Abstract

A novel and sensitive electrochemical sensor for the electrochemical investigation of pantoprazole (PPZ) have been established based on single-walled carbon nanotubes-modified carbon paste electrode (SWCNTs/CPE). The developed SWCNTs/CPE has been characterized by scanning electron microscopy (SEM), cyclic voltammetry (CV), and electrochemical impedance spectroscopy (EIS). An excellent electrocatalytic activity is observed for the modified electrode with respect to pantoprazole. The phosphate buffer solution (PBS) of pH 7.0 was used as an analytical medium, in which the pantoprazole exhibited well-defined oxidation peak at + 1.09 V and the process was found to be irreversible and diffusion-controlled. The effects of various experimental parameters such as pH, scan rate (υ), and concentration (C) on the voltammetric response are investigated. The electrochemical parameters such as surface concentration (Γ), electron transfer coefficient (α), and standard rate constant (k0) of pantoprazole at modified electrode have been determined. Under the optimized experimental conditions, the proposed sensor is found to exhibit a rapid response towards pantoprazole in the linear range from 10 × 10−9 to 400 × 10−9 M with low detection limit of 4.9 × 10−10 M. The analytical applicability of the proposed sensor has been successfully evaluated for the determination of pantoprazole present in pharmaceutical dosages, human serum, and urine samples with respect to sensitivity, repeatability, reproducibility, specificity, accuracy, and precision.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Acid-related disorders are common management problems in clinical practices. These disorders include gastro-esophageal reflux disease (GORD), peptic ulcer disease, and stress-related erosive syndrome. The effective management of these acid-related disorders is successful suppression of gastric acid production [1]. The commonly used medications to treat the acid-related disorders include antacids, H2-receptor antagonists (H2RAs), and proton pump inhibitors (PPIs).

The PPIs are the most important group of drugs whose main action is a pronounced and long-lasting reduction of gastric acid production. The PPIs are present in the field of gastroenterology since from the past 15 years and they are the most potent inhibitors of acid secretion [2]. They are much more effective than H2RAs in the management of GORD [3] and peptic disease [4]. The PPIs are working by undergoing acid-catalyzed conversion to reactive species, which are permanent cations. These reactive species then bind covalently to H+, K+-ATPase, causing irreversible inhibition of the final step in gastric acid secretion [1]. There are only a few commercially available PPIs at worldwide; among those, pantoprazole is one of the most important PPIs for treatment of acid-related problems.

Pantoprazole, 5-(difluoromethoxy)-2-{[(3,4-dimethoxy-2pyridyl)methyl]sulfinyl}-1H-benzimidazole, is a highly gastric potent PPI being used in the treatment for disorders of gastric acid hyper secretion, ulcer disease, relief of symptoms, and healing of lesions in gastro-esophageal reflux disease [5].

Pantoprazole is the third PPI marketed in 1995 [6, 7] and is very effective against acid-peptic diseases such as duodenal and gastric ulcers, reflux esophagitis, and Helicobacter pylori eradication. It controls gastric acid secretion by inhibition of gastric H+, K+-ATPase, i.e., the enzyme responsible for final step in secretion of hydrochloric acid by gastric parietal cells [8, 9]. The pantoprazole was introduced as an alternative to anti-histamines, since those have more side effects when administered against for the treatment of gastrointestinal ulcers [10]. During the research, it has been revealed that there are no significant differences between pantoprazole and other PPIs in the rate of endoscopic healing of reflux esophagitis after 8 weeks [11], in upper gastrointestinal hemorrhage induced by hypertensive encephalorrhagia [12], and in regard to transfusion units, death, surgery, and rebleeding [13]. However, there is a difference in pharmacokinetic and pharmacodynamic profiles that might influence their clinical utility.

The methods used for its assay determination in pharmaceutical formulations and in biological samples involve high-performance liquid chromatography [14,15,16,17,18,19], capillary electrophoresis [20], spectrophotometry [21,22,23], and potentiometry [10]. However, these methods have several disadvantages such as high-cost, long analysis time, lengthy procedures for sample preparation, low sensitivity, less selectivity, and in some cases make them unsuitable for routine analyses [24]. Recently, electrochemical techniques have been widely explored for the determination of biologically important molecules in regular clinical and industrial applications because of their advantages of high sensitivity, less time-consuming, and low costs over other analytical methods [25]. Since pantoprazole is an electroactive molecule, it can be determined using electroanalytical techniques. However, at traditional electrode surface, pantoprazole exhibits sluggish voltammetric response. Hence, considerable efforts have been devoted to develop chemically modified electrodes (CMEs) to enhance the voltammetric response and analytical performance for the detection of electroactive organic compounds, since CMEs have the ability to catalyze the electrode processes through (i) a significant decrease in over-potential and (ii) a selective interaction of electron mediator with the target analyte [26, 27]. Thus, the development of novel, simple, sensitive, and cost-effective modified electrodes for investigation of pantoprazole present in pharmaceutical formulations and biological samples is of great importance. In the literature, there are very few electrochemical methods reported for the determination of pantoprazole, such as hanging mercury drop electrode (HMDE) [27, 28], glassy carbon electrode, ex situ plated antimony film electrode, and carbon paste electrode (CPE) [28, 29].

Recently, the electrochemical methods have established a considerable attention in the field of pharmaceutical analysis as well as biologically important molecules due to their significant advantages and extensive applications. The methods have attracted enormous interest due to their advantages of simplicity, rapid response, excellent reproducibility, good stability, sensitivity, and low cost and also these techniques attained reasonable accuracy and precision. Moreover, during the analysis from these methods, there is no need for derivatization or time-consuming extraction steps over other techniques [30]. Further, the electrochemical methods offer the practical advantages including wide linear concentration range, low expense of instrument, possibility of miniaturization, suitability for real-time detection, and less sensitivity to matrix effects in comparison with separation and spectral methods [31]. Therefore, it is essential to develop a better and more significant method for the routine analysis of biologically important molecules. Hence, in recent years, the electrochemical method has attracted wide attention and plays a crucial role.

