Abstract

Soaking is an important pre-requisite for soybean meal processing including fermentation. Soybean meal is soaked at 20, 30, 40, 50 and 60 °C for 10 h in order to investigate the effect of soaking on moisture gain and nutritional properties including crude protein content, carbohydrate content and antioxidant activity. The properties of the soaking water (pH, turbidity and colour parameters using L*a*b* scale) are also investigated. For soybean meal, the effective moisture diffusivity varied from 1.14 × 10−11 to 2.07 × 10−11 m2 s−1 and the water absorption data fitted well with Peleg and Abu-Ghannam models. The total phenolic content and DPPH radical-scavenging activity are found to be significantly (p < 0.05) affected by soaking time and temperature and a maximum decrease of 90% and 20% are observed, respectively. For phenolic compounds, the effective diffusivity varied from 0.9 × 10−11 to 1.19 × 10−11 m2 s−1 and the data fitted with the second order kinetic model. Crude protein and carbohydrate content decrease by 7% and 4%, respectively and are significantly (p < 0.05) affected by soaking time only. The pH of the soaking water reduces to mildly acidic (6–6.5), a* and b* values increase but L* value decreases. Both time and temperature are found to have significant (p < 0.05) effects on all tested properties of soaking water. The best conditions for soybean meal soaking are found to be 50 °C and 1 h within the range used. At these conditions, the desirable moisture content (45–55%) can be achieved in a reasonable time and with minimum loss of nutrients.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Defatted soybean meal (SBM) has traditionally been used as an important source of tons and accounted for 62.5% of oil meals [1]. It also represented 61% of the proteins used to feed livestock and 16% of compound feeds (in 2014, SBM production reached 190 million) [2]. SBM is the material remaining after extraction of oil from soybean flakes. It is considered as a dried material (12% db) as it is solid and is in the form of particles [3]. With crude protein content as high as 48% and a balanced amino acid content that is rich in lysine (upto 2.8%), SBM has the merits of being a rich protein source for food as well as for feed [4]. Soya protein is also a rich source of natural antioxidants like isoflavones (mainly daidzein and genistein) and other phenolic compounds (galic acid, ferulic acid, etc) that can scavenge free radicals, act as metal–ion chelator, oxygen quencher or hydrogen donor [5,6,7]. Intake of food derived antioxidants is considered best for prevention of free-radical related cell and tissue damages [7].

Moisture hydration through soaking has been ubiquitously associated with the preparation of soybean foods, especially the fermented ones [8, 9]. Fermentation of SBM also requires prior soaking in order to convert the dry SBM into a wet fermentable form (moisture content approx. 45–55% db) and to remove water-soluble anti-nutrients like oligosaccharides. Usually, fermentation of SBM is carried out in solid state form, which makes the moisture hydration step the most important pretreatment. Soaking is a slow process controlled by the diffusion of water. Thus soaking at room temperature may provoke microbial contamination, which affects quality attributes (such as color, taste and smell) of the product. Soaking has several benefits including loss of carbohydrates like raffinose and stachyose which may cause flatulence upon consumption by humans [9, 10]. However, soaking also results in loss of a fraction of proteins and phenolics [11, 12] which is undesirable. Thus soaking must be carried out under optimal time and temperature in order to minimize nutrient loss. Release of different compounds into the soaking medium also in turn influences the physical and chemical properties of the water used [13] and thus any change in the properties of soaking water is an indication of the substances leached out from SBM during the thermal processing. Therefore, the properties of soaking water should also be investigated to understand the process as well as to evaluate its suitability as discharge and/or its reusability.

The water absorption during soaking mainly depends upon the time–temperature binomial [14]. The phenomenon of water absorption can be explained by models based on concepts of chemical kinetics [15], and by analytic expressions derived from Fick’s second law of diffusion [16]. Processes such as the water absorption can be explained by physical or empirical modeling [17]. Empirical models are not derived from the physical aspect of the phenomenon and thus have the advantages of bypassing phenomenological modeling inaccuracies arising from uncertainties and inadequacies of the assumptions made. Studies on the water absorption process in various agricultural products are presented by Abu-Ghannam and McKenna [18], Clemente et al. [19], and more recently by Pramiu et al. [17]. Turhan et al. [20] studied the effects of different hydration temperatures and their influence on water absorption using Peleg model whereas McKenna [18] used a differential equation model to explain hydration kinetics of red kidney beans.

Although soaking of soybean and the associated parameters such as moisture content, solid loss and properties of the water used for soaking are well documented [8, 10, 11] but effects of hydration on SBM and subsequent changes in the properties of water used for soaking are still lacking in literature [21]. The main objectives of the present study are to analyze the moisture content using semi-emperical models and also the various nutritional properties (example crude protein content and antioxidant activity) of SBM at various soaking time and temperature, and to analyze their effect on the physicochemical properties of water (for example pH, turbidity and color) to predict an optimal hydration behavior.

Materials and methods

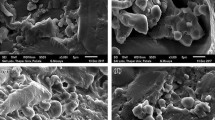

JS 9560 early variety soybean seeds procured from local market in Kolkata are used to prepare SBM. The crude fat content of the SBM is determined using AOAC method [22]. Sieve analysis determines the average size of the particles in the SBM to be 1022 µm (− 16/+ 18 mesh). All chemicals used are of analytical grade.

