Abstract

The interaction of components in the Dy-Sm-Ge system at 873 K was investigated by means of x-ray phase and structural analyses, microstructural analysis and energy dispersive x-ray spectroscopy. The existence of the continuous solid solutions between the isostructural binary germanides of the Dy1−xSmxGe (CrB-type), Dy5-xSmxGe4 (Sm5Ge4-type) and Dy5-xSmxGe3 (Mn5Si3-type) were established. The limited solid solutions based on the binary germanides of the SmGe2 (α-ThSi2-type), DyGe2 (TbGe2-type) and Dy11Ge10 (Ho11Ge10-type) are formed. The solubility of Dy in SmGe2 is 15 at.%, Sm in DyGe2 and Dy11Ge10 − 10 at.%, Sm. Two ternary SmxDy1−xGe1.5 (x = 0.15-0.50) and Sm2Dy2Ge7 compounds were found. SmxDy1−xGe1.5 crystallizes in AlB2 structure type. The crystal structure of the new ternary compound of the Sm2Dy2Ge7 (ordered superstructure to Nd4Ge7-type, Pearson symbol oS44, space group C2221, a = 0.5942(1), b = 1.3823(4), c = 1.1801(3) nm, V = 0.9694 nm3) was investigated by means of x-ray single crystal diffraction. The germanium atoms form 3D anionic network the existence of which was confirmed by electronic structure calculations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rare-earth intermetallics have been extensively studied in different fields and applications, including magnetic materials, thermoelectric, hydrogen storage materials and other.[1,2] The development of new materials on the base of rare-earth metals alloys requires systematic investigation of interactions between the components in binary, ternary and multicomponent systems, construction of their phase diagrams, and determination of crystal structure of the obtained phases.

In literature there are experimental data on ternary R-R’-Ge systems, where R and R’—rare earth metals cerium or yttrium subgroups. The most detailed were studied the sections between digermanides RGe2-R’Ge2.[3] On these sections the solid solutions as well as individual ternary phases are formed. The continuous solid solution for DyGe2-TbGe2 section was observed. In the DyGe2-RGe2 (were R = Er, Ho, Tm and Lu) sections forms the limited solid solutions. In the ternary systems with dysprosium the intermetallic compounds Dy0.67Tm0.33Ge1.85,[4] Dy0.5Ho0.5Ge1.75[5] and Dy0.6Lu0.4Ge2[6] were observed. In the systems with samarium only one ternary compound of Sm0.625Lu0.375Ge1.85[7] was studied.

In this contribution we report experimental results of the investigation of isothermal section at 873 K of phase diagram of the Dy-Sm-Ge ternary system in full concentration range.

2 Literature Data on Boundary Binary Diagrams

2.1 Sm-Ge System

The Sm-Ge phase diagram (Fig. 1a) was critically assessed by Gokhale and Abbaschian[8] based on experimental data of Eremenko et al.[9] Five binary compounds Sm5Ge3, Sm5Ge4, SmGe, SmGe1.5, SmGe2 forms in the Sm-Ge binary system. Sm5Ge3 phase melts congruently at 1973 K. The Sm5Ge4, SmGe and Sm2Ge3 (SmGe1.5) forms peritectically.

SmGe1.5 (or Sm2Ge3) compound exists in three polymorphic modifications. The polymorphic transition α-SmGe1.5 ↔ β-SmGe1.5 occurs at 1018 K, and the β-SmGe1.5 ↔ γ-SmGe1.5 polymorphic transition is at 1358 К. The orthorhombic and hexagonal Sm3Ge5[10,11] phases are the α-SmGe1.5 and β-SmGe1.5 polymorphic modifications respectively.

The SmGe2[12] compound according to the structural data has a composition of SmGe1.63[9] and forms by peritectoid reaction.

The described earlier Sm4Ge7[13,14] and SmGe5[15] compounds which are not observed on phase diagram, probably, are metastable phases. Crystals of Sm4Ge7 was prepared by Zhang et al.[14] using the flux method, flux In (99.99 wt.%), heated to 1373 K at a rate of 300 K h−1, heated at 1373 K for 1.5-3 h, cooled to 673 K over 20 h and structurally investigated by both x-ray and electron diffraction. This structure belongs to superstructure of RGe2−x with the α-ThSi2 or α-GdSi2 types at x = 1/4. The orthorhombic structure is realized through the long-range order of vacant Ge positions. The high-pressure phase SmGe5[15] synthesized by heating of pure elements at 1123 K and 10 GPa. New germanide Sm2Ge9 was received by thermal decomposition of high-pressure phase SmGe5[16]

Crystallographic characteristics of all known Sm-Ge binary compounds are presented in Table 1.

2.2 Dy-Ge System

The Dy-Ge phase diagram (Fig. 1b) is redrawn from Eremenko et al.[17] Seven binary compounds: Dy5Ge3, Dy5Ge4, DyGe, DyGe1.59 (Dy2Ge3), Dy3Ge5, DyGe1.85 and DyGe3 forms in this system.[18,19,20,21,22,23,24,25,26] The DyGe3, DyGe1.85, DyGe1.59, DyGe and Dy5Ge4 phases are formed by peritectic reactions.

