Abstract

Blueberries are recognized, by the scientific community and consumers, for their health promoting potential. This fact makes blueberries, and blueberry derived products, prime candidates to aid in the development of healthier foodstuffs that are easily recognized as such by consumers. As blueberries health promoting properties are frequently associated with their phenolic, particularly anthocyanins, composition the present work aimed to establish a simple, food safe, approach to extract these compounds. One that, while being food safe also allowed for a relatively easy scale up process. To accomplish this, four different solvents (water, ethanol, methanol and acetone) acidified or not, were evaluated for their extraction capabilities. The results obtained demonstrated that ethanol acidified with 0.01% HCl was an effective extractant of both phenolic compounds and anthocyanins. Acetone was significantly more effective in extracting phenolic compounds but it was almost unable to extract anthocyanins, with the addition of acid allowing for an increase of anthocyanin yield but reducing the overall phenolic yield. The extraction of anthocyanins may be further improved with the addition of an ultrasound treatment to the extraction process, though no significant differences were observed when considering the overall phenolic content. Furthermore, if seeking a condensed extract, purification using solid phase extraction columns allowed the production of an extract comprised of ca. 40% (w w−1) anthocyanins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increase in life expectancy has led to a rising concern with life quality. One of the main consequences of this has been an increase of the consumers’ demand for healthier and more nutritive products, preferably without the addition of chemical additives (which have gained a negative connotation). So, as the consumers’ search for healthier and ‘more natural’ products grew, so did the industry’s attempts to explore this need, namely through the development of additives that, while granting foodstuffs some functionality, may also function as natural additives [1, 2].

Blueberries, dubbed by the media as a superfruit and with a health promoting connotation solidified in the consumer mind, present an interesting opportunity. By adding blueberries to a product the consumers’ will easily associate said foodstuff with a healthy diet. Furthermore, as blueberries are rich in phenolic compounds (natural antioxidants), and anthocyanins in particular (water soluble pigments frequently associated with several health promoting activities), the addition of blueberry extracts to a given product may allow for the replacement of some traditional antioxidant and colorant additives [1, 3]. However, the production of blueberry extracts that, while rich in anthocyanins and other phenolics, remain food safe, using relatively simple, low cost and easy to scale up processes has some limitations. Firstly, anthocyanins are notoriously sensitive to heat, with authors recommending temperatures as low as 30–35 °C in order to extract anthocyanins without promoting degradation that will lead to alterations of the final extract [4–6]. Secondly, the cost associated with the use of high-tech solutions may make the overall process too expensive to be used in the food industry, especially if further purification processes are required [7].

Considering the above made arguments the present work aimed to define an extraction process that allowed for the production of an anthocyanin/phenolic compound rich extract using a solid liquid extraction (SLE), a relatively simple and low cost approach, while also providing a possible solution for purification (solid phase extraction, SPE).

Materials and methods

Materials

Blueberries (Vaccinium corymbosum ‘Goldtraube’) used in the present work were kindly provided by Mirtilusa SA (Sever do Vouga, Portugal). The fruits were collected from bushes in 2013 and stored at −20 °C until processing.

Effect of blueberry mass/solvent ratio

Blueberries were pulped using an appliance mill. The pulp was then suspended in methanol (1, 5, 10, 15 and 20% w v−1), acidified with 0.01% HCl, homogenized using an Ultra-Turrax T18 (IKA, Staufen, Germany) and left to extract at 40 °C in a light-tight container. After 1 h, the mixture was centrifuged (6026×g, 4 °C, for 15 min) and filtered through a 4–7 µm filter (Prat Dumas, Couze St. Front, France) [7]. The resulting extracts were assayed for their total phenolic (TPC) and total anthocyanin content (ACY). Each extraction was performed in triplicate.

Effect of the extraction solvent

Ethanol, acetone, deionized water and methanol [with and without 0.01% HCl) were mixed with blueberry pulp (10% (w v−1)] and extracted, in triplicate, as described in “Effect of blueberry mass/solvent ratio” section. The resulting extracts were assayed for their TPC and ACY.

