Abstract

Underground fires are slow spreading, long-lasting and low temperature smoldering combustion without flames, mainly occurring in peatlands and wetlands with rich organic matter. The spread of the smoldering is maintained by heat released during combustion and monitoring this is an important approach to detect underground fires. The Daxing’an Mountains region is a hotspot for underground fires in northeast China. This study examined a Larix gmelinii plantation in the Tatou wetlands of the Daxing’an Mountains and determined the maximum temperature variation of humus of varying particle sizes, and the temperature rising process based on non-linear mixed effects models by an indoor combustion experiment. Maximum combustion temperatures up to 897.5 °C, increased with humus depth; among the three models tested, Richard’s equations were best for characterizing temperature variations; a non-linear equation with three parameters had the highest accuracy in fitting the combustion temperature variations with varying humus particle sizes. These results are informative for predicting temperature variations and provide technical support for underground fire monitoring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Forest fires are classified into surface, canopy, and underground fires. Underground fires occur less frequently than the other types, but the damage can be significant (Watts and Kobziar 2013). Underground forest fire is slow spreading, long-lasting and having low temperature smoldering combustion without flame (Ohlemiller 1985; Rein 2013). These fires cause fatal damage to plant roots (Page et al. 2002; Davies et al. 2013), destruction of soil structure and ground collapse (Hadden et al. 2013), and higher greenhouse gas emissions than other categories of forest fires (Turetsky et al. 2004). Forested peatlands and wetlands with rich organic matter, such as those in boreal and tropical forests, are prone to underground fire (Huang et al. 2016). Soil carbon in these forests accounts for 25% of carbon reserves on land and plays essential roles in ecosystem stability, biodiversity maintenance, and hydrological cycling (Page et al. 2011). Therefore, large underground fires will substantially impact global climate, ecology, and human health (Davies et al. 2013; Hu et al. 2018). Wetlands were previously assumed to be fire-resistant due to their high humidity (Kuhry 1994). However, recent studies reported that smoldering has been widely observed in wetlands (Turetsky et al. 2004; Shetler et al. 2008). Quantitative studies in the field on smouldering events are seldom conducted as they are challenging due to their randomness and unpredictability (Davies et al. 2013). Therefore, combustion studies simulating underground fires are often carried out in the laboratory (Huang et al. 2015).

Large-scale underground fires have been recorded in Indonesia, Russia, Spain, and in other countries in recent years (Page et al. 2002; Cancellieri et al. 2012; Turetsky et al. 2015; Pastor et al. 2018). Underground fires are caused by surface fires or lightning (Davies 2016; Restuccia et al. 2017) with strong concealment and always accompanied by surface fires. There are considerable difficulties in monitoring and extinguishing them (Rein et al. 2008a, b). Their behavior is significantly different from other types of fires (Rein 2013), and could occur with a fuel moisture content of 100% or higher (Reardon et al. 2007; Lin et al. 2019), and persist through heavy rains, weather changes, extinguishing of surface fires, and may last for months or even years (Zaccone et al. 2014). The spread of an underground fire is maintained by heat released during combustion (Pastor et al. 2018), which is key to monitoring (Hartford and Frandsen 1992). Studies of smoldering have mainly focused on combustion characteristics (Pastor et al. 2018), contributing factors (Achtemeier 2006; Wang et al. 2017), combustion spread (Huang and Rein 2017), carbon release (Davies et al. 2013; Hu et al. 2018) and other aspects.

Non-linear mixed effects (NLME) modeling was first proposed by Sheiner and Beal (1980), which included both fixed and random effects parameters, and could identifying average prediction and individual prediction by calculating the estimated value of random effect parameters (Leites and Robinson 2004; Dorado et al. 2006; Yang et al. 2009). A mixed-effects model is a statistical method used in forestry, agriculture, ecology, biomedicine, sociology, economics, and in other fields (Calegario et al. 2005). In forestry, NLME modeling has been used in the studies of tree heights and diameters, growth processes, average growth, and basal area (Budhathoki et al. 2008; Mehtatalo et al. 2014; Ciceu et al. 2020) but has been seldom applied to forest fires. The mechanism of underground fire smoldering is complicated, so its occurrence and development are difficult to predict. The gradually rising temperature of a smoldering fire is like the growth process of a tree, so NLME modeling is applicable to smoldering. NLME modeling can achieve prediction accuracy with fewer independent variables and is suitable for studies on underground fire.

