Abstract

Selected carbonaceous nanomaterial–modified carbon paste electrodes (CPEs) were compared for trace-level determination of dopamine (DA) by direct cathodic square wave voltammetry (SWV). The advanced nanomaterials containing electrodes were obtained from homemade multiwalled carbon nanotubes (MWCNTs) in their native and functionalized (ox-MWCNTs) forms, commercially available MWCNTs, single-walled carbon nanotubes, and fullerene, by a very simple drop coating method, and from classical CPE which consists of graphite powder and paraffin oil only. The comparative SWV measurements confirmed the priority of ox-MWCNT/CPE as it exhibited the best analytical performance with a well-shaped and intensive DA signal, which strongly depended upon pH and exhibited the most favorable characteristics at pH 6.3 (0.1 M phosphate buffer solution). The cyclic voltammetric (CV) characterization of DA on ox-MWCNT/CPE confirmed the reversible process and much higher sensitivity of this electrode in comparison with the other ones. Fourier transform infrared (FTIR) and Raman spectroscopic measurements indicated a significant difference between MWCNTs and ox-MWCNTs, which is the consequence of the chemical oxidation/functionalization of the latter one having a positive influence on its sensing properties. The optimized SWV method was characterized by a linear concentration range of 16.15–192.70 ng mL−1 DA, a relative standard deviation (RSD) lower than 1.3%, and a detection limit in the model solution of 4.89 ng mL−1. Also, interferences from ascorbic acid were negligible. The developed method was successfully applied for DA determination in injection/selected infusion matrix solutions, whereby the obtained results were in good agreement with DA content declared by the producer with RSD of the method below 1.0%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dopamine (DA) is the predominant catecholamine neurotransmitter in the mammalian brain that plays a vital role in maintaining the functional activities of central nervous, cardiovascular, and hormonal systems [1,2,3,4]. Additionally, it influences a variety of activities such as behavior, attention, memory, and learning [5]. DA can be found not only in brain tissues but also in body fluids. Its unusual concentrations are linked to many diseases including Parkinson’s disease, Alzheimer’s disease, and schizophrenia [4,5,6,7,8,9]. Having in mind the wide range of physiological and pathophysiological implications, the development of analytical method for precise and selective measurement of DA (and/or its metabolites) at the low concentration levels characteristic for living systems (26–40 nM (3.98–6.13 ng mL−1) and below) can make a great contribution to disease diagnosis [10]. On the other hand, a long series of experiments and clinical investigations lead to the development of L-DOPA therapy and then to other types of medications to improve the patient’s symptoms [11], so the quality control of these products is of great interest as well.

In the last several decades, various analytical techniques have been exploited for the analysis of DA in different matrices. Based on the International Pharmacopoeia (Eighth Edition) [12], potentiometric non-aqueous titration was proposed as assay for DA hydrochloride determination considering its basic crystalline form. Since DA is a highly electroactive molecule, electrochemical methods proved to be convenient tools for its determination as well, due to their numerous advantages over other traditional methods including cost effectiveness, high sensitivity, simplicity, and fast analytical response [13, 14]. Moreover, they can also enable biomolecule detection in a miniaturized analytical device which suggests their suitability for point-of-care testing [8]. However, at bare electrodes generally the electron-transfer rate is slow, the electrochemical reactions are mainly irreversible and require high overpotentials, and the pronounced electrode fouling often results in poor selectivity and reproducibility [15, 16]. Therefore, the electrode modification is required to have a selective and sensitive method for DA determination [17]. One of the main advantages of carbon paste electrodes (CPE) is their easy and simple modification. Due to the heterogeneous, composite nature of the electrode material, modifying agents can be added directly to the paste, either to the material in its final state or during its preparation [18]. Also, manipulating the nature of the CPE surface is possible by deliberately attaching chemical reagents to its surface which can result in improvement of analytical performance of the electrode for determination of different target analytes [19]. Nowadays, different carbon-based materials such as carbon nanotubes (CNTs) are promising building elements of electrochemical sensors/biosensors. CNTs are known as rolled-up graphene sheets that exist as hollow tubes, and they can appear in a variety of forms including two basic types, i.e., single-walled (SWCNTs) and multiwalled (MWCNTs) carbon nanotubes. Each of them has unique structure and mechanical, thermal, and electronic properties that have led to a rising number of important electroanalytical applications in recent years [20,21,22,23]. CNTs increase the electroactive surface area and enhance electron transfer so the CNT-based electrodes are widely used for determination of various biomolecules with high sensitivity and selectivity among which are neurotransmitters/neurochemicals [24, 25]. Additionally, in most cases the nanotubes are purified via oxidizing treatment, typically in mineral acids such as HNO3 or H2SO4 to remove the end caps, which creates defect sites and oxygen functional groups (e.g., quinones and carboxylic acids in polar solvents), and therefore, fine tuning the amount of such elements improves the mediator/electrocatalytic properties of nanotubes [24, 26]. Up to now, different strategies were employed for designing electrochemical sensors based on CNTs for determination of DA individually or simultaneously with some other biomolecules that coexist together with DA in biological systems. For this purpose, a glassy carbon electrode (GCE) was coated with MWCNTs dispersed in dihexadecyl hydrogen phosphate [27] or Nafion [28], then with acid-functionalized MWCNTs [21], boron-doped CNTs [29], poly(allylamine hydrochloride) [30] and poly(diallyldimethylammonium chloride) [31] functionalized helical CNTs or layer-by-layer assembled MWCNTs [32]. Additionally, not only GCE was used for fabrication of DA working electrodes but also CNT-modified graphite [33, 34], gold [35], screen-printed [36] electrodes, carbon fiber [37, 38], and boron-doped ultrananocrystalline diamond [39] microelectrodes, as well as carbon nanotube paste electrode based on bromoform as binder [40]. Most of published papers dealt with the oxidation of DA, whereby one of the recent elaborated sensitive methods was proposed by Tan et al. [39] for DA detection down to 9.5 nM (1.46 ng mL−1) using a 100-nm “thin” film microelectrode in model solutions. In contrast, a very small number of reported methods are based on electrochemical reduction of DA. One such example is GCE modified with hybrid material SiO2/graphene oxide decorated with Ag nanoparticles which was used for simultaneous determination of epinephrine and DA employing square wave voltammetry (SWV), and the achieved detection limit for DA was 0.26 μmol L−1 (39.83 ng mL−1) [41].