Effect of an ultrasound treatment

Extracts were prepared using ethanol (with and without 0.01% HCl) as described in “Effect of blueberry mass/solvent ratio” section with a minor modification viz., before centrifuging the extracts were placed in an ultrasound (US) bath (35 KHz, Bandelin Sonorex, Berlin, Germany) for 15 min. The TPC and ACY were then evaluated. Each extraction was performed in triplicate.

Purification of the extracts—process audit

The extract produced using acidified ethanol and including US treatment was considered the most effective and, therefore was submitted to purification using Bond Elut Plexa SPE columns [8]. Briefly, ethanol was removed from the extracts using a rotary evaporator (175 bar, 40 °C, R-210, Buchi, Switzerland) and the resulting powder was ressuspended in deionized water acidified with 0.01% HCl. The resulting solution was loaded into the SPE columns (previously activated with ethanol and conditioned with acidified water). After loading the extracts, the columns were washed with acidified water and the phenolic compounds were eluted using acidified ethanol (0.01% HCl). In each step the TPC and ACY were determined. The purification was assayed in triplicate. Purification efficacy was evaluated through the comparison of the amount of TPC and ACY per mg of dried extract. Furthermore, eventual losses in TPC and ACY (in µg per g of blueberry) were also monitored at the following steps: (i) original extract (original); (ii) extract after being dried by rotary evaporator and reconstituted in water (dried); (iii) extract after SPE purification (purified); (iv) extract after being dried by rotary evaporator (final).

Total phenolic content determination

The TPC of the extracts was determined using the Folin–Ciocalteu phenol’s reagent method as described by Gião, González-Sanjosé [9]. Briefly, to 50 µL of sample (diluted when needed) 50 µL of Folin–Ciocalteu reagent (Merck, Darmstadt, Germany), 1 mL of a 75 g L−1 sodium carbonate solution and 1.4 mL of deionized water were added. After 1 h, the optical density (OD) at 750 nm was measured and the TPC was calculated using a gallic acid calibration curve, with the results being expressed in gallic acid equivalents. All assays were performed in triplicate.

Total anthocyanin content determination

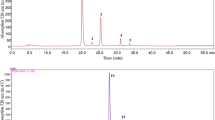

The determination of the total anthocyanin content was determined through the calculation of the area under the curve of the extracts chromatogram, at 520 nm, according to the protocol described elsewhere [10, 11]. The ACY was determined using a cyanidin-3-glucoside (Extrasynthese, Geney Cedex, France) standard curve, with the results being expressed in equivalents of C3Glu.

Statistical analysis

Statistical analysis of the results was performed using IBM SPSS Statistics v21.0.0.0. (New York, USA). The normality of the distribution was evaluated using the Shapiro–Wilk’s test. Since the samples followed a normal distribution, the One-way ANOVA with Turkey’s post-hoc test was used. Differences were considered statistically significant for p-values bellow 0.05. The different extraction solvents used were grouped, using a K-means cluster analysis, using standardized TPC and ACY values (z-scores). The clusters were considered significant for p-values bellow 0.05.

Results and discussion

Acidified methanol was used to determine the effect of the solvent/mass proportion as it has been classically used as extraction solvent when seeking to characterize the anthocyanin content of berries [12]. As can be seen in Fig. 1a, the amount of anthocyanins being extracted appeared to become somewhat stable for mass/solvent proportions above 10% (288.6 ± 16.8 µg mL−1) while for the TPC this stabilization occurred only for solvent/mass ratios of 15% (4695.7 ± 68.9 µg mL−1). This means that the optimum proportion, when seeking to extract both anthocyanins and phenolic compounds would be 15%. However, when using concentrations above 10% the filtration process became significantly longer. Fact that, could not only allow for the oxidation of the extracted compounds but also place a significant hamper in any future scale up attempts [13]. Consequently, the 10% proportion was selected to be used henceforth.

