Abstract

Stress analysis, a fundamental aspect of engineering and design, is critically dependent on experimental methods, with photoelasticity being a key technique. Despite its effectiveness, photoelasticity is often limited by subjective human interpretation, leading to variable stress measurement results. To address this, we have concentrated on the practical applications of this method, employing a circular disc analyzed under various compressive loads. Our research introduces a novel algorithm specifically developed for processing photoelastic images. This algorithm enhances the clarity of thinned fringes, enabling more precise measurement of the principal stress differences. Our findings indicate that the digitally processed photoelastic images align closely with analytical solutions, suggesting a more reliable and consistent approach to stress analysis. This advancement mitigates the subjectivity inherent in traditional photoelastic methods, thus improving the accuracy of stress measurement. The implications of this study are significant for the broader field of engineering. The developed methodology can be applied to diverse scales of instruments and facilities, offering a versatile tool for identifying stress patterns. Overall, our work also improves the accuracy of such a tool and technique, making it more useful for failure analysis scenarios understanding.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Stress analysis is essential that is kept under careful observation while designing any machine component and experimental techniques developed over the years have made it handy to perform stress analysis [1]. One of the effective techniques is stress analysis using photo-elasticity. Photoelasticity refers to alterations in the optical characteristics of a substance when subjected to mechanical strain [2]. It is an inherent quality found in all dielectric materials and is commonly employed to analyze and ascertain the distribution of stress within a material. Photoelasticity has also proven its effectiveness and easiness of implementation in highly complex industrial cases where quasi practical measurements were the only way to calculate tri-axial stress states. Due to this, photoelasticity is also a useful tool and techniques for failure analysis purposes [3].

The experiments in photoelastic which is sometimes called simply, photoelasticity are often used to find out stress at crucial points in any given specimen. The use of photoelasticity also extends to examine concentration of stress in non-uniform geometries [4].

Photoelasticity is also very important when it comes to analyze the localized stress state. In some of the complicated problems such as pressure vessels, numerical methods of stress may fail to provide accurate results. Photoelastic stress analysis when coupled with enhanced quality of photography often gives the accurate and effective results [5].

Manual method of evaluating the distribution of stress has been used since decades. All these methods exhibit some drawbacks such as less accuracy, manual calculations and dependency on human judgment. Fringe order at a point is used to examine the principal stress difference. The thickness of fringe sometimes acts as a hindrance in evaluation the exact value of fringe order at a point and this leads to variation in results.

In this work we have made a circular disc using Araldite CY-230 and Hardener HY-951, the disc is observed under a circular polariscope with the load being diametrically compressive. The photoelastic images of circular disc are captured. We have created an algorithm that can precisely perform fringe sharpening. By this we can accurately obtain the value of fringe order and utilize it to calculate principal stress difference at a point.

The field of digital photoelasticity has seen significant advancements in data collection, largely influenced by the contributions of various researchers. Ramesh and colleagues have played a crucial role in the automation of data acquisition, underscoring the necessity of high-quality image capture for effective analysis. Their exploration of future research directions in digital photoelasticity has laid groundwork for continued advancements in this area [6].

The work of Patterson et al. has been notable in illustrating the enhanced capabilities of photoelasticity through digital technology integration. They provide a detailed theoretical framework for digital fringe processing, offering insights into both the methodology and the practical applications of these emerging technologies in a range of optical devices, from conventional to modern [1].

Ramji and team’s research has significantly contributed to the field of stress separation. Their study emphasizes the independent analysis of major and normal stresses, recommending a data smoothing approach, particularly for isoclinic patterns. This method has shown effectiveness in improving the accuracy of the shear difference technique in stress analysis of interconnected objects, thereby facilitating more refined stress separation [7].

Earlier contributions in the field of manual photoelasticity and digital photoelasticity have helped us in developing this algorithm. Their work in this field has acted as a guiding light for us in developing this algorithm.

