Abstract

The aim of this study was to evaluate the bioactive properties of propolis extract prepared using different solvents and different extraction methods. The extracts were analyzed by gas chromatography–mass spectrometry (GC–MS) and the differences between their antibacterial activities were evaluated by disc diffusion method. At the same time, bioactive properties of different concentrations of propolis extracts were investigated on human umbilical vein endothelial cells (HUVEC). The proliferative effects and cytotoxic effects of the extracts were determined by 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) and lactate dehydrogenase (LDH) analyzes, respectively. Total antioxidant capacity (TAC) and total oxidative status (TOS) parameters were used in assessing biochemical effects in the HUVEC cell line. The DNA damage was also analyzed by 8-oxo-2-deoxyguanosine (8-OHdG) level as indicators of genotoxicity. As a result of the MTT analysis conducted within the scope of the present study, the extracts tested were sorted as 95% ethanol extract of propolis (PEE95) > ultrasonic ethanol extract of propolis (PUEE) > 50% ethanol extract of propolis (PEE50) > ultrasonic water extract of propolis (PUWE) in terms of the effectiveness of their cell viabilities. It was observed that high concentrations of PEE95 induced LDH release. In addition to this, our findings have shown that PEE50, PUEE and PUWE increased oxidative stress at high concentrations. According to 8-OH-dG analysis, all tested extracts were found to be non-genotoxic. The results obtained from antibacterial activity and minimum inhibition concentration tests showed that PUEE and PEE95 had stronger antibacterial effects than PEE50 and PUWE. All these results indicated that propolis has beneficial effects for human health and therefore it is a valuable product which can be used as a food supplement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In Turkey, which has a rich flora, beekeeping is carried out since the ancient era, and moreover, as in the whole World, in recent years, bee products increasingly come to the fore in Turkey, because of the characteristic of being a more functional food type. As a result of beekeeping activities, many products such as honey, beeswax, royal jelly, pollen, bee venom, apilarnil, bee bread, and propolis are obtained [1].

Raw propolis is a chemically complex product that collected from the buds and exudates of the plants such as poplar, willow, pine, and alder. The chemical content of propolis and thus the bioactive component potential vary depending on the plant flora, collection time, and bee race in the area where it is collected [2]. This product, which is collected by bees and brought to the hive, is used in the hive for many operations such as protection, defense, and polishing the honeycomb sections [3]. It has also been widely used by humans in recent years, due to its bioactive properties, as processed a food supplements. The product obtained as a result of the processes to remove unwanted impurities in the raw propolis and to take the bioactive components into a solvent medium (ethanol, water, polyethylene glycol etc.) is called processed propolis [4, 5]. Since the raw propolis is a resinous substance, it is primarily converted to powder in the extraction step and then extracted in an alcoholic or aqueous medium. Because the substances in the chemical structure of propolis are mostly lipophilic, ethanol is widely used in the extraction process [6, 7]. In the case that methanol is used, flavonones and flavonols, which are among the most important bioactive components of propolis, are obtained in a higher yield, however, it is a disadvantage that methanol is a toxic solvent for human health [7, 8]. Similarly, in the case of the use of water as a solvent, the dissolution of only a small portion of the propolis components (10%) is also shown as another negative aspect [7, 9]. In the step of taking the bioactive components into the liquid medium, the extraction method is also a very important step. In this respect, in addition to traditional maceration, different methods such as ultrasonic assisted, soxhlet, supercritical fluid and microwave extraction have been used for extraction of propolis [10].

Processed propolis have many bioactive properties such as antibacterial [11, 12], antifungal [13, 14], anticancer [15, 16], antioxidant [17,18,19], and anti-inflammatory effects [20]. Therefore, in this study, differences in the chemical content and antimicrobial activity of propolis were evaluated using different solvents (ethanol and water) and extraction techniques (maceration and ultrasonic-assisted methods). At the same time, the proliferative (MTT assay), cytotoxic (LDH assay), antioxidant (TAC assay), and oxidant (TOS assay) effects of different propolis extracts on human umbilical vein endothelial cells (HUVECs) were investigated. Furthermore, the oxidative DNA damage levels of the extracts on HUVEC cells were investigated by evaluating levels of 8-hydroxy-2′-deoxyguanosine (8-OH-dG).

Materials and methods

Chemicals

Dulbecco's Modified Eagle Medium (DMEM), fetal bovine serum (FBS), penicillin/streptomycin (100 U penicillin/mL, 100 mg streptomycin/mL) and trypsin were obtained from Gibco, Invitrogen Inc., (Grand Island, New York, USA). In addition, l-glutamine (CAS No: 56-85-9) DMSO (dimethyl sulfoxide) and ethanol (≥ 99.5%) were obtained from Sigma-Aldrich (St. Louis, MO, USA).

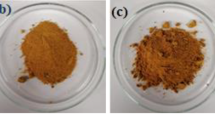

Propolis sample

Propolis sample (raw material) were obtained from Eastern Anatolia Region of Turkey in 2017. Propolis sample was pulverized using a mechanical grinder and stored in the fridge (− 18 °C) to until analyses.

Preparation of propolis extracts

Maceration method

Thirty grams of powdered raw propolis was macerated in 100 mL ethanol with two different concentrations (50 and 95%). Mixtures of these two different concentrations were kept in the incubator at 30 °C for 4 weeks in a tightly closed nontransparent bottle. After 4 weeks, the supernatants were filtered twice with Whatman No. 4 and No. 1 filter paper, respectively. They were transferred to 150 mL amber bottles and kept in the refrigerator (+ 4 C) until analysis [2]. These extracts were called as 50% ethanol extract of propolis (PEE50) and 95% ethanol extract of propolis (PEE95).

