Abstract

Derris reticulata or “Oi Sam Saun” is an extremely sweet Thai plant, rich in bioactive compounds, and widely used for its medicinal properties. In this study, sweet aqueous extracts from the stems of “Oi Sam Saun” were prepared using ultrasound-assisted extraction (UAE). Phenolic, flavonoid, and sugar compound extraction was optimised using response surface methodology based on the Box–Behnken design (BBD). Three independent variables—extraction temperature (40–80 °C), sonication time (20–60 min), and extraction ratio (1:10–1:30 g/mL)—were investigated, and the values of 80 °C, 60 min, and a ratio 1:10 g/mL, respectively, were optimal. Under these conditions, experimental values were well correlated with predicted values, and phenolic, flavonoid, and sugar contents were 0.483 ± 0.032 mg GAE/g DW, 0.149 ± 0.033 mg CE/g DW, and 4.802 ± 0.651 mg/g DW, respectively. High performance liquid chromatography-diode array detector (HPLC–DAD) analysis showed that the “Oi Sam Saun” UAE extract contained gallic acid, p-coumaric acid, quercetin, and kaempferol. Moreover, the extract contained 18β-glycyrrhetinic acid (0.529 ± 0.002 mg/100 mg) and was 166 times sweeter than sucrose. Therefore, this Thai medicinal plant, which has several pharmacological benefits, is highly potent and can be utilised as a sweetening agent or sugar substitute in foods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sweetness is one of five basic tastes and plays an important role in human diet. Most sweet tastes originate from sugars. However, excessive sugar intake can cause diseases, such as dental caries, hypertension, obesity, and diabetes [1]. Currently, non-nutritive sweeteners and non-sugar sweetening agents are being consumed to avoid high sugar intake-related health problems. Most non-nutritive sweeteners currently available globally are artificial sweeteners, such as aspartame, sucralose, saccharin, and acesulfame-K, some of which are reportedly biologically harmful [2].

Many research attempts have been made to discover and develop natural, plant-based non-nutritive sweetening compounds, which have been successful, but only a few of these compounds, such as stevioside, rebaudioside, glycyrrhizin, mogroside, brazzein, and thaumatin have been commercialised as sweeteners [3]. However, these sweeteners have problems such as aftertaste bitterness, astringency, grassy taste, and thermal labile [4,5,6].

Normally, most sweetening agents of plant origin are phenolics, flavonoids, and terpenoids, which attach to sugars as glycoside structures. For example, glycyphyllin is a phenolic glycoside, naringin dihydrochalcone is a flavanone glycoside, and dihydroquercetin 3-O-acetate is a flavanone glycoside. Terpenoid glycosides which give sweet taste are periandrin, abrusosides, and glycyrrhizin [3]. Glycyrrhizin is a well-known low-calorie sweetener, which is a glycosylated pentacyclic triterpenoid, containing one molecule of 18β-glycyrrhetinic acid, and two molecules of glucuronic acid. 18β-glycyrrhetinic acid is also found in liquorice (local name in Thai “Cha em”) which widely used as herbal medicine. In addition, it is native to southern Europe and parts of Asia, including Thailand [7].

Thailand has a biodiversity of interesting plants such as “Oi Sam Saun” or “Cha em Nua” (Derris reticulata Craib.), found in semi-shaded areas of dry evergreen forests, the edge of evergreen mixed (dipterocarp) forests, bamboo forests, or along streams (50–450 m). The stems of this plant give a sweet taste similar to liquorice; it is a sweetener in local medicine and as a laxative [8]. Although flavonoids, such as lupinifolin, dereticulatin, and pyranoflavonone, were reported in “Oi Sam Saun” [9,10,11], these compounds did not show sweet tastes. Oi Sam Saun and liquorice have a similar sweet taste and a part of the Fabaceae family [8], and they can be substituted for each other in Thai traditional medicine (TTC).

Generally, sweetening compounds are extracted via conventional methods, such as maceration, Soxhlet extraction, and supercritical fluid extraction [12,13,14]. Extraction is a crucial step for the isolation of bioactive sweetening compounds from plant materials. However, conventional methods have certain limitations, such as low yield, excessive solvents, and bitter tastes caused by the materials used [15]. Therefore, modern techniques, such as ultrasound-assisted extraction (UAE), microwave-assisted extraction, and pressurised liquid extraction, are modified approaches with significant advantages over conventional methods [16]. These techniques have been applied in extracting commercial natural sweeteners, such as glycyrrhizin, stevioside, and mogroside [5, 17, 18].

UAE has received considerable attention as a promising alternative to conventional methods [19]. It has been applied in several research and development fields, including phytochemical product extraction and the food industry [20]. It is a simple, low cost, and highly effective technique that exhibits a high-efficiency yield in a short time [21]. The UAE process is an eco-friendly and economically viable process, and is easier to scale up for industrial applications, compared to microwave-assisted extraction and supercritical extraction [22]. Based on studies of UAE scale up, the yield of bioactive compounds increased when compare to lab-scale processes [23,24,25,26]. Furthermore, the cost of UAE equipment, manufacturing, and operational labour are lower than supercritical CO2 extraction [27]. According to some reports, UAE has been applied for the extraction of natural sweeteners; Charpe and Rathod extracted glycyrrhizic acid from liquorice root using ultrasound [18], and Liu et al. extracted total carbohydrate and rebaudioside A from stevia leaves by UAE [28].

