Abstract

The aim of this investigation was to enhance the quality of high free fatty acid olive oil (HFFAO). Silica gel (SG) was used as adsorbent by applying filtration and stirring techniques. Alkali treatments with NaOH and Ca(OH)2 were also conducted to neutralize high acidity of HFFAO. The levels of linoleic acid (C18:2) in neutralized oils were lower than in reference olive oil. Untreated and treated HFFAO samples were stored under oxidative conditions for 30 days at 60 °C. The progress of oxidation was followed by measuring acid value (AV), the formation of oxidative products [i.e., peroxide value (PV) and p-anisidine value (AnV)], total phenolic compounds (TPC), radical scavenging activity toward 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical and inhibition of β-carotene in a linoleate model system. The results indicated that SG and alkali treatments were effective in reducing the acidity of HFFAO. Alkali treatments reduced the AV of HFFAO, while treatments with SG induced variable degrees of reduction in HFFAO acidity. The percentage of reduction in the PV for HFFAO using SG was in the range of 10.5–47.3 %. Filtration with SG had a significant effect on AnV. Levels of TPC were reduced (ca. 70 %) with alkali treatments, while treatments with SG resulted in reduction of about 22–48 %. After 60 min incubation with DPPH, 78 % of DPPH radicals were quenched by control sample, while HFFAO treated with SG or alkali were able to quench from 48 to 56 %. SG and alkali treatments were not effective in inhibiting the oxidation of linoleic acid and the subsequent bleaching of β-carotene in comparison with control oil. During autoxidation experiments the same trends of results were noted for both control and treated oils. The results stated that SG with permitted high adsorbing capacity reduced free fatty acids levels in HFFAO and the effect was close to that induced with chemical treatments which are used commercially in a large scale to improve oil quality.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The annual world productions of olive oil reached 2,800,000 tons wherein 98 % of this production is found in the Mediterranean basin. Several factors have affected the olive production and processing systems in the last decades. The crisis of traditional agriculture and the valorization of olive oil, due to its organoleptic attributes and its beneficial influence on health, are the main factors. As a consequence great advances have been made in olive oil technology [1, www.iamz.ciheam.org].

During vegetable oil processing, degumming, neutralization, bleaching and deodorization are common refining steps. Crude oil must be separated from other seed materials and refined to remove FFA and other impurities that affect oil flavor, odor and appearance [2]. The de-acidification process greatly influences the economics of vegetable oil production. The purpose of de-acidification in the conventional chemical process is to remove non-glyceride impurities consisting of FFA that contribute to bitter and soapy flavor in food as well as significant quantities of mucilaginous substances, phospholipids and pigments [3, 4]. Traditional approaches to refine low-FFA oils include degumming, dewaxing, alkali refining, bleaching, and deodorization. Several methods to remove FFA were developed to enhance the quality of degraded vegetable oils such as physical refining based on distillation and chemical refining with sodium hydroxide [2]. Distillation is an effective method for neutralizing oils with high acidity, but the operation is energy intensive. Moreover, heating oils under reduced pressure generates reactions that alter their physicochemical and organoleptic properties [5]. Alkali treatment prior to membrane filtration was shown to reduce about 90 % of FFA [2]. These approaches, however, lead to high refining loss when applied to high-FFA oils. Several authors have proposed physical refining for high-FFA oils [6–9]. Physical refining is a sequence of stages that starts with a degumming process, may include a bleaching stage, and definitively includes a steam refining stage. Steam refining stage is a desorption process that includes steam and vacuum. Physical refining results in large quantities of distilled fatty acids with reduction in the quantity of the original oil, especially when the oil being processed is high in FFA content [2]. Alternative approaches were proposed to reduce neutral oil loss during physical refining. Liquid–liquid extraction with polar solvents (e.g., azeotropic isopropanol) was a good process for extracting FFA along with color and oxides [10].

Treating frying oil with a mixture of gel-derived alumina and activated clay or magnesium silicate had reduced the amount of fatty acids, aldehydes, ketones, odor- and color-forming compounds [11]. Lin et al. [12] used combinations of four filter aids (Britesorb, Hubersorb, Frypowder and Magnesol) to recover the used frying oils, wherein the levels of FFA were reduced by 82.6–87.6 %. Care must be taken in the selection of filter aids because some of these substances can affect the stability of the oil [13]. Clay minerals were able to absorb particular amount of trace metals, to reduce the components giving color and chlorophyll, to remove soap and phosphates and to reduce FFA [14]. Sepiolite (Si12Mg8O30(OH)4(H2O)48H2O), was used for the purification of edible oils, such as olive, cotton, soybean, sunflower oils [15]. The highly desirable tocopherols were reduced during soybean oil refining, and this removal reduced stability and nutritional value of the refined oil when compared to the crude oil [16]. Tocopherols are more volatile than the neutral triacylglycerols and can be removed with the high temperature and high vacuum of deodorization.

