Abstract

Celiac disease affected patients have permanent in-tolerance to ingested gluten. Hence they need to adhere to a gluten free diet. Study was carried out to formulate the biscuit from composite non gluten flours. Flours of amaranth (AF), puffed chickpea (PCF) were combined in different ratios and evaluated for pasting characteristics. Addition of different hydrocolloids and emulsifiers to the formulation resulted in greater elastic modulus G′ than viscous modulus G″ throughout the frequency range, whereas the tanδ was lower than control sample. The spread ratio was higher and breaking strength was lower than the wheat flour biscuit. Incorporation of corn (CS) and potato starches (PS), hydrocolloids and emulsifiers to composite flour however significantly improved the sensory scores. The formulation containing AF:PCF:PS (50:25:25) with gum Arabic + sodium stearoyl lactylate was found to be comparable to wheat flour biscuit. There was significant increase in the protein content from 8.25 to 12.5 g/100 g and marginal increase in fat content compared to control biscuits. The in vitro protein and in vitro starch digestibility also increased in composite gluten free biscuits.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Celiac disease (CD) is an inflammatory disease of the small intestine triggered by gluten proteins from wheat, barley and rye. Its prevalence is 1:1000–1:2000 in any population over the world and CD patients must adhere to a lifelong gluten free diet. Therefore, gluten-free (GF) products commercialization has grown at an annual rate of 28% in past few years [1].

Amaranth is a promising source of gluten free protein for people that are sensitive to gluten [2]. Amaranth (Amaranthus caudatus) grain contains about 30% more protein than cereals like rice, sorghum and rye [3]. Amaranth flour is a rich source of lysine, an essential amino acid which is low in other grains [2]. Amaranth grain also contains thiamine, niacin, riboflavin, folate, and dietary minerals including calcium, iron, magnesium, phosphorus, zinc, copper and manganese that are comparable to common grains such as wheat germ, oats and others. Amaranth also has a valuable nutrient content for gluten free diets compared to buckwheat, corn, millet, rice, oats and quinoa [4].

GF products are frequently produced with addition of various proteins to starchy base, to increase the nutritional value. The incorporation of dairy proteins has long been established in the baking industry, but legumes can also be a good supplement for cereal based foods since they increase the protein content and complement the nutritional value of cereal proteins. They contain high amounts of lysine, leucine, aspartic acid, glutamic acid and arginine, and provide well balanced essential amino acids when consumed with cereals and other foods rich in sulphur containing amino acids and tryptophan. Apart from their nutritional properties, legume protein possesses functional properties that play an important role in food formulation and processing [5]. The functional properties of legume protein such as chickpea flour (Cicer arietinum L.), pea protein isolate (Pisum Sativum L.) and carob germ flour (Ceratonia siliqua L.) have been used in the preparation and development of bakery products, soups, extruded products and ready- to-eat snacks. The functional properties of chickpea protein provide good baking characteristics in gluten-free and wheat breads [6].

The gluten replacement in bakery products represents a major technological problem due to structure building properties. Gluten removal weakens dough structure to develop properly during kneading and baking. Therefore, absence of gluten results in liquid batter rather than a dough and with poor product quality [7]. Unlike pasta and bread, gluten network in cookies and biscuits requires minimum development [8]. The texture of baked biscuits is primarily attributed to starch gelatinization and supercooled sugar rather than a protein/starch structure [7]. Nevertheless, commercial gluten-free biscuits are generally based on pure starch, thus have poor organoleptic quality [8].

Hydrocolloids or gums are widely used as additives in the food industry. In addition to the obvious benefits of taste, texture, mouthfeel, moisture control, and water mobility, they also improve the overall product quality and stability by withstanding the demands of processing, distribution, and final preparation [9]. Emulsifiers usually used in bread can be classified, according to their functionality, as dough strengtheners or crumb softeners. Emulsifiers in GF bread formulations have been studied in order to strengthen the dough and soften the crumb [10, 11]. Arednt et al. [12], studied the effect of rice, corn, soya, millet, buckwheat and potato starches, in combination with different fat sources on the formulation of GF biscuits. Biscuits consisting of rice, corn, potato and soya with high fat powders produced biscuit dough which was sheetable and was comparable to quality of wheat flour biscuits. Gluten-free bread and cookies were made from raw and popped amaranth flour [13]. Composite flour biscuits have been suggested as better than bread because of their ready to eat form, wide consumption, longer shelf life and better eating quality. However, none of the prior studies included both amaranth and chickpea flour with combination of starches, hydrocolloids, and emulsifiers in biscuit formulation. So the objective of the present investigation was to formulate composite biscuits from non-gluten flours namely amaranth, puffed chickpea and also incorporating different starches, hydrocolloids, and emulsifiers. Characterisation of GF composite doughs and evaluation of newly developed composite GF biscuits with respect to physicochemical and sensory properties was also studied.

