Abstract

Molybdenum disulfide (MoS2), an emerging two-dimensional semiconductor material, has been keenly studied for field-effect transistors (FETs). In this work, we explored the optical and electrical properties of FETs fabricated by MoS2 flakes grown by chemical vapor deposition (CVD) and transferred to the electrodes through propylene carbonate film. Large-area, high-quality and highly crystalline MoS2 monolayers up to 58 µm are obtained through CVD. Flakes are characterized by optical microscopy, atomic force microscopy, Raman spectroscopy, and photoluminescence analysis. The back-gated measurements are performed in ambient conditions without any encapsulation of the device. The fabricated device reveals n-type behavior with high field-effect mobility of 32 cm2/V s and high current ON/OFF ratio of 106. Good ohmic contact is achieved while using indium as source/drain electrodes. The large sized, highly crystalline flakes of MoS2 and the fabricated device showing high field-effect mobility and ON/OFF ratio make them potential candidates for high-performance nanoelectronics and optoelectronics devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Because of its unique and remarkable electrical properties, graphene has potential for substitution in typical Si-based semiconductor devices.1 Although graphene has extraordinary high carrier mobility,2 its zero band gap limits its use in logic applications. Inspired by the invention of graphene monolayers, transition metal dichalcogenides (TMDs) such as MoS2, MoSe2, WS2 and WSe2 have gained significant consideration for their excellent potentials in research fields of nanotechnology, microelectronics, photonics, and optoelectronics.3,4 TMDs possess a layered hexagonal structure having a dangling bond-free surface, excellent thermal conductivity, and stability.5 Among these TMDs, MoS2 has been studied widely as it exhibits excellent flexibility, electrical and optical properties.6 In MoS2, each Mo atom is covalently bonded to two sulfur atoms. This covalent bonding provides great mechanical strength to MoS2. MoS2 has an outstanding ON/OFF ratio of about 108 and carrier mobility almost equal to 200 cm2/V s at standard temperature.7 MoS2 has a tunable bandgap, from 1 to 2 eV.8,9 The bandgap of MoS2 changed from an indirect to a direct one from bulk MoS2 to monolayer MoS.9 Monolayer MoS2 has a direct bandgap of 1.9 eV which makes it suitable for use in electronic and optoelectronic devices.10

Thin layers of MoS2 can be obtained by various methods such as mechanical exfoliation,7 liquid exfoliation,11 chemical vapor deposition (CVD),12 sulfurization,13 physical vapor deposition,14 and hydrothermal15 and electrochemical synthesis.16 Flakes of high quality can be achieved by exfoliation, but these flakes are randomly dispersed, limiting control of the number of layers of MoS2. Hence, these methods are not designed for large-scale device fabrication. By synthesis, MoS2 forms nanotubes (one-dimensional) or closed (zero-dimensional) structures. It is very rare to obtain large-area, high-quality, layer-controlled and high-yield MoS2 for bulk fabrication of devices with excellent electrical properties. CVD is used extensively to produce large-area layers of MoS2 with control over the number of layers, but this method does not ensure the high quality of the flakes. Enhanced scalability has been reported by using various methods, for example sulfurization of molybdenum and its oxides, vapor-liquid growth by using powder MoO3 and sulfur, thermal decomposition of ammonium thiomolybdates, and vapor-solid growth of MoS2 monolayers by using powder of MoS2.17 In emerging CVD methods, sulfurization is done after spin coating of a solution of metal on a substrate.18 Sulfurization with sulfur vapor has been demonstrated to be useful for fabricating sputtered-multilayer MoS2 films with an approximately 4-nm thickness with enhanced mobility.19Monolayers of MoS2 have been achieved by CVD on a mica substrate. A 7.5-nm-thick MoS2 film was produced. Except for monolayers, no other layers of MoS2 have been fabricated. With the help of a nucleation promoter, perylene-3,4,9,10-tetracarboxylic acid tetrapotassium salt (PTAS), a highly crystalline and uniform monolayer of MoS2 has been fabricated.20 However, it is very hard to use this monolayer uniformly on a large substrate. Wafer-scale monolayers of MoS2 have been synthesized which exhibit on/off ratios ranging from 105 to 108 and carrier mobility up to 1.2 cm2/V s.21 A recent work investigating field-effect transistors (FETs) fabricated on monolayer MoS2 produced by CVD showed carrier mobility of 1.45 cm2/V s with an ON/OFF ratio of 104.22 MoS2 FETs fabricated by mechanical exfoliation have shown good carrier mobility, but FETs based on CVD-grown MoS2 exhibited low electrical performance. Growing a layer-controlled, contamination-free, high-quality, large-scale MoS2 films for nano-devices with excellent performance is still challenging. Moreover, no optimized parameters and methods have been reported for the growth of monolayer MoS2.

