Abstract

An in-depth understanding about the reactions in the high-temperature zone of a blast furnace is significant to optimize both the current and future blast furnace process. The interfaces between coke, slag, and metal were observed using scanning electronic microscope with samples obtained from the tuyere level of a blast furnace. Two types of slag phases were identified, one originating from coke ash and the other from the bosh slag. Slag formed by coke ash was seen to cover the coke surface, which may hinder the reaction of coke with both gas and liquid iron. The reduction of FeO from the bosh slag (originated from the primary slag) occurs in the coke/slag interface with the reduced iron forming a metal layer surrounding the coke surface. The reduction of SiO2 occurs both in and outside the coke, and the reduced silicon reacts with iron to form iron silicide if the two species come into contact. Further study is proposed based on the results of this study.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Blast furnace (BF) ironmaking continues to evolve under the double pressure of high cost and emission reduction.[1–3] As a counter-current reduction furnace, the bed permeability at lower section, between the cohesive zone and hearth, is critical for its influence on the characteristics of reactions in this area, which in turn affect the product quality, production rate, and fuel consumption as well as campaign life of the blast furnace, as discussed in recent publications.[4,5]

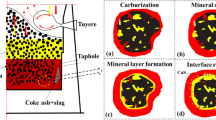

Due to the complexity and severity of environment (high temperature, high pressure, and multiphase coexistence) of the BF lower zone, it is impossible to observe phenomena that occur inside directly. Thus, very little is known as yet about the interactions of various materials (coke-to-slag, coke-to-metal, slag-to-metal) in this area, and no report has been published about the interfaces between coke, metal, and slag in this area. However, a tuyere drilling technique, which allows to obtain samples from an operating blast furnace, provides a source of potentially useful information about various important inner phenomena in the tuyere level.[6,7] As the primary solid material in the BF lower zone, coke is the main sample obtained using the tuyere drilling technique. Thus, previous studies about tuyere drilling samples focused mainly on the changes in coke characteristics in this zone,[8] i.e., carbon structural order,[9–12] mineral transformation,[10,13–16] and reactivity and strength.[17] However, besides solid coke, slag and metal also exist in liquid state in the tuyere level, and they can be extracted with coke samples simultaneously during the tuyere drilling process. As shown in Figure 1, below the cohesive zone, the preheated blast blown into the furnace through the tuyeres reacts with all the phases in this zone; primary slag is formed from the unreduced ore, limestone, and ash of coke and coal as well as impurities of the ore; liquid iron is formed by the reduction of iron oxides from the primary slag; the metal and slag descend through the coke bed together; and then, the metal descends through the slag zone and joints to the metal pool. Thus, coke–slag reaction, coke–metal reaction, and metal–slag reaction all may occur in the tuyere level due to their coexistence in this zone.[18] The samples in which coke, slag, and metal coexist could provide meaningful information about the interactions between them. In the present study, the interactions are postulated based on the interfaces of the three phases, an approach not employed before.

Tuyere samples were obtained from a small-size blast furnace (530 m3) and a large-size blast furnace (4000 m3) through core drilling as detailed elsewhere.[9,19] The operating data of the small-size blast furnace during the drilling period are summarized in Table I, while those of the large-size blast furnace were shown in the previous report.[19] The slag and iron were not separated from the coke. Coke lumps covered with slag or iron and mixtures of slag and iron were selected for further investigation. Pieces about 20 mm long, 20 mm wide, and 5 to 8 mm thick were cut from the selected samples under dry conditions and then placed in a rounded plastic container with 25 mm diameter which was filled with resin. The material was ground and polished similar to the previous study.[19] The samples were coated with carbon and then examined with a Quanta 250 Environmental scanning electron microscope (SEM) equipped with energy-dispersive X-ray spectrometer (EDS) for chemical analysis and mapping.