The frequency of underground fires in the boreal forests has increased in recent years (Sinclair et al. 2020), due to global climate change and the impact of human activities (Turetsky et al. 2015). The coniferous forests in the Daxing’an Mountains region, the southernmost margin of the Far Eastern Siberia boreal forests into China, is characterized by the largest number of underground fires in the country. The growth of Larix gmelinii (Rupr.) Rupr. planted in the Tatou wetlands of the Daxing’an Mountains has been poor because of the geographical and climatic conditions, and the decomposition of fallen branches and leaves slow so that the content of organic matter in humus increased, providing abundant fuel for underground fires. Rising temperature is one of the stages during the smoldering (Pastor et al. 2018); one of these is the buildup of temperatures causing significant damages. However, this process is easily monitored. This study focused on the process of rising temperatures in a Larix gmelinii plantation in the Tatou wetlands, analyzed smoldering temperature variations of humus of different particle sizes, and developed a method to predict temperatures of underground fires by non-linear mixed effects (NLME) modeling to provide support for underground fire monitoring and control.

Materials and methods

Study area

Forest fires in the Daxing’an Mountains region occur frequently; the area burned is largest in China. The study area is in the Jiagedaqi Forest Management Technology Promotion Station (123°57′–124°0′ E, 50°20′–50°23′ N), located in the northwest of Heilongjiang province, on the southeast slopes of the Daxing’an Mountains (Fig. 1a). The region has a continental monsoon climate with four distinctive seasons, a changeable climate and large diurnal and seasonal temperature differences. Annual average temperatures are − 1 to 2 °C, the annual effective accumulative temperature 1800–2000 °C, the frost-free period 90–120 days, and annual rainfall 450–500 mm. The technology promotion station was founded in 1973, 15 km to the south of the Jiagedaqi region, the north and west portions of the station is connected with the Dongfeng Forest Station of the Jiagedaqi Forestry Bureau. The total area of the station is 7326 ha2. The main species in the study area are Larix gmelinii, Quercus mongolica Fisch, Betula platyphylla Suk., Populus davidiana Dode, and Betula dahurica Pallas (Tang et al. 2022).

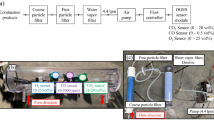

Sample collection and processing

Three 30 m × 20 m sample fields were established and three 0.5 cm × 0.5 cm quadrats selected (sampling depth was the 46-cm thickness of the humus layer) in the diagonals according to Pastor (2018) (Fig. 1b, c). All the humus in the quadrats was collected, and after removal of surface litter and in the humus layer, taken to the laboratory, stored in kraft paper sacks and dried for 48 h at 105 °C to remove as much moisture as possible. As an uneven distribution of humus particles will affect the temperature measurements accuracy (Huang and Rein 2017), the dried humus was ground and sieved into particle sizes of ≤ 20 mesh (moisture content 0.28%), ≤ 40 mesh (moisture content 0.49%), ≤ 60 mesh (moisture content 0.43%), and ≤ 80 mesh (moisture content 0.49%) for the combustion experiments(Fig. 1d).

Combustion experiments

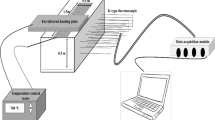

The combustion furnace was designed for studying a one-dimensional downward combustion process (Fig. 2) (Huang and Rein 2017). The unit was cylindrical (20- cm high with 10- cm walls) of aluminum silicate ceramic fiber with excellent heat insulation. A K-type thermocouple (30 cm long × 2 mm diameter) recorded temperature variations of the humus during combustion. The data were transmitted to a laptop by data acquisition module composed of a 16-channel NI9213 voltage acquisition board card and DAQ-9174 case (4 card slots), with temperature measurement accuracy < 0.25 °C. The data acquisition software (Labview2018) recorded temperature variations collected by the thermocouples. A far-infrared heating plate (30 cm long × 20 cm wide × 5 cm thick) was used as an ignition device. A temperature control meter between the far-infrared heating plate and the power supply kept the temperature of the heating plate constant.

