Abstract

Thin layer drying of the Citrus macroptera samples pretreated with 2% NaCl, 10% sucrose, and 10% glucose solution was accomplished in a humidity chamber to evaluate the effects of drying temperatures (45, 50, and 55 °C) on drying kinetics and check the relative biochemical properties, and the microbial load. The drying data were fitted using the moisture ratio (MR) to predict the drying kinetics. The fitness was measured for the Newton, Henderson and Pabis, and Page model. The changes in water loss were fitted to Peleg model and Weibull distribution model to predict the water loss distribution during drying. Page’s mathematical model was selected as the best-fitted model for explaining drying kinetics based on the highest R2 and the lowest Root Mean Square Error (RMSE) values. The Peleg’s model was found to fit well for equilibrium moisture content at different temperatures. Drying of the Satkara samples at 45 °C showed better results in the retention of color, total flavonoid content, total phenolic content (TPC), vitamin C, citric acid, vitamin B1, and B6 at different pre-treatment conditions. Antioxidant activity was significantly higher (p < 0.05) in the dried Satkara slices dried at 55 °C. Among the B-vitamins, vitamin B3 was comparatively stable during the drying process. Sucrose pre-treated samples showed better results in the retention of color, TPC, citric acid, ascorbic acid, and antioxidant activity. The microbial load (bacterial load: 3.4 × 103 to 1.5 × 103 CFU/g and fungal load < 104 CFU/g) was at an acceptable level in all the dried samples. According to the findings, drying of the Satkara at 55 °C pretreated with 10% sucrose was comparatively better while considering the minimum time required for drying and considerable loss of nutritional factors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Citrus macroptera belongs to the Rutaceae family, is popularly known as ‘Satkara’ in Bangladesh. This semi-wild orange fruit plant is only found to grow in the hilly areas of the Sylhet division of Bangladesh and the Northeast region of India [1, 2]. It is widely appreciated as a vegetable fruit due to its distinctive flavor and taste. Generally, the rind of this fruit is used in homemade chicken curry, meat dishes, and pickles. It produces a minimal amount of juice with a very sour and bitter taste. It is also used as a popular folk medicine in Bangladesh [2, 3]. Earlier studies remarked the medicinal value of this fruit and exerted various remedies against abdominal pains, alimentary disorders, hypertension, flu, fever, and diarrhea in infants [1, 3]. This citrus fruit contains natural antioxidants and vitamins B and C. A significant anti-cancer activity of this fruit pulp juice was reported in an earlier study due to the combined effect of lectin, polyphenols, and flavonoids [3]. Uddin et al. (2014) reported the antimicrobial properties of C. macroptera against five fungi strains and five bacteria [4]. A recent study suggested that C. macroptera has the cardioprotective potentiality by reducing the anti-oxidative stress [1]. Various studies on this wild orange suggest its high nutritional value and health effective properties [1,2,3,4].

Due to insufficient preservation, this valuable fruit is not available to the consumer in the off-season. Drying has been used as one of the most effective practices for preserving fruits as it may reduce the post-harvest loss and make it available in the offseason as well [5, 6]. It is an essential and challenging operation required to process various foods in the food industry to preserve the product for a long time. However, it is well established that the nutritional values and antioxidant compounds are decreased due to the thermal effect of drying [7, 8]. Some heat-sensitive nutrients such as ascorbic acid, β-carotene, B-vitamins, and folic acid are destroyed in the heat treatment process [8,9,10, 12]. Pre-treatment of the samples before drying with osmotic solutions (such as NaCl, sucrose, fructose, trehalose, etc.) may reduce the drying time and contribute to higher retention of physicochemical properties in dried samples by lowering the initial moisture content or altering the microstructure of the fruits and vegetables [5]. Pre-treatments also increase the drying pace and enhance the quality of agricultural products, such as colour, texture, and nutritional and rehydration properties [13]. Determination of drying kinetics and modeling of a specific sample is essential for the effective drying process. Food drying kinetics is a complicated process that necessitates simple models to predict drying characteristics and optimize drying conditions. A number of thin-layer drying models are found in the literature that can be used to explain the drying behavior of agricultural goods. Many researchers have studied the thin-layer drying of several fruits and vegetables mathematically and experimentally, for example, pineapple [9], Garcinia pedunculata [14], cabbage [15], and kiwi [16], etc. Consequently, the thin-layer drying equation may be used as it is practical and provides a satisfactory outcome. Till now, information on this wild orange is not sufficient due to a lack of research on this potential citrus fruit. This study may help determine the appropriate drying model and the effects of drying on the physicochemical properties of C. macroptera. Besides, no previous study has been found in the literature to evaluate the physicochemical, nutritional and microbial properties of pre-treated dried C. macroptera. Considering all of the above factors, this study was undertaken to dry C. macroptera at low temperatures such as 45, 50, and 55 °C. For efficient drying, three different pre-treatments, namely dipping in 10% Fructose, 10% sucrose, and 2% NaCl solution was used prior to drying. The drying temperatures and pre-treatments used were based on the literature and trial experiments to ensure efficient drying [5, 8]. During drying, the Newtonian, Hendarson and Pabis, and Page models were used to fit the drying data to predict the drying kinetics and establish the best-suited drying model based on moisture ratio (MR). All the dried samples were further analyzed for physicochemical, such as color, antioxidant activities, nutritional qualities, and microbial load count to find out the best combination of temperature and pre-treatment for quality retention of dried C. macroptera.

Materials and methods

Preparation of sample

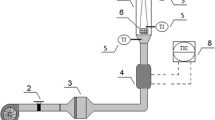

The fresh Satkara fruit samples were purchased from the local Market of Sylhet, Bangladesh. The whole fruits were cleaned and appropriately washed with distilled water to remove any dirt and foreign parts. The core and seeds of the fruits were removed and the edible portions (peel) of the fruits were separated carefully and sliced into a particular size (8 cm × 2 cm) for drying [9, 14]. Then the slices were pretreated with 10% Fructose, 10% sucrose, and 2% NaCl by dipping them for 30 min at room temperature. Some of them were kept untreated (control) [5]. The birds’ eye view of the entire research design has been presented in Fig. 1.