Figure 2 shows some coke particles surrounded by a form of slag. The size of the large coke particle is about 2 to 3 mm (Figure 2(a) A and C), which is considerably smaller than coke lump size in the tuyere level of over 11 mm.[11] There are also many coke particles less than 1 mm in the slag (Figure 2(a) A and C). Most of those coke particles have reacted greatly with gas or liquid while descending from the cohesive zone to the tuyere level. This can be confirmed from the porous structure of coke matrix with many large pores greater than 50 μm (Figure 2(a) B). From the EDS mapping of the phases in slag and coke (Figures 2(a) D and (b) B), it can be seen that the slag consisted of mainly Si, Al, and O. The composition of this slag is similar to that of coke ash (see the mineral phases of coke in Figure 2(a) D) with SiO2 and Al2O3 being the main constituents.[8] In addition, accumulation of Si and Al can be found in the slag. This may be due to the existence of SiO2 [melting point, 1650 °C (1923 K)] and Al2O3 [melting point, 2045 °C (2818 K)] which may be from coke minerals.[13] The above observations indicate that this kind of slag may be originated from the coke ash. The presence of potassium in the slag phase confirmed the existence of recirculating potassium in the tuyere level of a blast furnace, which has also been reported by Gupta et al.[10] It can be proposed that coke minerals will form a type slag in the high-temperature zone of the blast furnace and exuded from within the coke to coat the surface. This effect may hinder the contact of coke carbon with other oxidizing agents such as FeO and SiO2, whose reduction is significant to the melting and production process of a blast furnace.

SEM micrographs and EDS maps showing the interaction between coke and slag originated from coke ash. (a) Samples extracted from 530 m3 blast furnace, and the EDS maps were taken from image D. (b) Samples extracted from 4000 m3 blast furnace, and the EDS maps were taken from image B. See text for details

Figure 3 shows some coke particles covered with a different slag which is composed of CaO-SiO2-MgO-Al2O3 with small amounts of K2O and BaO, typical composition of standard blast furnace slag. Also, a metal layer was observed at the interface of this slag with coke particles (Figures 3A through C). Therefore, this kind of slag was believed to be the bosh slag which was originated from the primary slag. The existence of FeO was not confirmed in the slag phase (Figure 3C), which indicated that the FeO has been reduced completely in this selected area. In a fundamental study, Kasai[20] found that a coke lump reacting with molten slag containing FeO forms a local dimple and thin reaction layer at the coke surface and discharges coke particles by slag attack. Consequently, those coke particles may form in the process of FeO reduction by coke. This confirmed the degradation of coke quality by slag attack in the high-temperature zone of an operating blast furnace. The reduced iron appears to form a layer surrounding the coke surface and then flow away from the surface to the lower part of the blast furnace. As a highly endothermic reaction, the reduction of FeO is the most important reaction in the ironmaking process and was required to be further understood for its role not only in current blast furnace process, but also in future low-temperature and compact blast furnaces.[21]

The interaction of coke and metal is shown in Figure 4. From the EDS mapping of the coke/metal interface (Figure 4(a) B), it can be seen that both FeO and SiO2 have been reduced to form Fe-Si alloy droplets. EDS data confirmed that the iron silicide is mainly fersilicite (FeSi), the highest Si-containing compound, compared with gupeiite (Fe3Si) which was found to be the most common ferro-silicon alloys present in tuyere coke.[16] This difference may be caused by the different reduction conditions for SiO2 in coke and slag. The reduction of SiO2 from liquid slag may be easier than that from solid SiO2 in coke due to its lower activity. Because the amount of carbon dissolved in liquid iron depends on the silicon content,[22] droplets under-saturated with silicon may react better and penetrate deeper into the coke matrix, as shown in Figure 4(b) B. The flake-like graphite as that in cast iron is observed in the droplets, which was also reported by Gornostayev et al.[23] Detailed experimental study about the sequence of coke dissolution into hot metal was conducted by Chapman et al.,[24–27] while the Monte Carlo simulation study of carbon dissolution in hot metal in atomic scale was conducted by Khanna and Sahajwalla et al.[28–32] A contact between carbon and melt leads to the dissociation of C from the graphite to the melt with the rate of mass transfer of C in the melt being slower than the corresponding dissociation rate at the interface.[30] Thus, carbon dissolution into liquid iron is considered to be a first-order kinetic process and is generally described as being limited by liquid-phase mass transfer of carbon in iron.[26] However, due to the influence of coke minerals,[25–27] the formation of a mineral layer (a thin ribbon-like appearance interspersed with large alumina or calcium aluminate agglomerates) was interpreted as an additional barrier for the dissolution of carbon from coke, and hence a mixed control regime where both mass transfer and diffusion through the mineral (product) layer should be considered.[25–27] From Figure 4(a) B, oxides of aluminum and barium were found to form a layer between the coke and ferro-silicon alloy, which may be caused by their high melting points and the difficulty to be reduced under these conditions. This emphasizes the negative effect of high-melting point minerals in the lower zone of a blast furnace. Except for alumina or calcium aluminate which was proposed by Chapman et al.,[27] barium oxide was also confirmed as a constituent of this mineral barrier.

