Abstract

The article aims to investigate the influence of cryogenic and ambient grinding on powder quality of king chilli (Capsicum chinense L.). The grinding experiments were performed using a laboratory scale ball mill. Quality of the powders was accessed by measuring the properties such as densities, Hausner ratio, compressibility index, particle size distribution, colour change, microstructural changes, and mineral compositions. Bulk density (483 kg m−3) and tapped density (556 kg m‒3) of ambient ground powder was relatively higher than that of cryo-ground powder, (bulk density 414 kg m‒3 and tapped density 480 kg m‒3). However, Hausner ratio and compressibility index of ambient ground chilli powder were significantly lower than that of cryo-ground powder. The surface morphology, shape, and size of particles of cryo-ground powder were comparatively smoother, regular and smaller in size. Moreover, the major mineral (K) content and the colour (redness, yellowness, and lightness) were found to be relatively superior for cryo-ground powder. The overall results showed cryogenic grinding provides a better and finer quality ground powder than the conventional grinding methods. The results of this study will provide the spice industries, an opportunity to select the better grinding method based on the flow and sensory quality of the powder. The powder properties may further be utilized in the process modelling and design of packaging, grinding and handling equipment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Spices are among the most demanding agricultural products in the world due to distinct pungency, aroma, taste and appetizing senses. The spices can be used for different purposes such as flavoring and preserving agent in foods, in pharmaceuticals and cosmetics. India is well known as “The Spice Bowl of the World” [1,2,3] and is the leading producer, exporter, and consumer of the finest quality of spices in the world. A total of 109 spices are reported by ISO, out of which India shares around 69% [4]. Chillies are one of the major spices produced in India which belong to the genus Capsicum of family Solanaceae. Chillies are globally known for its distinct sensory attributes such as pungency, flavour, and colour; hence, became an integral part of our diet. They can be used for various purposes such as to impart pungent flavour in food, natural plant colour, pharmaceutical ingredients, riot control spray and self-defence, especially for women. The pungent flavour of chillies is because of a chemical group of a related alkaloid called capsaicinoids which is present only in the genus Capsicum [5].

There are more than 400 different varieties of chillies found all over the world. King chilli (Capsicum chinense L.) is one the hottest chilli in the world and is cultivated mainly in the hilly terrain of Assam, India. It is also grown in other states of North-East India viz. Manipur, Nagaland and Mizoram and known by different local names, for example, Bhut Jolokia in Assam, Umorok in Manipur, Naga chilli in Nagaland, etc. This wonder spice has various varieties which are grown for condiments, vegetables, sauces and pickles purposes. Chilli plays an important role in our day today’s diet. Chilli is an inseparable spice item in everyone’s kitchen, because of its regular use as a condiment in different forms. Among the spices consumed, dried chilli fruits or its powder form constitute a major share. Since time immemorial, chillies are used for not only as a spice in cuisines but also as medicines and beverages for health problems for examples, as a pain reliever, high blood pressure and cholesterol, skin diseases, and as an appetizer [6]. The red colour of chilli is because of a pigment known as ‘Capsanthin,’ whereas its biting pungency is attributed to ‘capsaicin’ [7]. In the commercial market, chilli is popular in powder form.

Grinding is one of the critical unit operations for size reduction of a sample. However, there are high chances of quality deterioration of powder due to heat generation during the grinding process [8, 9]. Reduction of size after grinding increases the available surface area of fine ground product that ultimately helps to increase the higher availability of constituents such as flavours, fragrance, nutrients and other volatile components. Size reduction also aids in the easy mixing of ingredients, transportation as well as storage which are major process parameters used in different industries viz. chemical, foods, agricultural, pharmaceuticals, etc. Due to higher moisture and volatile oil or fat content, grinding of spices by conventional grinding techniques always have a disadvantage of distorting the natural qualities of spices such as nutritional, flavour and medicinal properties because of heat generation during the process [10,11,12]. These undesirable problems of conventional grinding can be overcome by adopting cryogenic grinding technique in which spices are ground at a very low temperature (lower than their glass transition temperature) by using cryogens such as liquid nitrogen (LN2) and liquid carbon dioxide (commonly used for food products) to get high-quality ground powder [13].