However, the UAE method needs to be optimised depending on several factors that can influence the phytochemical extraction yield, including the extraction temperature, ultrasonic time, solvent composition, particle diameter, liquid–solid ratio, and electrical acoustic intensity [29]. Currently, response surface methodology (RSM) is a mathematical tool widely used in the research and food industry. Its advantages include decreasing the number of experimental runs, evaluating the effect of several variables, and optimising conditions [21]. Among many classes of RSM designs, BBDs are a class of rotatable or nearly rotatable second-order designs based on three-level incomplete factorial designs. BBDs are slightly more efficient with fewer experimental runs than the central composite designs (CCDs) [30].

Therefore, this study aimed to extract such compounds (phenolics, flavonoids, and sugars) from “Oi Sam Saun” using UAE, optimise them using RSM, and investigate their sweetness potency. In addition, there is a lack of information on sweetening compounds and their related compounds from Oi Sam Saun, with only a few reports on suitable extraction methods for these compounds.

Materials and methods

Chemicals

Folin–Ciocalteu reagent, sodium carbonate, methanol, acetonitrile, and formic acid were purchased from Sigma (Singapore). All solvents and standard compounds were of HPLC grade and all chemicals were of analytical grade.

Plant materials

Derris reticulata Craib. (Leguminosae) or Oi Sam Saun stems were collected on July 2015 from central regions of Thailand. Botanical identification was graciously performed by Assoc. Prof. Saranya Vajrodaya of the Faculty of Botany, Kasetsart University, Bangkok, Thailand. Voucher specimen (BK no. 069447) was then deposited at the Forest Herbarium-BKF, Bangkok, Thailand. Stems were dried at 50 °C until they attained constant weight (12% moisture content), ground to powder, sieved through a 40-mesh sieve, and kept at room temperature before the experiments.

Extraction of Oi Sam Saun by ultrasound-assisted extraction (UAE)

UAE was conducted using an ultrasonic bath (Elmasonic E70H), which was rated by the manufacturer with an effective acoustic power rating and frequency of 120 W and 37 kHz. Plant powder was extracted using distilled water at different extraction temperatures (40, 60, and 80 °C), times (20, 40, and 60 min), and ratios (1:10, 1:20 and 1:30 w/v). The experimental parameters were chosen based on preliminary studies [31,32,33]. A thermocouple was used in the solution to monitor and maintain the desired temperature. However, the ultrasonic bath temperature may increase during the process and exceed the set value. To maintain desired temperatures, ice cubes were added to the water bath when necessary. At designated extraction intervals, the mixture was taken and filtered with a Whatman No.1 filter paper; the Oi Sam Saun UAE extracts were collected to determine the physico-chemical characteristics, including extraction yield, colour, total phenolic, total flavonoid, and total sugar content.

Determination of physico-chemical characteristics in Oi Sam Saun extract

Extraction yield

Oi Sam Saun UAE extracts were collected, the water was removed under vacuum using a rotary evaporator (Buchi, Germany) at 40 °C, and they were freeze-dried. The percentage yield of the dried crude extracts was determined and calculated according to Eq. (1):

Colour measurement

Colours of the Oi Sam Saun UAE extracts were measured using a HunterLab colorimeter (Miniscan EZ; Hunter Associates Laboratory Inc., Reston, USA). Each sample was measured in triplicates and analysed using the CIE L* a* b* system. Here, L* represents the lightness of the colours from 0 (dark) to 100 (light), a* represents the greenness/redness parameter (negative a* is green and positive a* is red), and b* represents the grade of blueness/yellowness (negative b* is blue and positive b* is yellow). The angular coordinates of the hue angle (h°) were calculated according to Eq. (2a), (2b), and (2c):

For the browning index (BI) of Oi Sam Saun UAE extracts, BI was calculated using Eq. (3a) and (3b):

where:

The BI represents the purity of the brown colour or brown pigment concentration [34, 35].

Total phenolic content

All extracts were determined phenolic content using the Folin-Ciocalteu method described by Gonçalves et al. [36]. Folin reagent (2.5 mL, diluted 10×) was added to 0.5 mL of the extract (10 mg/mL), to which 2 mL of sodium carbonate (5 g/L) was then added. The mixture was then placed in the dark for 1 h before the absorbance was read at 760 nm. Gallic acid was a reference standard and the total phenolic content was expressed as gallic acid equivalents (GAE, mg/g extract).

Total flavonoid content

All extracts were determined total flavonoids using a spectrophotometric assay developed by Dini [37]. About 0.5 mL of the extract (10 mg/mL) and catechin standard (20–100 mg/L) were mixed in a test tube with 2 mL of distilled water, and 5% sodium nitrite (0.15 mL) was added to the test tube. After 5 min, 10% aluminium chloride (0.15 mL) was added to the mixture. At 6 min, 1 M sodium hydroxide (1 mL) and distilled water (1.2 mL) were added, and the mixture was mixed. The absorbance of the mixture was measured against a blank at 510 nm. The total flavonoids of the extracts were expressed as mg catechin equivalent (CE)/g dry weight of the plant.

Total sugar content

Total sugar content was determined based on a colorimetric method [38]. The extract (1 mL, 10 mg/mL) was mixed with 5% phenol (1 mL), and 5 mL of concentrated sulphuric acid was then added. The reaction mixture was incubated at 25 °C for 20 min, and the absorbance was measured at 490 nm with glucose as standard. The total sugar content was expressed as mg glucose/g dry weight of plant (mg/g DW).