Ultrasonic-assisted extraction method

The process of extraction from raw propolis by ultrasound treatment was performed using a 25 kHz ultrasonic processor (model VCX 750; Sonics & Materials, Inc., Newtown, CT, USA). Thirty grams of propolis powder was dispersed with 100 mL of ethanol (%95) and distilled water. Sonication was carried out in a double-walled stainless steel chamber using a titanium probe with an emitting face 19 mm in diameter that was kept immersed 2 cm below the surface of the sample during sonication. The temperature was kept constant throughout sonication by circulating water through the jacket of the chamber. The samples were exposed to extract at 40% amplitude for 5 min at 30 °C. The extracts were cooled to room temperature and filtered through Whatman no 1 filter paper and 0.22 µm polypropylene filter, then transferred to amber bottles and stored at + 4 °C until analysis. These extracts were called as ethanol extract of propolis (PUEE) and water extract of propolis (PUWE) by ultrasonic-assisted extraction method.

Determination of the chemical profile of propolis extracts with GC–MS

1.5 mL propolis extracts (PEE50, PEE95, PEUE and PUWE) prepared as described under title “Preparation of propolis extracts” were transferred to a vial and evaporated to dryness. About 5 mg of the dry propolis was mixed with 75 µL of dry pyridine and 50 µL bis(trimethylsilyl)trifluoroacetamide (BSTFA) and heated at 80 °C for 20 min, and then, the final supernatant was analyzed by gas GC–MS. Samples were analyzed using a GC 6890N from Agilent (Palo Alto, CA, USA) coupled with mass detector (MS5973, Agilent) equipped with a DB-5 MS capillary column (30 m × 0.25 mm and 0.25 µm of film thickness). The column oven temperature was initially maintained at 50 °C for 1 min and then programmed to rise to 150 °C at 10 °C/min and maintained for 2 min. Finally, the temperature was increased to 280 °C at 20 °C/min and maintained at 280 °C for 30 min. Helium was used as the carrier gas at a flow rate of 0.7 mL/min [2].

Determination of antimicrobial activity of propolis extracts

Test microorganisms

In this study, five Gram-positive bacteria (Bacillus cereus BC 6830, Enterococcus faecalis NCTC 12697, Staphylococcus aureus NCTC 10788, S. aureus BC 7231, S. aureus ATCC 25923); five Gram-negative bacteria (Escherichia coli NCTC 9001, E. coli BC 1402, Pseudomonas aeruginosa NCTC 12924, Salmonella Typhimurium RSSK 95091, Yersinia enterocolitica ATCC 27729) were used for determination of antibacterial activity of propolis extracts. All microorganisms were provided from the Bayburt University, Vocational School of Health Services. Bacterial strains were cultured overnight at 37 oC in the trypticase soy broth (Oxoid). Suspensions were adjusted to 0.5 McFarland standard turbidity and used as inoculum for determination of antibacterial activity of propolis [21].

Screening for antimicrobial activity

The in vitro inhibitory activities of propolis extracts were investigated by the disc diffusion method using Mueller-Hinton Agar, (MHA, Oxoid). The inhibitory activities of the propolis extracts were detected as a clear zone around the discs. At this stage, all samples of extracted propolis were lyophilized and then ethanol/water-free propolis extracts were adjusted to 10 mg/mL concentration with 10% DMSO for disc diffusion assays. After these process, 20 µL propolis extracts were impregnated on antimicrobial susceptibility discs (Oxoid) and discs were left to dry for 2 h. Clear zones around the discs were measured after 24 h of incubation at 37 oC. The susceptibility of the microorganisms was also tested with commercial discs of ampicillin (10 µg-Oxoid) as a positive control and the 10% dimethylsulfoxide (DMSO) as a negative control. All tests were performed in duplicate [22].

Minimum inhibitory concentrations

Minimum inhibitory concentrations (MIC) values against selected pathogen bacteria have been determined by microbroth dilution method using 96-well microplates. At this stage, all samples of propolis extracts were lyophilized and then ethanol/water-free propolis extracts adjusted to 800 µg/mL concentration with 10% DMSO for determination of MIC values. Initially, all wells were filled with 95 µL Mueller Hinton Broth medium (MHB) and 5 µL inoculum. Then, 100 µL DMSO extracted propolis samples (800 µg/mL) was added to the first wells and were gently mixed at least three times with a multichannel micropipette. Afterwards, half of the liquid medium-extract mixtures (100 µL) in the first wells was transferred to the second wells and this process was repeated successively up to 8th well. Thus, the 400 µg/mL starting concentration of propolis samples in the first wells were diluted in half at each step. Immediately, after these procedures, the absorbance values of the suspensions in the wells were measured and recorded at 600 nm wavelength via microplate reader (Thermo, Multiskan Go). After these processes, the microplates were incubated at 37 °C for 24 h and the absorbance values were again measured and recorded at the end of the incubation period. After the 24 h incubation period, the first wells in which the absorbance values increased were considered as non-bactericidal or non-bacteriostatic concentrations. MIC was defined as the lowest concentration which provides complete inhibition on the microbial growth after incubation. All tests were performed in duplicates [23].

