Abstract

We report the facile synthesis of molybdenum disulfide (MoS2) nanosheets on graphene nanosheets (MoS2@GNSs) via simple thermal decomposition of ammonium tetrathiomolybdate in Ar-H2 atmosphere. When used as anode materials for sodium-ion batteries (SIBs), the as-prepared MoS2@GNSs electrode delivers reversible capacities of 389 and 383 mA h g−1 at current densities of 200 mA g−1 and 500 mA g−1 after 200 cycles, respectively, which is much higher than that of the MoS2 electrode (253 mA h g−1 after 171 cycles at 200 mA g−1). The superior sodium storage performance of MoS2@GNSs including excellent cycle stability and rate performance can be attributed to the introduction of graphene materials, which not only buffer the volume changes of MoS2 upon sodiation/desodiation but also improve the electrical conductivity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Sodium-ion batteries (SIBs) are attracting increasing interest and have been considered as a promising alternative for the currently widely used lithium-ion batteries (LIBs) [1,2,3,4], owing to the abundant and inexpensive sodium resources on earth. Even though SIBs show similar working mechanism with that of the LIBs, the current SIBs usually exhibit slower reaction kinetics, low specific capacity, and poor cycle life because of the large ionic radius of Na+ (ca. 1.02 Å) than that of Li+ (ca. 0.76 Å), and the heavier molar mass of Na+ (22.99 g mol−1) than that of Li+ (6.94 g mol−1) [5, 6]. Therefore, the ongoing researches on SIBs are mainly focusing on exploring novel electrode materials with higher sodium storage capacity and better cycling behavior, and metal sulfides with a high theoretical specific capacity have been considered as promising anodes for rechargeable SIBs [7,8,9].

Among various candidate anode materials for SIBs, MoS2 has attracted considerable attentions as a high-performance potential anode material for SIBs due to its layered structure and high theoretical capacity of 670 mA h g−1 [10,11,12,13]. Notably, MoS2 possesses a relatively wide interlayer structure, which is beneficial for fast Na+ insertion/extraction [14,15,16,17]. However, because of the low electronic conductivity and serious volume expansion of MoS2 during sodiation, the battery usually displays low specific capacity and poor cycling stability, which makes it extremely challenging in practical applications [18]. To solve this problem, a common and effective method is to combine MoS2 with a conductive carbonaceous material. For example, Bang et al. reported the synthesis of liquid-phase exfoliated MoS2 nanosheets, delivering a discharge capacity of 165 mA h g−1 after 50 cycles at a current density of 20 mA g−1, when hybridized with rGO as anode for SIBs [19,20,21]. Yang et al. reported the synthesis of MoS2/graphite composite for SIBs which displayed a high reversible capacity of 358.2 mA h g−1 at 100 mA g−1 [22]. Kong et al. reported MoS2/graphene paper which can provide a capacity of 76.8 mA h g−1 after 300 cycles at 100 mA g−1 [23]. Chen et al. synthesized MoS2 /carbon nanofibers and the electrode showed discharge capacities of 380 mA h g−1 after 50 cycles at 50 mA g−1 [24, 25].

However, due to the high cost and complexity of these sample preparation processes, these methods are still difficult for large scale applications. This has inspired us to design and develop a facile and low-cost synthesis process to improve the sodium-ion storage characteristics of MoS2. Herein, MoS2@GNSs with unique structure and excellent electrochemical performance is designed and manufactured by a facile and low-cost method, namely, via a simple thermal decomposition of ammonium tetrathiomolybdate with the presence of graphene nanosheets.

Experimental section

Material synthesis

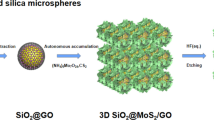

For synthesis of MoS2, 0.2 g of ammonium tetrathiomolybdate ((NH4)2MoS4, J&K Scientific) was placed in a tube furnace and annealed at 800 °C for 2 h in mixed Ar-H2 (10% H2+ 90% Ar) at a heating rate of 10 °C min−1. In the typical synthesis of MoS2@GNSs, 5 mg of graphene nanosheets (GNSs) and 0.1 g of ammonium tetrathiomolybdate were mixed/dissolved in 4 mL of N, N-dimethylformamide (DMF, C3H7NO, Shanghai Macklin Biochemical) under ultrasound irradiation for 2 h, and then the solution was transferred and kept in an oven at 100 °C for 1 h, in order to completely evaporate the DMF. Thus, obtained black product was annealed at 800 °C for 2 h under the same condition.

