Abstract

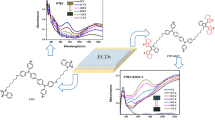

Electrochromism is defined as change of the optical property under potential applied. Among the organic electrochromic materials, poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT:PSS) is considered as one of the most valuable conductive polymers due to its excellent transmittance in the visible light range, high mechanical flexibility, and easy processing and existing in large quantity as commercial ink. To enhanced the conductivity and the electrochromic properties of the PEDOT:PSS, we recently developed a new method based on the addition of black carbon (BC) leading to PEDOT:PSS + BC composites. Herein, highly conductive and transparent composite thin film–based PEDOT:PSS + BC were facilely fabricated using dip-coating deposition. Thin films made from composite inks exhibit good durability, fast switching time, high transmittance modulations (ΔT ≈ 91% at 550 nm), and high coloration efficiency (CE ≈ 45 cm2 C−1). Finally, symmetric composite electrochromic devices combining two electrochromic composite film based PEDOT:PSS + BC, via a lithium-based electrolyte membrane plastified with PMMA, show good stability, nice reversibility, and simultaneously reversible color change from dark blue to transparent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, the energy demand for heating, air-conditioning, ventilation, and light source has been increasing due to climate change and the development of buildings, vehicles, and technology devices. They produce more greenhouse gas emissions and hence induce global warming and climate change. The energy increment has reached approximately 40% in the EU, 30% in the USA, and 30–40% in the world of primary energy [1,2,3]. This energy can be reduced using optical devices to prevent and reduce excessive heating and lighting where necessary. Electrochromic (EC) devices have received great attention during the past few decades due to their various applications in displays, automotive rear-view mirrors, gas sensors, and smart windows [4,5,6,7,8,9]. Many organic electrochromic materials were used for different electrochromic applications [10]. Among these family, conductive polymers such as poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) have attracted tremendous attention thanks to their fast switching time between colored and bleached state, mechanical flexibility, environmental stability, easy processing, and existing as commercial ink [11,12,13]. Many studies have proved that the conductivity of the electrochromic film plays an important role to enhance the durability, stability, and switching time between oxidation and reduction state of the electrochromic materials. Over the past decade, many approaches have been reported to improve the conductivity of PEDOT:PSS films, for example, solvent additive method, polar solvent post-treatment, ionic liquid treatment, surfactant treatment, and salt solution treatment [14]. In 2014, Kim et al. found significant electrical conductivity enhancement when directly dripping or immersing PEDOT:PSS films into H2SO4, which resulted in the highest conductivity value of 4380 S.cm−1[15]. Mixing the advantages of inorganic and organic materials, hybrid systems offer great potential of exploration. Among those hybrid composite materials, mixtures of poly(ethylene-3,4-dioxythiophene):poly(styrenesulfonic acid) (PEDOT:PSS) and WO3 [16] or with TiO2 [17] are characterized by good properties.

Recently, Cai et al. [18] have shown that the silver grid/PEDOT:PSS hybrid film is with high conductivity and excellent stability. Its functionality for flexible electrochromic applications is demonstrated by coating one layer of WO3 nanoparticles on the silver grid/PEDOT:PSS hybrid film. In the same context, the authors employed a silver grid/PEDOT:PSS as alternatives to ITO for smart devices. Besides its performance as electrochromic materials, hybrids and composite films based on PEDOT:PSS can be used as a current collector which replaces ITO in optoelectronic devices.

In this study, adding black carbon (BC) element to PEDOT:PSS ink is an effective way to enhance the electrical conductivity of PEDOT:PSS films. Although a lot of papers about how to improve the conductivity of PEDOT:PSS have been published, there are few reports on its long-term stability, especially for the case of addition of the black carbon to the PEDOT:PSS ink. So, in this paper, we focused on the long-term stability, fast switching time, and good coloration efficiency of the novel composite thin films (PEDOT:PSS + BC) compared to pure PEDOT:PSS film. We demonstrate the effect of (BC) addition on the electrochromic properties of PEDOT:PSS thin films by dip-coating deposition. We proved the electrochromic performance of the new composite films through prototype device based on the association of two-composite electrode-based (PEDOT:PSS + BC) thin films, using electrolyte membrane based on 1 M LiClO4/PC plastified with polymethylmethacrylate (PMMA) as ion conductor.