Olive oil (virgin) is consumed unrefined, although a great proportion of olive oil has to be refined to render it edible [17]. Refining is needed to reduce the content of minor substances that may affect oil quality, such as phospholipids, FFA, pigments, oxides, traces of metals, herbicides and volatile components. Phenolic compounds are among the substances eliminated during refining [18, 19]. At present, three types of olive oils with high levels of acidity are subjected to refining including lampante olive oil, olive pomace oil and olive oil recovered after second centrifugation. Lampante olive oil is obtained from fruits by mechanical means, but it has undesirable organoleptic or chemical characteristics that make it unsuitable for consumption. Likewise, the olive paste obtained during the dual-phase centrifugation used for olive oil extraction is stored for months and subjected to extraction with hexane to produce the traditional olive pomace oil [20], or it can undergo a second centrifugation to yield refined olive oil [21]. Olive pomace oil has a high percentage of FFA, ranging from 5 to 60 % by weight [22]. Thus, the elimination of FFA is an important refining operation.

The present study was carried out to improve the quality of HFFAO and to assess the feasibility of de-acidification of HFFAO using SG regeneration agent by applying filtering and stirring techniques. The efficacy of the aforementioned SG as a regeneration agent was compared with alkali treatment and their mode of action is discussed. In addition, the changes in the quality of HFFAO and treated HFFAO during storage under oxidation conditions was tested.

Materials and methods

Materials

Lampante HFFAO (Lampante) was from El-Salheya olive oil Company (El-Salhya City, Egypt). The peroxide value (PV) of the HFFAO was 19 meq peroxide kg−1 oil and the acid value (AV) was 3 mg KOH g−1 oil. SG (60–120 mesh) was obtained from BDH Chemicals Ltd. (Poole, UK). Solvents and reagents were of analytical grade and used without further purification.

Methods

De-acidification of HFFAO with SG

Filtration

SG was activated by heating at 120 °C for 2 h. Glass chromatographic column (50 cm × 10 cm) was filled with activated SG. HFFAO samples dissolved in hexane (3 g oil: 1 mL hexane) were filtered through SG. This process was repeated three times using two ratios of SG to HFFAO (1:2 and 1:3, w/w).

Stirring

SG were added to HFFAO (3 g oil: 1 mL hexane) and mechanically stirred on magnetic stirrer for 120 min at 25 °C then filtered through Whatman No. 1 filter paper. This process was repeated three times using two ratios of SG to HFFAO (1:2 and 1:3, w/w). The untreated HFFAO was also filtered through Whatman No. 1 filter paper.

Neutralization of HFFAO using NaOH or Ca(OH)2

Alkali treatments using soda (NaOH) or lime [Ca(OH)2] were conducted to neutralize the acidity of HFFAO. Neutralization with NaOH or Ca(OH)2 was carried out as follow: 0.1 g NaOH was dissolved in 1 mL distilled water then the mixture was added to 150 g olive oil and stirred for 30 min at room temperature. Hexane (15 mL) was added and the mixture was stirred for 30 min. The mixture was centrifuged at 3500 rpm for 30 min and hexane was evaporated at 40 °C in vacuo and the oil was used for further analyses.

Oxidation test

Samples of treated and untreated HFFAO were placed in 20 mL transparent glass bottles. The bottles were completely filled with oil and sealed. No headspace was left in the bottles. The oxidation reaction was accelerated in a forced-draft air oven T6 (Heraeus Instruments GmbH; Hanau, Germany) set at 60 ± 2 °C for up to 30 days. Immediately after storage intervals, oil samples were withdrawn for triplicate analyses.

Screening of oxidative deterioration

Progress of the oxidative deterioration of the oils during storage was followed by measuring the following parameters.

