydimethylsiloxane (DVB/CAR/PDMS, 50/30 µm, SF 23GA Auto, 57,299-U, Sigma) fiber for the isolation of volatile compounds. Chromatographic separations were done by a DB-Wax column (30m × 250μm × 0.25μm; 122–7032, Agilent Tech., Santa Clara, USA) with the following parameters: Pre-incubation time/temperature, 10min/60°C; extraction time/temperature, 25min/60°C; agitation speed, 500rpm; desorption time, 180s; desorption temperature, 250°C; carrier gas, helium (2 mL/min). The splitless mode was used in the analysis. The temperature was boosted from 40°C (kept for 2min) to 70°C at 5°C/min (kept for 1min) and then elevated to 240°C at 10°C/min (kept for 4min). The MS was performed in the electron impact mode at 70eV ionization energy. The mass range was m/z 30–400. Agilent MSD Chemstation (ver. F.01.03.2357) and OpenChrom (ver. 1.4.0) programs helped to evaluate the data sets. Analytical standards and using NIST14 and Wiley7 libraries were used for authentication of volatile compounds. The authentication of volatile compounds was verified with spectral deconvolution by using an automated mass spectral deconvolution and identification system (AMDIS). The quantification step was carried out by using an internal standard (4-nonanol at 9µg/µL concentration). The injection of a mixture of n-alkanes as calibration standards (C8-C40, SupelCo, PA, USA) was conducted for the computation of the retention indices [30].

Statistical analysis

The statistical evaluation of the data sets was done by using independent two sample t-test or analysis of variance (One-way ANOVA). SPSS 22 statistical package for Windows (SPSS Inc., Chicago, IL, USA) was used in the statistical comparisons and p-values less than 0.05 were considered as the threshold point. RSM for the optimization was performed using Design expert 7.0 (Stat-Ease Inc., Minneapolis, MN). The data were fitted in multiple linear regressions to create a quadratic polynomial model and regression coefficients Eq.(5):

where Y is predicted responses (TPC, TAC, DPPH radical scavenging activity, and ABTS radical scavenging activity), β0, βi, βii, and βij are the regression coefficients of intercept, linear, quadratic, and interaction, respectively; XiXj is the interplay between the main impacts; n is the variable number.

Results and discussion

Optimal extraction conditions

The studies conducted regarding the extraction of bioactive compounds from plant materials showed that the diffusion rates (extraction efficiency) of biological structures are affected by different parameters including extraction temperature, extraction time, and the ratio of sample to solvent [31, 32]. Therefore, the optimization process was applied to determine the superior conditions for the extraction of bioactive compounds from roselle in the current study. In this context, recovery of bioactive constituents from roselle was performed at different temperatures (40–100°C) and extraction times (5-120min). This optimization system focused on maximizing TPC, TAC, and antioxidant capacities of the extracts as indicators of extraction efficiency. Experimental design obtained by using RSM and the levels of selected responses namely TPC, TAC, and antioxidant activity (DPPH and ABTS) depending on independent factors are presented in Table1. The lower and upper levels were 1173 and 2581mg GAE/100g for TPC, 470 and 1190mg Dp-3-sam/100g for TAC, 9.04 and 29.94g sample/g DPPH for DPPH radical scavenging activity, and 1718 and 5516mg TEAC/100g for ABTS radical scavenging activity.

Model coefficients and ANOVA outputs are presented in Table2. The coefficient of determination (R2), adjusted coefficient of determination (R2adj), p-value, and lack of fit test were guided in determining plausible models (linear, interactive, quadratic, and cubic) with good predictions. The best-fitted models for TPC, DPPH, and ABTS were quadratic models with R2 and R2adj values within 0.9227 and 0.9718, whereas the best-fitted model for TAC was a linear model with R2 and R2adj values of 0.8843 and 0.8457, respectively. Moreover, low p-values (< 0.0001–0.0002) and non-significant lack of fit values (0.0740–0.2951) for each response also supported the suitability of the specified models. The temperature had a significant effect (p < 0.001) on all the responses, whereas time displayed an insignificant effect (p > 0.05) for TAC and DPPH but a significant effect (p < 0.001) on TPC and ABTS. Also, the interaction between temperature and time significantly influenced TAC and DPPH. Increasing temperature and time led to the increments in TPC. Phenolics display greater solubility as the temperature of the aqueous phase increases [33]. These phenomena could be associated with changes in the structure of water as the raise in temperature lowers the polarity of water [7]. TAC was influenced by temperature and interaction of multiple variables but not time alone. The extracts obtained at lower temperatures were richer in anthocyanins; indicating that temperature displayed a negative effect on these bioactive structures. The scientific literature stated that excessive extraction temperature was not an efficient way of obtaining anthocyanins due to their low thermal stability [34]. The temperature was statistically significant for both antioxidant methods. Additionally, ABTS radical scavenging activity was affected by time. The effects of the binary combination of independent variables on DPPH radical scavenging activity were observed but not time alone. This might be due to the reaction mechanisms of the antioxidant methods [22] in which ABTS reacts better with non-polar antioxidants than DPPH.