Some of the advantages of cryogenic grinding of spices were acknowledged by various studies [4, 11, 14, 15]: (a) reduces spice oils oxidation and also increases stability of the volatile oil; (b) Super-fine grinding can achieved at very low temperatures as the product becomes highly brittle; (c) lowers the loss of volatile components; whereas, increases flavoring ability; (d) treatment at very low-temperature tends to lower the microbial contamination.

Several studies had been carried out on the cryogenic grinding of spices in the recent time which proved the superiority of this technique over conventional methods, showing enhancement in their volatile oil content or their valuable active flavouring components, better colour, finer size particles, more uniform distribution of particle size, higher surface area, lesser specific energy consumption, better output along with negligible air pollutants and microbial contamination as compared to normal grinding process [1, 4] The research on cryogenic and ambient grinding of fenugreek samples delineated that the requirement of specific energy for grinding and the powder flowability are influenced remarkably by the ambient and cryogenic grinding methods [16, 17].

Research on powder properties of king chilli and effects of different grinding parameters, for example, grinding temperature, moisture content, etc. are still scanty. Taking this into account, a comparative study on the cryogenic and ambient grinding of king chilli was undertaken with an emphasis on the powder properties viz. flowability, colour, particle size distribution (PSD), structural morphology and mineral composition. This will help in better understanding of the process mechanisms of handling, conveying, feeding, processing, mixing, packaging, transportation, etc. which are integral parts of an equipment designing. This study will not only help in economisation of the powder processing industries by providing them reliable information on powder flowability, the effect of the temperature–time combination of grinding to the powder properties etc. but also to the researchers, especially for cryogenic grinding of king chilli.

Materials and methods

Raw material

Dried king chilli samples were purchased from local sellers of Imphal, Manipur, India in the month of July 2016. Good quality of chillies was randomly selected for the analysis. The samples were manually cleaned by removing foreign matters, chaffs, broken and immature samples. The dried king chilli samples of mean dimensions; length (L) = 41.49 ± 0.78 mm, width (w) = 18.70 ± 0.34 mm, thickness (t) = 10.05 mm with a sphericity of 0.49 ± 0.08 (sample size 100) were subjected to cryogenic grinding using liquid nitrogen (LN2) as a cryogen. The cleaned samples moisture content of 11.10% dry basis (db) which was analyzed by the Entrainment method (US ISO 939) [18] was kept constant for further experimentations by packaging and storing the chillies inside moisture resistance bags under refrigeration (5 °C).

Making of chilli powder

A laboratory scale ball mill was used as a grinder to get the chilli powder at four different moisture contents and two different grinding temperatures of − 90 ± 3 °C (well below − 86.09 °C glass transition temperature of king chilli; unpublished work), 30 ± 2 °C (ambient and hand pounding). The powder after grinding was passed through a classified screen of opening size 500 µm (ASTM 35 mesh size). The cryogenically ground powder will hereafter be referred as cryo-ground powder, whereas, ambient ground powder for the powder obtained by grinding under atmospheric condition. Hand pounded samples were taken as a standard for comparing different properties of powders. For further analysis, ground powders were placed in moisture resistance polyethylene bags under refrigeration (5 °C).

Flowability of ground chilli powder

The flowability of ground chilli powders is directly or indirectly related to their Hausner ratio (Hr) and compressibility index (CI) values which are related to bulk and tapped densities of the ground powders.

Bulk and tapped densities of chilli powder

Both the bulk and tapped densities of the powders were measured by using a graduated measuring cylinder of volume 100 mL [16]. The chilli powder was poured into the cylinder using a regular funnel up to a fixed level of the cylinder and the upper layer was flattened carefully by using an iron strip. The volume and the weight of powder in the cylinder were marked and measured cautiously and the bulk density of king chilli powder was calculated by using the Eq. (1) [11].

where ρb is the bulk density (kg m−3), mp is the mass of the powder (kg), Vp is the volume of the powder (m3).

