Abstract

A polymer derived from poly-9-bis[4-(thiophen-3,4-yloxy)biphenyl)]-9H-carbazole containing a carbazole and thiophene group, abbreviated as B2, was synthesized via the oxidation method by using FeCl3 as an oxidant. Additionally, the electrochemical polymer of B2 was synthesized and coated onto an ITO–glass surface via electrochemical oxidative polymerization. The electrochemical synthesis of the polymer was performed in 0.05 M AN/LiClO4 solvent/electrolyte solution containing 0.1 M concentration of B2 between +0.3 and +1.4 V potentials. The compounds were characterized by FT-IR, NMR, and elemental analysis techniques. The spectroelectrochemical and electrochromic properties of this polymer were also investigated in 0.05 M AN/LiClO4 solvent/electrolyte solution for 200 s and at a constant potential of +1.4 V. Switching ability of this polymer was measured as the percent transmittance (∆T%) at its changing point of maximum contrast. Additionally, the scan rate study was performed at different scan rates: 400, 300, 200, 100, 50, 20 mV/s. According to the electrochromic measurements, the synthesized polymer had a light blue color when it was oxidized, and when it was reduced, it had a transparent color. As a result, the synthesized polymer P(B2) can be used to produce new polymeric electrochromic devices, and it can be considered a good candidate for applications of electrochromic devices (ECDs) because of its short response time of 3.5 s.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymers have been synthesized via various synthesis methods such as electrochemical [1–6], oxidative polymerization [7–9], HBr elimination [10–12], and Suzuki coupling reactions [13, 14].

Recently, electrochemical polymerization has used to obtain many electrochromic polymers and semi- or conducting polymeric materials. This polymerization process involves reduction and oxidation stages, namely it depends on redox reactions. According to these reactions, thiophene [15, 16], carbazole [6, 17], pyrrole [18], and 3,4-ethylenedioxythiophene (EDOT) [19] derivatives are successfully polymerized by using the electrochemical method. Moreover, fluorene derivatives can be used in electrochromic applications. For example, Jiang and et al have published a manuscript about design and synthesis of 9,9-dioctyl-9H-fluorene-based electrochromic polymers. According to this work, the synthesized polymers exhibited excellent redox activity and electrochromic performance. The polymer, named P(EDOT-F-EDOT), exhibited a maximum optical contrast of 25.8 % at 500 nm in the visible region with a response time of 1.2 s [20].

The electrochemical method involves an electrochemical polymerization technique form an insoluble polymer film directly on the ITO (indium tin oxide) substrate. The obtained materials using this method are generally used in electrochromic applications. Electrochromic materials have the reversible color change of electro-active groups (thiophene, pyrrole, carbazole, etc.) through a redox reaction. Therefore, electrochromic materials synthesized via the electrochemical polymerization can be used in a wide range of applications such as smart windows, electronic displays, LED (light emitting diode) devices, and camouflage textiles [21–23]. They are highly sought after to lower production cost, and hence to be more competitive for the commercialization of these materials [24].

Nowadays, technology develops rapidly, and accordingly, electronic devices have attracted more attention. Therefore, electrochromic materials are very important for electrochromic and electronic applications. Additionally, more color scales are needed for use in their electrochromic applications. Therefore, there is a need for the synthesis of new polymers.

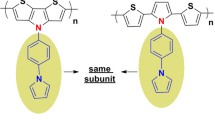

Herein, we primarily aimed to investigate whether the electrochromic properties of the synthesized polymeric compound (B2), which was synthesized by using FeCl3 as an oxidant. Additionally, we reported the synthesis of a new electrochromic polymer obtained from a polymer containing carbazole and thiophene units. For this purpose, firstly, 9-bis[4-(thiophen-3,4-yloxy)biphenyl)]-9H-carbazole (B1) was synthesized with carbazole, 4-iodo phenol and 3,4-dibromo thiophene [6]. Then, the oxidative polymerization reaction of B1 was performed in chloroform solution with the FeCl3 oxidant and poly-9-bis[4-(thiophen-3,4-yloxy)biphenyl)]-9H-carbazole, the abbreviated polymer B2 was obtained [5], and thus B2 was formed for the electrochemical polymerization reaction. P(B2) was synthesized via electrochemical polymerization in a 0.05 M LiClO4 supporting electrolyte in acetonitrile (AN) solvent. UV–Vis, FT-IR, 1H-NMR, and CV were used for structural characterization. According to the obtained data after the measurements, the synthesized polymer is a good candidate for electrochromic displays due to its switching stability. Moreover, this work on electrochromic features is important because it involves the exhibited materials are light blue and transparent in color.