Experimental design

Box–Behnken experimental design (BBD) with three levels and three factors was selected to investigate the influence of the process factors on RSM. Maximum and minimum treatment levels were selected by carrying out preliminary screening tests. Therefore, the selection of conditions of the main experiments include 40–80 °C for temperatures, 20–60 min for extraction times; and 1:10–1:30 g/mL for extraction ratios. The effects of the three main factors (ratio, temperature, and sonication time) on three responses (phenolic, flavonoid, and sugar contents) were determined. Table 1 lists the original and code values of the extraction factors and their levels in the extraction process. The experimental design involves 17 experimental runs, including five replicates at centre points, used to allow for the estimation of a pure error sum of squares, and the total number of experimental runs were evaluated from Eq. (4) [19].

where K is the number of experimental factors and C0 is the number of central points.

A second-order polynomial equation was fitted to the data by linear regression (Eq. 5):

where Y is the dependent variable (flavonoid and phenolic), \(\beta_{0}\) is the model constant, βi, βii, βij are the model coefficients, X is the independent variable, k is the number of independent factors, and \(\varepsilon\) is the error. The parameters βi, βii, and βij represent the linear, quadratic, and interaction effects of the variables, respectively.

Optimisation of sweetening compound extraction conditions

BBD experimental data were used to determine the optimal conditions for the model. All response variables (total phenolic, flavonoid, and sugar contents) were kept at maximum, and the independent variables (temperature (X1), time (X2) and ratio (X3)) were kept within the desired range (between lower and higher level). Statistica 9.0 software (StatSoft Inc., Tulsa, OK) generated the optimal conditions based on BBD data. Further, the optimal condition gave the model a predicted value for each response, for comparison with the experimental value. Hence, the experiments were performed at the suggested optimal condition, and the response values obtained were compared with the model’s predicted values. After, the extract from the optimal condition was used to analyse the phenolic; flavonoid; and sugar compounds, concentration of 18β-glycyrrhetinic acid, and sweetness intensity.

Phenolic and flavonoid analysis

Under optimal conditions, Oi Sam Saun UAE extract (≈10 mg) was hydrolysed using 10 mL of 1 M trifluoroacetic acid (TFA) at 90 °C for 60 min. Next, the solution was mixed with 40 mL methanol and exposed in a rotary evaporator at 40 °C, until the remaining TFA was removed. The hydrolysed sample was mixed with 20 mL deionised water and filtered with a 0.45 μm syringe filter used for phenolic and flavonoid determination.

Phenolic and flavonoid compounds were determined under optimal Oi Sam Saun UAE conditions. The extracts were analysed using an HPLC–DAD (diode array detector; 1200 Series, Agilent Technologies, USA), using an Eclipse XDB-C18 column (4.6 mm ID × 250 mm, 5 μm) and a linear gradient with water (pH 2.5) containing TFA (A) and acetonitrile (B) for 65 min at a flow rate of 1.0 mL/min. The gradient was set as 0–20 min, 95–90% A; 20–50 min, 95–70% A; 50–55 min, 70–50% A; 55–60 min, 50–95% A; 60–65, 95% A. The samples (5 μL) were loaded into the HPLC–DAD. The DAD detector was set at 280 and 350 nm for phenolic and flavonoid detection, respectively.

Sugar analysis

Sugar type and content were identified by high performance liquid chromatography-evaporating light scattering detector (HPLC-ELSD; Alltech, Buchi, Switzerland). Oi Sam Saun UAE extracts, under optimal conditions, were dissolved in distilled water at a concentration of 1000 ppm and filtered through 0.45 μm (Millipore) filters. Separation was achieved using a Rezex RPM Monosaccharide column (300 mm × 7.8 mm ID, 8 μm particle size). The mobile phase was water in isocratic elution with a flow rate of 0.6 mL/min for 30 min. The detection of analytes was conducted using an evaporative light scattering detection (Alltech, Buchi, Switzerland) technique which detects organic molecules by mass; hence, it is useful in the quantitative determination of non-UV-sensitive compounds. The drift tubes for ELSD were set at 105 °C and the flow rate of nebulising gas (N2) was 2.6 standard litre per minute (SLM). The sugar standard chromatograms were for glucose, fructose, and sucrose.

Determination of 18β-glycyrrhetinic acid

The 18β-glycyrrhetinic acid content of the Oi Sam Saun UAE extract, under optimal conditions, was identified by the modified method of Esmaeili et al. [39], using 1200 series Agilent HPLC system with a 20 μL sample loop attached to a DAD. HPLC analysis was completed using a reversed phase XDB-C18 column (250 × 4.6 mm, 5 mm) and 18β-glycyrrhetinic acid was determined using an acetonitrile/phosphoric acid (3/1, v/v; pH 2.5) mobile phase at flow rates of 1.0 mL/min (0–8 min) and 0.6 mL/min (8–20 min) at a detector wavelength of 230 nm.

Sensory evaluation and sweetness intensity estimation of Oi Sam Saun UAE aqueous extracts

Sensory evaluation of Oi Sam Saun UAE extracts, under optimal conditions, was conducted by 10 semi-trained assessors (3 males and 7 females) aged 24–30 years old. The intensity of each attribute, including sweet, sour, and bitter tastes, using a nine-point intensity scale, in which zero indicated an unperceived attribute intensity and nine indicated a strong attribute intensity. Sucrose (1–6%, interval 0.4%), citric acid (0.00061–5.00 mM, interval twofold), and caffeine (0.05–8.7 mM, interval 0.25 mM) were used as standards for the sweet, sour, and bitter tastes, respectively. Evaluating Oi Sam Saun UAE extract (1 mL) was conducted at room temperature under clean air conditions and served in opaque disposable plastic cups [40]. Moreover, the sensory evaluation of extracts was repeated twice.