Similarly, the tapped density was determined by using the same cylinder of volume100 mL and pouring the powder carefully into the cylinder up to the fixed level and then manually tapping the cylinder vertically by hand for six minutes (180 taps) [19, 20]. Tapping was stopped at the time when the height of powder in the cylinder does not change with further tapping [21]. The tapped density of king chilli powder was measured by using Eq. (2) [11].

where ρt is the tapped density (kg m−3), mt is the tapped mass of the chilli powder (kg), Vt is the tapped volume of the chilli powder (m3).

Hausner ratio (Hr)

Hr of chilli powder can be defined as the ratio of the tapped density of powder to the bulk density of king chilli powder Eq. (3) [16]. This ratio relates well with the flowability of the powder.

where Hr is the Hausner ratio (dimensional number).

Compressibility index (CI)

CI gives concept about flowing characteristics of the powder and can be presumed as an alternative measure of bulk density, surface area, size and shape, and the materials cohesiveness because all of these are linked and affect with the value of CI. Both CI and Hr were determined by estimating both the bulk density and tapped density of the ground powder. CI value (dimensionless) was measured by Eq. (4) [16].

Particle size analysis

The parameters that decide the quality of a ground food powder are fineness or size of the particles, uniformity in size distribution, and physicochemical properties. The particle size (µm), particle size distribution (PSD) and specific surface area (cm2 cm−3) of cryo-ground, ambient and hand pounded chilli powders were analysed based on laser diffraction principle with the help of a Laser Particle Size Analyser (Fritsch Analysette 22; MicroTech Plus, Germany) which was connected to a computer system having analysis software ‘MaScontrol’. Through the application of special algorithms, MaScontrol software enables an analysis based on Fraunhofer theory. It provides an opportunity to analyse different mean diameters of the ground powders viz. arithmetic, geometric, harmonic, quadratic square mean diameters, mode, and median; PSD and specific surface area. It also helps to examine the statistical parameters of size reduction of the powders such as coefficient of variation, skewness, kurtosis and uniformity. The comparisons were made between the three representative powder samples using the above-mentioned particle size analysis parameters.

Colour

The surface colour of the whole king chilli, as well as the ground king chilli powders, was directly analyzed as reflected colour in the Hunter Lab (L, a, b) colour scales using Chromameter CR-400 Colourimeter (Konica Minolta Sensing; Inc., Japan). Lightness “L” ranging from 0 for black to 100 for white, “a” denotes redness when positive and greenness when negative, and “b” denotes yellowness at positive value and blueness at a negative value. The whole king chilli sample was considered as a standard to measure the total colour difference (ΔE*) Eq. (5) [12].

where ΔE* is the colour difference between whole king chilli sample; L1, a1, b1 is the values of king chilli powders ground by different grinding methods; L2, a2, b2 is the values of whole king chilli sample.

Analysis of surface morphology and mineral composition of the powder

Scanning electron microscope (SEM) (Model EVO 60; Carl ZEISS SMT, Germany) was employed to analyse the topographical characteristics of the surface and its regularity, size and shape of the powder particles using the analysis software (SmartSEM). As a part of sample preparation technique, the sample was adhered with a carbon tape and the gold–palladium alloy coating was done to the sample (to make it conductive) in a coating machine for 10 min under pressurised argon gas (4 to 10 torr). The major mineral constituent that is potassium of the chilli powders was determined using SEM–EDX technique that was accompanied by an investigation software INCA PentaFET × 3 (Oxford Instrument, UK).

Statistical analysis

The experiments were performed in triplicates. All the experimental data were analysed statistically by using statistical software Statistical Package for the Social Sciences (SPSS) (IBM Corporation, USA, Version 20.0). The significant difference among the mean values was analysed using ANOVA (Analysis of variance) with the help of Dunkan test. Each significant value was denoted by levels of significances (a–d) and considered significant at p < 0.05.