Humus of different particle sizes were placed in the combustion furnace at ambient temperatures and the shape of the particles maintained as much as possible. Holes were arranged every 3 cm on the side of combustion furnace and K-type thermocouples inserted into the humus through the holes. The K-type thermocouples and data acquisition module were connected temperature variation data transmitted to the laptop every 10 s. To ensure combustion continued after removing the heating plate (ignition device), heating time and temperature were set to 1.5 h and 500 °C. A 2-cm gap between the heating plate and combustion furnace allowed for air flow.

Non-linear mixed effects model

The general form of a non-linear mixed effects model is:

where \(T_{i}\) is the dependent variable of subject \(i\) and refers to the predicted combustion temperature; \(f\) is the actual value, specific parameter vector \(\varphi_{i}\) and variable value vector \(t_{i}\) of the differentiable function in the subject, and refers to actual combustion temperature of the underground fire; \(\beta\) is the \(p\)-dimensional fixed effect parameter vector; \(b_{i}\) is the \(q\)-dimensional random effect parameter vector; \(D\) is the covariance matrix between random effects; \(A_{i}\) and \(B_{i}\) are correlation matrices with appropriate dimensions ( 0 or 1); \(t_{i}\) is the independent matrix; \(\varepsilon_{i}\) is the random error vector associated with \(T_{i}\); and,\(\sigma^{2}\) is the covariance matrix of the random error.

Base model

Logistic, Richards, and Korf nonlinear models, widely used in forestry to predict the tree growth, height, and DBH (Calama and Montero 2004; Rijal 2012; Sharma et al. 2016; Pan et al. 2020) (Table 1), were selected as the base models to study temperature variations in the combustion process.

Model selection and validation

The base model was selected according to the values of Akaike’s Information Criterion-(AIC) and Schwarz’s Bayesian Information Criterion-(BIC). Model accuracy was evaluated with different parameters according to the values of Root Mean Square Error (RMSE). Smaller values of AIC and BIC indicate the better fitting degree of the equation; smaller values of RMSE indicates the higher accuracy of the model (Akaike 1974).

where \(T_{ij}\) is the actual value, \(\hat{T}_{ij}\) the predicted value, n the sample amount, L the maximum likelihood (ML) value, and p is the number of model parameters.

Statistical analysis

Excel and Origin were used to analyze the combustion temperature variation data with different humus particle sizes and from different depths, and the relationship between the maximum temperature and the combustion depth; NLMIXED and NLINE modules of Statistical Analysis System-(SAS) were used to select, fit, and verify the nonlinear mixed effect models.

Results

Maximum combustion temperature variations of humus of different particle sizes

There was no flame or spark during humus smoldering, and the surface was carbon black and the deep layer brick red after combustion. The maximum combustion temperature of different particle sizes increased with depth. There was a positive linear relationship between depth and temperature (P < 0.05) in both particle ≤ 40 mesh size and ≤ 80 mesh size. The equations were y = 435.68 + 27.87 x and y = 453.82 + 21.82 x respectively. The highest combustion temperature of all particle sizes was at the 15-cm depth with particles ≤ 40 mesh size (897.5 °C), the highest combustion temperature with particle ≤ 80 mesh size was 844.9 °C.

There was a positive linear relationship between depth and temperature (P < 0.01) in both particle ≤ 20 mesh size and ≤ 60 mesh size; the equations were y = 474.76 + 17.42 x and y = 468.84 + 20.21x, respectively. Combustion temperature variations with particle size ≤ 20 mesh at different depths fluctuated the lowest, the highest combustion temperature was 741.6 °C and the lowest was 543.3 °C. The highest combustion temperature with particle size ≤ 60 mesh was 780.4 °C and the lowest was 553.3 °C (Fig. 3).