Experimental Setup

The main procedure of photoelastic experiment depends on the birefringence property of the material which is intrinsically present in certain transparent material. The phenomenon where two refractive indices is experiences by any ray of light after passing through a given material is referred to as birefringence. Such phenomenon of the birefringes (or double refraction) is often found in many optical crystals. It is observed that when a stress is applied on photoelastic material then, it shows the property of birefringence. It was also found that the state of stress shows direct influence on the magnitude of the refractive indices at that particular point. The measurement and other details regarding maximum shear stress and from where the orientation is applied, is very well analyzed by understanding birefringence by the use of polariscope [8].

The electromagnetic component of the ray of light is resolved into two principal stress directions. It is seen that both components experiences different refractive indices. This phenomenon takes place due to the property of birefringence. This difference or the possession of two refractive indices in a material leads to phase retardation or relative delay due to which fringes are formed. In a thin isotropic material specimen, two-dimensional photoelasticity is feasible, the measurement of its magnitude of relative is often computed by stress-optic law [8].

where C is the stress-optic coefficient, σ1 & σ2 are the first and second principal stresses (in N/mm2), λ is the vacuum wavelength (in mm), Δ is the induced retardation i.e., relative angular phase shift, t is the specimen thickness (in mm), respectively. The retardation changes the polarization of transmitted light. The transmitted light is now changed, because its polarization is altered by the phased retardation. The role of polariscope is to combine different states of polarization before and after passing through the specimen. When such an event takes place the interference of the two waves produces fringe pattern. And, the number of such fringe order N is expressed as which is formed mainly due to the influence of phased or relative retardation. There is a pattern developed by the fringes which is crucial in estimating the stress at any specific points in the given material [8]:

Stress analysis is also possible in the material that does not completely exhibits photoelastic behavior. The methodology is to build the model by the use of material that shows photoelastic properties which has a similar geometry with respect to the real structure. The rest process like the loading is applied in similar fashion. The result will give most appropriate estimation for stress analysis in the real structure.

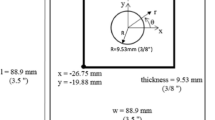

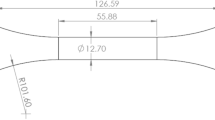

In this work, we have used a model made by using epoxy resin, Araldite CY 230 and Hardener HY 951. The ratio of resin and hardener is 10:1. A circular disc is prepared by using this mixture. Radius of the disc is 24.65 mm and thickness is 11.4 mm. The cener of the disc is marked and a point a distance of 10 mm is marked [9].

The stress analyzes in the three-dimension and two-dimension systems are effectively possible by the use of photoelasticity. The complexities occur in the three-dimensional systems are more when compared to the two-dimensional systems. Therefore, this section deals only with the photoelasticity in a plane stress system. When the thickness of the object being studied is significantly smaller than its dimensions in the plane, then stress that acts parallel to the model’s plane is taken into consideration while the other stress components are considered as negligible. The set up for the experimentation may vary as per the specific experiment but mostly the two fundamental types are; the plane polariscope and the circular polariscope [10].

The main principle that works in the case of two-dimensional experiments allows examination of retardation, difference between first and second principal stress and also their orientation. The value of each component of stress can also be taken out by another method called stress separation. The individual stress components can also be found out by additional information provided by ample theoretical and experimental methods [11].

Two quarter-wave plates can be further added in the setup of the plane polariscope which will then form the setup of the circular polariscope. First quarter wave plate can be placed between specimen and polarizer then we can place the second quarter wave plate between specimen and the analyzer. The effect of this setup is wit the source side polarizer gives us the circularly polarized light through the specimen. Then the light moves ahead and its interaction with the quarter wave plate converts the circular polarized state back to linear state before the passing of light through the analyzer [12].

The circular polariscope is mostly preferred over the plane polariscope because it gives only the isochromatics and the isoclinics are eliminated. This enhances efficiency and the removes the problem of differentiation [13].

Digital Photoelasticity

The two-dimensional picture is processed in a computer using the digital image processing (DIP) technique. An array of real numbers that are represented by a finite number of bits is called as a digital image. The method starts when a regular photograph or a slide is digitalised. This photograph is then stored in the Matrix of binary digits in the memory of the computer. This image can now be processed and worked upon and even displayed on high resolution monitor. Image processing has evolved from the processing from big computers such as PDP 11 system from the newly plug-in card system which can transform personal computer into highly advanced image processing station. These cards are also referred to as, 'frame grabber' which are present in market in various types such as monochrome or color frame grabbers. In the recent times, digital image processing is widely used in various techniques like, remote sensing via satellites, fringe pattern analysis in photomechanics, medical image processing, automated inspection of machine parts, robotics etc. [14].