Nowadays, electrochemical sensors and biosensors for pharmaceutical, food, agricultural, and environmental analyses have been growing rapidly due to electrochemical behavior of drugs and biomolecules and partly due to advances in electrochemical measuring systems. The merger between fast, sensitive, selective, accurate, miniaturizable, and low-cost electrochemistry-based sensing and fields like proteomics, biochemistry, molecular biology, nanotechnology, and pharmaceutical analysis leads to the evolution of electrochemical sensors [32].

Since the first report of electrode modification through the chemical approaches in 1979, it is still a field of paramount importance and an open area of research in modern electrochemistry. This is because the use of bare electrodes for the electrochemical determinations has a number of limitations, such as low sensitivity, poor reproducibility, slow electron-transfer kinetics, low stability over a wide range of solution compositions, and high overpotential at which the electron-transfer process occurs [33]. Hence, a major attention has been focused on the development of CMEs during the last few decades and they exploit the ability of certain surface-bound redox mediators to enhance the electron-transfer kinetics and thus lower the operating potentials. Therefore, relatively large amounts of electrochemical researches have been devoted to the development and applications of different types of CMEs.

The chemical modifications of bare electrodes with a suitable electroactive species offer significant advantages in the design and development of electrochemical sensors. In practice, the modification of electrode surface has been tried to reducing the overvoltage and overcoming the slow kinetics of many electrode processes. A further advantage of CMEs is that they are less prone to surface fouling and oxide formation compared to inert substrate electrodes and also they can able to separate the electroanalytical signals of solution components [34]. Presently, the CPEs are widely utilized to perform the electrochemical investigations of a variety of biological and pharmaceutical species owing to their low residual current and noise, ease of fabrication, wide anodic and cathodic potential ranges, rapid surface renewal, and low cost. Moreover, the CMEs can be easily prepared with by adding different substances to the bulk of CPEs in order to increase efficiency of electrochemical sensor with low cost towards the electrochemical investigations of biologically important molecules [30].

At present, among various modifiers, the carbon microtubules also known as carbon nanotubes (CNTs) in 1991 by Iijima [35] are gaining popularity in the modern electrochemistry as they are offering unique mechanical and electronic properties and chemical stability as the CNTs display intrinsic properties that include extremely large surface area, high mechanical strength, high electrical conductivities, and their inherent size and hollow geometry, which make them extremely attractive as substrates for heterogeneous catalysis and the subtle electronic properties suggest that CNTs have the ability to promote electron transfer rate [30, 36]. This is because of pentagonal defects and extra dimensional curvature present at the tips that can enhance the electron transfer rates and hence, the electrochemical sensors based on CNTs are proved to have excellent electrochemical properties, such as wide potential window and small background current, and also which showed very stable electrochemical behaviors, it could be used to catalyze the electrochemical reaction of some organic and bio-molecules [37].

Therefore, at present, the nanotechnology has become one of the most exciting fields at the forefront of analytical chemistry. A wide variety of nanomaterials, especially nanoparticles with different properties, have found a broad array of applications in different types of analytical methods. Owing to their small sizes (1–100 nm), the nanoparticles exhibit unique chemical, physical, and electronic properties that are different from those of bulk materials, and they can be used to construct novel and improved sensing devices, in particular electrochemical sensors which lead to growing interest in developing a new enhanced material and designing novel sensors with controlled features on a nanometric scale. Therefore, the integration of nanotechnology with electrochemistry is expected to produce major advances in the field of electrochemical sensors [38].

To the best of our knowledge, there are no reports on the usage of single-walled carbon nanotubes-modified carbon paste electrode (SWCNTs/CPE) for the electrochemical investigation of pantoprazole. Hence, in this article, development of SWCNTs/CPE for the electrochemical investigation of pantoprazole present in pharmaceuticals and biological samples using cyclic voltammetry (CV) and square wave voltammetry (SWV) has been presented Scheme 1.

Experimental

Chemicals and reagents

Pantoprazole was procured from Sigma-Aldrich, Bangalore, Karnataka, India, and used as received without purification. A stock solution of 1 μM pantoprazole was prepared in PBS of pH 7.0. The tablets containing pantoprazole content such as Pentab-20 mg and Pantozec-40 mg were purchased from local pharmaceutical shops, Shivamogga, Karnataka, India. The potassium di-hydrogen phosphate (KH2PO4) and di-potassium hydrogen phosphate (K2HPO4) were procured from Merck, Mumbai, India. Potassium ferricyanide (K3[Fe(CN)6]) was procured from Merck, Darmstadt, Germany. All the chemicals used were of analytical grade. The 0.2 M PBS was prepared and pH of the solutions was adjusted either by using H3PO4 or NaOH. All the reagents were prepared using double-distilled water.

Instrumentations

Electrochemical measurements were performed using electrochemical workstation (CHI660D, CH Instruments, USA) procured from Sinsil International, Bengaluru, Karnataka, India, and all the experiments were conducted in a standard three-electrode assembly, incorporating CPE or SWCNTs/CPE as working electrode, platinum wire as auxiliary electrode, and Ag/AgCl as reference electrode. The surface morphology of the modified electrode was analyzed by field emission scanning electron microscope (model: VEGA3 TESCAN) procured from Bangalore, India.

Analytical procedure

A stock solution of 1 μM pantoprazole was prepared by dissolving the required quantity of drug sample in 0.2 M PBS of pH 7.0 and CVs were recorded at sweep rates ranging from 10 to 170 mV s−1 with an initial sweep towards the positive potentials. A SWV technique was used for the determination of pantoprazole and optimized SWV parameters are as follows: initial potential (E) + 0.6 V s−1, final potential (E) + 1.3 V s−1, square wave amplitude (Esw) 0.01 V, square wave frequency (f) 15 Hz, and quiet time of 2 s.

Preparation of electrodes (CPE and SWCNTs/CPE)

The CPE was prepared by mixing pure graphite powder with binder oil (mineral oil) in the ratio 80:20 w/w. The mixture was uniformly ground using pestle and mortar for a period of 30 min. After homogenization, the resultant mixture was packed carefully without air gap in a glass tube of 3 mm inner diameter and a height of 6 cm. A copper wire was inserted to establish electrical contact. The surface of the electrode was renewed each time with butter paper. Similarly, the SWCNTs/CPEs were prepared using same procedure in addition to different concentrations of modifier (SWCNTs).

