Abstract

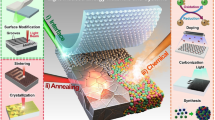

At present, self-repairing, intelligent materials are being considered as future material. In this perspective, the electroactive materials are unique for their adaptability, sharp response time, control over the system, quick response rate, low power consumption, and compactness. The electroactive materials include electroactive polymers (EAPs), piezoelectric materials, electroactive gels, and fullerene compounds. The photonic interaction of light with the electroactive material converts light energy into mechanical energy and leads to multi-directional applications. Contemporarily with increased interest and emphasis on ‘green’ technological solutions, efforts are focussed on utilizing these electroactive materials with light energy. Corresponding to this, biomimetic and artificial intelligence are advancing to develop various optoelectronic devices, energy conversion and storage devices, photoresistors, vehicle components, sensors, robots, and medical devices. A better understanding of such light illumination with electroactive materials and prospective applications contributes to the planning of beneficial smart materials. Hence, this review article focusses on the interaction of light with different electroactive materials, their applications, and prospects of the current and future investigations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Smart material technology has opened up new directions for a variety of materials with excellent characteristics.1,2,3,4,5 Electroactive materials are key smart materials for their excellent qualities such as higher reaction rate, low density, high actuation displacement, mechanical friendliness, quick response to stimuli, strain rate, reliability, and low price.6,7,8,9,10,11,12,13 These materials are excellent for sensing, optoelectronic applications, piezoelectric transducers, ferroelectric memory devices, electrodes for electrochemical energy conversion and storage, sensors, electroceramic and organic devices, magnetic and optical devices, photoresistors, and embedded capacitors in actuators applications, among others.14,15,16,17,18,19,20,21 The interaction of light with the electroactive polymers (EAPs) leads to the point where the light energy is converted to mechanical energy.22,23,24,25,26,27,28,29 Varied stimuli such as light and magnetic and electrical field leads to the diverse shape-memory effect for EAPs; piezoelectric electroactive material (e.g. polyvinylidene fluoride, PVDF) films produce electric voltage when exposed to infrared (IR) light due to the strong piezoelectric constant.15,30 External stimuli such as light, temperature, and electric field controls the material interface via a switchable surface that is applied for either ‘on-off’ or reversible changes.31,32,33,34,35,36 The ‘light–electroactive material interaction’ is a subject of immense importance. In nature some of plants exhibit actuation; for example, a sunflower detects the movement of the sun throughout the day so to maximize the utilization of sunlight, and the Cornish Mallow leaf avoids sunlight through a light-sensitive photobase.37,38,39,40 The interaction of light with that of electroactive material is important for medical applications, e.g. exploring lenses that can rapidly focus without a change of location with the intensity or sensitivity change of light which, for example, could be applied in human eyes for image interpretation and reorganization.41,42,43,44 One of the benefits of the photoresponsive polymer is the recovery of the shape after remote activation which is otherwise not possible for thermoresponsive shape memory polymers (SMPs).44,45,46,47,48 Organic conjugated materials such as electroactive material are gaining much attention currently for light-emitting diode (LED) applications,33 light-emitting electrochemical cells,49 photodetectors,50 field-effect transistors,51 solar cells, and laser applications.52 Optically pumped organic solid-state lasers, which are based on conjugated polymers, oligomers and charge transfer systems, are already in use.3,53,54 Such approaches are very important and can lead to the driving of nanomachines and micromachines without the assistance of motors, gears, or batteries and only using laser beam irradiation.55 High-energy lights can drive actuators and can thus be used wirelessly without any hardware connections or physical contacts. Thus, these actuators can be used in hostile environments such as near nuclear radiation, chemical contamination, and strong electromagnetic fields. Other practical applications include photophones, optical switches, microactuators, optical projection systems, and optorobots.56,57,58,59 A high-energy light can be used for shape memory polymers and does not require hardwire connections for actuator applications and performs in hostile atmosphere.57,60

Thus, here it can be seen that the interaction between electroactive material and light depends upon the electroactive material and leads to multiple applications. A thorough understanding of such interactions and present applications and prospects enables the design of more environment-friendly ‘smart materials’. Therefore, in this review article, we briefly discuss the interaction of light with different electroactive materials such as electroactive polymers (EAPs), piezoelectric materials, electroactive gels, and fullerene compounds, as well as their applications and current and future investigation perspectives.

Interaction of Light with Different Electroactive Material

Light–Electroactive Polymer Interaction

A general photo-induced electron transfer process is expressed as in Scheme 1.

Here, the donors and acceptors are either covalently bonded or spatially close. The donor (D)-acceptor (A), units are at each of the steps, returned back to the ground state either by radiative or non-radiative relaxation; data from Ref. 52.

For EAPs, the presence of a group affects its ionization potential thus affecting quantum efficiency. For example, in cyano-polyphenylene vinylene (CN-PPV), the presence of -CN groups causes more electron affinity for the CN-PPV group than of the poly[2-methoxy-5-(2’-ethylhexyloxy)-1,4-phenylene vinylene (MEH-PPV) MEH-PPV chain, making the CN-PPV more suitable for LED applications than MEH-PPV80 (Fig. 1). The electroactive polymer containing cinnamic groups (-CHCOOH) change shape, e.g. spirals, arches, tubes, by ultra-violet (UV) light irradiation and return to the original shape at ambient temperature and UV light exposure of different wavelengths61 (Fig. 2). The surface relief feature is observed for oligomers and azobenzene polymers when irradiated by polarized light.62,63 For side-chain azobenzene, the peaks and troughs depend upon the structure of the polymer. It is considered that the contraction of the polymer chain between the excited molecules in the illuminated region and surrounding shrinkage is due to laser-induced phase transitions.37,63 For nematic solids, up to 400% shape change can be performed optically, and these changes are reversible in nature; the trans-cis isomerization conversion to bent cis-trans occurs upon UV irradiation.23 The rate of such photoisomerization depends upon factors such as intensity of light (I) and cos2θ where the angle between the given rod and the vector of the electric field of the applied illumination is θ and if the reversible elongation is along the director; the rate of conversion for trans dye molecule is as follows:

η is the rate of absorption of I as a function of Q which accompanies a change in nematic order parameter and a function of temperature; ρ is the concentration of trans dye molecule.23

Effect of light illumination introduces electron (e−) and hole (h+) transfer on the (a) Poly[2-methoxy-5-(2’-ethylhexyloxy)-1,4-phenylene vinylene (MEH-PPV) and (b) Cyano-Polyphenylene vinylene (CN-PPV); data from Ref. 64.