Results and discussion

Flowability

The grinding conditions of chilli tremendously affected the flowability of the chilli powders. The values of flow parameters were increased with the fall in grinding temperature, i.e., Hausner Ratio (Hr) (from 1.11 for hand pounded to 1.16 for cryogenic) and Compressibility Index (CI) (from 10.31 to 13.79), that indicates a reduction in cohesiveness (Table 1). The least value of Hr, i.e., 1.11 among the ground powders was noted for hand pounded powder (depicting comparatively less cohesiveness), whereas the highest Hr was 1.16 (relatively more cohesive) for cryo-ground powder. Food powders and their flowability can be categorised according to the value of Hr: free-flowing (Hr of 1.00–1.25), slightly flowing (Hr of 1.25–1.40) and cohesive (Hr of 1.40); therefore, the king chilli powders can be represented as a free-flowing powder [22,23,24]. Further, with the decreased of grinding temperature the bulk and tapped densities also decreased, i.e., when the methods adopted from hand pounding to cryogenic as shown in Table 1.

The reasons for these results can be described by the following concept: the decrease in the temperature of grinding caused the reduction in size of ground particles or rise in the value of specific surface area that may lead to more cohesiveness, as the chance to build inter-particle bonding and other interactions between the particles increased due to ease accessibility of the binding sites. The results obtained for flowability (Hr and CI) are in line with the several studies on the powders [11].

Particle size, particle size distribution (PSD) and specific surface area

At a lower grinding temperature of − 90 °C, cryogenic grinding, fine ground chilli powder was obtained as compared to those obtained from ambient grinding and hand pounding. The average particle diameters (arithmetic mean) of the powder obtained by ambient grinding and hand pounding techniques were 27.56 and 37.75% bigger than cryo-ground powder, respectively (Table 2). Above all, it can be seen that particle size showed a significant dependency on grinding temperature. Similar results were obtained for cumin [25], cassia [8] and black pepper [11].

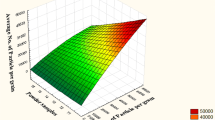

A substantial rise in the specific surface areas of the ground powder was found (3278.56 and 4326.41 for hand pounded and ambient grinding respectively, to 24181.55 cm−2 cm−3 when adopted cryogenic grinding), as the temperature and time of grinding went down as demonstrated in Table 2 (p ≤ 0.05). When the temperature of grinding reduces, the material becomes more brittle (glassy) below its glass transition temperature − 86.09 to − 89.40 °C (unpublished work) that breaks the material into small pieces on receiving small smashing force and lead in a particle of smaller size with larger specific surface area [11]. With the increment in the surface area of the ground particles, the chance to build inter-particles bonding as well as their interactions due to rise in the accessibility of particles binding sites increases. A better powder quality having smaller particle size and larger specific area (17.96 µm and 24181.55 cm−2 cm−3 respectively) was found for cryogenic grinding as compared to ambient and hand pounding methods (Table 2).

The difference in the particle size distribution (PSD) of the king chilli powders obtained from hand-pounding, ambient and cryogenic grinding techniques with appropriate accumulative mass fractions are represented in Fig. 1a–c in which the red, blue and black colour lines show PSD of the three consecutive measurements, i.e., the accumulative mass fraction of the ground powders against the allotted range of size, on the other hand, the occurrence frequency of a specific size particle was denoted by the rectangular bar histograms.

In Fig. 1a–c the abscissas describe the particle size (µm), and ordinates enumerate to the frequencies of the particular size of particles by right ordinate (dQ3 (×) [%]) and the progressive data of flow of powder by left ordinate (Q3 (×) [%]). It also shows that by lowering the grinding temperature finer powders were produced and the particle size distributions were right-skewed and among the distributions, the highest peakedness was obtained for the cryo-ground powder. As the grinding temperature goes down, the brittleness of the material increases which has resulted in the finer powder with higher uniformity.