For sweetness intensity estimation, the individual assessors who participated in the study were trained to distinguish intensities of a series of sweet solutions. The sweet solution (10 mL), at a concentration of 1, 2, 5, and 10% sucrose, was selected for the first session, and 0.5, 1, 2, and 3% sucrose were used for training in the second session [41]. Oi Sam Saun UAE extract was evaluated by 10 trained assessors in the manner described by Yoshikawa et al. [42] and Darise et al. [43]. All trained assessors were asked to taste a sucrose solution and estimate its total taste intensity relative to the sample solution. Assessors tested in this way four times for each sample. The sweetness potency of Oi Sam Saun UAE extract, relative to that of sucrose, was calculated using Eq. (6):

where A is the concentration (% w/v) of sample solution at 10%, and B is the concentration (% w/v) of sucrose with the same sweetness as sample, which calculated from the linear regression formula of the sweetness score (1–9 point) against sucrose concentration (0–10% w/v).

Statistical analysis

All tests were performed in triplicate. Statistical analysis was performed by the analysis of variance (ANOVA) and least significant difference (LSD) test, using SAS statistical software, version 9 (SAS Institute Inc., Cary, NC, USA), at 95% confidential interval or probability at ≤ 0.05. The three-dimensional (3D) response surface plots of the experimental model were generated using the Statistica 9.0 program (StatSoft Inc., Tulsa, OK).

Results and discussion

Fitting the response surface model

The preparation process of Oi Sam Saun UAE extracts and the overall experiment is illustrated in Fig. 1. In this study, UAE involved three important factors—temperature, sonication time, and extraction ratio—which can strongly influence the yield, colour, and phenolic, flavonoid, and sugar contents of Oi Sam Saun extracts. Experiments were applied to determine the optimum temperature, time, and extraction ratio for yield, colour, and phenolic, flavonoid, and sugar compounds in the extract, based on BBD.

The extraction yield, L*, h° and BI of Oi Sam Saun UAE extracts ranged between 2.01–2.35%, 85.12–86.62, 51.1–53.4, and 0.190–0.192, respectively. The colour and hue value of Oi Sam Saun UAE extracts represented the light brown colour of the extracts. The light brown colour of the extract could be from some phenolic, flavonoid, or other compounds such as polyphenol or pigments in plants [44]. However, the main three factors, including temperature, sonication time and extraction ratio did not possess significant interaction with the extraction yield, colour, and BI (p > 0.05). Contrarily, there were significant interactions between total phenolic, total flavonoid, and total sugar contents with these parameters. Therefore, phenolic, flavonoid and sugar contents were selected as the criteria to determine the optimal condition for the Oi Sam Saun UAE process.

The experimental results for the 17 experimental points included five central points from the BBD, which were calculated from Eq. (5), and are shown in Table 1. The quadratic model was applied to show the influence of variables over phenolic, flavonoid, and sugar contents in the extract. The quadratic model regression analysis equations, which were calculated from Eq. 6 of Oi Sam Saun, were obtained. The results showed that the experimental data fit a quadratic model in the phenolic, flavonoid, and sugar contents of Oi Sam Saun based on ANOVA (Table 2), with significant R2 values (> 0.90) for the effect of extraction temperature, sonication time, and extraction ratio on phenolic, flavonoid, and sugar contents. The second-order equations for these variables are shown as Eqs. (7)–(9), respectively.

where X1 temperature (°C), X2 sonication time (min), and X3 solid/liquid ratio (mL/g).

ANOVA was used to evaluate the significance of the quadratic polynomial models. The linear terms of temperature (X1), time (X2), and ratio (X3) showed a significant effect (p ≤ 0.05) on phenolic content. The quadratic terms of time (X22) and ratio (X32) on phenolic content also exhibited a significant effect (p ≤ 0.05), whereas the effect of temperature was insignificant (p > 0.05). The combined effect on phenolic contents was significantly (p ≤ 0.05) influenced by temperature and time.

The linear and quadratic effects of all three parameters on flavonoid content were significant (p ≤ 0.05). ANOVA showed that, in combination, flavonoid contents were significantly influenced by temperature (X1) and time (X2) (p ≤ 0.05). Moreover, in combination, flavonoid content was also significantly influenced by extraction temperature (X1) and ratio (X2), and time (X1) and ratio (X3) (p ≤ 0.05).

The linear effects of temperature (X1) and ratio (X3), and the quadratic effect of ratio (X32) on sugar content in the Oi Sam Saun UAE extract was significantly different (p ≤ 0.05). In combination, only the interaction between time and ratio had a significant (p ≤ 0.05) effect on sugar content. Moreover, the highest values of estimated regression coefficients for extraction ratio (β3 = − 0.147, − 0.058, and − 1.415) indicated that it was the most important linear variable influencing phenolic, flavonoid, and sugar contents. The negative value implied that phenolic, flavonoid, and sugar contents increased with decreasing extraction ratio. In addition, the model fitness was investigated using the lack-of-fit test (p ≤ 0.05), which indicated the suitability of models for accurate prediction of the variation [45].

However, the range of temperature and times using for extraction depended on the plant’s part. Because of the plant cell wall, in stem of Oi Sam Saun, comprises cellulose, hemicellulose, and lignin and also targeted phenolic and flavonoid compounds bound in plant cell, these compounds were extracted using high temperature and long extraction time (80 °C, 60 min) to improve the extraction yield [46]. Jovanovic et al. [47] reported that high temperature (80 °C) had a positive effect on the polyphenols yield from the Thymus serpyllum L. herb. Meanwhile, longer sonication time can enhance the mechanical effects to promote extraction efficiency [48].