Photoswitchable molecule changes by light interaction of one wavelength and returns to initial state either by thermal treatment or light irradiation of a different wavelength; data from Ref. 61.

For a photo-responsive polymer (e.g. interpenetrating polymer network, IPN, polymer), when irradiated by UV light, the colloid segments of the chains are elongated in the permanent amorphous network (Scheme 2). The fixation of the strain could be due to the generation of new chemical net points while the lower fixity rate causes the elastic contraction of the straight-chain segments. The chromophores which are covalently bonded and inserted onto the permanent polymer network (filled circles, permanent cross-links) form the photoresponsive cross-links (filled diamonds).61,65 Usually, the spiral shape is formed because of the formation of two layers, and the shape change is fixed at the top layer while the layer beneath it keeps its elasticity fixed.61 The adjacent points in a shaped polymer must be covalently cross-linked and amorphous to be photoresponsive. If a photoresponsive polymer carries a cinnamic group, cycloaddition reactions [2+2] take place in the presence of alternating light wavelength.61 As seen in Scheme 2, if UV> 260 nm is applied for a certain time (e.g. 60 min), it causes stretching and photo-fixing and leads to an elongation up to 20%. Once this external stimulus is removed it remains in an elongated form, and when this elongated polymer is exposed to this wavelength again for 60 min it causes photocleavage or change of the cross-linked polymers, and the shape is recovered.61 After a few cycles under UV light, the light-induced rearrangement reaction might lead to a color change of the electroactive polymer film, although the properties remain intact. Some changes in the macroscopic level can take place due to the partial cleavage of cross-linking.61

Elongation of the colloidal segments of the amorphous network upon UV light irradiation; data from Ref. 61.

To design on-off switching initiated by such light stimulation, photosensitive electroactive polymer interaction can be promoted by the bimolecular adhesion of the surface, such as protein.31

In compound types such as Fig. 3a, silicon functions as a weak charge transmitter where donor and acceptor phenyl-Si-phenyl moieties are connected together.66 In such a compound, the polysilanyl bridge plays the role of the intramolecular charge transfer from the donor to the acceptor. For, such a compound the cyclohexasilane ring is found to be more effective as an electron releasing group than its open-chain counterpart.66 The improved optical nonlinearities under UV for compounds such as Fig. 3a and b at first may be due to the added easy charge transfer in the cyclohexasilanyl-phenyl acceptor moiety (Fig. 3).

Electroactive cyclohexasilanes showing nonlinear optical properties of (a) 1-ferrocenyl-4-((2,2-dicyanoethenyl)-phenyl)-decamethylcyclohexasilane, (b) 1-ferrocenyl-3-( (2,2-dicyanoethenyl)-phenyl)-decamethylcyclohexasilane; data from Ref. 66

When a material comprises both poly(N-isoprylamide) (pNIPAM) and photoresponsive spirobenzopyran (SP), controlling of the cellular growth is enabled in the spatial direction of the UV light.31,36 When the oligo-m,p-phenylenevinylenes are replaced by an alkoxy group, absorption and emission spectra are seen at higher wavelengths than the oligomers where the oxygen group is absent directly attached to the backbone.67 If p-phenyl is replaced by 4,4'-biphenyl moieties, there is a hypsochromic shift in the optical spectra (Fig. 4).67 The bending direction of the film can be controlled by changing the direction of the polarization of the illuminated light (Scheme 3).62,68

Dipolar silicon compounds with an extended transparency range combined with interesting nonlinear optical activities; data from Ref. 67

For azobenzene moieties, light of a particular direction leads to cis-trans isomerization in a specific domain where the azobenzene moieties are aligned along the direction of the polarized light.62 Size contraction by light illumination also leads to volume contraction, and such bending of the whole film leads to the cooperative movement of polymer segments and the liquid-crystal moieties to efficiently convert the light energy into mechanical energy.62 This photoselective volume shrinkage introduces a photomechanical effect which is useful in advanced high-speed actuators for microscale or nanoscale instruments such as microrobots in medicine or optical microtweezers by remote laser radiation without the aid of motors, gears or batteries.55,63

Photoreactive polymer, poly-(4-vinyl benzyl-thiocyanate (PVBT), changes refractive index upon UV irradiation.69 The change in refractive index is due to the photoinduced isomerization of thiocyanate (SCN) to isothiocyanate (NCS). Irradiated PVBT modified with 1-naphthyl methylamine, causes a further increase in the refractive index. By employing the periodical variation of the refractive index of the active medium, optical feedback in a waveguide can be introduced.69 This concept of distributed feedback (DFB) has been applied for films of conducting homopolymers (e.g. PPV) derivatives cast onto SiO2 or ladder-type poly-(para-phenylene) (m-LPPP) cast onto flexible plastic substrates.69 As an example, poly(vinyl cinnamate) (PVCi) undergoes a [2 + 2] cycloaddition under UV irradiation and the photoreaction causes a reduction of the refractive index.69 There are reports of the change in refractive index of PVBT when irradiated under UV light, and these photoreactions proceed via radical intermediates. The UV irradiation of PVBT films leads to photoisomerization of the thiocyanate (-SCN) units which represents a 100% conversion of -SCN to isothiocyanate (-NCS) units. During the photoisomerization of PVBT, the side reaction can also contribute to the change in refractive index. The change in refractive index for PVBT is greater compared to other photoreactive polymers (e.g. PVCi).69 It is important to modify the refractive index pattern so that it remains stable even under intense UV illumination, or else the photochemically carved phase gratings are depleted under laser illumination. Although changes in the refractive index of PVBT are favorable for carving phase gratings, the unilluminated areas are still active to UV and, therefore, fail to achieve a long-lasting impact. The -SCN groups in PVBT change to -NCS by UV illumination and undergo addition reactions with amines (-NH2) to form thiourea derivatives while the unirradiated areas still contain stable -SCN groups, consequently resulting in a different response.69