Figure 5 shows an iron droplet encapsulated by a dense layer of slag. Interestingly, silicon was not clearly observed in the iron phase, while carbon accumulation was evident. The depletion of Si in the layer indicates that it is easier to reduce FeO than SiO2 with carbon in the lower zone of a blast furnace, which can be explained with the widely used Ellingham Diagram.[33] Because the samples in this research were coated with carbon, which was a standard procedure for SEM/EDS studies, carbon content cannot be detected semi-quantitatively. However, the relative abundances of carbon can be distinguished in the EDS maps, which confirmed the accumulation of carbon in the iron phase, indicating carburization of the metal as it descends through the lower section of the furnace. A layer containing FeO was clearly observed in the slag/iron interface, which confirmed that the reduction of FeO of liquid slag by carbon of liquid metal occurs in the metal/slag interface. The EDS mapping also shows depletion of some carbon from the metal close to the interface.

In addition to the interactions between slag, metal, and coke, the reduction of coke minerals in the tuyere level is also an important reaction in this high-temperature zone. In a recent study about tuyere coke minerals, Gupta et al.[10] found that the predominant minerals of the feed coke (quartz and mullite) decreased significantly or completely disappeared at most of the tuyere-level locations, while SiC and gupeiite (Fe3Si) were formed to be the most notable Si-bearing compounds. Figure 6 exhibits SEM images and analysis of the mineral-related phases present in coke. From Figure 6D, it can be seen that SiO2 existing as quartz particles can be readily reduced to silicon by the coke carbon at high temperature, while SiO2 present in the form of compounds of aluminum, calcium, and magnesium oxides remains unreduced due to their higher chemical stability. The reduced silicon will react with liquid iron to form iron silicide if the species come into contact in tuyere coke (Figures 6E and F) or outside the coke (Figure 4). As lowering the Si content of hot metal can not only reduce the fuel ratio, but also provide good conditions for steelmaking, it is necessary to hinder the reduction of SiO2 inside the coke considering that the main source of silicon is from the reduction of SiO2 of coke ash which may also occur in the hot metal. The reduction of minerals especially SiO2 inside coke warrants further study.

Altogether, the interfaces between coke, slag, and metal were observed under scanning electronic microscope with samples obtained from the tuyere level of a blast furnace. Slags formed by coke ash were identified to warp the coke surface, which may hinder the reaction of coke with both gas and liquid iron. The reduction of FeO of bosh slag originated from primary slag occurs in the coke/slag interface, and the reduced iron seems to form a metal layer surrounding the coke surface and then flows away from the surface to the lower part of the blast furnace. The degradation of coke quality by slag attack in the high-temperature zone of an operating blast furnace was confirmed. Further study is required to investigate the slag attack on coke quality to improve the evaluation system of coke quality. Except for alumina or calcium aluminate agglomerates, barium oxide was also confirmed as a constituent of the mineral barrier for the dissolution of carbon into hot metal. Thus, it is essential to further study the possible influence of other high-melting point oxides on the coke dissolution process. The reduction of SiO2 occurs both in and outside the coke, and the reduced silicon will react with iron to form iron silicide if those two matters contact with each other in tuyere coke or outside the coke. An in-depth understanding about the reactions in the high-temperature zone of a blast furnace is significant to optimize both the current and the future blast furnace process in which the high-temperature endothermic reactions were required to be at high speed and highly efficient.

References

T. Ariyama, R. Murai, J. Ishii and M. Sato: ISIJ Int., 2005, vol. 45, pp. 1371-78.

K. Li, J. Zhang, Z. Liu and X. Jiang: Chin. J. Proc. Eng., 2014, vol. 14, pp. 162-72.

K. Li, R. Khanna, J. Zhang, Z. Liu, V. Sahajwalla, T. Yang and D. Kong: Fuel, 2014, vol. 133, pp. 194-215.

H. L. George, R. J. Longbottom, S. J. Chew and B. J. Monaghan: ISIJ Int., 2014, vol. 54, pp. 820-26.

H. L. George, B. J. Monaghan, R. J. Longbottom, S. J. Chew and P. R. Austin: ISIJ Int., 2013, vol. 53, pp. 1172-79.

O. Kerkkonen: AISTECH-Conference Proceedings No. 1, 2004.

W. Xu, W. Jiang, L. Zhang, P. Zong, K. Wu, X. Li and F. Zhang: Iron Making, 2004, vol. 23, pp. 13-17.

S. Gupta, D. French, R. Sakurovs, M. Grigore, H. Sun, T. Cham, T. Hilding, M. Hallin, B. Lindblom and V. Sahajwalla: Prog. Engerg. Combust., 2008, vol. 34, pp. 155-97.