Image Processing Using MATLAB

The analogy of Zebra black and white stripes was used to create this algorithm where we have to find out central location of each black stripe.

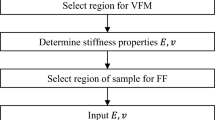

The provided MATLAB script is used to process an image and generate a thinned image with curved stripes. The script follows a series of steps to achieve the final result. Before the implantation of MATLAB script, the raw image needs to be cropped in accordance with the shape of the object, in our case it was circular disc, so the image was cropped circularly to remove extra noise from the image [15].

The cropped image was imported to the MATLAB and converted to gray scale image. While taking the image, the intensity of light is uneven in the captured image to correct that image is sliced into n equal parts. In each part, color threshold was evaluated using ‘colorthresholder’ app. This threshold will be used to create binary mask in the imported image. The threshold values of each slice are adjusted to obtain a sharp fringe skeleton. In the next stage, image edge was identified and stored using ‘edge’ function. Later the image edge is smoothened, and then white space was located in between the black stripes. Row wise black stripes are located and then within the same row midpoint of the black stripes have been located. Index of these midpoints was noted and later replaced with white spaces. Using these white spots, a line was created and then later smoothened. At the end all the sliced image is again added to give a single image. This is how fringe thinning algorithm is processed in the MATLAB [16].

Calculations Involved in Analytical, Manual and Digital Methods

The value of principal stress difference can be determined by using three methods namely analytical, manual photoelasticity and digital photoelasticity.

Analytical Solution

The calculation work is carried out by using closed form solution for circular disc under diametral compressive load. These analytical results are compared with the results obtained by Manual and Digital methods of photoelasticity.

Equation used to calculate principal stress difference (σ1 − σ2) at a given point in a circular disc [13]:

where P, Load (in N); R, Radius (in mm); t, Thickness (in mm); x, Horizontal distance measured from cener of the disc (in mm); y, Vertical distance measured from cener of the disc (in mm)

In this case, y = 0;

The equation becomes;

R = 24.65 mm

x = 10 mm

t = 11.4 mm

The results are obtained for fringe orders from 0.5 to 5. Three observations have been noted for each fringe order and standard deviation is obtained accordingly (Figs. 1, 2, 3, 4, 5, and 6).

Here, P1, P2 & P3 are the three observations and Pavg. is the average load (in kg).

Experimental Results—Using Manual Photoelasticity

In experimental calculations it is necessary to determine the value of Material Fringe Constant \({(f}_{\sigma })\).The value of \({f}_{\sigma }\) is determined by using the relation [8]:

To determine the value of P/N, observations are noted for loads corresponding to fringe orders 1, 2 & 3 and a curve is plotted (shown in Fig. 7) between P and N. The slope of this curve represents P/N.

The value of \({f}_{\sigma }\) is found to be 12.26 N/mm-fringe. Now, the value of Principal Stress Difference (σ1 − σ2) is determined by using the following equation [8]:

Experimental Results—Using Digital Photoelasticity

The images obtained from Manual Photoelasticity are now used as input images in MATLAB code and the output image is used to ascertain the values of fractional fringe order at the point 10 mm from the cener of the disc. Three observations are noted in order to reduce the deviation (Figs. 8, 9 and 10).

Results and discussions

Digital Photoelasticity Pose Better Solutions as Compared to Manual Photoelasticity

Previously, for calculating the principal stress difference, manual method of photoelasticity was thought to be more suitable (Tables 1, 2, 3, 4, 5). Then, with advancement in technologies, several other methods were tested. We have considered an algorithm for measuring the value of fractional fringe order and we report that the value obtained through digital method improves coherence with analytical solution in regards with manual methodology.

Error in Digital Photoelasticity is Lower as Compared to Manual Photoelasticity Method

The results obtained through manual and digital method shows variation regards to those obtained by analytical method. Variations are computed and a ratio of manual/digital processing is expressed.