In Fig. 2a comparison between different solvents can be observed. With regard to the non-acidified solvents it can be seen that water and acetone were less effective in extracting anthocyanins (46.7 ± 2.6 and 32.8 ± 2.9 µg mL−1 less, respectively). Methanolic and ethanolic extracts exhibited the highest ACY values among the four solvents tested with no statistically significant (p > 0.05) differences being found between them. However, when considering the TPC content, ethanol and methanol were not the best extractants. Acetone exhibited the highest TPC values (34388.5 ± 889.3 µg mL−1, up to four times higher than ethanol or methanol), with water remaining the less effective extraction solvent (3329.9 ± 236.0 µg mL−1). The acidification of water significantly (p < 0.05) increased its capacity to extract anthocyanins and phenolic compounds (5.1 and 2.2 times higher for ACY and TPC, respectively). On the other hand, for acetone, while acidification led to an increase of the ACY content (1.8 times higher). It also led to a large (14.1 times) significant (p < 0.01) decrease in the TPC value. Additionally, it is interesting to note that no significant differences in TPC and ACY values were observed for either acidified methanol or ethanol. From the analysis of Fig. 3 it became clear that the different solvents, whether acidified or not, could be grouped into three different clusters, all statistically significant (p < 0.01): one where high amounts of TPC can be found but the anthocyanin content is low (cluster 2 comprised only of non-acidified acetone), another were relatively low amounts of both phenolics and anthocyanins can be found (cluster 3 comprised of water and acidified acetone) and lastly one that, while possessing TPC values not much higher than those of cluster 3, have higher ACY values (cluster 1 comprised of acidified ethanol and methanol, plain ethanol and methanol and acidified water). While this last clustering (cluster 1) indicated that these extracts appeared to be quite similar between them, a closer analysis shows that cluster 1’s data is somewhat dispersed in regards to their ACY content. This is reinforced by the fact that, as can be seen in Fig. 2, acidified methanol and ethanol exhibited statistically significant (p < 0.05) higher values than acidified water. Considering that no significant differences were found between acidified and non-acidified ethanol and methanol, the selection of the best extraction solvent was between these two solvents (acidified or not) and, considering both the toxicity of methanol and the goal of producing food-grade extracts, only ethanol and acidified ethanol were used henceforth [14].

Scatterplot relating the TPC and ACY of the extract obtained using different extraction solvents; Metanol (black triangle), acidified methanol (gray triangle), ethanol (black circle), acidified ethanol (gray circle), water (black diamond), acidified water (gray diamond), acetone (black square) and acidified acetone (gray square). The circles mark statistically significant (p < 0.05) clusters

Previous works have demonstrated that high power US (with frequencies from 20 to 40 kHz) may have different effects when considering the anthocyanin content of an extract, with some reporting increases in the ACY while others stating the opposite [15, 16]. Nonetheless, as works with jussara (a berry that is relatively similar to blueberries) demonstrated that it could be effective, the effect of a 32 kHz treatment was assessed. In Fig. 4 it can be seen that the US treatment only appeared to have a significant (p < 0.05) impact on anthocyanin extraction, with this additional step leading to an increase in ACY of 18.1 to 28.4% (without and with 0.01% HCl, respectively). It is interesting to note that no significant differences (p < 0.05) were found between acidified and non-acidified ethanol after US treatment. Consequently, both could be considered the best conditions to produce a food grade extract. Nonetheless, as anthocyanins are reported as considerably more stable under acidic conditions acidified ethanol was considered the preferable solution, when coupled to the US treatment to allow for a higher anthocyanin extraction [12, 17, 18].