Experimental

Materials

Carbazole, potassium carbonate (K2CO3), potassium hydroxide (KOH), 18-Crown-6, ethanol, methanol, chloroform (CHCl3), acetonitrile (AN), tetrahydrofuran (THF), sodium hypochloride (NaOCl), ferric (III) chloride (anhydrous) (FeCl3), 3,4-dibromo thiophene and toluene were supplied from Merck Chemical Co. (Germany) and used as received. 4-iodo phenol was supplied from Aldrich Chemical Co. (USA). 18-Crown-6 was used as phase transfer catalysis.

Synthesis of the starting compounds

Synthesis routes of 4-(9H-carbazol-9-yl) phenol (A1) and bis-4-(9H-carbazol-9-yl) phenyl-3,4-diyloxy thiophene, i.e. the compound named B1, is given in reference 6 (See ref. 6 and Scheme 1a, b) [6].

Synthesis of B2 via the FeCl3 oxidation method

Compound B1 (0.3 g, 0.5 mmol) in chloroform (10 mL) is added to a suspension of FeCl3 (1.35 g, 5 mmol) in chloroform (10 mL) in one portion under argon atmosphere. The reaction mixture is stirred for 72 h at room temperature. The reaction mixture is then diluted with chloroform and washed with water. Then, the organic phase is separated and followed by washing with water (3 × 150 mL) to remove unreacted FeCl3. The organic phase is separated from the aqueous phase, and the solution is then poured into methanol, and the precipitate is collected by evaporating the solvents (methanol and chloroform). After this process, the polymer (B2) is obtained as a purple solid. (Yield: 60 %). The synthetic route is shown in Scheme 1b [4, 5].

B2

FT-IR (cm −1 ): v (C = C phenyl) 1590, 1557 s, v (C-N) 1450 s, v (C-O-C) 1232, v (C-S) 752, 725 s. 1 H NMR (DMSO): δ H ppm, 7.150 (d, 4H, Ha, Hd), 7.477, 7.378 (m, 4H, Hb, Hc), 8.103 (d, 4H, He, Hf), 7.883 (s, 2H, Hg). Calculated: C, 80.98; H, 3.37; N, 4.72; S, 5.40. Found: C, 81.00; H, 3.90; N, 4.80; S, 5.00.

Electrochemical polymerization

Cyclic voltammetry (CV) measurements were performed by using an Ivium potentiostat at different potential scan rates. CV was employed to assay the electrical activity of the compound (B2) and determine its reduction–oxidation (redox) peak potentials. The system consists of a CV cell containing an ITO (indium tin oxide)-coated glass plate as the working electrode, a platinum wire as the counter electrode, and an Ag wire as the reference electrode. The CV measurements were performed by using a (0.05 M) LiClO4/acetonitrile (AN) electrolyte/solvent mixture at room temperature during 200 s [25]. The electropolymerization reactions involved dissolving B2 (0.1 M) in 10 mL of supporting electrolyte in AN and placing the resulting solution into the CV cell. Next, the solution was repeatedly scanned between +0.3 and +1.4 V. The resulting polymer film was washed with AN to remove LiClO4 and the unreacted monomer units [6]. The electrochemical polymerization synthesis of P(B2) is given in Scheme 2.