Fatty acid composition

Fatty acids were transesterified into fatty acid methyl esters (FAME) using N-trimethylsulfoniumhydroxide (TMSH, Macherey–Nagel, Düren, Germany) according to the procedure reported by Arens et al. [23]. In brief, 10 mg of HFFAO sample was dissolved in 500 µL of tert-butyl methyl ether then 250 µL of TMSH was added and the mixture was vortexed for 30 s before injection. FAME were identified on a Shimadzu GC-14A gas chromatography (GC) equipped with flame ionization detector (FID) and C-R4AX chromatopac integrator (Kyoto, Japan). The flow rate of the carrier gas helium was 0.6 mL/min and the split value with a ratio of 1:40. A sample of 1 µL was injected on a 30 m × 0.25 mm × 0.2 µm film thickness Supelco SPTM-2380 (Bellefonte, PA, USA) capillary column. The injector and FID temperature was set at 250 °C. The initial column temperature was 100 °C programmed by 5 °C/min until 175 °C and kept 10 min at 175 °C, then 8 °C/min until 220 °C and kept for 10 min at 220 °C. A comparison between the retention times of the samples with those of reference compounds mixture, run on the same column under the same conditions, was made to facilitate identification.

Acid value (AV)

A known weight of oil sample (ca. 2 g) was dissolved in neutralized alcohol (50 mL) and titrated with KOH (0.1 mol L−1) according to AOAC [24].

Peroxide value (PV)

A known weight of oil sample (ca. 2 g) was dissolved in 30 mL chloroform: acetic acid (3:2, v/v) then 1 mL freshly prepared saturated KI solution was added and the mixture vortexed for exactly 1 min. Distilled water (30 mL) and starch solution (0.5 mL, 1 %) were added and the liberated iodine was titrated with sodium thiosulfate (0.1 mol L−1) according to AOAC [24].

p-Anisidine value (AnV)

AnV was measured according to the Official Methods of the American Oil Chemists’ Society Cd 18–90 [25].

Total phenolic compounds (TPC)

Aliquots of oil (2 g) were dissolved in n-hexane (5 mL) and mixed with 10 mL methanol–water (80:20, v/v) in a glass tube and vortex for two min. After centrifugation at 3000 rpm for 10 min, the hydroalcoholic extracts were separated from the lipid phase by using Pasteur pipet then combined and concentrated in vacuo at 35 °C until a syrup consistency was reached. The lipidic residue was redissolved in 10 mL methanol–water (80:20, v/v) and the extraction was repeated twice. Hydroalcoholic extracts were redissolved in acetonitrile (15 mL) and the mixture was washed with n-hexane three times (15 mL each). Purified phenols in acetonitrile were concentrated in vacuo at 30 °C then dissolved in methanol for further analysis. Aliquots (0.2 mL) of phenolic extracts were evaporated to dryness under nitrogen. The residue was redissolved in 0.2 mL water and diluted (1:30, v/v) Folin–Ciocalteu’s phenol reagent (1 mL) was added. After 3 min, 7.5 % sodium carbonate (0.8 mL) was added. After a further 30 min, the absorbance was measured at 765 nm using UV-260 visible recording spectrophotometer (Shimadzu, Kyoto, Japan). Caffeic acid was used for the calibration and the results of triplicate analyses were expressed as parts per million of caffeic acid.

Antioxidant activity

β-Carotene-linoleic acid assay

The antioxidant activity of HFFAO was evaluated using the β-carotene–linoleic acid assay. Approximately 2 mg β-carotene were dissolved in 10 mL of chloroform. One milliliter of this solution was pipetted into a round bottom flask. After removal of chloroform using a rotary evaporator, 20 mg of linoleic acid, 200 mg of Tween 40 and 50 mL of distilled water were added to the flask with vigorous stirring. Aliquots (5 mL) of the prepared emulsion were transferred to a series of tubes containing 2 mg each of HFFAO. The samples were put in a water bath at 50 °C over a period of 120 min and the absorbance was read at 470 nm.

Radical scavenging activity (RSA) against DPPH radical

Antiradical action of oil samples was examined by reduction of DPPH in toluene according to Ramadan et al. [26]. Toluene solution of DPPH radicals was freshly prepared at a concentration of 10−4 M. The radicals, in the absence of antioxidant compounds, were stable for more than 2 h of kinetic assay. Ten mg of oil (in 100 µL toluene) was mixed with 390 µL toluene solution of DPPH radicals and the mixture was vortexed for 20 s at ambient temperature. Against a blank of pure toluene without DPPH, the decrease in absorption at 515 nm was measured in 1-cm quartz cells after 60 min of mixing using UV-260 visible recording spectrophotometer (Shimadzu, Kyoto, Japan). RSA toward DPPH radicals was estimated from the differences in absorbance of DPPH solution in toluene with or without sample (control) and the inhibition percent was calculated from the following equation:

All results presented were mean values of at least three experiments, wherein no statistically significant difference (P > 0.05) was found among the experiments.