After modeling, the optimum extraction conditions were determined as: temperature of 54°C and time of 120min. The obtained extract displayed TPC of 2032mg GAE/100g, TAC of 995.37mg Dp-3-sam/100g, DPPH radical scavenging activity of 9.48g sample/g DPPH, and ABTS radical scavenging activity of 3326mg TEAC/100g at this point. Thereafter, the extraction was conducted at the optimum point and the obtained extracts were used for further analyses.

FTIR spectrums for authentication of instant soluble tea production

FTIR analyses of extract, maltodextrin, and powders were conducted to demonstrate a successful microencapsulation process by showing specific groups of raw materials (extract and maltodextrin) in the spectra of powder products. The FTIR spectrums of samples are given in Fig.1. A broad stretching band of extract and maltodextrin was observed at 3300cm− 1 corresponding to the hydroxyl (–OH) groups. A similar band for phenolic and maltodextrin was reported in a previous study [35]. The bands representing the raw materials in wavenumber of 3300cm− 1 were also detected in powders spectrums. However, their levels tended to decrease; indicating that desired microencapsulation process was carried out as these bands were closely associated with the evaporation of water molecules in the samples during the process. A similar comment was declared for laurel infusion microcapsules obtained by using maltodextrin [36]. The molecular finger peaks related to the extracts appeared at a wavelength of 1560–1770cm− 1 as no notable formation was monitored in the maltodextrin spectrum in this range although these bands were observed in powders. These peaks are associated with aromatic compounds found in the extract [37]. Similar spectrum distributions for anthocyanin-rich extracts were noted in the literature [38]. Additionally, the detected wavelength at around 1000cm− 1 in powders represented maltodextrin since no band was observed in the extracts in this region. Similar spectra were obtained in studies conducted regarding microencapsulation of herbal extracts by spray drying [39]. The results obtained from the current study showed the loaded extract in the maltodextrin matrix. This was evidence of a successful microencapsulation process.

Physicochemical properties of instant soluble tea powders

The relevance of microencapsulation systems is closely related to MY and MEE. Therefore, after the encapsulation process was confirmed, the MY and ME values were discussed. The results regarding these values are given in Table3. The MY was 76.53% when the air inlet temperature of the dryer was adjusted to 165°C. Increasing the microencapsulation temperature had positive effects on MY (p < 0.05) that reached to 80.03% at 200°C. Increasing air inlet temperature in polyphenol microencapsulation is a sensible approach for upgrading MY [26]. The MEE values were evaluated depending on surface (uncoated) phenolics. The MEE values (98.53–98.78%) indicated that more than 98% of active components in the powders were entrapped into the microcapsules in each drying temperature. Similar values and comments were noted for polyphenolic microcapsules produced in a previous study [40]. High content of dry matter and low water activity values for both powders were 2 parameters ensuring the prevention of microbial and non-enzymatic reactions. For the solubility value, a significant impact of air inlet temperature was found (p < 0.05). Changing the air inlet temperature from 165°C (96.86%) to 200°C (90.22%) led to a lower aqueous solubility (p < 0.05). The higher air inlet temperatures draw attention due to their adverse influence on the solubility of phenolic microcapsules [41]. High Carr index values of both powders indicated the necessity for the improvement of flow characteristics. This means that powders with a smooth flow were not obtained [22]. The lower b* value in the extract coated by maltodextrin at 200°C could be explained by the degradation of anthocyanins at a higher air inlet temperature.