Material characterization

The phase structure of the products were characterized by X-ray diffraction (XRD) analysis under Cu K a radiation (k = 1.5418 Å) at 30 kV and 10 mA in the range of 10–80o. Scanning electron microscopy (SEM) was carried out with Quanta 250F FEI SEM. Transmission electron microscopy (TEM) was performed with JEOL-2100 TEM operated at 200 kV. Thermogravimetric analysis (TGA) was performed at a heating rate of 10 °C min−1 in air using a Mettler Toledo Thermal Analysis TGA-DSC thermal analyzer system. The composition and chemical state of the products were recorded using a Physical Electronics PHI-5802 analysis system by X-ray photoelectron spectroscopy (XPS) with a monochromatic Al Ka X-ray source. Raman measurements were performed on a Renishaw RE01 system with an excitation wavelength of 633 nm.

Electrochemical measurements

The electrochemical properties were tested using CR2025 coin-type cell assembled in an Ar-filled glovebox where the contents of H2O and O2 were less than 0.1 ppm. The active materials, carbon black, and polyacrylic acid (PAA) were mixed at a weight ratio of 80:10:10 and pasted on a copper foil current collector, followed by drying under vacuum at 60 °C for 12 h. The loading of the active material was in the range of 1.0–1.2 mg cm−2. The sodium foil was used as the counter electrode and a Whatman glass fiber membrane was used as the separator. The electrolyte was prepared by dissolving 1 M NaClO4 in ethylene carbonate/dimethyl carbonate (EC/DMC, volume ratio 1:1) with addition of 5% of fluoroethylene carbonate (FEC) by volume. Cyclic voltammograms (CV) were performed using an electrochemical station (Autolab 302 N) with a voltage range of 0.01–3.0 V at a scan rate of 0.2 mV s−1. The discharge-charge test was performed using a battery test system (Neware BTS, China) in the range of 0.01–3.0 V. Electrochemical impedance spectroscopy (EIS) was also performed using an electrochemical station in the frequency range of 10 MHz to 0.01 Hz. The specific capacity is calculated based on the composite mass of MoS2 and MoS2@GNSs.

Results and discussion

Figure 1a compares the X-ray diffraction (XRD) patterns of the MoS2 and MoS2@GNSs. Both products display almost identical diffraction profiles, and all the diffraction peaks can be indexed to the MoS2 (JCPDS No. 65-7025), in which the prominent peaks located at 14.4°, 33.5°, 39.6°, and 58.3° can be assigned to the (002), (101), (103), and (110) planes of the MoS2 phase. Notably, the presence of the outstanding (002) diffraction peak at 14.4° with d-spacing of ~ 0.61 nm indicates the layered crystalline structure. No peaks belonging to other materials can be observed, indicating the high purity of the product and the feasibility of producing layered MoS2 by directly annealing (NH4)2MoS4 under Ar-H2 flow. To determine the graphene content in the MoS2@GNSs composites, TGA test (Fig. 1b) was performed in the temperature ranging from 25 to 800 °C in air. The sharp weight loss at around 400 °C is attributed to the oxidation of MoS2 to MoO3, resulting the formation of MoO3, while the weight loss at 400 to 500 °C is due to the oxidation of carbon to CO2. On the basis of the following Eqs. (1–3) [26], the weight percentages of MoS2 and graphene in the MoS2@GNSs are calculated as 91.4% and 8.6%, which is consistent with the theoretical values.

The morphology and the microstructure of MoS2 were examined by SEM and TEM. Figure 2a and b show the typical SEM images of MoS2, exhibiting an irregular morphology with aggregates of nanosheets. Figure 2c and d show the TEM/HRTEM images of an aggregate of MoS2, which is composed of aligned nanosheets. Furthermore, HRTEM image clearly displays the well-defined lattice fringes with d-spacing of 0.61 nm, which can be indexed to the (002) reflection of the MoS2 (Fig. 1d).