Materials and methods

Materials

Commercially available wheat flour (WF-moisture 11.2 g/100 g, ash 0.41 g/100 g, fat 1.20 g/100 g and protein 9.54 g/100 g), amaranth flour (AF-moisture 9.7 g/100 g, ash 2.52 g/100 g, fat 1.9 g/100 g and protein 15.2 g/100 g), puffed chickpea (PCF-moisture 10.1 g/100 g, ash 1.70 g/100 g, fat 4.8 g/100 g and protein 21.7 g/100 g), corn starch (CS), potato starch (PS) and sugar were procured from local market. Skimmed milk powder (Gujarat Co-operative Milk Marketing Federation Ltd, India), shortening (Marvo, Hindustan Lever Ltd, India), sodium and ammonium bicarbonate (S.D. Fine Chemicals, India), glyceroyl monosterate (GMS) and sodium stearoyl-2- lactylate (SSL) were procured from Biocon India Pvt. Ltd, Mumbai, India. Hydrocolloids of varying viscosity (0.5%) were selected for the studies. Arabic gum (GA), Carageenan, (CARR-Himedia Laboratories Pvt Ltd., Mumbai, India) and Hydroxy propyl methyl cellulose (HPMC -K4W-DOW Chemical’s International Ltd., Mumbai) were used.

Preparation of emulsifier gel

Gels were prepared using emulsifier and water in the ratio of 1:4. First dispersions were made and then dispersions under continuous agitation were heated to a temperature of 65 °C for GMS and 45 °C for SSL. On cooling gels were obtained. For all the experiments the gels were added in order that there was 0.5% emulsifier on flour basis.

Preparation of blend

The blends were prepared using mixtures of amaranth flour (AF) and puffed chickpea flour (PCF) at different levels in the ratios of AF:PCF 50:50 and 50:25 respectively. Corn starch (CS) and potato starch (PS) was incorporated separately in blend of AF:PCF:CS 50:25:25 and AF:PCF:PS 50:25:25.

Pasting characteristics

Pasting characteristics of composite GF biscuit samples were studied using Brabender-visco-amylograph (Brabender OHG, Duisburg, Germany), following the AACC method [14]. The flour blends were weighed based on 14 g moisture content per 100 g of flour blend and mixed with water (100 ml) and made into paste. This slurry was transferred into visco-amylograph bowl and allowed to heat up to 90–151 °C and mixed with the speed of 250 rev/min. The pasting characteristics were measured in the range of 0–1000 Brabender units (BU) using 300 cmg cartridge spring for the time of 27.50 min.

Biscuit preparation

In order to determine composite GF biscuit dough formulation, the ratio of principal ingredients was varied until dough of good handling properties was obtained. The formulation is presented in Table 1. Biscuit dough from WF was prepared as control samples. Test baking of biscuits was carried out for different blends AF:PCF-(50:50) AF:PCF-(50:25), AF:PCF:PS-(50:25:25), AF:PCF:CS-(50:25:25), AF:PCF:PS + GMS-(50:25:25 + 0.5%), AF/PCF/PS + SSL, AF/PCF/PS + HPMC, AF/PCF/PS + GR, AF/PCF/PS + GA, AF/PCF/PS + SSL + CARR, AF/PCF/PS + GA. The formula used was: 100 g flour, 30 g sugar, 20 g shortening, 1 g sodium chloride, 0.75 g sodium bicarbonate, 1 g ammonium bicarbonate, 2 g dextrose, 2 g skimmed milk powder and 20–45 ml water. Fat and sugar powder were creamed in a Hobart mixer (model N 50, North York, ON, Canada) at speed 1 (61 rpm) for 1 min and continued creaming at speed 3 (178 rpm) for 4 min. Dextrose, milk powder made into suspension in water, baking chemicals and sodium chloride dissolved in water were transferred to the above cream and mixed at speed 1 (61 rpm) for 2 min with further mixing for 2 min at speed 2 (125 rpm) to get a smooth cream. Flour was transferred to the above cream and mixed for 2 min at speed 1 (61 rpm) to get the biscuit dough. After mixing, biscuit dough was sheeted manually to a thickness of 3.5 mm, cut using a circular mould (51 mm diameter), cut dough was transferred to aluminium trays and placed in baking oven and baked at 200 °C for 9–10 min. Biscuits were cooled to room temperature, packed in polypropylene pouches and sealed [15]. Hydrocolloids (HPMC, CARR and GA) and emulsifiers (GMS and SSL) were used to improve the quality of biscuits.

Fundamental techniques: rheological characterisation of biscuit dough

Rheological measurement was performed on a controlled stress and strain rheometer (Anton Paar MCR 301, Ostfilden, Germany), using a parallel plate geometry (75 mm diameter) with a gap between the two plates of 2 mm. The outer edge of the plate was sealed with a thin layer of paraffin oil to prevent dehydration during the test. All rheological measurements were carried out at 25 °C. A strain sweep experiment was conducted initially to determine the limits of linear viscoelasticity; then frequency sweep was carried out to obtain elastic (storage) modulus (G′) and viscous (loss) modulus (G″) at frequencies ranging from 0.1 to 10 rad/s. A strain of 0.5 which was within linear viscoelastic range was used for dynamic experiments. All rheological measurements for biscuit dough samples were performed in duplicates.

