Abstract

As Egypt is the largest wheat importer globally, the government is aiming to find alternatives to reduce wheat imports and to cultivate reclaimed lands. Comparative studies were conducted to investigate the effect of substituting portions of wheat flour with quinoa, cassava and guar flours at levels of 20%, 30%, and 5%, respectively, on chemical, rheological and sensory characteristics of the Egyptian balady bread that is currently produced from wheat only and to enhance its nutritional and baking quality. The study was carried out in the Agricultural Research Center, Egypt. Results proved that guar gave poor sensory characteristics, in addition to its insignificant substitution level (5%). Substituting wheat flour with 20% quinoa resulted in elevating protein, fat and fiber percentages than that of wheat flour (16.4, 2.15 and 1.01%, respectively). Bread made from quinoa–wheat blend gave the lowest fungal count and the highest shelf life (8 days), but resulted in significant changes in stability, volumes, texture, and structure. Substituting wheat with 30% cassava gave the highest carbohydrate content, didn’t change any of the rheological properties and no significant difference was noticed between wheat flour and 30% cassava–wheat bread in all sensory tests. Substituting wheat with quinoa or cassava at the above-mentioned percentages is acceptable and appropriate in terms of their flavor. Although cassava has higher substitution level than that of quinoa, still, we recommend expanding quinoa cultivation in Egypt due to its acceptability, suitability to the Egyptian environment, health benefits, low input cost and more importantly its high protein and fiber contents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bread is one of the most important staple foods consumed all over the world, Bread wheat is an Egyptian product that represents the main source of carbohydrate and the main diet component for rich and poor Egyptian consumers [1]. Litwinek et al. [2] stated that the total production of wheat grains covers only about 50% of the total Egyptian needs; therefore, the total yield does not satisfy the requirements of the country. For centuries, wheat has been the central component of the typical diet of the country’s inhabitants, so per capita consumption of this cereal is amongst the highest in the world as stated by FAO [3], Egypt is not only the largest importer of wheat but also the largest wheat consumer and bread eater per capita in the world because the heavy dependency on wheat, according to a report issued by the CAPMAS [4] for consumption in 2015, the average consumption per capita of wheat reached 141.1 kg in 2015 versus 133.6 kg in 2014.Therefore, searching for other cereal sources, which could be integrated in making wheat flour bread is needed to overcome the wheat gap and satisfy consumers’ needs [2]. In addition, this would reduce the dependency on wheat imports and increase livelihoods of local farmers who produce crops that may be applied in flour composites [5].

Quinoa seeds; (Chenopodium quinoa, Willd, family: Chenopodiaceae), are disintegrated to a whole flour meal with a high content of protein, minerals, and polyphenols [6]. Protein content is higher in quinoa than that of wheat and corn, ranging from 12 to 18%. It contains a balanced set of essential amino acids and is considered as a good source of dietary fiber and phosphorus. In addition, quinoa has high magnesium and iron contents as well as vitamins such as E and those of the group B. Quinoa is also gluten-free and is easy to digest, especially for those who are allergic to wheat gluten [7]. Quinoa has been cultivated in Egypt since 2005, first in the south of Sinai to test its resilience to harsh conditions. Soon after, it was introduced in Upper Egypt by local community leaders as a less expensive means to provide schoolchildren with nutritious meals, The government strategy is calling on Egyptians to gradually start including the grain in one form or another in their diets, perhaps most notably, by encouraging the substitution of 10–20% of the wheat flour used in bread with quinoa flour to raise the nutritional value of the loaf [8]. Quinoa can be eaten as a breakfast food, it can be used to make flour for baking, for soup, and varieties of dishes, it can be cooked like rice, used as a nutritional thickener for soups, in salads and desserts [9].

Cassava plant (Manihot esculenta Crantz) is another complementary crop. It is one of the essential crops in Africa and is considered as a major root crop that provides an important staple food for over 500 million people in the developing world [10]. High-quality cassava flour has been identified as a local alternative to substitute portions of wheat flour into composite flour. Cassava is known to be cheap, widely grown, readily available and is a reliable source for carbohydrate as it is rich in starch [11]. An estimated 40% of Africans rely on the crop as a significant source of calories [12]. Cassava is considered as a new non-traditional vegetable crop in Egypt. Introduction and cultivation of cassava in newly reclaimed lands showed great success [13]. In addition, Amr Shams [14] stated that cultivation of cassava in traditional agriculture is carried out with no applied fertilizers mainly in North Sinai and North West Coast.

On the other hand, guar cluster bean, Cyamopsis tetragonoloba (L.) is one of the hardiest legume vegetables. Guar seed is a major source of gum having several industrial applications. Gaur gum is rich in protein (38–55%) as stated by Kumar et al. [15]. It bears also a good proportion of fibers and has proved to hold other health benefits as well. This plant proved to be drought tolerant and grown in the arid and semi-arid land, cultivated successfully under the Egyptian environmental conditions, especially in Sinai as stated by Khater and Rania [16].