In this work, we fabricated uniform, highly crystalline, large-area, high-quality monolayers of MoS2 by CVD on SiO2 substrates. Atomic force microscopy (AFM), Raman spectroscopy, and photoluminescence (PL) analysis confirmed that our monolayers of MoS2 are highly scalable, uniform, and crystalline in nature. We also fabricated FETs on CVD-synthesized monolayer MoS2 films which exhibited an on/off ratio of 106 with comparative carrier mobility of 32 cm2/V s. The contact between the metal electrodes and the MoS2 becomes one of the most critical aspects restricting device performance. Good ohmic contact is attained when we use indium (In) as electrodes, which improves the performance of the MoS2-based FETs. Our research work demonstrates that excellent electrical performance of devices based on MoS2 can be achieved by controlled growth of large-area and high-quality MoS2 films.

Experimental Setup

MoS2 Synthesis

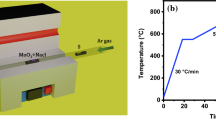

Figure 1 demonstrates the setup of the experiment. Thin films of MoS2 are grown on O2 plasma treated 100 nm SiO2/Si substrates in 2-zone CVD with 5 cm quartz. The substrate was pre-treated with O2 plasma for 120 seconds at 110 W to attain a hydrophilic surface. MoO3 and sulfur powders purchased from Sigma-Aldrich are used as precursors. Two milligrams of MoO3 powder was taken in a quartz boat with the substrate in a face-down position arranged on the top of boat. Next, 300 mg of sulfur powder was placed in a separate boat. A distance of 15 cm was maintained between boats containing the MoO3 and sulfur powder. Sulfur was placed in an upstream position in the furnace. Thin layers of MoS2 were grown at 750°C under 500 sccm Ar flow.

The shape, density, and growth of the MoS2 flakes were observed by optical microscopy (OM). The uniformity, smoothness and surface structure were examined by a NanoMagnetics ezAFM system. Raman and PL analysis of MoS2 flakes were performed using a Renishaw inVia confocal Raman microscope system with an objective lens of 100× with numerical aperture of 0.75 A. continuous wave laser of 532 nm with power of 1 mW was used. Integration time of 0.3 s was used for Raman spectra and 0.02 for PL analysis.

Device Fabrication and Characterizations

The back-gated FET was fabricated by transferring the CVD-grown MoS2 monolayer on the SiO2/Si substrate, and Au/In metal electrodes were deposited on it by optical lithography. A total of 80 nm of Au was deposited on 20 nm indium (In) to make electrodes. The MoS2 flakes synthesized via CVD were relocated onto a SiO2/Si substrate using a pick-up technique involving the application of propylene carbonate (PC). The PC solution was made by combining methoxybenzene with PC particles at a mass fraction of around 10%. PC solution was drop-cast on the SiO2/Si substrate containing CVD-grown MoS2 flakes. The PC solution was hardened into the PC film by placing it on a hot plate for 10 min at 110°C. The PC film worked as a stamp and carried the MoS2 layers out of the substrate. Then this PC film was moved to the targeted substrate. At 80°C, the PC film loosened its adhesion and MoS2 layers were transferred on the desired substrate by removing the PC film. The transfer characteristics of the MoS2 -based FET were measured with a Keithley 2400 source meter.