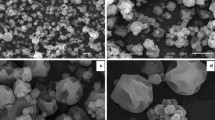

Morphology of instant soluble tea powders

The micrographs of the powders were described by scanning electron microscopy (SEM) and the images are given in Fig.2. The particles displayed semi-spherical morphology and their sizes were heterogeneous. Similar size distribution and semi-spherical photographs were reported for microencapsulated grape polyphenols [42] and cinnamon infusions [35]. Notable differences between the surface structures of powders were not observed. Indentations/wrinkles and some collapses were detected in the powder structures. These visible collapses could be associated with the rapid removal of water as a requirement of the spray drying system [43]. None of the powders contained cracks, holes, and hollow in appearance; indicating that the bioactive compounds were coated adequately. The absence of these formations provides stability to the final product since the permeability of gases and the release of the bioactive compounds are limited [27]. Additionally, the presence of cracks and holes in microcapsules is a negative indicator of MEE [44]. Based on this literature approach, the SEM images were compatible with high MEE values (98.78% for 165°C and 98.53 for 200°C).

Anthocyanins by HPLC

The focus of this part was to characterize possible changes in TAC during the extraction and spray drying process. For this, the amount of these bioactive substances in the plant, extract, and powders were investigated by the HPLC. The results are presented in Table4 and were expressed as mg cyn-3-O-glu/100g and mg cyn-3-O-rut/100g. The stability of anthocyanins was significantly dependent on the both extraction method and the air inlet temperature of spray drying (p < 0.05). The maximum anthocyanin content was found in the plant (4576mg cyn-3-O-glu/100g and 5414mg cyn-3-O-rut/100g) followed by the powder produced at 165°C (4346mg cyn-3-O-glu/100g and 5149mg cyn-3-O-rut/100g), the powder produced at 200°C (4209mg cyn-3-O-glu/100g and 4990mg cyn-3-O-rut/100g), and the extract (3913mg cyn-3-O-glu/100g and 4837mg cyn-3-O-rut/100g). There might be two reasons for the detection of more anthocyanins in the plant compared to others. These are the used solvent and the applied extraction temperature. The use of methanol rather than the aqueous phase as a solvent in anthocyanins extraction is preferred in terms of extraction efficiency [45]. As such, the first hypothesis was supported by literature data. However, it was not correct to make the same interpretation for the second hypothesis since the extraction temperature (54°C) was lower than the degradation temperature (> 70 ℃) stated for anthocyanins [46]. Otherwise, temperature appeared a remarkable factor affecting anthocyanin degradation during the spray drying process. Gradual degradation of anthocyanins occurred when the air inlet temperature was shifted to 200°C. Anthocyanins are less prone to degradation in processes carried out using low temperatures in the spray drying technique [47].

Antioxidant activity of instant soluble tea powders

The antioxidant activity of the powders was measured by the primary techniques, namely TPC, β-carotene bleaching assay, DPPH radical scavenging activity, and ABTS radical scavenging activity and the results are presented in Table5. The antioxidant activity of roselle extract powders was slightly affected by the air inlet temperature of spray drying. No remarkable changes were reported with changing the air inlet temperature from 130 to 200°C in the biological activity including anti-oxidative effects of microcapsules containing plant extracts [7]. The antioxidant capacity values of roselle powder were lower compared to the reported values of lemon balm powder [7] and mint powder [22], but were higher than ginger extract powder [48]. This result might be associated with the concentration and composition of antioxidant substances (especially phenolic compounds) in the starting materials.

Variations in the volatile compounds during the production process

The volatile compounds and their amounts in roselle plant, extract, extract-maltodextrin mixture, and spray-dried powders at 165 and 200°C are presented in Table6. A total of 40, 33, 35, 20, 22 volatile compounds were identified in the roselle plant, extract, extract-maltodextrin mixture, powders at 165, and powder at 200°C, respectively. Total concentration of volatile compounds was higher in the roselle plant (28080.7µg/kg) than extract (19080.9µg/kg), extract-maltodextrin mixture (18091.7µg/kg), powder at 200°C (1773.2µg/kg), and powder 165°C (1443.5µg/kg). The amounts of volatile compounds in the analyzed samples differed significantly depending on the extraction and spray drying.