Selection and validation of NLME models

The NLME models were selected based on 60% of the humus combustion data with different particle sizes. AIC, BIC evaluated the approximation based on the three models. The AIC (135,343) and BIC (135,373) values of the Richards equation with different particle sizes were the smallest. It may be concluded that Richards equation provided the best approximation and was therefore chosen as the basic equation for the relationship between humus combustion temperature and time (Table 2).

Richards equations of combustion temperature variation were set with no parameter mixing, and one, two, and three parameters mixing for different particle sizes. All equations with different parameters were convergent, and the RMSE values of models with mixed parameters were smaller than the traditional models. The precision of models with mixed parameters was higher than the conventional models. The RMSE value of the three parameters was the least, therefore, the accuracy of Richards equation with three parameters mixing was the highest (Table 3).

Mixed-effects model approximation of Richards equation

The relationship between combustion temperature and time at different depths with different particle sizes was fitted by Richards equation with three parameters mixing. According to the temperature variation,\(\beta_{1}\),\(\beta_{2}\) and \(\beta_{3}\) were the estimated values of equations at 15- cm depth for each particle size, and \(b_{ij}\) was the parameter mixing effect at different depths (Table 4). The approximation of Richards equations with different particle sizes is shown in Fig. 4

Discussion and conclusions

Variation characteristics of humus combustion temperature

Peatland and humus are the main combustibles of underground fires, and peatland fires is of wide concern for the frequent occurrence of large-scale fires (Davies et al. 2013). Commercial peat moss with its homogenous texture and consistent components has been widely used in characterizing smoldering and contributing factors, instead of using peatlands in the field (Huang and Rein 2017). More researchers have started using underground combustibles to approximate reality (Pastor et al. 2018). In this study, actual humus from the Tatou wetlands of the Daxing’an Mountains was used to study temperature variations of vertical smoldering, and the results are reliable and highly applicable.

Smoldering combustion of humus is sustained by the heat released by itself. The maximum temperature was 897.5 °C in this study, close to 900 °C of a similar study using peat (Huang et al 2015). Most studies have reported that the maximum temperature of peat smoldering was around 600 °C (Bar-Ilan et al. 2004; Huang and Rein 2017), lower than our result. Using different experiment devices and materials might account for the difference. It could also reflect the different temperatures of humus and peat smoldering. The mass loss of combustibles was small, and the humus afterwards was brick red due to sufficient burning and high temperatures (Fig. 3) and in addition, there was no ash after combustion, only a thin layer of carbonized humus. The heat release was impeded by the humus of the upper layers when the fire was spreading downwards, so the temperature of humus smoldering was higher and increased with depth. But the mass loss of combustibles in peat smoldering was larger according to Huang and Rein (2014). Without being impeded by upper layers, the heat released quickly so the temperature was lower than the humus.

Combustion depth could go to more than 50 cm (Ballhom et al. 2009). However, the combustion depth was found to be deeper due to the increased aridity of peatlands and wetlands due to global warming (Turetsky et al. 2015). The combustion process is also affected by oxygen levels, so when oxygen decreases as depth increases, combustion might be extinguished. This observation requires further study.

Applicability of NLME in smoldering temperature variation

Unlike surface and canopy fires, the heat released in underground fires is the manifestation of the smoldering process, which is also the important basis for fire monitoring and fighting. Fire intensity and spread rate are both predicted by the heat released (Rein et al. 2008a, b; Kirschke et al. 2013); the heat released, and temperature change of the ground surface are useful for judging the occurrence of underground fires and the direction for digging fire breaks. Therefore, thermos physical models are essential tools for studying the mechanism of underground fire occurrence and development (Huang and Rein 2014), and an important basis for fire monitoring and fighting.

This study was based on NLME modeling to predict temperatures of underground fires and focused on the prediction of temperature during smoldering. Simple statistical models are better for prediction research, and NLME is better than ordinary regression models. Many statistical models have been applied to forest fire prediction (Bem et al. 2018; Nadeem et al. 2020) and have increased prediction accuracy. The variation of temperatures during underground fire combustion showed a slow rise at the beginning, then a rapid rise, and finally, a stable temperature after reaching the maximum temperature. The change curves of the three basic models in this paper are “S” type, which are consistent with the change curves of underground fires, so the models could be applied to the prediction of temperatures during these fires.