Results and Discussion

Optical Characterization

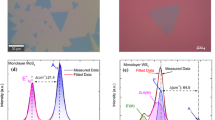

Figure 2a presents the OM images of CVD-grown MoS2 flakes with triangular shape. PL images of MoS2 flakes can be seen in Fig. 2b. In Fig. 2c and d the density of the CVD-grown MoS2 flakes can be seen. We observed maximum crystal size up to 58 µm for this growth. The OM image of a MoS2 triangle with edges longer than 52.58 µm can be seen in Fig. 2e. In Fig. 2f, a smooth, uniform, highly crystalline and large-area layer structure of MoS2 flake can be observed with AFM.

Figure 3a presents the Raman spectra of MoS2. Most significantly, the Raman spectra of MoS2 show two prominent peaks of MoS2. Two non-resonant characteristic peaks of MoS2 are found. These two peaks are dominated by two vibrational modes. E12g (in-plane vibration) is due to the in-plane vibration of two sulfur atoms with Mo atoms. The E12g mode appeared at 382 c/m. The A1g mode (out of plane) refers to the out-of-plane vibrations of sulfur atoms in opposite directions. The A1g mode is observed at 404 c/m. These two modes are very sensitive to the thickness of the MoS2 structure. The thickness and number of layers of MoS2 are determined by the peak positions of these two modes. The difference between these two peaks tells us about the number of layers of MoS2. The difference between these two peaks, observed from our Raman spectra, is A1g − E12g = 405 − 385 = 20 c/m and ratio of A1g/E12g = 1.057 ≈ 1. The difference of 20 c/m shows that our MoS2 is monolayer.23,24 Figure 3b presents the PL spectra of MoS2. Excitons are the electron-hole pairs which are formed by optical excitation of electrons from valence band to conduction band when MoS2 is exposed to laser of energy below than 670 nm. As these excited electrons are unstable, they come back from the conduction band to the valence band and relax. In the relaxation state, these electrons recombine with the holes produced in the valence band after their excitation. Radiation is induced because of this recombination. As a result, we observed various peaks of MoS2 in its PL spectra. Two well-defined peaks are observed in bare MoS2 spectra at 1.84 eV and 2.08 eV. These peaks are referred to as A exciton and B exciton, respectively. These peaks demonstrate the exciton formation, and this difference in energy between these two peaks is attributable to the spin-orbit splitting of the valence band.25

Electrical Characterization

Figure 4a shows a cross-sectional illustration of the CVD-grown MoS2-based FET device. The device is fabricated on a SiO2/Si substrate. SiO2 with a thickness of 300 nm acts as the gate oxide layer deposited on 500-nm-thick Si. It acts as a back gate to control the fabricated FET. The channel length LC of the active region is 5 µm and channel width Wc is 6 µm. Figure 4b shows the optical image of the fabricated MoS2-based FET. Figure 4c, d demonstrates the output and transfer characteristics of the monolayer MoS2-based FET in contact with In. Output curves of the FET were obtained by taking the Vg from −60 V to 60 V. Good ohmic contact with In was achieved. All electrical measurements were taken in ambient conditions. It is obvious from the transfer curve in Fig. 3d that MoS2-based FET exhibits n-type behavior. From the saturation region of the on-state conducting channel, threshold voltage VTH is defined. VTH is obtained from the intercept made from linear extrapolation on the ID–VG graph. FET is usually in the on state when VG = 0 V, which represents the collective conduction of electrons. Figure 3e represents the ID−VG curves demonstrating the distinct n-type characteristics with ON/OFF = 10.6

The field-effect mobility of the MoS2 -based FET is obtained by using the following equation.

where µFE is field-effective mobility, gm is transconductance = \(\frac{\partial Id}{\partial Vgs}\), Lc is the length of the channel, Cgo is the capacitance of the gate oxide, VD is the drain voltage and Wc is the width of the channel. Cgo = ɛg0 / tog where ɛgo is the dielectric constant of the gate oxide and tog is the thickness of the gate oxide. This device shows good electronic performance. High mobility of 32 cm2/V s and an ON/OFF ratio of 106 is attained, which is comparatively higher than the previous reported devices fabricated on CVD-grown MoS2 monolayers.22,26,27