Drying procedure

Drying of the prepared samples was accomplished under three drying air temperatures (45, 50, and 55 °C) and constant relative humidity (30% RH) in a temperature and humidity-controlled chamber (Model: VS-8111H-150, Vision Scientific Co. Ltd., South Korea). The drying temperatures were selected based on the prior studies and trial experiments [5, 14, 17,18,19,20]. The low-temperature drying was expected to help better retention of physicochemical and nutritional quality of C. macroptera, as found from previous studies [9, 14, 18]. In every individual drying operation, the air velocity was kept constant at 3 m s−1. The drying operation was continued until it reaches an equilibrium moisture content for each specific drying condition. The moisture content values in each condition were recorded at a specific time interval [16]. Initially, data were recorded at 15 min interval up to 1 h, followed by 30 min, 1 h, and 2 h interval until equilibrium moisture content was achieved.

Mathematical models

The drying characteristics of C. macroptera slices were measured by applying the thin-layer drying models, including Newton, Henderson and Pabis, and Page models, as shown in Table 1. These three models are extensively used for most foodstuffs and organic materials. In general, these models are obtained by simplifying the linear equation of Fick's second law. The first term of a general series solution of Fick's second law is the Henderson and Pabis model. The Newton (Lewis) model is a variant of the Henderson and Pabis model with a unity intercept. The Page model is an experimental adaptation of Newton's (Lewis) model that was effectively utilized to describe the drying properties of particular agricultural goods to solve its limitations [18]. The Moisture Ratio (MR) was calculated by Eq. (1), followed by Zzaman et al. [5].

where, M is the moisture content, Me is the equilibrium moisture content, and M0 is the initial moisture content, and (all are in decimal dry basis). The dry basis moisture content was measured by following the Eq. (2)

where, \(M{C}_{db}\) is the moisture content in dry basis, \({W}_{w}\) is the wet weight, and \({W}_{d}\) is the dry weight of the sample.

Fitting of mathematical models

The statistical parameters deemed for selecting the model that will adequately explain the variation in the moisture ratio values of C. macroptera during the drying process were the correlation coefficient (R2), root mean square error (RMSE) and reduced mean square of the deviation or the reduced chi-square (χ2). The correlation coefficient was used as the primary parameter to determine the fit's quality. The model with the lowest values of reduced RMSE and χ2, and the highest value of R2 was considered the best-fitted model. The χ2, R2, and RMSE values were calculated by using Eqs. (3, 4, 5), according to Doymaz, and Ismail [21].

where, \({MR}_{pre, i}\) and \({MR}_{exp,i}\) are the predicted and experimental dimensionless moisture ratios, respectively; N and z = number of observations and number of constants, respectively.

Mass transfer models during drying

The mass transfer was achieved by eliminating moisture content during drying. The performance parameters and water loss were computed using Eq. (6) and termed as the units of net water loss per unit of the fresh sample at time t based on a starting dried weight (g) [22].

where, Wi and Wf are the initial and final weight (g) of the sample; Si and Sf are the initial (t = 0) and final (t = t) moisture content (g moisture/g dry matter) of the sample, respectively. The following two mass transfer models were implemented for the moisture loss model:

Peleg model

Equation (7), which reaches equilibrium asymptotically and explains the kinetics of moisture sorption, was used to build the two-parameter model for water loss [22, 23].

where, \({k}_{1}^{w}\) and \({k}_{2}^{w}\) are the water loss parameters. The reciprocal value of \({k}_{1}^{w}\) is the initial rate of water loss, whereas \({k}_{2}^{w}\) is known as the Peleg capacity constants.

Weibull’s distribution model

Because of its flexibility, the Weibull distribution, which represents probability distribution functions, was frequently utilized in life science data analysis. It can be used to predict the moisture content of a material as it dries. Equation (8) can be used to express the fractional quantity of moisture loss during drying [22,23,24].

where, MR is the dimensionless moisture ratio, \({\alpha }_{w}\) is scale parameter, \({\beta }_{w}\) is dimensionless shape parameter and t are sampling time. \({\alpha }_{w}\) and \({\beta }_{w}\) are the parameters of the Weibull model related to the process rate.

Surface color measurement

Surface color measurements of Citrus macroptera peel pieces were evaluated through a CIE colorimeter (PCE-CSM4). A white ceramic plate was used to standardize the instrument prior to the estimations. CIE lab color values (L*, a*, and b*) were assessed, and average values were calculated for each sample to evaluate the change in color of all samples. Here, L* represents the lightness of the treated sample, and a* indicates the redness (positive value) and greenness (negative value) of the sample, and b* estimates yellow (positive value) and blue (negative value) color of the sample. L0*, a0*, b0* are color parameters of the fresh sample. Measurements were done by triplicate taking samples from different zones of the fruit. Then, the hue angle, chroma, and overall color change parameters were estimated by using the following Eqs. (9, 10, 11, 12) [9].

Antioxidant properties

Extract preparation

The dry samples were powdered using a laboratory blender (Model: 3390D40, Thomas Scientific, USA). Ten grams of powdered sample was mixed with 40 mL ethanol (60%). The mixture was homogenized well and centrifuged at 1000 rpm for 5 min. Then, the supernatant was gathered, and the precipitate was re-extracted by following a similar procedure with 20 mL 60% ethanol. This extraction procedure was repeated four times, and the supernatant was collected. All the supernatants were combined and concentrated below 30 °C under vacuum conditions. Then the extracted supernatants were stored at -20 °C until used to analyze the total polyphenol, total flavonoids, antioxidant capacity, ascorbic acid, and citric acid [25, 26].

Total phenolic content

Phenolic content in the Satkara samples was measured following the slightly modified Folin–Ciocalteau method of Saikia et al. [27]. The analysis was accomplished by adding 20 µL of each extract to 1.58 mL of distilled water and 100 µL Folin–Ciocalteau. They were mixed well by shaking, and 300 µL of 20% sodium carbonate was added within 8 min. Again, the mixture was vortexed and stood in dark conditions at 40 °C for 30 min. The absorbance reading was taken at 765 nm using a UV–Vis spectrophotometer (Model-UV-1800, Shimadzu Scientific Instruments, Japan). The total phenolic content of the samples was measured by using the following standard curve equation (Eq. 13):

The results were determined in mg Gallic acid equivalent (GAE)/100 g.