Biscuit evaluation

Geometrical properties

Weight (w) of the biscuits was measured. Diameter (W) and thickness (T) of biscuits were measured by placing them edge-to-edge and stacking, respectively. Biscuits were rearranged and measurements were made. The spread ratio W/T was calculated. Density of biscuit was calculated using w/v where v is the volume of the biscuit.

Texture analysis

Evaluation of texture expressed as breaking strength (Kgf) was measured using the triple beam snap (three-point break) technique of Gains [16] using an Instron Universal Testing Instrument (Model 4301, Instron Ltd., High Wycombe, Bucks, UK) equipped with 50 kg load cell. The hardness of the biscuit was indicated by the maximum peak force required to break the biscuits. The slotted Inserts are adjusted and secured on the Heavy Duty Platform to fit sample size and position centrally under the knife edge. The biscuit was rested on two supporting beams spaced at a distance of 3 cm. The instrument was set to ‘return to start’ cycle, a pretest speed of 1.5 mm/s test speed of 2.0 mm/s, post-test speed of 10 mm/s, and a distance of 5.0 mm. The maximum peak force (Kgf) from the force–deformation curve was recorded.

Color analysis

The surface colour of the biscuit samples were measured using Hunter Lab colour measuring system (Labscan XE, USA). The colorimeter was calibrated using a standard white plate. Biscuit sample was placed in a transparent glass bowl and placed on a slit opening and the surface color was measured thrice. The color values L*, a* and b* were measured with a D65 illuminant and a 10° geometry. L* (Lightness factor, 0 = black, −100 = white), a* (+value = red, −value = green), and b* (+value = yellow, −value = blue) values were recorded. Each value was an average of 15 different measurements.

Sensory evaluation

Quantitative descriptive analysis (QDA) was used to measure the sensory attributes of composite GF biscuit samples prepared with different additives. Fifteen judges (8 Females and 7 Males) from the Institute participated in the analysis, and they had experience in descriptive analysis. A structured scale of 15 cm anchored at 1.25 cm on both ends representing low (detection threshold) and high (saturation threshold). Biscuit samples were served to the panelists in glazed chinaware/porcelain containers coded with three-digit random numbers. Water was served along with the samples for palate cleansing. The order of serving the sample was randomized so that bias due to presentation sequence was minimized. Panellists were asked to mark the perceived intensity of each attribute listed on the score card by drawing a vertical line on the scale and writing the code number (on the serving container). The scores for each attribute for a given sample were tabulated, representing the judgment of individual panellists. Finally, mean value was taken for each attribute of a sample, representing the panel’s verdict about the sensory quality of the product. This is represented graphically as sensory profile.

Nutritional quality parameters of GF biscuits

The control biscuit (WF) as well as composite GF biscuits containing 0.25 g/100 g gum Arabic and 0.25 g/100 g SSL were analyzed for various nutritional quality parameters such as ash content and protein content according to the AACC methods [14]. IVSD (in-vitro starch digestibility) was according to the method followed by Goni [15] IVPD (in-vitro protein digestibility) was estimated using pepsin pancreatin protein digest index method [18]. The nitrogen content of the sample and the undigested residue were determined by the Microkjeldahl method [14]. The digestible protein of the sample was calculated by subtracting residual protein from total protein of the sample.

Immunological validation and enzyme linked immunosorbent assay (ELISA)

Gluten analysis was performed for control and composite GF biscuits using the RIDASCREENR-7001 Gliadin ELISA (RBiopharm, Germany) according to Sarabhai et al. [19]. Extraction procedure was followed as described in the kit (R Biopharm, Germany).

Statistical analysis

Results were statistically analysed using Duncan’s new multiple range test with different experiment groups appropriate to the completely randomized design with three replicates each, at p < 0.05 as described by Steel and Torrie [20].

Results and discussion

Pasting characteristics of flours and its blends

The pasting parameters for AF, PCF and blends of AF:PCF and starches are presented in Table 2. The peak temperature of amaranth flour was 64.7 °C, whereas puffed chickpea flour had 73.1 °C respectively. Amaranth (AF) flour showed the highest peak viscosity (PV), cold paste viscosity (CPV) and breakdown (BD) compared to puffed chickpea flour. Blending puffed chickpea flour (PCF) with AF strongly decreased the viscosity parameters. AF:PCF blends also showed reduction of viscosity and setback parameters. This could be due to higher amount of protein thereby diluting the amount of carbohydrates present. The highest swelling ability was observed for the 50:25 blend, followed by the 50:50 blend. The bonding forces within the granules in the mixes could affect the swelling behavior and could explain the rapid increase in viscosity shown by these blends. As the percentage of AF increased, the setback and peak viscosity (PV) increased. Pasting property of chickpea, cowpea and yellow pea starches were influenced by granule swelling, as pointed out by Ratnayake et al. [21]. It has been speculated that high contents of other components, especially fat and protein, influence the swelling power and pasting properties of starches [22]. A negative correlation was found between peak viscosity and protein content of flour blends caused by the presence of proteins, as negative correlation between protein concentration and peak viscosity in rice flour and corn starch have been reported [24]. Another possible reason could be the higher lipid content of chickpea flour which leads to a decrease in the viscosity function through the formation of lipid-amylose complexes [24]. The high pasting temperature may be due to the higher resistance to swelling and rupture of chickpea starch [25] and its high content of protein. It was observed that in there was drastic decrease in CPV and SB for AF:PCF (50:50) blend than AF alone. The CPV is largely determined by the retrogradation of soluble amylose upon cooling. The differences in CPV values could be due to the low amylose content of the amaranth starch which provides less soluble amylose upon cooling; therefore, less amylose retrogradation takes place, as indicated by the lower CPV values. These results were in agreement with Balasubramanian et al. [26] who reported that there was a decreasing trend in degree of gelatinization with increase in legume incorporation level. Miles et al. [27] reported that increase in final viscosity might be due to the aggregation of the amylose molecules.