Conclusion

We have demonstrated the optical and electronic properties of a FET device based on MoS2 flakes grown by CVD. A uniform, highly crystalline, large-area, high-quality monolayer of MoS2 is achieved by CVD on SiO2 substrates. Electrodes are fabricated by optical lithography and MoS2, grown by CVD, is transferred through PC film. AFM, Raman, PL, and back-gated measurements are performed in ambient conditions without any encapsulation of the device. The fabricated device reveals n-type behavior with high field-effect mobility of 32 cm2/V s and high current ON/OFF ratio of 106. Good ohmic contact is achieved when using In as source/drain electrodes. The large-sized, highly crystalline flakes of MoS2 and the fabricated device showing high field-effect mobility and ON/OFF ratio make them potential candidates for high-performance nanoelectronic and optoelectronic devices.

References

K.S. Novoselov, D. Jiang, F. Schedin, T. Booth, V. Khotkevich, S. Morozov, and A.K. Geim, Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. 102(30), 10451 (2005).

K.S. Novoselov, L. Colombo, P. Gellert, M. Schwab, and K. Kim, A roadmap for graphene. Nature 490(7419), 192 (2012).

G. Cunningham, U. Khan, C. Backes, D. Hanlon, D. McCloskey, J.F. Donegan, and J.N. Coleman, Photoconductivity of solution-processed MoS2 films. J. Mater. Chem. C 1(41), 6899 (2013).

Y. Gong, J. Lin, X. Wang, G. Shi, S. Lei, Z. Lin, X. Zou, G. Ye, R. Vajtai, and B.I. Yakobson, Vertical and in-plane heterostructures from WS2/MoS2 monolayers. Nat. Mater. 13(12), 1135 (2014).

Z. Lin, C. Wang, and Y. Chai, Emerging group-VI elemental 2d materials: preparations, properties, and device applications. Small 16(41), 2003319 (2020).

O. Lopez-Sanchez, D. Lembke, M. Kayci, A. Radenovic, and A. Kis, Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 8(7), 497 (2013).

B. Radisavljevic, A. Radenovic, J. Brivio, V. Giacometti, and A. Kis, Single-layer MoS2 transistors. Nat. Nanotechnol. 6(3), 147 (2011).

Z. Yu, Z.Y. Ong, S. Li, J.B. Xu, G. Zhang, Y.W. Zhang, Y. Shi, and X. Wang, Analyzing the carrier mobility in transition-metal dichalcogenide MoS2 field-effect transistors. Adv. Funct. Mater. 27(19), 1604093 (2017).

H.V. Phuc, N.N. Hieu, B.D. Hoi, N.V. Hieu, T.V. Thu, N.M. Hung, V.V. Ilyasov, N.A. Poklonski, and C.V. Nguyen, Tuning the electronic properties, effective mass and carrier mobility of MoS2 monolayer by strain engineering: first-principle calculations. J. Electron. Mater. 47, 730 (2018).

R. Sundaram, M. Engel, A. Lombardo, R. Krupke, A. Ferrari, P. Avouris, and M. Steiner, Electroluminescence in single layer MoS2. Nano Lett. 13(4), 1416 (2013).

K.G. Zhou, N.N. Mao, H.X. Wang, Y. Peng, and H.L. Zhang, A mixed-solvent strategy for efficient exfoliation of inorganic graphene analogues. Angew. Chem. 123(46), 11031 (2011).

Y. Zhan, Z. Liu, S. Najmaei, P.M. Ajayan, and J. Lou, Large-area vapor-phase growth and characterization of MoS2 atomic layers on a SiO2 substrate. Small 8(7), 966 (2012).