The polymorphic transitions α-DyGe1.59 ↔ β-DyGe1.61 and β-DyGe1.61 ↔ γ-DyGe1.5 at 1160 К and 1573 К are observed respectively. The reaction of formation of the Dy3Ge5 is peritectoid.

The Dy5Ge3 germanide melts congruently at 2100 К and has a has an insignificant ~2 at.% homogeneity region.

During the investigation of polymorphism in the binary rare-earth metal germanides the new hexagonal phase of Dy3Ge5 was observed at 120 K by Tobash et al.[27]

The DyGe1.90, Dy3Ge4 (T = 20 K)[28] and Dy11Ge10[21] compounds for which crystal structures were studied, but are not displayed on the diagram.

New cubic phase DyGe2.85 crystallized in the cubic AuCu3 structure type was synthesized at a pressure of 8 GPa and described by Tsvyashchenko et al.[29]

Crystallographic characteristics of known Dy-Ge binary compounds are presented in Table 2.

2.3 Dy-Sm System

The Dy-Sm phase diagram (Fig. 1b) is redrawn from Okamoto.[30] Dysprosium exists in two allotropic modifications: α-Dy (Mg-type) and β-Dy (W-type). The transformation α-Dy ↔ β-Dy occurs at 1654 K. Samarium exists in three allotropic modifications: α-Sm (Sm-type), β-Sm (Mg-type) and γ-Sm (W-type). The transformation of α-Sm to β-Sm occurs at 1007 K and the following transformation of β-Sm ↔ γ-Sm is at 1195 K.

Based on the high-temperature modifications β-Dy and γ-Sm and low-temperature modifications α-Dy and β-Sm forms continuous series of solid solutions (β-Dy/γ-Sm and α-Dy/β-Sm). Based on low-temperature modifications of α-Sm limited solid solution is formed, and the homogeneity region of which extends from 15 to 25 at.% Dy at room temperature.

3 Experimental Details

Samarium, dysprosium and germanium, all with a nominal purity greater than 99.9 wt.%, were used as starting materials. The 64 samples a total mass of each about 2 g were prepared by arc melting of pure metals in a high-purity argon atmosphere. The mass losses after the melting were less than 1 wt.%. After the melting the samples were sealed in evacuated quartz ampoules and annealed at 873 K during 720 h. After annealing the ampoules with the samples were quenched in cold water.

Phase analysis of the samples was carried out with the use of powder x-ray diffraction (XRD) (DRON-4.0M and STOE STADI P diffractometers with Fe- and Cu-Kα radiation, respectively). The obtained powder diffraction data were analyzed by Rietveld method using Fullprof software.[31] Wavelength Dispersive Spectrometry (WDS) and CAMECA SX-100 Electron Probe Micro Analyser (EPMA) and REMMA-102-02 scanning microscope were used to measure the number of phases and their qualitative and quantitative chemical compositions some alloys.

Single crystal diffraction data were collected by Xcalibur™3 CCD diffractometer with graphite-monochromated Mo-Kα radiation. Scans were taken in the ω mode, the analytical absorption corrections were made by CrysalisRed[32] The crystal structure was solved by direct methods and refined using the SHELX-97 program package.[33,34]

The electronic structures of the ternary compound was calculated using the tight-binding linear muffin-tin orbital (TB-LMTO) method in the atomic spheres approximation (TB-LMTO-ASA[35,36,37]) using the experimental crystallographic data reported here. The exchange and correlation were interpreted in the local density approximation.[38] All the figures and graphics concerning electron structure calculations were generated using wxDragon.[39]

4 Results and Discussion

4.1 Isothermal Section at 873 K of the Dy-Sm-Ge System

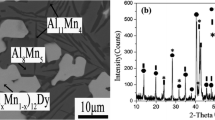

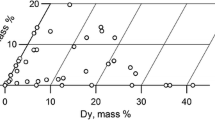

The isothermal section of the Dy-Sm-Ge system at 873 K was constructed by XRD and SEM-EPMA methods based on the phase analysis of 13 binary and 51 ternary alloys (Fig. 2a, b). This isothermal section in the full concentration region consists of 11 three-phase, 23 two-phase and 13 single-phase regions. From Fig. 3(a)-(h), it can be seen that in the germanium-rich region at 870 K the stable phases are the Dy2Sm2Ge7 ternary compound, solid solutions phases based on SmGe2, DyGe1.9 and DyGe3 binary compounds. Formation of other binary phases known from the literature (metastable) or solid solutions based on these phases are not observed. The binary SmGe2-x phase with α-ThSi2 structure type has homogeneity region from SmGe2 to SmGe1.67, although in the literature[9,12] for these compositions were indicated different structural types (α-ThSi2 and AlB2 respectively). From the SmGe1.6 to SmGe1.5 (α-SmGe1.5) realized hexagonal Sm3Ge5 structure type.