The effect of corn and potato starches on pasting characteristics of amaranth–puffed chickpea blends was also studied. Pasting temperature in the blends varied from 67.6 to 69.6 °C Incorporation of CS increased the peak viscosity whereas addition of PS decreased the same. The highest PV was observed in AF:PCF:CS (50:25:25) blend. The higher peak viscosity of AF:PCF:CS mixture may be attributed due to higher phosphorus and lower amylose content of CS, which caused the higher swelling of CS than PS. However, the amylose content of CS is supposed to be lower than that of AF and PCF flours. Thus, the viscosity of the AF:PCF:CS mixture was higher than that of the control because AF:PCF starch was diluted by the starches in the mixtures. The low viscosity indicates flour with high enzymatic activity resulting in low water holding capacity. AF:PCF:CS (50:25:25) had higher setback value of 190 BU compared to all the composite blends.

Quality characteristics of biscuits

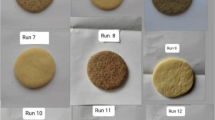

Quality characteristics of composite biscuits

The physical characteristics of biscuits as affected by the AF:PCF blends are presented in Table 3. The diameter of the control biscuit was 5.6 cm and thickness was 0.55 cm. Biscuits prepared from AF and PCF composite had the diameter between 5.5 and 5.6 cm and thickness ranged between 0.50 and 0.53 cm. Hence the spread ratio was in the range between 10.57 and 10.62 indicating the incorporation of PCF has marginal effect on these parameters. Sinduja et al. [28] reported that inclusion of amaranth flour in cookies reduced the spread and increased the thickness. The changes in the physical parameters may be attributed to the higher protein content of these flours which might have changed the dough characteristics. Biscuits with the composite blends were slightly denser than the control as seen in the higher values for the composite biscuits. The breaking strength for control biscuit was 1.17 Kgf, whereas the composite biscuits containing AF at higher ratios were slightly harder as seen in the higher values of the breaking strength. Sindhuja et al. [28] reported harder texture for the cookies with amaranth flour. McWatters et al. [29] attributed the harder texture of sugar cookies with added cowpea which led to the increased protein content and its interaction during dough development. The biscuit containing AF and PCF was lighter in color compared with WF biscuits since the dimension L means lightness with 100 for white and 0 for black. All the biscuits showed the redness in different degrees. The a value (9.49) and b value (22.34) was higher for the control WF biscuit and the AF:PCF biscuit had lower a and b values. The surface color of the biscuits generated in the baking process is due to non-enzymatic browning (Maillard reactions) between reducing sugars and amino acids, but also possibly to starch dextrinisation and sugar caramelisation [30]. It has also been reported that protein content has a negative correlation with the lightness. Therefore, the differences observed when the chickpea flours inclusion could be attributed to the high protein content and the different amino acid composition of the composite flours compared to the wheat flour. Cady et al. [31] also attributed lower L values, which are directly related to the lightness, to the increased presence of reducing sugars in biscuits with darker top surfaces, and more of a browner hue were also reported for incorporation of other composite flours which included cowpea and foni [29] soy protein [31] and hulls from wheat, rice, oats and barley [15].

Sensory attributes were tested by descriptive sensory analysis. Ten parameters such as color, surface, firmness, crispness, crumbliness, dryness, sweetness, flavour and overall quality were analyzed by trained panelists. Sensory evaluation of biscuits prepared by substituting AF and PCF is presented in Fig. 2a. Substitution of AF and PCF influences all sensory parameters significantly except the shape of the biscuit. The surface colour score of 10.4 for control was greatly improved by incorporation of AF:PCF up to 50:50 (13.2) and 50:25 (12) substitution level respectively. Significant reduction in surface characteristics was observed in biscuits prepared from AF:PCF (50:50) compared to AF:PCF (50:25) incorporated biscuits. Surface of biscuits prepared from composite flour was rough when compared to WF biscuits. A similar trend was observed for the texture score of biscuits. Decrease in texture score could be correlated with hardness value of the biscuits (Table 4). Biscuit containing AF:PCF (50:25) was crisper. Mouthfeel and flavour score of the biscuit was more influenced with incorporation PCF in the biscuits. The sensory panel reported acceptable flavour of the biscuit. Overall quality of biscuits reduced from 12.5 for control WF biscuit to 9.5 at 50:50 AF:PCF substitution levels. There was no significant change in overall quality AF:PCF (50:25) substitution.