In this work, CPE based on graphite powder and paraffin oil was surface modified with different carbonaceous nanomaterials (SWCNTs, commercially available and homemade native MWCNTs, chemically oxidized homemade MWCNTs (ox-MWCNTs), and fullerene (C60)) by a simple drop coating method. The applicability of prepared working electrodes was investigated for trace-level determination of DA by direct SWV and mainly based on its electrochemical reduction. After optimization steps concerning the selection of the working electrode, the pH of the supporting electrolyte, and the amount of the CPE modifier, the developed analytical method was applied for determination of DA in the pharmaceutical formulation sample, i.e., DA hydrochloride injection, in its basic form, and later after dilution with three different infusion solutions as well.

Materials and methods

Chemicals and reagents

All used chemicals were of analytical reagent grade, and the solutions were prepared with doubly distilled water. Stock solution of DA hydrochloride (99%, Acros Organics, Belgium) at a concentration of 1.0 × 105 ng mL−1 was prepared by dissolving the appropriate amount of solid substance in doubly distilled water, and for experimental work, it was further diluted as required. Ascorbic acid (Merck) was used for interference study. Phosphate buffer solutions (0.1 M) in the pH range from 5.8 to 8.0 were obtained by mixing corresponding volumes of 0.1 M Na2HPO4 (p.a., Alkaloid, Skopje, R. Macedonia) and 0.1 M KH2PO4 (p.a., Merck-Alkaloid, Skopje, R. Macedonia) aqueous solutions. Native MWCNTs were synthesized by catalytic chemical vapor deposition [42], and they were functionalized by refluxing in conc. HNO3 for 6 h to receive their oxidized form (ox-MWCNTs) after their first washing with room temperature conc. HNO3. The standard carbonaceous nanomaterials, SWCNTs, MWCNTs, and C60 were purchased from Sigma. Absolute ethanol (Carlo Erba, Italy) was used to prepare suspensions of mentioned carbon-based nanomaterials which were necessary for surface modification of the CP working electrode. DA hydrochloride injection (Dopamin Admeda 50, concentrate for infusion solution, 50 mg/5 mL, Haupt Pharma Wülfing GmbH for Admeda Arzneimittel GmbH, Germany) was analyzed as real sample. Based on the declaration of the producer, besides having DA hydrochloride as an active component, the injection also contains other ingredients as follows: L-cysteine hydrochloride monohydrate, sodium chloride, citric acid monohydrate, sodium hydroxide, water for injections, and hydrochloric acid. Three types of infusion solutions (0.9% NaCl, 5% glucose, and Ringer’s solutions, Hemofarm, Vršac, Serbia) were obtained from a local pharmacy in Novi Sad and served for preparation of DA infusions.

Apparatus

All voltammetric measurements were performed on an Autolab PGSTAT12 electrochemical analyzer operated via GPES 4.9 software (Metrohm, Netherlands). The voltammetric cell included a three-electrode system with an unmodified CPE or CPE surface modified with SWCNTs, MWCNTs, ox-MWCNTs, or C60 (SWCNT/CPE, MWCNT/CPE, ox-MWCNT/CPE, and C60/CPE, respectively) as the working electrode, a saturated calomel electrode (SCE) as reference, and a platinum auxiliary electrode. All potentials referred in this work are given as values against the SCE.

The physical characterization of the commercially available and homemade native MWCNTs was performed by a FEI Tecnai G2 200-kV HR transmission electron microscope (TEM). Additionally, Fourier-transform infrared (FTIR) spectra of MWCNTs and ox-MWCNTs were recorded using a Bruker Vertex 70 IR spectrometer, while Raman spectra were acquired in a Thermo Scientific DXR Raman microscope.

pH values were measured with a digital pH meter (inoLab® Multi 9620 IDS, Germany) using a combined glass electrode.

Characterization of nanomaterials by TEM, FTIR, and Raman spectroscopy

The TEM imaging was performed for native commercially available and homemade MWCNTs under the same magnification. FTIR spectra were recorded for homemade native MWCNTs and ox-MWCNTs in the wavenumber range of 4500–500 cm−1 on solid samples prepared by the KBr method. Namely, 10.0 mg of nanomaterials was mixed with 100.0 mg KBr, pressed into pellets, and measured in the transmission mode. Raman spectra were measured at 532-nm laser excitation with 2.5 mW power, using a long focus objective (×50) in the case of same materials. All spectra were collected with three accumulations of 20 s each and then corrected for background effects.

Preparation of the working electrodes

Bare CPE was made by thoroughly hand-mixing of 0.5 g graphite powder (< 20 μm, synthetic, Sigma-Aldrich) with 0.2 mL paraffin oil (Kemika, Zagreb, Croatia) as binding liquid in accordance with our previously published papers [43,44,45]. The piston type of the Teflon holder with a diameter of 2 mm [46] was filled with carbon paste, and before the measurements, the CPE surface was renewed mechanically by squeezing out a small amount of paste from the electrode body and wiping the electrode surface with a piece of clean smooth filter paper. The suspensions for CPE surface modification were prepared by dispersing 1.5 mg of selected carbon nanomaterial in 1.0 mL of absolute ethanol and sonicating for 20 min using ultrasound bath (Bandelin) similarly as it was elaborated in our previous works [44, 45, 47]. The surface modification of CPE was carried out as follows: 3.0 μL of prepared suspensions was drop coated by a micropipette on the electrode surface, and after drying at room temperature, the obtained working electrodes were used for voltammetric measurements. In the case of ox-MWCNT/CPE, 3.0 μL, 4.0 μL, and 5.0 μL of ethanol suspension were tested for the optimization of modifier amount on the CPE surface.

Voltammetric measurements in model systems

Cyclic voltammetric (CV) characterization of the prepared working electrodes was performed in 10 mM Fe(CN)63−/4- test solution containing 0.5 M Na2SO4 in the potential range from 1.0 to − 0.4 V starting in cathodic direction at different scan rates (v). As for the target analyte characterization, CV experiments were carried out with CPE and ox-MWCNT/CPE in 0.1 M phosphate buffer solution pH 6.3 in the absence and presence of 7343 ng mL−1 DA. In this case, the voltammograms were recorded in the potential span from 0.6 to − 0.4 V while v was 25, 50, 75, 100, 150, 200, 250, 300, 350, 400, 450, or 500 mV s−1.

SW voltammograms of DA were recorded using CPE, SWCNT/CPE, MWCNT/CPE, ox-MWCNT/CPE, and C60/CPE in the presence of 10.0 mL of phosphate buffer solution pH 6.3 (0.1 M) as the supporting electrolyte in appropriate DA concentration range depending on the working electrode. For the optimization of pH of the supporting electrolyte, SWV measurements were performed with ox-MWCNT/CPE in the phosphate buffer in the pH interval from 5.8 to 8.0 (0.1 M), while the concentration of DA was 120.97 ng mL−1. The measurement parameters in SWV were as follows: potential range from 0.60 to − 0.80 V, the pulse amplitude 25 mV, step potential 4 mV, and frequency 50 Hz. Prior to the SWV measurements, all investigated working electrodes were electrochemically activated by cycling in the phosphate buffer of appropriate pH value (0.1 M, 3 cycles, from 0.60 to − 0.80 V, 100 mV s−1) similarly as in our earlier works [45, 47, 48].