Optimisation of the extraction process

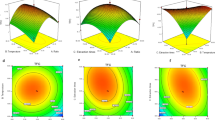

The 3D response surface plots and two-dimensional (2D) contour plots were constructed from the regression equations to visualise and study the relationship between the response (temperature, sonication time, and extraction ratio) and sweetening compound (phenolic, flavonoid, and sugar) extraction variables shown in Fig. 2.

For phenolic compounds in the Oi Sam Saun extracts, the 3D and 2D RSM plots are shown as a function of temperature and sonication time in Fig. 2a. ANOVA results indicated that X1 (temperature) and X2 (sonication time) had positive interaction effects on phenolic content (p ≤ 0.05; Table 2). Phenolic content increased with increasing extraction temperature and time, probably due to enhanced mass transfer rate and diffusibility at higher temperatures of solvent into the plant cell matrix. Further, the solubility of phenolic compounds also increased at higher temperatures. These phenomena create bubble cavitation in liquid medium and cause bubble collapse, which damages the plant cell matrix [18, 20, 46]. It can be concluded that the maximum phenolic content of Oi Sam Saun UAE extract was attained when extraction temperature and sonication time were ≈80 °C and 60 min, respectively.

The 3D and 2D RSM plots of Oi Sam Saun flavonoid contents are shown in Fig. 2b–2d. Based on ANOVA, the combined effect of temperature and sonication time, temperature, and ratio, and sonication time and ratio were statistically significant (p ≤ 0.05). The flavonoid content increased with increasing temperature and sonication time (Fig. 2b). Increasing the sonication time influenced flavonoid content due to swelling, and hydration of plant material could be accelerated by the cavitation effect of ultrasound waves during the initial extraction period. The asymmetric collapse of micro-bubbles near surfaces was also associated with micro-jets that could cause the disruption and penetration of water into the matrix through diffusion, improving the washing out of flavonoid content from plant material to surrounding water and enhancing extraction [21]. Figure 2c, d show the effect of temperature and extraction ratio and sonication time and extraction on flavonoid content, respectively. As seen in Fig. 2c, flavonoid content increased with increasing temperature and decreasing extraction ratio. Figure 2d shows that increasing sonication time and decreasing extraction ratio increased flavonoid content. This phenomenon was also reported in the UAE of polyphenols from Sparganium stoloniferum [49]. Taken together, it can be concluded that flavonoid content was the highest when the extraction ratio, temperature, and sonication time were 1:10 g/mL, 80 °C, and 60 min, respectively.

For sugar compounds, Fig. 2e demonstrates the interactive effect of sonication time and extraction ratio on sugar content. ANOVA showed that sugar content depended on sonication time and extraction ratio, combined (p ≤ 0.05). Sugar content increased with increasing sonication time and decreasing extraction ratio. According to Fig. 2e, the longer the sonication time, the higher is the sugar content, which is like the phenolic and flavonoid contents. Therefore, sugar content was the highest when the extraction ratio and sonication time were around 1:10 g/mL and 60 min, respectively.

RSM optimisation and model validation

The numerical optimisation method was used to optimise the UAE conditions. The optimal Oi Sam Saun UAE conditions, which gave the maximum phenolic, flavonoid, and sugar content were 1.0 (temperature), 1.0 (sonication time), and − 1.0 (extraction ratio), in coded form. The corresponding actual optimum extraction conditions were 80 °C, 60 min, and 1:10 g/mL, based on the regression analysis and 3D surface plots of the independent variables. Under these conditions, the predicted values for phenolic, flavonoid, and sugar contents were 0.4725 mg/g, 0.1688 mg/g, and 5.2454 mg/g, respectively (Table 3). The experimental values were compared with the predicted values obtained from the model equation to verify that the selected conditions were suitable. Therefore, phenolic, flavonoid, sugar compounds, 18β-glycyrrhetinic acid and sweetness intensity were analysed from the optimised Oi Sam Saun UAE extract.

Quantification of phenolic and flavonoid of optimised Oi Sam Saun UAE extract

Some phenolics and flavonoids have been reported for their sweetening properties, which were glycoside forms [3]. However, there are no reports on the type of phenolic and flavonoid compounds in Oi Sam Saun UAE extracts. Thus, the determination and identification of phenolic and flavonoid compounds in Oi Sam Saun UAE extract was done. Under optimised UAE conditions, the extract of Oi Sam Saun (80 °C, and 60 min, 1:10 g/mL) was investigated in the presence of phenolic and flavonoid compounds. The extract was hydrolysed by TFA to give free phenolics and flavonoids before analysis. The hydrolysed compounds were identified by comparing their retention times and UV absorption spectrum with those of standards. Eight compounds were shown in the chromatogram, but only four compounds were identified and quantified—two phenolics (gallic acid, 0.108 ± 0.012 mg/g extract and p-coumaric acid, 0.082 ± 0.007 mg/g extract), and two flavonoids (quercetin, 0.047 ± 0.008 mg/g extract and kaempferol, 0.031 ± 0.002 mg/g extract) (Fig. 3; Table 4). These phenolic and flavonoid compounds might be attached to sugars as a glycoside form, or bound in the cell wall [50], which might give a sweet taste. For example, quercetin and kaempferol structures might have similar dihydroflavonol or glycoside forms as other sweet phenolic and flavonoid compounds, such as glycyphyllin, a dihydrochalcone glycoside, or (2R, 3R)-dihydroquercetin 3-O-acetate, a dihydroflavonol [3], giving a sweet taste to Oi Sam Saun extract. Hence, the unknown phenolic and flavonoid compounds may be the key to the sweet taste of this plant extract.