Influence of starches on biscuit quality characteristics

The effects of addition of corn and potato starch to AF:PCF blend are shown in Table 3. Incorporation of corn starch marginally increased the diameter and thickness, whereas with potato starch, the thickness decreased to a greater extent. Thereby the spread ratio and density decreased with corn starch and increased with potato starch addition. This may be attributed to the higher swelling power of starch granules present in the potato starch. Corn starch granules exhibit lower swelling power than potato starch granules, because of the small granule size, higher lipid content and gelatinization temperature [33]. The addition of corn and potato starch may also have affected the formula water content that increased the dough extensibility which resulted in biscuits with higher spread factors. Chanderashekhra and Shurpalekar [34] reported higher extensibility of dough made by the addition of potato starch from different Indian potato cultivars. The results clearly reveal that potato starch having the higher peak resulted in biscuits with a higher spread factor and vice-versa. The L values decreased with the addition of both corn and potato starches in the biscuits. Biscuits containing corn starch showed higher L value at 50.92 than those having potato starch 50.29. Addition of both corn and potato starches to AF:PCF reduced the fracture force of biscuits (Table 3). Biscuits with addition of starches required a force 0.90 and 0.56 Kgf respectively to fracture. The addition of either of the starches increased the starch and the pigment contents that may have resulted biscuits with lower L values after baking. The a and b values decreased with the addition of either of the starches. The variation in the colour characteristics among all the biscuits made with the addition of corn and potato starch may be attributed due to the differences in the pigment content of the respective flours and also due the difference swelling behaviour and melting of starch crystallites of corn and potato starches.

Effect of emulsifiers and hydrocolloids

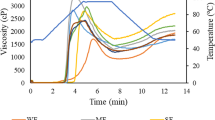

Rheological properties of biscuit dough

The dynamic viscoelastic properties of dough have been related to the quality of food product [35]. The G′ elastic (storage) moduli and G″ viscous (loss) moduli against the frequency for biscuit doughs with different hydrocolloids and emulsifiers are displayed in Fig. 1a, b. Both moduli (G′ and G″) for all samples increased with increasing frequencies. Moreover, elastic modulus G′ was greater than viscous G″ modulus throughout the frequency range (Fig. 1a, b) This indicate that all dough samples with potato starch and different additives including control biscuit dough had more elastic properties than viscous properties [35]. The rheological properties of potato starch have been reported to depend on granular structure, amylose to amylopectin ratio and presence of phosphate ester [36, 37] that may have affected the rheological properties. Addition of potato starch to the dough system increased elastic modulus and decreased tanδ, suggesting that presence of potato starch increased the strength and elasticity of gluten free composite dough. Similar observations on dynamic rheological studies have been previously reported for gluten free bread dough supplemented with carob flour [38] and for rice flour dough [39]. However biscuit dough is characterized by high moisture and high fat and sugar content when compared with bread dough, it exhibited higher elastic modulus than gluten free bread dough composed of rice and buckwheat flour [40]. According to previous conducted studies, addition of fat [41] and reduction in water level in both glutens free [39] and in wheat led to increase in dough elastic modulus. Combination of emulsifier and hydrocolloid (SSL + CARR) showed the largest effect on G′ with the most enhanced softening effect in composite biscuit dough with addition of additives. The combined effect of SSL and Carrageenan seemed to be most suitable option because it involved the largest reduction in both moduli and, thus the more pronounced positive effects in the dough firmness of composite dough.

Mechanical spectra of wheat and composite GF biscuits containing potato starch and additives: Gʹ (storage modulus), Gʹʹ (loss modulus) and tanδ (damping factor). WF wheat flour, AF Amaranth flour, PCF Puffed chickpea flour, PS Potato starch, HPMC hydroxypropyl methylcellulose, GA Arabic gum, CARR Carrageenan, GMS glycerol monosterate, SSL sodium stearoyl-2- lactylate, AF/PCF/PS (50:25:25), AF/PCF/PS + GMS (containing 0.5% GMS), AF/PCF/PS + SSL (containing 0.5% SSL), AF/PCF/PS + HPMC (containing 0.5% HPMC), AF/PCF/PS + CARR (containing 0.5% CARR), AF/PCF/PS + GA (containing 0.5% GA), AF/PCF/PS + SSL + GA (containing 0.5% SSL + 0.5% GA)

Similarly, the tanδ (G″/G′) varied significantly for the composite doughs when compared with control dough Fig. 1c. In most of the cases, the value of tanδ was lower the control. It is noteworthy that the large increase of tanδ values was observed with only SSL in whole range of angular frequency. This fact was directly related to reduction in elastic properties and increase in viscous properties which is promoted by SSL into control dough. Overall, the additives modified the slope of tanδ with angular frequency of control dough by increasing the elastic contribution at high angular frequencies. Especially tanδ decreased in the presence of GA + SSL and CARR + SSL with increasing angular frequency.