Determination of cytological, biochemical and genetic activity of propolis extracts

Cell culture

In this study, human umbilical cord vein endothelial cell line (HUVEC, PCS-100-013TM) was used. The HUVEC cell line was purchased from American Type Culture Collection (ATCC, USA). It was replicated from stocks available from the Cell Culture Laboratory at Atatürk University, Faculty of Medicine, Medical Pharmacology Department. The HUVEC cell line is grown in medium containing 89% DMEM, 10% FBS, 1% penicillin/streptomycin and 2% l-glutamine. When the cells in the culture dishes were 80% confluent, the cells were resected with the cell scraper. HUVEC cells were collected by centrifugation technique and cell solution was prepared at 1/1 with 0.1% trypan blue dye. 10 µL of this mixture was placed on a Cedex device (Roche®, Manheim, Germany) and cell count was performed. 5 × 104 HUVEC cells were cultured in each wells. Propolis extracts were prepared in different concentrations (12.5, 25, 50, 100 µg/mL). The concentrations were selected according to the work of Xuan et al. [24].

MTT cell proliferation assay

MTT (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) proliferation assay kit (Cayman Chemical Company® Ann Arbor, U.S.A.) was used for cell viability analysis. HUVEC cells were incubated at 37 °C in a humidified 5% CO2/95% air mixture and treated with propolis extracts at different concentrations for 24 h. Cell culture was terminated after 24 h. 10 µL MTT solution were added to each well. The plate was incubated for 4 h at 37 °C in a CO2-incubator. DMSO solution was added to each well, and the preparations were thoroughly mixed on a plate shaker with the cell containing formazan crystals. After the dissolution of all crystals using DMSO, the absorbance intensity of each sample was measured by using a ELISA reader (Bio-Tek®, USA) at 570 nm wavelength [25,26,27].

Lactate dehydrogenase (LDH) cytotoxicity assay

LDH assay kit (Cayman Chemical Company® Ann Arbor, U.S.A.) was used for LDH analysis. After 24 h, the cell culture was terminated and the plate was centrifuged at 400×g for 5 min. 100 µL culture medium from each well were added to a new plate. 100 µL of the reaction solution (9.6 mL of buffer, 100 × NAD+, 100 × lactic acid, 100 × INT) was added to each well. The prepared plate was shaken gently with the orbital shaker for 30 min. After 30 minutes, the plate was placed in the ELISA reader to read the absorbance at 490 nm [26].

Total antioxidant capacity (TAC)

In this analysis, TAC kits produced by Rel Assay Diagnostics® were used 500 µL of Reagent 1 solution was added to the wells containing 30 µL of sample. The first absorbance at 660 nm was read. Then, 75 µL of Reagent 2 was added to the same wells and kept at room temperature for 10 min. The second absorbance at 660 nm was read [28, 29]. To perform the calculation, the unit of TAC, mmol Trolox equivalent/L, and was calculated using the following formula;

Total oxidant status (TOS)

In this analysis, TOS kits produced by Rel Assay Diagnostics® were used. 500 µL of Reagent 1 solution was added to the wells containing 75 µL of sample. The first absorbance at 530 nm was read. Then, 25 µL of Reagent 2 was added to the same wells and kept at room temperature for 10 min. The second absorbance at 530 nm was read [27, 28]. To perform the calculation, the unit of TOS, mmol H2O2 Equiv./L, and was calculated using the following formula;

DNA/RNA oxidative damage assay

The purpose of this analysis was to determine the oxidative DNA damage in the cells by calculating the 8-OH-dG level. Therefore, DNA/RNA Oxidative Damage kit (Cayman Chemical Company, USA) kit (Cayman Chemical Company® Ann Arbor, U.S.A.) was used for oxidative DNA damage assay in the culture medium. Experimental stages were carried out considering the kit procedure [30].

Statistical analysis

Statistical analysis was performed using SPSS Software (version 18.0, SPSS®, 10 Chicago, IL, USA). One Way ANOVA test followed by appropriate post-hoc test (Duncan test) and values with p < 0.05 were considered as significantly different.

Results

Chemical analysis

GC–MS analysis was performed to observe changes in bioactive substance content of propolis, depending on solvent and method of extraction. The results of chemical analysis by GC–MS of propolis extracts are given in Table 1. Accordingly, in the propolis extracts, generally hydrocarbons, carboxylic acid and esters, cinnamic acid and esters, flavonoid and the compounds belonging to sesquiterpene groups were detected.

When the compound groups included in the propolis extracts were evaluated, it was determined that the other extracts except PUWE contained totally high levels of flavonoid group compounds. The flavonoid contents of PEE95, PEE50, PUEE and PUWE were determined as 15.01%, 17.63%, 49.39% and 1.83% respectively. Hydrocarbon group compounds were found in PUEE (1.61%) and PUWE (13.37%), while they were not detected in the other two (PEE95, PEE50) extracts. When the flavonoid compositions of the extracts were evaluated, it was observed that the chrysin, galangin, pinocembrin, pinostrobin chalcone, tectochrysin and 3-methylgalangin compounds belong to this group. From the flavonoid group; chrysin, galangin and pinocembrin were among the individual chemical compounds determined in the structure of PEE95; chrysin, galangin, pinocembrin and pinostrobin chalcone were among the individual chemical compounds determined in the structure of PEE50; chrysin, galangin, pinocembrin, pinostrobin chalcone, tectochrysin and 3-methylgalangin were among the individual chemical compounds determined in the structure of PUEE; and pinostrobin chalcone was among the individual chemical compounds determined in the structure of PUWE. Another group of compounds found in the structure of propolis is the carboxylic acid and its esters. The compounds belonging to this group were determined as 4-pentenoic acid, 5-phenyl- and benzoic acid (4.75% and 5.17%, respectively in total) in PEE95 and PEE50. Cinnamic acid and esters were found in the ratios of 23.52% (PEE95), 24.32% (PEE50) and 1.18% (PUEE) in other extracts except PUWE.