Light–Piezoelectric Electroactive Polymer Actuators Interaction

For, the photostrictive materials, photo-restriction or opto-piezoelectricity is a photo-deformation process which includes the photovoltaic effect and converse piezoelectric effect 56, 57, 70]. The photostrictive materials are ferroelectric, e.g lead-lanthanum-zirconate-titanate (PLZT) [(Ph, La)(Zr, Ti)O3]. These materials find wide applications such as in photostrictive actuators when doped with PbO, TiO2, Nb2O3, La2O3, ZrO2. For the photostrictive materials, the bonding layer is opaque to the light transmission, and therefore, the light absorbed by the top layer cannot penetrate to the bottom layer. When the top of the surface layer is illuminated by high-energy uniform illumination, a current induction on the top layer takes place due to the photovoltaic effect opposite to the direction of the polarized light.56,70 Because of this, an in-plane electric field is generated as the induced charge flow causes the flow of the charge at the end surface of the paired electrodes.56,70 As a result, a positive strain is generated on the side of the illumination and a negative strain is generated in the opposite direction, i.e. the dark side, due to the converse piezoelectric effect. This coupling effect is the reason behind the bending or the photodeformation of the photostrictive optical actuators (Scheme 4).56,57

The optomechanical actuators are made up of two layers of photostrictive materials and they are placed in opposite polarities, the bimorph arrangement.57 As seen in Scheme 5, the common electrodes are positioned at the two ends on the z-axis and the light is irradiated from the direction of the y-axis. At the illumination, a series of photochemical reactions take place where the absorbed light causes the induction of the positive charge on the top of the surface and formation of a negative charge which leads to the deformation of the shape. It is important to note that, at the same time, some of the light energy causes an increase in temperature by converting to thermal energy. As a result, a secondary strain takes place due to the thermal effect which causes the generation of the additional charge that leads to the pyroelectric effect. If a continuous transverse illumination of light is applied to an opto-electrochemical actuator system, an electric field is generated which can be written,57

Light interaction with a 2D distributed opto-electromechanical actuator system; data from Ref. 57.

Here, Es is the saturated photovoltaic field, Eo is the initial field between the electrodes, Cois the capacitance between the electrodes, Ro is a constant, where Ro = (αoIoCo)−1, Io is continuous illumination intensity, αo is a constant related to the geometrical configuration.

Again, the light illumination on the surface of the opto-electromechanical actuator induces an electric field simultaneously converting the light energy to heat energy. When the temperature of the system increases, an additional electric voltage is generated because of the pyroelectric effect. The heat equilibrium equation of the actuator results owing to the light illumination I (tj+1) and the increase in temperature at time Δt, and can be given as:57

Here, P is the heat absorbed due to the light illumination, I(tj+1) is unit intensity per unit time, H is heat capacity of the actuator, θ(tj) is body temperature, Δθ is the temperature variation, γo is the heat transfer rate from the actuator to the structure.

The light-induced resultant strain of the polymer actuator (Sokk) is induced by (a) opto-piezothermoelstic effect, (b) opto-thermoelastic effect, and (c) opto-electromechanical effect:71

λiis thermal stress coefficient coupling, Yop is Young’s modulus of the opto-electrochemical actuator.

The control of the motion of the electroactive polymers depends on the nature of the material, its geometry, and the induced electric field.56,72

For light modulation, a AlGaN/InGaN multiple quantum well laser with piezoelectric anti-reflection coatings over the Fabry–Pérot aperture, such 2D gratings (e.g. rectangular pillars and circular pillars) can be applied as they introduce more grating space and show elevated resonant perturbation and susceptibility which causes thin Fabry–Perot mode reflectance dips, focal to an intensified Fabry–Perot excited mode.73 It is seen that the presence and percentage of carbon nanotubes,74 gold nanoparticles,75 or magnetite76 affect the photoresponse of the thermoresponsive hydrogel material. The directional control of such ‘swimming’ can be controlled by directing the light source. For the UV responsive thin-film liquid crystal layer, a similar bi-directional control also can be performed by changing the polarization direction of the light source.77 There are some instances for the irreversible responses of bending via UV illumination which suggests that the light initiates final assembly of microwaves (Scheme 5).78

Light–Electroactive Gel Interaction

The shape-change of the polyelectrolyte gels by the introduction of light can be explained by the mechano-photochemical effect.62,79 The high-intensity light irradiation on the gel caused ionization which causes the development of osmotic pressure, and when the light is removed, the gel collapses and returns to its original state, e.g. poly(p-N,N-dimethylamine)-N-gamma-D-glutamanilide).62,80 The speed of such change depends upon the speed of the photochemical ionization and subsequent recombination of the ions (Scheme 6).63

For the electroactive gels, the physical properties that direct the shape change by light irradiation are as follows:

-

Suitable conjugation of the ionizable groups

-

Cross-linked, porous gel matrix

-

High crystalline or polymeric amorphous structure

The transition in shape by the high-intensity light illumination could be due to heat generation.63 The intensity of the incident light on the gel depends upon the gel to cause the change, and the process of the transition may change from continuous to discontinuous and lowering of the transition temperature.63,79 The chromophores incorporated in the gel cause radiationless transition by absorbing the light energy and then dissipating the heat.63,79