Preparations of pharmaceutical formulations

Pharmaceutical tablets containing pantoprazole such as Pantozec-40 mg and Pentab-20 mg were powdered separately. A suitable quantity of Pantozec-40 mg (10.85 mg) and Pentab-20 mg (20.96 mg) tablet powders were separately placed in 10-ml conical flasks. To the flask, about 5 ml of the PBS (pH 7.0) was added and sonicated for about 10 min at room temperature. The sonicated volumes of the flasks were making up to the mark using same PBS and sonicated once for about 20 min in order to achieve complete dissolution. The resultant solutions were filtered off using Whatman filter paper and used for the electrochemical studies.

Sample preparations of real matrices

Three real samples such as human serum and two different urine samples were collected from patients undergoing a treatment with Pantozec-40 mg (pantoprazole) at Kuvempu University Health Centre, Shivamogga, Karnataka, India, and the collected samples were used for the experiments immediately at short periods. Before electrochemical measurements, the collected serum sample was treated with 3 ml methanol as protein precipitating agent and the precipitated proteins were separated out by centrifugation for about 10 min at 10,000 rpm using REMI cooling centrifuge (model no. C-24PLUS Sr. No. 5330). The supernatant layer was filtered off through a 0.45-μm Millipore filter to obtain a protein-free serum sample. The urine samples of two different individuals were centrifuged separately at 10,000 rpm for about 10 min and the resultant solutions were filtered off using Whatman filter paper separately and used for further electrochemical studies.

Results and discussion

Surface morphology of CPE and SWCNTs/CPE

Scanning electron microscope (SEM) is a powerful tool to characterize the surface morphology of different composites. The surface morphology of CPE and SWCNTs/CPE were compared with each other. Figure 1a, b depicts the morphological features of CPE and SWCNTs/CPE, respectively. Figures showed a significant difference in the surface morphology of the electrodes. The SEM profile of CPE (Fig. 1a) shows porous and irregular flake-like structures of graphite powder. Also it is evident that the CPE is heterogeneous in nature with many cavities [39]. However, the surface morphology of modified SWCNTs/CPE shows a uniform distribution of SWCNTs with graphite powder (Fig. 1b) and forms a uniform surface with smaller number of cavities.

Electrochemical behavior of K3[Fe(CN)6] at CPE and SWCNTs/CPE

The K3[Fe(CN)6] is an important and valuable probe to verify the modification of electrodes as electrochemical behavior of K3[Fe(CN)6] varies with various electrodes. Therefore, the study of electrochemical behavior of K3[Fe(CN)6] at unmodified (CPE) and modified electrodes (SWCNTs/CPE) is very significant. Figure 2a depicts the CVs for blank solution (curve a) and 1 mM K3[Fe(CN)6] in 0.1 M KCl solution at CPE and SWCNTs/CPE (curves b and c, respectively). From Fig. 2a, it is evident that K3[Fe(CN)6] exhibits a poor electrochemical performance at CPE with large peak-to-peak potential separation (ΔEp) of 277 mV vs. Ag/AgCl electrode and broad wave shape. However, at the surface of SWCNTs/CPE, the electrochemical behavior of K3[Fe(CN)6] shows a significant improvement. A reduction in the value of ΔEp (163 mV) with subsequent increase in the magnitude of peak current clearly indicates that there could be a better reversible charge transfer process at SWCNTs/CPE. A better electrocatalytic activity at the surface of SWCNTs/CPE is attributed to the presence of SWCNTs, which increase the active surface area of the electrode and hence increased the rate of charge transfer reactions at modified electrode surface [40].

Electrochemical impedance spectroscopy (EIS) is another effective and significant technique to verify the characteristic surface modification features of different electrodes. The EIS plays a crucial role in studying the electrical conductivity, capacitance, and determination of electrochemical behavior of electrode surface in the modification processes [41]. Thus, EIS has been applied for the study of interfacial properties of CPE and SWCNTs/CPE using 1 mM K3[Fe(CN)6] in 0.1 M KCl. Figure 2b illustrates the results of EIS for unmodified CPE and modified SWCNTs/CPE electrodes. In Nyquist plots, diameter of the semicircle at higher frequencies presents interfacial electron transfer resistance and the linear portion at low frequencies corresponds to diffusion process [42, 43]. The inset in Fig. 2b shows the Randles equivalent circuit in which Rs represents resistance of electrolyte, and Cdl and Rct represent double-layer capacitance and charge resistance at electrode/electrolyte interface, respectively. From Randles equivalent circuits, the Rct values for unmodified CPE and modified SWCNTs/CPE are found to be 27.57 and 7.42 kΩ, respectively. The unmodified CPE exhibits a large semicircle with high Rct value, whereas the modified SWCNTs/CPE shows a small semicircle with low Rct value (within the interfacial layer). Therefore, the electron transfer apparent rate constant (kapp) can be determined by applying the equation:

where R is universal gas constant in J K−1 mol−1, T is absolute temperature in K, F is Faraday’s constant in C mol−1, and C is concentration in mM of K3[Fe(CN)6] solution. The calculated kapp values for the unmodified and modified electrodes are found to be 9.65 × 10−9 and 3.57 × 10−8 cm s−1, respectively. Therefore, the high kapp and low Rct values for the modified SWCNTs/CPE are an indicative of faster electron transfer process at the surface of modified electrode. The surface inhomogeneity (n) of SWCNTs/CPE and CPE were found to be 0.8353 and 0.9173, respectively. Lower value of surface inhomogeneity for SWCNTs/CPE indicates high heterogeneous nature of the modified electrode as compare to unmodified electrode (also observed in Fig. 1a, b).

The active surface area (A) of CPE and SWCNTs/CPE electrodes is determined using CV technique using 1 mM K3[Fe(CN)6] in 0.1 M KCl solution at different scan rates using the Randles-Sevcik for a reversible process.

where ip is anodic peak current in A, n is number of electrons transferred, A is surface area of the electrode in cm2, Do is diffusion coefficient in cm2 s−1, υ is scan rate in V s−1, and \( {C}_o^{\ast } \) is concentration of K3[Fe(CN)6] in mol L−1. For 1 mM K3[Fe(CN)6] in 0.1 M KCl solution, n = 1 and Do = 7.6 × 10−6 cm2 s−1; then from the slope of the plot of ipa vs. υ1/2, the active surface area of the electrode is calculated. The active surface areas of CPE and SWCNTs/CPE are found to be 0.0116 and 0.0197 cm2, respectively.