Sugar profile of Oi Sam Saun UAE extract

The sugar composition of the optimised Oi Sam Saun UAE extract was quantified via HPLC-ELSD. Glucose, fructose, sucrose, and maltose were used as sugar standards. The chromatogram results showed that the extract (Fig. 4) contained known sugars including sucrose (1.333 ± 0.098 mg/g extract), glucose (0.705 ± 0.051 mg/g extract), and fructose (0.891 ± 0.074 mg/g extract), and three unknown sugars (Table 4). The type and concentration of sugars were related to the sweetness intensity of the plant. Glucose in this plant might be in the form of glycoside and impart a sweet taste, like glycyphyllin, which has glucose in its structure. Sucrose also gives a sweet taste to this plant, depending on the concentration. Moreover, sugars in this extract might be bound with phenolics and flavonoids as a glycoside structure, which related to the BI value of extracts. It indicates that the light brown colour of extracts in all conditions is not from the oxidation of sugar (caramelisation). Therefore, analysis of the phenolic, flavonoid, and sugar components suggested that phenolic and flavonoid compounds in Oi Sam Saun UAE extract exist in glycoside forms, which might impart a sweet taste to it [3].

The 18β-glycyrrhetinic acid content of optimised Oi Sam Saun UAE extract

The chromatogram in Fig. 5 shows the 18β-glycyrrhetinic acid content was 0.529 ± 0.002 mg/100 mg of the optimised Oi San Saun UAE extract (0.529%; Table 4). The typical amount of 18β-glycyrrhetinic acid found in liquorice root was 0.1–1.6%, depending on the region of cultivation, species, and extraction method [51]. Therefore, this is the first time 18β-glycyrrhetinic acid in Oi Sam Saun UAE extract has been reported. 18β-glycyrrhetinic acid gives a sweet taste due to the hydroxyl group as a functional group (R) at C-3 position. When R is another compound such as an anionic NHCO(CH2)CO2K side chain or glucuronic acids, a different sweetening effect can be found [52].

Nevertheless, Oi Sam Saun UAE extracts are non-toxic due to the toxicological result (data not shown). From the study of Kumkrai et al. [53], D. reticulata aqueous extract did not produce clinical signs of toxicity by sub-chronic administration. 18β-glycyrrhetinic acid has also been shown to possess several pharmacological benefits, such as an anti-ulcerative effect, anti-inflammatory activity, direct and indirect antiviral activity, interferon inducibility, an antihepatitic effect, and an antihyperglycemic effect [54]. Furthermore, 18β-glycyrrhetinic acid was found in liquorice diet gum, cough mixtures, tea herbal medicine, and candy [55]. In addition, the UAE method is a green extraction technology for bioactive compounds applied in food industry, because of its safety and cost efficiency [32]. This suggests that Oi Sam Saun UAE extract containing 18β-glycyrrhetinic acid has the potential to use in food application.

Sweetness intensity of optimised Oi Sam Saun UAE extracts

The optimised Oi Sam Saun UAE extract (80 °C, 60 min, 1:10 g/mL) was selected for sensory tests. The number of assessors in this study including 3 males and 7 females appeared sufficient for sensory evaluation [56]. In addition, the number of assessors could be varied from 5 to 30 assessors [40]. Moreover, the number of genders did not affect the result of the sensory test because the assessors were selected by qualitative different test, especially sweet perception for this study [40, 41]. The sensory scores for each stimulus (sweetness, sourness, and bitterness) on an adjective scale were detected as 6.94, 0.24, and 1.26, respectively (Table 3).

The relationship between the sweetness score from the individual assessors who participated in the study and the sucrose concentration was determined, and the equation, y = 0.6981x (R2 = 0.9656), was generated, and then used to calculate the B value in Eq. (6). The Oi Sam Saun extract was 166 times sweeter than sucrose, which could be attributed to the combined effect of several compounds in the plant’s crude extracts, such as polyphenols, alkaloids, and other pigments, which contribute to the sweet taste and concentration of sweetening compounds in the crude extracts. Polyphenols are responsible for some important sensory properties associated with foods. This complex and large family of molecules is responsible for the production of taste sensations, ranging from bitter to astringent and pungent, depending on the polyphenol composition of the food [57]. Therefore, the different concentrations of phytochemical compounds, including flavonoids, sugars, and phenolics, elicited similar or better sensory responses from the individual assessors who participated in the study. It has been indicated that phenolic, flavonoid compounds bound with sugars as glycosides and 18β-glycyrrhetinic acid enhanced the overall preference for Oi Sam Saun UAE extracts due to their sweet tastes [3]. High concentrations of these compounds may also play a beneficial role when incorporated as part of sweeteners because they contribute to antioxidant activity inherent in UAE extracts [58, 59].

Conclusion

For the first time, the phenolic, flavonoid, and sugar compounds from Oi Sam Saun were extracted using UAE. This BBD with RSM optimisation study showed that UAE gives the best yield of phenolic, flavonoid, and sugar sweetening compounds. The optimal conditions for Oi Sam Saun extraction was achieved with an ultrasonic treatment of 80 °C for extraction temperature, sonication time of 60 min; and extraction ratio of 1:10 g/mL. Under the optimal condition, the experimental results agreed closely with the predicted results. The phenolics, including gallic and p-coumaric acid; flavonoids, including quercetin and kaempferol; sugars including glucose, fructose, and sucrose; and 18β-glycyrrhetinic acid were found. In addition, the Oi Sam Saun UAE extract was 166 times sweeter than sucrose. These results revealed the potential application of this Thai medicinal plant in foods as a sweetening agent to substitute sugars and provide several pharmacological benefits. Moreover, its application as a sweetening compound may be rationalised for suitable processing to improve taste and sweetness potency. However, the fractionation, purification, and identification processes of individual sweetening compounds need to be investigated. Therefore, further studies should focus on identifying the new sweetening compounds via liquid chromatography with tandem mass spectrometry.