Experimental

Composite ink preparation and film deposition

The composite electrochromic inks were formulated from the mixture of the commercial PEDOT:PSS ink Heraeus (Clevios PH 1000) and commercial black carbon (purchased from sigma, BC content > 99%). The different composite inks were prepared by mixing PEDOT:PSS and black carbon and dispersed using ultrasonic and stirred for 30 min at room temperature (Fig. 1). The proportions between PEDOT:PSS ink and black carbon were determined using this equation: weight ratio of (PEDOT:PSS ink)/(BC) = (100 − x)/x, with x = 0%, 1%, and 5%.

After ink formulation, PEDOT:PSS film and composite film were deposited by dip coating onto ITO glass and then were dried at 120 °C on a hot plate for 15 min in air (Fig. 1).

Film characterization

The thickness of the PEDOT:PSS and composite (PEDOT:PSS + BC) thin films prepared by dip coating was measured by an alpha step surface profiler (Veeco Dektak 150). The surface morphology was recorded on a Cambridge Instruments Stereoscan 120. The crystallinity and the crystal phases of the composites films were evaluated by X-ray diffraction (XRD) obtained on a X’Pert Pro PANalytical diffractometer with Cu Ka radiation (λ = 1.5418 Ả) and graphite monochromator. The XRD measurements were carried out by applying a step scanning method (2Ɵ range from 10 to 80), the scanning rate is 0.0178 s−1, and the step time is 1 s.

Electrochromic characterization

The electrochromic properties of the composite films were evaluated by electrochemical and optical measurements. Electrochemical activity was evaluated using voltammetry cyclic (CV) and chronoamperometry cyclic (CA). The composite inks (PEDOT:PSS + BC) were deposited on ITO/glass substrate and cycled in a three-electrode cell configuration using a BioLogic SP150 potentiostat/galvanostat apparatus. The working electrode is (PEDOT:PSS + BC) on the ITO/glass, the counter electrode and reference electrode consisted of a platinum foil and saturated calomel electrode, respectively. The operating voltage was controlled between − 1 V and + 1 V for voltammetry cyclic and chronoamperometry analysis, in a 1 M lithium perchlorate (LiClO4) in propylene carbonate (PC) which was used as electrolytic solution. All the electrochemical measurements were performed at room temperature. The optical transmittance of dip-coating composite thin films was measured in situ using a Varian Cary 5000 UV–vis-NIR spectrophotometer between 250 and 1000 nm.

Fabrication of the composite electrochromic device

To test our composite electrode in a real application, an electrochromic device ECD consisting of two-composite thin films separated by an electrolytic membrane was assembled. The two-composite thin film–based (PEDOT:PSS + BC) were deposit by the “dip-coating” deposition from the inks prepared in the first part. The transparent electrolytic membrane was prepared using the mixture of the electrolyte-based Li (1 M LiClO4/PC) in 50% in PMMA. Viscous mixture of 1 M LiClO4/PC) in 50% in PMMA was deposited under ambient atmosphere on the electrochromic composite thin film–based PEDOT:PSS + BC and dried for 15 min at 80 °C. After, the two electrode-based active materials and electrolyte membrane were assembled, and the electrochromic device was built.

Results and discussion

Film characterization

The thickness of the dip-coating films without and with additive of 1 wt% and 5 wt% of black carbon (BC) is shown in Fig. 2. It is obvious that the film thickness is discriminatory at different compositions. For the only PEDOT:PSS, the thickness is 410 ± 9 nm. For the composite film (PEDOT:PSS + BC), the thickness increases with increasing of the BC, and with 1 wt% and 5 wt%, the thickness is 421 ± 8 nm and 502 ± 11 nm, respectively. This result can be explained by the variation of the viscosity of the ink after the addition of black carbon (BC). The crystallinity of the composite films (PEDOT:PSS + BC) was studied by X-ray diffraction analysis (Figure X). The PEDOT:PSS (Fig. 3a) shows an amorphous behavior, whereas for the composite film with 1 wt% of carbon black (BC), a first peak of (BC) can be identified with a very weak signal associated with a low content (Fig. 3b). For the 5 wt% (BC) composite film, the peak intensities increase (Fig. 3c). According to the literature [19], the distinct peak located at 24.3° is attributed to (002) peak in the structure of the (BC).

The morphology of various films was evaluated using the scanning electron microscopy (SEM). Figure 4 shows SEM images of the different films (PEDOT:PSS, 99%PEDOT:PSS + 1% BC, and 95%PEDOT:PSS + 5%BC) obtained by dip-coating deposition. There was no big change in the morphology before and after (BC) addition. Indeed, the PEDOT:PSS film appears homogenous with smooth surface (Fig. 4a), while a homogenous dispersion of the black carbon (BC) nanoparticles in the PEDOT:PSS ink is visible for the two-composite thin films (%PEDOT:PSS + %BC) (Fig. 4b and c).