The surface concentration (Γ) of electroactive species was determined using the slope of plot of ip vs. υ [44]. The Γ has been calculated using the formula ip = n2F2υAΓ/4RT, where n is number of electrons transferred, F is Faraday’s constant (C mol−1), A is area of the electrode (cm2), Γ is surface concentration of the analyte (mol cm−2), and υ is scan rate (V s−1). The surface concentration (Γ) of pantoprazole is found to be 1.91 × 10−10 and 1.17 × 10−11 mol cm−2 for SWCNTs/CPE and CPE, respectively. The higher value for SWCNTs/CPE clearly proves that the presence of single-walled carbon nanotubes increases the surface concentration of pantoprazole at SWCNTs/CPE.

Influence of modifier concentration (SWCNTs)

The mixing of carbon paste with some selective adsorptive species (modifiers) remarkably increases the sensitivity of the CPEs [45, 46]. In the present study, single-walled carbon nanotubes were tested as modifiers, because of their good adsorptive properties [47]. The effect of modifier concentrations (SWCNTs) towards the determination of pantoprazole has been studied using 1 μM pantoprazole in PBS of pH 7.0. Figure 3 illustrates the electrochemical response of 1 μM pantoprazole in 0.2 M PBS of pH 7.0 at various wt% of SWCNTs [(2.5, 5.0, 7.5, 10.0, 12.5, 15, and 17.5 mg) (a–g)]; scan rate of 100 mV s−1; inset: effect of wt% of SWCNTs in CPE on anodic peak current of 1 μM pantoprazole at a scan rate of 100 mV s−1. The optimum modifier concentration should give the highest peak current, good resolution, and the longest distance from discharging current of the background [45, 48]. From Fig. 3, it is seen that a concentration of 5 wt% of SWCNTs/CPE (12.5 mg of SWCNTs) gives a highest peak intensity values in contras, to other concentrations of SWCNTs electrodes. This may be due to the fact that CPE with a modifier concentration of more than 5 wt% gives resistive voltammetric signals [49]. The modifier (SWCNTs) also influences the oxidation potential values. Therefore, based on the above observations, the electrode with 5 wt% of SWCNTs has been selected as the optimum concentration for development of SWCNTs/CPE as a sensor for better electrochemical investigation of pantoprazole in the present study.

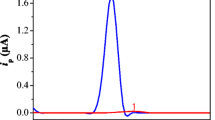

Electrochemical response of pantoprazole at CPE and SWCNTs/CPE

The electrochemical behavior of pantoprazole at CPE and SWCNTs/CPE has been studied by CV in potential range of 0.8–1.2 V at scan rate of 100 mV s−1. Figure 4a illustrates the electrochemical behavior of 0.2 M PBS of pH 7.0 (blank solution) at SWCNTs/CPE (curve a) and 1 μM pantoprazole at CPE (curve b) and SWCNTs/CPE (curve c) with scan rate of 100 mV s−1 (vs. Ag/AgCl). It is found that there are no observable redox peaks for 0.2 M PBS of pH 7.0 (blank solution) at CPE and SWCNTs/CPE, which indicate the electrochemical inactivity of the electrode towards PBS in the applied potential range [50]. Whereas in the same analytical medium, the pantoprazole gives irreversible oxidation peaks at CPE and SWCNTs/CPE in the applied potential range. The pantoprazole at CPE (curve b) showed poor electrochemical response. It oxidizes irreversibly at 1.12 V vs. Ag/AgCl with small peak current and broad peak shape. The pantoprazole at SWCNTs/CPE (curve c) in the same experimental conditions showed a better electrochemical performance as compare to that of CPE. At SWCNTs/CPE, the pantoprazole gave well-defined irreversible oxidation peak at 1.09 V vs. Ag/AgCl with a remarkable increase in peak current which is about twofold higher than that of CPE. The increase in oxidation peak current is attributed to the enhancement of electrode surface area due to the presence of SWCNTs (modifier) on the modified electrode SWCNTs/CPE. This increases conductivity and facilitates electron transfer between the analyte and electrode surface. However, during successive CVs, there is a decrease in the oxidation peak current at SWCNTs/CPE. Figure 4b illustrates the successive CVs of 1 μM pantoprazole in 0.2 M PBS of pH 7.0. The decrease in the oxidation peak current as the number of successive sweeps is ascribed to the adsorption of oxidation product of pantoprazole on the surface of modified electrode, which leads to the saturation of active surface area of the electrode [51]. Hence, to achieve more accuracy and precession, the voltammograms corresponding to the first cycle were recorded.

Effect of pH

The influence of pH on electro-oxidation of pantoprazole has been studied as the pH of a solution strongly influences the shape of voltammograms. Therefore, in the present system, the effects of pH ranging from 3.0 to 10.0 are studied by CVs. The peak current (ip), peak potential (Ep), and shape of the peak are significant in the estimation of an electroactive compound. Figure 5a illustrates the effect of pH of the solutions on oxidation peak current (ip) of pantoprazole at SWCNTs/CPE. The result showed that the pantoprazole shows the maximum peak current with well-defined oxidation peak at pH 7.0. Therefore, an optimum pH 7.0 is used for further electrochemical studies of pantoprazole. Similarly, the influence of solution pH on oxidation peak potential has been studied. It has been noticed that the peak potential (Ep) shifted to a less positive value with increase in solution pH from 3.0 to 10.0. Figure 5b illustrates the relationship between solution pH and the oxidation potential (Ep) of pantoprazole of different pH solutions ranging from 3.0 to 10.0 at SWCNTs/CPE. The oxidation potential (Ep) has been shifted to a less positive value with increase in solution pH from 3.0 to 10.0, which indicates the involvement of protons in the oxidation process [52, 53]. The plot of Ep vs. pH shows a linear relationship between formal potential (E0) and pH of the solution. The corresponding linear equation can be represented as follows: Epa = 0.0453 pH (3.0–10.0) + (− 1.44356); R = 0.98277 vs. Ag/AgCl. In order to substantiate the percentage of deviation of Ep values from linearity, the error bars have been included and the deviation is well within 1.5%. Here, the slope value of 45.3 mV/pH is close to anticipated Nernstian value of 59 mV for electrochemical processes involving same number of protons and electrons [41]. This suggests that the processes involve the transfer of same number of protons coupled to the same number of electrons [29, 54].