Data availability

All data that are relevant to the study are reported within the article.

References

V.S. Malik, M.B. Schulze, F.B. Hu, Am. J. Clin. Nutr. 84, 274 (2006)

C.R. Whitehouse, J. Boullata, L.A. McCauley, AAOHN J. 56, 251 (2008)

N.C. Kim, A.D. Kinghorn, Arch. Pharm. Res. 25, 725 (2002)

V. Jaitak, B.S. Bandna, V.K. Kaul, Phytochem. Anal. 20, 240 (2009)

A.B. Rao, G.R. Reddy, P. Ernala, S. Sridhar, Y.V. Ravikumar, Int. J. Food. Sci. Tech. 47, 2554 (2012)

J.C. Fry, in Natural Food Additives, Ingredients and Flavourings, ed. by D. Baines, R. Seal (Woodhead Publishing Limited, Cambridge, 2012) p. 488

K.F. Khattak, T.J. Simpson, Radiat. Phys. Chem. 79, 507 (2010)

Y. Sirichamorn, F. Adema, P. Van Welzen, Syst. Bot. 37, 404 (2012)

K. Yusook, O. Weeranantanapan, Y. Hua, P. Kumkrai, N. Chudapongse, J. Nat. Med. 71, 357 (2017)

C. Mahidol, H. Prawat, W. Kaweetripob, Heterocycles 57, 1287 (2002)

C. Mahidol, H. Prawat, S. Ruchirawat, K. Lihkitwitayawuid, L.Z. Lin, G.A. Cordell, Phytochemistry 45, 825 (1997)

Y. Xia, M.E. Rivero-Huguet, B.H. Hughes, W.D. Marshall, Food Chem. 107, 1022 (2008)

G.Y. Koh, G. Chou, Z. Liu, J. Agric. Food. Chem. 57, 5000 (2009)

Y.H. Choi, I. Kim, K.D. Yoon, S.J. Lee, C.Y. Kim, K.P. Yoo, Y.H. Choi, K. Jinwoong, Chromatographia 55, 617 (2002)

J.O. Chaves, M.C. de Souza, L.C. da Silva, D. Lachos-Perez, P.C. Torres-Mayanga, A.P.D.F. Machado, T. Forster-Carneiro, M. Vázquez-Espinosa, A.V. González-de-Peredo, G.F. Barbero, M.A. Rostagno, Front. Chem. 8, 1 (2020)

C. Tanase, S. Cosarca, D. Muntean, Molecules 24, 1 (2019)

X. Pan, H. Liu, G. Jia, Y.Y. Shu, Biochem. Eng. J. 5, 173 (2000)

T.W. Charpe, V.K. Rathod, Chem. Eng. Process. 54, 37 (2012)

J.P. Maran, B. Priya, Int. J. Food Sci. Tech. 53, 792 (2016)

S. Farooq, M.A. Shah, M.W. Siddiqui, B.N. Dar, S.A. Mir, A. Ali, J. Food Meas. 14, 3508 (2020)

X. Yin, X. Zhang, D. Li, J. Food Meas. 14, 694 (2020)

D.-C. Pham, H.-C. Nguyen, T.-H.L. Nguyen, H.-L. Ho, T.-K. Trinh, J. Riyaphan, C.-F. Weng, Biomed. Res. Int. 2020, 3497107 (2020)

O. Dorosh, M.M. Moreira, F. Rodrigues, A.F. Peixoto, C. Freire, S. Morais, C. Delerue-Matos, Molecules 25, 1739 (2020)

S. Boonkird, C. Phisalaphong, M. Phisalaphong, Ultrason. Sonochem. 15, 1075 (2008)

L. Paniwnyk, H. Cai, S. Albu, T.J. Mason, R. Cole, Ultrason. Sonochem. 16, 287 (2009)

S. Achat, V. Tomao, K. Madani, M. Chibane, M. Elmaataoui, O. Dangles, F. Chemat, Ultrason. Sonochem. 19, 777 (2012)

J. M. Prado, P. C. Veggi, M.A.A. Meireles, in Global Food Security and Wellness, ed. by G. V. Barbosa-Cánovas, G. M.Pastore, K. Candoğan, I. G. M. Meza, S. C. da S. Lannes, K. Buckle, R. Y. Yada, A. Rosenthal (Springer, New York, 2017) p. 517

J. Liu, J.W. Li, J. Tang, Food Bioprod. Process 88, 215 (2010)

Z. Sheng, B. Wang, J. Zhao, W. Yu, Int. J. Food Eng. 13 (2017)

S.C. Ferreira, R. Bruns, H. Ferreira, G. Matos, J. David, G. Brandao, E.G.P. da Silvaa, L.A. Portugala, P.S. dos Reisca, A.S. Souzaa, W.N.L. dos Santosc, Anal. Chim. Acta. 597, 179 (2007)

C. Wen, J. Zhang, H. Zhang, C.S. Dzah, M. Zandile, Y. Duan, H. Ma, X. Luo, Ultrason. Sonochem. 48, 538 (2018)

F. Chemat, N. Rombaut, A.-G. Sicaire, A. Meullemiestre, A.-S. Fabiano-Tixier, M. Abert-Vian, Ultrason. Sonochem. 34, 540 (2017)