Figure 3a and b show the SEM images of MoS2@GNSs which were obtained by annealing the (NH4)2MoS4/GNSs under Ar-H2 flow. Significantly, thinner nanosheets can be observed, as compared with the pure MoS2 counterpart (Fig. 2a, b). As shown in the TEM image (Fig. 3c), the nanosheets are flexible to some extent. HRTEM image in Fig. 3d reveals that nanosheets are aggregated but with different orientation, and the lattice fringes with d-spacing of 0.62 nm correspond to the (002) plane of MoS2. As revealed by HAADF-STEM image and the corresponding EDS maps, the thin MoS2 nanosheets are standing on the graphene nanosheets. The Mo and S elemental maps are well overlapped, while the graphene nanosheets serve as a support (Fig. 3e). In addition, N-doping may happen owing to the generation of the ammonium by the decomposition of (NH4)2MoS4.

The chemical composition and the valence state of the obtained MoS2@GNSs were examined by X-ray photoelectron spectroscopy (XPS). Figure 4 a shows the survey XPS spectrum of the MoS2@GNSs, revealing the presence of Mo, S, and C elements [27]. In the Mo 3d XPS spectrum (Fig. 4b), two distinct characteristic peaks at 228.7 and 231.8 eV can be attributed to the Mo 3d5/2 and Mo 3d3/2, respectively, with oxidation state of Mo4+. In addition, the minor peak at 235.4 eV can be assigned to the formation of Mo6+-O. The peak at 225.8 eV corresponds to S 2 s. Figure 4c shows the core level S 2p spectrum of the MoS2@GNSs, in which the deconvolved two peaks at 161.5 and 162.7 eV correspondingly relate to the S 2p3/2 and S 2p1/2, indicating that sulfur is present as S2− ions. Figure 4d depicts the overlapped N1s and Mo 3p XPS spectrum, in which the prominent peaks with binding energy at 394.7 eV corresponds to Mo 3p3/2, while the peak with binding energy at 397.4 eV can be assigned to the nitride type of N atom, indicating the formation of N-Mo bond [28,29,30]. Raman spectrum of the MoS2@GNSs shows two distinct peaks at about 378 and 406 cm−1, corresponding to the E1 2g and A1g vibration modes of MoS2, respectively. The A1g mode comes from out-of-plane vibration, while the E1 2g mode originates from the Mo-S in-plane vibration [30,31,32]. Besides, two broad bands at about 1326 cm−1 (disorder-induced D-band) and 1597 cm−1 (graphite G-band) are observed and originated from the graphene nanosheets (Figure S1) [33, 34].

The electrochemical properties of the MoS2 and MoS2@GNSs were examined as anode materials for SIBs using sodium foil as the reference and counter electrode. Figure 5a shows the initial five CV curves of the MoS2@GNSs electrode at a scan rate of 0.2 mV s−1 in the voltage range of 0.01 to 3 V. In the first cathodic scan, a distinct reduction peak located at around 0.71 V is observed, which can be attributed to the insertion of Na+ into the MoS2 interlayer (MoS2 + xNa+ +xe− → NaxMoS2) and formation of a solid electrolyte interphase (SEI) layer [35,36,37]. In the anodic scan, the broad peak at 1.85 V can be attributed to the oxidation of metallic Mo to MoS2. Since the second CV onwards, the prominent anode and cathode peaks are changed a little and locate at approximately 1.77 and 0.76 V, respectively. Except for the first cycle, the CV curves overlap well in the profile, which reflects the high reversibility and good cycle stability of MoS2@GNSs.

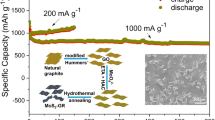

Figure 5b presents the discharge and charge voltage profiles of the MoS2@GNSs electrode at the 1st, 2nd, 10th, 50th, 100th, and 150th cycles at a current density of 0.5 A g−1. The initial discharge and charge capacities of the MoS2@GNSs composite are 526.4 and 374.7 mA h g−1, respectively, displaying a columbic efficiency of 71.2%. The irreversible capacity loss and thus resulting low columbic efficiency is attributed to the irreversible formation of the SEI layer on the surface of the electrode [38,39,40]. Surprisingly, the reversible capacity of 343 at the 2nd cycle increases to 380 mA h g−1 after 150 cycles, with a columbic efficiency as high as 97.3%. This indicates that the MoS2@GNSs electrode provides a stable capacity at a current density of 0.5 A g−1, implying high capacity and good reversibility.

