Abstract

In this study, the effect of different carriers including maltodextrin (MD), gum arabic (GA) and whey protein concentrate (WPC) and their combination on the production yield, moisture content, bulk and tapped density, solubility, wettability, flowability indexes (Hausner ratio, compressibility, angle of repose), hygroscopicity and deliquescence process, color index and microstructure of spray dried sour cherry juice concentrate was investigated. The results showed increased powder production yield with a mixture of MD and GA (40:10 weight ratio). Use of 5% WPC in combination with the GA and MD increased powder production yield from 45.66 to 55.66% and 42.23 to 52.86%, respectively. Bulk density, tapped density, solubility and wettability significantly decreased with increasing concentration of WPC. Also, the use of 30% WPC in combination with the MD or GA increased particle size substantially. The surface morphology of the particles (with a smooth, shrunk and dented surfaces) was affected by feed composition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sour cherry (Prunus cerasus L.) is native to Iran and its juice is widely used in the food industry. It can be used in the jellies, jams, wine and other drinks [1]. Sour cherry juice is a rich source of anthocyanins, especially cyanidin 3-glucoside [2]. Anthocyanins are polyphenolic compounds and water soluble pigments that are widely available in nature. Atherosclerosis, cardiovascular disease and cancer prevention can be noted as their health benefits [3, 4]. Also, use of the sour cherry juice concentrates decreased lipid, serum glucose and blood pressure in the people with diabetes Type 2 [5]. However, fruits are seasonal and perishable products with a short shelf life that cause problems in storage, transport and their use. Therefore, much research has been done to increase the shelf life of these products. One of these methods, is moisture removing and increasing chemical and biological stability by drying. Among the different methods of drying, spray drying is a common, economic and flexible method for conversion of variety of the liquid products (such as extract, syrup, fruit juices and concentrates) to powder form [6].

The benefits of juice powders can be mentioned as chemical and biological stability and ease of transportation, packaging, storage and use as additives in various products compared to the liquid forms [7,8,9]. Spray drying process is mainly under the influence of various parameters such as the composition of raw material, type, composition and carrier concentration, inlet and outlet air temperatures, rheological properties, feed rate, inlet air humidity, atomizer type and drying air velocity [10]. Several indicators assessed to determine process efficiency and quality of spray dried powder. Parameters such as moisture content, water activity, density, wettability, solubility and hygroscopicity are the most qualitative indicators of spray dried powder [11]. Moisture content is an important property of the spray dried product and plays an important role in determining its flowability, stickiness and storage stability [12]. Water activity is the availability of free water in a food product. Higher water activity indicates more biochemical or microbiological reactions and shorter storage stability [13]. In relation to the density of powders, economics and functional reasons has increased the importance of determining this factor as a physical property. Also, packaging, transportation and the amount of material needed to fill a certain volume of the package will be influenced by the density [14]. Also, the measurement of bulk density and tapped density are essential in determining some of the flowability indexes (such as the Hausner ratio and compressibility index). Evaluation of flowability behavior in addition to the type and structure of the particles, can be used for determination of usability, packaging and transport conditions by the spray dried powder. Solubility is an important functional property of food powders (especially in the production of instant products) [15]. Wettability is one of the main physical indices which affect the reconstitution rate of powders in water [16]. Moisture absorption from the surrounding environment has a negative effect on the physicochemical properties, flowability and stability of food powders. For this reason, hygroscopicity is one of the most important factors determining the stability and shelf life of the spray dried powders in inappropriate conditions of packaging and storage [17].