A. Altemimi, R. Choudhary, D.G. Watson, D.A. Lightfoot, Ultrason. Sonochem. 24, 247 (2015)

S. Guerrero, S. Alzamora, L. Gerschenson, J. Food Eng. 28, 307 (1996)

E. Palou, A. López-Malo, G. Barbosa-Cánovas, J. Welti-Chanes, B. Swanson, J. Food Sci. 64, 42 (1999)

S. Gonçalves, D. Gomes, P. Costa, A. Romano, Ind. Crops Prod. 43, 465 (2013)

I. Dini, Food Chem. 124, 884 (2011)

M. Dubois, K.A. Gilles, J.K. Hamilton, P.T. Rebers, F. Smith, Anal. Chem. 28, 350 (1956)

S. Esmaeili, F. Naghibi, M. Mosaddegh, N. Nader, Iran. J. Pharm. Sci. 2, 137–141 (2010)

ISO 6658, Sensory Analysis-Methodology-General Guidance (International Organization for Standardization, Genève, 2017) p. 26

M.C. Meilgaard, B.T. Carr, G.V. Civille, Sensory Evaluation Techniques (CRC Press, Florida, 2006).

M. Yoshikawa, T. Morikawa, K. Nakano, Y. Pongpiriyadacha, T. Murakami, H. Matsuda, J. Nat. Prod. 65, 1638 (2002)

M. Darise, K. Mizutani, R. Kasai, O. Tanaka, S. Kitahata, S. Okada, S. Ogawa, F. Murakami, F.H. Chen, Agric. Biol. Chem. 48, 2483 (1984)

H. Kelebek, A. Canbas, M. Jourdes, P.L. Teissedre, Ind. Crops Prod. 31, 499 (2010)

M. Yolmeh, M.B.H. Najafi, R. Farhoosh, Food Chem. 155, 319 (2014)

A.T. Mustapha, C. Zhou, H. Wahia, F. Sarpong, M.M. Nasiru, Y.B. Adegbemiga, H. Ma, J. Food Process Preserv. (2020). https://doi.org/10.1111/jfpp.14325

A.A. Jovanović, V.B. Đorđević, G.M. Zdunić, D.S. Pljevljakušić, K.P. Šavikin, D.M. Gođevac, B.M. Bugarski, Sep. Purif. Technol. 179, 369 (2017)

P. Wang, C. Cheng, Y. Ma, M. Jia, Sep. Purif. Technol. 247, 116967 (2020)

X. Wang, Y. Wu, G. Chen, W. Yue, Q. Liang, Q. Wu, Ultrason. Sonochem. 20, 846 (2013)

J.-C. Cocuron, M.I. Casas, F. Yang, E. Grotewold, A.P. Alonso, J. Chromatogr. A 1589, 93 (2019)

C. Sabbioni, A. Ferranti, F. Bugamelli, G.C. Forti, M.A. Raggi, Phytochem. Anal. 17, 25 (2006)

S. Ijichi, S. Tamagaki, Chem. Lett. 34, 356 (2005)

P. Kumkrai, O. Weeranantanapan, N. Chudapongse, B.M.C. Complem, Altern. Med. 15, 35 (2015)

P. Kalaiarasi, K.V. Pugalendi, Eur. J. Pharmacol. 606, 269 (2009)

M.R. Deutch, D. Grimm, M. Wehland, M. Infanger, M. Krüger, Foods 8, 495 (2019)

H. Heymann, B. Machado, L. Torri, A.L. Robinson, J. Sens. Stud. 27, 111 (2012)

R. Kaushik, P. Narayanan, V. Vasudevan, G. Muthukumaran, A. Usha, Int. J. Food Sci. Tech. 47, 27 (2010)

A. Mocan, M. Schafberg, G. Crișan, S. Rohn, J. Funct. Foods 24, 579 (2016)

F. Chikari, J. Han, Y. Wang, P. Luo, X. He, E. Kwaw, P. Out, J. Food Process Eng. (2020). https://doi.org/10.1111/jfpe.13366

Acknowledgements

The authors are thankful to Thailand Research Fund through the Royal Golden Jubilee Ph.D. Program (Grant No. PHD/0073/2554), King Mongkut’s University of Technology Thonburi (KMUTT), Bangkok, Thailand for providing all the necessary facilities to conduct the research work.

Funding

This work was financially supported by Thailand Research Fund through the Royal Golden Jubilee Ph.D. Program (Grant No. PHD/0073/2554), King Mongkut’s University of Technology Thonburi (KMUTT), Bangkok, Thailand.

Author information

Authors and Affiliations

Contributions

KT designed the study and reviewed the manuscript concept, structure, topics, performed the research experiments, interpreted the results, acquired the data, and wrote the manuscript with original draft, review, and editing. NL as supervision designed, reviewed, and developed the manuscript concept, structure, and topics. OK, PV, and WM were involved in the analysis. All authors read and approved the final manuscript of publication.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

All the authors have read and agreed the ethics for publishing the manuscript. The study was conducted in compliance with the ethical principles stated in the ethical guideline in human experiments from King Mongkut's University of Technology Thonburi (2018) and the protocol for this study. Ethics Committee approval number is KMUTT-IRD-62-115. The appropriateness of this study was reviewed and approved by the ethics committee of each participating facility.

Informed consent

Written informed consent was obtained from all participants in this study.

Consent for publication

The authors approved the consent for publishing the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thamapan, K., Laohakunjit, N., Kerdchoechuen, O. et al. Ultrasound-assisted extraction for simultaneous quantitation of potential sweetening compounds from Derris reticulata aqueous extracts: a response surface methodology approach. Food Measure 15, 2251–2263 (2021). https://doi.org/10.1007/s11694-020-00805-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00805-6