In this study, well-replicated underground fire temperatures with varying depths and particle sizes were studied (Hall and Bailey 2001). NLME modeling was shown to be significantly superior in handling longitudinal, multi-level and replicated data (Calegario et al. 2005). Richards equations exhibited the best applicability in fitting humus combustion temperatures after evaluating three models and have been widely used owing to their biological significance, strong adaptability, and high accuracy (Li and Zhang 2010). Hang et al. (1997) and Hall and Bailey (2001) also found high accuracy of Richards equations, consistent with the results of our study.

Conventionally, the least square method was used to estimate model parameters of multilevel data, but this method tended to use data lacking independence, time correlation and space heterogeneity, and would lead to large prediction errors (Mensah et al. 2018). NLME modeling has higher accuracy (Sharma et al. 2016) through set up, fixed effect, and random effect parameters (Kalle 2009). Based on the results of RMSE in this study, the accuracy of models with mixing parameters were much higher than traditional nonlinear models, and the accuracy increased as the number of parameters increased. Ciceu et al. (2020) also reported the high precision of NLME models, although the parameters were different due to the research contents and basic models. Meng et al. (2009) found that a NLME model with two parameters was highly accurate. Pan et al. (2020) reported that one with three parameters had high precision.

Prospect of using NLME modeling in forest fire research

Studies with mixed effects models are emerging research areas in forestry (Calegario et al. 2005), but their applications in forest fire research are rarely reported. Studies of forest fires, based on multi-level aspects, such as combustible characteristics, fire forecasting and fire behavior, should reflect both overall change trend and individual differences, so NLME has more advantages (Guillermo et al. 2006). NLME also has the advantages of high reliability, flexibility and accuracy (Sharma et al. 2016), and have great application potential in the study of forest fire.

References

Achtemeier GL (2006) Measurements of moisture in smoldering smoke and implications for fog. Int J Wildland Fire 15:517–525

Akaike H (1974) A new look at the statistical model identification. Trans Autom Control 19:716–723

Ballhom U, Siegert F, Mason M, Limin S (2009) Derivation of burn scar depths and estimation of carbon emissions with LIDAR in Indonesian peatlands. Proc Natl Acad Sci USA 106:21213–21218

Bar-Ilan A, Rein G, Fernandez-Pello AC, Torero JL, Urban DL (2004) Forced forward smoldering experiments in microgravity. Exp Thermal Fluid Sci 28:743–751

Bem PD, Osmar ACJ, Matricardi E, Guimarães RF, Gomes RAT (2018) Predicting wildfire vulnerability using logistic regression and artificial neural networks: a case study in Brazil. Int J Wildland Fire 28:35–45

Budhathoki CB, Lynch TB, Guldin JM (2008) Nonlinear mixed modeling of basal area growth for shortleaf pine. For Ecol Manag 255:3440–3446

Calama R, Montero G (2004) Interregional nonlinear height-diameter model with random coefficients for stone pine in Spain. Can J For Res 34:150–163

Calegario N, Daniels RF, Maestri R, Neiva R (2005) Modeling dominant height growth based on nonlinear mixed-effects model: a clonal eucalyptus plantation case study. For Ecol Manag 204:11–21

Cancellieri D, Leroy-Cancellieri V, Leoni E, Simeoni A, Kuzin AY, Filkov AI, Rein G (2012) Kinetic investigation on the smouldering combustion of boreal peat. Fuel 93:479–485

Ciceu A, Garcia-Duro J, Seceleanu I, Badea O (2020) A generalized nonlinear mixed-effects height-diameter model for Norway spruce in mixed-uneven aged stands. For Ecol Manag 477:118507

Davies GM (2016) Vegetation structure and fire weather influence variation in burn severity and fuel consumption during peatland wildfires. Biogeoences 13:389–398

Davies GM, Gray A, Rein G, Legg CJ (2013) Peat consumption and carbon loss due to smouldering wildfire in a temperate peatland. For Ecol Manage 308:169–177

Dorado FC, Diéguez-Aranda U, Anta BM, Rodríguez MS, Gadow K (2006) A generalized height-diameter model including random components for radiata pine plantations in northwestern Spain. For Ecol Manag 229:202–213