Spray drying of sour cherry juice concentrate as well as other concentrates, syrup and fruit juices is very difficult because it is a rich source of low molecular weight sugars, organic acids which have low glass transition temperature. The most common solution to reduce the adhesion of these products, is use of high molecular weight drying aids such as gum arabic, and a variety of starch and its derivatives such as maltodextrin [17,18,19,20,21,22,23]. Each of these carriers show advantages and disadvantages in terms of cost, process efficiency and effect on the characteristics of the final product. Gum arabic shows better performance than maltodextrin due to the higher glass transition temperature, but its high cost compared to maltodextrin is its disadvantage [24, 25]. For this reason different studies were performed on the effects of combining or replacing part of the carrier with other carriers or compounds with the purpose of modifying the surface structure, reducing the hygroscopicity, degree of caking, adhesion and increasing powder production yield. Among these studies application of protein as alternative/complementary to the maltodextrin in various spray dried products can be noted. These compounds are used due to good surface activity, preferential migration to the particle surface, connection ability to each other via hydrophobic interactions and film forming ability with low hygroscopicity. Due to these features, application of small amounts of proteins increase the production yield of different adhesive products [15, 26,27,28]. Since the effect of different carrier combination (maltodextrin, gum arabic and WPC) on spray drying process of the sour cherry juice concentrate has not been studied, the aim of this study was to evaluate the effect of the combination of the carriers on the production yield, physicochemical characteristics and surface morphology of the spray dried sour cherry juice concentrate powder.

Materials and methods

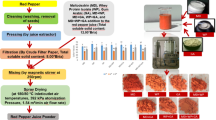

Sour cherry juice concentrate

To prepare the concentrate, fresh sour cherries were purchased from local market. Sour cherry juice produced by pressing followed by filtration and clarification. Sour cherry juice concentration was processed by using a vacuum evaporator at 35 °C to reach final Brix 61 (61°Bx). The soluble solids were determined by using a refractometer (MASTER-80H, ATAGO, Japan), pH and acidity of the samples were measured according to the method described by AOAC [29] and were 61, 3.35 and 7.94%, respectively.

Feed solution preparation

According to the initial trial and error, each carrier of MD (with dextrose equivalent of 18–20) or GA and their combination were used in a ratio of 50% based on wet weight of the sour cherry juice concentrate (BX = 61). To evaluate the effect of carriers, the weight ratio of MD to GA (4:1, 1:1 and 1:4) and whey protein concentrate (in a ratio of 5, 10, 15 and 20%) were used as supplement of MD or GA in the feed production. The carrier was completely solubilized in the distilled water using a magnetic stirrer (L-81, Labinco B.V, The Netherlands) and then mixed with the sour cherry juice concentrate. Finally, for all the samples, feed solution with a solid content of 30% was used in the spray drying process.

Spray drying

In this study, a pilot-scale spray dryer (Maham sanat, Neyshabur, Iran) was used. It has a cylindrical chamber with a bottom diameter of 1 m and total height of 2 m. The dryer equipped with a peristaltic volumetric feed pump with variable feed rate and maximum fluid capacity of 3 l/h and a pressure of 1 bar to send feed to atomizer. A rotary atomizer with 5 cm diameter was used for spraying of the feed solution into the dryer chamber. In all examinations, the inlet air temperature, atomizer rotational speed, feed flow rate, feed temperature and atomizer pressure were kept constant at 170 °C, 18,000 rpm, 12 ml/min, 25 ± 1 °C and 4.2 ± 0.1 bar, respectively. In all experiments, the outlet air temperature ranged from 81.3 to 84.7 °C. Inlet air as co-current with feed was applied for the drying process. The collected powder placed in the desiccator to achieve a constant temperature and preventing humidity change until used. Powders in the conical part of dryer were collected with sweeping process. The remaining powder on the internal wall of drier also was discarded due to heat damage. Distilled water fed to the dryer 10 min before and after each process.

Powder production yield

The production yield was calculated as the ratio of the mass of solids accumulated after spray-drying to the amount of solids in the feed solutions (dry basis).

Moisture content

About 2 g of the powder were placed in a petri dish in an air drier oven for 2–3 h. The moisture content of powder was determined by drying at the temperature of 105 °C in the oven until a constant weight was obtained. Finally the samples were cooled in desiccators and weighed. The moisture content was calculated by percentage of weight difference between samples before and after the oven drying [30].

Bulk density and tapped density

Bulk and tapped density of powders were determined by the method of Jangam and Thorat [31] with some modifications. Bulk density was determined by gently adding 2 g of the powder into an empty 10 ml graduated cylinder and the ratio of mass of the powder and the volume occupied in the cylinder was determined as the bulk density value. Then by using a tapped densitometer, continuous beats were applied to the cylinder (an average of 400 beats), as long as the volume changes of powder stop and the tapped density measured.