Total flavonoid content

The flavonoid content in the fresh and pre-treated dried samples was measured by following the aluminum trichloride method [28]. For this measurement, 0.5 mL of the extract was added with 1.5 mL of ethanol (95%), 0.1 mL of aluminum-trichloride (10%), 0.1 mL of 1 M potassium-acetate, and 2.8 mL of deionized water. Then, the mixtures were incubated at room temperature for 40 min. After incubation, the absorbances of the solutions were taken at 415 nm against deionized water blank in a UV–Vis spectrophotometer (Model-UV-1800, Shimadzu Scientific Instruments, Japan). The following standard curve equation was used to measure the flavonoid content (Eq. 14):

Results were represented as quercetin equivalent (mg QE)/100 g of the sample.

Determination of citric acid

For the measurement of citric acid, 10 mL samples were taken from each prepared filtrate diluted with 20 mL deionized water. Then, this was titrated with 0.1 M NaOH using phenolphthalein as the indicator [5]. The value of citric acid was estimated by using the following Eq. (15):

where, Citric acid factor = 64 mg.

DPPH radical scavenging activity

The DPPH radical scavenging activity of the sample extracts was estimated by evaluating the inhibition rate of DPPH (2, 2-diphenyl-1-picrylhydrazyl) radical following the method of Brand-Williams et al. [29] modified by Rahman et al. [30]. At first, 1.4 mL methanolic solution of DPPH radical (10−4 M) was mixed with 100 μL of extracts. A UV–Vis spectrophotometer (Model-UV-1800, Shimadzu Scientific Instruments, Japan) was used to read the absorbance at 517 nm after 30 min of incubation. A solution of 100 µL methanol in 1.4 mL of DPPH radical was used as blank. Following Eq. (16) was used to calculate the results:

where, Ao, and As are the absorbance of the control blank, and sample extract, respectively.

Nutritional properties

Determination of Vitamin C

The vitamin C content was determined based on the reduction of 2,6-dichlorophenol-indophenol following the method of Ranganna [31]. About 5 g of sample was taken, and made up to 50 mL with 3% of HPO3. After that, Whatman No. 1 filter paper was done to filtrate the extract. Then, 10 mL filtrate was taken into a conical flask and titrated with dye solution from the burette. The dye solution was added until a pink color was found to be persistent for about 15 s. The amount of dye solution was the titre value. Ascorbic acid content was calculated by using Eq. (17):

Determination of B Vitamins

All the Satkara samples were examined spectrophotometrically for measuring the amount of B-vitamins by following the method described by Fernandes et al. [32]. In brief, 5 g of each sample was homogenized with distilled water (10 mL) and followingly added 0.25 M (1 mL) sulfuric acid. The resulted mixture was heat treated for 30 min in a temperature-controlled water bath at 70 °C. Then, the mixture’s pH was adjusted to 4.5 using 0.5 M NaOH solution and transferred into an ice bath. Following that, it was centrifuged for 30 min at 4000 rpm using a centrifuge (2–16 LK centrifuge, Sigma, Germany) and filtered. Absorbance readings of the collected supernatant were taken with a UV–Vis spectrophotometer (Model-UV-1800, Shimadzu Scientific Instruments, Japan) at 254 nm (B1), 265 nm (B3), and 480 nm (B6). Calibration curves were prepared using standard thiamine hydrochloride (B1), nicotinamide (B3), and pyridoxine (B6).

Microbial load determination (bacterial and fungal)

The samples’ microbial load was measured as total bacterial and fungal count by following the method described in AOAC [33]. For bacterial and fungal load determination, standard plate count agar and Mortin Rose Bengal Agar media were made by dissolving 18 g of each agar sample in 1000 mL distilled water. Again, 1.0 g of the blended samples were mixed to 10 mL of autoclaved water to prepare the sample solutions. The solution was then allowed to serial dilution to aid in counting. About 18-20 mL of media was poured in each petri plate and allowed to solidify. Then, 1 mL from each diluted sample was taken into each petri dish and spread well by a sterile glass rod to ensure the proper mixing. Finally, the petri dishes were kept in an incubator at 30 and 37 °C for fungi and bacteria, respectively. A digital colony counter was used to count the number of colonies in each petri dish after 24 and 72 h of incubation for bacteria and fungi, respectively.

Results and discussion

Drying model prediction

The drying curves for the untreated and the treated Satkara samples dried at 45, 50, and 55 °C have been shown in Fig. 2. These characteristic drying curves were found by adopting the values of moisture ratio Vs. drying time. From Fig. 2, the drying time (hr) versus moisture ratio (MR) curves showed that the time (hr) required to reach the moisture ratio to a safe level vary significantly with different pre-treatment and drying temperature. The minimum drying time was observed in fructose treated sample and the maximum for the untreated sample. Drying rate in the samples were fructose treated (FT) > sucrose treated (ST) > NaCl treated (NaClT) > untreated (UT). The 10% fructose-treated sample needed the minimum drying time. Osmotic pre-treatment showed a significant effect on Satkara’s drying rate, and it may be because of the increased moisture diffusion rate. It was also found that the drying rate was increased with the increasing drying temperature from 45–55 °C. A higher drying rate was observed in a previous study for NaCl-treated onion slice drying than the untreated onion [34]. Hossain et al. found that increased drying temperature and osmotic pre-treatment significantly affect the Garcinia pedunculata’s drying time [14]. Zzaman et al. found that sucrose pre-treated pineapple slices required a lower time (12.04 h) than untreated one (19.18 h) when dried at 55 °C temperature [5]. Rani and Tripathy found that osmotic pre-treatment by KMS significantly reduce the drying time from 10.5 to 8.0 h for pineapple slices [35]. Drying time was found to decrease due to the increased diffusion rate when the various fruits such as apple, apricots, and guava were treated with osmotic solutions in different studies [36,37,38].

The drying temperature was found to influence the drying kinetics of the Satkara samples. The 55 °C drying temperature needed the lowest time to reach all the samples at a moisture ratio of about 0.00. The drying rate increased with the increasing air temperature from 45 to 55 °C, at a constant relative humidity (30%) and air velocity (1 m s−1) (Fig. 2). Increasing temperature results in a large water vapor pressure deficit and high moisture diffusivity in the sample responsible for the lower drying time [16]. A similar consequence of temperature was noticed in the drying of lemongrass by Fadhel et al. (2009) [16]. Aktas et al. (2013) found that an increase in the drying temperature from 50 to 70 °C highly reduced the drying time for apple slices, which is also in line with our findings [36].