Real sample analysis

The DA hydrochloride injection sample was diluted with bidistilled water or with three different infusion solution matrices (0.9% NaCl, 5% glucose or Ringer’s solution) in the volume ratio 1:100. The content of DA in these samples was determined by the standard addition method using optimized analytical protocol (ox-MWCNT/CPE, 0.1 M phosphate buffer pH 6.3). During SWV measurements, after recording the baseline (10.0 mL 0.1 M phosphate buffer pH 6.3), 5.0 μL of diluted sample was added into the voltammetric cell, followed by three standard additions of DA with their final concentrations as: 19.36, 38.71, and 58.02 ng mL−1. All measurements were performed in triplicates.

Results and discussion

TEM, FTIR, and Raman spectroscopic characterization of the native MWCNTs and ox-MWCNTs

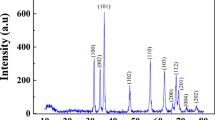

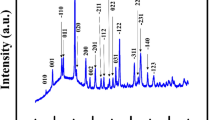

A few techniques including TEM, FTIR, and Raman spectroscopy were employed for characterization of native and oxidized forms of MWCNTs, which served, among others, as surface modifiers of CPE. TEM images of commercially available (Fig. 1a) and homemade (Fig. 1b) native MWCNTs showed that the nanotubes have the analogous basic structure with a similar length. In the case of commercially available MWCNTs, three different fractions with outer diameters of around 5, 10, and 20 nm were recognized, and their thickness is comparable with homemade MWCNTs which are with outer diameters from 10 to 30 nm with two dominant fractions as 10 and 20 nm. These homemade MWCNTs were further characterized by FTIR and Raman spectroscopy together with their chemically oxidized form. The obtained FTIR spectra for both forms were compared (Fig. 1c). As can be seen, an intensive band at wavenumbers around 3400 cm−1 was recognized in both cases which according to the literature data [49,50,51] belongs to stretching vibrations of isolated surface –OH moieties and/or –OH in carboxyl groups and in adsorbed water. Additionally, the bands in the 1750–1550 cm−1 range can be assigned to C=O groups in carboxylic acid or ketone/quinone groups and to C=C in aromatic rings, while the presence of C–O bonds can be confirmed by the bands in the range of 1300–950 cm−1 [49,50,51]. In the present case, the FTIR studies showed some distinct differences between the native and ox-MWCNTs. Additional bands at 1707, 1634, and 1564 cm−1 were observed on ox-MWCNT spectra proving the presence of C=O groups, and similar as it is elaborated by Stobinski et al. [49], the increase and partial separation of bands in the 1250–950 cm−1 range can be also recognized indicating the increased amount of hydrated surface oxides compared to MWCNTs. In the next step, the Raman spectra of synthesized MWCNTs and ox-MWCNTs were recorded and the obtained results (Fig. 1d) are comparable and in accordance with those found in the literature for MWCNTs [49, 50, 52, 53]. Native homemade MWCNTs showed two typical graphite bands at 1344 cm−1 and 1580 cm−1 assigned as D and G bands, respectively. The G band is related to the in-plane vibration of the C–C bond, and the D band is activated by the presence of a disorder in carbon systems [49, 50, 52, 53]. Also, one intensive band called the G′ band appears at 2682 cm−1 and it is attributed to the overtone of the D band. In the case of ox-MWCNTs, the intensity of mentioned bands is increased visibly, and they are a little bit shifted (around 5 cm−1) to more positive values compared to MWCNTs. Additionally, the G band is with a shoulder around 1617 cm−1 called the D′ band, typical of defective graphite-like materials. The integrated D and G band Raman intensity ratio (ID/IG) was calculated for both homemade native MWCNTs and ox-MWCNTs, and obtained values were 0.78 and 1.07, respectively. Since this parameter can be used to evaluate the disorder density of the nanotube walls, i.e., low ID/IG represents low defect concentration [50, 52], it is confirmed that there are obvious differences between the native MWCNTs and ox-MWCNTs.

Cyclic and square wave voltammetric characterization of the working electrodes

In addition to the structure characterization of synthesized nanomaterials, voltammetric measurements were carried out to get a deeper insight into the electrochemical behavior of advanced working electrodes in the Fe(CN)63−/4− test solution and into their performance with respect to the DA redox reaction similarly as it was described in previously published procedures for electroanalytical determination of different target analytes [54,55,56].

As first, CV characterization of the working electrodes, CPE (Fig. S1a), SWCNT/CPE, MWCNT/CPE, ox-MWCNT/CPE (Fig. S1b), and C60/CPE, were performed by Fe(CN)63−/4-(10 mM) test solution in Na2SO4 supporting electrolyte (0.5 M) with v between 25 and 500 mV s−1. In the case of all tested electrodes, the well-defined oxidation peak with a peak potential (Ep,a) in the range from around 0.3 to 0.4 V and, in reverse half cycle, one reduction peak with peak potential (Ep,c) from around 0.1 to 0.0 V were received with recognizable shifts at different v, and with almost equal anodic (Ip,a) and cathodic (Ip,c) peak maxima ratios at all v. The Ep,a and Ep,c differences, ΔEp, were considered as well, and for example at v = 50 mV s−1 they were 0.173, 0.128, 0.140, 0.227, 0.094, and 0.226 V for CPE, SWCNT/CPE, MWCNT/CPE, MWCNT(homemade)/CPE, ox-MWCNT/CPE, and C60/CPE, respectively. These values indicate the deviation from ideal reversible behavior of the electrode processes, but due to the presence of paraffin oil pasting liquid in CPE, ΔEp is not ideal even for reversible systems and as a consequence widening of the distance between anodic and cathodic peak potentials can occur for such substrate electrode, which is in accordance with earlier reported data [57, 58]. Additionally, as it can be seen this value can be influenced significantly by the surface chemistry of the modifier layer(s) as well [59]. The correlation of Ip,a and Ip,c peak currents vs the square root of scan rates (v1/2) for all electrodes can be described by linear equation which confirms the diffusion-controlled behavior of the redox processes, and for the CPE and ox-MWCNT/CPE it could be expressed with the ones elaborated in Table S1. By comparing the slopes of Ip-v1/2 dependences, it can be concluded that ox-MWCNT/CPE has almost 2.7 times higher surface area than the basic CPE. In the case of SWCNT/CPE and both MWCNT/CPEs, the value of this slope was something lower than the value received by ox-MWCNT/CPE. However, it should be kept in mind that Fe(CN)63−/4− is an outer-sphere redox system concerning its charge transfer reaction which is quite complex and dependent both on the electrode surface chemistry, conductivity of the material, and interactions with cations in solution [60, 61]. It seems that the C60/CPE in present form showed a similar performance as CPE, while the carbon nanotube–modified electrodes were with increased peak currents especially the ox-MWCNT/CPE due to the enlarged highly conductive surface area of the electrode, pronounced hydrophilic property, and, probably, possible catalytic effect of the surface functional groups.