Accordingly, the present study aimed to examine the effect of substituting portions of wheat flour with a blend of flour of cassava, quinoa and guar at different levels (30, 20 and 5%, respectively), and also to study their influence on the chemical and rheological properties of the produced flour and on the sensory characteristics of the produced wheat bread as well. The study also investigated the shelf life and microbial load of each type of bread. Optimistically, this study could contribute to reducing the amount of wheat used in making wheat bread in the country, in addition to enhancing its nutritional and healthy value and persistence.

Materials and methods

The current study was carried out during the period of 2016–2017 in the laboratories of the Regional Center for Food and Feed (RCFF), ARC, to determine the effect of substituting portions of pure wheat flour with different alternatives, e.g. flour of quinoa, cassava and guar in order to enhance wheat bread nutritional value and decrease the amount of wheat used in preparing this type of bread.

Source of the crops used

Wheat flour 72% extraction rate, obtained from a local market in Giza, was used as a control during the whole study. In addition, commercial samples of quinoa seeds and cassava roots, taken from the Field Crops Research Institute, and guar seeds, taken from the Horticultural Research Institute, were substituted at different levels (both Institutes are affiliated to ARC, Ministry of Agriculture and Land Reclamation, Egypt).

Preparation of the alternative flours

Preparation of quinoa and guar flour

Quinoa seeds were cleaned to remove foreign materials, and then were thoroughly washed with tap water for 20 min. until no more foam was found in the washing water, in order to eliminate their bitter taste and toxic saponins. Washed seeds were dried at 45 °C for 12 h. Dried seeds were then packed in polyethylene bags and stored till used [17]. On the other hand, guar seeds were cleaned to remove broken ones as well as foreign materials. Both quinoa and guar seeds, were then grinded separately in a mill (Model 3100). The process was carried out in the Wheat and Flour Laboratory, (ARC).

Preparation of cassava flour

The preparation of cassava flour was carried out in the Wheat and Flour Laboratory (ARC). The fresh roots of cassava were washed, peeled, rewashed again, then roots are chopped into small pieces, about 5 × 0.5 × 0.2 cm, and sun-dried for 3 days. The moisture content of the cassava chips should reach less than 8% according to the FFTC [18]. The chips were then milled into flour by using an attrition milling machine, then sieved through a 200-microsieve. Finally, the flour is packaged in plastic bags.

The study tests

Determination of substitution percentages

Seeds of quinoa and guar and roots of cassava were treated - as previously mentioned, milled and incorporated at various levels to wheat flour to determine the most suitable substitution levels depending on the chemical and rheological analysis. In case of cassava four percentages were tested, i.e. 15, 30, 35 and 40%. Meanwhile, tested percentages of quinoa were; 10, 15, 20, and 25%. In addition, guar tested percentages were 5, 10 and 15%. The best percentages were identified according to the level of gluten existence.

The chemical analyses

-

Moisture, ash, fiber, fat and protein (dry base) of flour were determined according to the AACC [19]. The total carbohydrate content was calculated according to Ihekoronye and Ngoddy [20] by using the equation:

Total carbohydrate = 100 − (moisture + crude protein + crude fat + crude fiber + ash).

-

Falling number:

Falling number analysis is an indicator of kernel germination (sprouting) and the resulting increases in alpha amylase activity. The falling Number was determined according to AACC method No. 56-81B [21] by using a Perten equipment (Falling Number, model 1500), where it was measured by the time the plunger takes to fall through a measured amount of flour slurry suspension heated at 100 °C in water bath. Falling number results are recorded as an index of enzyme activity in the wheat flour sample and the results were expressed in seconds.

-

Sedimentation of protein:

The test concerning the sedimentation of protein was conducted according to the No. 56-60, AACC [21]. The sedimentation test was conducted by holding the wheat or flour sample in an acid solution. The sedimentation value of wheat flours is based on the fact that the gluten protein absorbs water and considerably swells when treated with lactic acid. The sedimentation test provides information on the protein quantity and the quality of flour samples.

Rheological analysis (physical dough test)

Gluten

Gluten was obtained from flour through using the gluten washing apparatus depending on the Gloutomatic Unit. Both Gluten Index Content (GI) and Dry Gluten Content (DG) were determined in wet gluten. All tests were conducted according to 38-12, AACC [21]. Wet gluten content was determined by washing the flour sample with a salt solution to remove the starch and other soluble materials from the sample. The residues remained after washing are the wet gluten. During centrifugation, the gluten was forced through a sieve and the percentage of gluten remained on the sieve was defined as the Gluten Index, which will be the indication of gluten strength.

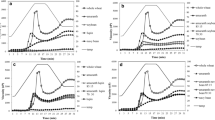

Alveographe test

Alveographe test is carried out as an indicator of dough gluten strength through measuring the force required to blow and break a bubble of dough according to AACC [21]. By using Chopin equipment (Alveoconsistographe) where the results were measured by electronic measure. Alveoconsistographe apparatus was used to measure the resistance of dough to extension and the extent to which it could be starched under the experimental conditions of 20 °C and 80% relative humidity. Various measurements were made, i.e. tenacity (P) indicating dough resistance to deformation, extensibility (L) representing the length of the curve (the average of the abscissas at the rupture of the curves length), (G) which represents the average of the swelling index on the calculation chart and corresponds with the rupture abscises “L”. In addition, baking strength of flour (W), surface area of the curve, (i.e. deformation action of dough) was also studied, (P/L) ratio which represents the balance between dough strength and extensibility.