Flowability (static angle of repose)

An amount of 10 g of the powder weighed using a digital balance (Saturius, the BM150, Germany) and was dumped on a flat horizontal surface from a fixed height through a funnel with 12 mm outlet diameter, to obtain a cone. Angle formed between the side surface and the base of the cone was measured and represented as repose angle [32].

Compressibility and Hausner ratio

Cohesiveness and compressibility of the powders was evaluated by the Hausner ratio (HR) and Carr index (CI), respectively [33]. Both CI and HR indexes were calculated from the amount of bulk and tapped density of the powders by using Eqs. 1 and 2 as follows:

where BD is the bulk density, TD is the tapped density of the powders, respectively.

Table 1 shows the empirical relationship between the values of cohesiveness and compressibility with flowability behavior of powders, which presented based on the previous research [32, 33].

Solubility

The solubility of spray dried powders was determined using the procedure developed by Cano-Chauca et al. [34] with some modifications. 1 g of the powder (dry basis) was dispersed in 100 ml distilled water by blending at 400 rpm for 4 min using a magnetic stirrer. The resulting solution was then centrifuged at 3000×g for 4 min. A 25 ml aliquot of the supernatant was pipetted and transferred to a pre weighted petri dish and then oven-dried at 105 °C for 4–5 h. The weight of dried solid matter as a percentage of the initial powder was used in order to determine the solubility in water.

Wettability

The wettability of the powders was determined using the method of Fuchs et al. [35] with some modifications. The powder samples (0.2 g) were poured over the surface of 100 ml of distilled water at 20 °C without agitation. The time taken for powder particles to submerge so that no particles are left on the surface was recorded as the wettability index.

Hygroscopicity

The hygroscopicity of the powders was determined as grams of adsorbed moisture per 100 g dry powder during 7 days storage at room temperature (30 °C) and relative humidity of RH = 75% in a desiccator with saturated NaCl solution [36].

Color

The color characteristics of the produced powder was measured by L*, a* and b* indexes. Imaging of the samples was done by a digital camera (Canon Powershot A3400) with sensitivity of 16 megapixel in a chamber designed for photography in stationary condition. Each of the powder samples was separately photographed and the photos were saved in the JPEG format. Analysis of the samples was performed using Image J software (http://imagej.net). The hue angle and chroma were calculated as follows:

Scanning electron microscopy (SEM)

The structure of the powder particles was evaluated using a scanning electron microscope (HITACHI PS-230, Japan). The samples were placed separately on an aluminum plate using two-sided adhesive tape. Then the particles were coated with a thin layer of gold. Finally the coated samples were observed under a microscope and surface structure of particles were evaluated.

Statistical analysis

One-way analysis of variance (ANOVA) (using SPSS 19.0 statistical software, SPSS Inc., Chicago, IL) was used for the determination of the differences between different treatment. The results were expressed as the mean ± standard error (SE) and considered significantly different when (P < 0.05).

Results and discussion

Powder production yield

The powder yield is the main indicator for evaluating the economic and performance aspect of the process. The production yield of the sour cherry concentrate powder was varied between 42.2 and 57.1% (Fig. 1). In this study, use of 10% GA in combination with MD increased the production yield from 42.23 to 54.41%. Combination of MD and GA showed better performance on the yield production compared to using them alone (P < 0.05). These results are in agreement with the research of Fazaeli et al. [19] that studied the effect of MD with different dextrose equivalent (DE 6, 9 and 20), GA and percentage of replacing MD with GA on the drying yield of the black berry juice powder. In that study, the highest powder production yield was 82% for the mixture of MD (DE 6) and GA. Use of 5% WPC in combination with each of MD and GA substantially increased the recovery percentage of the sour cherry concentrate powder (P < 0.05). This can be due to preferential migration of protein to the surface of the droplet/particles which form a protein rich film, thereby reducing the adhesion of the particles to each other and to the wall chamber. However, application of higher concentrations of WPC did not show a positive effect on the production yield.