Micrographs of selected samples from the Ge-rich region of Dy-Sm-Ge system: (a) Dy20Sm5Ge75 (light grey phase—Dy1−xSmxGe1.9, composition from EPMA Dy24.6(4)Sm9.2(4)Ge66.2(5); grey phase—DyxSm1−xGe3, Dy20.1(3)Sm4.8(3)Ge75.1(4); dark phase—Ge); (b) Dy10Sm10Ge80 (grey phase—Dy2Sm2Ge7, Dy17.5(2)Sm18.1(2)Ge64.4(3); dark phase—Ge); (c) Dy18Sm10Ge72 (light grey phase—Dy1−xSmxGe1.9, Dy23.1(3)Sm10.6(3)Ge66.3(4); grey phase—Dy2Sm2Ge7, Dy17.7(2)Sm18.1(2)Ge64.2(3); dark phase—Ge); (d) Dy10Sm18Ge72 (light grey phase—DyxSm1−xGe2, Dy10.1(3)Sm23.6(3)Ge66.3(4) grey phase—Dy2Sm2Ge7, Dy17.6(3)Sm18.2(3)Ge64.2(4); dark phase—Ge); (e) Dy24Sm10Ge66 (grey phase—Dy1−xSmxGe1.9, Dy23.7(3)Sm10.1(3)Ge66.2(4); single dark spots—Ge); (f) Dy17Sm17Ge66 (grey phase—Dy2Sm2Ge7, Dy17.7(2)Sm18.2(2)Ge64.1(3); single dark spots—Ge); (g) Dy10Sm24Ge66 (grey phase—Sm1−xDyxGe2, Dy10.7(2)Sm22.9(3)Ge66.4(4); single dark spots—Ge)

The following three-phase regions were detected:

Dy1−xSmxGe1.9+ Dy1−xSmxGe3+Ge, Dy1−xSmxGe1.9+ Dy2Sm2Ge7+Ge,

Dy1−xSmxGe2+ Dy2Sm2Ge7+Ge, Dy1−xSmxGe1.9+ Dy2Sm2Ge7+SmxDy1−xGe1.5,

DyxSm1−xGe2+ Dy2Sm2Ge7+Dy1−xSmxGe1.5, Sm1−xDyxGe2+Dy1−xSmxGe+Dy1−xSmxGe1.5,

Dy5-xSmxGe4+Dy1−xSmxGe+Dy11−xSmxGe10, Dy1−xSmxGe1.9+Dy1−xSmxGe1.5+Dy3Ge5,

Dy1−xSmxGe1.5+DyGe1.59+Dy3Ge5, SmxDy1−xGe1.5+DyGe1.59+ Dy1−xSmxGe,

DyxSm1−xGe2+SmGe1.5+Dy1−xSmxGe. The micrographs of selected three-phase samples are shown Fig. 4(a-f).

Micrographs of selected three-phase samples from Dy-Sm-Ge system: (a) Dy21Sm17Ge62 (light grey phase—Dy1−xSmxGe1.5, composition from EPMA Dy22.6(4)Sm17.2(4)Ge60.2(4); grey phase—Dy1−xSmxGe1.9, Dy24.6(4)Sm9.2(4)Ge66.2(5); dark grey phase—Dy2Sm2Ge7, Dy17.4(2)Sm18.1(2)Ge64.5(4); Ge); (b) Dy17Sm21Ge62 (light grey phase—Dy1−xSmxGe1.5, Dy23.1(4)Sm16.8(4)Ge60.1(4); grey phase—Dy2Sm2Ge7, Dy17.4(2)Sm18.4(2)Ge64.2(4); Ge); dark grey phase—DyxSm1−xGe2, Dy11.6(4)Sm22.1(4)Ge66.3(5); (c) Dy20Sm26Ge54 (light grey phase—Dy1−xSmxGe, Dy13.0(3)Sm43.6(3)Ge33.4(5); grey phase—Dy1−xSmxGe1.5, Dy20.2(4)Sm19.6(4)Ge60.2(4); dark grey phase—DyxSm1−xGe2, Dy11.1(4)Sm22.6(4)Ge66.3(5); (d) Dy5Sm55Ge40 (dark grey phase—DyxSm1−xGe2, Dy11.1(4)Sm22.6(4)Ge66.3(5); grey phase—SmGe1.5, Sm39.6(3)Ge60.4(4) bright phase—Dy1−xSmxGe, Dy8.1(3)Sm58.5(3)Ge33.4(5); (e) Dy33Sm5Ge62 (light grey phase—DyGe1.59, Dy38.7(3)Ge61.3(4); grey phase—Dy1−xSmxGe1.5, Dy31.1(4)Sm8.8(4)Ge60.1(4); dark grey phase—Dy3Ge5, Dy37.6(3)Ge62.4(5); (f) Dy32Sm20Ge48 (light grey phase—Dy5-xSmxGe4, Dy33.2(2)Sm22.3(2)Ge44.5(3); grey phase—Dy11−xSmxGe10, Dy43.1(4)Sm9.4(4)Ge47.5(5); dark grey phase—Dy1−xSmxGe, Dy17.0(3)Sm49.6(3)Ge33.4(5))