Best levels of fortified flour with natural material were determined and compared to wheat flour (control) to forward appropriate manufacturing process. According to the tests, the best levels of natural sources supplementation were selected for producing wheat bread were; 30% cassava, 20% quinoa and 5% guar flour where their properties were the highest in the rheological analyses especially wet gluten (WG) that indicates flour plasticity properties and reproduced the tensions the gluten net supports during fermentation and cooking, and also dough strength (w) which indicates dough behavior during baking process. Therefore, these ratios (30% cassava, 20% quinoa and 5% guar) were chosen to be the basis for the current study.

Balady bread making

Preparation of the bread

Egyptian balady flat bread was prepared according to the common method described in the manual of Wheat and Flour Testing Methods [22]. About 100 g of wheat flour (extraction 72%), 1.5 g compressed yeast, 1.0 g salt, in addition to 65–70 g water, enough to make sticky dough of 14% moisture basis, were used. Flour was added to the yeast suspension and the salty solution, mixed to the optimum dough development stage and then placed in a fermentation cabinet at 28 °C and 85% relative humidity for about 40 to 50 min. After removal from the fermentation cabinet, the dough was divided into equal pieces and formed into balls by hand. Pieces were left to rest for 10–20 min and then dusted with flour and compressed by hand. The dough pieces were returned to the fermentation cabinet and proofed for 30–45 min. Finally, dough pieces were baked in an oven on 450–500 °C for 1 to 2 min.

-

Types of the prepared balady bread:

Four types of balady bread were prepared to be used in the study tests depending on the results of the determination of substitution levels, mentioned above:

-

1.

Wheat flour bread (control): prepared from 100% wheat flour (extraction 72%).

-

2.

Wheat/cassava bread: prepared from 70% wheat flour (extraction 72%) + 30% cassava flour.

-

3.

Wheat/quinoa bread: prepared from 80% wheat flour (extraction 72%) + 20% quinoa seeds flour.

-

4.

Wheat/guar bread: was prepared from 95% wheat flour (extraction 72%) + 5% guar seeds flour.

Sensory characteristics

The loaves of bread were allowed to cool down on racks for about 1 h after baking. The following tests were carried out:

Sensory evaluation of bread samples

According to See et al. [23], loaves were cooled down for another 1–2 h at room temperature (25 °C) in a sealed plastic bag before evaluation. The bread was then cut into small slices using a bread knife. Sensory evaluation was performed using 15 panelists. Samples were randomly assigned to each panelist. The panelists were asked to evaluate each loaf for its color, odor, roundness, separation of layers, crumb distribution, taste after swallowing and overall acceptability. (10) Point hedonic scale was used where 1 = extremely dislike and 10 = extremely like, expect for both taste and general appearance the scale was from (20) points.

Loaf volume

The loaf volume was determined by using rape seed displacement method 10-05.01, AACC [21]. This was carried out by loading millet grains into an empty box with calibrated mark until it reached the marked level and unloaded back. The bread sample was put into the box and the measured millet was loaded back again. The remaining millet grains left outside the box was measured using measuring cylinder and recorded as loaf volume in cm3.

The specific volume (volume to mass ratio) (cm3/g) was, thereafter calculated according to the following equation:

Determination of microbial load

The microbial load was determined by counting the total fungi and total bacteria i.e. total coli form and fecal coliform counts, in order to inspect the bread shelf-life. The process was carried out as follows:

Fungi isolation and identification

Bread samples were stored at room temperature to determine shelf life of bread remains. Bread was cut into small pieces carefully and aseptically transferred to ready plates of potato dextrose agar (PDA) medium. Plates were then incubated at 25 °C and observations were daily recorded up to the day 7. The emerged fungi were counted, and then purified using the single spore technique. Fungal and hypha type isolation and identification were carried out according to Eissa et al. [24] and the hypha tip techniques were implemented as stated by Bassuony et al. [25]. Tests were carried out in the Regional Center for Food and Feed RCFF and confirmed by the Plant Pathology Department (ARC).

Total fungi and yeast count

Ten grams were taken from each sample and added to 90 ml portion of sterile saline solution (0.85% NaCl) in an Erlenmeyers flask of 500 ml and homogenized thoroughly by an electric shaker at a constant speed for 15 min. Tenfold serial dilutions were then prepared. One ml portion of the suitable dilutions was used to inoculate Petri dishes containing 15 ml Rose Bengal Agar fortified by 0.5 mg chloromphnicol/ml medium. Plates were inverted and incubated at 32 °C for 3 days; colonies of each plate were then counted. The plates containing fewer than 150 colonies were retained [26].

Statistical analysis

Results were statistically analyzed using SPSS Statistical Package according to the analysis of variance (ANOVA). Duncan’s Multiple Range test and LSD were chosen to determine any significant difference among various treatments at p < 0.05.