Soaking experiments

Soaking of SBM is done at 20, 30, 40, 50 and 60 °C for time intervals 1–10 h. Temperatures higher than 60 °C are not chosen in order to avoid thermal degradation of SBM nutrients, especially the heat sensitive ones (vitamins, proteins). For soaking at each time and temperature, SBM is added to deionized water (1:10 ratio of SBM to water) and maintained at that temperature in incubators. SBM to water ratio (1:10) is selected based on the availability of sufficient soaking water after 12 h of soaking at all the temperatures used to ensure that the moisture content could reach equilibrium. A lower water ratio results in complete evaporation of water at higher temperatures before the experiment ends and a higher ratio results in abundance of water leading to difficulty in separation. After soaking, the samples are centrifuged for 5 min and then filtered using Whatman Filter paper (GE HealthCare UK Limited, Buckinghamshire, UK). For the measurement of moisture content (in % db), previously weighed soaked samples are then dried in a hot air oven (Mac PharmaTech, India) at 103 °C for 24 h [23]. The samples are then covered with aluminum foil and weighed immediately after drying.

Preparation of SBM hydrolysate

SBM hydrolysate (SBMH) is prepared according to the method described by Amadou et al. [6] for carrying out further chemical analysis. For this, 5 g ml−1 of soaked SBM is homogenized for 1 min and incubated at 37 °C for 60 min. The incubated mixture is centrifuged at 4900 g for 2 min, the residue is washed with 20 ml distilled water, centrifuged again at the same speed and time and the supernatants are then combined.

Properties of SBM

Total phenolic content

Total phenols in the SBMH are determined by Folin–Ciocalteu reagent using gallic acid as a standard [24]. One hundred µl solution of SBMH is added to 500 µl of Folin–Ciocalteu reagent. After 10 min, 400 µl of 7.5% Na2CO3 is added and the mixture is incubated at 50 °C for 5 min. The absorbance of the blue color is read spectrophotometrically (U-2000 Spectro, Hitachi, Japan) at 760 nm. The total phenolic content is expressed as gallic acid equivalents (GAE) in mg per g extract. The calibration equation of gallic acid standard curve is y = 0.043x − 0.036 (R2 = 0.997) which covers the concentration range between 0.1 and 1.0 mg ml−1.

2,2-Diphenyl-1-picrylhydrazyl (DPPH) radical-scavenging activity

Measurement of scavenging activity of antioxidants reflects the overall antioxidative potential of SBM. The scavenging effect of SBMH fractions on DPPH free radical is measured according to the method of Amadou et al. [6]. 2 ml of each SBMH solution are added to 2 ml of 0.1 mM DPPH dissolved in 95% ethanol. The mixture is shaken and left at room temperature for 30 min and the absorbance of resulting solution is read at 517 nm in spectrophotometer. The scavenging effect is expressed as follows:

Crude protein content

The crude protein content of SBMH is measured using the method of Folin–Ciocalteu (Lowry protein assay) using BSA (Bovine Serum Albumin) as the standard protein [25]. The absorbance is measured at 660 nm in spectrophotometer.

Total carbohydrate loss

The total carbohydrate loss after soaking is measured indirectly by measuring the total carbohydrate content of the soaking water and assuming that the initially no carbohydrate is present in the water used for soaking. Anthrone test with glucose as the standard carbohydrate is used for measuring the total carbohydrate content of the soaking water as it is widely used for determination of starch and soluble sugars in plant material [26]. The absorbance is measured at 620 nm in spectrophotometer.

Properties of soaking water

As for the physicochemical properties of soaking water, parameters such as pH, turbidity (absorbance at 500 nm) and color of water are measured at 25 °C by using pH-meter (Eutech Instruments, Singapore), spectrophotometer and Hunter-Lab colorimeter (Colorflex, USA), respectively. Note that the measurement of color by tristimulus colorimetry in terms of Hunter scale (L*, a* and b*) values has been accepted as simple and accurate method of color detections compared to spectrophotometric systems [13].

Statistical analysis

Multivariate analysis of variance (MANOVA) with replication is performed by using the R statistical software package (R v3.1.0, 2014) with two independent variables (soaking time and temperature) and three dependent variables (crude protein loss, total carbohydrate loss and loss of antioxidant activity) for SBM and four dependent variables (turbidity, L*-value, a*-value, b*-value) for soaking water. Furthermore, Pillai–Bartlett trace [27] and Wilks’ Lambda test [28] are done to check if significant differences existed between the groups. This analysis is carried out for a level of significance of 5% i.e. for a 95% level of confidence.

Moisture sorption models

Peleg model

The Peleg model is typically represented as:

where M(t) is the moisture content of the product at a given instant of time, and M0 is the initial moisture content, t is time, and the plus sign is used to denote water uptake. The k1 and k2 parameters are the constants of Peleg, which are associated with the initial rate of water transfer and with the concentrations of water in equilibrium conditions. Values of k1 and k2 are obtained from the linearized form of the equation.