Results

Effect of de-acidification on the oil recovery and fatty acid profile

Applying SG and alkali treatments resulted in weight loss. Table 1 presents the weight loss during processing. Stirring techniques with SG led to higher weight loss (14–16 %) followed by the filtration technique (12–13 %), while alkali treatments with soda and lime resulted in moderate weight loss (7–8 %). The major loss in the de-acidification processes could be related to the adsorption of the oil on the adsorbent surface. The FA compositions of the HFFAO samples, before and after neutralization and de-acidification, are also shown in Table 1. The percentages of linoleic acid (C18:2) in the neutralized and de-acidified oils were lower than those in the reference olive oil. A reduction in the percentage of palmitic acid (C16:0) was noted in the treated oils especially in alkali-treated oils, as well as a very clear increase in the percentage of oleic acid (C18:1n-9). These two fatty acids made up the bulk of the free fatty acids in the oil. The results are in agreement with Essid et al. [27] who used lime (calcium hydroxide) and soda (sodium hydroxide) as neutralizing agents for refining HFFAO.

Effect of de-acidification on AV of HFFAO

The most important chemical characteristics for the determination of olive oil quality are AV, PV, AnV and phenolics content [1]. It has been reported that humidity could be a factor affecting hydrolysis of oils [28]. The initial values of HFFAO were AV (3 mg KOH g−1 oil), PV (19 meq peroxide kg−1 oil), AnV [20], while the total phenolics amount was 0.43 mg/kg (as caffeic acid equivalent). These findings indicate that the HFFAO was characterized by high level of acidity. FFA removal profiles with SG as well as alkali treatments are shown in Fig. 1. Generally, alkali treatments with soda or lime significantly reduced the AV of HFFAO. On the other hand, treatments with SG improved the quality of HFFAO. Filtration through SG resulted in greater FFA removal than the stirring technique. As shown in the figure, at zero time, maximum FFA removal observed with SG filtration technique (was about 57.6 %) when the ratio 2:1 was applied. Moreover, nearly 21.6 % of FFA removal was achieved with SG stirring technique when the ratio 3:1 was applied.

During storage for 30 days under accelerated oxidation conditions at 60 °C the treatment of HFFAO with alkali (NaOH or Ca(OH)2) greatly lowered the FFA levels. The effects of filtration and stirring techniques using SG were nearly the same during the oxidation experiment.

Effect of de-acidification on the PV and AnV

Peroxides and hydroperoxides, the primary products of oil oxidation, decompose to form aldehydes, ketones, acids, alcohols, hydrocarbons and other compounds [29, 30]. The products of oil degradation as defined by International Union of Pure and Applied Chemistry [31] are polar materials. The polar fraction is composed of FFA, monoglycerides, oxidized triglycerides and oligomeric triglycerides. All treatments used in the present work caused an improvement in stored and treated HFFAO quality comparable to that of fresh oil.

The initial PV of HFFAO was 19 meq peroxide kg−1 oil. Alkali treatments with soda and/or lime increased the PV levels to 35 and 28 meq peroxide kg−1 oil for HFFAO treated with soda and lime, respectively (Fig. 2). The reduction in the PV (%) for HFFAO oil using SG was in the range of 10.5–47.3 %. These results demonstrated that the adsorbing efficiency of SG permitted high adsorbing capacity and very good ability to scavenge peroxides in HFFAO. Yates et al. [32] added powdered silicates and subsequently removed them by filtration in order to regenerate the quality of used oils. In this respect, Kalapathy and Proctor [33] prepared sodium silicate films from rice hull ash silica and reported that FFA content gradually decreased with treatment time for all films. The PV for the treated oils was progressively increased during storage under accelerated oxidation conditions. However, PV were reduced after 30 days of storage in the samples treated with SG and this finding could be due to the volatilization of some peroxides under oxidation conditions. The relative efficiencies of the various SG: oil ratios (1:2 and 1:3, w/w) for lowering the PV of HFFAO oil were approximately the same.