Table 2 represents the values of drying coefficients (a and n) and drying constant (k) of three thin-layer drying models, such as Newton, Henderson and Pabis, and Page model. It is clear from the table that the drying constant is a function of temperature, which was increased with the increasing drying temperature. The best-fitted model was selected based on the highest R2 and the lowest Root Mean Square Error (RMSE), and reduced chi-square (χ2) values [16]. In Table 2, the R2 value ranges from 0.96047 to 0.99944, RMSE value ranges from 0.00738 to 0.08951, and the χ2 value ranges from 0.00006 to 0.00929. These values represent that three tested thin layer models can adequately predict the drying behavior of pre-treated C. macroptera samples. In all cases, the R2 value was greater than 0.96047, which indicates a good fit of the tested models [21]. All the pre-treated samples dried at 45 and 50 °C had the highest R2 value and the lowest RMSE and χ2 values in the Page model (Table 2). It determines the best fit with the Page model. The un-treated sample showed a different result when it was dried at 55 ˚C temperature. The lowest value of R2 and the highest value of RMSE and χ2 were observed in the Henderson and Pabi’s model, which leads to a comparatively poorer fit than the other two models. Again, NaCl, sucrose, and fructose treated samples dried at 55 ˚C showed the best fit with the page model.

Water loss during drying

During the drying process, moisture was transferred from satkara fruit at various drying periods, and water loss was measured at 45, 50, and 55 °C. The moisture ratio (Eq. (8)) was calculated using the acquired water loss data. Figure 3 depicts the differences in moisture loss as a function of sample drying time. Due to the initial fast moisture loss, the moisture ratio was initially steeper, but it became shallow after a certain period. Because of the solid osmotic motivating factor between the dilute juice of the fresh satkara fruit and the adjacent hyperosmotic solution, moisture loss was rapid at first. Sharma and Dash (2019) also found a similar result for osmotic dehydrated black jamun fruits [22].

Peleg model

The appropriateness of Peleg's equation was evaluated using experimental data. The non-linear regression factor analysis revealed Peleg parameters for water loss, as shown in Table 3. The Peleg model was fitted to estimate the drying process's equilibrium moisture content (EMC). Table 3 shows Peleg's model parameters for water loss (\({k}_{1}^{w}\) and \({k}_{2}^{w}\)). Fitting the mass transfer parameter for water loss data during drying processing time revealed the average \({R}^{2}\), \({\chi }^{2}\), \(SSE\), and \(RMSE\) values of 0.97238, 0.02577, 0.01938, and 0.14715, respectively for the UT sample. The analogous values \({R}^{2}\), \({\chi }^{2}\), \(SSE\), and \(RMSE\) for NaClT were 0.97024, 0.05695, 0.03925, and 0.21884, respectively; for ST, they were 0.96988, 0.06451, 0.04317, and 0.23420; and for FT, they were 0.97483, 0.04820, 0.02769, and 0.19276, respectively. As a result, the high \({R}^{2}\) values and low \({\chi }^{2}\) (chi-square), \(SSE\), and \(RMSE\) values (Table 3) showed that Peleg's equation was adequate for describing mass transfer kinetics terms during drying of satkara fruit at specified temperatures over time. The appropriateness of Peleg's equation characterized the mass transfer kinetics during osmotic dehydration of jamun fruit with the fitting of high \({R}^{2}\) and low \({\chi }^{2}\) (chi-square), and \(RMSE\) values [22]. Corzo & Bracho also found the goodness of fit of the Peleg model using various brine solutions and temperatures to fit linear regression models during osmotic dehydration [39].

The reciprocal of \({k}_{1}^{w}\) described the initial mass transfer rate (water loss), e.g., the lower the \({k}_{1}^{w}\), the higher mass transfer rate. Table 3 describes the \({k}_{1}^{w}\) values at different pretreatment condition that decreased with the range of temperature 45–55 °C, which specifies an increase in the initial mass transfer rate. Sharma & Dash found that during osmotic dehydration of jamun fruit, \({k}_{1}^{w}\) was also decreased with increasing temperature by 30–50 °C [22]. Besides, Yüksel et al. observed that during microwave drying of enriched couscous, \({k}_{1}^{w}\) values also decreased with increasing temperature and power [23]. The Peleg capacity constants (\({k}_{2}^{w}\)) are based on the equilibrium moisture constant, which indicates that decreasing the \({k}_{2}^{w}\) value will increase the equilibrium moisture content and mass transfer rate [11]. The inverse value of \({k}_{2}^{w}\) allows for the calculation of the equilibrium moisture. Table 3 represents the \({k}_{2}^{w}\) values at different pretreatments conditions with the range of temperature 45–55 °C. The changes in \({k}_{2}^{w}\) demonstrated that temperature and pretreatment process had substantial effects the Peleg constant \({k}_{2}^{w}\) for water loss during drying of satkara fruit.

Weibull’s distribution model

The Weibull model is an empirical model that is used to represent food drying rates. It is based on exponential behavior [40, 41]. To calculate the moisture ratio, the Weibull model uses equilibrium moisture content (\({WL}_{\infty }\)) data. Parameters of the Weibull model \({\alpha }_{w}\) was a scale parameter for water loss that was linked to the process rate. At the start of the operation, \({\beta }_{w}\) was a shape parameter for water loss that was linked to the mass transfer rate [42]. The data acquired by various pretreatments and drying temperatures of 45, 50, and 55 °C were fitted with the Weibull model (Eq. (8)), and the predicted parameters are given in Table 3. With drying time, the moisture ratio declined exponentially, and the reduction rate was faster at higher drying temperatures.

The results revealed that pretreatment technique and drying process temperature had an impact on \({\alpha }_{w}\) and \({\beta }_{w}\). (Table 3). The higher \({R}^{2}\) (0.99562–0.99961) with lowered \({\chi }^{2}\) (0.00004–0.00048), \(SSE\) (0.00003–0.00041), and \(RMSE\) (0.00563–0.02015) values imply that the Weibull model had a good fit for predicting the moisture ratio. The results revealed that the experimental data were well-fitted to the models employed in this study. With increasing drying air temperature, the scale parameter (\({\alpha }_{w}\)) decreased significantly. Nadian et al. [24] and Yüksel et al. [23] also found that the Weibull model was satisfactorily fitted with the experimental data and decreased the scale parameter (\({\alpha }_{w}\)) with increasing temperature for apple slices and couscous.

Color

Table 4 represents the drying effects on color parameters of dried Satkara fruit samples. Pre-treatment of the samples with NaCl, sucrose, and fructose significantly affected the color of dried Satkara. The L* value of fresh C. macroptera was 92.14 ± 0.30, and it was found to decrease with the increasing temperature.