Colour

The grinding temperatures substantially affected the total colour difference of ground powders. It is evident from Table 3 that there is a significant drop in the value of the total colour difference of ground chilli powder obtained from cryogenic grinding method to hand pounding method, as the processing temperature increases. The positive value of ‘a’ decreases from 17.54 ± 0.04 (cryo-ground powder) to 12.85 ± 0.41 (hand pounded powder), that means the redness of ground chilli powder decreases as the grinding temperature increases. A similar pattern was noticed for positive ‘L’ value and ‘b’ values, that is lightness and yellowness qualities of ground powders were deteriorated as grinding temperature rises. These results are in good agreement with the studies for black pepper [1, 26], cumin [15] and cassia [8].

Morphological analysis and mineral composition of the powders

SEM micrographs are shown in Fig. 2a–c confirm the outcomes of particle size and particle size distribution (PSD) discussed above. From these Fig. 2a–c micrographs of resolution 200 µm, it could be revealed that with the increase in the grinding temperature, fineness, surface smoothness and homogeneity of the powder particles were decreased. The cryo-ground powder was more uniformly distributed as compared to the powders obtained by other two techniques. As the particle size reduces, sphericity and surface regularity were increased (Fig. 2) resulting in more cohesiveness of the bulk powder. Higher cohesiveness for the bulk powders was observed when there is smaller deviation of particle shape from sphericity that was observed to the powders of smaller size [19]. Surface with the highest roughness, the smallest specific surface area and the lowest uniformity were detected for hand pounded ground-powder as shown in Fig. 2c.

The major mineral constituent potassium (K), in weight (%) and atomic (%), of the ground powders was significantly dependent on the grinding method which is indicated by the results in Table 4. Calcium (Ca) and iron (Fe) minerals were also found; however, their quantity was too less such that it cannot be presented in the graph. The mineral content of the cryo-ground powder was considerably higher (9.36 by wt% and 3.51 by at.%) as compared to the powders obtained by other techniques. SEM-EDX spectra for the cryo-ground chilli powder is shown in Fig. 3, the highest peaks were obtained for mineral K (potassium).

Conclusions

The flowability properties such as Hr, CI, bulk density and tapped density of powders obtained by cryo-grinding, hand pounding, and ambient grinding had significantly different values. Most of the powders were classified as a free-flowing powder. Moreover, finer particle size, higher uniformity and larger specific surface area of ground powder were recorded for cryo-ground powder than that of hand pounded and ambient ground powder. Better colour retention, smoother and more regular surface along with higher mineral content (K) of the cryo-grinding powder concluded the superiority of cryogenic grinding technique over conventional counterparts.

References

B.M. Ghodki, T.K. Goswami, Thermal and mechanical properties of black pepper at different temperatures. J. Food Process Eng. 40, e12342 (2017)

B.M. Ghodki, T.K. Goswami, DEM simulation of flow of black pepper seeds in cryogenic grinding system. J. Food Eng. 196, 36–51 (2017)

R. Gayathri, M. Saravanan, A Study on the Performance of major spices in India. Asia Pac. J. Manag. Entrep. Res. 3, 37–46 (2014)

S. Balasubramanian, M.K. Gupta, K.K. Singh, Cryogenics and its application with reference to spice grinding: a review. Crit. Rev. Food Sci. Nutr. 52, 781–794 (2012)

P.G. Hoffman, M.C. Lego, W.G. Galetto, Separation and quantitation of red pepper major heat principles by reverse-phase high-pressure liquid chromatography. J. Agric. Food Chem. 31, 1326–1330 (1983)

S.S. Pawar, N.V. Bharude, S.S. Sonone, R.S. Deshmukh, A.K. Raut, A.R. Umarkar, Chillies as food, spice and medicine: a perspective. Int. J. Pharm. Biol. Sci. 1, 2230–7605 (2011)

R. Arimboor, R.B. Nataranjan, K.R. Menon, L.P. Chandrasekhar, V. Moorkoth, Red pepper (Capsicum annuum) carotenoids as a source of natural food colours: analysis and stability: a review. J. Food Technol. 52, 1258–1271 (2015)