The p-anisidine value (AnV), which measures the unsaturated aldehydes (principally 2-alkenals and 2,4-dienals) in oils, was determined by reacting p-anisidine with the oil in iso-octane and the resultant color was measured at 350 nm. The initial AnV for HFFAO was 20 and it was observed that treatments with SG or alkali resulted in reduction of AnV (Fig. 3). In addition, filtration with SG was more effective in reduction of AnV than the stirring technique. During autoxidation at 60 °C in the dark (Fig. 3), treated HFFAO were more stable than the control oil. Here again, SG with high polarity led to a higher adsorbing capacity in removing the secondary oxides of HFFAO. However, at the end of the oxidation experiment the AnV levels in treated HFFAO (except for oil treated with lime) were higher than control oil. The results demonstrated that all treated HFFAO had oxidative stability (OS) higher than control oil. Meanwhile, treatment with SG and alkali caused a decrease in both peroxide and p-anisidine levels during incubation intervals for 30 days.

Effect of de-acidification on the TPC

Figure 4 presents the impact of different treatments on the TPC of HFFAO during heating experiment. The initial TPC in HFFAO was 43 mg/kg oil and the levels of TPC were significantly reduced (ca. 70 %) with alkali treatments. Treatments with SG also resulted in relative reduction (ca. 22–48 %) in the TPC levels. During oxidation at 60 °C (Fig. 4), all samples showed a gradual decrease in TPC, while SG-treated HFFAO oils were more stable than alkali-treated oils. The TPC of olive oil was reduced almost to zero with refining [34], while Nergiz [35] reported that a residual amount of total phenols and o-diphenols could be found in refined olive oils.

Effect of de-acidification on the antioxidant activity

Interest has increased in the past few years in the free radical theory of disease causation, particularly in vascular diseases and certain forms of cancer. These developments have led to investigations on dietary agents, the antioxidant nutrients (mainly vitamins A, C, and E), in a possible prophylactic, even curative, role in the disease process. Closely related to this probable benefit of natural antioxidants is the antioxidant role in controlling free radicals as they may lead to pathological effects such as vascular diseases and cancer [30, 36]. The evidence in the literature begins to make an overwhelming case for the existence of a relationship between high blood levels of antioxidant nutrients and a lowered incidence of disease [37, 38]. The antioxidant activity of phenolic compounds may inhibit free radicals from initiating the oxidation process and radical chain reaction. For this reason, two different methods were used for the determination of the antioxidant activity of the extracts: inhibition of β-carotene co-oxidation in a linoleate model system and DPPH free radical scavenging.

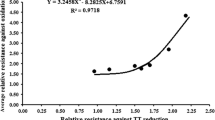

The OS of vegetable oils depends on the fatty acid profile, the presence of minor fat-soluble bioactives and the initial amount of oxides [29, 30]. Antiradical properties of HFFAO were compared using stable DPPH free radicals. Figure 5 shows that control sample of HFFAO had higher RSA than HFFAO treated with SG or alkali. After 1 h incubation, 78 % of DPPH radicals were quenched by control sample, while HFFAO treated with SG or alkali were able to quench from 48 to 56 % at the same time of incubation. During the oxidation experiment, the same trend of RSA was noted for control and treated oils. It could be concluded that treatment of HFFAO with SG or alkali resulted in reduction in the levels of polar bioactive antioxidants responsible for antiradical action. It could be said that the RSA of oils could be due to the action of different antioxidants [39, 40].

Figure 6 shows the decrease in absorbance of β-carotene in the presence of different HFFAO in the coupled system of β-carotene and linoleic acid at 50 °C. It shows that the treated HFFAO oxidized more rapidly. Different SG and alkali treatments were not effective in inhibiting the oxidation of linoleic acid and the subsequent bleaching of β-carotene in comparison with the control. During oxidation experiment, the same trends of results were recorded for all samples wherein untreated samples recording the highest level of inhibition of linoleic acid oxidation. In addition, there was no direct correlation between the level of phenolic compounds in the oils and their antioxidant activity.

Discussion

The oil production cannot cope with the high demands of oils especially in the developed countries. In addition, many countries tend to produce biofuels from vegetable oils which increases the oil crisis [41, 42]. Therefore, any method that extends the useful life of used oils could provide enormous returns for the food services industries. In this respect, several adsorbent agents are used to purify used oils [12, 43]. Most of these agents, such as clay, magnesium silicate, activated alumina, and charcoal remove one or more of the impurities or colored bodies. Several reports have indicated that adsorbents improved the color and viscosity of the oil [44]. Furthermore, these materials reduce the total polar materials and oxidation products which normally lead to the deterioration of low quality used oil. It is well accepted that during processing partial hydrolysis of the oil takes place and FFA content increases. Another factor that promotes oil hydrolysis is the presence of moisture [42]. As the crude olive oil in this work was dried over anhydrous sodium sulfate, the effect of moisture could be excluded from the discussion.