Structural characterization

The FT-IR spectra of the compounds were recorded on a Perkin Elmer RX I FT-IR spectrometer with KBr pellets in the range 4000–400 cm−1. 1H NMR spectra (Bruker AC FT-NMR spectrometer operating at 400 and 100.6 MHz) were also recorded using DMSO-d6 as the solvent at 25 °C. Tetramethylsilane was used as an internal standard. An Ivium potentiostat was used to supply a constant potential during the electrochemical synthesis and cyclic voltammetry experiments. An Agilent 8453 UV–vis spectrophotometer was used for the spectroelectrochemical studies and characterization of the compounds.

Spectroelectrochemical characterization

The polymer film, which had been electrochemically deposited onto ITO-coated glass slides, was used to perform the spectroelectrochemical experiments. Spectroelectrochemical and electrochromic measurements were conducted in a LiClO4 /AN solution and by using an Ag wire as the reference and a Pt wire as the auxiliary electrode. The data obtained from the cyclic voltammetry measurements were used for the spectroelectrochemical measurements of the polymer film [26]. These measurements were performed to account for the absorption spectra of the polymer film under the applied potentials. The spectroelectrochemical cell included a quartz cuvette, an Ag wire (RE), a Pt wire counter electrode (CE) and the polymer film on ITO/glass as a transparent working electrode (WE). These measurements were performed in a 0.05 M LiClO4 supporting electrolyte in AN solvent. Five cycles were chosen for each CV measurement [27].

Results and discussion

The structures of the compounds

The FT-IR and NMR spectral data related to A1 and B1 from the synthesized compounds are presented in reference 6 (See ref. 6) [6].

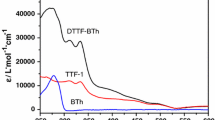

B2 possesses a C-S stretching peak of a thiophene group, C = C, C-N and C-O-C peaks at 752 and 725; 1590 and 1557; 1450; 1232, respectively (See Fig. 1a). The broad bands in the FT-IR spectrum of B2 prove the presence of poly-conjugation. Coupled C–C and C-O-C stretching peaks appear at about 1050 cm−1 and 1250 cm−1, respectively. In the FT-IR spectrum of B2, a peak at approximately 1050 cm−1 progresses over 3- and 6- positions in the carbazole unit of the polymerization process of B2, as expected [28]. Furthermore, 1H NMR spectrum of B2 also confirms that the polymerization reaction with FeCl3 occurs. The FT-IR spectra related to the polymer B2 and the starting compound B1 are shown in Fig. 1a to compare their FT-IR spectra (See Fig. 1a). As seen in their spectra, B2 has broad bands because of the polymerization when B1 is compared with B2. Additionally, C-S peak in the FT-IR spectrum of B2 is a broader peak when compared with those of B1. This shows that the polymerization occurs. Additionally, the results of these FT-IR studies clearly indicate that polymerization is successfully achieved.

UV measurement of B2 is performed in DMSO solution. At the UV spectrum of B2, K bands of phenolic and carbazole groups are observed in 261 and 295 nm, respectively. Additionally, R bands related to benzene groups are observed in 326 and 339 nm [29]. Absorption spectrum of B2 is given in Fig. 1b. The FT-IR and UV–vis spectrum of B2 is given in Fig. 1.

The obtained compounds have different colors such as a light yellow for B1 and purple for B2 in their solid states. Additionally, the compounds B1 and B2 are at powder form. The compounds are easily soluble in polar organic solvents, such as DMSO. Therefore, they are also characterized by 1H NMR analysis and using DMSO-d6 as the solvent [30]. The 1H NMR spectrum of B2 is given in Fig. 2. According to its 1H NMR spectrum, significant differences are observed in the1H NMR spectrum of B2. It can be said that the polymeric structure has different terminal ends. When the peaks for B1 are compared with those for B2, B2 has more splayed peaks. The most important reason for this is the polymerization process. The C-C coupling peaks arising from the binding between the carbazole units are monitored nearby 1200–1000 cm−1 in the FT-IR spectrum [6]. The decreased intensity of the Hb peak in the structure of B2 confirms that the polymerization progresses over the 3- and 6- positions on the carbazole moiety of B1 [2, 5, 31]. Additionally, the intensity of the Hg peak in the thiophene group decreases after the polymerization process, as expected. This means that polymerization progresses over the 2- and 5- positions on the thiophene group.