Fullerene-Polymer Combination As an Electroactive Material

For plastic solar cells, one of the limiting factors is their mismatching with the solar spectrum, and to overcome this problem, one way is to lower the band gap of the polymer (<1.8 eV). For electroactive semiconducting polymers, if the generation of the photoinduced free charge carrier takes place, simultaneously, the electroluminescence device shows light emission for forward bias and a photocurrent under a reverse bias.9,81 Under reverse bias for photodetection, the potential difference between the electrodes should be high enough to overcome the Coulomb attraction of the photogenerated excitons. The absorbed photons will mainly create excitons which decay either in a radiative manner with photoluminescence or in a non-radiative manner. To overcome the limitation of photoinduced charge carrier generation, the donor/acceptor (dual molecule) is an approach.45,52 An example is a composite thin film with a conjugated polymer/fullerene mixture, where the single-composite photoactive film leads to the formation of a bulk heterojunction between the electron donors and acceptors.45,54,82 When the single composite photoactive films are in conjunction with an electron acceptor, prolonged charge separation is achieved based on the stability of the photoinduced nonlinear excitations on the conjugated polymer backbone. There are reports of further development of the power conversion efficiency by using acceptor-type conjugated polymers in an interpenetrating polymer-polymer composite with poly-(2-methoxy-5-(2'-ethyl-hexoxy)-p-phenylene (MEH-PPV).9,64 MEH-PPV mixed with fullerenes (e.g. C60) exhibited ultrafast, reversible, metastable photo-induced electron transfer from the conjugated polymers onto the buckminsterfullerene, and the power conversion from MEH-PPV/methano-fullerene was increased.83,84 In a recent study, the forward transfer of the photoexcited electrons from conjugated polymer donors onto phenyl-C61-butyric acid methyl ester (PCBM) suggests the relaxation of the excited polymer chain from radiative to non-radiative fashion when mixed with PCBM in the polymer matrix.9,52 A study on the mixture of conjugated polymer and fullerenes suggests a reversible, ultrafast, metastable photo-induced electron transfer from the conjugated polymer onto the buckminsterfullerene in solid films (Fig. 5, Scheme 7).9

Interaction of PCBM with poly-(2-methoxy-5-(2'-ethyl-hexoxy)-p-phenylene (MEH-PPV) upon light irradiation; data from Ref. 85.

Photo-induced electron transfer inside the composite due to the formation of a heterojunction donor/acceptor layer (a) short-circuit conditions, (b) without interfacial layer formed between the metal/semiconductor interface; data from Ref. 85.

Future Directions

The EAP-based adaptive optical systems have a bright future for a wide range of applications, from retinal tissue diagnosis to advanced astronomical telescope development. For example, electromagnetic interference (EMI) shielding is very important for military and civil applications in the microwave region; the use of microwave absorbing electroactive polymers in a gapless way helps to deactivate EMI by radar detection.9 The increase in shielding efficiency (SE) is a subject of research to enable military vehicles not to be detected by radar.1,9 For significant SE, either or both the magnetic field and electric field interact with the radiated electromagnetic field.9 Many challenges are associated with the development of space technology equipment (e.g. space robots); advanced suitable smart materials for such application are a challenge and the electroactive materials are very promising in this regard.

Contemporarily, EAPs find application in a wide range of categories, such as ionic polymer–metal composite (IPMC) gels, conducting polymers, and carbon nanotubes (CNTs).86 The requirement for flexibility and lower density are some of the features that are required to be developed for the proper biomimicry of natural muscles which require advanced EAP.87,88 The interaction of light with an electroactive polymer or material for the development of the artificial muscle and tissue engineering is also very important.89,92,93,92 Understanding the behavior of EAP design, repeatable fabrication with light is required for it to advance to effective and superior mechanism performance.93,96,97,98,99,98 Passive sensor applications for the electroactive materials, e.g. soft liquid hydrogel micro-lenses, by using light can be applied for endoscopy.99,102,101

There are reports of the development of polypyrrole (PPy), conducting polymer (CP) trilayer actuator arrays which can be applied to other adaptive optics actuator technologies, such as piezoelectric actuators or electrostatic electrodes.16 There are reports of the designing of an EAP-piston tilt mirror that can be used for retinal diagnostics. In such an arrangement, the active optical component, EAP actuated tilt mirror along with a wavefront sensor and a data acquisition computer, a mirror, a power management unit (PMU), and a switching control unit (SCU) are the main components.102 The EAP-piston tilt mirror contains a circular array of four EAP actuators, the positions of which are expressed by their respective coordinal directions as north (n), south (s), east (e), west (w), and an ordered stimulation of each actuator initiates three distinct degrees of freedom, useful for tilting and optical adjustments. Although such applications require further investigation, it should be noted here that an Australian company, Quantum Technology Pty. Ltd, developed EAP actuators for Braille cells as an aid for the visually impaired and blind.103 Optical switching of protein interaction with photoresponsive electroactive polymers is discussed in depth by Wallace et al.31 Multimodal switching in response to light is very important for the field of bionics where the remote and temporal controlling of the properties of the material is very important.31 Polymers that change volume due to light interaction are considered to be made of ‘jump molecules’ and extensive investigation is going on in this field.63

Combining EAPs, such as polyaniline, polythiophene, or polypyrrole, are combined with metal nanoparticles also combines the electrical conductivity of the metal nanoparticle to that of the mechanical flexibility and the processing properties of the polymer; such enhancement promises considerable advancement as a smart material.104,105 But the problem with this material is their lower degradation issues which result in serious environmental concerns as well as processing problems, affecting their long-term operational functionality and reliability. To address these issues, the development of smart materials using electroactive polymers and carbon nanotubes through in situ polymerization methods can be used to develop highly functional materials ranging from flexible electronic devices to wearable textiles. These materials consist of nanometer-diameter graphene cylinders with micrometer length that contribute to superior optical properties along with other properties, such as structural, mechanical, thermal, and electronic properties. These smart materials are luminescent and optically active and they can be converted into coatings, films, and fibers.104 For biodegradable SMPs, there is potential for light-induced applications.26,27,61,85,106 Understanding these mechanisms will help in designing high-speed actuators for nanoscale or microscale application that can be controlled locally, for new motors and traffic lights.30,62,107,110,111,110 PVBT and related polymers are considered appropriate matrix materials (e.g. PVBT films, conjugated polymer/PCBM composite) for producing optically pumped organic laser setups which can be used for deep UV-holographic recordings and organic distributed feedback lasers (DFB).9,69