Vegetable oils that have been degraded by hydrolysis must be refined before use. Olive-residue oil has a high percentage of FFA, ranging from 5 to 60 % by weight. The elimination of FFA is the most important refining operation. Several methods to remove FFA have been developed to enhance the value of degraded vegetable oils including physical refining based on distillation and chemical refining with sodium hydroxide. Distillation is an effective method to neutralize oils with high acidity, but this operation is also energy intensive [41]. Moreover, heating oils to high temperature under reduced pressure generates secondary reactions that alter their physicochemical characteristics and organoleptic properties. Thermal and catalytic reactions lead to the formation of olefin hydrocarbons, di- and tri-terpenes, and aromatic products as a consequence of tocotrienol degradation [27].

Sodium hydroxide not only neutralizes FFA, but also attacks neutral oil by saponification, leading to reduce output and the formation of mono- and di-acylglycerols in neutral oil. From an economic viewpoint, neutralization with soda in a liquid–liquid biphasic medium cannot be applied to oils having acidity >15 % because the quantity of neutral oil that is saponified becomes very significant [44, 45]. In addition, soda eliminates some of the principal components responsible for OS, such as tocopherols, and can involve losses of sterols, which constitute 30–60 % of the unsaponifiables.

The data indicated that SG was an effective adsorbing substance in removing secondary oxidation substances from HFFAO. SG does not exhibit any harmful effects to the handler and possesses adsorbing efficiency in removing secondary oxidation substances. In addition, the price of SG is comparable to Magnesol XL and would therefore be useful for regenerating the quality of used oils and high FFA oils. According to the chemical structure of SG, it exhibits dual functions (polar and non-polar characters). In general, it was stated that SG had the highest adsorbing capacity than that of other adsorbing agents [45]. In this respect, SG offers great potential for refining the edible oil in industry. It is noteworthy that the silicone atoms of SG are joined via oxygen atoms in a giant covalent structure. However, at the surface of the SG, the silicone atoms are attached to –OH groups. Making the surface of the SG very polar enabling the –OH groups to form hydrogen bonds with the secondary oxidation products as well as Van der Waals dispersion forces and dipole–dipole attractions [44]. In fact, the most important features of SG are the presence of silanol (Si–OH) groups that are polar and ionisable and siloxane linkage (Si–O–Si) that has a hydrophobic character. Figure 7 shows the existence of silanol groups (polar) at the surface while the siloxane groups (non-polar) are located in the interior part of the SG molecules.

It is known that oxidation products are mainly polar and some are non-polar substances. SG molecules have polar and non-polar groups which associate with the secondary oxidation products according to the fact ‘likes dissolve likes’. Thus, SG structure helps in improving the quality of oils with high polar compounds. It could be concluded that SG with small particle size permitted high adsorbing capacity and could be used commercially in a large scale to improve oil quality.

Conclusion

Crude vegetable oils refined to remove FFA as well as other impurities that affect flavor, odor and appearance of oils. Deacidification process significantly influences the economics of oil production. Several methods to remove FFA were developed to enhance the value of degraded vegetable oils. In this work, the quality of HFFAO was improved using SG as an adsorbent by applying filtration and stirring methods. The results stated that SG permitted high adsorbing capacity close to that induced with chemical treatments which are used commercially to enhance oil quality.

References

A. Allalout, D. Krichene, K. Methenni, A. Taamalli, D. Daoud, M. Zarrouk, Behavior of Super-intensive Spanish and Greek olive cultivars grown in northern Tunisia. J. Food Biochem. 35, 27–43 (2011)

M.M. Prieto, J.C. Bada, M. León-Camacho, E.G. Constante, Deacidification and recovery of distillates in the physical refining of edible oils. Eur. J. Lipid Sci. Technol. 110, 101–110 (2008)

F.V.K. Young, C. Poot, E. Biernoth, N. Krog, N.G.J. Davidson, F.D. Gunstone, Processing of fats and oils, in The Lipid Handbook, 2nd edn., ed. by F.D. Gunstone, J.L. Harwood, F.B. Padley (Chapman & Hall, London, 1994), pp. 281–284

J.C. Bada, M.M. Prieto, J. Xiberta, E. Graciani, M. León, Application of two heating methods in physical refining of high-FA olive and sunflower oils. J. Am. Oil Chem. Soc. 79, 209–214 (2002)