These results are in agreement with the research of Shi et al. [28] that studied the effect of substitution of MD with WPI on the production yield of the honey powder. According to their research, no powder was produced by the replacement of 40% soluble solids of the honey with MD. However, replacing of 0.1, 0.25 and 0.5% of MD with WPI increased the production yield from 0 to 7.6, 47.6 and 57.4%, respectively. Replacing more than 2.5% MD with WPI had no effect on the production yield. Other similar findings that can be mentioned were evaluated the effect of WPI [37], pea protein isolates and sodium caseinate [15], WPI [26], WPI [27], WPC [21] and WPC [38], alone or in combination with other carriers on the production yield of honey, fructose and sucrose, bayberry juice, soy sauce, tamarind pulp and beetroot juice concentrate powders.

Moisture content

The moisture content of the spray dried sour cherry concentrate powders was varied between 3.46 and 5.57% (Table 2). In this study, increasing replacement of MD with GA reduced the moisture content of powders (P < 0.05). The use of MD with high DE created a more cohesive structure in particles than does GA, which reduces the rate of moisture removal during the drying and thus increases the final moisture content. These findings are consistent with the research of Fazaeli et al. [19] that reported by increasing replacement of MD with GA, the moisture content of the black berry juice powder was decreased. However, Şahin-Nadeem et al. [39] observed more moisture content in the instant soluble sage powders with GA. This result is due to higher water retention capacity of the hydrocolloids compared to the starch derivatives. However, by increasing replacement of MD and GA with WPC the moisture content of the samples increased significantly (P < 0.05). This effect can be attributed to the high-speed film formation of proteins [15] and high water retention capacity of the protein in the amorphous state [21].

The results of this study were in agreement with the research of Shi et al. [28] that studied the effect of reducing moisture content of the honey powders as a result of reducing the concentration of WPI. But, Wang et al. [27] and Botrel et al. [17] did not observe any changes in the moisture content of the dried soy sauce powder and spray dried fish oil by increasing MD replacement with WPI. These different results indicate that the moisture content of the powders depend on the composition of the raw material, type, and concentration and composition of the carriers.

Bulk and tapped density

Table 2 shows the bulk and tapped density of the spray dried cherry juice concentrate powder, under the influence of type and combination of the carriers. The bulk and tapped density of the spray dried powders was different in the range of 0.246–0.425 and 0.889–0.586 g/ml, respectively. The samples based on MD and GA had the highest and the lowest bulk and tapped density, respectively. For example a complete replacement of MD with GA reduced the bulk and tapped density from 0.662 to 0.425 and 0.889 to 0.586 g/ml. Among different carriers, increasing the concentration of WPC had the greatest impact on reducing the amount of powder density (P < 0.05). This result is due to the film-forming ability of proteins, adhesion reduction, and production of thermoplastic particles, increase of feed viscosity and the volume of trapped air in particles [12, 34]. The above findings, is in agreement with the results of Fazaeli et al. [19], Shi et al. [28], Bhusari et al. [21] and Bazaria and Kumar [38] that studied the effect of type, concentration and composition of the different carrier on density of the black currant juice powder, honey, tamarind pulp and beetroot juice concentrate, respectively.

Solubility

Figure 2 shows the solubility of the spray dried sour cherry juice concentrate powder. Depending on the type and combination of carriers solubility of the powders were different from 83.38 to 95.55%. The powders contained MD showed higher solubility than the powders produced by GA as carrier. Among all samples the use of WPC in combination with each carrier of MD and GA led to the highest solubility reduction (P < 0.05). For example, using 20% WPC in combination with MD or GA reduced the solubility from 95.55 to 86.23% and 93.24 to 83.38%, respectively.

Several studies examined the effect of GA and MD on the solubility of spray dried products. In some of them, the solubility of spray dried product using MD as carrier was more than GA [34, 40], some less [19, 41] and in some cases no significant difference was observed. In general, the carrier effect on the solubility of spray dried powder can be dependent on the nature of the raw material, composition, carrier concentration and drying temperature. Also, formation of insoluble materials during drying process and sticking to the drying chamber can lead to reduced solubility of the powders [42]. The amount of insoluble material is variable depending on the raw material and carrier composition, possible reactions between them and drying air temperature. On the other hand, particle size and morphology are also among the factors that affect the solubility of the produced powders. For example, Ferrari et al. [43, 44] and Fazaeli et al. [19] reported that the powders with less diameter size are more soluble in water. This is because the smallest dimensions of the microparticles, enhancing the total surface exposed to the solvent. Wang and Zhou [22] studied the effect of different carriers such as a mixture of cellulose and MD or waxy starch and MD in the fixed ratio of 30% w/v on the solubility of soy sauce powder. The powders produced by MD showed the solubility of 97.9%, and by the addition of cellulose or waxy starch to MD this amount was reduced to 80%.