Generally, the most abundant volatile compound in the samples was furfural, providing a caramel-like aroma. Similar results were reported for dried roselle plant [49], cold and hot roselle infusions [6], and spray-dried powder of roselle extract [18]. Besides, Ramírez-Rodrigues et al. [50] reported that furfural was not found in fresh roselle. In contrast, Juhari et al. [51] showed the presence of furfural in fresh roselle calyx. Also, the authors reported an increase in furfural content when the calyces are dried. Furans such as furfural and 5-methyl furfural derive from the Maillard reaction between the sugars and the amino acids, which may be catalyzed by drying at high temperatures [50]. In this study, the amount of furfural was significantly reduced under optimized extraction conditions depending on the bioactive properties of roselle extract. Mixing the extract with maltodextrin did not affect the amount of furfural. However, a significant loss of furfural was observed with the spray drying process. On the other hand, the furfural content in powder of 200°C was higher than that in powder of 165°C. A similar finding was reported in the study of Gonzalez-Palomares et al. [18] where an ethanolic extract of fresh roselle was spray-dried at temperatures ranging from 150 to 210°C.

Other dominant compounds were terpenes such as carvone and cumin aldehyde in the samples. The concentration of these components decreased significantly with the application of the extraction and spray drying processes. However, no significant difference was measured between spray drying temperatures. The extract, extract-maltodextrin mixture, and spray-dried powders, unlike dried roselle plant, did not contain some compounds including 1,4-cineole, limonene, eucalyptol, (E)-2-hexenal, methyl octanoate, benzyl acetate, and methyl eugenol. Furthermore, some compounds (butanoic acid, dodecanal, methyl dodecanoate, (E, E)-2,4-decadienal, heptanoic acid) -not found in the plant and the extract- were detected in the extract-maltodextrin mixture. After spray drying, the amount of these compounds except for dodecanal decreased or was below the detection limit. Besides, ethyl decanoate, ethyl dodecanoate, 1-tridecanol were only observed in spray-dried powders. These results indicated that the loss of volatile compounds was inevitable during the production of bioactive compounds-rich extract and powders. Extraction conditions, drying aid, and spray drying temperature were closely related to the loss or formation of volatile compounds.

A principal component analysis (PCA) was also performed to better distinguish the samples according to the volatile compounds affected by the extraction and spray drying processes. A total of 48 variables (volatile compounds) was taken into consideration for PCA. Figure3 shows the bi-plot (the combination plot of scores and loadings) on the two first principal components (PC1 and PC2), representing the differences or similarities among the samples. The percent of the cumulative contribution of variance of the first two PCs was 89.03%. PC1 and PC2 represented 64.96% and 24.07% of the total variation, respectively. The frequency of conglomeration of volatile compounds was low on the 3rd and 4th quadrants (upper and lower left parts). Regardless of the temperature applied, powders were clearly separated from the other samples. The powders were well characterized by their close proximity to the variables including ethyl decanoate, ethyl dodecanoate, 1-tridecanol, and 1-dodecanol. High abundances of these components in the powders resulted from the conditions of spray drying as these components were absent when the extract was mixed with maltodextrin but not spray dried. Plant and extract were similarly correlated with the same variables but plant had higher correlations with variables than the extract, indicating the richness of the plant in terms of volatiles compared to the extract. PCA results helped to interpret the changes in volatile compounds for each step from extraction to powder production.

Conclusion

With the modern lifestyle, remarkable changes have occurred in the consumption habits and the demands for instant (ready-to-use) products have increased in recent years. Therefore, many studies on these product groups have been conducted in order to respond to these demands in the food industry and scientific literature. In the previous studies, the focus was on minimizing possible problems that may negatively affect the bioactive substances in the natural structure of the product and on obtaining final products (ready-to-use) with high nutritional value. In the current study, a similar approach was followed and the effects of process parameters on the physicochemical and functionality of the final product were investigated during the production (from extraction to obtaining powder form) of the powder form of roselle extract. It was emphasized in the obtained results that higher air inlet temperature was reasonable if a high yield was desired in the powder production by spray drying but lower temperatures for high solubility were plausible. In addition, the loss amounts for each step from extraction to powder production in terms of anthocyanins and volatile compounds were revealed. The degree of anthocyanin loss compared to volatiles was insignificant. The current study might be a guide for further studies regarding the conversion of herbal extracts rich in anthocyanins and aroma substances into powder form. In order to increase the marketing and consumption of the instant soluble roselle powders, these powders can be evaluated as an ingredient in different product groups or ready-to-use tea in future studies.