Different piezoelectric material-light interactions are applied for both dynamic and static applications as adaptive (or smart) structures and microelectromechanical systems (MENS) which include actuators, e.g. pressure generators, ink/fuel injectors, displacement actuators, self-sensing actuators, modal actuators, and vibration and noise damping controllers. The piezoelectric materials also find applications in medical fields, e.g. disposable sensors, ultrasonic devices, as well as robotics and mechatronics, e.g. precision/microrobots, robot grippers, flexible robot control. Instruments such as piezoelectric test instruments, voltage dielectric, and ferroelectric test systems are developed and of low price.15,30,56,57,70

Both flexibility and firmness of the ionic EAPs can be advantageous for procuring smart structures, possessing shape control and self-sensing abilities, and extensive investigation is ongoing to advance different polymers that change volume upon light exposure.63 One such polymer is liquid crystal elastomers (LCE) which show piezoelectricity and a spinning movement in water when irradiated by light on a dye-doped LCE sample, which enables differentiating between left- and right-handedness of pharmaceutical drugs. Some other applications of the photo-responsive gels include switches and memory devices, actuators, and artificial muscles.67

Carbon nanotube (CNT)-modified fullerene-EAP composites are a new class of smart materials that have significant mechanical and piezoelectric properties and shape-changing ability with applications in lightweight sensor systems, membrane structures with actuation, and power generation. Fullerenols as biocompatible actuators, electroactive polymers, and sulfonated polyetherimide (SPEI) are developed for electroactive artificial muscles.111,112 At the same time, various fullerenes, metallofullerenes and metallofullerenes modified by hydroxyl and carboxyl groups are being investigated for photovoltaic devices, fuel cells, membrane technology, and biosensors.111,113 Recently, buckminsterfullerenes with conjugated semiconductor polymers, e.g. poly-(2-methoxy-5-(2’-ethyl-hexoxy)-p-phenylene, tetrathiafulvalene (ITF), that induce an ultrafast, reversible, metastable photo-induced electron transfer have been studied for developing polymeric photovoltaic devices, and plastic solar cells.9,82 The efficiencies of these photovoltaic cells are markedly higher than the photovoltaic cells made of conjugated polymers alone.

Based on the conditions and progress, many EAP, piezoelectric, fullerene-based products are already on the market. EAMAX Corporation, a Japanese company, developed EAP actuators for various medical applications, e.g. nursing, guidewires, catheters, rehabilitation instruments. The same firm developed actuators and sensors by ion active actuator rods, ion conductive membranes, conductive polymer actuators, autofocus devices for mobile phones and fuel cell micro-pumps. A Denmark-based company, ElastiSense, developed portable test kits and displacement sensors based on EAP technologies. Environmental Robots Incorporated from the USA developed IPMC-based ionic actuators, sensors, and transducers, and also developed devices for medical and biomedical engineering applications based on IPMC and a conductive polymer. PolyK Technologies, another USA-based company, developed various EAP-based R & D products for academic research applications. The company developed dielectric test systems to measure dielectric constant and its loss with change in temperature, frequency, D.C. bias voltage. For medical devices, StretchSense Limited, a New Zealand company, developed sensors with soft polymer and Bluetooth connectivity; the instrument enables the quick measure of soft structures of the human body. EAPs based on high-energy strain actuators and density capacitors, e.g. high dielectric constant fluoropolymers, are marketed by Strategic Polymer Sciences, Inc (SPS). Vivitech, a USA-based company, used EAP technology power generation, valves, pumps, sensors, medical devices, and optical positions. With these technologies, high-definition (HD) mobile phones, tablets, gaming controllers are to be developed for ‘cinematic sensation’ with a better sense of listening, visualization, and sensuality.103

Conclusion

In this paper, we discuss the interaction of light with different electroactive polymers, piezoelectric ceramics, electroactive gels, fullerenes, and other conjugated polymers as smart materials. There are different parameters such as light wavelength, refractive index, nature and composition of the material, its geometry, and induced electric field that affect its performance. Depending upon its type, the electroactive materials have wide applications; EAP facilitates development of actuators, medical devices, sensors, and mechanical tools without any gears, bearings, or complicated techniques. For piezoelectric materials, fullerenes and conjugated polymers have many applications in LEDs, light-emitting electrochemical cells, light-emitting photodetectors, field-effect transistors, solar cells, optically pumped solid-state lasers, and medical devices. Although the electroactive materials have wide applications, they are still bound by many challenges and environmental concerns that must be addressed by the robotics, materials, and synthetic chemistry communities. As can be seen, works have been done to exploit light interaction with various electroactive materials, yet this field requires further investigation to exploit the full potential of light-electroactive material interaction.

Abbreviations

- EAPs:

-

Electroactive polymers

- e− :

-

Electron

- h+ :

-

Hole

- IR:

-

Infrared

- UV:

-

Ultra-violet

References

M. Bashir and P. Rajendran, J. Intell. Mater. Syst. Struct. 29, 3681 (2018).

J.H. Burroughes, D.D.C. Bradley, A.R. Brown, R.N. Marks, K. Mackay, R.H. Friend, P.L. Burns, and A.B. Holmes, Nature 347, 539 (1990).

M.D. McGehee, M.A. Dı́az-Garcı́a, F. Hide, R. Gupta, E.K. Miller, D. Moses, and A.J. Heeger, Appl. Phys. Lett. 72, 1536 (1998)

B.F. Spencer Jr., M.E. Ruiz-Sandoval, and N. Kurata. Struct. Control Health Monitor. 11, 349 (2004).