The single-phase regions consist new ternary compounds of Dy2Sm2Ge7 and Dy1−xSmxGe1.5, limited solid solutions based on binary compounds: Dy1−xSmxGe3, Dy1−xSmxGe1.9, DyxSm1−xGe2, Dy11−xSmxGe10 and continuous solid solutions: Dy1−xSmxGe, Dy5-xSmxGe4 and Dy5-xSmxGe3. A solid solutions between the isostructural binary compounds of Sm-Ge and Dy-Ge systems are unlimited. All solid solution forms by mutual substitution of Dy and Sm. The solubility of Sm in DyGe3 is less than 5 at.% Sm. At 873 K we are not confirmed the existence of Dy3Ge5 compound, which was presented on the Dy-Ge phase diagram (Fig. 1b)[15], instead, we confirmed the existence of Dy11Ge10 phase which earlier was studied by Tharp et al.[18], but is absent in Fig. 1(b).

4.2 Limited Solid Solutions

Limited solid solution from the SmGe2—DyGe1.9 section. The SEM/EPMA and XRD phase analysis of alloys (Fig. 3, and Fig. S1) from the isoconcentrate Sm34Ge66—Dy34Ge66 shows that the SmGe2 (α-ThSi2- type) solve up to 15 at.% Dy and DyGe1.9 (TbGe2- type) solve up to 10 at.% Sm. Between these limited solutions, the formation of a new ternary phase of Dy2Sm2Ge7 was found (Fig. 3c-e). The lattice parameters for alloys from the homogeneity range of Sm1−xDyxGe2 solid solution were determined and refined by powder diffraction data (Table 3 and Fig. 5a). The lattice parameters show an decreasing trend with increasing Dy content and the relative changes of the unit cell volume of Sm1−xDyxGe2/SmGe2 with the increase of Dy content is presented in Fig. 5(a).

According to SEM/EPMA and XRD phase analysis data (Fig. 3b, and Fig. S2) the DyGe1.9 (TbGe2- type) solve up to 10 at.% Sm. The lattice parameters for alloys from the homogeneity range of Dy1−xSmxGe1.9, (x = 0-0.30) solid solution were determined and refined by powder diffraction data are presented in Table 4). The lattice parameters increase with increasing Sm content. The relative changes of the unit cell volume of Dy1−xSmxGe1.9/DyGe1.9 Dy11−xSmxGe10/Dy11Ge10 (d) with the increase of Sm content is shown in Fig. 5(b).

Dy11−xSmxGe10, (x = 0-2.1) limited solid solution. The x-ray diffraction patterns of the studied Dy11-xSmxGe10, (x = 0 and 2.1) alloys were similar to each other and they corresponded to single phase material with the tetragonal Ho11Ge10-type of crystal structure. The alloy with x = 3.1 is no single phase and in addition to the tetragonal phase, contains additional hexagonal DyxSm5-xGe3 and orthorhombic DyxSm1−xGe phases. In Table 3 the appropriate unit cell parameters and calculated unit cell volumes are presented. Careful analysis of the values of the lattice parameters and the unit cell volumes indicates insignificant increase of these parameters with partial substitution of Dy by Sm atoms up to 10 at.% (Fig. 5c). Rietveld refinement of the crystal structure of this solid solution for the alloy with x = 2.1 (Fig. 6) showed that the substitution of Dy by Sm occurs in two crystallographic positions 8h and 4e. At the final, all parameters were refined up to RB = 8.27, RF = 6.93, Rp = 5.12, Rwp = 6.84 and χ2 = 1.47.

4.3 Continuous Solid Solutions

Three series Dy1−xSmxGe, Dy5-xSmxGe3 and Dy5-xSmxGe4 of continuous solid solutions at the 873 K in the Dy-Sm-Ge system are observed. The SEM micrographs of selected samples from homogeneity regions of continuous solid solutions show their almost single phase state (Fig. S3).

Dy1−xSmxGe, (x = 0-1) continuous solid solution. Both equiatomic binary DyGe and SmGe compounds crystallises in a orthorhombic CrB—type in which the 4c crystallographic site occupy atoms of rare earth metals. Between these binary compound four ternary alloys were prepared and studied by SEM, EPMA (Fig. S3a-c) and XRD (Fig. S4) method of analysis. Almost linear changes in the unit cell parameters and volume are observed in fully concentration range of this solid solution (Table 5) The relative changes of the unit cell volume of Dy1−xSmxGe/DyGe with the increase of Sm content is presented in Fig. 7(a).

Dy5-xSmxGe3, (x = 0-5) continuous solid solution. The Dy5-xSmxGe3 (x = 0-5) continuous solid solution was detected by SEM, EPMA (Fig. 8d-f) and XRD (Fig. S5) methods on the Dy5Ge3—Sm5Ge3 section. All samples consist hexagonal phase with Mn5Si3 structure type. This solid solution is formed by mutual substitution of rare earth metals (Sm and Dy). The lattice parameters for alloys from the homogeneity range of this solid solution were determined and refined by powder diffraction data (Table 6). The relative changes of the unit cell volume of Dy5-xSmxGe3/Dy5Ge3 obtained in this work show a tendency to increase cell volume with increasing Sm content (Fig. 7b).