The lowest value of lightness (74.42 ± 1.36) was noted in NaCl treated sample dried at 55 °C. Both the temperature and the pre-treatment solution were found to affect the lightness of the sample significantly. Karabulut et al. (2007) explained the reduction in lightness with temperature by developing brown pigment during drying [43]. In most cases, the redness (a*) and yellowness (b*) value of the samples were increased with the increasing temperature of drying. Conversely, the hue value was decreased with the rising temperature. Ali et al. found similar results in a previous study, where the lightness values of dried guava slices were decreased with the elevated temperature, while redness and yellowness were increased [44]. A similar effect was also noticed in the convective drying of date fruit at 60 to 80 °C temperature [45]. The results of overall color changes are represented in Table 4. The maximum color change (ΔE = 18.04 ± 2.13) was noticed in NaCl treated sample dried at 55 °C. It was found to increase with temperature. Sucrose treated samples had the lowest color change compared to the NaCl and fructose treated samples. Color changes in the dried fruit samples maybe because of the breakdown of the color pigments, for example, carotenoids, chlorophylls, and the generation of pigments by enzymatic or non-enzymatic browning process [46, 47]. The Maillard reaction and caramelization changed the Browning index of the thermally treated samples. Carbonyl compounds and the furfural compounds produced from the degradation reactions during heat treatment are responsible for browning, affecting the color change in the final product [12, 48]. It is desirable to retain the higher lightness (L*), and lower yellowness (b*), and ΔE* values in the dried fruit samples [44]. The sucrose-treated samples had shown the best retention of color parameters in the dried Satkara in present study.

Antioxidant properties

Total phenolic content

Table 5 represents the total phenolic content (TPC) of fresh and treated samples at different drying temperatures. Fresh Satkara had the highest TPC of 4.66 ± 0.82 mg GAE/100 g. The TPC was found to decrease with rising temperatures in each treated sample. The lowest value of TPC (3.07 ± 0.07) was noticed in untreated samples dried at 55 °C. While considering the pretreatment effects, sucrose-treated samples had the maximum value of TPC. Rodríguez et al. (2017) reported that high drying temperatures and the presence of active enzymes are responsible for the degradation of phenolic compounds in dried pineapple [10]. Phenolic compounds were also found to degrade at elevated temperatures during the drying process of pomegranate peel and lemon slices [49, 50]. The degradation of the phenolic compounds held at a different rate and it depends on the physicochemical characteristics of specific phenolic acids and the interactions with other ingredients of the food matrix. Many of them are very heat sensitive, and some are relatively stable during high thermal processing [8, 12, 51,52,53]. Comparatively, sucrose pretreated samples contain more phenolic content than the fructose and NaCl treated samples dried at various studied temperatures. A Different result was observed during the drying of apple and the pineapple fruit, which had the higher retention of TPC in trehalose and fructose treatment, respectively [5, 36].

Total flavonoid content

The highest flavonoid content was observed in the fresh sample 123.79 ± 1.40 mg QE/ 100 g. The drying temperature significantly affected the amount of flavonoid content in the dried sample, and it was found to decrease with the elevated temperature. The pretreatments also significantly affected the retention of flavonoid compounds in the final dry product. Maximum retention of the flavonoid compound was observed in sucrose-treated samples (Table 5). The untreated sample dried at 55 ºC had the lowest TFC (61.27 ± 1.26 mg QE/100 g). Retention of flavonoid compounds in different pretreated Satkara samples was decreased gradually from 45 to 55 ºC as they are thermo-liable compounds that degraded with increasing temperature. The hydrolytic and oxidative enzymes are also released due to cell wall breakdown, which can destroy flavonoids during drying [10]. Structural transformation in flavonoid compounds during heat treatment may also influence the overall antioxidant activities of dried products [54, 55].

Citric acid

As Satkara is a citrus fruit, its citric acid content was also measured in fresh samples and after drying. The sucrose-treated sample had maximum citric acid (2.15 ± 0.06%) among all the samples dried at 45 °C (Table 5). In every treated sample, the amount of citric acid was found to decrease with elevated temperature. Un-treated samples had a maximum loss of citric acid during the drying process. The food moisture and drying temperature influenced the depletion of citric acid. The citric acid loss for the Satkara samples was in the order of 55 > 50 > 45 °C (Table 5). Rodríguez et al. (2017) reported citric acid as a heat-sensitive compound that may destroy during the drying process [10].

DPPH radical scavenging activity

The antioxidant activity was evaluated as the DPPH free radical scavenging activity. The radical scavenging activity (RSA) of dried samples decreased significantly from the fresh sample. The maximum RSA (79.03 ± 1.3%) was found in the fresh Satkara sample. The lowest value (25.32 ± 0.95) was observed in the fructose-treated dried sample at 45 °C. Among the dried samples, radical scavenging activity (RSA) was in the order of 55 > 50 > 45 °C (Table 5). Again, RSA was higher in: ST > NaClT > UT > FT. Sucrose-treated samples retained the highest RSA among all the dried samples. RSA was increased with the elevated drying temperature in this study. The increase in antioxidant capacity may be related to the shorter drying time and the formation of new antioxidant compounds [47]. Some interactions between components should occur during heat treatment, and new products are formed by Maillard reaction and caramelization [56]. The stable intermediate products produced by the breakdown mechanism exhibited strong antioxidant activities [47, 56]. The RSA was increased with rising temperature during drying of the pomegranate peel, and Burmese grape pulp and seed, which agrees with our findings [26, 49]. Hossain et al. (2021b) found that an increase of drying temperature from 60–70 °C helped better retention of DPPH radical scavenging activity in foam mat dried tomato powder [6]. Zzaman et al. (2021) and Hossain et al. (2021b) reported a similar effect of temperature on the antioxidant activity of osmotic pretreated drying of pineapple and Gracinia pendaculata slices in earlier studies [5, 14]. They found that when pineapple and G. pendaculata slices were pretreated with 10% sucrose, 10% fructose and 2% NaCl, they preserve the antioxidants than untreated samples. Besides, high temperature (55–60 °C) drying of pineapple and G. pendaculata slices also showed higher antioxidant activities than low temperature (45–50 °C) drying. This might be due to a shorter drying time, i.e. lower exposure for degradation of antioxidants at higher drying temperature [5, 14].