Hadden RM, Rein G, Belcher CM (2013) Study of the competing chemical reactions in the initiation and spread of smouldering combustion in peat. Proc Combust Inst 34:2547–2553

Hall DB, Bailey RL (2001) Modeling and prediction of forest growth variables based on multilevel nonlinear mixed models. For Sci 47:311–321

Hang LZ (1997) Cross-validation of non-Linear growth functions for modeling tree height-diameter relationships. Ann Bot 79:251–257

Hartford R, Frandsen W (1992) When it’s hot, it’s hot or maybe it’s not! surface flaming may not portend extensive soil heating. Int J Wildland Fire 2:139–144

Hu Y, Fernandez-Anez N, Smith TEL, Rein G (2018) Review of emissions from smouldering peat fires and their contribution to regional haze episodes. Int J Wildland Fire 27:293–312

Huang X, Rein G (2014) Smouldering combustion of peat in wildfires: inverse modelling of the drying and the thermal and oxidative decomposition kinetics. Combust Flame 161:1633–1644

Huang X, Rein G (2017) Downward spread of smouldering peat fire: the role of moisture, density and oxygen supply. Int J Wildland Fire 26:907–918

Huang X, Rein G, Chen H (2015) computational smoldering combustion: predicting the roles of moisture and inert contents in peat wildfires. Proc Combust Inst 35:2673–2681

Huang X, Restuccia F, Gramola M, Rein G (2016) Experimental study of the formation and collapse of an overhang in the lateral spread of smouldering peat fires. Combust Flame 168:393–402

Kalle E (2009) A multivariate linear mixed-effects model for the generalization of sample tree heights and crown ratios in the Finnish national forest inventory. For Sci 55:480–493

Kirschke S, Bousquet P, Ciais P, Saunois M, Zeng G (2013) Three decades of global methane sources and sinks. Nat Geosci 6:813–823

Kuhry P (1994) The role of fire in the development of sphagnum-dominated peatlands in western boreal Canada. J Ecol 82:899–910

Leites LP, Robinson AP (2004) Improving taper equations of loblolly pine with crown dimensions in a mixed-effects modeling framework. For Sci 50:204–212

Li C, Zhang H (2010) Modeling dominant height for Chinese fir plantation using a nonlinear mixed-effects modeling approach. Scientia Silvae Sinicae 46:89–95

Lin S, Sun P, Huang X (2019) Can peat soil support a flaming wildfire? Int J Wildland Fire 28:601–613

Mehtatalo L, Peltola H, Kilpelainen A, Ikonen VP (2014) The response of basal area growth of scots pine to thinning: a longitudinal analysis of tree-specific series using a nonlinear mixed-effects model. For Sci 60:636–644

Meng S, Huang S (2009) Improved calibration of nonlinear mixed-effects models demonstrated on a height growth function. For Sci 55:238–248

Mensah S, Pienaar OL, Kunneke A, Toit S, Seydack A, Uhl E, Pretzsch H, Seifert T (2018) Height-diameter allometry in south Africa’s indigenous high forests: assessing generic models’ performance and function forms. For Ecol Manag 410:1–11

Nadeem K, Taylor SW, Woolford DG, Dean CB (2020) Mesoscale spatiotemporal predictive models of daily human- and lightning-caused wildland fire occurrence in British Columbia. Int J Wildland Fire 29:11–27

Ohlemiller TJ (1985) Modeling of smoldering combustion propagation. Prog Energy Combust Sci 11:277–310

Page SE, Siegert F, Rieley JO, Boehm HDV, Jaya A, Limin S (2002) The amount of carbon released from peat and forest fires in Indonesia during 1997. Nature 420:61–65

Page SE, Rieley JO, Banks CJ (2011) Global and regional importance of the tropical peatland carbon pool. Glob Change Biol 17:798–818

Pan L, Mei G, Wang Y, Saeed S, Chen L, Cao Y, Sun Y (2020) Generalized nonlinear mixed-effect model of individual tree height to crown base for Larix olgensis Henry in Northeast China. J Sustain For 39:1–14