Dy5-xSmxGe4, (x = 0-5) continuous solid solution. Six alloys from the Dy5Ge4—Sm5Ge4 section were prepared and analysed by SEM/EPMA (Fig. S3j-i) and XRD (Fig. 7c) methods. Both binary phases crystallises in orthorhombic Sm5Ge4-type. The x-ray powder diffraction patterns obtained for all the investigated alloy samples were completely indexed on the basis of the Sm5Ge4-type structure by the assuming a statistical distribution of the Dy and Sm atoms on the both 8d and 4c sites. The Rietveld analysis (Fig. 8) performed for the alloy of the Dy20Sm35.5Ge44.5 composition has shown that the distribution of its constituent atoms of rare earth metals in all sites are an statistical mixed. The structural parameters were refined up to RB = 6.43, RF = 5.92, Rp = 2.34, Rwp = 3.07 and χ2 = 0.33. The lattice parameters for alloys from the homogeneity range of this solid solution are presented in Table 5 and Fig. 7(c) presents the relative changes of the unit cell volume of Dy5-xSmxGe4/Dy5Ge4 with the increase of Sm content.

4.4 Ternary Compounds

4.4.1 Dy2Sm2Ge7 Ternary Compound

During a study of alloys from the Sm34Ge66—Dy34Ge66 concentration section the formation of a new ternary phase of Dy2Sm2Ge7 was found. The powder diffraction pattern indicated that the Dy17Sm14Ge66 alloy consists as main phase of the Dy2Sm2Ge7 and small amounts of Ge (Fig. 9a). The irregular form single crystal was extracted from this alloy after its defragmentation (Fig. 9b) and diffraction pattern is presented in Fig. 9(c). The crystal structure of Dy2Sm2Ge7 was investigated by single crystal experiments and was successfully solved by direct methods using SHELX-97 package programs. This compound may be viewed as the ordered superstructure to Nd4Ge7-type.[14] The orthorhombic unit cell with C2221 space group of this intermetallic compound contains 44 atoms occupying 7 different Wyckoff sites. In the Nd4Ge7-type the all neodymium atoms occupy the 4a, 4b and 8c sites, instead, in the Dy2Sm2Ge7 ternary phase, the first two sites occupy the atoms of dysprosium, and the third site is occupied by the atoms of samarium. This distribution of atoms gives the nominal composition of Sm18.2Dy18.2Ge63.6, which is very consistent with the composition Sm18.2(2)Dy17,7(2)Ge64,1(3) received from EPMA data. The crystal data and refined atomic parameters for Dy2Sm2Ge7 are listed in Tables 7 and 8 respectively. The structural parameters from single crystal was confirmed by Rietveld refinements of powder data (Rp = 4.99, Rwp = 6.36, RB = 8.11, RF = 9.73 and χ2 = 1.15). The projection of the unit cell and coordination polyhedra of the atoms is shown in Fig. 10. The distorted equatorial four-capped trigonal prisms [RGe10] are typical for all rare-earth atoms. The germanium atoms are enclosed in to tricapped trigonal prisms. The germanium atoms form 3D network (Fig. 11a) and atoms of rare-earth metals form filled and empty trigonal prisms which a linked by lateral faces (Fig. 11b). The electronic structure calculations by TB-LMTO-ASA confirm the existence of 3D network and the isosurfaces of electron localization function (ELF) around the Ge atoms at the 0.70 level is presented in Fig. 12(a).

The distribution of electron localization function around Ge atoms and crystal chemical analysis suggest that 3D network from germanium atoms form negatively charged n[Ge7]4m- polyanions, which are compensated by positively charged 2nDym+ and 2nSmm+ polycations. It should be noted, that for intermetallics there are known examples of compounds with polyanions, here are some of the previously investigated: LiGe, (n[Ge6]4- polyanion),[40] Li4Ge2B (n[B3Ge6]m-),[41] Li9Al4Sn5 (n[Al4Sn5]m-),[42] TmNi1−xLixSn2 (n[Sn]m-)[43] and La4Mg5Ge6 (n[Mg5Ge6]δ−).[44]

The description of chemical bonding used by us to some extent was based on the Zintl-Klemm concept according to which structure consists of a polyanion with cations located between the anionic lattice. In the typical Zintl phases the anion-cation interaction prevails, and they have low conductivity, or semiconductivity. This causes an insignificant density of states or a pseudo-gap at the Fermi level. The Dy2Sm2Ge7 structure, like other similar phases well-known from literature, has a predominant metallic bonding, and cation-anion interaction is an additional interaction based on partial charges.

The total and partial density of states (DOS) for the Dy2Sm2Ge7 is shown in Fig. 12(b). The higher density of electronic states at the Fermi level confirm the metallic behaviour. The feature of this structure is a very intense peaks from the overlapping of the f orbitals of Dy and Sm with p orbital of Ge in the valence band nearly Fermi level.