Results and discussion

This study was carried out to identify the most suitable wheat substitution levels with each of quinoa, cassava and guar crops in order to increase the nutritional value of balady bread, the main type of bread in Egypt, and to decrease the amount of wheat used in the production of this bread.

Substitution percentages

Table 1 presents the results obtained when testing the different wheat substitution levels for each of the studied crops, i.e. quinoa, cassava and guar. The best percentages were identified according to the level of gluten. Singh and Singh [27] emphasized that the minimum gluten content of wet wheat flour should reach about 24%, while the dry one should be around 8%. Gluten is an important constituent of wheat because it provides strength to dough and texture to the baked wheat products. Higher gluten content in wheat flour is recommended for bread and lower gluten content is found better for biscuits and cookies as mentioned by Kumar et al. [28]. Results showed that the best percentage of wheat substitution with cassava crop was found to be 30%, as the percentage of 35 and 40% did not show any gluten in the tested samples. In case of quinoa, four percentages were tested, (10, 15, 20 and 25%) and results proved that the best ratio for wheat substitution was 20%, where gluten disappeared when higher percentages of quinoa were used. Guar, on the other hand, showed its best level at 5% where higher percentage showed no gluten as well. Therefore, those three percentages, i.e. 30% cassava, 20% quinoa and 5% guar flours, were used throughout the whole study.

Study tests

Tests were carried out to investigate the possibility of using substitutions of the whole (20% quinoa + 80% wheat flour, 30% cassava + 70% wheat flour and 5% guar + 95% wheat flour), to produce balady bread with acceptable characteristics. The chemical and rheological properties of the produced flour were evaluated. Sensory characteristics of balady bread and its shelf life were also determined.

Chemical composition

Results of the chemical composition of the flour produced from substituting portions of wheat with the previously determined percentages of the supplementary crops are recorded in Table 2.

Moisture

The moisture content showed its highest percentage in wheat and cassava flour; i.e. 12.87% and 12.50%, respectively, followed by quinoa flour 11.38%. Guar flour recorded the lowest percentage of all the tested crops (9.97%). On the other hand, blends of the different crops with wheat proved that 5% guar–wheat flour gave the highest moisture contents (11.4%), followed by the blends of 30% cassava (11.03%) and 20% quinoa (10.53%).

Protein

When testing each crop separately, the highest protein percentages, i.e. 43% was obtained from guar flour, followed by quinoa and wheat flours; 21.5%, 14.47%, respectively. Meanwhile, the least percentage of protein was found in the cassava flour where it registered a percentage of 2.1%, and this was also found by FAO [29], which proved that cassava is very low in protein contents (only 2.0%). However, when calculating the protein percentage in the studied blends, it was found that mixing 20% quinoa with 80% wheat flour gave the highest protein percentage, i.e. 16.4%, while 5% guar mixed with 95% wheat flour recorded 15.5%. Both percentages are higher than that of wheat flour (control). Koyro and Eisa [30] stated similar results where they mentioned that protein content increases in these seeds. 30% cassava–wheat flour showed a protein percentage of 11.5%, which is much higher than that of cassava flour alone, but still proved to be the least of all blends. Kumar et al. [28] highlighted that protein content of flour is an important parameter for flour types as it affects the final product’s quality.

Ash

Ash, on the other hand, showed its highest percentage in cassava flour (5.0%), while the least percentage was found in guar followed by wheat flour; 0.58 and 0.6%, respectively. The highest ash percentage in the different blends was noticed in the mixture of 20% quinoa (1.1%), while 30% cassava blend recorded the lowest percentage of all blends, i.e. 0.67%. The increase in cassava flour substitution level with wheat flour caused a decrease in the ash content of cassava blend.

Fat

Results of analyzing fat percentage in each crop separately showed that quinoa flour gave the highest percentage in all the tested plants, followed by guar, cassava and wheat 7.55, 2.45, 0.52 and 0.08%, respectively. On the other hand, blends of the different crops with wheat proved that 20% quinoa–wheat flour has the highest fat contents; 2.15%, while both 30% cassava and 5% guar gave close percentages as shown in Table 2. These findings match with what was found by Valencia-Chamorro [31], who stated that quinoa contains a high amount of fat and fatty acids, in addition, Koziol [32] highlighted that some quinoa varieties show oil concentrations up to 9.5% and that quinoa could be considered as a potentially valuable new oil crop.

Crude fiber

High fiber percentage is a required characteristic in bread flour. Results of the current study showed that guar flour alone gave the highest Crude fiber contents among all the tested samples, i.e. 17.45%, while each of quinoa and cassava recorded 4.98 and 2.13%, respectively. Kumar et al. [15] and Butt et al. [33] found similar results where they stated that guar is a rich source of fibers. On the other hand, 5% guar mixed with 95% wheat proved also to have the highest fiber contents among all mixtures followed by the blend of 20% quinoa, as shown in Table 2.