To investigate the redox behavior of the DA at bare CPE (Fig. 2a) and particularly at the ox-MWCNT/CPE (Fig. 2b, c), CVs of the target analyte were recorded in phosphate buffer solution pH 6.3 (0.1 M). In the case of both working electrodes, one pair of reduction/oxidation peak was clearly recognized. The larger background current was obtained with ox-MWCNT/CPE which can be attributed to the enlarged surface of the electrode. Comparing the cathodic and anodic DA peak potentials, the modification of CPE with ox-MWCNTs results in the significant decrease in ∆Ep; for example, at v = 25 mV s−1 the values were 0.198 V and 0.020 V for CPE (Fig. 2a) and ox-MWCNT/CPE (Fig. 2b), respectively. Moreover, the peak current maxima were more than 15 times higher in the case of the modified electrode. The obtained results indicate that additionally to the enlarged surface area there is probably a catalytic effect of ox-MWCNTs toward DA redox reaction together with enhancement of the hydrophilic surface behavior, electron transfer kinetics, and reversibility of the process. Furthermore, CVs of DA recorded at different v with ox-MWCNT/CPE (Fig. 2c) and CPE (not shown) were tested and the Ip-v1/2 correlations for anodic (1) and cathodic (2) processes were constructed as it is presented in Fig. 2d. From these experiments, derived data are summarized in Table 1. In both cases, the peak currents increase linearly with the square root of the scan rate, which implies that the electrode reaction is diffusion controlled [59].

Cyclic voltammetric measurements performed in phosphate buffer supporting electrolyte pH 6.3 (0.1 M) by CPE (a) and ox-MWCNT/CPE (b) in the absence (dashed lines) and in the presence of 7343 ng mL−1 DA (full lines) at v = 25 mV s−1. CVs of DA (7343 ng mL−1) recorded by ox-MWCNT/CPE at different v as 25, 50, 75, 100, 150, 200, 250, 300, 350, 400, 450, and 500 mV s−1 (curves from 1 to 12, respectively, c) together with corresponding Ip-v1/2 correlations (d) for the anodic (1) and cathodic (2) processes

Comparing the nanomaterial-modified CPEs and substrate CPE by direct cathodic SWV for the target analyte reduction, DA signals were recorded at the same experimental conditions, and the obtained results were analyzed (Fig. 3). At the investigated concentration of DA (1584 ng mL−1), the ox-MWCNT/CPE (Fig. 3a) gives a sharp, well-defined reduction peak with a maximum close to 0.2 V at pH 6.3 (which is the optimal pH value of supporting electrolyte; see later). In contrast, the DA reduction signal obtained by MWCNT (homemade)/CPE (Fig. 3b) is recognizable, but the baseline peak which appeared at around 0.05 V interferes with the DA signal and as the consequence of this unfavorable effect the possible LOQ is at a higher concentration as 800.0 ng mL−1. Obviously, the separation between these two peaks is not appropriate at a higher concentration of DA as 7343 ng mL−1, too (inset, Fig. 3b). The SWCNT/CPE (Fig. 3c) showed a DA reduction signal at around 0.2 V, but in comparison to the ox-MWCNT/CPE, its response is with significantly lower intensity (more than 200 times based on their peak maxima comparison). In the case of MWCNT (commercially available)/CPE (Fig. 3d) and C60/CPE (Fig. 3e) due to the presence of the dominant baseline peaks, they disable the determination of DA as these peaks probably overlapped the DA reduction signal, and the same holds for signals recorded by both electrodes at the higher DA concentration (insets, Fig. 3d and e). The bare CPE (Fig. 3f) showed poor analytical response in the examined concentration range of DA. So, it can be concluded that the ox-MWCNT/CPE is the most appropriate working electrode for development of the direct cathodic SWV method for DA determination, while the SWCNT/CPE can be the second choice although the response of this electrode is with lower sensitivity.

Comparison of SW voltammograms recorded by CPEs modified with ox-MWCNTs (a), homemade MWCNTs (b), commercially available SWCNTs (c), MWCNTs (d), C60 (e), and bare CPE (f) in the absence (dashed lines) and presence of 1584 ng mL−1 DA (full lines). Insets (b, d, e) presents SWVs recorded at higher concentration level of DA (7343 ng mL−1). Supporting electrolyte, 0.1 M phosphate buffer pH 6.3. Volume of modifier suspension, 3.0 μL

Optimization of the analytical method for DA determination by ox-MWCNT/CPE

To ensure a high-quality sensing process of DA, the basic requirement was to optimize the implemented amount of modifier on the CPE surface which was performed by drop coating different volumes of ethanol ox-MWCNT suspension from 3.0 to 5.0 μL. Based on Fig. 4a, the CVs were recorded in the supporting electrolyte pH 6.3 with electrodes obtained by drop coating 3.0 μL (curve 1), 4.0 μL (curve 2), and 5.0 μL (curve 3) modifier suspension, and the increase in background current was observed which indicates that the electrode surface increased as well. Under mentioned conditions with all three types of ox-MWCNT/CPEs, two reduction peaks were recognized on the CVs of the supporting electrolyte with maxima close to − 0.1 V and – 0.4 V and with counterparts in the positive half cycle of polarization. It is clearly visible that by the increase in the modifier amount at the CPE surface layer, the peaks of the baselines are with much pronounced form. The DA test solution SWV response recorded by ox-MWCNT/CPEs made from 3.0 μL (curve 2) and 5.0 μL (curve 4) together with appropriate blank curves (curves 1 and 3, respectively) confirmed that the increase in the amount of ox-MWCNTs on the electrode surface deteriorates the intensity of the SWV DA reduction signal (Fig. 4b), as the baseline peak is overlapped notably with the analytical one. It is important to note that the ox-MWCNTs have remarkable affinity to the substrate CPE, and thanks to such favorable mutual interaction the modifier is immobilized spontaneously forming a stable self-assembled surface layer of the ox-MWCNTs with appropriate mechanical stability of the ensemble for analytical purposes without significant leaching/losing of the nanomaterial from the working electrode.