Antimicrobial activity tests

Results from antibacterial activity tests using disk diffusion method showed that PUEE and PEE95 had a satisfactory level of antibacterial effect, respectively. In addition, it was observed that the PEE50 had a very weak antibacterial effect against B. cereus BC 6830, E. faecalis NCTC 12697 and S. aureus NCTC 10788 strains. It was observed that the inhibition zones changed in 9–13 mm diameter and there was no antibacterial effect against other strains. Finally, in tests performed with PUWE, it was determined that PUWE had an inhibitory effect against only E. faecalis NCTC 12697 strain and there was no inhibitory effect against other strains (Table 2).

Microbroth dilution method was used to determine the minimum inhibition concentration (MIC) values (Table 2). The MIC values was defined as the lowest concentration which provides complete inhibition on the microbial growth after incubation. MICs were determined to be between 50 and 400 µg/mL against strains tested with PUEE but there was no inhibitory activity against E. coli NCTC 9001, E. coli BC1402 and P. aeruginosa NCTC 12924 among the Gram-negative strains. In the tests performed with PEE95, it was determined that MIC values ranged from 100 to 400 µg/mL, however, PEE95 did not show any inhibitory effect against E. coli NCTC 9001, E. coli BC1402, P. aeruginosa NCTC 12924 and Salmonella Typhimurium RSSK 95091 strains. In the applications performed with the PEE50, it was observed that MIC values were 400 µg/mL and the inhibitory effects were only against B. cereus BC 6830 and S. aureus NCTC 10788 strains. Finally, it was observed that the PUWE sample had an inhibitory effect against only E. faecalis NCTC 12697 strain and no inhibitory effect on other pathogens.

3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) assay

We investigated the effect of propolis extracts at various concentrations on the proliferation of the HUVEC cell line. According to the results of MTT analysis, PEE50 was reported to increase cell viability only at a concentration of 200 µg/mL (p < 0.01). 25 and 50 µg/mL concentrations of PEE95 increased cell viability compared to control value, and three other concentrations (12.5, 100 and 200 µg/mL) did not cause a statistically significant increase in cell viability (Fig. 1). 100 and 200 µg/mL concentrations of PUEE showed a statistically significant increase in cell proliferation. On the other hand, it was observed that PUWE applied to HUVEC cell culture did not show a statistically significant increase in cell proliferation for 24 h.

LDH assay

LDH release test was used to determine the cytotoxic effects of the propolis extracts dissolved in different solvents on HUVEC cells. LDH release of PEE95 was compared with the control value, 100 and 200 µg/mL concentrations were found to increase LDH release in a statistically significant amount. When LDH release in the other extracts was considered, it was observed that PEE50 and PUEE did not cause any changes in LDH release compared to the control value. However, it was observed that PUWE reduced LDH release at all concentrations (Fig. 2).

TAC assay

Propolis extracts were applied into cultures at concentrations of 12.5, 25, 50, 100 and 200 µg/mL for 24 h on HUVEC cells to determine the total antioxidant capacity measurements. It was observed that PEE95 and PEE50 did not cause any change in antioxidant capacity at low concentrations, but both extracts were found to reduce TAC levels at 100 and 200 µg/mL concentrations (Fig. 3). When PUEE's TAC values were considered, it was observed that only the lowest dose (12.5 µg/mL) increased the TAC level (Fig. 3). On the other hand, PUWE did not change the antioxidant capacity compared to the control value at all administered concentrations (p > 0.05).

TOS assay

TOS analysis was used to determine the total oxidant status of propolis extracts at different concentrations for 24 h on HUVEC cells. It was determined that all concentrations on the HUVEC cell line exposed to PEE95 did not increase the TOS levels compared to the control values (p > 0.05). On the contrary, high concentrations of PEE50, PUEE, and PUWE (100 and 200 µg/mL) caused oxidative stress (Fig. 4).

Oxidative DNA/RNA damage

8-OH-dG levels in cells were determined in order to find out the levels of oxidative DNA damage on HUVEC cells of different concentrations of extracts (12.5, 25, 50, 100, 200 µg/mL). When compared to the control group, 8-OH-dG levels caused by propolis extracts were found to be statistically insignificant (p > 0.05) compared to the 8-OH-dG level caused by the control group (Table 3).