This model can be widely used to study water uptake in farm products, and its solution shows moisture content as a function of time, allowing for its estimate after certain periods of time [17]. This model has been used to study absorption and desorption processes in several studies [17, 20].

Abu-Ghannam model

General series solution of Fick’s second law [29] considering spherical coordinates, in terms of moisture ratio (MR), is given as:

where Deff is the effective diffusivity (m2 s−1), R is the equivalent radius of SBM granule, M is the moisture content in time t, M0 is the initial and Me is the final moisture content. The equivalent radius is measured by the method described in Luz et al. [30]. The slope of the curve ln(MR) versus time is k can be related to Deff by the following equation:

In this study, Fick’s law of diffusion is used in order to calculate the effective diffusivity of SBM. For simplicity, it is assumed that the volume of SBM does not change during soaking and the surface reaches the equilibrium moisture content instantaneously upon immersion in water [31]. The phenomenon of soaking can be explained with the following mathematical model that can be derived from Eq. 2

where coefficient k > 0 is specified for hydration or drying processes by an Arrhenius type of equation. The minus sign in Eq. 5 is used to maintain the consistency between the mathematical and the physical formulation and shows that this equation describes water uptake phenomena. Taking M(0) = M0 at t = 0 as initial condition, the above equation can be written as

whose analytical solution is given by

where k is the rate constant of the hydration expressed as h−1.

This model has been originally proposed by Abu-Ghannam and McKenna [18] and is obtained when considering the hypothesis that the moisture content M depends only on time, the final moisture content is constant over time and the body is homogeneous and isotropic. Furthermore, the rate of change in moisture content at time t is proportional to the difference between the moisture in any time t and the final (equilibrium) moisture content \({M_e}\).

Kinetic analysis for loss of phenolic compounds

The kinetics of loss of phenolic compounds during soaking of SBM can be established by estimating some kinetics parameters using nonlinear regression between concentration of phenolic compounds and time [32]. The following simplified hyperbolic function has been found to explicitly expressing the nonlinear relationship between concentration and time:

CTP(s), CTP(t) represent the total phenolic content in the equilibrium (mg g−1) and at time t while k is the second order rate constant of the process (g mg−1 h−1) respectively. Equation 8 may be transformed into following linearized form:

The initial rate of loss, h (mg g−1 h−1), when t approaches 0, can be defined as:

Plotting t/CTP(t) vs t gives a straight line with intercept = 1/kC2TP(s) and slope = 1/CTP(s). This model can be used to predict the behavior of total phenolic content loss during soaking of SBM. This model also explains the changes in rate of loss during different phases of soaking.

The second order rate constant k increases with temperature and can be described according to Arrhenius law:

where k is the extraction rate constant (g mg−1 h−1), k0 the temperature-independent factor (g mg−1 h−1), Ea the activation energy for the extraction (kJ mol−1), R the gas constant (8.314 J mol−1 K−1) and T is the absolute soaking temperature (K). A plot of ln(k) against 1/T gives the value of the activation energy (Ea) from slope.

Results and discussion

Determination of moisture content

The moisture content of SBM increases with increasing soaking time and temperature. As seen in Fig. 1, the value almost reached equilibrium within 8 h and barely increased with time thereafter. It is also evident from the figure that although the moisture soaking profiles at temperatures 40, 50 and 60 °C are similar and that the maximum moisture content reached after soaking for 8 h at these temperatures are almost identical (approximately 70% of the total absorption), the rate of increase in moisture is higher for higher temperatures. During the initial hours, this rate is the highest and then it slowed down to a great extent, in particular from 2 h of soaking reaching an almost constant value after 8 h for all the temperatures used in the present study. The moisture uptake behavior with temperature observed in this study is similar to the reports available in literature for soaking of raw soybeans [10, 31, 33]. The results suggest that a higher temperature, say 50 or 60 °C could be used for soaking in order to speed up the process.

The initial moisture content of SBM is considered to be 12% (db) for all analytical and numerical solutions. The values for experimental equilibrium moisture content, diffusion coefficients, constants of Abu-Ghannam and Peleg models are tabulated in Table 1. The effective diffusivity is calculated by Eq. 3 using slopes derived from the linear regression of ln(MR) versus time. The effective diffusivity of water in SBM varied from 1.18 × 10−11 m2 s−1 at 20 °C to 2.07 × 10−11 m2 s−1 at 60 °C (see Table 1). The effective diffusivities of water for SBM found in this study are comparable, with SBM presenting slightly higher values for each temperature [16].

Figure 2 shows the hydration curves obtained from all treatments, considering the experimental data and the results from adjust of the Abu-Ghannam and McKenna [18] and Peleg [15] models. All hydration curves exhibit a similar behavior characterized by high uptake rate within the first 2 h of hydration, followed by a reduction in the rate of water uptake. Approximately 60% of total water grain is absorbed in the first phase of the process. After that the rate of water uptake drops considerably and the hydration time reduces with increasing temperature; results that can be confirmed with the works of Abu-Ghannam and McKenna [18], Gowen et al. [34] and Pramiu et al. [17].