Influence of potential scan rate

The nature of electrochemical process at SWCNTs/CPE is studied by CVs of 1 μM pantoprazole in 0.2 M PBS of pH 7.0 at scan rates of 10, 30, 50, 70, 90, 110, and 130 mV s−1. The CVs of 1 μM pantoprazole in 0.2 M PBS at different scan rates at SWCNTs/CPE are shown in Fig. 6a. The oxidation potential (Ep) of pantoprazole shifts to a more positive potential with a subsequent increase in anodic peak current (ipa) as the scan rate has been increased from 10 to 130 mV s−1. The plot of square root of scan rate (υ\( {\upsilon}^{\raisebox{1ex}{$1$}\!\left/ \!\raisebox{-1ex}{$2$}\right.} \)) vs. anodic peak current (ipa) shows a linear relationship, indicating an electrochemical behavior of diffusion-controlled process [55]. The corresponding linear equation expressed as:

a The CVs of 1 μM pantoprazole at SWCNTs/CPE in PBS of pH 7.0 at different scan rates (a) 10, (b) 30, (c) 50, (d) 70, (e) 90, (f) 110, and (g) 130 mV s−1. b The relationship between oxidation peak current with square root of scan rate. c The relationship between oxidation peak potential with logarithmic scan rate

Figure 6b illustrates the relationship between anodic peak current (ipa) and square root of scan rate. The results clearly indicate a diffusion-controlled electrochemical process of pantoprazole at SWCNTs/CPE [56]. The error bars have been included and the deviation is well within 2.5%. Similarly, the plot of log ipa vs. log υ shows a linear relationship with corresponding equation as follows: log ipa (μA) = 0.25023 log υ + 0.20957; R = 0.98143, which provides further evidence for the diffusion-controlled process of pantoprazole at SWCNTs/CPE [57]. The error bars were inserted to notice the deviation from the linearity and the deviation is within 1.5%.

A linear relationship is obtained between the oxidation potential (Ep) of pantoprazole and logarithms of scan rates (log υ) (Fig. 6c). The corresponding linear equation can be expressed as follows: Ep (V) = 0.05134 log υ + 0.97274. The inserted error bars showed a deviation is well within 0.2%.

For irreversible electrode process, according to Laviron’s equation [58], the slope of Ep vs. log υ equals to 2.303RT/(1 − α)nF for anodic peak [59]. Therefore, on the basis of line slope, the value of charge-transfer coefficient (α) and number of transferred electrons (n) have been calculated and found to be 0.57 and 2.16, respectively. Consequently, the standard rate constant (k0) is determined using the following equation [60]:

where α is charge transfer coefficient, k0 is standard rate constant of the reaction (s−1), n is number of electrons transferred, υ is scan rate (mV s−1), R is universal gas constant (J K−1 mol−1), F is Faraday’s constant (C mol−1), and T is temperature (T = 298 K, R = 8.314 J K−1 mol−1, and F = 96,480 C mol−1). The value of αn can be calculated from the slope of Ep vs. log υ, and for the present system, it is 1.1517. Generally, the value of α is assumed to be 0.5 for an irreversible electrode process; the number of electrons (n) transferred in the electro-oxidation of pantoprazole is calculated and found to be 2. The value of E0 is determined from the intercept of the plot of Ep vs. log υ by extrapolation. In the present work, intercept of the plot of Ep vs. log υ was found to be 0.05134. Therefore, from the above equation, the standard rate constant (k0) for the oxidation of pantoprazole has been calculated as 1.07 s−1.

Square wave voltammetry

The square wave voltammetry (SWV) is a sensitive technique which provides well-defined analytical peaks even at lower concentrations of given analyte. The SWVs have the advantages of low background current and improved resolution. The major benefit is the cancelation of the capacitive current contributions and the response is chiefly dependent on the parameters of the excitement signal [61].

Optimization of the SWV parameters

The SWVs of 5 × 10−7 M pantoprazole in PBS of pH 7.0 were recorded at various experimental conditions. The variables of interest were studied over 10–200 mV of pulse height, 5–200 Hz of frequency, 1–25 mV of scan increment, and 1–20 s of quiet time. The results show that a pulse height of 10 mV, frequency of 15 Hz, and scan increment of 4 mV with a quiet time of 2 s are optimum parameters which reflect a voltammogram of high sensitivity and good peak morphology. Hence, these parameters are considered for further studies.

Square wave voltammetric determination of pantoprazole at SWCNTs/CPE

Under the optimum experimental conditions, the SWV has been adopted to study the anodic peak current response of pantoprazole at SWCNTs/CPE in the applied potential range of 0.6–1.3 V. Figure 7a illustrates a typical SWVs for different concentrations of pantoprazole at SWCNTs/CPE. It is found that the oxidation peak current (ip) of pantoprazole increases linearly with the increase in concentration (C) of pantoprazole. Therefore, the developed sensor is highly sensitive towards the determination of pantoprazole.

a SWVs of pantoprazole at SWCNTs/CPE in PBS at pH 7.0. [PPZ] (1) blank, (2) 10 × 10−9 M, (3) 15 × 10−9 M, (4) 20 × 10−9 M, (5) 25 × 10−9 M, (6) 30 × 10−9 M, (7) 40 × 10−9 M, (8) 50 × 10−9 M, (9) 60 × 10−9 M, (10) 100 × 10−9 M, (11) 200 × 10−9 M, (12) 300 × 10−9 M, (13) 400 × 10−9 M; scan increment, 4 m; frequency, 15 Hz, pulse height 10 mV, and quiet time, 2 s. b Calibration plot of ip (μA) vs. [PPZ] in PBS of pH 7.0

Validation of the developed method

The validation of the proposed method has been demonstrated with respect to electrochemical parameters such as linearity, limit of detection (LOD), limit of quantification (LOQ), selectivity, accuracy and precision, stability, reproducibility, robustness, ruggedness, and analytical applicability to real samples.