H. Monner, Smart materials for active noise and vibration reduction, Novem-Noise and Vibration Emerging Methods. (Saint Raphael, France, 2005), pp. 18–21. https://www.dlr.de/fa/portaldata/17/resources/dokumente/publikationen/2005/15_monner.pdf

F.-R. Fan, J. Yang, L. Cai, D.W. Price, S.M. Dirk, D.V. Kosynkin, Y. Yao, A.M. Rawlett, J.M. Tour, and A.J. Bard, J. Am. Chem. Soc. 124, 5550 (2002).

N.D. Gupta, K.R. Sahu, I. Das, A. De, and U. De, Indian J. Phys. 84, 1413 (2010). https://springerlink.bibliotecabuap.elogim.com/article/10.1007/s12648-010-0133-9

R. Zhang, Z. Jin, C. Zhang, R. Yang, M. Sun, and C.-P. Wong, Colloid Polym. Sci. 296, 1365 (2018).

C.J. Brabec, and S.N. Sariciftci, In Materials, ed. Jürgen O.E. Besenhard, Sitte Werner, Stelzer Franz and Gamsjäger Heinz (Springer Vienna: Vienna, 2001), pp 1–11.

Y. Bar-Cohen and Q. Zhang, MRS Bull. 33, 173 (2011).

F. Carpi and D. De Rossi, In The First IEEE/RAS-EMBS international conference on biomedical robotics and biomechatronics, 2006 (BioRob, 2006), pp 1073–1078

C. Jo, D. Pugal, Oh. Il-Kwon, K.J. Kim, and K. Asaka, Prog. Polym. Sci. 38, 1037 (2013).

G.M. Sessler and J. Hillenbrand, MRS Proc. 600, 143 (1999).

S. Sukhoveyev, Microsyst. Technol. 14, 1099 (2008). http://ntsr.info/upload/My/suhoveev.pdf

V. Giurgiutiu, in Electroactive and Magnetoactive Materials, ed. by V. Giurgiutiu. Structural Health Monitoring with Piezoelectric Wafer Active Sensors, 2nd edn. (Academic Press, 2014), pp. 21–49. https://doi.org/10.1016/B978-0-12-418691-0.00002-2

R. Ansari, J. Chem. 3, 186 (2006).

I. Terzic, N.L. Meereboer, M. Acuautla, G. Portale, and K. Loos, Nat. Commun. 10, 601 (2019).

J.M. Jani, M. Leary, A. Subic, and M. Gibson, Mater. Des. 56, 1078 (2014). https://cpb-ap-se2.wpmucdn.com/uowblogs.com/dist/b/2950/files/2019/12/Review-1x5lz5z.pdf

G. Alici, Sens. Actuators, B Chem. 141, 284 (2009).

X. Xing, Q. Liu, W. Xu, W. Liang, J. Liu, B. Wang, and J. Lemmon, ACS Appl, Energy Mater. 2 (2019)

Q. Zhang, H. Li, M. Poh, F. Xia, Z.Y. Cheng, H. Xu, and C. Huang, Nature 419, 84 (2002)

C.D. Eisenbach, Polymer 21, 1175 (1980).

H. Finkelmann, E. Nishikawa, G.G. Pereira, and M. Warner, Phys. Rev. Lett. 87, 015501 (2001)

N.C.R. Holme, L. Nikolova, S. Hvilsted, P.H. Rasmussen, R.H. Berg, and P.S. Ramanujam, Appl. Phys. Lett. 74, 519 (1999).

F. El Feninat, G. Laroche, M. Fiset, and D. Mantovani, Adv. Eng. Mater. 4, 91 (2002).

G. Smets and F. de Blauwe, Chemical reactions in solid polymeric systems. Photomechanical phenomena. (1974)

K. Ren, R.S. Bortolin, and Q.M. Zhang, Appl. Phys. Lett. 108, 062901 (2016)

T. Ikeda, M. Nakano, and Y.L. Yu, O.sutsumi, and A. Kanazawa Adv. Mater. 15, 201 (2003).

J.-E. Lee, Y.J. Jang, W. Xu, Z. Feng, H.-Y. Park, J. Kim, and D. Ha Kim, J. Mater. Chem. A 5 (2017)

Y. Bar-Cohen, Bioinspir. Biomim. 1, P1 (2006).

A. Gelmi, M. Zanoni, M.J. Higgins, S. Gambhir, D.L. Officer, D. Diamond, and G.G. Wallace, J. Mater. Chem. B 1, 2162 (2013).

B. Spencer, M.R. Sandoval, and N. Kurata, Struct. Control. Health Monit. 11, 349 (2004).

D. Braun and A.J. Heeger, Appl. Phys. Lett. 58, 1982 (1991).

Y. Yamamoto, Sci. Technol. Adv. Mater. 13, 033001 (2012)

K. Hribar, R. Metter, J. Ifkovits, T. Troxler, and J. Burdick, Small 5, 1830 (2009).

A. Garcia, M. Marquez, T. Cai, R. Rosario, Hu. Zhibing, D. Gust, M. Hayes, S. Vail, and C.-D. Park, Langmuir: ACS J. Surf Colloids 23, 224 (2007).

Y. Bar-Cohen, Electroactive polymers as artificial muscles-reality and challenges. In 19th AIAA Applied Aerodynamics Conference, p. 1492. (2001). https://trs.jpl.nasa.gov/bitstream/handle/2014/39305/01-0277.pdf

V. Guarino, S. Zuppolini, A. Borriello, and L. Ambrosio, Polymers 8 (2016)

M.P.M. Dicker, J.M. Rossiter, I.P. Bond, and P.M. Weaver, Bioinspirat. Biomimet. 9, 036015 (2014)

I.D. Parker, J. Appl. Phys. 75, 1656 (1994).