Electrochromic properties of the composite thin film

In order to evaluate the impact of the black carbon addition on the electrochemical activity of the PEDOT:PSS film, voltammetry cyclic and electrochemical capacity were measured. Figure 5 shows the 5th cycles of the CV curves for the different films performed at room temperature in 1 M LiClO4 solution in propylene carbonate. It can be seen that the electrochemical response is different between the different conditions. The shape of the curve varies with the addition of black carbon. The rectangular-like shape of the CV observed in the presence of the 5 wt% BC is typical of a pseudo-capacitive behavior. As expected, the capacity increases with the increase of the black carbon (BC) (Fig. 5b). The capacity of the PEDOT:PSS increases with BC addition showing values of 22.4, 25.6, and 44.7 mC.cm−2 for PEDOT:PSS, PEDOT:PSS + 1 wt% BC, and PEDOT:PSS + 5 wt% BC respectively. The increasing in the electrochemical capacity was explained by the enhanced in the film conductivity.

The switching kinetic of the displays was investigated by chronoamperometry measurements. Figure 6 shows the current response (j–t) of the various dip-coating film for potential steps of + 1 V/20 s and − 1 V/20 s. A symmetric behavior is also observed between colored and bleached state. For the PEDOT:PSS alone, the switching time is of the order of 2 s. While for the two-composite film, the switching time in between colored and bleached state is about 0.5 s (Fig. 6b). The corresponding cyclic voltammperograms and chronoamperograms illustrate good electrochemical capacity and fast kinetics upon redox process for the composite films. In the following, we focus our attention on the composite film (95%PEDOT:PSS + 5 wt% BC).

The durability is an important parameter to evaluate the electrochromic performance of the materials. Figure 7 shows the 2nd and 5000th cycles of the composite film cycled in the LiClO4/PC. No degradation in capacity was observed after 5000 cycles, and the repeated cycles are well superposed which indicates that the composite film is stable under these conditions.

Upon reduction and oxidation sweeping, the transparent thin films show one-step electrochromism from transparent to dark blue (Fig. 7b).

The in situ transmittance upon cycling of the composite film (PEDOT:PSS + 5 wt% BC) is displayed in Fig. 8. The colored dark blue state (− 1 V) and the bleached transparent state at (+ 1 V) are associated with transmittance values of about Tc ≈ 92% and Tb ≈ 1% at 550 nm, respectively, corresponding to a total optical transmittance modulation of ΔT ≈ 91%.

The coloration efficiency (CE) is an important parameter to evaluate the electrochromic performances of the materials and is defined as the change in optical density (OD) per unit charge (Q) inserted into or extracted from the electrochromic films and can be calculated from the following equation:

where ΔOD = log (Tc/Tb), Q is the electrochemical capacity injected into the electrochromic material per unit area, Tc is the transmittance in the reduced dark blue state, and Tb is the transmittance in the oxidized transparent state, a coloration efficiency 45 cm2 C−1 is obtained.

To evaluate the electrochromic stability of the composite film after 5000 cycles, we measured the colorimetric parameters in the CIE L*a*b* colorimetric space before and after 5000 cycles. The optical contrast (ΔE*) between two color states was calculated using the equation:

For the first cycle, the L*, a*, and b* parameters measured at blue reduced state (at − 1 V) are 34, − 1, and − 31, respectively, while for the transparent oxidized state (at + 1 V), the L*, a*, and b* parameters are 72, − 2, and − 2, respectively. The contrast ∆E* = [(L*1 − L*2)2 + (a*1 − a*2)2 + (b*1 − b*2)2]1/2 is of 48.

After the 5000th cycles, the L*, a*, and b* parameters in the blue reduced state (at − 1 V) are 33, − 1, and − 29, respectively, while for the transparent oxidized state (at + 1 V), the L*, a*, and b* parameters are 74, 1, and − 2, respectively. The contrast ∆E* = [(L*1 − L*2)2 + (a*1 − a*2)2 + (b*1 − b*2)2]1/2 is of 49.

The analysis of the L*a*b parameters of 5%BC@95%PEDOT:PSS film at the initial state and after 5000th cycles shows that there is no change in chromaticity parameters after long cycling. This demonstrates that of 5%BC@95%PEDOT:PSS film, they possess great electrochromic color memory properties with excellent color stability at the oxidized/reduced state.