H.Y. Jeong, Y. Jin, S.J. Yun, J. Zhao, J. Baik, D.H. Keum, H.S. Lee, and Y.H. Lee, Heterogeneous defect domains in single-crystalline hexagonal WS2. Adv. Mater. 29(15), 1605043 (2017).

S. Helveg, J.V. Lauritsen, E. Lægsgaard, I. Stensgaard, J.K. Nørskov, B. Clausen, H. Topsøe, and F. Besenbacher, Atomic-scale structure of single-layer MoS2 nanoclusters. Phys. Rev. Lett. 84(5), 951 (2000).

Y. Peng, Z. Meng, C. Zhong, J. Lu, W. Yu, Y. Jia, and Y. Qian, Hydrothermal synthesis and characterization of single-molecular-layer MoS2 and MoSe2. Chem. Lett. 30(8), 772 (2001).

Q. Li, J. Newberg, E. Walter, J. Hemminger, and R. Penner, Polycrystalline molybdenum disulfide (2H–MoS2) nano-and microribbons by electrochemical/chemical synthesis. Nano Lett. 4(2), 277 (2004).

X. Li and H. Zhu, Two-dimensional MoS2: properties, preparation, and applications. J. Mater. 1(1), 33 (2015).

J. Pütz and M.A. Aegerter, Liquid film deposition of chalcogenide thin films. J. Sol-Gel Sci. Technol. 26(1), 807 (2003).

K. Matsuura, T. Ohashi, I. Muneta, S. Ishihara, K. Kakushima, K. Tsutsui, A. Ogura, and H. Wakabayashi, Low-carrier-density sputtered MoS2 film by vapor-phase sulfurization. J. Electron. Mater. 47, 3497 (2018).

Y.C. Kim, Y.H. Ahn, S. Lee, and J.-Y. Park, Large-area growth of high-quality graphene/MoS2 vertical heterostructures by chemical vapor deposition with nucleation control. Carbon 168, 580 (2020).

F.K. Perkins, A.L. Friedman, E. Cobas, P. Campbell, G. Jernigan, and B.T. Jonker, Chemical vapor sensing with monolayer MoS2. Nano Lett. 13(2), 668 (2013).

H. Şar, A. Özden, B. Yorulmaz, C. Sevik, N. Kosku Perkgoz, and F. Ay, A comparative device performance assesment of CVD grown MoS2 and WS2 monolayers. J. Mater. Sci. Mater. Electron. 29(10), 8785 (2018).

C. Lee, H. Yan, L.E. Brus, T.F. Heinz, J. Hone, and S. Ryu, Anomalous lattice vibrations of single-and few-layer MoS2. ACS Nano 4(5), 2695 (2010).

H. Li, Q. Zhang, C.C.R. Yap, B.K. Tay, T.H.T. Edwin, A. Olivier, and D. Baillargeat, From bulk to monolayer MoS2: evolution of Raman scattering. Adv. Funct. Mater. 22(7), 1385 (2012).

J. Zhang, H. Yu, W. Chen, X. Tian, D. Liu, M. Cheng, G. Xie, W. Yang, R. Yang, and X. Bai, Scalable growth of high-quality polycrystalline MoS2 monolayers on SiO2 with tunable grain sizes. ACS Nano 8(6), 6024 (2014).

S.S. Withanage, H. Kalita, H.-S. Chung, T. Roy, Y. Jung, and S.I. Khondaker, Uniform vapor-pressure-based chemical vapor deposition growth of MoS2 using MoO3 thin film as a precursor for coevaporation. ACS Omega 3(12), 18943 (2018).

S.K. Kang and H.S. Lee, Study on growth parameters for monolayer MoS2 synthesized by CVD using solution-based metal precursors. Appl. Sci. Converg. Technol. 28(5), 159 (2019).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mustafa, H., Khan, J., Sattar, A. et al. High-Performance Field-Effect Transistor Fabricated on CVD-Grown MoS2 Monolayers with Indium Contacts. J. Electron. Mater. 52, 7157–7163 (2023). https://doi.org/10.1007/s11664-023-10625-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10625-1