Nutritional properties

Vitamin C

Vitamin C (ascorbic acid) is regarded as the index of the nutritional quality of a dried food sample. Higher retention of this compound in the dried food may also indicate the best retention of other nutrients [57]. The highest ascorbic acid value was found in the fresh Satkara sample (332 mg/100 g). The reduction in vitamin C content was observed with the elevated drying temperature in this present study. The sucrose-treated sample had the highest retention of ascorbic acid (153.14 ± 5.89 mg/100 g) when dried at 45 °C temperature. The maximum loss of vitamin C was found for NaCl-treated samples. This study shows a clear and significant loss of ascorbic acid in the dried Satkara samples in the order of 55 > 50 > 45 °C (Table 6). The degradation of vitamin C is dependent on moisture, temperature, and time of drying [10]. Exposure of ascorbic acid to oxygen and high drying temperatures were reported as the main reason for the loss of ascorbic acid in earlier studies [49, 58]. The maximum retention of vitamin C was previously observed in pretreated tomato samples with the osmotic solution, and it was due to the proliferated coating on the cut surface of the sample [57]. Sucrose pretreated dried apple slices had comparatively higher ascorbic acid, as it was found earlier that sucrose has ascorbic acid retention capability [36]. In this current study, the lowest ascorbic acid value (104.06 ± 3.4 mg/100 g) was noticed in the NaCl treated sample dried at 55 °C. The loss of ascorbic acid may occur by leaching during the soaking of Satkara slices in the osmotic solution. Zzaman et al. (2021) reported an ascorbic acid loss in pineapple slices during soaking as it is a water-soluble vitamin [5].

B Vitamins

Table 6 represents the value of vitamin B1, B3, B6 in the fresh and the osmotic solution treated dried samples at different temperatures. The maximum amount of vitamin B (B1- 108 ± 0.96, B2—95.04 ± 0.13, B3-17.54 ± 1.23) µg/g were noticed in fresh Satkara samples. Loss of vitamin B1 (Thiamin) during drying was much higher, and the loss was observed as in the order of 55 > 50 > 45 °C. The pretreatment exerted loss of thiamin was also noticed in the dried sample (Table 6). The maximum loss of thiamin was in NaCl and fructose treated dried samples. It may be due to the solubility of the thiamin in water. During the osmotic pretreatment, the loss of water-soluble vitamins occurred. Previous studies also reported thiamin as the most heat-sensitive vitamin among the B vitamins, and the degradation follows the first-order reaction kinetics [10, 58]. Vitamin B3 (niacin) was found to be more stable than thiamin during the drying process. Considering other B vitamins, the drying temperature had a minimal effect on the retention of niacin. The value of niacin ranged from (93.25 ± 0.24 to 87.44 ± 0.20) µg/g of dried sample. Slight loss of niacin may be held by leaching during soaking in the osmotic solutions. Many other researchers also reported niacin as the most stable B vitamin, while thermal processing of various food [59]. A significant loss of vitamin B6 was noticed in this study. Fresh samples had a much higher amount of vitamin B6 (17.54 ± 1.23 µg/g) than the dried samples (6.15 ± 0.19 to 2.47 ± 0.05 µg/g). Prolonged drying time and the light sensitivity of vitamin B6 may influence the degradation of this compound [59]. According to our findings, it is clear that lower drying temperature significantly contributes to the retention of B-vitamins, and the best result was observed for 45 °C.

Microbial load in the dried samples

Fruits are dried for gaining a longer shelf-life of the product. Microbial load in the dried product determines the sanitary quality. Figure 4 represents the microbial load in the dried Satkara samples at different treatment conditions as well as fresh sample. The fresh sample had the maximum bacterial load (7,000 CFU/g) than all other dried samples. It was gradually decreased with the elevated drying temperature in most of the cases. Pretreatment solutions also influenced the survival of the bacterial cell. Dehydration of bacteria cells may occur during pretreatment with the osmotic solution, resulting in protein denaturation, DNA and RNA breakdown, cell wall damage, and alteration in the cytoplasmic membrane [60]. The lowest value of the bacterial load (1100 CFU/g) was noticed in NaCl treated samples dried at 55 °C. Bacterial load was found as in the order: UT > ST > FT > NaClT (Fig. 4a). Previous stuies reported that some emerging pathogens, for example E. coli, S. anatum, S. typhimurium, and B. subtilis were found to survive in dried fruits and vegetables at different drying temperature ranges from 40 to 70 °C [61].

Figure 4b represents the maximum fungal load in the fresh sample (19,000 CFU/g). It is well known that salt and sugar solutions reduce microbial growth. They do it by reducing water activity inside foods, intervening in microbes’ enzyme activity, diminishing microbes' DNA structure, and accelerating beneficial microbes [61]. The drying temperatures influenced the fungal load count strongly in most of the dried samples. The lowest fungal load was noticed in the sucrose-treated sample, when dried at 55 °C. Some popular dried fruits, for example, pineapples, dates, guavas, mangoes, and prunes, were found to have high levels of fungal contamination, ranging from 3.8 × 103 to 6.3 × 103 CFU/g [5, 60, 62]. Elevated drying temperature contributed to the reduction of the fungal load in the dried Satkara sample. Increasing temperature showed better results in the reduction of microbial load. Sucrose-treated samples had the lowest microbial load (1 × 103 CFU/g) at 55 °C. The maximum allowable limit of fungi and yeast counts was reported as 1.0 × 104 CFU/g in the dried fruits and vegetables [5]. The overall microbial load was at an acceptable limit in all the treated samples and consistent with the results of Fong-in et al. [63] and Hossain et al. [14].

The research findings show that fructose solutions and 55 °C drying temperature required minimum drying time compared with other applications but negatively impact the nutritional properties of the fruit. Again, sucrose-treated samples resulted in better color properties, citric acid, ascorbic acid, TPC, TFC, and antioxidant activity retention. Antioxidant activity retention was increased with elevated temperature. Sucrose-treated samples showed better results in vitamin C retention. All of the vitamins were reduced due to heat, while vitamin B3 was relatively heat stable. Vitamin B1 and B6 were better in the untreated sample; thus, the water-soluble vitamins leach out during pretreatment of the samples. In the case of the treated samples, sucrose-treated samples showed better results.