The quality of adjustment of the implemented models is done based on their coefficient of determination (R2) and root mean square error (RMSE) values [17]. It is evident from Table 1 that Abu-Ghannam model suits the experimental data and agrees with literature [17, 18, 34]. RMSE values for Peleg model vary between 2.73 and 3.79, with 20 °C having the lowest and 50 °C having the highest value. For Abu-Ghannam model, RMSE varies between 0.83 and 6.15 with 50 °C and 30 °C having the lowest and the highest value, respectively. Thus a comparison of RMSE values along with R2 values for both models used in this study indicates that Abu-Ghannam model is efficient enough to describe the soaking behavior of SBM. Table 1 also lists the values for the hydration constant k (Abu-Ghannam model) which are found to be from 3.65 × 10−1 to 5.8 × 10−1 h−1 and is higher than values reported by Gowen et al. [34]. This can be attributed to SBM being significantly different from soybean in its physicochemical characteristics which may influence hydration. Similarly, Peleg’s constants k1 and k2 and the quality of adjustment are in accordance with literature [17]. The values for constants k1 and k2 are found to be from 2.5 × 10−2 to 1.0 × 10−2 h db−1 and from 1.7 × 10−2 to 1.5 × 10−2 db−1. The constant k2 is said to be related to the maximum capacity of water uptake of feedstock i.e. a small k2 implies high absorption capacity. The effect of temperature on k2 i.e. on feedstock water uptake capacity, varies with the type of feedstock used, and also whether the loss of soluble solids during soaking is taken into account in the calculation of moisture content [17, 18]. In contrast, the constant k1 varies linearly with temperature and an increased rate of water uptake, i.e. a decreased k1 with increasing temperature is an expected behavior of sorption. A similar behavior of both constants is observed in the present study, although the values are different than those reported for other legumes, which can be attributed to the physicochemical difference of SBM from others.

Properties of soybean meal

Total phenolic content

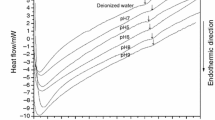

The phenolic content is correlated with antioxidant activity [35] and typically a positive linear correlation exists between total polyphenolic content and antioxidant activity [36]. Thus a reduction in phenolic content during soaking will result in loss of antioxidant activity of SBM. Soaking results in significant (p < 0.05) decrease in total phenolic content of SBM as seen in Fig. 3 (represented in terms of increase in phenolic content of soaking water), the highest loss occurring at the highest soaking temperature and time (60 °C and 8 h). The total phenolic content of unsoaked SBM is found to be 8.84 mg GAE/g extract which is in agreement with Ramadan et al. [37]. As is evident from the figure, soaking results in a sharp decrease in total phenolic content of SBM during the first 2 h for all the temperatures used but the rate is approximately twice for higher temperatures (50 and 60 °C). After 2 h of soaking the rate of decrease of total phenolic content reduces, becoming almost negligible after 4 h as the concentrations of phenolic compounds in SBM and soaking water reach equilibrium. This is in concurrence with Fig. 1 where during the initial hours of soaking, the moisture uptake rate is higher than the later hours.

Kinetic analysis of the phenolic content is done in order to calculate the effective diffusivity of phenolic compounds in water and the initial rate of loss. Table 2 lists the calculated effective diffusivities of phenolic compounds in water, respective initial rate of loss and parameters for measuring the goodness of fit of the model used at different soaking temperatures used in this study. The effective diffusivities of phenolic compounds are found out to be 0.9 × 10−11, 1.02 × 10−11 and 1.19 × 10−11 m2 s−1 for 40, 50 and 60 °C, respectively. The initial rate of loss (h) increases gradually with temperature and this is in agreement with the moisture uptake behavior of SBM. A second order kinetic model is used to predict the changes in phenolic content during soaking. It is evident from Table 2 and Fig. 3 that this model shows a good fit in terms of both R2 and RMSE values.

The model constant k is dependent on temperature and shows a constant increase with increasing temperature. Using Eq. 11 and ln(k) versus 1/T plot, the activation energy Ea can be calculated for any process. The empirical relationship for the loss of total polyphenols during soaking can be written as:

and the coefficient of determination is R2 = 0.990.

The value of activation energy is found to be positive (36.939 kJ mol−1), denoting the endothermic nature of the process. This value fits between the Ea values reported in literature for the solid–liquid extraction of bioactive compounds from biomass. The activation energy value is situated between 20 and 40 kJ mol−1, which implies that the loss of phenolic compounds during SBM soaking is governed by both reaction and diffusion regime. According to Wang et al. [5] and González-Centeno et al. [32], if the Ea value is lower than 20 kJ mol−1 the extraction process is managed by diffusion, and if the Ea value is higher than 40 kJ mol−1 the process is controlled by solubilization reaction.