Wettability

Time of wettability of spray dried sour cherry concentrate powder was significantly influenced (P < 0.05) by the composition of the feed solution (Table 2). In this study, wettability of powders varied from 2.07 to 292.19 s. Among dried samples, the powders produced with MD had the highest wettability rate. However, use of WPC in combination with MD and GA (especially GA) caused significant reductions in the wettability of powders. Botrel et al. [17] also studied combined effect of different carriers on the powders wettability containing fish oil. Results indicate that with replacement of WPI with MD and inulin the time of wettability decrease from 226 to 130 and 112 s. It was believed that reduction in the wettability time was due to increase in the hydrophilic groups and reduction of oil on the surface of particles [23].

Flowability (angle of repose)

Table 3 shows the effect of different carriers on angle of repose of the sour cherry juice concentrate powder. Use of 5% WPC in combination with MD and complete replacement of MD with GA improved the flowability and reduced the angle of repose (P < 0.05). Type and concentration of carrier influenced the flowability of particles by affecting moisture content, cohesiveness, shape and morphology of the particles. Effect of GA and WPC on reducing the angle of repose can be due to larger size, and less adhesion of the particles. However, reduction in the friction force and contact area between the adjacent particles as a result of increasing particle size is one of the factors reducing the angle of repose in powders [45]. Increasing the angle of repose as a result of higher concentrations of WPC can be attributed to its effect on surface morphology and the moisture content of the powders. Similar findings was reported by Moreira et al. [46] that increasing the inlet air temperature and carrier concentration increased the flowability of acerola pulp powders.

Cohesiveness and compressibility

The compressibility index and Hausner ratio are important in determining the flowability of powders. Increase of these two indexes indicate high compressibility, cohesiveness and cause reduction in the flowability of powders [47]. In this study, use of 5% WPC in combination with the MD or GA reduced the cohesiveness and compressibility of the spray dried sour cherry juice concentrate powders (P < 0.05). This result is in agreement with the research of Chandralekha et al. [48] that studied the effect of different carriers (sodium caseinate, maltodextrin, whey protein and corn starch) on the flowability of the spray dried yeast powder. Among the carriers, combination of corn starch and whey protein had a better effect on the flowability of the samples. However, in another study the tamarind pulp powder produced by WPC compared with MD and GA showed better flowability and less cohesiveness due to the larger size, reduced surface contact, formation of inter particle connections and medium moisture content of the particles [21]. Surface morphology of the particles also had an effect on the flowability of powders. The particles with high shrinkage and wrinkled surface showed more inter-particle contact compared to the particles with smooth surfaces [49].

Hygroscopicity

The hygroscopicity of spray dried sour cherry juice concentrate powders significantly affected by the carrier type and combination (P < 0.05). Figure 3, shows hygroscopicity of the powders as affected by different carrier type and combination. The hygroscopicity of powders was varied from 19.06 to 25.13%. Complete replacement of MD with GA increased the hygroscopicity of powders. However, use of high concentrations of WPC in combination with each of the MD and GA reduced the hygroscopicity of powders. This result was due to film forming ability of the proteins with less cohesiveness and hygroscopicity. The hygroscopicity of sour cherry juice concentrate powders was near to the hygroscopicity amount of honey powder [28] and Jamun fruit juice [23] with hygroscopicity of 20.13–25.29% and 17–25.33%, respectively. The results of this study were in accordance with the findings of Tonon et al. [50], Shi et al. [28], Bhusari et al. [21], Manickavasagan et al. [41] and Bazaria and Kumar [38] that studied the effect of different carriers on the hygroscopicity of acai, honey, Jamun fruit juice, date syrup and beetroot juice concentrate powders, respectively.