Conclusion

In this study, the impact of several pretreatments and drying air temperatures on the drying characteristics and some quality parameters of C. macroptera were explored. Sucrose (10%), fructose (10%) and NaCl (2%) solutions were used as pretreatments. This study demonstrates that C. macroptera fruits are rich sources of total phenols, total flavonoid, critic acid, vitamin B1, B3, and B6 and ascorbic acids. Both temperature and pretreatment of the samples have exerted significant effects on the end-product quality. Measured values associated with the drying time and quality attributes of samples showed that pretreatment of Satkara samples with the 10% sucrose solution and drying at 55 °C can comparatively better preserve the quality properties and is highly recommended for the drying of this fruit. This study may help preserve Satkara fruits and make them available to consumers throughout the year.

References

S. Paul, S. Das, E. Tanvir, M.S. Hossen, M. Saha, R. Afroz, M.A. Islam, M.S. Hossain, S.H. Gan, M.I. Khalil, Biomed. Pharmacother. 94, 256–264 (2017). https://doi.org/10.1016/j.biopha.2017.07.080

M. Majumdar, S.A. Khan, S.C. Biswas, D.N. Roy, A.S. Panja, T.K. Misra, J. Mol. Liq. 302, 112586 (2020). https://doi.org/10.1016/j.molliq.2020.112586

M.M. Hasan, M.S. Islam, K.M.F. Hoque, A. Haque, M.A. Reza, Toxicol. Res. 35, 271–277 (2019). https://doi.org/10.5487/TR.2019.35.3.271

N. Uddin, M.R. Hasan, M.M. Hasan, M.M. Hossain, M.R. Alam, M.R. Hasan, A.M. Islam, T. Rahman, M.S. Rana, PLoS ONE 9, e111101 (2014). https://doi.org/10.1371/journal.pone.0111101

W. Zzaman, R. Biswas, M.A. Hossain, Heliyon 7, e05882 (2021). https://doi.org/10.1016/j.heliyon.2020.e05882

M.A. Hossain, S. Mitra, M. Belal, W. Zzaman, Food Res. (2021). https://doi.org/10.26656/fr.2017.5(1).372

C. Ratti, A. Mujumdar, Sol. Energy 60, 151–157 (1997). https://doi.org/10.1016/S0038-092X(97)00002-9

S.P. Ong, C.L. Law, Drying Technol. 29, 429–441 (2011). https://doi.org/10.1080/07373937.2010.503332

L.A. Ramallo, R.H. Mascheroni, Food Bioprod. Process. 90, 275–283 (2012). https://doi.org/10.1016/j.fbp.2011.06.001

Ó. Rodríguez, W. Gomes, S. Rodrigues, F.A. Fernandes, Ultrason. Sonochem. 35, 92–102 (2017). https://doi.org/10.1016/j.ultsonch.2016.09.006

A. Rózek, J.V. García-Pérez, F. López, C. Güell, M. Ferrando, J. Food Eng. 99, 142–150 (2010). https://doi.org/10.1016/j.jfoodeng.2010.02.011

J.H. Shourove, W. Zzaman, R.S. Chowdhury, M.M. Hoque, Asian Food Sci J. 14, 41–53 (2020). https://doi.org/10.9734/afsj/2020/v14i330133

A. Fijalkowska, M. Nowacka, A. Wiktor et al., J. Food Process Eng 39, 256–265 (2016). https://doi.org/10.1111/jfpe.12217

M.A. Hossain, P. Dey, R.I. Joy, Saudi J. Biol. Sci. (2021). https://doi.org/10.1016/j.sjbs.2021.08.038

A. Sarkar, S. Rahman, M. Roy, M. Alam, M.A. Hossain, T. Ahmed, Food Res. 5, 393–400 (2021). https://doi.org/10.26656/fr.2017.5(2).556

N. Izli, G. Izli, O. Taskin, Food Meas. Charact. 11, 64–74 (2017). https://doi.org/10.1007/s11694-016-9372-6

B. Önal, G. Adiletta, A. Crescitelli, M. Di Matteo, P. Russo, Food Bioprod. Process. 115, 87–99 (2019). https://doi.org/10.1016/j.fbp.2019.03.002

R. Goyal, A. Kingsly, M. Manikantan, S. Ilyas, Biosyst. Eng. 95, 43–49 (2006). https://doi.org/10.1016/j.biosystemseng.2006.05.001

S.M. Oliveira, T.R. Brandao, C.L. Silva, Food Eng. Rev. 8, 134–163 (2016). https://doi.org/10.1007/s12393-015-9124-0

G. Adiletta, C. Warshamana Dewayalage, W. Senadeera, P. Russo, A. Crescitelli, Ital. J. Food Sci. 30, 684–706 (2018). https://doi.org/10.14674/IJFS-1176

I. Doymaz, O. Ismail, Food Bioprod. Process. 89, 31–38 (2011). https://doi.org/10.1016/j.fbp.2010.03.006

M. Sharma, K.K. Dash, Ultrasonics Sonochem. 58, 104693 (2019). https://doi.org/10.1016/j.ultsonch.2019.104693

A.N. Yüksel, M.D. Oner, M. Bayram, M.E. Oner, J. Food Meas. Charact. 12, 1723–1733 (2018). https://doi.org/10.1016/j.ultsonch.2019.104693

M.H. Nadian, S. Rafiee, M.R. Golzarian, J. Food Meas. Charact. 10, 493–506 (2016). https://doi.org/10.1007/s11694-016-9328-x

M.A. Hossain, M. Evan, M. Moazzem, M. Roy, W. Zzaman, J. Sci. Res. 12, 397–409 (2020). https://doi.org/10.3329/jsr.v12i3.44459

M.A. Hossain, M.S. Hossain, Biomass Convers. Biorefin. (2021). https://doi.org/10.1007/s13399-021-01761-x

S. Saikia, N.K. Mahnot, C.L. Mahanta, Food Sci. Technol. Int. 22, 288–301 (2016)

A. Del Caro, A. Piga, I. Pinna, P.M. Fenu, M. Agabbio, J. Agric. Food Chem. 52, 4780–4784 (2004). https://doi.org/10.1021/jf049889j

W. Brand-Williams, M.-E. Cuvelier, C. Berset, LWT-Food Sci. Techno. 28, 25–30 (1995). https://doi.org/10.1016/S0023-6438(95)80008-5

M. Rahman, F. Khan, R. Das, M.A. Hossain, Int. Food Res. J. 23, 2399 (2016)

S. Ranganna, Handbook of Analysis and Quality Control for Fruit and Vegetable Products (Tata McGraw-Hill Education, New York, 1986)

