Abstract

The isothermal section of the Dy-Mn-As ternary system at 773 K has been investigated by using x-ray diffraction, scanning electron microscopy and energy dispersive spectroscopy. This isothermal section consists of 12 single-phase regions, 21 two-phase regions and 10 three-phase regions. The highest solid solubility of Dy in MnAs is about 0.65 at.%Dy, and that of Mn in DyAs is less than 0.79 at.%Mn. The maximum solubility of As in DyMn2 is less than 0.33 at.%As. No ternary compound was found to exist in this section at 773 K.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

MnAs alloy has been found to have a giant magnetocaloric effect, but it is accompanied with large thermal hysteresis which is unfavorable for practical application in magnetic refrigeration. Thus, many researchers do their best to improve the magnetic refrigeration effect of alloy MnAs by substituting Mn with the third element such as Cr, Al, Cu, Ti and V.[1-4] Dysprosium-based alloys are extensively studied because of their magnetic properties and applications in the magnetic refrigeration field.[5-7] However, the effect of the addition of Dy on magnetic properties of MnAs alloy has not been reported. In order to provide valuable information for developing new materials, the 773 K isothermal section of the Dy-Mn-As system has been constructed in the present work.

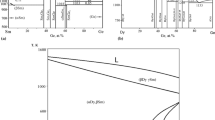

The phase diagram of the Dy-Mn binary system is available in literatures.[8-11] It was investigated experimentally by Kirchmayr and Lugscheider using differential thermal analysis,[9] as shown in Fig. 1(a). It is found that there are three phases: the MgCu2-type phase DyMn2, the Th6Mn23-type phase Dy6Mn23 and the ThMn12-type tetragonal phase DyMn12.[10]

The assessed Mn-As phase diagram is adopted primarily from Ref 12, which determined the Mn-rich liquidus boundaries, as shown in Fig. 1(b). The As-rich part of this binary phase diagram is still unknown. It includes these following phases: NiAs-type phase γAsMn existing between the congruent melting point at 1208 and 398 K, MnP-type phase βAsMn existing between 398 and 318 K, ferromagnetic NiAs-type phase αAsMn below 318 K, tetragonal phase As3Mn4, βAs2Mn3 phase, αAs2Mn3 phase, tetragonal Cu2Sb-type phase AsMn2 with a congruent melting point at 1302 K, orthorhombic phase AsMn3.

The phase diagram of the Dy-As system was based primarily on the work of Ref 13, as shown in Fig. 1(c). The NaCl-type phase AsDy has been found. Using a differential calorimetry method, Hanks and Faktor had measured the formation enthalpy of AsDy and the value was up to ∆H SAsDy = −163 kJ/mol.[14] Crystallographic data on Dy-Mn, Mn-As and Dy-As binary compounds are collected in Table 1.

Experimental Procedure

All samples with total masses of about 1.5 g were prepared from highly pure materials (the purity of Mn, Dy and As was 99.95, 99.99 and 99.999 wt.%, respectively).

The samples with less than 10 wt.%As were prepared by arc melting under highly pure argon atmosphere. To compensate for sublimation loss of Mn and As, the extra 3 wt.%Mn and 30 wt.%As were added. The alloy buttons were remelted at least four times to ensure a good homogeneity. During the melting, the melting current should be suitably controlled in order to reduce the loss of As. The mass loss of each sample was kept below 1 wt.%. All the as-cast samples were sealed in quartz tubes pre-evacuated and refilled with purified argon, and then annealed at 773 K for 30 days.

Considering the sublimation of Arsenic at below 900 K in atmospheric pressure, the other samples with more than 10 wt.%As were synthesized by using solid-state diffusion reaction. The starting materials were made into small powders, mixed according to the stoichiometry and compacted into pellets. The prepared pellets wrapped completely in Tantalum foil (in order to reduce the sublimation) were sealed in evacuated quartz tubes and then annealed at 773 K for 5 days, cooled, grinded to powder, pressed into pellets, sealed again and annealed for 15 days to ensure homogeneity. Finally, all ampoules with the samples were quenched into ice water. After the thermal treatment, the mass loss of each sample was also checked and kept below 1 wt.%.

All samples were grinded into powder in acetone to prevent sample oxidation. Powder were sealed again in evacuated quartz tubes and annealed at 773 K for 100 h to eliminate the stress and quenched in water for XRD. Powder XRD analysis was performed from 20° to 80° with a step size of 0.02°. The patterns were analyzed using MDI Jade 6.0 software with the JCPDS-ICDD Powder Diffraction File database. The scanning electron microscopy (SEM) images were from backscattered electrons. A combination of energy dispersive spectroscopy (EDS) phase composition analyses, XRD with Cu Kα radiation (λ = 0.154184 nm), peak matching from patterns of known phases in the JCPDS database, and metallography were used to elucidate the phases present in this study. The Rietveld method was used to determine the lattice parameters of samples by means of the MDI Jade 6 software for XRD pattern processing and the residual R values of less than 9% were considered to be reasonable.