Cyclic voltammetry measurements

The cyclic voltammogram measurement of P(B2) in an AN/LiClO4 solvent/electrolyte solution was performed by dissolving B2 (0.1 M) in 10 mL of supporting electrolyte in AN, namely using a (0.05 M) LiClO4/acetonitrile (AN) electrolyte/solvent mixture at room temperature for five cycles. Its cyclic voltammogram was obtained by scanning from +0.3 to +1.4 V. Additionally, it possesses one consecutive oxidation peak at +0.83 V, and simultaneously, this peak intensity increases gradually. Furthermore, the increase in each cycle of the oxidation peak at +0.83 V shows that the polymerization process successfully occurs. According to its voltammogram, it has one more oxidation peak at about +1.18 V. It can be said that this oxidation peak decreases gradually. Figure 3a shows that the synthesized polymer has two reduction peaks at about +0.58 and +1.12 V, as expected. As seen in Figure 3a, the increasing oxidation peak potentials at +0.83 and +1.18 V after repeated scans for P(B2) is evidence of the electropolymerization, the formation of a poly-conjugated structure, and a reduction in the electrochemical band gap. The decrease in the peak current after repeated scans occurs because of polymer adsorption onto the electrode surface, which causes a sensitivity decrease in the electrode. Also, the decreased oxidation potential after repeated scans is evidence of electropolymerization. The CV behavior of P(B2) shows an increase in peak intensity for the repeated scans [32]. When the synthesized polymer is oxidized, it has a light blue color between +1.0 and +1.4 V. Additionally, when the film is reduced, it has a transparent color between +0.3 and +0.5 V. During the growth of the P(B2) film, as cycle number increases, reduction coupling shifts at a lower potential, which can be attributed to the oxidative doping (i.e., polaron and bipolaron formation) and reductive dedoping of the formed polymer [33].

Figure 3b shows CV voltammogram of P(B2) between +0.3 and +1.4 V during 200 s. This measurement is performed in a 0.05 M AN/LiClO4 solvent/electrolyte solution for five cycles. As seen in Fig. 3b, the polymer film P(B2) is quite stable (See Fig. 3b), and it can be said that its cycle stability is very good because the peak intensity is not changed as cycle number increases. This state can be clearly seen in Fig. 3b.

Electrochemical polymerization reactions are depended on redox reaction processes. Therefore, the mechanism of these reactions is very important to determine the progress of the electrochemical polymerization reaction. Thiophene derivatives readily undergo a one-electron oxidation to form a radical cation (polaron) when their α-positions are unsubstituted. Continual oxidation affords higher ordered oligomers via a radical coupling mechanism that ultimately forms a polymer [34]. As known, electro-active groups such as carbazole, pyrrole, and thiophene are expected to be the first oxidized species, and the polymerization starts by forming the polaron structure (radical cation) of carbazole, which is obtained by applying the potential. Thus, the monomer is oxidized to form its radical cation. The other monomers (carbazole, thiophene, pyrrole, etc.) are added to these radical cations (called polarons). After the reduction process, the polymer chain is extended by adding monomer units. The studies related to the electropolymerization progressing on carbazole units are available in the literature [6, 35, 36].

Scan rate measurements were performed in a solution of 0.05 M LiClO4/AN containing 0.1 M of the monomer B2 at a constant potential of +1.4 V during 200 s. Scan rates were adjusted as 400, 300, 200, 100, 50, 20 mV/s, respectively (See Fig. 4a). In the scan rate study, the peak current changes were examined depending on scan rate. The obtained graph by plotting depending on scan rate of the oxidation and reduction peak potentials shows a linear increase. Also, it shows that the electropolymerization is not diffusion-controlled and the polymer film is stored very well on the ITO surface. The current responses are directly proportional to the scan rate indicating that the polymer film is electro-active and well adhered to the electrode. The scan rates for the anodic and cathodic peak currents show a linear dependence as a function of the scan rate as illustrated in Fig. 4b. This demonstrates that the electrochemical processes are not diffusion limited and reversible even at very high scan rates (See Fig. 4b) [37].