References

P. Singh, M. Khan, H. Hailemariam, J. Nutr. Heal. Food Eng. 6, (2017)

G. Riaz, R. Chopra, Biomed. Pharmacother 102, 575 (2018)

A.L. Hopkins, M.G. Lamm, J.L. Funk, C. Ritenbaugh, Fitoterapia 85, 84 (2013)

I. Da-Costa-Rocha, B. Bonnlaender, H. Sievers, I. Pischel, M. Heinrich, Food Chem. 165, 424 (2014)

I. Borrás-Linares, S. Fernández-Arroyo, D. Arráez-Roman, P.A. Palmeros-Suárez, R. Del Val-Díaz, I. Andrade-Gonzáles, A. Fernández-Gutiérrez, J.F. Gómez-Leyva, A. Segura-Carretero, Ind. Crops Prod. 69, 385 (2015)

O. Zannou, H. Kelebek, S. Selli, Food Res. Int. 133, 109133 (2020)

Z. Tülek, H. Alaşalvar, B. Başyiğit, S. Berktas, P. Salum, Z. Erbay, I. Telci, M. Çam, J. Food Process. Preserv. 45, (2021)

C. Someswararao, P.P. Srivastav, Innov. Food Sci. Emerg. Technol. 16, 143 (2012)

K. Kapp, E. Hakala, A. Orav, L. Pohjala, P. Vuorela, T. Püssa, H. Vuorela, A. Raal, Food Res. Int. 53, 758 (2013)

B. Romagnoli, V. Menna, N. Gruppioni, C. Bergamini, Food Control 18, 697 (2007)

Q.V. Nguyen, H. Van Chuyen, Beverages 6, (2020)

H. Alaşalvar, M. Çam, Food Sci. Biotechnol. 28, 779 (2019)

D. Archaina, F. Vasile, J. Jiménez-Guzmán, L. Alamilla-Beltrán, C. Schebor, J. Food Process. Preserv 43, e14065 (2019)

D. Díaz-Bandera, A. Villanueva-Carvajal, O. Dublán-García, B. Quintero-Salazar, A. Dominguez-Lopez, LWT - Food Sci. Technol. 64, 693 (2015)

M.S. Navidad-Murrieta, A. Pérez-Larios, J.A. Sanchéz-Burgos, J.A. Ragazzo-Sánchez, G. Luna-Bárcenas, S.G. Sáyago-Ayerdi, Foods 2020, Vol.9, Page 128 9, 128 (2020)

Q.D. Nguyen, T.T. Dang, T.V.L. Nguyen, T.T.D. Nguyen, N.N. Nguyen, Int. J. Food Prop. 25, 359 (2022)

Q.D. Nguyen, T.T. Dang, T.V.L. Nguyen, T.T.D. Nguyen, N.N. Nguyen, Food Sci. Nutr. 10, 191 (2022)

S. Gonzalez-Palomares, M. Estarrón-Espinosa, J. F. Gómez-Leyva, and I. Andrade-González. Plant. Foods Hum. Nutr. 64, 62 (2009)

V.L. Singleton, R. Orthofer, and R. M. Lamuela-Raventós. Methods Enzymol. 299, 152 (1999)

M. Çam, Y. Hişil, G. Durmaz, Food Chem. 112, 721 (2009)

W. Brand-Williams, M.E. Cuvelier, C. Berset, LWT - Food Sci. Technol. 28, 25 (1995)

M. Cam, B. Basyigit, H. Alasalvar, M. Yilmaztekin, A. Ahhmed, O. Sagdic, Y. Konca, I. Telci, Food Biosci. 35, 100577 (2020)

R. Re, N. Pellegrini, A. Proteggente, A. Pannala, M. Yang, and C. Rice-Evans, Free Radic. Biol. Med. 26, 1231 (1999)

R.P. Singh, K.N. Chidambara, Murthy, G.K. Jayaprakasha, J. Agric. Food Chem. 50, 81 (2002)

M. Yücetepe, B. Başyiğit, M. Karaaslan, LWT 143, 111162 (2021)

M. Çam, N.C. Içyer, F. Erdoǧan, LWT - Food Sci. Technol. 55, 117 (2014)

S.E. Molina Ortiz, A. Mauri, E.S. Monterrey-Quintero, M.A. Trindade, A.S. Santana, C.S. Favaro-Trindade, LWT - Food Sci. Technol. 42, 919 (2009)