G. Cecchi, Transformation of sterols during the manufacture of vegetable squalene: incidence of this transformation on the presence of sterane in squalene olive origin. OCL. 5, 149–156 (1998)

D.C. Tandy, W.J. McPherson, Physical refining of edible oil. J. Am. Oil Chem. Soc. 61, 1253–1258 (1984)

S.K. Kim, C.J. Kim, H.S. Cheigh, S.H. Yoon, Effect of caustic refining, solvent refining and steam refining on the deacidification and color of rice bran oil. J. Am. Oil Chem. Soc. 62, 1492–1495 (1985)

J. Cvengros, Physical refining of edible oils. J. Am. Oil Chem. Soc. 72, 1193–1196 (1995)

B.K. De, D.K. Bhattacharyya, Physical refining of rice bran oil in relation to degumming and dewaxing. J. Am. Oil Chem. Soc. 75, 1683–1686 (1998)

M. León Camacho, M.V. Ruiz-Méndez, M.M. Graciani Constante, E. Graciani Constante, Kinetics of cis-trans isomerization of linoleic acid in the deodorization and/or physical refining of edible fats. Eur. J. Lipid Sci. Technol. 103, 85–92 (2001)

A.C. Bhattacharyya, S. Majumdar, D.K. Bhattacharyya, Refining of high FFA rice bran oil by isopropanol extraction and alkali neutralization. Ol. Corps Gras Lipides 42, 431–433 (1987)

S. Lin, C.C. Akoh, A.E. Reynolds, Determination of optimal conditions for selected adsorbent combinations to recover used frying oils. J. Am. Oil Chem. Soc. 76, 739–744 (1999)

R.A. Yates, J.D. Caldwell, Regeneration of oils used for deepfrying: comparison of active filter aids. J. Am. Oil Chem. Soc. 70, 507–511 (1993)

M. Rossi, M. Gianazza, C. Alamprese, F. Stanga, The role of bleaching clays and synthetic silica in palm oil physical refining. Food Chem. 82, 291–296 (2003)

M. Ugurlu, I. Kula, The removal of colour, carotene and acidity from crude olive oil by using sepiolite. Int. J. Food Sci. Technol. 42, 359–365 (2007)

M.Y. Jung, S.H. Yoon, D.B. Min, Effect of processing steps on the contents of minor compounds and oxidation of soybean oil. J. Am. Oil Chem. Soc. 66, 118–120 (1989)

R.M. Tubaileh, M.M. Graciani Constante, M. León-Camacho, A. Lopez Lopez, E. Graciani Constante, Kinetics of the decomposition of total aliphatic waxes in olive oil during deodorization. J. Am. Oil Chem. Soc. 79, 971–976 (2002)

A.G.G. Krishna, S. Khatoon, P.M. Shiela, C.V. Sarmandal, T.N. Indira, A. Mishra, Effect of refining of crude rice bran oil on the retention of oryzanol in the refined oil. J. Am. Oil Chem. Soc. 78, 127–131 (2001)

L. Matos, S. Cunha, J. Amaral, J. Pereira, P. Andrade, R. Seabra, B. Oliveira, Chemometric characterization of three varietal olive oils (Cvs. Cobrancosa, Madural and Verdeal Transmontana) extracted from olives with different maturation indices. Food Chem. 102, 406–414 (2007)

M.V. Ruiz-Méndez, M.C. Dobarganes, Olive oil and olive pomace oil refining. Ol. Corps Gras Lipides 6, 56–60 (1999)

J. Alba, F. Hidalgo, M.A. Ruiz, F. Martínez, M.J. Moyano, A. Cert, M.C. Pérez, M.V. Ruiz-Méndez, Características de los aceites de oliva de primera y segunda centrifugación. Grasas Aceites 47, 163–181 (1996)

A. Nefzaoui, Valorization of by-products of the olive tree. CIHEAM-Mediterranean Options 16, 101–108 (1991)

M. Arens, E. Schulte, K. Weber, Fettsäuremethylester, umesterung mit trimethylsulfoniumhydroxid (schnellverfahren). Fat. Sci. Technol. 96, 67–68 (1994)

AOAC, Official methods of analysis of the association of agricultural chemists, 17th edn. (AOAC, Washington, 2000)

AOCS, Official methods and recommended practices of the American oil chemists’ society, 4th edn. (AOCS, Champaign, 2000)

M.F. Ramadan, M.M.S. Asker, Z.K. Ibrahim, Functional bioactive compounds and biological activities of spirulina platensis lipids. Czech J. Food Sci. 26, 211–222 (2008)