Effect of ox-MWCNTs amount on the ox-MWCNT/CPE: a cyclic voltammograms recorded by ox-MWCNT/CPEs made from CPE and 3.0 μL (curve 1), 4.0 μL (curve 2), or 5.0 μL (curve 3) of ox-MWCNTs suspension for supporting electrolyte pH 6.3 (0.1 M) and b direct cathodic SWVs recorded by ox-MWCNT/CPE made from CPE and 3.0 μL (curves 1 and 2) or 5.0 μL (curves 3 and 4) of ox-MWCNTs suspension for supporting electrolyte (curves 1 and 3) and DA (80.57 ng mL−1) in supporting electrolyte (curves 2 and 4)

The influence of the pH of the supporting electrolyte on the DA signal was examined by direct cathodic SWV from 0.40 to − 0.20 V and ox-MWCNT/CPE in phosphate buffer solutions in the pH range from 5.8 to 8.0 (0.1 M). Illustrative responses at selected pH values are shown in Fig. 5a. As it can be seen, one well-defined reduction peak of DA appears with maxima from 0.233 to 0.101 V depending on the pH value. This signal is suitable for analytical purposes between pH 5.8 and 7.4 since under such conditions it can be considered as separated acceptably from the characteristic peak of the baseline. The DA peak potentials shift to the negative direction with the increasing pH of the supporting electrolyte, and the same holds for the baseline peak as well. The Ep-pH dependence of the DA reduction peak (Fig. 5b) is described with the following equation: Ep[V] = 0.577–0.05924 pH, r = – 0.999, which shows that the number of the exchanged electrons and protons in the direct cathodic electrochemical reaction is the same as its slope value is very close to the Nernstian one. The intensity of the DA reduction peak maxima increases from pH 5.8 to 6.3, and after that it decreases up to pH 8.0 for more than two times (Fig. 5c), so pH 6.3 was selected as the optimal value for the experimental work.

For the development of the trace-level analytical method, simply direct cathodic SWV measurements were performed by ox-MWCNT/CPE in the concentration range of DA from 16.15 to 192.70 ng mL−1 in 0.1 M phosphate buffer pH 6.3 (Fig. 6a) and the calibration curve was constructed from the peak maxima intensities and corresponding DA concentrations (inset, Fig. 6a). The basic analytical parameters were evaluated from there and are presented in Table 2. The repeatability of the analytical signal was investigated by six subsequently recorded SWV curves with the same sensor surface for the DA concentration of 80.57 ng mL−1 (Fig. 6b), and the relative standard deviation (RSD) was 1.23%. The reproducibility was evaluated from the DA signals obtained with three different electrode surfaces which were prepared by the three times independently repeated optimized drop coating protocol, and the RSD did not exceed 4.5% for the abovementioned DA concentration level.

SW voltammograms recorded at ox-MWCNT/CPE for different DA concentrations in 0.1 M phosphate buffer solution pH 6.3 for its cathodic reaction (a) together with the corresponding calibration curve (insets, a). Dashed line illustrates the appropriate voltammogram of the baseline. The repeatability (b) of reduction DA signals at the concentration level of 80.57 ng mL−1 by the direct SWV method (n = 6). The volume of modifier suspension, 3.0 μL

Having in mind the reversibility of DA redox reaction, the oxidation of this target analyte by ox-MWCNT/CPE and optimized SWV method was examined as well. The direct anodic SW voltammograms are presented in Fig. S2a together with the corresponding calibration curve (inset, Fig. S2a). It can be seen that although a wider linear range was achieved, the oxidation signals of DA are with lower intensity/peak maxima compared to reduction ones, which consequently leads to four times higher LOQ and LOD values (Table 2). The repeatability (Fig. S2b) was measured/calculated as 1.95%. However, it was also noticed that if the anodic run is started immediately after recording the cathodic SWV in the potential range from 0.6 to − 0.8 V, the DA oxidation signal is with similar intensity in comparison to the reduction one, but with the next three subsequent anodic runs, it decreases significantly (around three times) to the constant value. So, it can be assumed that to receive the highest sensitivity in anodic determination, some additional cathodic activation of the working electrode is recommended to be applied before every single run, which made the determination process more time consuming.

Although the sensitivity of the method is lower at pH values higher than 6.3, the applicability of ox-MWCNT/CPE for cathodic SWV determination of DA at pH 7.4 was investigated as well, since this pH is very close to physiological one. The reduction peak currents increased linearly with the concentrations of DA in the range of 24.21–224.60 ng mL−1 (for details, see Table 2). The very similar sensitivity was obtained in the 0.1 M phosphate buffer solution pH 7.4 that contains 0.9% of NaCl. However, it was noticed that in this case the peak of DA is slightly broadened in comparison with that obtained without the NaCl concerning its shape, but the designed electrode is still applicable for DA determination in such environment confirming its good analytical potential in the case of in vitro physiological samples.

As it was mentioned above, the SWCNT/CPE can be also considered/employed for cathodic DA determination, but in comparison with ox-MWCNT/CPE, the calibration curve can be described by two linear parts (80.69–281.71 ng mL−1 and 281.71–1583.72 ng mL−1), while the achieved LOQ and LOD values were about five times higher (Table 2).

It is very important to underline that the LOQ and LOD values of the developed very simple direct cathodic SWV method in combination with ox-MWCNT/CPE are significantly lower or at last in the same range as the majority of previously reported ones related to determination of DA by various advanced electrodes with more expensive nanomaterials including some noble metals solely or their nanocomposite forms, and/or contemporary organic polymer building units as well, which served firstly for the measurements of the target analyte oxidation signals, as can be seen from selected examples presented in Table 3.

Beside the 0.9% NaCl, ascorbic acid (AA) is usually present in vivo at concentrations 100 to 1000 times higher than DA [28, 66] and therefore is one of the main interfering substances during DA determination, so its influence was investigated. As can be seen from Fig. 7a when the baseline SWV response (curve 1) was compared with SWV recorded in the presence of AA (curve 2, 1.0 mM), no reduction peak was found for AA in the investigated potential range at pH 6.3, which is in accordance with the well-known behavior of AA since its electrochemical reaction can be described as irreversible oxidation process [41]. Furthermore, after recording the SWV curves in the same supporting electrolyte in the absence (curve 1) and presence of DA (curve 2, 153.17 ng mL−1, i.e., 1.0 μM), subsequent SWVs were recorded in 500 and 1000 times higher molar concentrations of AA than DA (Fig. 7b, curves 3 and 4, respectively). It is evident that the intensity of the DA reduction peak does not change to a great extent in the presence of AA (the relative error was less than 2.6%), indicating good selectivity of the proposed method.