S. Dong, N. Paterson, S. Kazarian, D. Dugwell and R. Kandiyoti: Energy Fuels, 2007, vol. 21, pp. 3446-54.

S. Gupta, Z. Ye, B.-C. Kim, O. Kerkkonen, R. Kanniala and V. Sahajwalla: Fuel Process. Tech., 2014, vol. 117, pp. 30-37.

S. Gupta, Z. Ye, R. Kanniala, O. Kerkkonen and V. Sahajwalla: Fuel, 2013, vol. 113, pp. 77-85.

W. Wang, K. Thomas, R. Poultney and R. Willmers: Carbon, 1995, vol. 33, pp. 1525-35.

S. Gornostayev and J. Harkki: Metall. Mater. Trans. B, 2005, vol. 36, pp. 303-05.

S. Gornostayev, P. Tanskanen, E. Heikkinen, O. Kerkkonen and J. Härkki: Energy Fuels, 2007, vol. 21, pp. 2637-41.

S. S. Gornostayev and J. J. Härkki: Carbon, 2007, vol. 45, pp. 1145-51.

Z. Ye, S. Gupta, O. Kerkkonen, R. Kanniala and V. Sahajwalla: ISIJ Int., 2013, vol. 53, pp. 181-83.

O. Kerkkonen and R. Kanniala: AIST Proceedings, AISTech 2007, No. 2007.

X. Dong, A. Yu, S. Chew and P. Zulli: Metall. Mater. Trans. B, 2010, vol. 41, pp. 330-49.

K. Li, J. Zhang, Z. Liu, T. Wang, X. Ning, J. Zhong, R. Xu, G. Wang, S. Ren and T. Yang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 1581-88.

A. Kasai, J. Kiguchi, T. Kamijo and M. Shimizu: Tetsu-to-Hagane, 1998, vol. 84, pp. 697-701.

K. Ishii and J.-I. Yagi: Tetsu-to-Hagane, 2001, vol. 87, pp. 207-20.

J. Lacaze and B. Sundman: Metallurgical Transactions A, 1991, vol. 22, pp. 2211-23.

S. S. Gornostayev, T. M. Fabritius, O. Kerkkonen and J. J. Härkki: International Journal of Minerals, Metallurgy, and Materials, 2012, vol. 19, pp. 478-82.

M. W. Chapman, B. J. Monaghan, S. A. Nightingale, J. G. Mathieson and R. J. Nightingale: Metall. Mater. Trans. B, 2011, vol. 42, pp. 642-51.

M. W. Chapman: University of Wollongong Thesis Collection, 2009, p. 3039.

M. W. Chapman, B. J. Monaghan, S. A. Nightingale, J. G. Mathieson and R. J. Nightingale: Metall. Mater. Trans. B, 2008, vol. 39, pp. 418-30.

M. W. Chapman, B. J. Monaghan, S. A. Nightingale, J. G. Mathieson and R. J. Nightingale: ISIJ Int., 2007, vol. 47, pp. 973-81.

R. Khanna and V. Sahajwalla: Acta materialia, 2005, vol. 53, pp. 1205-14.

V. Sahajwalla and R. Khanna: Acta materialia, 2002, vol. 50, pp. 663-71.

V. Sahajwalla and R. Khanna: Metall. Mater. Trans. B, 2000, vol. 31, pp. 1517-25.

V. Sahajwalla and R. Khanna: Acta materialia, 1999, vol. 47, pp. 793-800.

R. Khanna and V. Sahajwalla: Scripta materialia, 1999, vol. 40, pp. 1289-94.

H. Ellingham: J. Soc. Chem. Ind., 1944, vol. 63, pp. 125-33.

This work was financially supported by the Open Foundation of the State Key Laboratory of Advanced Metallurgy (41603007), the National Natural Science Foundation of China, Baosteel Group Co., Ltd., of Shanghai for the Key Joint Project (U1260202), and the National Science Foundation for Young Scientists of China (51304014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 17, 2015.

Rights and permissions

About this article

Cite this article

Li, K., Zhang, J., Liu, Z. et al. Interfaces Between Coke, Slag, and Metal in the Tuyere Level of a Blast Furnace. Metall Mater Trans B 46, 1104–1111 (2015). https://doi.org/10.1007/s11663-015-0335-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0335-9