A. Lendlein and R. Langer, Science (New York, NY, 2002), vol 296, pp 1673-6

H. Ren and Wu. Shin-Tson, Appl. Sci. 8, 1085 (2018).

S. Shian, R. Diebold, and D. Clarke, Opt. Express 21, 8669 (2013).

X. Zeng and H. Jiang, Appl. Phys. Lett. 93, 151101 (2008).

G. Yu, J. Gao, J.C. Hummelen, F. Wudl, and A.J. Heeger, Science 270, 1789 (1995).

W. Browne and B. Feringa, Annu. Rev. Phys. Chem. 60, 407 (2008).

K. Oliver, A. Seddon, and R.S. Trask, J. Mater. Sci. 51, 10663 (2016).

V. Cârlescu, P. Cârlescu, D. Olaru, and G. Prisacaru, Roman. Rev. Precis. Mech. 40, 209 (2011).

Q. Pei, Yu. Gang, C. Zhang, Y. Yang, and A.J. Heeger, Science 269, 1086 (1995).

R. Peña, R. Romero, S.L. Martínez, R. Natividad, and A. Ramírez, Fuel 110, 63 (2013).

F. Garnier, R. Hajlaoui, A. Yassar, and P. Srivastava, Science 265, 1684 (1994).

N.S. Sariciftci, L. Smilowitz, A.J. Heeger, and F. Wudl, Science 258, 1474 (1992).

N. Tessler, G.J. Denton, and R.H. Friend, Nature 382, 695 (1996).

M. Hallermann, S. Haneder, and E. Da Como, Appl. Phys. Lett. 93 (2008)

P. Martins, C.M. Costa, M. Benelmekki, G. Botelho, and S. Lanceros-Mendez, CrystEngComm 14, 2807 (2012).

H.S. Tzou, H.J. Lee, and S.M. Arnold, Mech. Adv. Mater. Struct. 11, 367 (2004).

B. Liu and H. Tzou, J. Vib. Acoust. 120, 937 (1998). https://doi.org/10.1115/1.2893923

N. Kamely and M. Ujihara, J. Nanopart. Res. 20, 172 (2018).

Md. Billah, Md. Raisuddin Khan, and A.A. Shafie, in Proceedings of the IEEE ICIT, (2015). http://icit.zuj.edu.jo/icit15/DOI/Modeling_and_Simulations/0091.pdf

N.C. Greenham, S.C. Moratti, D.D.C. Bradley, R.H. Friend, and A.B. Holmes, Nature 365, 628 (1993).

A. Lendlein, H. Jiang, O. Jünger, and R. Langer, Nature 434, 879 (2005).

Y. Yu, M. Nakano and T. Ikeda, Nature 425, 145 (2003).

R. Samatham, K. J. Kim, D. Dogruer, H. R. Choi, M. Konyo, J. D. Madden, Y. Nakabo, J. D. Nam, J. Su, S. Tadokoro, W. Yim and M. Yamakita, In Electroactive polymers for robotic applications: artificial muscles and sensors, ed. Kwang J. Kim and Tadokoro Satoshi (Springer London: London, 2007), pp 1–36.

G. Yu, and A.J. Heeger, J. Appl. Phys. 78, 4510 (1995).

M.R. Andersson, G. Yu, and A.J. Heeger, Synth. Met. 85, 1275 (1997).

C. Grogger, H. Rautz, and H. Stüger, In Materials, ed. Jürgen O.E., Besenhard, Sitte Werner, Stelzer Franz and Gamsjäger Heinz (Springer, Vienna, 2001), pp 33–44.

H. Schlick, F. Stelzer, and G. Leising, In Materials ed. Jürgen O.E. Besenhard, Sitte Werner, Stelzer Franz and Gamsjäger Heinz (Springer, Vienna, 2001), pp 21–32.

Yu. Yanlei, M. Nakano, and T. Ikeda, Nature 425, 145 (2003).

T. Kavc, W. Kern, C. Zenz, G. Leising, G. Kranzelbinder, and E. Toussaere, In Materials, ed.Jürgen O.E., Besenhard, Sitte Werner, Stelzer Franz and Gamsjäger Heinz (Springer, Vienna, 2001), pp 111–120

P.S. Brody, Ferroelectrics 50, 27 (1983).

H.S. Tzou, and R. Ye, J. Vib. Acoust. 116, 489 (1994). https://doi.org/10.1115/1.2930454

H. Tzou, and H.Q. Fu, J. Sound Vib. 172, 261 (1994). https://doi.org/10.1006/jsvi.1994.1173

S. Pechprasarn, S. Sasivimolkul, and P. Suvarnaphaet, Sensors 21, 4958 (2021).

H. Zhang, H. Xia, and Y. Zhao, J. Mater. Chem. 22, 845 (2012).

K.C. Hribar, R.B. Metter, J.L. Ifkovits, T. Troxler, and J.A. Burdick, In Small (Weinheim an der Bergstrasse, Germany, 2009), vol. 5, pp 1830–1834.

Q. Zhao, J.W.C. Dunlop, X. Qiu, F. Huang, Z. Zhang, J. Heyda, J. Dzubiella, M. Antonietti, and J. Yuan, Nat. Commun. 5, 4293 (2014)

S. Serak, N. Tabiryan, R. Vergara, T.J. White, R.A. Vaia, and T.J. Bunning, Soft Matter 6, 779 (2010).

Z. Xiong, M.-L. Zheng, X.-Z. Dong, W.-Q. Chen, F. Jin, Z.-S. Zhao, and X.-M. Duan, Soft Matter 7, 10353 (2011).

A. Suzuki, and T. Tanaka, Nature 346, 345 (1990).

A. Aviram, Macromolecules 11, 1275 (1978).

N.S. Sariciftci, L. Smilowitz, A.J. Heeger and F.A Wudl, In Science (New York, N.Y., 1992) vol 258, pp 1474–6.