Interference study from AA: a SWVs of the supporting electrolyte (curve 1) and 1.0 mM AA (curve 2), b voltammogram of the baseline (curve 1) together with SWV signals of 153.17 ng mL−1 (1.0 μM) DA in the absence (curve 2) and presence of 500 (curve 3) and 1000 (curve 4) times higher molar concentration of AA. Supporting electrolyte, 0.1 M phosphate buffer solution pH 6.3

Determination of DA in injection and selected infusion matrix samples

The optimized SWV method in combination with ox-MWCNT/CPE was applied for determination of DA in real samples, i.e., DA hydrochloride injection with the aim of its quality control concerning the target analyte content. According to the manufacturer’s instructions, this injection is intended solely for intravenous infusion and may be used only after dilution with an appropriate infusion solution such as 0.9% NaCl, 5% glucose, or Ringer lactate. So, it is also important to control the concentration of the active ingredient DA after its dilution in the recommended way. DA injection was diluted with bidistilled water or appropriate infusion solution (for details, see “Materials and methods”), and then the concentration of DA was determined in 0.1 M phosphate buffer pH 6.3 as supporting electrolyte by the standard addition method to avoid the possible influence of the matrix. All measurements were performed in triplicates whereby one set of measurements/experiments involves recording SW voltammograms of the sample and three standard additions of DA. It was noted that in the case when the injection sample is diluted with bidistilled water, four sets of measurements could be performed with the same ox-MWCNT/CPE surface without significant loss of method sensitivity. On the other hand, when the infusion solutions were used for injection dilution, more reliable was to prepare a new electrode surface for each set of measurements because with every new set, a faster saturation of analytical curve was observed probably due to the influence of some components of the matrix and passivation of the electrode surface. However, the modification of CPE with ox-MWCNTs is very simple, it is not time consuming, and, above all, reproducibility is very good which makes the proposed electrode suitable for real sample analysis with such surface renewing. In Fig. 8, representative examples of SWV determination of DA in the injection sample after its dilution with 0.9% NaCl solution with two independently prepared ox-MWCNT/CPE surfaces (a, b) are presented together with corresponding analytical curves (insets), demonstrating the good reproducibility of the method as well as drop coating procedure. As it can be seen from Table 4, the obtained results for the DA hydrochloride content in the injection sample were in good agreement with the declared value by the producer (50 mg in 5 mL of injection solution) in all cases with RSD of the method below 1.0% and recovery in the range from 99.44 to 99.94%. Also, it can be concluded that the expected concentration of DA hydrochloride was found in all investigated types of infusion solutions meaning that the matrix did not affect the change in concentration of the active ingredient.

SWV determination of DA in injection sample previously diluted with 0.9% NaCl infusion by the standard addition method and two independently prepared ox-MWCNT/CPE surfaces (a, b). The curves: baseline (1), sample (2), and successive DA standard additions (3–5). The insets present the appropriate analytical curves. Supporting electrolyte, 0.1 M phosphate buffer pH 6.3

The present study elaborates a very simple, easy to prepare and use advanced working electrode design, made only from the oxidized form of MWCNTs and a classical CPE, and its excellent analytical voltammetric behavior via direct cathodic SWV determination of DA in the low micromolar concentration range. The superior DA reduction signal generation on ox-MWCNT/CPE in regard to those received by homemade and commercially available MWCNTs containing CPEs and the SWCNT/CPE allows the assumption that the further fine chemical tuning of the types and amounts of oxo functional groups at the MWCNTs can lead to the next stage of direct cathodic DA analytical signal sensitivity enhancement.

Conclusions

A very simple, low-cost, and reliable direct SWV method for trace-level determination of DA based on its reduction was developed. Different carbon-based nanomaterials either homemade or commercially available were used for CPE surface modification, whereby the best analytical performance showed an electrode modified with chemically oxidized MWCNTs (ox-MWCNT/CPE) which exhibits remarkable electrocatalytic effects on the DA redox reaction. ox-MWCNT/CPE in the optimized form concerning the amount of the modifier together with 0.1 M phosphate buffer pH 6.3 as supporting electrolyte proved to be a convenient analytical tool for an enhanced trace-level detection of DA down to 4.89 ng mL−1 in the model solution. Beside the easy preparation procedure, good sensitivity, and selectivity, the designed sensor showed excellent repeatability and reproducibility. Additionally, it was successfully applied for determination of DA content in the injection sample after its dilution with the appropriate type of infusion solution using the optimized analytical protocol. So, the developed SWV method was found to be effective for obtaining fast information in terms of quality control of pharmaceutical formulations containing DA as active ingredient. Further work will be directed toward the improvement of the existing method as well as expansion of the application field of ox-MWCNT/CPE and similar types of electrodes, especially concerning the determination of some other biologically important compounds.

References

Missale C, Nash SR, Robinson SW, Jaber M, Caron MG (1998) Dopamine receptors: from structure to function. Physiol Rev 78:189–225

Sajid M, Nazal MK, Mansha M, Alsharaa A, Jillani SMS, Basheer C (2016) Chemically modified electrodes for electrochemical detection of dopamine in the presence of uric acid and ascorbic acid: a review. Trends Anal Chem 76:15–29

Li Y, Gu Y, Zheng B, Luo L, Li C, Yan X, Zhang T, Lu N, Zhang Z (2017) A novel electrochemical biomimetic sensor based on poly(Cu-AMT) with reduced graphene oxide for ultrasensitive detection of dopamine. Talanta 162:80–89

Pourghobadi Z, Neamatollahi D (2017) Voltammetric determination of dopamine using modified glassy carbon electrode by electrografting of catechol. J Serb Chem Soc 82:1053–1061

Dhanjai SA, Lu X, Wu L, Tan D, Li Y, Chen J, Jain R (2018) Voltammetric sensing of biomolecules at carbon based electrode interfaces: a review. Trends Anal Chem 98:174–189

Gupta AK, Swarnkar S, Kumar GK, Goyal V, Chadda RK, Hariprasad G (2017) Dopamine based pharmaco-therapeutics of schizophrenia and Parkinson’s disease: two ends of one spectrum. Ann Pharmacol Pharm 2:1–6

Perry M, Li Q, Kennedy RT (2009) Review of recent advances in analytical techniques for the determination of neurotransmitters. Anal Chim Acta 653:1–22

Baranwal A, Chandra P (2018) Clinical implications and electrochemical biosensing of monoamine neurotransmitters in body fluids, in vitro, in vivo, and ex vivo models. Biosens Bioelectron 121:137–152

Li N, Zheng L, Liao F, Zheng H, Suye S (2019) Fabrication of PEI-Fc/SGO multilayer films modified electrode through LBL assembly technique for the detection of dopamine. Ionics 25:2823–2833

Jackowska K, Krysinski P (2013) New trends in the electrochemical sensing of dopamine. Anal Bioanal Chem 405:3753–3771

Nieoullon A (2002) Dopamine and the regulation of cognition and attention. Prog Neurobiol 67:53–83