DPPH radical-scavenging activity

Soaking reduces the overall antioxidant activity of SBM as measured in terms of DPPH radical-scavenging activity. The initial DPPH radical-scavenging activity of SBM is measured to be approximately 13% and after soaking at 60 °C for 8 h the loss of antioxidant activity is found to be 20%. Soaking at 70 °C results in approximately 50% loss of activity, thus higher temperatures are not considered for soaking and this decrease shows dependence on both soaking time and temperature. The reduction in DPPH radical-scavenging activity is in agreement with the literature [12, 38] for various other beans after soaking. However the percentage loss of antioxidant activity found in this study is higher than the values reported for black beans (6–8%) [12], which can be attributed to the structural changes occurring during SBM production from soybeans that in turn resulted in easier removal of compounds including vitamins (see later). This removal of soluble compounds along with probable degradation of heat sensitive compounds at higher soaking temperature contributed largely to the loss of antioxidant activity with increasing soaking time and temperature.

Analysis of crude protein content

Soaking treatment results in decrease in crude protein content of SBM, whose initial value is measured to be approximately 46%. The maximum loss is around 7% which occurrs at highest temperature (60 °C) and highest soaking time (8 h), though the difference between percentage losses of different temperature are insignificant (p > 0.05). Table 3 represents the percentage loss of crude protein at different soaking temperature after equilibrium soaking time. This value is however much higher than the value reported for soybean [10], which could be attributed to the increased nutrient extraction rate due to a higher surface area to volume ratio of SBM.

Analysis of total carbohydrate

The primary water-soluble carbohydrates of SBM are reported to be galacto-oligosaccharides, stachyose, raffinose and verbascose [39]. Lo et al. [9] reported that carbohydrates including raffinose and stachyose are removed during soaking of soybeans which can be observed by their presence in the soaking medium. A maximum of 4% carbohydrate is measured in soaked water at 60 °C for 8 h (Table 3), although the soaking temperature does not have significant effect (Table 4). Removal of carbohydrates like raffinose and stachyose could have beneficial effects on the acceptability of SBM based products [9, 10].

Properties of soaking water

Changes in pH

During soaking of SBM, the pH of the soaking water (initial pH of 7–7.2) reduced to being slightly acidic (approx 6–6.5). With increase in soaking time, the extraction process increased resulting in decreasing pH values. The pH value however did not reduce beyond 6 in the temperature range used for soaking in the present study. Leaching of acidic compounds, like amino acids, is primarily responsible for low pH resulting in physicochemical changes in water [13]. Although SBM contains both basic (arginine, lysine and histidine) and acidic (aspartate and glutamate) amino acids that are hydrophilic, concentrations as well as solubility of the acidic ones are much higher [40] causing the pH range of the soaked water to be shifted from neutral to mildly acidic.

Changes in turbidity

A change in turbidity is a direct indicator of release of nutrients from SBM to water during soaking [41]. It occurs due to extraction of several components like proteins, sugars, pigments and other soluble compounds. Figure 4 shows the changes in measured absorbance at 500 nm at different time and temperatures due to moisture uptake in SBM. Turbidity of soaking water increased with increasing time and temperature, highest being at 8 h—60 °C within the parametric range of this study. For 40 and 50 °C, the turbidity increased gradually with soaking time, while for 60 °C, the turbidity increased rapidly after 2 h of soaking. This sudden increase in turbidity at 60 °C occurred due to much higher rate of extraction at this temperature compared to the other temperatures. After 2 h of soaking, the initially-dried SBM gained enough water for easier removal of nutrients resulting in a rapid increase in turbidity. Using soybean, Bayram et al. [13] also reported a similar behavior in turbidity of soaking water.

Colorimetric analysis

The color measurement gives an insight into the nature of compounds that are being released from SBM into the water during soaking [13]. Whole mature soybeans contain pigments of carotenoid class along with small amounts of chlorophyll and water-soluble vitamins like thiamine, niacin, biotin, pantothenic acid [41]. In comparison, SBM also contains xanthophylls, a yellow pigment of carotenoid class, though in lesser amount (2 mg kg−1 of SBM). The change in color of soaking water is clearly visible in this study and is attributed to the release of pigments and water-soluble vitamins [13, 41].

Changes in the L*, a*, b* values of soaking water with respect to time at different soaking temperatures, respectively are shown in Fig. 5. The values change considerably with changes in soaking time and temperature. The L*-value representing the “lightness” of soaking water decreases with time (Fig. 5a). It is found to be maximum for 40 °C and decreases with increasing temperature. The decreasing L*-value with increasing temperature could be due to multiple reactions like recrystallization of sugar and formation of pigment derivatives that resulted in darker compounds [43] which in turn are released into the soaking water. The a*-value of soaking water is found to be negative (Fig. 5b) which indicates the presence of the colour green caused due to traces of chlorophyll and its derivatives from immature soybeans that might have been used alongside the mature soybeans during SBM production [41]. Small amount of green pigments could have leached out during soaking at elevated temperature, thereby increasing the a-value [13]. At 60 °C, changes in greenness are much higher than the previous two temperatures i.e. 40 and 50 °C, which can be attributed to the fact that pigments are removed faster with increase in temperature. The b*-value that represents yellowness are found to be positive and increased with temperature (Fig. 5c). Yellowness of the water is highest for 60 °C and a rapid increase after 2 h of soaking is observed. This could be explained by the leaching of yellow pigments and vitamins during soaking. The results are in agreement with the report of soybean soaking by Bayram et al. [13].