Results and Discussion

Phase Analysis

X-ray diffraction (XRD) analysis of the alloys in these Dy-Mn, Mn-As and As-Dy binary systems confirmed the existence of nine binary compounds at 773 K: DyMn2, Dy6Mn23, DyMn12, γAsMn, As3Mn4, αAs2Mn3, AsMn2, AsMn3, AsDy, which are good agreement with those reported in Ref 9,11,12. Most of the PDF files of these binary compounds mentioned above are available on JCPDS PDF Cards (2004), except for the Dy6Mn23 compound. The XRD patterns for the Dy6Mn23 compound were calculated from their crystallographic data of Ref 15 by using the PCW 2.3 software. It is found that the calculated results are fully consistent with the experimental XRD patterns of this sample with the nominal composition Dy6Mn23 prepared by arc melting and annealed at 773 K for 30 days, as shown in Fig. 2.

(a) Calculated pattern for phase Dy6Mn23 from Ref 15; (b) the XRD pattern of alloy Dy6Mn23 annealed at 773 K for 30 days

Solid Solubility

In order to determine the solid solubility of Dy in MnAs, a series of alloys Dy x Mn1−x As (x = 0, 0.005, 0.01, 0.015, 0.02, 0.03) annealed at 773 K for 20 days were prepared, and their XRD results are shown in Fig. 3. A second phase AsDy was observed with Dy content x increasing to 0.02. The corresponding unit cell volumes were calculated by using the Rietveld method in the MDI Jade 6 program. The relationship between the unit cell volume and the Dy content x is displayed by the solid line, as presented in Fig. 4. It shows that the solubility limit of Dy in MnAs is about 0.65 at.%Dy corresponding to the intersection of the two solid lines.

In order to determine the solid solubility of Mn in AsDy, the alloys Mn x Dy1−x As (x = 0, 0.01, 0.02, 0.025, 0.03) annealed at 773 K for 20 days were prepared and their XRD patterns are shown in Fig. 5. A second phase MnAs was observed with Mn content x increasing to 0.025. The corresponding lattice parameters were calculated by using the Rietveld method in the MDI Jade 6 program. The relationship between the lattice parameters and the Mn content x is displayed by the solid line, as presented in Fig. 6. This indicates that the solubility limit of Mn in DyAs is about 0.79 at.%Mn corresponding to the intersection of the two solid lines.

In order to determine the solid solubility of As in DyMn2, the alloys DyMn2(1−x)As x (x = 0, 0.01, 0.02) annealed at 773 K for 20 days were prepared, and their XRD patterns are shown in Fig. 7. The second phase AsDy was observed with As content x increasing to 0.01. This means that the maximum solubility of As in DyMn2 is less than 0.33 at.%As.

Dy-Mn-As Ternary System at 773 K

In total, 50 samples in the Dy-Mn-As system were studied by XRD as well as SEM and energy dispersion spectroscopy for some selected characteristic samples to determine the phase compositions.

As far as can be seen from the binary systems, the As-rich side is unknown. Thus, we prepared alloys Dy30Mn10As60, Dy20Mn20As60, Dy10Mn30As60 annealed at 773 K for 20 days in the As-rich corner of the Dy-Mn-As ternary system and their XRD patterns are shown in Fig. 8. One can visualize that all of them are confirmed to be located in the three-phase region: As + AsDy + γAsMn.

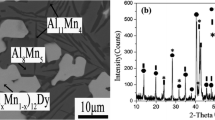

The results of XRD and SEM measurements on the Dy50Mn40As10 alloy annealed at 773 K for 20 days, which were used to determine the one three-phase region of Dy-Mn-As system, are displayed in Fig. 9. From the XRD data, it can be clearly identified that the alloy Dy50Mn40As10 consists of three phases: DyMn2, DyAs and αDy. Meanwhile, the SEM micrograph shown in Fig. 9(b) also demonstrates that it includes the same three phases. The similar experimental observation is also found in other alloys. The alloy Dy30Mn60As10 is located in the DyMn2, Dy6Mn23 and DyAs three-phase region (see Fig. 10) and the alloy Dy20Mn70As10 contains three phases: Dy6Mn23, DyMn12 and DyAs, as illustrated in Fig. 11.

By analyzing the XRD patterns, the Dy10Mn80As10 alloy can be identified to include two phases: αMn and DyAs, as shown in Fig. 12, and the alloy Dy10Mn70As20 consists of three phases: αMn, DyAs and AsMn3, as presented in Fig. 13. In order to determine one two-phase region, a series of alloys Dy40Mn10As50, Dy30Mn20As50, Dy20Mn30As50 and Dy10Mn40As50 were prepared and their XRD patterns are shown in Fig. 14. All of them confirm the existence of the γAsMn and DyAs two-phase region.

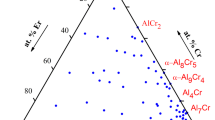

Table 2 lists the phase compositions and phase relations of the selected characteristic samples which are crucial to determine the phase boundaries or phase regions. By comparing and analyzing all the results obtained, the isothermal section of the ternary system Dy-Mn-As at 773 K was constructed, as shown in Fig. 15. This section includes 12 single-phase regions, 21 two-phase regions and 10 three-phase regions.