Figure 4 shows the effect of surface moisture absorption on formation of liquid bridge, merging and finally, deliquescence process of the powders. Moisture absorbed mainly through formation of hydrogen bonds between the hydrogen atom of water and hydroxyl groups present in the amorphous areas of substrate [28]. Amount of hygroscopicity of particles depends on combination of raw material, type and carrier concentration, particle size, moisture content and glass transition temperature of product [51]. Due to the water-solubility of particles, liquid bridges are containing core ingredients. Moisture absorption by core materials increase the viscosity of the liquid bridges and their strong adhesion to each other [52]. Finally, depending on the type of raw material, moisture absorption can lead to full integration of particles to each other and the phenomenon of deliquescence [53]. However, evaporation of moisture from the liquid bridges between the particles cause formation of a stable solid bridges that this phenomenon is called sintering [54].

Color

Color is one of the important quality attributes of the powders. Table 4 shows the color index values under influence of the type and combination of various carriers. Samples contained GA showed lower lightness (L* value) than the powders produced with MD. Use of WPC in combination with MD and GA had no effect on the lightness of the samples. The a* value of the powders decreased with increasing concentrations of GA and application of WPC in combination with MD and GA. Decrease in a* value indicates a reduction of red color and a tendency to green color. Similar results obtained from the research of Bazaria and Kumar [38] and Daza et al. [55] that studied the effect of increasing concentration of WPC and GA on the color of beetroot juice concentrate powders and Cagaita fruit juice, respectively. However, tamarind pulp powder produced by WPC and GA showed higher a* value due to non-enzymatic browning reaction between reducing sugars and protein components [21].

The b* value of samples increased with increasing substitution of MD by GA and WPC. The hue angle of the powders produced with GA was significantly higher than the powders produced by MD. The Chroma index of sour cherry juice powder produced with MD was higher than GA. Also, application of WPC in combination with each carrier reduced Chroma of samples. In general, the final color of the product significantly influenced by the color of raw material, type and carrier concentration and drying air temperature.

Scanning electron microscopy (SEM)

Scanning electron micrograph showed significant effect of size and type of wall material composition on the surface morphology of the particles (Fig. 5a–g). Particles produced with MD showed more surface shrinkage than the samples produced with GA. Also, the average of particle size obtained with MD and GA was 42.65 and 51.43 µm, respectively (Fig. 6). Replacement of 10% MD with GA increased the surface shrinkage and average of particle size (46.27 µm). Use of 5% WPC in combination with MD and GA produces irregular particles with shrunk and dented surfaces (Fig. 5b, e). The average size of the produced particles increased from 42.65 to 48.69 µm and 51.43 to 57.88 µm, respectively (Fig. 6). Increasing shrinkage and dents of particles under the influence of WPC can be due to rapid formation of a protein crust in the early stages of droplets drying and diffusion of the water molecules from larger molecules of carrier [49]. Wang and Langrish [49], Botrel et al. [17] and Bhusari et al. [21] reported the production of irregular particles and increase in shrinkage and dent in the soy sauce powder particles, encapsulated fish oil and spray dried tamarind pulp powder as a result of using whey proteins in combination with different carriers. Figures 5 and 6, represents the effect of using 20% WPC in combination with MD and GA that produced spherical particles with smooth surfaces with larger size (65.44 and 85.54 µm respectively). Increasing the particle size with increasing WPC content can be attributed to the increased viscosity of the feed solution and production of the larger particles during atomization [21].

These results show the effect of type, concentration, viscosity and viscoelastic behavior of the wall material on the surface structure and morphology of the spray dried particles [17]. SHEU and Rosenberg [56], Jafari et al. [57] and Chandralekha et al. [48] observed that the particles produced with proteins had less dent and shrinkage compared with the carriers such as starch and its derivatives. Also, all the produced particles had intact wall without any cracks, which indicate the lack of fragility on the capsule walls and wall constituents’ stability against the mechanical stresses in the early stages of drying (expansion and swelling) [57].