Quality characteristics of biscuits

Based on the data the combination of AF:PCF:PS (50:25:25) was considered as optimum. Emulsifiers and hydrocolloids were added in order to improve the quality of biscuits (Table 3). Addition of all the additives increased the spread ratio significantly (p < 0.05). The biscuits were denser than control biscuits. The most important improvement observed was a significant decrease in the breaking strength of biscuits when GMS and SSL were added. Emulsifiers are known to enhance the incorporation of air, creating great numbers of air bubbles, aid in dispersing the shortening in sufficiently small particles and produce the maximum number of effective nucleating site [42]. GMS with its lypophilic nature [43], was probably more efficient in providing many nucleating sites. Addition of different hydrocolloids also showed the similar effect as emulsifiers. Rosell et al. [44] reported that hydrocolloids can improve dough development and gas retention by increasing dough viscosity. Gómez et al. [45] working on the role of hydrocolloids in a cake system explained that this increase in viscosity slows down the rate of gas diffusion and allows its retention during the early stages of baking. Effect of emulsifiers and hydrocolloids on the dough hardness was also reflected in the breaking strength of their respective biscuits.

Among the different hydrocolloids, no significant difference was found in L values of biscuit. Biscuits containing combination of emulsifiers and hydrocolloids showed higher L value (53.52 and 52.15) respectively. The a values of biscuits were higher for SSL + CAR and SSL + GA formulations compared to that of AF:PCF:PS (50:25:25); the lowest a value was observed for the biscuit containing HPMC. No considerable differences in yellowness were found among the different samples. Among the composite biscuits, in the presence of SSL + CAR there was a significant difference in surface color.

Effect of emulsifiers and hydrocolloids on sensory characteristics of composite biscuits is presented in Fig. 2b. The results showed that the addition of GMS, SSL, HPMC, GA and CARR improved the crumb characteristics of composite biscuits with reference to color, texture and mouth feel. This is reflected in the increase in the overall quality score. The above results showed that improvement brought about by the addition of GA to the biscuits with combination of SSL was highest.

Relationship between dough characteristics and biscuit parameters

The relation between dough characteristics and biscuit parameters of AF + PCF + PS + GA + SSL combination is presented in Table 4 in the form of correlation matrix. It can be observed that some of the dough characteristics have affected the biscuit quality.The spread ratio of the biscuit, which is an important quality parameter, positively correlated to rheological parameters i.e. storage modulus (r = 0.98) and damping factor (r = 0.647) and negatively correlated to loss modulus (r = −0.648). Density which indicate the porosity of biscuits negatively correlated to storage modulus (r = −0.209) and spread ratio (r = −0.04), whereas it positively correlated to loss modulus and damping factor. Texture which contributes to biscuit quality to a greater extent negatively correlated to storage modulus and spread ratio and positively correlated to loss modulus, damping factor and density of biscuits. Overall quality of the biscuits positively correlated to storage modulus, damping factor, spread ratio density and texture, whereas the same negatively correlated to loss modulus. The study infers that results obtained from textural and geometrical measurements of biscuit were in accordance with the rheological properties of biscuit dough. Hadnadev et al. [46] have revealed that rheological properties of cookie dough determine the quality of final product. Accordingly, a firm, non-sticky dough results in firm and thin round cookies, whereas soft, sticky dough yields soft and thick oval cookies. Wani et al. [47] also reported that less extensible cookie dough resulted in harder cookies.

Nutritional characterization of biscuits

The wheat flour biscuits and composite GF flour biscuits from AF:PCF:PS + SSL + GA were selected to carry out the analysis for assessing the nutritional quality parameters (Table 5). There was significant increase in the protein content from 8.25 to 12.5 g/100 g. The fat content of the composite GF biscuit was marginally higher than the control biscuits. The IVSD increased from 28.86 to 30.76 g/100 g. Measurement of easily digestible starch content, slowly digestible starch content and resistant starch content predict the rate and extent of starch digestion in the human small intestine [48]. The IVSD and rapidly digestible glucose content values are useful in predicting glycaemic response to carbohydrates [49]. There was also a significant increase in the IVPD values from 56.2 g/100 g to 60.5 g/100 g. These results indicate that composite GF biscuits prepared from non-gluten flours have better nutritional profile when compared to wheat flour biscuits containing gluten. ELISA method confirms that the amount of gluten present in the final product was within the permissible limits (<20 ppm).

Conclusion

The present study was an attempt to prepare composite gluten free biscuits, where in non-gluten flours namely amaranth and puffed chick pea flours were used. Potato starch incorporation improved the quality of biscuits. Combination of gum Arabic and sodium stearoyl lactylate resulted in significant improvement in the overall acceptability of the biscuits. The textural and geometrical measurements of biscuit were in accordance with the rheological properties of biscuit dough. Composite gluten free biscuits can be prepared from non-gluten flours (amaranth and puffed chickpea) by incorporation of starches (potato starch), along with gums and emulsifiers. These biscuits were rich in protein and had better in vitro protein and starch digestibility. The biscuits thus prepared had very low gluten and can be termed as gluten free biscuits. These biscuits can thus be beneficial for patients suffering from celiac disease and for public in general as it is rich in high protein.