E. Morales-Luna, I.F. Pérez-Ramírez, L.M. Salgado, E. Castaño-Tostado, C.A. Gómez-Aldapa, R. Reynoso-Camacho, J. Sci. Food Agric. 99, 596 (2019)

P. Salum, Z. Erbay, Food Anal. Methods 12, 2216 (2019)

H. Van Den Dool, P.D. Kratz, Harvest (1963)

A. Pandey, T. Belwal, K.C. Sekar, I.D. Bhatt, R.S. Rawal, Ind. Crops Prod. 119, 218 (2018)

T. Belwal, P. Dhyani, I.D. Bhatt, R.S. Rawal, V. Pande, Food Chem. 207, 115 (2016)

C. Wang, L. Shi, L. Fan, Y. Ding, S. Zhao, Y. Liu, C. Ma, Ind. Crops Prod. 42, 587 (2013)

A. Castañeda-Ovando, MdeL. Pacheco-Hernández, M.E. Páez-Hernández, J.A. Rodríguez, and C. A. Galán-Vidal, Food Chem. 113, 859 (2009)

R. Santiago-Adame, L. Medina-Torres, J.A. Gallegos-Infante, F. Calderas, R.F. González-Laredo, N.E. Rocha-Guzmán, L.A. Ochoa-Martínez, M.J. Bernad-Bernad, LWT - Food Sci. Technol. 64, 571 (2015)

L. Medina-Torres, R. Santiago-Adame, F. Calderas, J.A. Gallegos-Infante, R.F. González-Laredo, N.E. Rocha-Guzmán, D.M. Núñez-Ramírez, M.J. Bernad-Bernad, O. Manero, Ind. Crops Prod. 90, 1 (2016)

H. Schulz, M. Baranska, Vib. Spectrosc. 43, 13 (2007)

H.Z. Amanah, R. Joshi, R.E. Masithoh, M.G. Choung, K.H. Kim, G. Kim, B.K. Cho, Infrared Phys. Technol. 111, 103477 (2020)

A.A. Mahdi, J.K. Mohammed, W. Al-Ansi, A.D.S. Ghaleb, Q.A. Al-Maqtari, M. Ma, M.I. Ahmed, H. Wang, Int. J. Biol. Macromol. 152, 1125 (2020)

B. Basyigit, I. Hayoglu, Acta Aliment. 48, 76 (2019)

M. Paini, B. Aliakbarian, A.A. Casazza, A. Lagazzo, R. Botter, P. Perego, LWT - Food Sci. Technol. 62, 177 (2015)

A. Tolun, Z. Altintas, N. Artik, J. Biotechnol. 239, 23 (2016)

S. Saikia, N.K. Mahnot, C.L. Mahanta, Food Chem. 171, 144 (2015)

H.C.F. Carneiro, R.V. Tonon, C.R.F. Grosso, M.D. Hubinger, J. Food Eng. 115, 443 (2013)

B. Lapornik, M. Prošek, A.G. Wondra, J. Food Eng. 71, 214 (2005)

G.B. Escher, M. Wen, L. Zhang, N.D. Rosso, D. Granato, Food Chem. 331, 127341 (2020)

T. Laokuldilok, N. Kanha, LWT - Food Sci. Technol. 64, 405 (2015)

K. Simon-Brown, K.M. Solval, A. Chotiko, L. Alfaro, V. Reyes, C. Liu, B. Dzandu, E. Kyereh, A. Goldson Barnaby, I. Thompson, Z. Xu, S. Sathivel, LWT 70, 119 (2016)

M.A. Farag, D.M. Rasheed, I.M. Kamal, Food Res. Int. 78, 327 (2015)

M.M. Ramírez-Rodrigues, M.O. Balaban, M.R. Marshall, R.L. Rouseff, J. Food Sci. 76, C212 (2011)

N.H. Juhari, H.J. Martens, M.A. Petersen, Mol. 2021, Vol.26, Page 6260 26, 6260 (2021)

Funding

This study was financially supported by Erciyes University Scientific Research Projects Unit (Project no: FYL-2018-8029).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations of interest

None.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Naji, A.M., Başyiğit, B., Alaşalvar, H. et al. Instant soluble roselle (Hibiscus sabdariffa L.) powder rich in bioactive compounds: Effect of the production process on volatile compounds. Food Measure 17, 108–120 (2023). https://doi.org/10.1007/s11694-022-01593-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01593-x