Linearity

The influence of concentration (C) of pantoprazole on oxidation peak current (ip) has been investigated using the modified SWCNTs/CPE. Figure 7b illustrates the influence of different concentrations of pantoprazole in 0.2 M PBS of pH 7.0 at SWCNTs/CPE. Under the optimized conditions, a very good linear correlation is observed between the peak current (ip) and concentration (C). A linear calibration range was obtained in the concentration range of 10 × 10−9 − 400 × 10−9 M. The corresponding regression equation is expressed as:

In order to substantiate the percentage of deviation of ipa values from linearity, the error bars have been inserted and the deviation is well within 1.5%.

Detection and quantification limit

The calibration curve data for detection of pantoprazole in bulk solution are given in Table 1. LOD and LOQ have been estimated using the linear calibration plot of peak current (ip) vs. concentration (C) of pantoprazole and the expressions are given by the following: kSDa/m, where k = 3 for LOD and 10 for LOQ, SDa is the standard deviation of blank runs of nine trials, and m is the slope of the calibration plot (Fig. 7b). The LOD and LOQ are found to be 4.9 × 10−10 and 1.64 × 10−9 M of pantoprazole, respectively. The achieved LOD and LOQ values from SWVs in the present work have clearly signified the sensitivity of the proposed method. Therefore, in order to substantiate the proposed method, the linear range and low detection limits are compared with the reported values of literature and tabulated in Table 1. This wide linear range, low detection and quantification values can be ascribed to the effect of SWCNTs, which provides a large surface area to increase the loading amount of pantoprazole from bulk solution. Meanwhile, increased electron transfer rate and amplified electrochemical signal at the electrode surface lead to good electric conductivity at SWCNTs/CPE as compare to that of CPE.

Stability of SWCNTs/CPE

To evaluate the stability of the developed sensor, it was placed in a PBS of pH 7.0 containing 5 × 10−7 M pantoprazole for 10 days and voltammograms were recorded and compared with the voltammograms obtained at regular intervals for the same sensor. The peak current (ip) decreases by 1.2% indicating a good stability of the developed sensor. The sensor is found to retain 99.7% of its initial peak current response for a concentration of 5 × 10−7 M at the end of 60 days, which shows a long-term storage stability of the sensor. Thus, the results indicate a good stability of the sensor towards determination of pantoprazole present in aqueous medium.

Specificity

The analyses of pharmaceutical and physiological samples by electrochemical methods using electrochemical sensors may be affected by some of interfering substances, which may affect the specificity of the sensors. The specificity of a sensor is defined its ability to measure the electrochemical response of an analyte (ip and Ep) in presence of some common interfering substances. Hence, specificity of the developed sensor towards the determination of pantoprazole is evaluated in presence of some probable interfering substances such as ascorbic acid, uric acid, glucose, alanine, tryptophan, glutamic acid, tyrosine, phenylalanine, Na+, K+, Ca+, and Mg+. The results show that the presence of interfering substances do not affect the determination of pantoprazole even when the concentrations of the interfering substances were tenfold higher than pantoprazole. The results clearly indicate that the developed SWCNTs/CPE has good efficacy towards the electrochemical investigation of pantoprazole in presence of probable interfering substances. Thus, the proposed procedure using SWCNTs/CPE is considered specific and can be successfully applied for electrochemical determination of pantoprazole present in aqueous samples.

Accuracy and precision

The accuracy and precision of the proposed method is verified by performing five replicate measurements for 5 × 10−7 M pantoprazole on a single day (intra-day assay) and after 5 days (inter-day assay). The intra-day precision of the method yields a relative standard deviation (RSD) of 1.5%. During real sample analysis, a good recovery percent is observed in the range of 98.32 to 101.96%, which indicates an excellent accuracy of the proposed method. Further, the inter-day precision is also investigated by measuring peak current (ip) response of the same solution (5 × 10−7 M pantoprazole) after a period of 5 days and the RSD is found to be 1.9% which clearly indicates a good reproducibility of present method. Hence, this method can be applied for the determination of pantoprazole present in aqueous samples.

Robustness

The robustness has been evaluated by introducing small variations in some of the important variables, such as pre-concentration potential, time, and pH. The results provide a reliability of the proposed method for the estimation of pantoprazole and hence it can be considered as robust. The mean percentage recoveries based on an average of five replicate measurements are not significantly affected within the studied range of variations of experimental parameters, and consequently, the proposed method can be considered as robust.

Ruggedness

Ruggedness is defined as the degree of reproducibility of results obtained by analysis of same sample under variety of normal test conditions such as different laboratories and different lots of reagents, under the same operational conditions at different elapsed time. The method is found to be rugged with the results of variation coefficients 1.95 and 2.61% for SWV method. Therefore, the results prove no statistical differences between different sets of experiments.

Comparison of analytical performance of present method with literature

A comparison between the analytical performance of SWCNTs/CPE towards determination of pantoprazole and previously reported methods is given in Table 1. The statistics have evidenced that SWCNTs/CPE has superior analytical performance with respect to LOD, wide linear range, selectivity, sensitivity, stability, and reproducibility over other reported methods. In addition, the present method is simple, low cost, and easy to perform.

Analytical applications

Analysis of pharmaceutical formulations

The analytical applicability of the proposed method was illustrated by the determination of pantoprazole present in pharmaceutical formulations such as Pantab-20 and Pantozec-40 tablets. The stock solutions were prepared as explained in the experimental section “Preparations of pharmaceutical formulations” and used for the studies. The SWVs were recorded under the optimized experimental conditions for Pantab-20 and Pantozec-40 tablet formulations and correlated with the calibration plot of Fig. 7b. The additions of pantoprazole were made using standard addition method and the results are tabulated in Table 2. The RSD of each sample for five parallel measurements are less than 2.35%. The percentage recovery of Pantab-20 and Pantozec-40 tablet formulations is investigated and the recovery values are found to be 99.36 and 101.96%, respectively. Thus, good percentage recovery values indicate that the determination of pantoprazole at SWCNTs/CPE is an effective method and it can be successfully applied for the quantitative estimation of pantoprazole in pharmaceutical formulations.