Carbohydrate

Another essential property tested in this study was the carbohydrate content of the different tested crops and their blends. Cassava flour recorded the highest carbohydrate percentage in all samples (77.78%), and even when mixed with wheat flour in a percentage of 30%, the carbohydrate contents recorded 75.4%. Charles et al. [34] ensured this result where they mentioned that cassava flour is a rich source of carbohydrate. Wheat flour, on the other hand, recoded a carbohydrate percentage of 71.39% whereas, quinoa flour alone registered a carbohydrate percentage of 52.83%, while 20% quinoa with 80% wheat recorded 68.8%. The lowest carbohydrate percentage in all the tested samples was found in guar flour, where it recorded 26.59%. Accordingly, the LSD test at 0.05, guar showed significant differences in all the chemical composition of all the tested samples as shown in Table 2. Koyro and Eisa [30] highlighted similar results where they reported that the total carbohydrate content decreases in these seeds (guar and quinoa).

Falling number

Results indicated that wheat flour (control) recorded a falling number of 341 s, while when substituted with 20% quinoa, 30% cassava and 5% guar, the falling numbers dropped to 303, 254, and 288 s, respectively. Falling number indicates flour quality; according to AACC [19] high falling number (above 300 s) indicates minimal enzyme activity and sound quality of wheat flour. A low falling number (below 250 s) indicates substantial enzyme activity and sprout-damaged wheat or flour.

Sedimentation of protein

Higher protein sediment was obtained at a percentage of 100% wheat flour, where it recorded 34.5 ml. Meanwhile, when substituted with5% guar, 20% quinoa and 30% cassava, the protein sedimentation dropped to levels of 30.67, 29.83 and 24 ml in the same samples, respectively (Table 3). The sedimentation test is an indication of the protein quality as was reported by Preston et al. [35]. Positive correlations were observed between sedimentation volume and gluten strength. The sedimentation value indicates correlation with gluten content, gluten quality and loaf volume and that depends upon the protein composition and is mostly correlated to the protein content [36].

Rheological properties

Gluten content

Wet, dry gluten and gluten index were determined in order to identify flour quality and establish blends baking aptitude as well. It was generally assumed that, high content of gluten in flour gives a product of a big volume. In the current study, wheat flour showed a significant difference in its wet and dry gluten content when compared to all the other tested blends as shown in Table 4.

Wet gluten

Wet gluten of wheat flour reached 31.7% followed by the 5% guar blend, where it recorded a percentage of 28.70. No significant differences were found between wet gluten in both 30% cassava and 20% quinoa blends. Increase in total protein content of the flour positively correlated with the gluten content [37]. The wet gluten yield indicates the quality of protein and baking quality of flour, the gluten content is directly correlated to the grain protein [38].

Dry gluten

The dry gluten yield of 100% wheat flour recorded the highest percentage in the mixtures tested, where it recorded 10.6%, followed by 5% guar blend (9.46%). The dry gluten content of the flour positively correlates to the wet gluten content. On the other hand, blends of 30% cassava and 20% quinoa gave close percentages where they recorded 7.50% and7.33%, respectively. LSD at 5% showed significant differences in the dry gluten of both.

Gluten index

On the other hand, gluten index is considered as an indicative parameter for wet gluten quality and protein content. It is directly proportional to the force of the gluten, although this fact is not always associated with the big bread. According to AACC [21] the optimum gluten index value for baking purposes should range from 60 to 90. In the current investigation the highest gluten index in the mixtures tested resulted from 5% guar blend where it recorded 97.44, followed by 20% quinoa (96.66), (Table 4). These results might be due to the good protein quality and content in them both, in addition, 30% cassava blend recorded the lowest gluten index (89.6), because cassava flour is very low in protein contents. FAO [29] and Shittu et al. [39] stated that cassava does not contain any gluten.

Alveograph test

Alveograph is a rheological method that indicates flour plasticity properties; it tries to reproduce the tensions the gluten net supports during fermentation and cooking. In the current study alveograph parameters were tested to get the necessary information about elasticity (P), extensibility (L), dough strength (W), and configuration rate (P/L) of the different tested blends. If these properties are to be high, a proper loaf volume and a good internal structure of bread will be produced. Moreover, dough strength indicates dough behavior during baking process. Data presented in Table 5 show that 100% wheat flour gave the highest baking strength (W) 368, followed by the blend of 5% guar that recorded 289. On the other hand, blends of 20% quinoa and 30% cassava recorded close results, i.e. 179 and 170, respectively.

The difference in the results could be attributed to the protein weakening [40]. The high baking strength of 100% wheat flour and 5% guar flour blend might be due to the good protein quality that characterizes them both as was mentioned by Chopin [41]. Gluten, the protein component of the flour, gives the dough elasticity and strength as was emphasized by Wieser [42].

On the other hand, when studying the tenacity (P); quinoa 20% showed the highest level among all treatments where it recorded (120), whereas the least tenacity was recorded in wheat flour (104).

The next tested parameter was the ability to swell (G); 100% wheat flour showed the highest swelling (21), each of 100% wheat flour and 5% guar, on one hand, and 30% cassava and 20% quinoa, on the other hand, gave almost the same results. High substitution of cassava flour reduces elasticity properties of wheat flour dough making the dough incapable of retaining the gas emanating from fermentation [43].