Statistical analysis

MANOVA is a statistical test procedure for comparing multivariate means of several groups [42,43,44]. It helps to determine whether changes in the independent variable(s) have significant effects on the dependent variables, relationships between the dependent variables as well as independent variables [44].

In this study, the soaking parameters are investigated for their effects on the properties of SBM. MANOVA results (Table 4) suggest that although the main factors, i.e. soaking time and temperature, have significant (p < 0.05) effects on the three dependent variables, i.e., losses of protein, carbohydrate and antioxidant activity, the interaction had none. Since the multivariate test is significant, individual ANOVAs for each of the three variables are performed in order to explore which of them are driving the significant differences.

As is evident from Table 5, the decreases in protein and carbohydrate contents as well as antioxidant activity are affected significantly (p < 0.05) by the soaking time, but soaking temperature has significant (p < 0.05) effect only on loss in antioxidant activity. This could be attributed to the antioxidative compounds being more sensitive to heat compared to protein and carbohydrate in the temperature range used (20–60 °C). This could be an interesting finding as soaking at higher temperature to minimize the soaking time might result in increased loss of antioxidant activity. Thus a temperature optimization is necessary to minimize this loss.

For the properties of soaking water, the main factors (soaking time and temperature) as well as their interaction are found to be significantly (p < 0.05) influencing the changes in the four dependent variables i.e., turbidity, L*-value representing lightness, a*-value representing greenness and b*-value representing yellowness (Table 4). The results of individual ANOVAs (Table 5) also show that both soaking time and temperature have significant effects on the properties of soaking water. These findings indicate that extraction of compounds like water-soluble vitamins, green and yellow pigments, etc are significantly (p < 0.05) dependent on the soaking time and temperature, thus an increase in these parameters would result in higher loss of these compounds.

For the purpose of deciding the best conditions for SBM soaking under the test range used in this study, a balance must be maintained so that the desired moisture level can be achieved in a reasonable time without losing too much nutritional value. The required moisture level that must be achieved for an optimal SBM fermentation is approximately 45–55% (db) [45]. The desired moisture level can be achieved in 1 h when soaking is done at 50 and 60 °C, while for 20, 30 and 40 °C the required soaking time is 6, 5 and 2 h, respectively. Therefore a further comparison of the reduction of nutritional components is carried out to obtain the most suitable soaking conditions. Table 6 compares the three properties of SBM investigated in this study that are affected by soaking. From this table, it is clear that soaking at 50 °C for 1 h results in minimum losses of nutrients (i.e., crude protein and antioxidant activity) although it also results in minimum loss of anti-nutrient (i.e. oligosaccharide) in this study. Therefore soaking SBM at 50 °C will not only speed up the soaking process (only 1 h), it will also minimize the amount of nutrient lost during the initial soaking before fermentation.

Conclusions

Soaking of SBM resulted in significant (p < 0.05) changes in its properties, in terms of crude protein (a maximum loss of 7%), total carbohydrate (maximum 4% decrease), total phenolic content (maximum 90%) and DPPH radical scavenging activity (a maximum of 20% loss in activity). Kinetic analysis for the loss of phenolic compounds during soaking shows that the rate of loss can be predicted using a second order kinetic model and the effective diffusivity of such compounds in water varied from 0.9 × 10−11 to 1.19 × 10−11 m2 s−1. The effective moisture diffusivity of water through SBM is calculated to be slightly higher than raw hydrated soybeans and varied from 1.14 × 10−11 to 2.07 × 10−11 m2 s−1 as the soaking temperature is increased from 20 to 60 °C. Hydration rate of SBM increased at elevated temperatures, absorbing the maximum amount of water during the initial 2 h of soaking. Both Peleg model and Abu-Ghannam models are used to describe the absorption kinetics of SBM. A comparison of the R2 and RMSE values revealed that the absorption data fitted well in to Abu-Ghannam model, suggesting that this model can be efficiently used to predict the moisture hydration kinetics of SBM. Physicochemical properties of the soaked water also considerably change during hydration, including the pH which turns mildly acidic. The changes in turbidity at lower temperatures (20 °C and 30 °C) is less compared to higher temperature (i.e. 60 °C) which implies that a rise in temperature aggravates the process of compound removal. MANOVA done on the SBM and soaking water properties indicate both the soaking parameters (time and temperature) have significant (p < 0.05) effect on leaching of various compounds like protein, oligosaccharides and antioxidative compounds. Comparison studies, keeping approximately 55% moisture content as the desirable level, find that within the time–temperature range used the most suitable conditions for SBM soaking is 1 h at 50 °C because it results minimum loss of antioxidative compounds (5%). The loss of crude protein, oligosaccharides and total phenolic content at these conditions are 1.1%, 0.1% and 55%, respectively. It is expected that the results of this study would help to understand and control the subsequent fermentation step without compromising the antioxidant property of the SBM.