S. Günes, Helmut Neugebauer and Niyazi Serdar Sariciftci. Chem. Rev. 107, 1324 (2007).

L. Smilowitz, N.S. Sariciftci, R. Wu, C. Gettinger, A.J. Heeger, and F. Wudl, Phys. Rev. B 47, 13835 (1993).

A.A. Zakhidov, H. Araki, K. Tada, and K. Yoshino, Synth. Met. 77, 127 (1996).

A. Lendlein and R. Langer, Science 296, 1673 (2002).

L. Leng, A. McAllister, B. Zhang, M. Radisic, and A. Günther, Adv. Mater. 24, 3650 (2012).

M. Segev-Bar, and H. Haick, ACS Nano 7, 8366 (2013).

J.D. Nam, H.R. Choi, J.C. Koo, Y. K. Lee, and K.J. Kim, In Electroactive polymers for robotic applications: artificial muscles and sensors, ed. Kwang J. Kim and Tadokoro Satoshi (Springer, London, 2007), pp 37–48.

Y. Bar-Cohen, In Proceedings. 2004 NASA/DoD conference on evolvable hardware. (2004), pp 309–317

A. Punning, K.J. Kim, V. Palmre, F. Vidal, C. Plesse, N. Festin, A. Maziz, K. Asaka, T. Sugino, G. Alici, G. Spinks, G. Wallace, I. Must, I. Põldsalu, V. Vunder, R. Temmer, K. Kruusamäe, J. Torop, F. Kaasik, P. Rinne, U. Johanson, A.-L. Peikolainen, T. Tamm, and A. Aabloo, Sci. Rep. 4, 6913 (2014).

C. Haines, N. Li, G. Spinks, A. Aliev, J. Di, and R. Baughman, In Proceedings of the national academy of sciences of the United States of America, vol 113 (2016)

S. Ribeiro, T. Ribeiro, C. Ribeiro, D. Correia, J.P. Farinha, A. Gomes, C. Baleizão and S. Lanceros-Méndez, Nanomaterials 8, 933 (2018). https://doi.org/10.3390/nano8110933

F. Kaasik, I. Must, I. Baranova, I. Põldsalu, E. Lust, U. Johanson, A. Punning, and A. Aabloo, Sens. Actuators, B Chem. 246, 154 (2017).

D. Rus and M.T. Tolley, Nature 521, 467 (2015).

T. Wang, M. Farajollahi, Y.S. Choi, I. Ting Lin, J.E. Marshall, N.M. Thompson, S. Kar-Narayan, J.D.W. Madden and S.K. Smoukov, In Interface focus, vol 6, pp 20160026 (2016)

S.A. Wilson, R.P.J. Jourdain, Q. Zhang, R.A. Dorey, C.R. Bowen, M. Willander, Q.U. Wahab, M. Willander, S.M. Al-hilli, O. Nur, E. Quandt, C. Johansson, E. Pagounis, M. Kohl, J. Matovic, B. Samel, W. van der Wijngaart, E.W.H. Jager, D. Carlsson, Z. Djinovic, M. Wegener, C. Moldovan, R. Iosub, E. Abad, M. Wendlandt, C. Rusu and K. Persson, Mater. Sci. Eng. Rep. 56, 1–129 (2007)

J. Biggs, K. Danielmeier, J. Hitzbleck, J. Krause, T. Kridl, S. Nowak, E. Orselli, X. Quan, D. Schapeler, W. Sutherland, and J. Wagner, Angew. Chem. Int. Ed. 52, 9409 (2013).

A. Vinogradov, J. Su, C. Jenkins, and Y. Bar-Cohen, In MRS Proceedings, vol 889, pp. 0889-W02-05 (2011)

X. Zeng and H. Jiang, Appl. Phys. Lett. 93, 151101 (2008)

H. Koerner, T.J. White, N.V. Tabiryan, T.J. Bunning, and R.A. Vaia, Mater. Today 11, 34 (2008).

U. Sait and M. Sreekumar, Recent Patents Mech. Eng. 4, 180 (2011)

A.D. Price, H.E. Naguib and F.B Amara. J. Intell. Mater. Syst. Struct. 26, 2556 (2014).

B.-C. Yoseph, In Electroactive Polymer Actuators and Devices (EAPAD), vol. 7642 (International Society for Optics and Photonics, 2010), p. 764206. https://trs.jpl.nasa.gov/bitstream/handle/2014/44786/10-0225_A1b.pdf?sequence=1

W. Maser, M. Teresa Martinez, and A. Benito, In Making smart materials using electroactive polymers and carbon nanotubes. (2007). https://www.researchgate.net/publication/242190325_Making_smart_materials_using_electroactive_polymers_and_carbon_nanotubes/link/0deec52aca511ba60e000000/download.

A.G. MacDiarmid, Angew. Chem. Int. Ed. 40, 2581 (2001).

A. Lendlein, and S. Kelch, Angew. Chem. Int. Ed. 41, 2034 (2002).

J.D. Madden, Science 318, 1094 (2007).

T. Torimoto, K. Maeda, J. Maenaka, and H. Yoneyama, J. Phys. Chem. 98, 13658 (1994).

D. Dorokhin, N. Tomczak, D.N. Reinhoudt, A.H. Velders and G. Julius Vancso, Nanotechnology 21, 285703 (2010)

S.G. Wax, R.R. Sands, and L.J. Buckley, MRS Proc. 600, 3 (2011).

A.V. Penkova, S.F.A. Acquah, L.B. Piotrovskiy, D.A. Markelov, A.S. Semisalova, and H.W. Kroto, Russian Chem. Rev., 86, 530 (2017)

J.-W. Lee, B.S. Ma, H.J. Kim, H.S. Kim, T.S. Kim, and B.J. Kim, JACS Au 1, 612 (2021).

J.-H. Jung, S. Vadahanambi, and Oh. Il-Kwon, Compos. Sci. Technol. 70, 584 (2010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kamely, N. Interaction of Light with Different Electroactive Materials: A Review. J. Electron. Mater. 51, 953–965 (2022). https://doi.org/10.1007/s11664-021-09362-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09362-0