The highest tendency for extensibility (L) was recorded in wheat, followed by 5% guar then 30% cassava, i.e. 89, 75 and 41 mm, respectively. These results are in agreement with Collar et al. [44]; who considered that a good protein provides a significant higher stability during heating. The values of P/L (configuration rates) were low in case of wheat flour followed by 5% guar where they recorded 1.17% and 1.43%, respectively. On the other hand, 30% cassava and 20% quinoa recorded higher numbers; 2.71% and 3.43%, respectively.

Sensory evaluation results

Results clarified that there were no significant differences between wheat flour bread (control) and bread produced from the blend of 30% cassava with 70% wheat, in all the sensory evaluation tests (taste, color, odor, roundness, separation layer, crumb distribution, taste after swallowing, general appearance and the overall scores) as shown in Table 6. These results were assured when blending 30% cassava didn’t change through the rheological examination and after baking. Similar results were reported by Sanful and Darko [45] who stated that properties of cassava flour were similar to those of wheat flour and therefore, can partially substituted for wheat flour in many wheat-based products. This result agrees with the findings of Iwe et al. [46] who reported that cassava flour can be used as a partial replacement for wheat flour in bread baking; cassava flour/wheat flour composites between 10 and 30% of cassava flour gave the best desirable sensory attributes.

On the other hand, results also showed significant differences between wheat flour bread (control) and produced bread of blends of 20% quinoa and 5% guar in all sensory evaluations. Produced bread of 20% quinoa was acceptable and recorded 73.02 out of 100 for total score, whereas the bread produced from 5% guar and 95% wheat recorded the lowest overall score (62.68). These results match the results of Hoefler [47] who reported that the evaluation of this bread reflected that the bread was darker and less acceptable. The addition of different types of fibers, as said by Sivam et al. [48], may affect the sensory attributes of baked products and sensory evaluation rate decreases as each of the dietary fiber increases.

Effect on specific volume

The effects of blends’ composition on the specific volume of balady bread were studied and results are presented in Table 7. Wheat flour bread and bread produced from30% cassava did not show any significant difference concerning the bread specific volume, i.e. 4.0 and 3.8, respectively at LSD 0.31. These results assured that 30% cassava didn’t change the rheological properties even after baking, this agrees with the findings of [46], who reported that cassava/wheat flour composites between 10 and 30% of cassava flour gave the best desirable sensory attributes, whereas blends of 20% quinoa and 5% guar flour showed significant changes in volume of the bread when compared to wheat. These results were similar to what was found by Park and Morita [49]. Those researchers reported that quinoa flour does not contain a gluten-forming protein, like wheat flour, and attributed to the reduction in loaf volume to gluten dilution effect and the increase in the alkaline-insoluble protein. They also stated that quinoa and guar are high fiber ingredients and their addition to bread causes volume reduction due to the interference of grain fibers with gluten development where the structure and baking quality of the bread is affected.

Shelf life for the produced bread

Shelf life for all bread types produced in this study, stored at room temperature, ranged from 6 to 8 days. The spoilage started to appear on the 6th day of storage in both wheat and 30% cassava bread (Table 8). Symptoms of spoilage included black, yellow and green coloration due to the presence of different fungi species. The longest shelf life, i.e. 8 days, occurred in the bread produced from 20% quinoa to 80% wheat. The reason for the long shelf life in this type of bread was attributed to the presence of a large variety of antioxidant compounds in quinoa seeds, such as carotenoids as stated by Eberhardt et al. [50] and Nsimba et al. [51]. Moreover, the bread produced from 5% guar to 95% wheat, showed a moderate shelf life compared to both wheat bread and bread produced from 20% quinoa blend, i.e. 7 days. Tsuda et al. [52] found similar results and attributed that to the same reason; that is the presence of antioxidants in guar bean. The least shelf life was found in the bread produced from 30% cassava.

Total mesophilic (total viable bacterial counts) and fungi counts (yeast and mould counts) were calculated in the different bread samples to determine the microbial load. Fungal symptoms were not detected on the bread of all treatments at zero time. Table 8 shows fungal isolates and their count in the different bread samples. Data revealed that Aspergillus niger was the predominant fungal species isolated from all samples, while A. flavuss appeared only in wheat flour bread. Results also clarified that the fungal counts ranged from 8 × 102 to 12 × 102 CFU/g of sample. Fungal isolates included Aspergillus, Penicillium, Eurotium, Trichoderma, and Rhizopus, in addition to Saccharomyces yeast. Results assured what was found by Kyzlink [53] where no coliforms were detected in any of the bread samples.