For lower fringe order, especially between 0 and 2, the fringe thickness is more visible and hence the manual fringe order counting results in higher deviation. Additionally, the analytical solution provides the result at a point and with negligible dimensions, which is not feasible in manual or in digital method. The percentage error for Manual Photoelasticity and Digital Photoelasticity is calculated considering Analytical Solution as base value. It is observed that, variation in the values of Principal Stress Difference (\({\sigma }_{1}-{\sigma }_{2}\)) is more in Manual method as compared to that in Digital method. The minimum variation ratio in Manual method as compared to that in Digital method was found to be 1.75.

Conclusions

Determination of stresses at a point depends mainly on fringe order counting. Manual counting of fringes results in lack of accuracy. The above is an attempt to show the effectiveness of use of digital photoelasticity, wherein the results has a better accuracy level in comparison to manual photoelasticty. Also digital photoelasticity method seems to be in higher accordance to the results obtained analytically. Use of proposed algorithm for image processing technique shows better levels comparatively. The algorithm can be further modified by choosing better threshold value and by increasing the number of slices.

Data Availability

The data that support the findings of this study are available from the corresponding author, Dr. Shubhrata Nagpal, upon reasonable request.

References

E.A. Patterson, Digital photoelasticity: principles, practice and potential: measurements lecture. Strain. 38, 27–39 (2002)

P.M. Ramachandra, S. Sutar, G.M. Kumara, Stress analysis of a gear using photoelastic method and Finite element method. Mater. Today Proc. 65, 3820–3828 (2022)

S. Dix, C. Schuler, S. Kolling, Digital full-field photoelasticity of tempered architectural glass: A review. Opt. Lasers Eng. 153, 106998 (2022)

S. Sasikumar, K. Ramesh, Framework to select refining parameters in Total fringe order photoelasticity (TFP). Opt. Lasers Eng. 160, 107277 (2023)

K. Ramesh, S. Gupta, A.A. Kelkar, Evaluation of stress field parameters in fracture mechanics by photoelasticity—revisited. Eng. Fract. Mech. 56, 25–45 (1997)

K. Ramesh, G. Lewis, Digital photoelasticity: advanced techniques and applications. Appl. Mech. Rev. 55, B69–B71 (2002)

M. Ramji, K. Ramesh, Whole field evaluation of stress components in digital photoelasticity—issues, implementation and application. Opt. Lasers Eng. 46, 257–271 (2008)

J.W. Dally, W.F. Riley, A. Kobayashi, Experimental stress analysis, (1978)

S. Nagpal, S. Sanyal, N. Jain, Mitigation curves for determination of relief holes to mitigate stress concentration factor in thin plates loaded axially for different discontinuities. Int. J. Eng. Innov. Technol. 2, 1–7 (2012)

L. Srinath, K. Ramesh, V. Ramamurti, Determination of characteristic parameters in three-dimensional photoelasticity. Opt. Eng. 27, 225–230 (1988)

M. Solaguren-Beascoa Fernández, J. Alegre Calderón, P. Bravo Diez, I. Cuesta Segura, Stress-separation techniques in photoelasticity: a review. J. Strain Anal. Eng. Des. 45, 1–17 (2010)

S. Natarajan, K. Ramesh, Simulating Isochromatic Fringes from Finite Element Results of FEniCS. Exp. Tech. (2023) 1-5

K. Ramesh, Digital photoelasticity. Meas. Sci. Technol. 11, 1826–1827 (2000)

A. Ajovalasit, G. Petrucci, M. Scafidi, Review of RGB photoelasticity. Opt. Lasers Eng. 68, 58–73 (2015)

M. Charbit, Digital Signal and Image Processing Using MATLAB. (John Wiley & Sons, 2010)

C. Solomon, T. Breckon, Fundamentals of Digital Image Processing: A Practical Approach with Examples in Matlab. (John Wiley & Sons, 2011)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chugh, R., Nagpal, S., Sanyal, S. et al. Analyzing the Impact of Diametral Compressive Loads on Stress Distribution in Circular Discs Through Advanced Photoelastic Techniques. J Fail. Anal. and Preven. 24, 1096–1105 (2024). https://doi.org/10.1007/s11668-024-01929-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01929-3