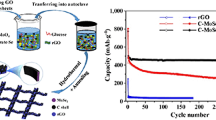

Figure 5c compares the cycling performance of the MoS2 and MoS2@GNSs electrodes at a current density of 0.2 and 0.5 A g−1. Although the initial capacity of the MoS2@GNSs electrode is lower than that of MoS2, and both MoS2 and MoS2@GNSs electrodes show increasing capacities with cycle number increasing to 130, the MoS2 electrodes show abrupt fast capacity fading, which may be due to the electrode pulverization upon cycling. Notably, the MoS2@GNSs electrodes show stable cycle performance, delivering reversible capacities of 389 and 383 mA h g−1 after 200 cycles at current densities of 0.2 and 0.5 A g−1, respectively. Furthermore, the rate performance of the MoS2@GNSs electrode is shown in Fig. 5d, and the MoS2@GNSs electrode exhibits discharge capacities of 377, 370, 354, 334, 308, and 267 mA h g−1 each after 10 cycles at successively increased current densities from 0.1, 0.2, 0.5, 1, 2 to even 5 A g−1, respectively. When the current density is back to 0.1 A g−1, the MoS2@GNSs electrode shows a high reversible capacity of 398 mA h g−1, indicating the superior rate capability of the MoS2@GNSs electrode. The excellent sodium-ion storage properties of the MoS2/GNSs composite can be attributed to the efficient hybridization of the few-layer MoS2 nanosheets with expanded d-spacing and the continuous graphene nanosheet networks. First, the reduced stacking of MoS2 nanosheets can relax partial strain, and the larger d-spacing can lower the barrier for Na+ insertion. Second, the dispersion of MoS2 nanosheets by the graphene nanosheets facilitates the Na+ accessibility into reaction sites and the infiltration of electrolyte during cycling. Third, the flexible graphene nanosheets not only offer cushions to relieve volume expansion but also enhance the electrical conductivity of the composite.

Conclusions

In summary, a hybrid of MoS2@GNSs with MoS2 nanosheets grown on graphene nanosheets (GNSs) has been successfully prepared by a facile pyrolysis of ammonium tetrathiomolybdate-GNSs. Owing to the introduction of GNSs, thinner MoS2 nanosheets were obtained and readily grown on the GNSs. When examined as anode materials for sodium-ion batteries, MoS2@GNSs electrode delivered high reversible capacity of 383 mA h g−1 after 200 cycles at 0.5 A g−1, demonstrating high sodium storage capacity, superior cycle stability, and rate capability. More importantly, this work provided a new simplified route for synthesis of MoS2 based anode materials for high-performance SIB materials, which can be expected for various applications in the field of electrochemical energy storage and conversion.

References

Kim S-W, Seo D-H, Ma X, Ceder G, Kang K (2012) Electrode materials for rechargeable sodium-ion batteries: potential alternatives to current lithium-ion batteries. Adv Energy Mater 2:710–721

Cao Y, Xiao L, Wang W, Choi D, Nie Z, Yu J, Saraf LV, Yang Z, Liu J (2011) Reversible sodium ion insertion in single crystalline manganese oxide nanowires with long cycle life. Adv Mater 23:3155–3160

Lu X, Wang Z, Liu K, Luo J, Wang P, Niu C, Wang H, Li W (2019) Hierarchical Sb2MoO6 microspheres for high-performance sodium-ion battery anode. Energy Storage Mater 17:101–110

Wang J, Cao D, Yang G, Yang Y, Wang H (2017) Synthesis of nis/carbon composites as anodes for high-performance sodium-ion batteries. J Solid State Electrochem 21:3047–3055

Park Y-U, Seo D-H, Kwon H-S, Kim B, Kim J, Kim H, Kim I, Yoo H-I, Kang K (2013) A new high-energy cathode for a na-ion battery with ultrahigh stability. J Am Chem Soc 135:13870–13878

Chevrier VL, Ceder G (2011) Challenges for na-ion negative electrodes. J Electrochem Soc 158:A1011–A1014

Zhang N, Han X, Liu Y, Hu X, Zhao Q, Chen J (2015) 3D porous gamma-Fe2O3@C nanocomposite as high-performance anode material of na-ion batteries. Adv Energy Mater 5:1401123

Zhou T, Pang WK, Zhang C, Yang J, Chen Z, Liu HK, Guo Z (2014) Enhanced sodium-ion battery performance by structural phase transition from two-dimensional hexagonal-SnS2 to orthorhombic-SnS. ACS Nano 8:8323–8333