Analysis of pantoprazole in human serum and urine samples

In order to evaluate the validity and practical applicability, the proposed method using SWCNTs/CPE has been applied for the assay of pantoprazole present in real biological samples such as human serum and urine samples. The aliquots of samples were centrifuged at ~ 10,000 rpm for about 10 min at room temperature. The resultant samples were diluted to five times using PBS of pH 7.0 and subjected to SWV analyses under optimized parameters. The SWVs were correlated with the calibration plot of Fig. 7b and the results are given in Table 3. The recovery percentage values for serum, urine sample-1, and urine sample-2 are found to be 98.32, 101.66, and 99.16%, respectively. Therefore, the above values with good recovery percentage clearly suggest that the proposed voltammetric method using SWCNTs/CPE is free from interference of sample matrix and a reliable method for the estimation of pantoprazole present in real biological samples.

Conclusions

In the present work, a novel and facile electrochemical sensor has been developed for electrochemical investigation of pantoprazole using square wave voltammetry. The prepared sensor SWCNTs/CPE showed good electrocatalytic activities with respect to pantoprazole oxidation compared to CPE. The LOD and LOQ of pantoprazole at SWCNTs/CPE were found to be 4.9 × 10−10 and 16.4 × 10−10 M, respectively. The proposed sensor displayed reproducibility and highly stable performance which was unsusceptible to some of the common, biological, and metal ion interfering substances. The developed sensor exhibited excellent selectivity, sensitivity, and repeatability towards the determination of pantoprazole. Furthermore, the applicability of SWCNTs/CPE for real sample analysis was demonstrated successfully through the evaluation of pantoprazole present in pharmaceutical formulations and biological fluids. Hence, the present work provided a better possibility for the electrochemical investigation of pantoprazole in clinical as well as in pharmaceutical fields.

References

Fock KM, Ang TL, Bee LC, Lee EJD (2008) Proton pump inhibitors do differences in pharmacokinetics translate into differences in clinical outcomes. Clin Pharmacokinet 47:1–6

Richardson P, Hawkey CJ, Stack WA (1998) Proton pump inhibitors pharmacology and rationale for use in gastrointestinal disorder. Drugs 56:307–335

Radi A (2003) Determination of pantoprazole by adsorptive stripping voltammetry at carbon paste electrode. Il Farmaco 58:535–539

Leontiadis GI, Sharma VK, Howden CW (2006) Proton pump inhibitor treatment for acute peptic ulcer bleeding. Cochrane Database Syst Rev 25:CD002094

Nezhadali A, Shadmehri R (2014) Neuro-genetic multi-objective optimization and computer-aided design of pantoprazole molecularly imprinted polypyrrole sensor. Sensors Actuators B 202:240–251

Bardou M, Martin J (2008) Pantoprazole: from drug metabolism to clinical relevance. Expert Opin Drug Metab Toxicol 4:471–483

Zhang Y, Shi S, Liu Y, Chen X, Peng M (2011) Differential effects of Cu(II) and Fe(III) on the binding of omeprazole and pantoprazole to bovine serum albumin: toxic effect of metal ions on drug. J Pharm Biomed Anal 56:1064–1068

Poole P (2001) Pantoprazole. Am J Health Syst Pharm 58:999–1008

Nigovic B, Hocevar SB (2013) Square-wave voltammetric determination of pantoprazole using ex situ plated antimony-film electrode. Electrochim Acta 109:818–822

Noronha BV, Bindewald EH, de Oliveira MC, Papi MAP, Bergamini MF, Marcolino LH Jr (2014) Potentiometric determination of pantoprazole using an ion-selective sensor based on polypyrrole doped films. Mater Sci Eng C 43:517–520

Zheng RN (2009) Comparative study of omeprazole, lansoprazole, pantoprazole and esomeprazole for symptom relief in patients with reflux esophagitis. World J Gastroenterol 15:990–995

Liu J, Yu HY, He XH, Yin W (2008) Effects of pantoprazole and omeprazole on upper gastrointestinal haemorrhage induced by hypertensive encephalorrhagia. J Chin Gen Pract 11:2173–2174

Shavakhi A, Ataei S, Ataei M, Khodadostan M, Mohammad MR (2008) The comparison of oral omeprazole and intravenous pantoprazole effects in high risk upper gastrointestinal bleeding patients. J Isfahan Medical School (I.U.M.S) 26(90):242–248

Marques FD, Vianna-Soares CD, Nunan ED, Moreira-Campos LM (2007) A fast, validated HPLC method applied to the dissolution test of gastro-resistant capsules of pantoprazole pellets. J Liq Chromatogr Relat Technol 30:1833–1843

Thanikachalam S, Rajappan M, Kannappan V (2008) Stability-indicating HPLC method for simultaneous determination of pantoprazole and domperidone from their combination drug product. Chromatographia 67:41–47

Letica J, Markovic S, Zirojevic J, Nikoli K, Agbaba D (2010) High-performance liquid chromatographic determination of pantoprazole and its main impurities in pharmaceuticals. J AOAC Int 93:1121–1128

Dotsikas Y, Apostolou C, Soumelas S, Kolocouri F, Ziaka A, Kousoulos C, Loukas JL (2010) Validation of a novel, fully automated high throughput high performance liquid chromatographic/tandem mass spectrometric method for quantification of pantoprazole in human plasma. J AOAC Int 93:1129–1136

Li Y, Ding MJ, Ma J, Wang S, Wu XL, Xu HJ, Lu ZY, Zou JJ, Fan HW, Zhou XM (2011) Quantification of pantoprazole in human plasma using LC MS/MS for pharmacokinetics and bioequivalence study. Eur J Drug Metab Pharmacokinet 35:147–155

Noubarani M, Keyhanfar F, Motevalian M, Mahmoudian M (2011) Improved HPLC method for determination of four PPIs, omeprazole, pantoprazole, lansoprazole and rabeprazole in human plasma. J Pharm Pharm Sci 13:1–10

Eberle D, Hummel RB, Kuhn R (1997) Chiral resolution of pantoprazole sodium and related sulfoxides by complex formation with bovine serum albumin in capillary electrophoresis. J Chromatogr A 759:185–192