Discussion

The chemical contents of propolis extracts prepared by different solvents and methods were determined by GC–MS in the first stage of this study. We detected pinostrobin chalcone compound from the flavonoid group at different rates in all extracts except PEE95. The highest percentage of flavonoid group compounds were determined in PUEE and the lowest rate was determined in PUWE. In addition, it was observed that PUWE contained a high proportion of hydrocarbon group compounds compared to ethyl alcohol extracts (PEE95, PEE50, and PUEE). According to the results, it was observed that there was an inverse ratio between the flavonoid group compounds and the hydrocarbon group. These results are similar to the results obtained by Ecem Bayram et al. [2] obtained for the propolis extracts in the Hakkari region. In recent years, studies conducted by independent research groups have shown that the chemical composition of the propolis samples is different [31,32,33]. Compounds such as flavonoids, phenolic compounds, essential oils, aromatic aldehydes, alcohols, and terpenes are among the compounds identified in the chemical structure of propolis extracts from different origins [34]. Silici [33] have stated in his research that phenolic compounds, alcohols, aldehydes, aliphatic and aromatic acids and esters, chalcones, terpenoids, steroids, sugars, and amino acids are within the chemical structure of propolis. As the result of the analysis using GC–MS on the propolis samples collected from different regions of Turkey, 8 of the identified 24 compounds for Ankara propolis, and 2 of the identified 18 compounds for Mugla propolis has been reported to be new compounds for propolis [35]. Extracts of propolis collected from different origins of Turkey were found to contain high concentrations of pinocembrin, pinostrobin, isalpine, pinobanksin, quercetin, naringenin, galangin, and chrysin flavonoids. Similarly, studies have shown that the extraction method is effective in revealing the chemical content of propolis. Da Silva Cunha et al. [36] reported that the extraction efficiency achieved in maceration was less than that of ultrasonic and microwave assisted methods. In our study, chemical analysis revealed that PUEE, which is found to contain high levels of flavonoid group compounds, which are closely associated with many activities of propolis [2], has a high biological activity, and the biological activity of PUWE is the lowest.

The antibacterial activity of propolis extracts was tested in the second stage of our study. Results from antibacterial tests have shown that propolis samples exhibit a stronger antibacterial effect, especially against gram-positive strains, and this effect is weaker against gram-negative bacteria. The results obtained are consistent with the results in the literature [21, 37, 38]. The results obtained in the studies show that propolis exhibits irregular diffusion properties [39]. The study by Stepanović et al. [40] also confirms these results. The results of the antibacterial activity and the minimum inhibition concentration tests showed that PUEE and PEE95 had a stronger antibacterial effect than PUWE and PEE50.

In this study, endothelial cell culture obtained from human umbilical cord vein involved in many vascular biological events such as vasoconstriction, coagulation and inflammation, covering the inner surface of the blood vessels and forming a distinctive surface between the blood vessels and the blood was used [41]. According to MTT analysis results; 25 and 50 µg/mL concentrations of PEE95 increased cell viability in the HUVEC cell line, while only 200 µg/mL concentration of PEE50 increased cell viability. On the other hand, PEE50 and PUEE only increased cell viability in high concentrations. Besides, PUWE did not cause proliferation in any of the concentrations used. As a result of biochemical researches (MTT analyzes) conducted in the present study, the tested extracts were listed as PEE95 > PUEE > PEE50 > PUWE in terms of cell viability effectiveness. In contrast to our study, Xuan et al. [24] investigated the effects of ethanol extract of Brazilian propolis on HUVEC cell line. As a result of their studies, they reported that Brazilian propolis may be an apoptosis-inducing agent at high concentrations and therefore should be used at safer levels for human health. Similarly, it was reported that 3 µg/mL concentration of Chinese red propolis extract dissolved in ethanol suppress vascular endothelial growth factor-induced proliferation on HUVEC cells [42]. In addition to this, caffeic acid phenethyl ester, is one of the active ingredients of propolis, has been shown to reduce the proliferation as dose-dependent manner on the HUVEC cell line [43]. Chikaraishi et al. [44] investigated the anti-angiogenic effects of the Brazilian green propolis and its active ingredient caffeoylquinic acid on the HUVEC cell line, resulting in angiogenic effects of propolis extract in both in vivo and in vitro analyses.

LDH released into the environment provides an index of cell death and membrane permeability, as well as the increase in LDH activity in the environment, as a result of cell membrane breakdown and enzyme leakage [45]. According to our LDH test results, 100 and 200 µg/mL concentrations of PEE95 increased the LDH levels, while PEE50 and PUEE extracts did not cause any changes in LDH levels. The PUWE reduced the LDH level at all concentrations used. These contrasts indicate that the biochemical activity of propolis may vary depending on the conditions (in vivo or in vitro) of the medium and the derivative spectrum of the compound.

The antioxidative effect of propolis has a great importance for the living organsims. Flavonoids and terpenes, which are of great importance in its structure, are very strong and are compounds that show antioxidant activity [3]. There are many studies reporting that the antioxidant activity of propolis is related to flavonoids in its chemical structure [46,47,48]. In our study, antioxidant capacity and oxidant status of propolis extracts were investigated by using TAC and TOS parameters, respectively. When the antioxidant capacity of the extracts was evaluated, it was observed that only 12.5 µg/mL concentration of PUEE increased the antioxidant capacity compared to the control group and the other extracts did not increase the antioxidant capacity. However, high concentrations of PEE95 and PEE50 (100 and 200 µg/mL) were found to decrease TAC levels.

The results support that the flavonoid content of PUEE is rich in other extracts, which indicates that such groups are responsible for the many biological activities of propolis. When we evaluated the TOD parameters, no concentration of PEE95 changed the TOS level, however, it was found that high concentrations of PEE50, PUEE, and PUWE increased the TOD levels. In parallel with the results of our study, Türkez et al. [19] found that 25, 50 and 100 µg/mL concentrations of propolis significantly increased the TAC level due to dose in hepatocyte cell culture, while cell viability and TOS levels were not affected. Malaysia propolis has been found to have antioxidant effect in streptozotocin-induced diabetic rats [49]. Propolis has been reported to significantly increase antioxidant capacity in skin fibroblast cell culture [50]. Shibata et al. [51] found that propolis reduces the reactive oxygen species formed in high glucose-induced rat lenses.