The purification step lead to a reduction of the overall extraction yield for both anthocyanins and phenolic compounds (525.8 and 77.4 µg per g of blueberry, respectively—Fig. 5). When considering the anthocyanin variation, it can be seen that the first drying step allows for a significant (p < 0.05) reduction of the ACY content (less 22.3 µg g−1 of blueberry). As the extraction was made with acidified ethanol it is possible that, when concentrating the extract, the consequent increase in HCl concentration may promote the hydrolysis of the glycoside bonds [17–19]. The largest reduction in ACY ensued during the purification step with only 69.4% of anthocyanins present after drying of the extract being found after purification. This loss may be due to either the columns’ inability to adsorb all anthocyanins present or with the eluent’s (acidified ethanol) inability to remove all of the retained anthocyanins [20]. However, considering the fact that there was a significant increase (p > 0.05) in TPC it is possible that some anthocyanin degradation occurred, one where species with higher reducing power (the true measure of the Folin–Ciocalteu method) were formed [21]. In spite of the reduction in both TPC and ACY yield, when comparing the composition of the extracts prior and after purification, it can be seen that the overall portion of both is significantly higher after purification (Fig. 6). In fact, after purification anthocyanins comprised ca. 41.6% (416.5 ± 4.5 µg mg−1 extract) of the extracted powder in contrast to the original 0.043% (ca. 0.43 µg mg−1 of extract). As for the TPC value it indicates that, after purification, the extract possessed 9323 µg mg−1 of extract. However, as this measure is based upon a non-specific assay that has several different interferents, this value must be considered carefully.

Conclusions

Out of all solvents tested, acidified ethanol proved to be the best solution when seeking to produce a food grade extract, from blueberries with high anthocyanin and phenolic content. The purification step may be important if seeking to produce a concentrated extract but, as it allows for the loss of some compounds, the use of the non-purified counterpart may also be interesting.

References

G.R. Gibson, C.M. Williams, Functional Foods: Concept to Product. (Woodhead Publishing Limited, Cambridge, 2000)

C.C. Neto, Mol. Nutr. Food Res. 51(6), 652–664 (2007)

T.C. Wallace, M. Giusti, Anthocyanins in Health and Disease. (Taylor & Francis Group, Boca Raton, 2013)

J.E. Cacace, G. Mazza, J. Food Eng. 59(4), 379–389 (2003)

J.E. Cacace, G. Mazza, J. Food Sci. 68(1), 240–248 (2003)

J.E. Cacace, G. Mazza, J. Agric. Food. Chem. 50(21), 5939–5946 (2002)

S. Silva, et al., Crit. Rev. Food Sci. Nutr. (2015), doi:10.1080/10408398.2015.1087963

S. Silva et al., J. Appl. Microbiol. 121, 693–703 (2016)

M.S. Gião et al., J. Sci. Food Agric. 87(14), 2638–2647 (2007)

J. Lee, C. Rennaker, R.E. Wrolstad, Food. Chem. 110(3), 782–786 (2008)

S. Silva et al., Food Control 51(0), 314–320 (2015)

A. Castañeda-Ovando et al., Food. Chem. 113(4), 859–871 (2009)

E.L. Attoe, J.H. Von Elbe, J. Food Sci. 46(6), 1934–1937 (1981)

T. Cabaroglu, Food Control 16(2), 177–181 (2005)

B.K. Tiwari et al., J. Agric. Food. Chem. 56(21), 10071–10077 (2008)

G.S. Vieira et al., J. Food Eng. 119(2), 196–204 (2013)

J. Fleschhut et al., Eur J Nutr 45(1), 7–18 (2006)

N.P. Seeram, L.D. Bourquin, M.G. Nair, J. Agric. Food. Chem. 49(10), 4924–4929 (2001)

A. Castañeda-Ovando et al., J. Chem. 2014, 9 (2014)

A. Kraemer-Schafhalter, H. Fuchs, W. Pfannhauser, J. Sci. Food Agric. 78(3), 435–440 (1998)

W. Vermerris, R.L. Nicholson, Biosynthesis of phenolic compounds, in Phenolic Compound Biochemistry. (Springer, New York, 2007, pp. 35–62)

Acknowledgements

The authors would like to acknowledge the project UID/Multi/50016/2013 granted by FCT for the funding provided and Mirtilusa SA (Sever do Vouga, Portugal) for providing the blueberries used. Additionally, the authors S. Silva and E.M. Costa would like to acknowledge FCT for their Ph.D. Grants, references SFRH/BD/90867/2012 and SFRH/BDE/103957/2014 respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, S., Costa, E.M., Calhau, C. et al. Production of a food grade blueberry extract rich in anthocyanins: selection of solvents, extraction conditions and purification method. Food Measure 11, 1248–1253 (2017). https://doi.org/10.1007/s11694-017-9502-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9502-9