Redox stability of the electro-active polymers towards multiple redox switching usually limits the utility as electrochromic materials in electrochromic devices (ECDs) application [37]. The main reasons for failure of electrochromic materials are high applied voltages and environmental conditions. To test the stability of the polymer, the potential was swept repeatedly between +0.3 and + 1.4 V with a scan rate of 400 mV/s for 50 cycles. Between the first and 50th cycles there was a significant decrease in the current, and also this decrease or loss of field was calculated as 82 %. As a result, it can be said that the polymer has a low stability due to a decrease in the current, but this situation is not an obstacle for use in the electrochromic applications. Also it could be used in electrochromic devices (ECDs) applications. Redox stability of P(B2) is shown in Fig. 4c.

Optical measurements

Spectroelectrochemistry is a good technique for examining changes in the optical properties of a polymer on ITO upon applying a potential. It also provides information about the properties of the synthesized polymer, such as the band gap (E g) and intergap states that appear upon doping. The polymer film was coated onto ITO at a constant potential of +1.4 V during 200 s. After the polymer film was washed with AN to remove LiClO4 and the unreacted monomer B2, spectroelectrochemical measurements were taken at different potentials with a 0.1 M B2 monomer concentration in a 0.05 M AN/LiClO4 electrolyte solution. Figure 4 shows the changes in the absorption spectrum of P(B2) in an AN/LiClO4 solution under various applied potentials. As the polymer device oxidized, the intensities of its π–π* transitions decreased, and its charge carrier bands at approximately 800–900 nm increased because of polaron formation [1–6]. Therefore, the π-π* transitions related to P(B2) was observed at 307 nm, and also polaron and bipolaron band formations at 407 nm and 685 nm, respectively. As emphasized, the band gap (E g) was calculated as 3.18 eV for the polymer film. The oxidized form of P(B2) possesses an absorption maximum at 407 nm, which corresponds to a blue color. Increasing the degree of oxidation in P(B2) gradually increases the absorbance intensity at 685 nm and, simultaneously, shifts a bit this band to a shorter wavelength (hypsochromic shift or shift to blue), which corresponds to the presence of positive carriers and the formation of fully doped polymeric chains. As the doping level increased, the sub-gap absorption grew at the expense of the π−π* transition [38]. The spectroelectrochemical spectrum related to P(B2) is shown in Fig. 5a.

(a) Spectroelectrochemical spectrum depending on various potentials of the polymer in 0.05 M AN/LiClO4 solvent/electrolyte solution between +0.3 and +1.4 V; (b) Absorbance changes of P(B2) depending on the applied various potentials for per 10 s; (c) Linearly increasing of the polymerization with the square root of the time

The in situ polymerization kinetics related to the synthesized polymer was performed [39, 40]. According to this process, a constant potential of +1.4 V was applied to the polymer film in order to determine the absorbance difference for per 10 s. These measurements were conducted for both 388 and 700 nm at two maximum absorbance wavelengths (See Fig. 5b). Additionally, it can be said that polymerization increases linearly up to 20 s in the course of time, and after 20 s, the polymerization increases linearly with the square root of the time. as shown in Fig. 5c. This means that the polymerization is not diffusion-controlled until 20 s, and after 20 s the polymerization is diffusion-controlled due to the formed double layer (See Fig. 5).