K. Essid, M. Trabelsi, M.H. Frikha, Effect of neutralization with lime on the quality of acid olive oil. J. Am. Oil Chem. Soc. 83, 879–884 (2006)

S. Omar, B. Girgis, F. Taha, Carbonaceous materials from seed hulls for bleaching of vegetable oils. Food Res. Int. 36, 11–17 (2003)

A.A.A. Mohdaly, M.A. Sarhan, A. Mahmoud, M.F. Ramadan, I. Smetanska, Antioxidant efficacy of potato peels and sugar beet pulp extracts in vegetable oils protection. Food Chem. 123, 1019–1026 (2010)

A.A.A. Mohdaly, I. Smetanska, M.F. Ramadan, M.A. Sarhan, A. Mahmoud, Antioxidant potential of sesame (Sesamum indicum) cake extract in stabilization of sunflower and soybean oils. Ind. Crops Prod. 34, 952–959 (2011)

IUPAC, in Standard methods for the analysis of oils, fats and derivatives, ed. by C. Paquot, A. Hautfenne (International Union of Pure and Applied Chemistry, Palo Alto, 1987)

R.H. Yates, Y.D. Cadwell, E.G. Perkins, Diffuse reflectance Fourier transform infrared spectroscopy of triglycerol and oleic acid adsorption on synthetic magnesium silicate. J. Am. Oil Chem. Soc. 74, 289–292 (1997)

U. Kalapathy, A.A. Proctor, new method for free fatty acid reduction in frying oil using silicate films produced from rice hull ash. J. Am. Oil Chem. Soc. 77, 593–598 (2000)

A. Vázquez, C. Janer del Valle, M.L. Janer del Valle, Determinación de los polifenoles totales del aceite de oliva. Grasas Aceites 24, 350–357 (1973)

C. Nergiz, The effect of refining processes on the total polyphenol and 1,2-diphenol content of olive oil. Int. J. Food Sci. Technol. 28, 461–464 (1993)

M.F. Ramadan, S.G. Kinni, M. Seshagiri, J.-T. Moersel, Fat-soluble bioactives, fatty acid profile and radical scavenging activity of Semecarpus anacardium seed oil. J. Am. Oil Chem. Soc. 87, 885–894 (2010)

M.F. Ramadan, J.-T. Moersel, Oil goldenberry (Physalis peruviana L.). J. Agri. Food Chem. 51, 969–974 (2003)

M.F. Ramadan, G. Sharanabasappa, Y.N. Seetharam, M. Seshagiri, J.-T. Moersel, Profile and levels of fatty acids and bioactive constituents in mahua butter from fruit-seeds of Buttercup tree [Madhuca longifolia (Koenig)]. Eur. Food Res. Technol. 222, 710–718 (2006)

M.F. Ramadan, J.-T. Moersel, Screening of the antiradical action of vegetable oils. J. Food Comp. Anal. 19, 838–842 (2006)

M.F. Ramadan, R. Zayed, H. El-Shamy, Screening of bioactive lipids and radical scavenging potential of some solanaceae plants. Food Chem. 103, 885–890 (2007)

W. Du, Y. Xu, D. Liu, J. Zeng, Comparative study on lipase catalyzed transformation of soybean oil for biodiesel production with different acyl acceptors. J. Mol. Cata. B 30, 125–130 (2004)

H. Kim, B. Kang, M. Kim, Transesterification of vegetable oil to biodiesel using heterogeneous base catalyst. Catal. Today 95, 315–320 (2004)

R.M. Bheemreddy, M.S. Chinnan, K.S. Pannu, A.E. Reynolds, Active treatment of frying oil for enhanced fry-life. J. Food Sci. 67, 1478–1484 (2002)

R.S. Farag, A.M. EL-Anany, Improving the quality of fried oils by using different filter aids. J. Sci. Food Agri. 86, 2228–2240 (2006)

R.S. Farag, A.M.M. Basuny, Improvement in the quality of used sunflower oil by organic and inorganic adsorbents. Int. J. Food Sci. Technol. 44, 1802–1808 (2009)

Acknowledgments

This study was supported by the research fund from Zagazig University (Egypt).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

None.

Human and Animal rights and Informed Consent

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Hassanien, M.F.R., Dohim, M.A., Abdel-Salam, A.S. et al. Physicochemical characteristics and oxidative stability of de-acidified lampante high acid olive oil. Food Measure 9, 564–574 (2015). https://doi.org/10.1007/s11694-015-9265-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-015-9265-0