References

FAO Cropping Database (2016). http://faostat3.fao.org. Accessed June 2016

A. Booth, FEFAC’s approach towards responsible soy, Chair FEFAC Sust. Committee (25 March 2015)

L.R. Genskow, W.E. Beimesch, J.P. Hecht, I.C. Kemp, T. Langrish, C. Schwartzbach, F.L. Smith, Chemical Engineers’ Handbook (Mc Graw Hill Professional, New York, 2007)

D. Teng, M. Gao, Y. Yang, B. Liu, Z. Tian, J. Wang, Bio-modification of soybean meal with Bacillus subtilis or Aspergillus oryzae. Biocatal. Agric. Biotechnol. 1, 32–38 (2012)

Y.G. Wang, S.T. Yue, D.Q. Li, M.J. Jin, C.Z. Li, Kinetics and mechanism of Y(iii) extraction with Ca-100 using a constant interfacial cell with laminar flow. Solvent Extr. Ion Exch. 20, 345–358 (2002)

I. Amadou, G.W. Le, Y.H. Shi, S. Jin, Reducing, radical scavenging, and chelation properties of fermented soy protein meal hydrolysate by Lactobacillus plantarum LP6. Int. J. Food Prop. 14, 654–665 (2011)

B. Mokatan, J. Saha, P.K. Sarkar, Antioxidant activities of soybean as affected by Bacillus-fermentation to kinema. Food Res. Int. 41, 586–593 (2008)

T. Toda, A. Sakamoto, T. Takayanagi, K. Yokotsuka, Changes in isoflavone composition of soybean during soaking in water. Food Sci. Technol. Res. 7, 314–319 (2001)

W.Y.-L. Lo, K.H. Steinkraus, D.B. Hand, L.R. Hackler, W.F. Wilkens, Soaking soybeans before extraction as it affects chemical composition and yield of soymilk. Food Technol. 22, 1188–1190 (1968)

Z. Pan, W. Tangratanavalee, Characteristics of soybeans as affected by soaking conditions. LWT-Food Sci. Technol. 36, 143–151 (2003)

A. Segev, H. Badani, L. Galili, R. Hovav, Y. Kapulnik, I. Shomar, S. Galili, Total phenolic content and antioxidant activity of chickpea (Cicer arietinum L.) as affected by soaking and cooking conditions. Food Nutr. Sci. 2, 724–730 (2011)

B.J. Xu, S.K.C. Chang, Total phenolic content and antioxidant properties of eclipse black beans (Phaseolus vulgaris l.) as affected by processing methods. J. Food Sci. 73, H19–H27 (2008)

M. Bayram, A. Kaya, M.D. Oner, Changes in properties of soaking water during production of soy-bulgur. J. Food Eng. 61, 221–230 (2004)

A. Dutta, A. Chanda, R. Chakraborty, A linear driving force (LDF) approximation of moisture diffusion kinetics in white rice. Int. J. Food Eng. (2008). https://doi.org/10.2202/1556-3758.1439

M. Peleg, An empirical model for the description of moisture sorption curves. J. Food Sci. 53, 1216–1217 (1988)

K.H. Hsu, Effect of temperature on water diffusion in soybean. J. Food Sci. 48, 1364–1365 (1983)

P.V. Pramiu, R.L. Rizzi, N.V. do Prado, S.R.M. Coelho, P.Z. Bassinello, Numerical modeling of chickpea (Cicer arietinum) hydration: the effects of temperature and low pressure. J. Food Eng. 165, 112–123 (2015)

N. Abu-Ghannam, B. McKenna, Hydration kinetics of red kidney beans (Phaseolus vulgaris L.). J. Food Sci. 62, 520–523 (1997)

A. Clemente, R. Sánchez-Vioque, J. Vioque, J. Bautista, F. Millán, Effect of processing on water absorption and softening kinetics in chickpea (Cicer arietinum L.) seeds. J. Sci. Food Agricult. 78, 169–174 (1998)

M. Turhan, S. Sayar, S. Gunasekaran, Application of Peleg model to study water absorption in chickpea during soaking. J. Food Eng. 53, 153–159 (2002)

R. Mukherjee, T. Sarkar, A. Dutta, R. Chakraborty, Evaluation of the effect of moisture hydration in soybean meal. In: Non Thermal Processing Techniques- Emerging Innovation for Sustainable, Safe & Healthy Foods (NTPT), Haldia (2014)

Association of Official Analytical Chemists (AOAC), Official Methods of Analysis of AOAC International, 18th edn. (AOAC International, Gaithersburg, 2006)

Association of Official Analytical Chemists (AOAC), Official Methods of Analysis of AOAC International, 16th edn. (AOAC International, Washington DC, 1995), pp. 27–29

M. Škerget, P. Kotnik, M. Hadolin, A.R. Hras, M. Simonic, Z. Knez, Phenols, proanthocyanidins, flavones and flavonols in some plant materials and their antioxidant activities. Food Chem. 89, 191–198 (2005)

O.H. Lowry, N.J. Rosebrough, A.L. Farr, R.J. Randall, Protein measurement with the Folin phenol reagent. J. Biol. Chem. 193, 265–275 (1951)