4.4.2 Dy1−xSmxGe1.5 (x = 0.15-0.50) Ternary Phase

The samples of the compositions Dy40Ge60, Dy35Sm5Ge60, Dy30Sm10Ge60, Dy20Sm20Ge60 and Dy10Sm30Ge60 were prepared and investigated by the XRD powder method (Fig. S6a). The extent of homogeneity region of Dy1−xSmxGe1.5, (x = 0.15-0.50) ternary phase was determined by the change in lattice parameters. The change in lattice parameters with varying concentrations of Sm are presented in Table 9. From the data of Table 9 it is obvious that replacement of Dy atoms by Sm atoms increases the unit cell volume of Dy1−xSmxGe1.5.

Rietveld matrix full-profile structure refinements confirm well the powder patterns calculated on the basis of defected AlB2 structure model (Fig. S6b). The 1a site fully occupied by statistical mixture of Dy and Sm atoms and the germanium atoms partially occupy the 2d site. For the Dy1−xSmxGe1.5 (x = 0.25) ternary phase after last cycle refinement the residual factors are: Rp = 6.57, Rwp = 8.93, RB = 8.37, Rf = 8.87, and χ2 = 1.54.

The Dy1−xSmxGe1.5 is a ternary compound with wide homogeneity of region, and can be interpreted as a residue of a high-temperature solid solution based on high temperature phase γ-DyGe1.5. It is known that germanium-rich phases exhibit structural instability and, depending on the conditions and methods of synthesis, the purity of metals, some phases may not form, and some, on the contrary, can stabilize (the formation of metastable phases). Also, the addition of a third component to binary germanides can lead to the stabilization of structures that are typical for metastable phases (as in the case of Sm4Ge7 and Dy2Sm2Ge7), or also stabilization of structures that are typical for high-temperature phases (as in the case of DyGe1.5 and Dy1−xSmxGe1.5). Similar cases are known in the literature, for example, in system Sm-Ni-Ge[45] and Sm-Rh-Ge,[46] the ternary phases SmNi0.5Ge1.5 and SmRh0.6Ge1.4 with the AlB2 structure type also formed at 600°C, although high temperature phase SmGe1.5 (AlB2-type structure) exist above 1085°C). It should be noted that the formation of superstructures to binary phases, as well as the decreasing of the temperature of formation of high-temperature phases at the addition of the third component, were found in other systems which do not contain germanium, such as La-Ni-Zn,[47] Mn-Al-Li[48] etc.

5 Summary

The isothermal section of phase diagram of the Dy-Sm-Ge system was studied in the full concentration range by means of x-ray phase and structural analyses, microstructural analysis and energy dispersive x-ray spectroscopy. Phase relations of this system were determined at 873 K by characterizing of 56 alloys. The features of this system are the formation of continuous solid solutions: Dy1−xSmxGe (x = 0-1), Dy5-xSmxGe3 (x = 0-5) and Dy5-xSmxGe4, (x = 0-5), and limited solid solutions: Dy1−xSmxGe1.9, (x = 0-0.30), DyxSm1−xGe2 (x = 0-0.45) and Dy11−xSmxGe10, (x = 0-2.1). All solid solutions are formed by the mutual substitution of atoms of rare earth metals.

Two ternary Dy1−xSmxGe1.5 (x = 0.15-0.50) and Sm2Dy2Ge7 compounds were found. The crystal structure of Sm2Dy2Ge7 was investigated by means of x-ray single crystal diffraction: Pearson symbol oS44, space group C2221, a = 0.5942(1), b = 1.3823(4), c = 1.1801(3) nm, V = 0.9694 nm3. This compound is ordered superstructure to Nd4Ge7-type. The electronic structure was calculated by the tight-binding linear muffin-tin orbital atomic spheres approximation method. The electron localization function is higher around the Ge atoms, which form an n[Ge7]4m- polyanion.

References

W.E. Wallace, Rare Earth Intermetallics, Academic Press, New York and London, 1973

Handbook on the Physics and Chemistry of Rare Earths. Edited by J.-C. G. Bünzli and V. K. Pecharsky, 2016, 50, p 2–427

Z. Shpyrka and L. Drab, The Investigation of the Section DyGe2-RGe2, Where R-Y, Gd, Tb, Ho, Er, Tm and Lu at 600 C, Visnyk Lviv University, Ser. Khim., 2008, 49, p 98-102

V. Vorotnyak, Z. Shpyrka, V. Pavlyuk and R. Serkiz, The Crystal Structure of the Dy0.67Tm0.33Ge1.85 Compound, Visnyk Lviv University, Ser. Khim., 2012, 53, p 66–71

Z. Shpyrka., O. Bodak and P. Starodub, The Crystal Structure of the Dy0.5Ho0.5Ge1.75 Compound, Visnyk Lviv University, Ser. Khim., 2002, 41, p 80–82

Z. Shpyrka, V.Pavlyuk, D. Berezyuk and P. Starodub, The crystal structure of the Dy0.6Lu0.4Ge2 compound, Coll. Abstr. XII conf. “Lviv Chemical Readings-2009”, Lviv, 2009, p H58

Z. M. Shpyrka, O. I. Bodak, I. R. Mokra and V. K. Pecharskij, Crystal structure of the Sm0.625Lu0.375Ge1.85, Coll. Abstr. VI Intern. Conf. on Crystal Chemistry of Intermetallic Compounds, Lviv, 1995, p 94