Conclusion

This isothermal section of the Dy-Mn-As ternary system at 773 K consists of 12 single-phase regions, 21 two-phase regions and 10 three-phase regions. No ternary compound was found to exist in this section at 773 K. The highest solid solubility of Dy in MnAs is about 0.65 at.%Dy, and that of Mn in DyAs is less than 0.79 at.%Mn. The maximum solubility of As in DyMn2 is less than 0.33 at%As.

References

N.K. Sun, W.B. Cui, D. Li, D.Y. Geng, F. Yang, and Z.D. Zhang, Giant Room-Temperature Magnetocaloric Effect in Mn1-xCrxAs, Appl. Phys. Lett., 2008, 92(7), p 072504

W.B. Cui, W. Liu, X.H. Liu, S. Guo, Z. Han, X.G. Zhao, and Z.D. Zhang, Beneficial Effect of Minor Al Substitution on the Magnetocaloric Effect of Mn1−xAlxAs, Mater. Lett., 2009, 63(6), p 595-597

D.L. Rocco, A. de Campos, A.M.G. Carvalho, L. Caron, A.A. Coelho, S. Gama et al., Ambient Pressure Colossal Magnetocaloric Effect in Mn1−xCuxAs Compounds, Appl. Phys. Lett., 2007, 90(24), p 242507

M. Balli, D. Fruchart, D. Gignoux, C. Dupuis, A. Kedous-Lebouc, and R. Zach, Giant Magnetocaloric Effect in Mn1-x(Ti0.5V0.5)xAs: Experiments and Calculations, J. Appl. Phys., 2008, 103(10), p 103908

X.X. Zhang, F.W. Wang, and G.H. Wen, Magnetic Entropy Change in RCoAl (R = Gd, Tb, Dy, and Ho) Compounds: Candidate Materials for Providing Magnetic Refrigeration in the Temperature Range 10 K to 100 K, J. Phys. Condens. Matter, 2001, 13(31), p L747

K.A. Gschneidner, Jr., and V.K. Pecharsky, Rare Earths and Magnetic Refrigeration, J. Rare Earths, 2006, 24(6), p 641-647

A.K. Pathak, I. Dubenko, S. Stadler, and N. Ali, Magnetic, Magnetocaloric, and Magnetotransport Properties of RCo1.8Mn0.2 (R = Er, Ho, Dy, and Tb) Compounds, J. Magn. Magn. Mater., 2011, 323(20), p 2436-2440

H. Landolt and R. Börnstein, Phase Equilibria, Crystallographic and Thermodynamic Data of Binary Alloys, Vol 3, Springer, Berlin, 1993

H.R. Kirchmayr and W. Lugscheider, Constitution of Binary Alloys of Gadolinium, Dysprosium, Holmium, and Erbium with Manganese, Z. Metallkd., 1967, 58, p 185

H. Okamoto, Dy-Mn (Dysprosium-Manganese), J. Phase Equilib. Diffus., 2011, 32, p 167

H. Okamoto and T.B. Massalski, Binary Alloy Phase Diagrams Requiring Further Studies, J. Phase Equilib., 1994, 15(5), p 500

M. Hansen and K. Anderko, Constitution of Binary Alloys, McGraw-Hill, New York, 1958

K.A. Gschneidner, Jr., and F.W. Calderwood, The Arsenic-Rare Earth Systems, Bull. Alloy Phase Diagr., 1986, 7, p 277

R. Hanks and M.M. Faktor, Quantitative Application of Dynamic Differential Calorimetry. Part 2—Heats of Formation of the Group 3 A Arsenides, Trans. Faraday Soc., 1967, 63, p 1130

Pierre Villars and Lauriston D. Calvert, Pearson’s Handbook of Crystallographic Data for Intermetallic Phases, Vol 2, American Society for Metals, Metals Park, OH, 1985

P. Villars, Pearson’s Handbook Desk Edition: Crystallographic Data for Intermetallic Phases, ASM International, Materials Park, OH, 1997

H. Landolt and R. Börnstein, Phase Equilibria, Crystallographic and Thermodynamic Data of Binary Alloys, Springer, Berlin, 1993

M.F. Hagedorn and W. Jeitschko, Synthesis and Crystal Structure of Mn4As3 and Its Relation to Other Manganese Arsenides, J. Solid State Chem., 1995, 119(2), p 344-348

L.Η. Dietrich, W. Jeitschko, and Μ.H. Möller, The Crystal Structure of Mn3As2 (I), Cryst. Mater., 1989, 190(1-4), p 259-270

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 50261002, 50661002 and 51161005) and National Basic Research Program of China (No. 2014CB643703).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, Z.F., Yu, S.L., Xu, C.F. et al. Experimental Investigation of the Phase Relations of the Dy-Mn-As System at 773 K. J. Phase Equilib. Diffus. 36, 306–316 (2015). https://doi.org/10.1007/s11669-015-0384-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-015-0384-4