Conclusion

In this study, the effect of different carriers and their combination on production yield, physical characteristics, deliquescence phenomenon and microstructure of the spray dried sour cherry juice concentrate was investigated. The results showed that the production yield of powders increased by using a combination of MD and GA as well as the use of WPC in combination with each of them. The moisture content, bulk and tapped density and color index of powders were affected by type and composition of the wall material. High concentrations of WPC in combination with MD and GA substantially reduces the solubility and wettability of the powders. Use of high concentrations of WPC in production of instant powder is not suitable. But addition of low concentration of WPC for production of powders with good flowability decreased the hygroscopicity of powders. Using a combination of MD and GA did not show any positive effect on reduction of the hygroscopicity and increasing the solubility of powders. The average particle size and surface morphology of the particles was significantly affected by the concentration of WPC. In general, application of low concentrations of WPC in combination with the MD or GA can increase the production yield along with maintaining appropriate physical and functional properties of the powders.

References

K.B. Belibağli, A.C. Dalgic, Int. J. Food Sci. Technol. 42, 773 (2007)

F. Blando, C. Gerardi, I. Nicoletti, Biomed. Res. Int. 2004, 253 (2004)

T. Tsuda, F. Horio, K. Uchida, H. Aoki, T. Osawa, J. Nutr. 133, 2125 (2003)

B. Jayaprakasam, G.A. Strasburg, M.G. Nair, Tetrahedron 60, 3109 (2004)

A. Ataie-Jafari, S. Hosseini, F. Karimi, M. Pajouhi, Nutr. Food Sci. 38, 355 (2008)

A. Gharsallaoui, G. Roudaut, O. Chambin, A. Voilley, R. Saurel, Food Res. Int. 40, 1107 (2007)

W.P. Oliveira, R.F. Bott, C.R.F. Souza, Dry. Technol. 24, 523 (2006)

A.K. Shrestha, T. Ua-Arak, B.P. Adhikari, T. Howes, B.R. Bhandari, Int. J. Food Prop. 10, 661 (2007)

A.M. Goula, K.G. Adamopoulos, Food Bioprod. Process. 90, 639 (2012)

S. Keshani, W.R.W. Daud, M.M. Nourouzi, F. Namvar, M. Ghasemi, J. Food Eng. 146, 152 (2015)

G.R. Chegini, B. Ghobadian, World. J. Agric. Sci. 3, 230 (2007)

A.K. Shrestha, T. Howes, B.P. Adhikari, B.R. Bhandari, LWT Food Sci. Technol. 40, 1593 (2007)

S.Y. Quek, N.K. Chok, P. Swedlund, Chem. Eng. Process. Process Intensif. 46, 386 (2007)

R.V. de Barros Fernandes, S.V. Borges, D.A. Botrel, Carbohydr. Polym. 101, 524 (2014)

M. Jayasundera, B. Adhikari, T. Howes, P. Aldred, Food Chem. 128, 1003 (2011)

E.K. Bae, S.J. Lee, J. Microencapsul. 25, 549 (2008)

D.A. Botrel, R.V. de Barros Fernandes, S.V. Borges, M.I. Yoshida, Food Res. Int. 62, 344 (2014)

A.M. Goula, K.G. Adamopoulos, Innov. Food Sci. Emerg. Technol. 11, 342 (2010)

M. Fazaeli, Z. Emam-Djomeh, A.K. Ashtari, M. Omid, Food Bioprod. Process. 90, 667 (2012)

M. Igual, S. Ramires, L.H. Mosquera, N. Martínez-Navarrete, Powder Technol. 256, 233 (2014)

S.N. Bhusari, K. Muzaffar, P. Kumar, Powder Technol. 266, 354 (2014)

W. Wang, W. Zhou, Food Chem. 168, 417 (2015)

S. Santhalakshmy, S.J.D. Bosco, S. Francis, M. Sabeena, Powder Technol. 274, 37 (2015)

A.M. Righetto, F.M. Netto, J. Sci. Food Agric. 86, 1202 (2006)

E.C. Frascareli, V.M. Silva, R.V Tonon, M.D. Hubinger, Food Bioprod. Process. 90, 413 (2012)

Z. Fang, B. Bhandari, Food Res. Int. 48, 478 (2012)

W. Wang, Y. Jiang, W. Zhou, J. Food Eng. 119, 724 (2013)

Q. Shi, Z. Fang, B. Bhandari, Dry. Technol. 31, 1681 (2013)

Association of A. O. A. C Chemists, Official methods of analysis. (Association of A. O. A. C Chemists, Arlington, 1990)