A.B. Gokhale and G.J. Abbaschian, The Ge-Sm (Germanium–Samarium) System, Bull Alloy Phase Diagr, 1988, 9, p 578-581

V.N. Eremenko, V.G. Batalin, and YuI, Buyanov, Phase Diagrams of Samarium–Germanium, Dop. Akad. Nauk Ukr. RSR B., 1977, 5, p 413-416

G. Venturini, Y. Ijjaali, and B. Malaman, Vacancy Ordering in AlB2—type RGe2−x Compounds (R = Y, Nd, Sm, Gd-Lu), J. Alloys Compd., 1999, 284, p 262-269

P.H. Tobash, D. Lins, S. Bobev, N. Hur, J.D. Thompson, and J.L. Sarrao, Vacancy Ordering in SmGe2-x and GdGe2-x (x = 0.33): Structure and Properties of Two Sm3Ge5 Polymorphs and of Gd3Ge5, Inorg. Chem., 2006, 45(18), p 7286-7294

I. Mayer and Y. Eshdat, MSixGe2−x Ternary Phases of the Rare Earth Metals, Inorg. Chem., 1968, 7, p 1904-1908

G. Venturini, I. Ijjaali, and B. Malaman, New Ordered ThSi2-type Derivatives in the Light Rare Earths Germanides. Crystal Structure of Nd4Ge7, J. Alloys Compd., 1999, 289, p 168-177

J. Zhang, P.H. Tobash, W.D. Pryz, D.J. Buttey, N. Hur, J.D. Thompson, J.L. Sarrao, and S. Bobev, Synthesis, Structural Characterization, and Physical Properties of the Early Rare-Earth Metal Digermanides REGe2−x (x ≈ 1/4) [RE = La-Nd, Sm]. A Case Study of Commensurately and Incommensurately Modulated Structures, Inorg. Chem., 2013, 52(2), p 953-964

K. Meier, C. Koz, A. Kerkau, and U. Schwarz, Crystal Structure of Samarium Pentagermanide, SmGe5, New Cryst. Struct., 2009, 224(3), p 349-350

K. Meier, A. Wosylus, R.H. Cardoso Gil, U. Burkhardt, C. Curfs, M. Hanfland, Y. Grin, and U. Schwarz, New Rare-Earth Metal Germanides RE2Ge9 (RE= Nd, Sm) by Thermal Decomposition of High-Pressure Phases REGe5, Z. Anorg. Allg. Chem., 2012, 638, p 1446-1451

V.N. Eremenko, V.G. Batalin, YuI, Buyanov, and I.M. Obushenko, The Dy-Ge Phase Diagram, Dop. Akad. Nauk Ukr. RSR B, 1977, 6, p 516-521

I. Mayer and I. Shidlovsky, M5X3-Type Rare Earth Silicides and Germanides and Their Ternary Phases with Carbon, Inorg. Chem., 1969, 8(6), p 1240-1243

G.S. Smith, A.G. Tharp, and Q. Johnson, Rare Earth-Germanium and-Silicon Compounds at 5:4 and 5:3 Compositions, Acta Cryst., 1967, 22, p 940-943

A.G. Tharp, G.S. Smith, and Q. Johnson, Structures of the Rare-Earth Germanides at or Near Equiatomic Proportions, Acta Cryst., 1966, 20, p 583-585

K. Sekizawa, Magnetic and Crystallographic Studies on Rare Earth Germanides, J. Phys. Soc. Jpn., 1966, 21, p 1137-1142

E.I. Gladyshevskii, Crystal Structure of the Digermanide of Rare Earth Elements, J. Struct. Chem., 1964, 5, p 523-529

G. Venturini, I. Ijjaali, and B. Malaman, RGe2−x Compounds (R= Y, Gd-Ho) with New Ordered ThSi2-Defect Structures, J. Alloys Compd., 1999, 285, p 194-203

I.R. Mokra, V.K. Pecharskii, Z.M. Shpyrka, O.I. Bodak, V.K. Belsky and I.E. Patz, Crystal Structure of the DyGe1.85, Dopov. Akad. Nauk Ukr. RSR Ser. B, 1989, p 3–45.

P. Schobinger Papamantellos, D.B. De Mooij, and K.H.J. Buschow, Crystallographic and Magnetic Structure of Dy3Ge5 and DyGe1.9, J. Less-Common Met., 1990, 163, p 319-330

P. Schobinger Papamantellos, D.B. De Mooij, and K.H.J. Buschow, Crystal Structure of the Compound DyGe3, J. Alloys Compd., 1992, 183, p 181-186

P.H. Tobash, S. Bobev, J.D. Thompson, and J.L. Sarrao, Polymorphism in Binary Rare-Earth Metal Germanides. Synthesis, Structure and Properties of the New Hexagonal forms of Tb3Ge5 and Dy3Ge5, J. Alloys Compd., 2009, 488, p 533-537