The higher amounts of the 8-OH-dG base level released in the cells allowed us to be informed about the way the cells were damaged. When all propolis extracts produced oxidative DNA damage in the HUVEC cell line, it was determined that there was no difference between the control group and all the concentrations applied in terms of 8-OH-dG levels (p > 0.05). Likewise, Uğur Aydin et al. [52] demonstrated that propolis did not cause any increase in 8-OH-dG level in human fibroblast cell culture when compared with the control group.

Conclusions

Ethanol extract prepared using ultrasound-assisted extraction method (PUEE) was found to contain a higher percentage of flavonoid than other extracts. However, in the method where water was used as the solvent despite the use of an ultrasonic supported method, it was observed that flavonoids were extracted at a very low rate. In addition to, toxicological properties of propolis extracts were investigated in dose dependent manner on HUVEC cell line. In specific doses, these propolis extracts didn’t show any toxic potential in the aspects of oxidative stress and mutagenic properties. On the other hand, cytotoxicity of the extracts was found strongly dependent with concentration. These results indicate that not only the extraction method but also the solvent type plays an important role during the processing of propolis. Because of the complex nature of natural products such as propolis, prior to human consumption, appropriate extraction methods and extraction solvents are required to be used to best elucidate its bioactive components. In order to make optimization in this regard, our detailed researches are continuing.

References

S.K.M. Ram, N. Jayapal, P. Nanaiah, G.S. Aswal, B.K. Ramnarayan, S.M. Taher, The therapeutic benefits of bee venom. Int. J. Curr. Microbiol. Appl. Sci. 3, 377–381 (2014)

N. Ecem Bayram, K. Sorkun, G.C. Öz, B. Salih, G. Topçu, Chemical characterization of 64 propolis samples from Hakkari, Turkey. Rec. Nat. Prod. 12(6), 569 (2018)

U. Kumova, A. Korkmaz, B.C. Avcı, G. Ceyran (2002) An important bee product: propolis. Uludağ Bee J. 2, 10–24

L. Kubiliene, V. Laugaliene, A. Pavilonis, A. Maruska, D. Majiene, K. Barcauskaite, R. Kubilius, G. Kasparaviciene, A. Savickas, Alternative preparation of propolis extracts: comparison of their composition and biological activities. BMC Complement Altern. Med. 15(1), 156 (2015)

T. Tomazevic, J. Jazbec, A double blind randomised placebo controlled study of propolis (bee glue) effectiveness in the treatment of severe oral mucositis in chemotherapy treated children. Complement Ther. Med. 21, 306–312 (2013)

B.A. Rocha, M.R. Rodrigues, P.C.P. Bueno, A.R. de Mello Costa-Machado, M.M.D.O.L. Leite, A.P. Nascimento, H.S. Barud, A.A. Berretta-Silva, Preparation and thermal characterization of inclusion complex of Brazilian green propolis and hydroxypropyl-β-cyclodextrin. J. Therm. Anal. Calorim. 108(1), 87–94 (2012)

M. Jug, M.Z. Končić, I. Kosalec, Modulation of antioxidant, chelating and antimicrobial activity of poplar chemo-type propolis by extraction procures. LWT-Food Sci. Technol. 57(2), 530–537 (2014)

M.G. Miguel, S. Nunes, S.A. Dandlen, A.M. Cavaco, M.D. Antunes, Phenols and antioxidant activity of hydro-alcoholic extracts of propolis from Algarve, South of Portugal. Food Chem. Toxicol. 48(12), 3418–3423 (2010)

J.M. Sforcin, V. Bankova, Propolis: is there a potential for the development of new drugs? J. Ethnopharmacol. 133(2), 253–260 (2011)

I.D.S. Cunha, A.C.H.F. Sawaya, F.M. Caetano, M.T. Shımızu, M.C. Marcucci, F.T. Drezza, G.S. Povıa, Carvalho PO factors that influence the yield and composition of Brazilian propolis. J. Braz. Chem. Soc. 15(6), 964–970 (2004)

J.B. Seibert, J.P. Bautista-Silva, T.R. Amparo, A. Petit, P. Pervier, J.C. Dos Santos Almeida, M.C. Azevedo, B.M. Silveira, G.C. Brandão, G.H.B. de Souza, L.F. de Medeiros Teixeira, O.D.H. Dos Santos, Development of propolis nanoemulsion with antioxidant and antimicrobial activity for use as a potential natural preservative. Food Chem. 30, 61–67 (2019)

S. El-Guendouz, S. Aazza, B. Lyoussi, V. Bankova, M. Popova, L. Neto, M.L. Faleiro, M.D.G. Miguel, Moroccan propolis: a natural antioxidant, antibacterial, and antibiofilm against Staphylococcus aureus with no ınduction of resistance after continuous exposure. Evid. Based Complement Altern. Med. 12, 1–19 (2018)

L. de Francisco, D. Pinto, H. Rosseto, L. Toledo, R. Santos, F. Tobaldini-Valerio, T. Svidzinskic, M. Bruschi, B. Sarmento, M.B.P.P. Oliveira, F. Rodrigues, Evaluation of radical scavenging activity, intestinal cell viability and antifungal activity of Brazilian propolis by-product. Food Res. Int. 105, 537–547 (2018)