C. Turchiuli, M.T.J. Munguia, M.H. Sanchez, H.C. Ferre, E. Dumoulin, Powder Technol. 255, 103 (2014)

S.V Jangam, B.N. Thorat, Dry. Technol. 28, 1426 (2010)

B.R. Bhandari, N. Datta, B.R. D’Arcy, G.B. Rintoul, LWT Food Sci. Technol. 31, 138 (1998)

N. Jinapong, M. Suphantharika, P. Jamnong, J. Food Eng. 84, 194 (2008)

M. Cano-Chauca, P.C. Stringheta, A.M. Ramos, J. Cal-Vidal, Innov. Food Sci. Emerg. Technol. 6, 420 (2005)

M. Fuchs, C. Turchiuli, M. Bohin, M.E. Cuvelier, C. Ordonnaud, M.N. Peyrat-Maillard, E. Dumoulin, J. Food Eng. 75, 27 (2006)

Y.Z. Cai, H. Corke, J. Food Sci. 65, 1248 (2000)

B. Adhikari, T. Howes, A.K. Shrestha, B.R. Bhandari, Chem. Eng. Process. Process Intensif. 46, 420 (2007)

B. Bazaria, P. Kumar, Food Biosci. 14, 21 (2016)

H. Şahin-Nadeem, C. Dinçer, M. Torun, A. Topuz, F. Özdemir, LWT Food Sci. Technol. 52, 31 (2013)

H. Ş. Nadeem, M. Torun, F. Özdemir, LWT Food Sci. Technol. 44, 1626 (2011)

A. Manickavasagan, K. Thangavel, S.R.S. Dev, D.S.A. Delfiya, E. Nambi, V. Orsat, G.S.V Raghavan, Dry. Technol. 33, 1114 (2015)

S.K. El-Samahy, E.A.A. El-Hady, R.A. Habiba, T.E. Moussa-Ayoub, J PACD 9, 136 (2007)

C.C. Ferrari, S.P.M. Germer, J.M. de Aguirre, Dry. Technol. 30, 154 (2012)

C.C. Ferrari, S.P. Marconi Germer, I.D. Alvim, J.M. de Aguirre, Dry. Technol. 31, 470 (2013)

G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, N. Vandewalle, Powder Technol. 224, 19 (2012)

G.E.G. Moreira, M.G.M. Costa, A.C.R. de Souza, E.S. de Brito, M.F.D. de Medeiros, H.M.C. de Azeredo, LWT Food Sci. Technol. 42, 641 (2009)

J.J. Fitzpatrick, K. Barry, P.S.M. Cerqueira, T. Iqbal, J. O’neill, Y.H. Roos, Int. Dairy J. 17, 383 (2007)

A. Chandralekha, A. Rani, H.A. Tavanandi, N. Amrutha, U. Hebbar, K. Raghavarao, Dry. Technol. (2016)

S. Wang, T. Langrish, Dry. Technol. 28, 341 (2010)

R.V. Tonon, C. Brabet, M.D. Hubinger, J. Food Eng. 88, 411 (2008)

C.C. Ferrari, S.P.M. Germer, J.M. Aguirre, in 2nd International ISEKI_FOOD Conference, (2011)

Y.D. Listiohadi, J.A. Hourigan, R.W. Sleigh, R.J. Steele, Aust. J. dairy Technol. 60, 207 (2005)

L.J. Mauer, L.S. Taylor, Annu. Rev. Food Sci. Technol. 1, 41 (2010)

M. Hartmann, S. Palzer, Powder Technol. 206, 112 (2011)

L.D. Daza, A. Fujita, C.S. Fávaro-Trindade, J. N. Rodrigues-Ract, D. Granato, M.I. Genovese, Food Bioprod. Process. 97, 20 (2016)

T. Sheu, M. Rosenberg, J. Food Sci. 63, 491 (1998)

S.M. Jafari, E. Assadpoor, Y. He, B. Bhandari, Dry. Technol. 26, 816 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarabandi, K., Peighambardoust, S.H., Mahoonak, A.S. et al. Effect of carrier types and compositions on the production yield, microstructure and physical characteristics of spray dried sour cherry juice concentrate. Food Measure 11, 1602–1612 (2017). https://doi.org/10.1007/s11694-017-9540-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9540-3