Conclusion

Bread in Egypt is an essential daily meal for all community classes, therefore, introducing supplementary crops to substitute wheat should produce new bread with acceptable flavor, color and shape that suits the Egyptian taste; and this was one of the priorities that were taken into consideration during this study. Results of this research proved that quinoa and cassava are preferable crops to play that role. The study introduced the best percentage of wheat substitution with cassava, quinoa and guar crops to be 30%, 20% and 5%, respectively. The bread produced using these mixing percentages proved that cassava was highly accepted by panelists followed by quinoa and finally guar, which was less accepted. As wheat 72% extraction is poor in its protein content, thus it was important to produce the new bread with higher protein content, in addition to the other nutritional composition. The study proved that the bread produced from 20% quinoa and 80% wheat, not only gave the highest protein content, but also the highest fiber percentage as well. Therefore, we support the idea of expanding quinoa cultivation in Egypt due to its high nutritional value, not to forget its suitability to the Egyptian environment. Cassava–wheat flour mixture, on the other hand, was high in its carbohydrate percentage and didn’t change any of the rheological properties even after baking, thus cassava also could be another important supplementary crop that might help in fulfilling the wheat gap in the country, especially with the high accepted taste. Accordingly, efforts should be made to use these crops as supplementary crops for bread production and continue searching for other new ones.

References

F.A.H. El-Soukkary, Plant Foods Hum. Nutr. 56, 365–384 (2001)

D. Litwinek, H. Gambuś, B. Mickowska, G. Zięć, W. Berski, J. Microbiol. Biotechnol. Food Sci. 2, 1725–1733 (2013)

Food and Agriculture Organization of the United Nations (FAO), Wheat Sector Review—Egypt, Report No. 21 September. (2015) http://www.fao.org/3/a-i4898e.pdf

Central Agency for Public Mobilisation and Statistics (CAPMAS), Egypt’s self-sufficiency of wheat 49-1. (2015). https://dailynewsegypt.com/2017/01/18/egypts-self-sufficiency-wheat-49-1-2015-capmas/

D. Mitchell, Policy Research Working Paper 4682.The World Bank Development Prospects Group. The World Bank, Washington (2008)

M. Jancurová, L. Minarovicová, A. Dandár, Chem. Pap. 63(6):738–741 (2009). https://doi.org/10.2478/s11696-009-0073-z

Y. Konishi, S. Hirano, H. Tsuboi, M. Wada, Seeds Biosci. Biotechnol. Biochem. 68, 231–234. (2004). https://doi.org/10.1271/bbb.68.231

Why quinoa needs to become top of the crops in Egypt. (2018) https://www.thenational.ae/lifestyle/food/why-quinoa-needs-to-become-top-of-the-crops-in-egypt-1.765684.

Development of Quinoa in Egypt. (2012). http://egypten.um.dk/en/about-us/news/newsdisplaypage/?newsid=500ad6da-4da4-485b-b42e-0f6dc4c1d781

K. Falade, J. Akingbala, Food Rev. Int. 27(1), 51–83 (2010). https://doi.org/10.1080/87559129.2010.518296

F. Nweke, F.A.O. Rome. (2005). http://www.fao.org/docrep/009/a0154e/A0154E00.HTM

F.I. Nweke, New challenges in the cassava transformation in Nigeria and Ghana (No. 118). International Food Policy Research Institute (2004)

M. Nagwa Hassan, Improvement of productivity and quality of cassava (Manihot esculenta Crantz) in newly reclaimed lands using some mineral and bio-fertilization treatments in relation to plant density. Ph.D. Thesis, Fac. Agric., Ain Shams Univ., Egypt (2008)

A. Shams, Int. J. Water Resour. Arid Environ. 1(5), 318–325 (2011)

R. Kumar, P.P. Gupta, B.L. Jalal, J. Mycol. Plant Pathol. 31(1), 38–41 (2001)

M. Khater, R. Rania, Effect of sowing dates and foliar spray with algae extract on cluster bean (Cyamopsis tetragonoloba L.). Int. J. Pharm. Tech. Res. 9(9), 75–84 (2016)

A.M. Ritva, C.V. Repo, L.A. Serna, Ciênc. Tecnol. Aliment. Campinas 31(1), 225–230 (2011). http://www.scielo.br/pdf/cta/v31n1/35

Food and Fertilizer Technology Center (FFTC), Processing Cassava into Flour for Human Food (FFTC Practical Technology, Post-harvest PT2003-17, 2003)

American Association of Cereal Chemists (AACC), Method 38-12A, 11th edn (American Association of Cereal Chemists, St Paul, 2005)

A.I. Ihekoronye, P.O. Ngoddy, Tropical Fruits and Vegetables, p. 306 (Macmillan Education Ltd., London, 1985)

American Association of Cereal, Chemists (AACC), The American Association of Cereal Chemists, 10th edn (American Association of Cereal, Chemists (AACC), St. Paul, 2000)

Wheat Associates, Wheat and Flour Testing Methods, Version 2 Wheat Inspection, U.S. Wheat Associates, Sect. 5: Product Tests, Flat Bread. (2007). https://www.grains.k-state.edu/igp/wheatflourbook/wheat-flour-book.pdf

E.F. See, W.A. Wan Nadiah, A.A. Noor Aziah, ASEAN Food J. 14(2), 123–130 (2007)