Electrochromic performance of the composite device

Finally, an symmetric composite electrochromic device was fabricated, from the association of two electrode-based (PEDOT:PSS + BC) thin films, using electrolyte membrane based on 1 M LiClO4/PC plastified with polymethylmethacrylate (PMMA) as ion conductor.

The durability and stability of the composite electrochromic device (PEDOT:PSS + BC//electrolyte membrane// PEDOT:PSS + BC) were evaluated by voltammetry cyclic. Figure 9 shows the 1st and 1000th cycles of the CV curves performed at room temperature. The repetitive cycling of (PEDOT:PSS + BC//electrolyte membrane// PEDOT:PSS + BC) at a scan rate of 10 mV/s illustrates a good stability, cyclability, and well reversibility under these conditions. The electrochemical response of the device was accompanied with a nice switch from dark blue to transparent (inset Fig. 9).

Figure 10a shows the in situ optical transmittance of composite device (PEDOT:PSS + BC//electrolyte membrane// PEDOT:PSS + BC). In fact, the bleached transparent state at + 1 V and the colored dark blue state at − 1 V are associated with transmittance values of about Tb ≈ 85% and Tc ≈ 50% at 550 nm, respectively, corresponding to a high in situ transmittance modulation of ΔT ≈ 35%. The response time or switching response in between colored and bleached state is a key characteristic of the performance of the electrochromic devices. The responses switching times of the composite electrochromic device were deduced from monitoring the transmittance at a wavelength of 550 nm under the application of voltages of 1 V and − 1 V for 20 s. Figure 10b shows the switching kinetics of the composite device (PEDOT:PSS + BC//electrolyte membrane// PEDOT:PSS + BC). Upon oxidation and reduction state, both response times are 6 s for the bleached state and 9 s for the colored state. The switching optical response in between alternating potentials and transmittance modulation (ΔT) is a key characteristic of electrochromic device. In this work, our symmetric device exhibit good cycling stability, high transmittance modulations (ΔT ≈ 35% at 550 nm), and fast switching speeds (6 − 9 s for coloration and bleaching at 550 nm). Such values nicely compared with values reported in the literature. Recently, Do et al. [13] succeeded in manufacturing a symmetric electrochromic device (ECD) based on PEDOT:PSS; their ECD is demonstrated by lower switching time (9 s for colored state and 23 s for bleached state) and transmittance modulations (ΔT ≈ 33% at 550 nm). In the same context, Mecerreyes et al. [20] have shown that the device based PEDOT:PSS presents a chromatic contrast in all the visible range with a maximum at 650 nm (ΔT = 0.15) between 0 and 3 V.

Conclusion

In summary, we successfully demonstrated an efficient way to improve the electrochromic properties of the PEDOT:PSS using the addition of the black carbon. The electrochromic performance of the composite film based PEDOT:PSS + BC in lithium-based electrolyte illustrates good stability, nice reversibility, and fast switching times. To conclude, a novel composite electrochromic device was built combining two thin film–based PEDOT:PSS + BC via lithium-based electrolyte plastified with PMMA. This device shows good stability upon cycling and nice electrochromic properties switching reversibly from dark blue to transparent.

References

Granqvist CG, Lansåker PC, Mlyuka NR, Niklasson GA, Avendaño E (2009) Progress in chromogenics: new results for electrochromic and thermochromic materials and devices. Sol Energy Mater Sol Cells 93:2032–2039. https://doi.org/10.1016/j.solmat.2009.02.026

Wang Y, Runnerstrom EL, Milliron DJ (2016) Switchable materials for smart windows. Annu Rev Chem Biomol Eng 7:283–304. https://doi.org/10.1146/annurev-chembioeng-080615-034647

Lu YR, Hsu HH, Chen JL, Chang HW, Chen CL, Chou WC, Dong CL (2016) Atomic and electronic aspects of the coloration mechanism of gasochromic Pt/Mo-modified V2O5 smart films: an in situ X-ray spectroscopic study. Phys Chem Chem Phys 18:5203–5210. https://doi.org/10.1039/c5cp06870c

Wanga K, Zhang H, Chen G, Tian T, Tao K, Liang L, Gao J, Cao H (2021) Long-term-stable WO3-PB complementary electrochromic devices. J Alloys Compds 861:158534. https://doi.org/10.1016/j.jallcom.2020.158534