References

K. Glover Companies expand gluten free offerings. J. Food Eng. 96, 295–303. http://industry.bnet.com/gluten-free bread formulations

USDA (2014) Nutrient database. http://ndb.nal.usda.gov/ndb/search/list, http://ndb.nal.usda.gov/ndb/foods/show/6238.

D.P. Macvean, Ethnobotany, in Tropical tree seed manual 1997, ed. by J.A. Vozzo (USDA Forest Service, Washington, 1997)

E. Gallagher, T.R. Gormley, E.K. Arendt, Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci. Technol 15(3), 143–152 (2004)

N. Aguilar, E. Albanell, B. Minarro, B. Guamis, M. Capellas, Effect of tigernut-derived products in gluten-free batter and bread. Food Sci. Technol. Int. (2015). doi:10.1177/1082013214535615

B. Minarro, E. Albanell, N. Aguilar, B. Guamis, M. Capellas, Effect of legume flours on baking characteristics of gluten free bread. J. Cereal Sci. 56, 476–481 (2012)

E. Gallagher (2002) The Application of Functional Ingredients in Short Dough Biscuits. MSc Thesis. Cork. Department of Food Technology, University College Cork, Ireland

T.J. Schober, C.M. O’Brien, D. McCarthy, A. Darnedde, E.K. Arendt, Influence of gluten-free flour mixes and fat powders on the quality of gluten-free biscuits. Eur. Food Res. Technol. 216, 369–376 (2003)

J. Xue, M. Ngadi, Effects of methylcellulose, xanthan gum and carboxymethylcellulose on thermal properties of batter systems formulated with different flour combinations. Food Hydrocoll. 23, 286–295 (2009)

I. Demirkesen, B. Mert, G. Sumnu, S. Sahin, Rheological properties of gluten-free bread formulations. J. Food Eng. 96(2), 295–303 (2010)

L.S. Sciarini, P.D. Ribotta, A.E. Leon, G.T. Perez, Incorporation of several additives into gluten free breads: effects on dough properties and bread quality. J Food Eng 111, 590–597 (2012)

E.K. Arendt, C.M. O’Brien, T. Schober, T.R. Gormley, E. Gallagher, Development of gluten-free cereal products. Farm Food 12, 21–27 (2002)

A.M.C. De la Barca, M.E. Rojas-Martínez, A.R. Islas-Rubi, F. Cabrera-Chavez, Gluten-free breads and cookies of raw and popped amaranth flours with attractive and technological and nutritional qualities. Plant Foods Hum. Nutr. 65, 241–246 (2010)

AACC International, Methods I0-50D and 10–52. Approved methods of the American Association of Cereal Chemists, 10th edn. (AACC, St. Paul, MN, 2002)

M.L. Sudha, R. Vetrimani, K. Leelavathi, Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 100, 1365–1370 (2007)

C.S. Gains, Instrumental measurement of hardness of cookies and crackers. Cereal Foods World 36, 989–991 (1991)

I. Goni, C. Valentin-Gamazo, Chickpea flour ingredient slows glycemic response to pasta in healthy volunteers. Food Chem. 81, 511–515 (2003)

W.R. Akeson, M.A.A. Stahmann, Pepsin-pancreatin digest index of protein quality. J. Nutr. 83, 257–261 (1964)

S. Sarabhai, D. Indrani, M. Vijaykrishnaraj, V. Arun Kumar, P. Prabhasankar, Effect of protein concentrates, emulsifiers on textural and sensory characteristics of gluten free cookies and its immunochemical validation. J. Food Sci. Technol. 52, 3763–3772 (2015)

R.G.D. Steel, J.H. Torrie, Principles and procedures of statistics (McGraw-Hill, New York, NY, 1960), pp. 99–131

W.S. Ratnayake, R. Hoover, F. Shahidi, C. Perera, J. Jane, Composition, molecular structure, and physicochemical properties of starches from four field pea (Pisum sativum L.) cultivars. Food Chem. 74, 89–202 (2001)

T.J. Schoch, E.C. Maywald, Preparation and properties of various legume starches. Cereal Chem. 45, 564–573 (1968)

Y. Tan, H. Corke, Factor analysis of physicochemical properties of 63 rice varieties. J. Sci. Food Agric. 82, 745–752 (2002)

J.A. Wood, Viscosity of chickpea flours. The technical journal of Newport Scientific April, 1–4 (2004)

N. Singh, M. Kaur, K.S. Sandhu, H.S. Guraya, Physicochemical, thermal, morphological and pasting properties of starches from some Indian black gram (Phaseolus mungo L.) cultivars. Starch Stärke 6, 535–544 (2004)

S. Balasubramanian, A. Borah, K. Singh, R. Patil, Rheological and nutritional quality of selected dehulled legumes blended rice extrudates. J. Food Sci. Technol. (2011). doi:10.1007/s13197-010-0206-y