F.A. Fernandes, S. Rodrigues, J.V. García-Pérez, J.A. Cárcel, Drying Technol. 34, 986–996 (2016). https://doi.org/10.1080/07373937.2015.1090445

A.O.A.C., Official Methods of Analysis, 17th edn. (AOAC, Gaithersburg, 2000)

A. Baroni, M. Hubinger, J. Dry. Technol. 16, 2083–2094 (1998). https://doi.org/10.1080/07373939808917513

P. Rani, P.P. Tripathy, J. Food Sci. Technol. (2019). https://doi.org/10.1007/s13197-019-03961-w

T. Aktas, P. Ulger, F. Daglioglu, F. Hasturk, J. Food Qual. 36, 411–425 (2013). https://doi.org/10.1111/jfq.12062

S. Mastrantonio, L. Pereira, M. Hubinger. Mass transfer and difusion coeficient determination in osmotically dehydrated guavas. In International Drying Symposium (2006)

M.R. Khoyi, J. Hesari, J. Food Eng. 78, 1355–1360 (2007). https://doi.org/10.1016/j.jfoodeng.2006.01.007

O. Corzo, N.J. Bracho, J. Food Eng. 75, 535–541 (2006). https://doi.org/10.1016/j.jfoodeng.2005.05.001

O. Corzo, N. Bracho, LWT-Food Sci. Technol. 41, 1108–1115 (2008). https://doi.org/10.1016/j.lwt.2007.06.018

Y. Deng, Y.J. Zhao, J. Food Eng. 85, 84–93 (2008). https://doi.org/10.1016/j.jfoodeng.2007.07.016

F.R. Assis, R.M. Morais, A.M. Morais, Food Eng. Rev. 8, 116–133 (2016). https://doi.org/10.1007/s12393-015-9123-1

I. Karabulut, A. Topcu, A. Duran, S. Turan, B. Ozturk, LWT-Food Sci. Technol. 40, 753–758 (2007). https://doi.org/10.1016/j.lwt.2006.05.001

M. Ali, Y.A. Yusof, N. Chin, M. Ibrahim, Int. Food Res. J. 23, S155–S161 (2016)

G. Izli, Food Sci. Technol. 37, 139–147 (2017). https://doi.org/10.1590/1678-457x.14516

C.H. Chong, C.L. Law, M. Cloke, C.L. Hii, L.C. Abdullah, W.R.W. Daud, J. Food Eng. 88, 522–527 (2008). https://doi.org/10.1016/j.jfoodeng.2008.03.013

D. Albanese, L. Cinquanta, G. Cuccurullo, M. Di Matteo, Int. J. Food Sci. Technol. 48, 1327–1333 (2013). https://doi.org/10.1111/ijfs.12095

N.R. Pereira, A. Marsaioli Jr., L.M. Ahrné, J. Food Eng. 81, 79–87 (2007). https://doi.org/10.1016/j.jfoodeng.2006.09.025

R.R. Mphahlele, O.A. Fawole, N.P. Makunga, U.L. Opara, BMC Complement. Altern. Med. 16, 143 (2016). https://doi.org/10.1016/j.jfca.2005.04.014

S. Ding, R. Wang, J. Zhang, G. Li, J. Zhang, S. Ou, Y. Shan, Food Sci. Biotechnol. 26, 1523–1533 (2017). https://doi.org/10.1007/s10068-017-0221-0

D.L. Luthria, S. Mukhopadhyay, J. Agric. Food Chem. 54, 41–47 (2006). https://doi.org/10.1021/jf0522457

M.A. Hossain, N.K. Disha, J.H. Shourove, P. Dey, Turk. J. Agric. -Food Sci. Technol. 8, 2749–2755 (2020). https://doi.org/10.24925/turjaf.v8i12.2749-2755.4038

S.M. Jeong, S.Y. Kim, D.R. Kim, S.C. Jo, K. Nam, D. Ahn, S.C. Lee, J. Agric. Food Chem. 52, 3389–3393 (2004). https://doi.org/10.1021/jf049899k

M.A. Hossain, M.Y. Arafat, M. Alam, Food Res. (2021). https://doi.org/10.26656/fr.2017.5(4).035

A.L.M. Ling, Int. J. Pharm. Phytopharmacol. Res. 3, 3 (2014)

P. Marfil, E. Santos, V. Telis, LWT-Food Sci. Technol. 41, 1642–1647 (2008). https://doi.org/10.1016/j.lwt.2007.11.003

E. Horuz, H. Bozkurt, H. Karataş, M. Maskan, Food Chem. 230, 295–305 (2017). https://doi.org/10.1016/j.foodchem.2017.03.046

L.M. Mauri, S.M. Alzamora, J. Chirife, M. Tomio, Int. J. Food Sci. Technol. 24, 1–9 (1989). https://doi.org/10.1111/j.1365-2621.1989.tb00613.x

E. Lešková, J. Kubíková, E. Kováčiková, M. Košická, J. Porubská, K. Holčíková, J. Food Compos. Anal. 19, 252–276 (2006). https://doi.org/10.1016/j.jfca.2005.04.014

S. Bourdoux, D. Li, A. Rajkovic, F. Devlieghere, M. Uyttendaele, Compr. Rev. Food Sci. Food Saf. 15, 1056–1066 (2016). https://doi.org/10.1111/1541-4337.12224

M. Leyva Salas, J. Mounier, F. Valence, M. Coton, A. Thierry, E. Coton, Microorganisms 5, 37 (2017). https://doi.org/10.3390/microorganisms5030037

N. Victor, C. Peter, K. Raphael, G.H. Tendekayi, G. Jephris, M. Taole, P.R. Portia, Afr. J. Microbiol. Res. 11, 185–193 (2017)

S. Fong-in, H. Nimitkeatkai, T. Prommajak et al., Food Meas. Charact. 15, 3590–3597 (2021). https://doi.org/10.1007/s11694-021-00931-9

Acknowledgements

Authors are grateful to the Department of Food Engineering and Tea Technology, Shahjalal University of Science and Technology, Sylhet, Bangladesh for providing the laboratory facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Roy, M., Bulbul, M.A.I., Hossain, M.A. et al. Study on the drying kinetics and quality parameters of osmotic pre-treated dried Satkara (Citrus macroptera) fruits. Food Measure 16, 471–485 (2022). https://doi.org/10.1007/s11694-021-01177-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-01177-1