A. Eissa Nawal, G.M. El-Habbaa, F.G. Mohamed, M.F. Abou-El-Ella, I.A. Sabek, Egypt. J. Appl. Sci. 27(5), 90–107 (2012)

N.I. Bassuony, M.F. Abol-Ela, M.A. Atwa, J. Agric. Sci. 31(5), 3139–3148 (2006)

N.I. Bassuony, A.F. Abdel-Salam, Z.M. Abdel-Ghany, A.M. El-Karamany, M. AAtwa, J. Food Dairy Sci. 3(12), 647–667 (2012)

B. Singh, N. Singh, J. Food Sci. Technol. 43(3), 251–255 (2006)

N. Kumar, B.S. Khatkar, R. Kaushik, Ann. Univ. Dunar. Jos Galati - Food Technol. 37(2), 68–81 (2013)

Food and Agriculture Organization (FAO), Guíatécnicapara producción y análisis de almidón de Yuca. Roma: FAO.ISSN, 10204334. (2007). http://www.fao.org/docrep/010/a1028s/a1028s00.htm

H. Koyro, S. Eisa, Plant Soil 302, 79–90 (2007). https://doi.org/10.1007/s11104-007-9457-4

S.A. Valencia-Chamorro, Food Science and Nutrition, vol. 8 (Academic Press, Amsterdam, 2003), pp. 4895–4902

M.J. Koziol, J. Food Compos. Anal. 5, 36–68 (1992)

M.S. Butt, N. Shahzadi, M.K. Sharif, M. Nasir, Food Sci. Nutria. 47, 389–396 (2007). https://doi.org/10.1080/10408390600846267

A. Charles, K. Sriroth, T. Huang, Food Chem. 92(4), 615–620 (2005)

K.R. Preston, P.R. March, K.H. Tipples, J. Plant Sci. 62(3), 545–553 (1982)

M. Hruskova, O. Famera, Czech. J. Food Sci. 21, 91–96 (2003)

H. Perten, K. Bondesson, A. Mjorndal, Cereal Foods World 37, 655–660 (1992)

G. Simic, D. Horvat, Z. Jurkovic, G. Drezner, D. Novoselovic, K. Dvojkovic, J Cent Eur. Agric. 7(1), 13–18 (2006)

T.A. Shittu, A.O. Raji, L.O. Sanni, Food Res. Int. 40: 280–290. (2007). https://doi.org/10.1016/j.foodres.2006.10.012

K. Kahraman, O. Sakyyan, S. Ozturk, H. Koksel, G. Sumnu, A. Dubat, Eur. Food Res. Technol. 227, 565–570 (2008)

F. Chopin, Applications Laboratory, France (2006) http://www.chopin.fr/media/docs/MAB-GB-Web-web

H. Wieser, Food Microbiol. 24, 115–119 (2007). https://doi.org/10.1016/j.fm.2006.07.004

G.Y. Giami, T. Amasisi, G. Ekiyor, J. Mater. Res. 1, 16–25 (2004)

C. Collar, C. Bollain, C.M. Rosell, Food Sci. Technol. Int. 13, 99–107. (2007). https://doi.org/10.1177/1082013207078341

R.E. Sanful, S. Darko, Pak. J. Nutr. 9(8), 810–814. (2010). https://doi.org/10.3923/pjn.2010.810.814. Asian Network for Scientific Information

M.O. Iwe, N. Michael, N.E. Madu, N.E. Obasi, G.I. Onwuka, T.U. Nwabueze, J.O. Onuh, V.U. Asumugha, Agro Technol. 6(3), 166. (2017). https://doi.org/10.4172/2168-9881.1000166

A. Hoefler, Hydrocolloids (Eagan Press Handbook Series, St. Paul, 2004), pp. 1–98

A.S. Sivam, D.S. Waterhouse, S.Y. Quek, C.O. Perera, J. FoodSci 75(8), 163–174. (2010). https://doi.org/10.1111/j.1750-3841.2010.01815.x

S.H. Park, N. Morita, Food Sci. Technol. Int. 11(6), 471–476 (2005). https://doi.org/10.1177/1082013205060766

M.V. Eberhardt, C.Y. Lee, R.H. Liu, Nature 405:903–904. (2000). https://doi.org/10.1038/35016151

Y.R. Nsimba, H. Kikuzaki, Y. Konishi, Seeds. Food Chem. 106, 760–766 (2008). https://doi.org/10.1016/j.foodchem.2007.06.004

T. Tsuda, Y. Makino, H. Kato, T. Osawa, S. Kawakishi, Biosci. Biotechnol. Biochem. 57(9), 1606–1608 (1993). https://doi.org/10.1271/bbb.57.1606

V. Kyzlink, Principles of Food Preservation (Elsevier Publications, Amsterdam, 2001), pp 247–370

Funding

This study was funded by the Government of Egypt.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soliman, A.S., Abbas, M.S., Abol-Ella, M.F. et al. Towards bridging wheat gap in Egypt by using cassava, quinoa and guar as supplements for the production of balady bread. Food Measure 13, 1873–1883 (2019). https://doi.org/10.1007/s11694-019-00106-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00106-7