Bouvard O, Lagier M, Burnier L, Krammer A, Schüler A (2021) Strong coloration of nanoporous tungsten oxides by in-vacuo lithiation for all-solid-state electrochromic devices. Thin Solid Films 730:138700. https://doi.org/10.1016/j.tsf.2021.138700

Zhao Y, Zhang X, Chen X, Li W, Li Z, Chen M, Sun W, Zhao J, Li Y (2021) All-solid-state electrochromic devices based on the LiAlSiO4 electrolyte. Mater Lett 292:129592. https://doi.org/10.1016/j.matlet.2021.129592

Zhao P, Cai Y, Liu C, Ge D, Li B, Chen H (2021) Study on the bio-inspired electrochromic device enabled via dielectric elastomer actuator. Opt Mater 111:110569. https://doi.org/10.1016/j.optmat.2020.110569

Han Q, Wang R, Zhu H, Wan M, Mai Y (2021) The preparation and investigation of all thin film electrochromic devices based on reactively sputtered MoO3 thin films. Mater Sci Semicond Process 126:105686. https://doi.org/10.1016/j.mssp.2021.105686

Li W, Zhang X, Chen X, Zhao Y, Sun W, Xiao Y, Li S, Zhao J, Li Y (2021) Long life all-solid-state electrochromic devices by annealing. Sol Energy Mater Sol Cells 224:110992. https://doi.org/10.1016/j.solmat.2021.110992

Zhang Y, Shi X, Xiao S, Xiao D (2021) Visible and infrared electrochromism of bis(2-(2-(2-hydroxyethoxy)ethoxy) ethyl) viologen with sodium carboxymethyl chitosan-based hydrogel electrolytes. Dyes Pigm 185:108893. https://doi.org/10.1016/j.dyepig.2020.108893

Chen C, Liu Y-H, Zhu M, Zhao S-Q, Xu W-W, Chen L, Huang W (2020) High-performance embedded nickel grid electrodes for fast-response and bendable all-solid PEDOT: PSS electrochromic devices. Org Electron 77:105506. https://doi.org/10.1016/j.orgel.2019.105506

Okutana M, Evecan D, Yıldırım S, Zayim EÖ, Deligöz H (2020) Investigating the effect of electrolyte types with various ionic liquids on the electrochromic performance of PEDOT:PSS based LbL multilayers. Microelectron Eng 234:111454. https://doi.org/10.1016/j.mee.2020.111454

Do M, Park C, Bae S, Kim J, Kim JH (2021) Design of highly stable and solution-processable electrochromic devices based on PEDOT:PSS. Org Electron 93:106106. https://doi.org/10.1016/j.orgel.2021.106106

Shi H, Liu C, Jiang Q, Xu J (2015) Effective approaches to improve the electrical conductivity of PEDOT:PSS: A Review. Adv Electron Mater 1. https://doi.org/10.1002/aelm.201500017

Kim N, Kee S, Lee SH, Lee BH, Kahng YH, Jo Y-R, Kim B-J, Lee K (2014) Adv Mater 26:2268–2272

Cai G, Cheng X, Layani M, Tan AWM, Li S, Eh AL-S, Gao D, Magdassi S, Lee PS (2018) Direct inkjet-patterning of energy efficient flexible electrochromics. Nano Energy 49:147–154. https://doi.org/10.1016/j.nanoen.2018.04.017

Choi D, Lee M, Kim H, Chu W, Chun D, Ahn S-H, Lee CS (2017) Fabrication of transparent conductive tri-composite film for electrochromic application. Appl Surf Sci 425:1006–1013. https://doi.org/10.1016/j.apsusc.2017.07.076

Cai G, Darmawan P, Cui M, Wang J, Chen J, Magdassi S, Lee PS (2016) Highly stable transparent conductive silver grid/PEDOT:PSS electrodes for integrated bifunctional flexible electrochromic supercapacitors. Adv Energy Mater 6:1501882

Yun K-S, Kim B-R, Kang W-S, Jung S-C, Myung S-T, Kim S-J (2013) Preparation of carbon blacks by liquid phase plasma (LPP) process. J Nanosci Nanotechnol 13:7381–7385

Mecerreyes D, Marcilla R, Ochoteco E, Grande H, Pomposo JA, Vergaz R, Pena JMS (2004) A simplified all-polymer flexible electrochromic device. Electrochim Acta 49:3555–3559. https://doi.org/10.1016/j.electacta.2004.03.032

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Almarri, A.H. Improving the electrochromic properties of the composite films for electrochromic device. Ionics 28, 407–414 (2022). https://doi.org/10.1007/s11581-021-04317-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-021-04317-1