World Health Organization (2018) The international pharmacopoeia - eighth edition. World Health Organization, Dept. of Essential Medicines and Pharmaceutical Policies, Geneva

Numan A, Shahid MM, Omar FS, Ramesh K, Ramesh S (2017) Facile fabrication of cobalt oxide nanograin-decorated reduced graphene oxide composite as ultrasensitive platform for dopamine detection. Sensors Actuators B Chem 238:1043–1051

Baig N, Rana A, Kawde A-N (2018) Modified electrodes for selective voltammetric detection of biomolecules. Electroanalysis 30:2551–2574

Huang D-Q, Chen C, Wu Y-M, Zhang H, Sheng L-Q, Xu H-J, Liu Z-D (2012) The determination of dopamine using glassy carbon electrode pretreated by a simple electrochemical method. Int J Electrochem Sci 7:5510–5520

Huang J, Liu Y, Hou H, You T (2008) Simultaneous electrochemical determination of dopamine, uric acid and ascorbic acid using palladium nanoparticle-loaded carbon nanofibers modified electrode. Biosens Bioelectron 24:632–637

Bagheri H, Pajooheshpour N, Jamali B, Amidi S, Hajian A, Khoshsafar H (2017) A novel electrochemical platform for sensitive and simultaneous determination of dopamine, uric acid and ascorbic acid based on Fe3O4-SnO2-Gr ternary nanocomposite. Microchem J 131:120–129

Kalcher K, Svancara I, Buzuk M, Vytras K, Walcarius A (2009) Electrochemical sensors and biosensors based on heterogeneous carbon materials. Monatsh Chem 140:861–889

Beyene NW, Kotzian P, Schachl K, Alemu H, Turkušić E, Chopra A, Moderegger H, Švancara I, Vytřas K, Kalcher K (2004) (Bio)sensors based on manganese dioxide-modified carbon substrates: retrospections, further improvements and applications. Talanta 64:1151–1159

Agüí L, Yáñez-Sedeño P, Pingarrón JM (2008) Role of carbon nanotubes in electroanalytical chemistry. A review. Anal Chim Acta 622:11–47

Alothman ZA, Bukhari N, Wabaidur SM, Haider S (2010) Simultaneous electrochemical determination of dopamine and acetaminophen using multiwall carbon nanotubes modified glassy carbon electrode. Sensors Actuators B Chem 146:314–320

Jo S, Jeong H, Bae SR, Jeon S (2008) Modified platinum electrode with phytic acid and single-walled carbon nanotube: application to the selective determination of dopamine in the presence of ascorbic and uric acids. Microchem J 88:1–6

Bandaru PR (2007) Electrical properties and applications of carbon nanotube structures. J Nanosci Nanotechnol 7:1–29

Yang C, Denno ME, Pyakurel P, Venton BJ (2015) Recent trends in carbon nanomaterial-based electrochemical sensors for biomolecules: a review. Anal Chim Acta 887:17–37

Henstridge MC, Dickinson EJF, Aslanoglu M, Batchelor-McAuley C, Compton RG (2010) Voltammetric selectivity conferred by the modification of electrodes using conductive porous layers or films: the oxidation of dopamine on glassy carbon electrodes modified with multiwalled carbon nanotubes. Sensors Actuators B Chem 145:417–427

Gooding JJ (2005) Nanostructuring electrodes with carbon nanotubes: a review on electrochemistry and applications for sensing. Electrochim Acta 50:3049–3060

Wu K, Fei J, Hu S (2003) Simultaneous determination of dopamine and serotonin on a glassy carbon electrode coated with a film of carbon nanotubes. Anal Biochem 318:100–106

Wu K, Hu S (2004) Electrochemical study and selective determination of dopamine at a multi-wall carbon nanotube-Nafion film coated glassy carbon electrode. Microchim Acta 144:131–137

Deng C, Chen J, Wang M, Xiao C, Nie Z, Yao S (2009) A novel and simple strategy for selective and sensitive determination of dopamine based on the boron-doped carbon nanotubes modified electrode. Biosens Bioelectron 24:2091–2094

Cui R, Wang X, Zhang G, Wang C (2012) Simultaneous determination of dopamine, ascorbic acid, and uric acid using helical carbon nanotubes modified electrode. Sensors Actuators B Chem 161:1139–1143

Zhang B, Huang D, Xu X, Alemu G, Zhang Y, Zhan F, Shen Y, Wang M (2013) Simultaneous electrochemical determination of ascorbic acid, dopamine and uric acid with helical carbon nanotubes. Electrochim Acta 91:261–266

Zhang M, Gong K, Zhang H, Mao L (2005) Layer-by-layer assembled carbon nanotubes for selective determination of dopamine in the presence of ascorbic acid. Biosens Bioelectron 20:1270–1276

Wang Z, Liu J, Liang Q, Wang Y, Luo G (2002) Carbon nanotube-modified electrodes for the simultaneous determination of dopamine and ascorbic acid. Analyst 127:653–658

Wang Z, Liang Q, Wang Y, Luo G (2003) Carbon nanotube-intercalated graphite electrodes for simultaneous determination of dopamine and serotonin in the presence of ascorbic acid. J Electroanal Chem 540:129–134

Zhang P, Wu F-H, Zhao G-C, Wei X-W (2005) Selective response of dopamine in the presence of ascorbic acid at multi-walled carbon nanotube modified gold electrode. Bioelectrochemistry 67:109–114

Moreno M, Sánchez Arribas A, Bermejo E, Chicharro M, Zapardiel A, Rodríguez MC, Jalit Y, Rivas GA (2010) Selective detection of dopamine in the presence of ascorbic acid using carbon nanotube modified screen-printed electrodes. Talanta 80:2149–2156

Hočevar SB, Wang J, Deo RP, Musameh M, Ogorevc B (2005) Carbon nanotube modified microelectrode for enhanced voltammetric detection of dopamine in the presence of ascorbate. Electroanalysis 17:417–422

Swamy BEK, Venton BJ (2007) Carbon nanotube-modified microelectrodes for simultaneous detection of dopamine and serotonin in vivo. Analyst 132:876–884

Tan C, Dutta G, Yin H, Siddiqui S, Arumugam PU (2018) Detection of neurochemicals with enhanced sensitivity and selectivity via hybrid multiwall carbon nanotube-ultrananocrystalline diamond microelectrodes. Sensors Actuators B Chem 258:193–203

Britto PJ, Santhanam KSV, Ajayan PM (1996) Carbon nanotube electrode for oxidation of dopamine. Bioelectrochem Bioenerg 41:121–125

Cincotto FH, Canevari TC, Campos AM, Landers R, Machado SAS (2014) Simultaneous determination of epinephrine and dopamine by electrochemical reduction on the hybrid material SiO2/graphene oxide decorated with Ag nanoparticles. Analyst 139:4634–4640