F. Mutlu Sariguzel, E. Berk, A.N. Koc, H. Sav, G. Demir, Antifungal activity of propolis against yeasts ısolated from blood culture: in vitro evaluation. J. Clin. Lab. Anal. 30(5), 513–516 (2016)

H. Rouibah, W. Kebsa, M. Lahouel, M. Zihlif, M. Ahram, B. Aburmeleih, E. Mustafa, H. El-Amir, Algerian propolis potentiates doxorubicin mediated anticancer effect against human pancreatic PANC-1 cancer cell line through cell cycle arrest, apoptosis ınduction and p-glycoprotein ınhibition. Anticancer Agents Med. Chem. 18(3), 375–387 (2018)

F. Narter, A. Diren, A. Kafkasli, A. Eronat, M. Seyhan, H. Yilmaz-Aydogan, S. Sarikaya, S.D. Hatpoğlu, K. Sarica, O. Öztürk, Anatolian propolis prevents oxalate kidney stones: dramatic reduction of crystal deposition in ethylene-glycol-induced rat model. Rec. Nat. Prod. 12, 445–459 (2018)

A. Zam, M. Othman, Antioxidant activity and other physicochemical characteristics of different propolis extracts. J. Pharm. Nutr. Sci. 8(2), 59–67 (2018)

C. da Silva, A. Prasniewski, M.A. Calegari, V.A. de Lima, T.L. Oldoni, Determination of total phenolic compounds and antioxidant activity of ethanolic extracts of propolis using ATR–FT-IR spectroscopy and chemometrics. Food Anal. Methods 11(7), 2013–2021 (2018)

H. Türkez, M.I. Yousef, F. Geyikoglu, Propolis protects against 2,3,7,8-tetrachlorodibenzo-p-dioxin-induced toxicity in rat hepatocytes. Food Chem. Toxicol. 50(6), 2142–2148 (2012)

V.U. Nna, A.B.A. Bakar, M.R.M.L. Lazin, M. Mohamed, Antioxidant, anti-inflammatory and synergistic anti-hyperglycemic effects of Malaysian propolis and metformin in streptozotocin–induced diabetic rats. Food Chem. Toxicol. 120, 305–320 (2018)

J.M. Sforcin, J.R. Fernandes, C.A.M. Lopes, V. Bankova, S.R.C. Funari, Seasonal effect on Brazilian propolis antibacterial activity. J. Ethnopharmacol. 73(1–2), 243–249 (2000)

S. Silici, S. Kutluca, Chemical composition and antibacterial activity of propolis collected by three different races of honeybees in the same region. J. Ethnopharmacol. 99(1), 69–73 (2005)

A. Adıgüzel, Ö. Hakan, S. Münevver, G. Medine, S. Atalay, K. Hamdullah, F. Şahin, Ö. Barış, Antimicrobial and antioxidant activity of the essential oil and methanol extract of Nepeta cataria. Pol. J. Microbiol. 58(1), 69–76 (2009)

H. Xuan, J. Zhao, J. Miao, Y. Li, Y. Chu, F. Hu, Effect of Brazilian propolis on human umbilical vein endothelial cell apoptosis. Food Chem. Toxicol. 49(1), 78–85 (2011)

M.V. Berridge, P.M. Herst, Tan, AS Tetrazolium dyes as tools in cell biology: new ınsights into their cellular reduction. Biotechnol. Annu. Rev. 11, 127–152 (2005)

B. Emsen, A. Aslan, B. Togar, H. Turkez, In vitro antitumor activities of the lichen compounds olivetoric, physodic and psoromic acid in rat neuron and glioblastoma cells. Pharm. Biol. 54(9), 1748–1762 (2016)

B. Emsen, H. Turkez, B. Togar, A. Aslan, Evaluation of antioxidant and cytotoxic effects of olivetoric and physodic acid in cultured human amnion fibroblasts. Hum. Exp. Toxicol. 36(4), 376–385 (2017)

O. Erel, A novel automated direct measurement method for total antioxidant capacity using a new generation, more stable ABTS radical cation. Clin. Biochem. 37, 277–285 (2004)

E. Sonmez, I. Cacciatore, F. Bakan, H. Turkez, Y.I. Mohtar, B. Togar, A.D. Stefano, Toxicity assessment of hydroxyapatite nanoparticles in rat liver cell model in vitro. Hum. Exp. Toxicol. 35(10), 1073–1083 (2016)

B. Emsen, A. Aslan, H. Turkez, A. Joughi, A. Kaya, The anti-cancer efficacies of diffractaic, lobaric, and usnic acid: In vitro inhibition of glioma. J. Cancer Res. Ther. 14(5), 941–951 (2018)

S. Bayram, N.E. Bayram, Y.C. Gerçek, G.C. Öz, K. Sorkun, Anticytotoxic and antimutagenic effects of propolis on human lymphocytes in vitro. Mellifera 16(2), 38–46 (2016)

A. Bouaroura, N. Segueni, J.G. Diaz, C. Bensouici, S. Akkal, S. Rhouati, Preliminary analysis of the chemical composition, antioxidant and anticholinesterase activities of Algerian propolis. Nat. Prod. Res. 12, 1–5 (2019)

Z. Ahangari, M. Naseri, F. Vatandoost, Propolis: chemical composition and its applications in endodontics. Iran. Endod. J. 13(3), 285–292 (2018)