Pastor E, Oliveras I, Urquiagaflores E, Quintanoloayza JA, Mant MI, Planas E (2018) A new method for performing smouldering combustion field experiments in peatlands and rich-organic soils. Int J Wildland Fire 26:1040–1052

Reardon J, Hungerford R, Ryan K (2007) Factors affecting sustained smouldering in organic soils from pocosin and pond pine woodland wetlands. Int J Wildland Fire 16:107–118

Rein G, Cleaver N, Ashton C, Pironi P, Torero JL (2008a) The severity of smouldering peat fires and damage to the forest soil. Catena 74:304–309

Rein G, Garcia J, Simeoni A, Tihay V, Ferrat L (2008b) Smouldering natural fires: comparison of burning dynamics in boreal peat and mediterranean humus. Model Monit Manag For Fires 119:183–192

Rein G (2013) Smouldering fires and natural fuels. In: Belcher Claire M (ed) Fire phenomena and the earth system: an interdisciplinary guide to fire science. Wiley, Oxford

Restuccia F, Huang X, Rein G (2017) Self-ignition of natural fuels: can wildfires of carbon-rich soil start by self-heating? Fire Saf J 91:828–834

Rijal B, Weiskittel A, Kershaw JA (2012) Development of regional height to diameter equations for 15 tree species in the North American Acadian region. Forestry 85:379–390

Sharma RP, Vacek Z, Vacek S (2016) Individual tree crown width models for Norway spruce and European beech in Czech Republic. For Ecol Manag 366:208–220

Sheiner LB, Beal SL (1980) Evaluation of methods for estimating population pharmacokinetic parameters. I. michaelis-menten model: routine clinical pharmacokinetic data. J Pharmacokinet Biopharm 8:553–571

Shetler G, Turetsky MR, Kane E, Kasischke E (2008) Sphagnum mosses limit total carbon consumption during fire in Alaskan black spruce forests. Can J for Res 38:2328–2336

Sinclair AL, Graham LLB, Putra EI, Saharjo BH, Applegate G, Grover SP, Cochrane MA (2020) Effects of distance from canal and degradation history on peat bulk density in a degraded tropical peatland. Sci Total Environ 699:134199

Tang SY, Yin SN, Shan YL, Gao B, Sun L, Han XY, Wang MX, Wang MY, Chen ZS (2022) A study of emissions and marker gases from smouldering combustion in Larix gmelinii plantations of the Daxing’an Mountains. J For Res 33:195–201. https://doi.org/10.1007/s11676-021-01323-x

Turetsky MR, Amiro BD, Bosch E, Bhatti JS (2004) Historical burn area in western Canadian peatlands and its relationship to fire weather indices. Global Biogeochem Cycles 18:1–9

Turetsky MR, Benscoter B, Page S, Rein G, Guido RW, Watts A (2015) Global vulnerability of peatlands to fire and carbon loss. Nature Geoence 8:11–14

Wang S, Huang X, Chen H, Liu N (2017) Interaction between flaming and smouldering in hot-particle ignition of forest fuels and effects of moisture and wind. Int J Wildland Fire 26:71–81

Watts AC, Kobziar LN (2013) Smoldering combustion and ground fires: ecological effects and multi-scale significance. Fire Ecol 9:124–132

Yang Y, Huang S, Meng SX (2009) Development of a tree-specific stem profile model for white spruce: a nonlinear mixed model approach with a generalized covariance structure. Forestry 82:541–555

Zaccone C, Rein G, Dorazio V, Hadden RM, Belcher CM, Miano TM (2014) Smouldering fire signatures in peat and their implications for palaeoenvironmental reconstructions. Geochim Cosmochim Acta 137:134–146

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Project funding: This research was funded by the National Natural Science Foundation of China (Grant No. 31971669).

The online version is available at http://www.springerlink.com

Corresponding editor: Yu Lei

Rights and permissions

About this article

Cite this article

Yin, S., Shan, Y., Gao, B. et al. Characterizing and predicting smoldering temperature variations based on non-linear mixed effects models. J. For. Res. 33, 1829–1839 (2022). https://doi.org/10.1007/s11676-022-01463-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11676-022-01463-8