O. Oleksyn, P. Schobinger Papamantellos, C. Ritter, C.H. De Groot, and K.H.J. Buschow, Antiferromagnetic Ordering in the Novel Dy3Ge4 and DyGe1.3 Compounds Studied by Neutron Diffraction and Magnetic Measurements, J. Alloys Compd., 1997, 262(263), p 492-497

A.V. Tsvyashchenko, A.V. Spasskiy, A.I. Velichkov, A.V. Salamatin, L.N. Fomicheva, D.A. Salamatin, G.K. Ryasny, A.V. Nikolaev, M. Budzynski, and R.A. Sadykov, 111Cd-TDPAC Study of Pressure Effect on the Valence of Yb in the YbGe2.85 Cubic Phase, J. Alloys Compd., 2013, 552, p 190-194

Desk Handbook: Phase Diagrams for Binary Alloys, Ed. by H. Okamoto, Materials Park (OH), American Society for Metals, 2000, p 828

J. Rodriguez-Carvajal, Recent Developments in the Program FullProf, in Commission on Powder Diffraction (IUCr), Newsletter, 2001, 26, p 12-19

CrysAlis PRO. UK Ltd, Yarnton, Oxfordshire, England, Agilent Technologies, 2011

G.M. Sheldrick, SHELXS, Program for the Solution of Crystal Structures, University of Goettingen, Goettingen, 1997

G.M. Sheldrick, SHELXL-97, Program for Crystal Structure Refinement, University of Goettingen, Goettingen, 1997

O.K. Andersen, Linear Methods in Band Theory, Phys. Rev. B, 1975, 12, p 3060-3083

O.K. Andersen and O. Jepsen, Explicit, First-Principles Tight-Binding Theory, Phys. Rev. Lett., 1984, 53, p 2571-2574

O.K. Andersen, Z. Pawlowska, and O. Jepsen, Illustration of the Linear-Muffin-Tin-Orbital Tight-Binding Representation: Compact Orbitals and Charge Density in Si, Phys. Rev. B, 1986, 34, p 5253-5270

U. von Barth and L. Hedin, A Local Exchange-Correlation Potential for the Spin Polarized Case, J. Phys. C Solid State, 1972, 5, p 1629-1642

Eck, B. wxDragon 1.6.6, Aachen, 1994–2010 [cited 2013 Apr 7]; Available from: http://www.ssc.rwth-aachen.de.

V. Pavlyuk, W. Ciesielski, D. Kulawik, W. Prochwicz, and B. Rozdzynska-Kiełbik, Li-Ge-H System: Hydrogenation and Structural Properties of LiGeHx (0 < x < 0.25) Phase, Solid State Sciences, 2016, 61, p 24-31

V. Pavlyuk, W. Ciesielski, B. Rozdzynska-Kielbik, G. Dmytriv, and H. Ehrenberg, Li4Ge2B as a New Derivative of the Mo2B5 and Li5Sn2 Structure Types, Acta Cryst. C, 2016, 72, p 561-565

V. Pavlyuk, G. Dmytriv, I. Tarasiuk, and H. Ehrenberg, Li9Al4Sn5 as a New Ordered Superstructure of the Li13Sn5 Type, Acta Cryst. C, 2017, 73, p 337-342

A. Stetskiv, I. Tarasiuk, R. Misztal and V. Pavlyuk, Thulium Nickel/Lithium Distannide, TmNi1−xLixSn2 (x = 0.035), Acta Cryst. E, 2013, 69, p i76

P. Solokha, S. De Negri, M. Skrobanska, A. Saccone, V. Pavlyuk, and D. Proserpio, New Ternary Germanides La4Mg5Ge6 and La4Mg7Ge6: Crystal Structure and Chemical Bonding, Inorg. Chem., 2012, 51, p 207-214

E.I. Gladyhevskii, O.I. Bodak, Compounds with Structures of the AlB2 Type in the System Ce-Ni-Si and in Related Systems, Dopov. Akad. Nauk Ukr. RSR, 1965, p 601-604

A.V. Morozkin, Y.D. Seropegin, and O.I. Bodak, Phase Equilibria in the Sm-{Ru, Rh }-{Si, Ge} Systems at 870, J. Alloys Compd., 1996, 234, p 143-150

V.V. Pavlyuk, I.M. Opaynych, O.I. Bodak, T. Palasinska, B. Rozdzynska, and H. Bala, Interaction of Components in the La-Ni-Zn System, Polish Journal of Chemistry, 1997, 71, p 309-313

V.V. Pavlyuk, T.I. Yanson, O.I. Bodak, R. Cerny, R.E. Gladyshevskii, K. Yvon, J. Stepien Damm, Structure Refinement of Orthorhombic MnAl3, Acta Cryst. C, 1995, 51, p 792-794

Acknowledgments

Financial support from the National Science Centre, Poland (No 2017/25/B/ST8/02179) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shpyrka, Z., Kluziak, K., Rożdżyńska-Kiełbik, B. et al. The Isothermal Section of the Phase Diagram of Dy-Sm-Ge Ternary System at 873 K. J. Phase Equilib. Diffus. 39, 750–765 (2018). https://doi.org/10.1007/s11669-018-0665-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-018-0665-9