Ch Madhu, J. Swapna, R.S. Spandana, I. Niharika, K.R. Raj, B. Kalyan, M. Rajarajeshwari, T. Prathyusha, Quantitative evaluation of carbohydrate levels in seeds for home use by UV-visible spectrophotometer. Asian J. Pharm. Anal. 2, 104–105 (2012)

K.C.S. Pillai, Some new test criteria in multivariate analysis. Ann. Math. Stat. 26, 117–121 (1955)

S.S. Wilks, Certain generalizations in the analysis of variance. Biometrika 24, 471–494 (1932)

J. Crank, The Mathematics of Diffusion (Oxford University Press, London, 1956)

G.R. Luz, N.C. Pereira, C.M.G. Andrade, L.M.deM. Jorge, P.R. Paraíso, Scientific note: mass transfer coefficient in the drying of soybean meal. Braz. J. Food Technol. 12, 92–96 (2009)

A. Dutta, R. Mukherjee, T. Sarkar, Z. Pinar, R. Chakraborty, A linear driving force (LDF) approximation of moisture uptake kinetics in soybean. Int. J. Agric. Food Sci. Technol. 5, 203–210 (2014)

M.R. González-Centeno, F. Comas-Serra, A. Femenia, C. Rosselló, S. Simal, Effect of power ultrasound application on aqueous extraction of phenolic compounds and antioxidant capacity from grape pomace (Vitis vinifera l.): experimental kinetics and modeling. Ultrason. Sonochem. 22, 506–514 (2015)

R. Chopra, D.N. Prasad, Standardization of soaking conditions for soybean seeds/cotyledons for improved quality of soymilk. Indian J. Anim. Sci. 64, 405–410 (1994)

A. Gowen, N. Abu-Ghannam, J. Frias, J. Oliveira, Influence of pre-blanching on the water absorption kinetics of soybeans. J. Food Eng. 78, 965–971 (2007)

M. Garcia-Alonso, S. de Pascual-Teresa, C. Santos-Buelga, J.C. Rivas-Gonzalo, Evaluation of the antioxidant properties of fruits. Food Chem. 84, 13–18 (2004)

D. Malencic´, J. Cvejic´, J. Miladinovic, Polyphenol content and antioxidant properties of colored soybean seeds from central Europe. J. Med. Food. 15, 89–95 (2012)

M.M. Ramadan, M.A. Elbandy, M. Fadel, K.Z. Ghanem, Biotechnological production of volatile and non-volatile antioxidant compounds from fermented soybean meal with Trichoderma sp. Res. J. Pharm. Biol. Chem. Sci. 5, 537–547 (2014)

S. Siah, J.A. Wood, S. Agboola, I. Konczak, C.L. Blanchard, Effects of soaking, boiling and autoclaving on the phenolic contents and antioxidant activities of faba beans (Vicia faba l.) differing in seed coat colours. Food Chem. 142, 461–468 (2014)

L.K. Karr-Lilienthal, C.T. Kadzere, C.M. Grieshop, G.C. Fahey Jr., Chemical and nutritional properties of soybean carbohydrates as related to nonruminants: a review. Livest. Prod. Sci. 97, 1–12 (2005)

L.K. Karr-Lilienthal, C.M. Grieshop, J.K. Spears, G.C. Fahey Jr., Amino Acid, carbohydrate, and fat composition of soybean meals prepared at 55 commercial U.S. soybean processing plants. J. Agric. Food Chem. 53, 2146–2150 (2005)

H.E. Snyder, T.W. Kwon, Soybean Utilization (Van Nostrand Reinhold Company Press, New York, 1987)

I.M.L.B. Avila, C.L.M. Silva, Modelling kinetics of thermal degradation of color in peach puree. J. Food Eng. 39, 161–166 (1999)

R.T. Warne, A primer on multivariate analysis of variance (MANOVA) for behavioral scientists. Pract. Assess. Res. Eval. 19, 1–10 (2014)

J.P. Stevens, Applied Multivariate Statistics for the Social Sciences (Lawrence Erblaum, Mahwah, 2002)

E. Rigo, J.L. Ninow, M. di Luccio, J.V. Oliveira, A.E. Polloni, D. Remonatto, F. Arbter, R. Vardanega, D. de Oliveira, H. Treichel, Lipase production by solid fermentation of soybean meal with different supplements. Food Sci. Technol. 43, 1132–1137 (2010)

Acknowledgements

The study is financially supported by University Grants Commission (New Delhi, India) under the scheme “Basic Science Research Fellowship”. RM wants to acknowledge Abhijit Gupta, SQC & OR Unit, Indian Statistical Institute, Kolkata for his critical suggestions regarding the statistical analysis.

Author information

Authors and Affiliations

Contributions

RM collected, read and organized all the experimental data and drafted the manuscript. AD and RC revised the manuscript critically for necessary intellectual content, reviewed the content and gave final approval of the version to be published. All authors have read and approved the final manuscript.

Corresponding author

Rights and permissions

About this article

Cite this article

Mukherjee, R., Chakraborty, R. & Dutta, A. Soaking of soybean meal: evaluation of physicochemical properties and kinetic studies. Food Measure 13, 390–403 (2019). https://doi.org/10.1007/s11694-018-9954-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9954-6