M.J. Miles, V.J. Morris, P.D. Orford, S.G. Ring, The roles of amylose and amylopectin in the retrogradation of starch. Carbohydr. Res. 135, 271–281 (1985)

A. Sindhuja, M.L. Sudha, A. Rahim, Effect of incorporation of amaranth flour on the quality of cookies. Eur. Food Res. Technol. 221, 597–601 (2005)

K.H. McWatters, J.B. Ouedraogo, A.V. Resurreccion, Y.C. Hung, R.D. Phillips, Physical and sensory characteristics of sugar cookies containing mixtures of wheat, fonio (Digitaria exilis) and cowpea (Vigna unguiculata) flours. Int. J. Food Sci. Technol. 38, 403–410 (2003)

S. Chevallier, P. Colonna, D. Lourdin, Contribution of major ingredients during baking of biscuit dough systems. J. Cereal Sci. 31, 241–252 (2000)

N.D. Cady, A.E. Carter, B.E. Kayne, M.E. Zabik, M.A. Uebersax, Navy bean flour substitution in a master mix used for muffins and cookies. Cereal Chem. 64, 193–195 (1987)

M. Singh, A. Mohamed, Influence of gluten-soy protein blends on the quality of reduced carbohydrates cookies. LWT Food Sci. Technol. 40, 353–360 (2007)

J. Singh, N. Singh, Studies on the morphological and rheological properties of granular cold water soluble corn and potato starches. Food Hydrocoll. 17, 63–72 (2002)

S. Chandrashekara, S.R. Shurpalekar, On the use of potato and cassava flours in soft dough biscuits. J. Food Sci. Technol. 21, 239–241 (1984)

S. Lee, G.E. Inglett, Rheological and physical evaluation of jet-cooked oat bran in low calorie cookies. Int. J. Food Sci. Technol. 41, 553–559 (2006)

J. Singh, N. Singh, Studies on the morphological, thermal and rheological properties of starch from some Indian potato cultivars. Food Chem. 75, 67–77 (2001)

D.P. Wiesenborn, P.H. Orr, H.H. Casper, B.K. Tacke, Potato starch paste behaviour as related to some physical/chemical properties. J. Food Sci. 59, 644–648 (1994)

K. Tsatsaragkou, S. Yiannopoulos, A. Kontogiorgi, E. Poulli, M. Krokida, I. Mandala, Effect of carob flour addition on the rheological properties of gluten-free breads. Food Bioprocess Technol. 7, 868–876 (2014)

A. Lazaridou, D. Duta, M. Papageorgiou, N. Belc, C.G. Biliaderis, Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 79, 1033–1047 (2007)

A. Torbica, M. Hadnađev, T. Dapčević, Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocoll. 24, 626–632 (2010)

H.S. Gujral, I. Guardiola, J.V. Carbonell, C.M. Rosell, Effect of cyclodextrinase on dough rheology and bread quality from rice flour. J. Agric. Food Chem. 51, 3814–3818 (2003)

B.S. Kamel, Creaming, emulsions, and emulsifiers, in The science of cookie cracker production, ed. by H. Faridi (Chapman and Hall, London, 1994)

B.S. Kamel, J.G.J. Ponte, Emulsifiers in baking, in Advances in baking technology, ed. by B. S. Kamel, CE. Stauffer (Blackie, London, 1993)

C.M. Rosell, J.A. Rojas, C.B. de Barber, Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 15, 75–81 (2001)

M. Gomez, F. Ronda, P.A. Coballera, C.A. Blanco, C.M. Rosell, Functionality of different hydrocolloids on the on dough rheology and bread quality. Food Hydrocoll 15, 75–81 (2007)

T.R. Hadnađev, A.M. Torbica, M.S. Hadnađev, Influence of buckwheat flour and carboxymethyl cellulose on rheological behaviour and baking performance of gluten-free cookie dough. Food Bioprocess Technol. 6, 1770–1781 (2013)

A.A. Wani, D.S. Sogi, P. Singh, P. Sharma, A. Pangal, Dough-handling and cookie-making properties of wheat flour–watermelon protein isolate blends. Food Bioprocess Technol. 5, 1612–1621 (2012)

H.N. Englyst, G.J. Hudson, The classification and measurement of dietary carbohydrates. Food Chem. 57, 15–21 (1996)

H.N. Englyst, J. Veenstra, G.J. Hudson, Measurement of rapidly available glucose (RAG) in plant foods: a potential in-vitro predictor of glycaemia responses. Br. J. Nutr. 75, 327–337 (1996)

Acknowledgements

The authors thank University Grant Commission (UGC) New Delhi for the grant of Junior Research Fellowship to carry out this research work and also CSIR-CFTRI for providing facilities for carrying out the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarabhai, S., Sudha, M.L. & Prabhasankar, P. Rheological characterization and biscuit making potential of gluten free flours. Food Measure 11, 1449–1461 (2017). https://doi.org/10.1007/s11694-017-9524-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9524-3