Electrochromic performance

The ability of a polymer to switch without delay and exhibit a sharp color change are very significant for electrochromic applications. Double potential step chronoamperometry was performed for estimate the response time of the polymer film. The potential was stepped between fully oxidized and neutral states of the polymer film with a residence time of 5 s. This measurement was performed by using the obtained polymer film, which was coated onto ITO in a 0.05 M AN/LiClO4 solvent/electrolyte system at a constant potential of +1.4 V during 120 s. During this experiment, the percent transmittance change (∆T%) at the wavelength of maximum contrast was measured using a UV–vis spectrophotometer. The measurements were conducted using a single wavelength with obviously changing absorption intensity. The polymer film was deposited onto the ITO-coated glass slides under constant potential conditions, as mentioned above, and its absorbance was monitored at λmax while switching between potentials of +0.3 and +1.4 V. For P(B2) maximum contrast (∆T%) and switching time were measured from Fig. 6 as 47 % and 3.5 s for 685 nm by stepping the potential between +0.3 and +1.4 V with a residence time of 5 s. The stability of the redox states during the scans is the most useful property for an electro-active polymer in constructing new electrochromic devices [2, 4, 5, 41]. The response time of the polymer can be a bit high when compared with similar research in the literature. For example, Jiang and et al said that the synthesized polymer exhibited a maximum optical contrast of 25.8 % at 500 nm in the visible region with a response time of 1.2 s in their work [20]. But, it can be said that, in this work, the polymer can be used in electrochromic applications, although the response time of the polymer is a bit high. Additionally, the ability of a material to exhibit a noteworthy color change is important for electrochromic applications. The synthesized electrochromic polymer on ITO-glass exhibits a transparent color in the reduced state and a light blue color in the oxidized state. The switching graph of P(B2) is given in Fig. 6a. Figure 6b shows the profile of the device recorded during double step spectrochronoamperometry (See Fig. 6).

Conclusion

A novel electrochromic polymer was synthesized via electrochemical polymerization and by using the abbreviated polymer as B2. This process was performed in a 0.05 M AN/LiClO4 solvent/electrolyte solution. The synthesized polymer had a light blue color when it was oxidized, and when it was reduced it had a transparent color. Additionally, scan rate study dependence of the peak currents was conducted at a constant potential of +1.4 V during 200 s. The scan rates for the anodic and cathodic peak currents showed a linear dependence as a function of the scan rate. The spectroelectrochemical measurements of the polymer film were performed, and the maximum absorbance wavelengths were determined as 407 and 685 nm. Also, the optical band gap was calculated as 3.18 eV for the polymer film. The electrochromic performance of the synthesized polymer was determined, and also its maximum contrast change (∆T%) and switching time were measured as 47 % and 3.5 s at 685 nm by stepping the potential between +0.3 and +1.4 V with a residence time of 5 s. According to the redox stability measurements, there was a significant decrease of 82 % in the current between the first and 50th cycles; however, this is acceptable for use in electrochromic devices (ECDs) application. Additionally, it can be said that the synthesized polymer is a good candidate for electrochromic displays due to its switching stability. Moreover, it is a suitable material for electrochromic applications due to having the short response time of 3.5 s.

References

Kaya İ, Aydın A (2012) A new approach for synthesis of electroactive phenol based polymer: 4-(2,5-Di(thiophen-2-yl)-1H-pyrrol-1-yl)phenol and its oxidative polymer. Prog Org Coat 73:239–249

Aydın A, Kaya İ (2012) Synthesis and characterization of yellow and green light emitting novel polymers containing carbazole and electroactive moieties. Electrochim Acta 65:104–114

Kaya İ, Bora E, Aydın A (2014) Synthesis and characterization of Schiff base derivative with pyrrole ring and electrochromic applications of its oligomer. Prog Org Coat 77:463–472

Aydın A, Kaya İ (2013) Syntheses of novel copolymers containing carbazole and their electrochromic properties. J Electroanal Chem 691:1–12

Aydın A, Kaya İ (2013) Syntheses, characterizations and electrochromic applications of polymers derived from carbazole containing thiophene rings in side chain with electrochemical and FeCl3 methods. Org Electron 14:730–743

Kocaeren AA (2015) Electrochemical synthesis and electrochromic application of a novel polymer based on carbazole. Org Electron 24:219–226

Kaya İ, Aydın A (2009) Synthesis, characterization, thermal degradation and electrical conductivity of oligo[2-(thien-2-ylmethylene) aminophenol] and oligomer-metal complexes. Chin J Polym Sci 27:465–477