Xu J, Zhang J, Zhang W, Lee C-S (2017) Interlayer nanoarchitectonics of two-dimensional transition-metal dichalcogenides nanosheets for energy storage and conversion applications. Adv Energy Mater 7:1700571

Huang X, Zeng Z, Zhang H (2013) Metal dichalcogenide nanosheets: preparation, properties and applications. Chem Soc Rev 42:1934–1946

Hu X, Zhang W, Liu X, Mei Y, Huang Y (2015) Nanostructured mo-based electrode materials for electrochemical energy storage. Chem Soc Rev 44:2376–2404

Balendhran S, Walia S, Nili H, Ou JZ, Zhuiykov S, Kaner RB, Sriram S, Bhaskaran M, Kalantar-zadeh K (2013) Two-dimensional molybdenum trioxide and dichalcogenides. Adv Funct Mater 23:3952–3970

Kang W, Wang Y, Xu J (2017) Recent progress in layered metal dichalcogenide nanostructures as electrodes for high-performance sodium-ion batteries. J Mater Chem A 5:7667–7690

Su D, Dou S, Wang G (2015) Ultrathin MoS2 nanosheets as anode materials for sodium-ion batteries with superior performance. Adv Energy Mater 5:1401205

Tan C, Zhang H (2015) Two-dimensional transition metal dichalcogenide nanosheet-based composites. Chem Soc Rev 44:2713–2731

Chhowalla M, Shin HS, Eda G, Li L-J, Loh KP, Zhang H (2013) The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat Chem 5:263–275

Zhang J, Wu M, Liu T, Kang W, Xu J (2017) Hierarchical nanotubes constructed from interlayer-expanded MoSe2 nanosheets as a highly durable electrode for sodium storage. J Mater Chem A 5:24859–24866

Wang X, Li Y, Guan Z, Wang Z, Chen L (2015) Micro-MoS2 with excellent reversible sodium-ion storage. Chem Europ J 21:6465–6468

Bang GS, Nam KW, Kim JY, Shin J, Choi JW, Choi S-Y (2014) Effective liquid-phase exfoliation and sodium ion battery application of MoS2 nanosheets. ACS Appl Mater Interfaces 6:7084–7089

You Y, Ye Y, Wei M, Sun W, Tang Q, Zhang J, Chen X, Li H, Xu J (2019) Three-dimensional MoS2/rGo foams as efficient sulfur hosts for high-performance lithium-sulfur batteries. Chem Eng J 355:671–678

Ren W, Zhou W, Zhang H, Cheng C (2017) Ald TiO2-coated flower-like MoS2 nanosheets on carbon cloth as sodium ion battery anode with enhanced cycling stability and rate capability. ACS Appl Mater Interfaces 9:487–495

Yang Q, Liu M, Hu Y, Xu Y, Kong L, Kang L (2018) Facile synthesis of MoS2/graphite intercalated composite with enhanced electrochemical performance for sodium ion battery. J Energy Chem 27:1208–1213

Kong D, Cheng C, Wang Y, Huang Z, Liu B, Von Lim Y, Ge Q, Yang HY (2017) Fe3O4 quantum dot decorated MoS2 nanosheet arrays on graphite paper as free-standing sodium-ion battery anodes. J Mater Chem A 5:9122–9131

Chen C, Li G, Lu Y, Zhu J, Jiang M, Hu Y, Cao L, Zhang X (2016) Chemical vapor deposited MoS2/electrospun carbon nanofiber composite as anode material for high-performance sodium-ion batteries. Electrochim Acta 222:1751–1760

Hou J, Cao T, Idrees F, Cao C (2016) A co-sol-emulsion-gel synthesis of tunable and uniform hollow carbon nanospheres with interconnected mesoporous shells. Nanoscale 8:451–457

Wang J, Luo C, Gao T, Langrock A, Mignerey AC, Wang C (2015) An advanced MoS2/carbon anode for high-performance sodium-ion batteries. Small 11:473–481

Zuo X, Chang K, Zhao J, Xie Z, Tang H, Li B, Chang Z (2016) Bubble-template-assisted synthesis of hollow fullerene-like MoS2 nanocages as a lithium ion battery anode material. J Mater Chem A 4:51–58