B.M. Ghodki, T.K. Goswami, Optimization of cryogenic grinding process for cassia (Cinnamomum loureirii Nees L.). J. Food Process Eng. 39, 659–675 (2016)

P. Barnwal, K.K. Singh, A. Mohite, A. Sharma, S.N. Saxena, Influence of cryogenic and ambient grinding on grinding characteristics of fenugreek powder: a comparative study. J. Food Process. Preserv. 39, 1243–1250 (2015)

T.K. Goswami, B.M. Ghodki, Cryogenic grinding of cassia. International conference on advance chemical, biological and environmental engineering pp. 242–249, 2015

B.M. Ghodki, T.K. Goswami, Effect of grinding temperatures on particle and physicochemical characteristics of black pepper powder. Powder Technol. 299, 168–177 (2016)

B.M. Ghodki, T.K. Goswami, J. Essent, Physico-thermal and flavoring characteristics of essential oil of cassia. Oil Bear. Plants 19, 854–862 (2016)

B.M. Ghodki, K.C. Kumar, T.K. Goswami, Modeling breakage and motion of black pepper seeds in cryogenic mill. Adv. Powder Technol. (2018). https://doi.org/10.1016/j.apt.2018.01.023

J.S. Pruthi, Chemistry, Natural Antimicrobials from Plants: Spices and Condiments Chemistry, Microbiology: Microbiology Technology (Academic Press, San Fransisco, 1980)

K.K. Singh, T.K. Goswami, Studies on cryogenic grinding of cumin seed. J. Food Process Eng. 22, 175–190 (1999)

M. Meghwal, T.K. Goswami, Ambient and cryogenic grinding of fenugreek and flow characterization of its powder. J. Food Process Eng. 36, 548–557 (2013)

M. Meghwal, T.K. Goswami, Comparative study on ambient and cryogenic grinding of fenugreek and black pepper seeds using rotor, ball, hammer and Pin mill. Powder Technol. 267, 245–255 (2014)

B.M. Ghodki, A.D.S. Tangirala, T.K. Goswami, Moisture dependent thermal properties of cassia. Cogent Food Agric. 2, 1227110 (2016)

E.C. Abdullah, D. Geldart, The use of bulk density measurements as flowability indicators. Powder Technol. 102, 151–165 (1999)

A. Santomaso, P. Lazzaro, P. Canu, Powder flowability and density ratios: the impact of granules packing. Chem. Eng. Sci. 58, 2857–2874 (2003)

J.A. De Jong, A.C. Hoffmann, J. Flinkers, Properly determine powder flowability to maximize plant output. Properly determine powder flowability to maximize plant output. Chem. Eng. Prog. 95, 25–34 (1999)

M. Leturia, M. Benali, S. Lagarde, I. Ronga, K. Saleh, Characterization of flow properties of cohesive powders: a comparative study of traditional and new testing methods. Powder Technol. 253, 406–423 (2014)

E. Domian, J. Cenkier, Flowability and homogeneity of food powders with plated oil ingredient. J. Food Process Eng. 36, 626–633 (2013)

H.Y. Saw, C.E. Davies, A.H.J. Paterson, J.R. John, Correlation between powder flow properties measured by shear testing and Hausner ratio. Procedia Eng. 102, 218–225 (2015)

K.K. Singh, T.K. Goswami, Design of a cryogenic grinding system for spices. J. Food Eng. 39, 359–368 (1999)

C.T. Murthy, S. Bhattarcharya, Cryogenic grinding of black pepper. J. Food Eng. 85, 18–28 (2008)

Acknowledgements

The author would like to acknowledge the Technicians of all the laboratories involved with the experimentations at Indian Institute of Technology Kharagpur, 721302 India. The opinions expressed in this article do by no means reflect the official opinion of the IIT Kharagpur and Indian Council of Agricultural Research or their representatives.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Singh, S.S., Ghodki, B.M. & Goswami, T.K. Effect of grinding methods on powder quality of king chilli. Food Measure 12, 1686–1694 (2018). https://doi.org/10.1007/s11694-018-9784-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9784-6