Kaya İ, Aydın A (2011) Synthesis and characterization of the polyaminophenol derivatives containing thiophene in side chain:thermal degradation, electrical conductivity, optical-electrochemical, and fluorescent properties. J Appl Polym Sci 121:3028–3040

Kaya İ, Aydın A (2008) Synthesis, characterization, thermal stability, conductivity and band gaps of monomer and oligo-4-[(thien-2-ylmethylene)amino] phenol. e-Polymers 071:1–14

Kaya İ, Temizkan K, Aydın A (2013) Synthesis, characterization, thermal stability, conductivity and band gaps of monomer and oligo-4-[(thien-2-ylmethylene)amino] phenol. J Electroanal Chem 708:54–61

Kaya İ, Temizkan K, Aydın A (2013) Synthesis and characterization of aromatic and aliphatic ether bridged polymers containing carbazole moieties. Mater Sci Eng B 178:863–874

Kaya İ, Aydın A, Temizkan K (2013) Synthesis and characterization of a new dyestuff polymer soluble in alkaline aqueous media. Chin J Polym Sci 31:1632–1646

Zhang Y, Gao X, Li J, Tu G (2015) Highly selective palladium-catalyzed Suzuki coupling reaction toward chlorine-containing electroluminescence polymers. Dyes Pigments 120:112–117

He Y, Cai C (2011) Polymer-supported macrocyclic Schiff base palladium complex: An efficient and reusable catalyst for Suzuki cross-coupling reaction under ambient condition. Catal Commun 12:678–683

Liu H, Wu F, Zhao B, Meng L, Wang G, Zhang J, Shen P, Tan S (2015) Synthesis and photovoltaic properties of the acceptor pended push–pull conjugated polymers incorporating thieno[3,2–b] thiophene in the backbone chain or side chains. Dyes Pigments 120:44–51

Ming S, Zhen S, Liu X, Lin K, Liu H, Zhao Y, Lu B, Xu J (2015) Chalcogenodiazolo[3,4-c]pyridine based donor–acceptor–donor polymers for green and near-infrared electrochromics. Polym Chem 6:8248–8258

Lin K, Ming S, Zhen S, Zhao Y, Lu B, Xu J (2015) Molecular design of DBT/DBF hybrid thiophenes π-conjugated systems and comparative study of their electropolymerization and optoelectronic properties: from comonomers to electrochromic polymers. Polym Chem 6:4575–4587

Koll DK, Taha AH, Giolando DM (2011) Photochemical “Self-healing” pyrrole based treatment of CdS/CdTe photovoltaics. Sol Energy Mater Sol Cells 95:1716–1719

Wang K, Zhang T, Hu Y, Yang W, Shi Y (2014) Synthesis and characterization of a novel multicolored electrochromic polymer based on a vinylene-linked EDOT-carbazole monomer. Electrochim Acta 130:46–51

Jiang Q, Zhen S, Mo D, Lin K, Ming S, Wang Z, Liu C, Xu J, Yao Y, Duan X, Zhu D, Shi H (2016) Design and synthesis of 9,9-dioctyl-9H-fluorene based electrochromic polymers. J Polym Sci Polym Chem 54:325–334

Thakur VK, Ding G, Ma J, Lee PS, Lu X (2012) Hybrid materials and polymer electrolytes for electrochromic device applications. Adv Mater 24:4071–4096

Beaujuge PM, Reynolds JR (2010) Color control in π-conjugated organic polymers for use in electrochromic devices. Chem Rev 110:268–320

Mi S, Wu J, Liu J, Zheng J, Xu C (2015) Donor–π-bridge–acceptor fluorescent polymers based on thiophene and triphenylamine derivatives as solution processable electrochromic materials. Org Electron 23:116–123

Padilla J, Österholm AM, Dyer AL, Reynolds JR (2015) Process controlled performance for soluble electrochromic polymers. Sol Energy Mater Sol Cells 140:54–60

Cysewska K, Karczewski J, Jasiński P (2015) Influence of electropolymerization conditions on the morphological and electrical properties of PEDOT film. Electrochim Acta 176:156–161