Teng Y, Zhao H, Zhang Z, Zhao L, Zhang Y, Li Z, Xia Q, Du Z, Świerczek K (2017) MoS2 nanosheets vertically grown on reduced graphene oxide via oxygen bonds with carbon coating as ultrafast sodium ion batteries anodes. Carbon 119:91–100

Hou J, Cao C, Idrees F, Ma X (2015) Hierarchical porous nitrogen-doped carbon nanosheets derived from silk for ultrahigh-capacity battery anodes and supercapacitors. ACS Nano 9:2556–2564

Zhang J, Kang W, Jiang M, You Y, Cao Y, Ng TW, Yu DY, Lee CS, Xu J (2017) Conversion of 1T-MoSe2 to 2H-MoS2xSe2-2x mesoporous nanospheres for superior sodium storage performance. Nanoscale 9:1484–1490

Kong D, Wang H, Cha JJ, Pasta M, Koski KJ, Yao J, Cui Y (2013) Synthesis of MoS2 and MoSe2 films with vertically aligned layers. Nano Lett 13:1341–1347

Cao X, Shi Y, Shi W, Rui X, Yan Q, Kong J, Zhang H (2013) Preparation of MoS2-coated three-dimensional graphene networks for high-performance anode material in lithium-ion batteries. Small 9:3433–3438

Hou J, Jiang K, Wei R, Tahir M, Wu X, Shen M, Wang X, Cao C (2017) Popcorn-derived porous carbon flakes with an ultrahigh specific surface area for superior performance supercapacitors. ACS Appl Mater Interfaces 9:30626–30634

Ren W, Zhang H, Guan C, Cheng C (2017) Ultrathin MoS2 nanosheets@metal organic framework-derived n-doped carbon nanowall arrays as sodium ion battery anode with superior cycling life and rate capability. Adv Funct Mater 27:1702116

Lu Y, Zhao Q, Zhang N, Lei K, Li F, Chen J (2016) Facile spraying synthesis and high-performance sodium storage of mesoporous MoS2/C microspheres. Adv Funct Mater 26:911–918

Lacey SD, Wan J, Cresce AW, Russell SM, Dai J, Bao W, Xu K, Hu L (2015) Atomic force microscopy studies on molybdenum disulfide flakes as sodium-ion anodes. Nano Lett 15:1018–1024

Hou J, Jiang K, Tahir M, Wu X, Idrees F, Shen M, Cao C (2017) Tunable porous structure of carbon nanosheets derived from puffed rice for high energy density supercapacitors. J Power Sources 371:148–155

Xu M, Yi F, Niu Y, Xie J, Hou J, Liu S, Hu W, Li Y, Li CM (2015) Solvent-mediated directionally self-assembling MoS2 nanosheets into a novel worm-like structure and its application in sodium batteries. J Mater Chem A 3:9932–9937

Qin W, Chen T, Pan L, Niu L, Hu B, Li D, Li J, Sun Z (2015) MoS2-reduced graphene oxide composites via microwave assisted synthesis for sodium ion battery anode with improved capacity and cycling performance. Electrochim Acta 153:55–61

Shi Z-T, Kang W, Xu J, Sun L-L, Wu C, Wang L, Yu Y-Q, Yu DYW, Zhang W, Lee C-S (2015) In situ carbon-doped Mo(Se0.85S0.15)2 hierarchical nanotubes as stable anodes for high-performance sodium-ion batteries. Small 11:5667–5674

Acknowledgments

We thank Mr. Chuansheng Ma and Ms. Yanzhu Dai at International Center for Dielectric Research (ICDR) of Xi’an Jiaotong University for the help with TEM/SEM measurements.

Funding

This work was supported by the Natural Science Basis Research Plan in Shaanxi Province of China (No. 2018JM5085) and the Key Laboratory Construction Program of Xi’an Municipal Bureau of Science and Technology (201805056ZD7CG40). H.W. appreciates the support of the Tang Scholar Program from the Cyrus Tang Foundation

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 114 kb)

Rights and permissions

About this article

Cite this article

Zhang, R., Wang, J., Li, C. et al. Facile synthesis of hybrid MoS2/graphene nanosheets as high-performance anode for sodium-ion batteries. Ionics 26, 711–717 (2020). https://doi.org/10.1007/s11581-019-03235-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-019-03235-7