Niesz K, Siska A, Vesselényi I, Hernadi K, Méhn D, Galbács G, Kónya Z, Kiricsi I (2002) Mechanical and chemical breaking of multiwalled carbon nanotubes. Catal Today 76:3–10

Zbiljić J, Vajdle O, Guzsvány V, Molnar J, Agbaba J, Dalmacija B, Kalcher K (2015) Hydrodynamic chronoamperometric method for the determination of H2O2 using MnO2-based carbon paste electrodes in groundwater treated by Fenton and Fenton-like reagents for natural organic matter removal. J Hazard Mater 283:292–301

Anojčić J, Guzsvány V, Vajdle O, Madarász D, Rónavári A, Kónya Z, Kalcher K (2016) Hydrodynamic chronoamperometric determination of hydrogen peroxide using carbon paste electrodes coated by multiwalled carbon nanotubes decorated with MnO2 or Pt particles. Sensors Actuators B Chem 233:83–92

Anojčić J, Guzsvány V, Vajdle O, Kónya Z, Kalcher K (2018) Rapid amperometric determination of H2O2 by a Pt nanoparticle/Vulcan XC72 composite-coated carbon paste electrode in disinfection and contact lens solutions. Monatsh Chem 149:1727–1738

Švancara I, Metelka R, Vytřas K (2005) Piston-driven carbon paste electrode holders for electrochemical measurements. In: Vytřas K, Kalcher K (eds) Sensing in electroanalysis. University of Pardubice, Pardubice, pp 7–18

Guzsvány V, Anojčić J, Radulović E, Vajdle O, Stanković I, Madarász D, Kónya Z, Kalcher K (2017) Screen-printed enzymatic glucose biosensor based on a composite made from multiwalled carbon nanotubes and palladium containing particles. Microchim Acta 184:1987–1996

Guzsvány V, Anojčić J, Vajdle O, Radulović E, Madarász D, Kónya Z, Kalcher K (2019) Amperometric determination of glucose in white grape and in tablets as ingredient by screen-printed electrode modified with glucose oxidase and composite of platinum and multiwalled carbon nanotubes. Food Anal Methods 12:570–580

Stobinski L, Lesiak B, Kövér L, Tóth J, Biniak S, Trykowski G, Judek J (2010) Multiwall carbon nanotubes purification and oxidation by nitric acid studied by the FTIR and electron spectroscopy methods. J Alloys Compd 501:77–84

Osswald S, Havel M, Gogotsi Y (2007) Monitoring oxidation of multiwalled carbon nanotubes by Raman spectroscopy. J Raman Spectrosc 38:728–736

Panic S, Guzsvány V, Kónya Z, Kukovecz Á, Boskovic G (2017) Kinetic, equilibrium and thermodynamic studies of thiamethoxam adsorption by multi-walled carbon nanotubes. Int J Environ Sci Technol 14:1297–1306

Ouyang Y, Cong LM, Chen L, Liu QX, Fang Y (2008) Raman study on single-walled carbon nanotubes and multi-walled carbon nanotubes with different laser excitation energies. Phys E 40:2386–2389

Bokobza L, Zhang J (2012) Raman spectroscopic characterization of multiwall carbon nanotubes and of composites. Express Polym Lett 6:601–608

Zhuang X, Chen D, Zhang S, Luan F, Chen L (2018) Reduced graphene oxide functionalized with a CoS2/ionic liquid composite and decorated with gold nanoparticles for voltammetric sensing of dopamine. Microchim Acta 185:166–174

Luan F, Zhang S, Chen D, Zheng K, Zhuang X (2018) CoS2-decorated ionic liquid-functionalized graphene as a novel hydrazine electrochemical sensor. Talanta 182:529–535

Chen D, Zhuang X, Zhai J, Zheng Y, Lu H, Chen L (2018) Preparation of highly sensitive Pt nanoparticles-carbon quantum dots/ionic liquid functionalized graphene oxide nanocomposites andapplication for H2O2 detection. Sensors Actuators B Chem 255:1500–1506

Švancara I, Kalcher K, Walcarius A, Vytras K (2012) Electroanalysis with carbon paste electrodes. CRC Press, Boca Raton

Mikysek T, Švancara I, Kalcher K, Bartoš M, Vytřas K, Ludvík J (2009) New approaches to the characterization of carbon paste electrodes using the ohmic resistance effect and qualitative carbon paste indexes. Anal Chem 81:6327–6333

Brownson DAC, Banks CE (2014) The handbook of graphene electrochemistry. Springer-Verlag, London

McCreery RL (2008) Advanced carbon electrode materials for molecular electrochemistry. Chem Rev 108:2646–2687

Wang J, Yang S, Guo D, Yu P, Li D, Ye J, Mao L (2009) Comparative studies on electrochemical activity of graphene nanosheets and carbon nanotubes. Electrochem Commun 11:1892–1895

Tashkhourian J, Sheydaei O, Nami-Ana SF (2018) Copper nanoclusters conjugated silica nanoparticles modified on carbon paste as an electrochemical sensor for the determination of dopamine. Appl Organomet Chem 32:e4196

Mazloum-Ardakani M, Beitollahi H, Ganjipour B, Naeimi H, Nejati M (2009) Electrochemical and catalytic investigations of dopamine and uric acid by modified carbon nanotube paste electrode. Bioelectrochemistry 75:1–8

Adekunle AS, Agboola BO, Pillay J, Ozoemena KI (2010) Electrocatalytic detection of dopamine at single-walled carbon nanotubes–iron(III) oxide nanoparticles platform. Sensors Actuators B Chem 148:93–102

Mazloum-Ardakani M, Naser-Sadrabadi A, Sheikh-Mohseni MA, Benvidi A, Naeimi H, Karshenas A (2013) An electrochemical sensor based on carbon nanotubes and a new Schiff base for selective determination of dopamine in the presence of uric acid, folic acid, and acetaminophen. Ionics 19:1663–1671

Nagy G, Rice MR, Adams RN (1982) A new type of enzyme electrode: the ascorbic acid eliminator electrode. Life Sci 31:2611–2616

Funding

The authors acknowledge the financial support of the Ministry of Science and Technological Development of the Republic of Serbia (Project Nos. 172012 and 172059) and the CEEPUSIII (CZ-0212-12-1819) network.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 493 kb)

Rights and permissions

About this article

Cite this article

Anojčić, J., Guzsvány, V., Kónya, Z. et al. Rapid, trace-level direct cathodic voltammetric determination of dopamine by oxidized multiwalled carbon nanotube–modified carbon paste electrode in selected samples of pharmaceutical importance. Ionics 25, 6093–6106 (2019). https://doi.org/10.1007/s11581-019-03156-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-019-03156-5