Alévêque O, Levillain E, Sanguinet L (2015) Spectroelectrochemistry on electroactive self-assembled monolayers: cyclic voltammetry coupled to spectrophotometry. Electrochem Commun 51:108–112

Yan R, Jin B (2015) Investigation on the redox mechanism of polyaniline film in acid solution by in situ rapid-scan time-resolved infrared spectroelectrochemistry. J Electroanal Chem 743:60–67

Romero DB, Nüesch F, Benazzi T, Adès D, Siove A, Zuppiroli L (1997) Electroluminescence from carbazole dimers. Adv Mater 9:1158–1161

Kaya İ, Yıldırım M, Aydın A, Şenol D (2010) Synthesis and characterization of fluorescent graft fluorene-co-polyphenol derivatives: the effect of substituent on solubility, thermal stability, conductivity, optical and electrochemical properties. React Funct Polym 70:815–826

Kaya İ, Aydın A (2011) Synthesis and characterization of chelate polymers containing etheric diphenyl ring in the backbone: thermal, optical, electrochemical, and morphological properties. Polym Adv Technol 22:951–961

Cloutet E, Olivero C, Adès D, Castex M-C, Siove A (2002) Synthesis and blue luminescence of a soluble newly designed carbazole main-chain polymer. Polymer 43:3489–3495

Berton N, Fabre-Francke I, Bourrat D, Chandezon F, Sadki S (2009) Poly(bisthiophene-carbazole-fullerene) double-cable polymer as new donor-acceptor material: preparation and electrochemical and spectroscopic characterization. J Phys Chem B 113:14087–14093

Yılmaz MD, Aytun T, Frasconi M, Stupp SI, Stoddart JF (2014) Photocurrent generation from a low band-gap and green BODIPY-based electrochromic polymer. Synth Met 197:52–57

Guarin SAP, Skene WG (2007) Thermal, photophysical, and electrochemical characterization of a conjugated polyazomethine prepared by anodic electropolymerization of a thiophenoazomethine co-monomer. Mater Lett 61:5102–5106

Qiu D, Guo Y, Wang H, Bao X, Feng Y, Huang Q, Zeng J, Qiu G (2011) Synthesis, crystal structure, photophysical property and electropolymerization of Pt(II) complexes with carbazole-grafting 2-(2-pyridyl)benzimidazole. Inorg Chem Commun 14:1520–1524

Pernites R, Ponnapati R, Felipe MJ, Advincula R (2011) Electropolymerization molecularly imprinted polymer (E-MIP) SPR sensing of drug molecules: Pre-polymerization complexed terthiophene and carbazole electroactive monomers. Biosens Bioelectron 26:2766–2771

Söyleyici HC, Ak M, Şahin Y, Demikol DO, Timur S (2013) New class of 2,5-di(2-thienyl)pyrrole compounds and novel optical properties of its conducting polymer. Mater Chem Phys 142:303–310

Rughooputh SDDV, Nowak M, Hotta S, Heeger AJ, Wudl F (1987) Spectroscopic studies of soluble poly(3-alkylthienylenes). Macromolecules 20:212–215

Yang X, Chi L, Chen C, Cui X, Wang Q (2015) The nearly 100% filling of PEDOT in TiO2 nanotube array by a simple electropolymerization method. Phys E 66:120–124

Dispenza C, Sabatino MA, Deghiedy N, Casaletto MP, Spadaro G, Piazza S, El-Rehim HAA (2015) In-situ polymerization of polyaniline in radiation functionalized polypropylene films. Polymer 67:128–138

Neo WT, Ye Q, Lin TT, Chua SJ, Xu J (2015) 4,9-Dihydro-s-indaceno[1,2-b:5,6-b’]dithiophene-embedded electrochromic conjugated polymers with high coloration efficiency and fast coloration time. Sol Energy Mater Sol Cells 136:92–99

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kocaeren, A.A. Synthesis and electrochromic performance of a novel polymer based on an oxidative polymer derived from carbazole and thiophene. J Polym Res 23, 66 (2016). https://doi.org/10.1007/s10965-016-0961-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-0961-1