V.S. Bankova, S.S. Popov, N.L. Marekov, A study on flavonoids of propolis. J. Nat. Prod. 46(4), 471–474 (1983)

M. Kartal, S. Kaya, S. Kurucu, GC-MS analysis of propolis samples from two different regions of Turkey. Zeitschrift für Naturforschung C 57(9–10), 905–909 (2002)

I.B. Cunha, M.L.T. Rodrigues, E.C. Meurer, V.S. Bankova, M.C. Marcucci, M. Eberlin, A.C.H. Frankland Sawaya, Effect of the maceration time on chemical composition of extracts of Brazilian propolis. J. Apic. Res. 45(3), 137–144 (2006)

O.K. Mirzoeva, R.N. Grishanin, P.C. Calder, Antimicrobial action of propolis and some of its components: the effects on growth, membrane potential and motility of bacteria. Microbiol. Res. 152, 239–246 (1997)

L. Drago, B. Mombelli, E. De Vecchi, M.C. Fassina, L. Tocalli, M.R. Gismondo, In vitro antimicrobial activity of propolis dry extract. J. Chemother. 12, 390–395 (2000)

K. Bosio, C. Avanzini, A. D'avolio, O. Ozino, D. Savoia, In vitro activity of propolis against Streptococcus pyogenes. Lett. Appl. Microbiol. 31(2), 174–177 (2000)

S. Stepanović, N. Antić, I. Dakić, M. Švabić-Vlahović, In vitro antimicrobial activity of propolis and synergism between propolis and antimicrobial drugs. Microbiol. Res. 158(4), 353–357 (2003)

Y. Yazır, H. Dalçık, An ımportant method in the ınvestigation of vascular pathologies: endothelial cell culture. Heart J. Kosuyolu 15(3), 137–142 (2012)

H. Izuta, M. Shimazawa, K. Tsuruma, Y. Araki, S. Mishima, H. Hara, Bee products prevent VEGF-induced angiogenesis in human umbilical vein endothelial cell. BMC Complement Altern. Med. 17, 9–45 (2009)

M. Burgazli, N. Aydogdu, A. Rafiq, M. Mericliler, R. Chasan, A. Erdogan, Effects of caffeic acid phenethyl ester (CAPE) on membrane potential and intracellular calcium in human endothelial cells. Eur. Rev. Med. Pharmacol. Sci. 17(6), 720–728 (2013)

Y. Chikaraishi, H. Izuta, M. Shimazawa, S. Mishima, H. Hara, Angiostatic effects of Brazilian green propolis and its chemical constituents. Mol. Nutr. Food Res. 54(4), 566–575 (2010)

K. Yokogawa, M. Yokogawa, H. Watanabe, M. Takeshita, Y. Nomura, K. Mano, Serum aminotransferase activity as apredictor of clearance of drugs metabolized by CYP isoforms in rats with acute hepatic failure induced by carbon tetrachloride. Int. J. Pharm. 269, 479–489 (2004)

M.I. Isla, M.N. Moreno, A.R. Sampietro, M.A. Vattuone, Antioxidant activity of Argentine propolis extracts. J. Ethnopharmacol. 76(2), 165–170 (2001)

J.K.S. Andrade, M. Denadai, C.S. de Oliveira, M.L. Nunes, N. Narain, Evaluation of bioactive compounds potential and antioxidant activity of brown, green and red propolis from Brazilian northeast region. Food Res. Int. 101(2017), 129–138 (2017)

A.S.A. Newairy, A.F. Salama, H.M. Hussien, M.I. Yousef, Propolis alleviates aluminium-induced lipid peroxidation and biochemical parameters in male rats. Food Chem. Toxicol. 47(6), 1093–1098 (2009)

V.U. Nna, A.B. Abu Bakar, M.R.M.L. Md Lazin, M. Mohamed, Antioxidant, anti-inflammatory and synergistic anti-hyperglycemic effects of Malaysian propolis and metformin in streptozotocin-induced diabetic rats. Food Chem. Toxicol. 120, 305–320 (2018)

M. Tyszka-Czochara, P. Paśko, W. Reczyński, M. Szlósarczyk, B. Bystrowska, W. Opoka, Zinc and propolis reduces cytotoxicity and proliferation in skin fibroblast cell culture: total polyphenol content and antioxidant capacity of propolis. Biol. Trace Elem. Res. 160(1), 123–131 (2014)

T. Shibata, S. Shibata, N. Shibata, E. Kiyokawa, H. Sasaki, D.P. Singh, E. Kubo, Propolis, a constituent of honey, ınhibits the development of sugar cataracts and high-glucose-ınduced reactive oxygen species in rat lenses. J. Ophthalmol. 2016, 1–6 (2016)

Z. Uğur Aydin, K.E. Akpinar, C. Hepokur, D. Erdönmez, Assessment of toxicity and oxidative DNA damage of sodium hypochlorite, chitosan and propolis on fibroblast cells. Braz. Oral Res. 29, 1–8 (2018)

Funding

This research was supported by Bayburt University, Scientific Research Projects Commission with Project Number 2017/02-69001-18

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest are declared related to the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ecem Bayram, N., Gerçek, Y.C., Bayram, S. et al. Effects of processing methods and extraction solvents on the chemical content and bioactive properties of propolis. Food Measure 14, 905–916 (2020). https://doi.org/10.1007/s11694-019-00340-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00340-z