Karljikovic-Rajic K, Novovic D, Marinkovic V, Agbaba D (2003) UV-derivative spectrophotometry in the analysis of omeprazole and pantoprazole sodium salt and corresponding impurities. J Pharm Biomed Anal 32:1019–1027

Salama F, El-Abasawy N, Razeq SAA, Ismail MMF, Fouad MM (2003) Validation of the spectrophotometric determination of omeprazole and pantoprazole sodium via their metal chelates. J Pharm Biomed Anal 33:411–421

Rahman N, Bano Z, Azmi SNH (2006) Kinetic spectrophotometric analysis of pantoprazole in commercial dosage forms. Anal Sci 22:983–988

Goyal RN, Gupta VK, Chatterjee S (2010) Voltammetric biosensors for the determination of paracetamol at carbon nanotube modified pyrolytic graphite electrode. Sensors Actuators B 149:252–258

Khashaba PY, Ali HRH, El-Wekil MM (2017) Complexation based voltammetric determination of pantoprazole sodium in pharmaceutical formulations and rabbit plasma. Electroanalysis 29:890–897

Tsai TH, Wang SH, Chen SM (2011) Electrodeposited indigotetrasulfonate film onto glutaraldehyde-cross-linked poly-l-lysine modified glassy carbon electrode for detection of dissolved oxygen. J Electroanal Chem 659:69–75

Sivasubramanian R, Sangaranarayanan MV (2011) Detection of lead ions in pico-molar concentration range using under potential deposition on silver nanoparticles deposited glassy carbon electrodes. Talanta 85:2142–2147

Erk N (2003) Differential pulse anodic voltammetric determination of pantoprazole in pharmaceutical dosage forms and human plasma using glassy carbon electrode. Anal Biochem 323:48–53

Elsied AM, Mohamed HGG (2015) Sensitive electrochemical determination of pantoprazole sodium in pure form pharmaceutical formulations and biological fluid at glassy carbon electrode using differential pulls and square wave techniques. Int J Electrochem Sci 10:7147–7158

Foroughi MM, Beitollahi H, Tajik S, Akbari A, Hosseinzadeh R (2014) Electrochemical determination of N-acetylcysteine and folic acid in pharmaceutical and biological samples using a modified carbon nanotube paste electrode. Int J Electrochem Sci 9:8407–8421

Molaakbari E, Mostafavi A, Beitollahi H (2015) Simultaneous electrochemical determination of dopamine, melatonin, methionine and caffeine. Sensors Actuators B 208:195–203

Beitollahi H, Nekooei S (2016) Application of a modified CuO nanoparticles carbon paste electrode for simultaneous determination of isoperenaline, acetaminophen and N-acetyl-L-cysteine. Electroanalysis 28:645–653

Beitollahi H, Ivari SG, Torkzadeh-Mahani M (2018) Application of antibody–nanogold–ionic liquid–carbon paste electrode for sensitive electrochemical immunoassay of thyroid-stimulating hormone. Biosens Bioelectron 110:97–102

Beitollahia H, Tajik S, Maleh HK, Hosseinzadeh R (2013) Application of a 1-benzyl-4-ferrocenyl-1H-[1,2,3]-triazole/carbon nanotube modified glassy carbon electrode for voltammetric determination of hydrazine in water samples. Appl Organomet Chem 27:444–450

Iijima S (1991) Helica microtubules of graphitic carbon. Nature 354:56–58

Beitollahi H, Karimi-Maleh H, Khabazzadeh H (2008) Nanomolar and selective determination of epinephrine in the presence of norepinephrine using carbon paste electrode modified with carbon nanotubes and novel 2-(4-oxo-3-phenyl-3,4-dihydroquinazolinyl)-N′-phenyl-hydrazinecarbothioamide. Anal Chem 80:9848–9851

Beitollahi H, Sheikhshoaie I (2012) Electrochemical behavior of carbon nanotube/Mn(III) salen doped carbon paste electrode and its application for sensitive determination of N-acetylcysteine in the presence of folic acid. Int J Electrochem Sci 7:7684–7698

Moghaddam HM, Beitollahi H, Tajik S, Sheikhshoaie I, Biparva P (2015) Fabrication of novel TiO2 nanoparticles/Mn(III) salen doped carbon paste electrode: application as electrochemical sensor for the determination of hydrazine in the presence of phenol. Environ Monit Assess 187:407

Nandini S, Nalini S, Manjunatha R, Shanmugam S, Melo JS, Suresh GS (2013) Electrochemical biosensor for the selective determination of hydrogen peroxide based on the co-deposition of palladium, horseradish peroxidase on functionalized-graphene modified graphite electrode as composite. J Electroanal Chem 689:233–242

Goyal RN, Singh SP (2006) Voltammetric determination of paracetamol at C60-modified glassy carbon electrode. Electrochim Acta 51:3008–3012

Bayraktepe DE, Yazan Z, Polat K (2016) Sensitive and selective voltammetric determination of anti˗cancer agent shikonin on sepiolite clay/TiO2 nanoparticle/MWCNTs composite carbon paste sensor and investigation of its electro˗oxidation mechanism. J Electroanal Chem 780:38–45

Saidin MI, Isa IM, Ahmad M, Hashima N, Ghani SA (2017) Analysis of trace nickel by square wave stripping voltammetry using chloropalladium(II) complex-modified MWCNTs paste electrode. Sensors Actuators B Chem 240:848–856

Fu XC, Wu J, Li J, Xie CG, Liu YS, Zhong Y, Liu JH (2013) Electrochemical determination of trace copper(II) with enhanced sensitivity and selectivity by gold nanoparticle/single-wall carbon nanotube hybrids containing three-dimensional l-cysteine molecular adapters. Sensors Actuators B Chem 182:382–389

Ibrahim H, Temerk Y (2015) Novel sensor for sensitive electrochemical determination of luteolin based on In2O3 nanoparticles modified glassy carbon paste electrode. Sensors Actuators B 206:744–752

Lozano-Chaves ME, Palacios-Santander JM, Cubillana-Aguilera LM, Naranjo-Rodrıguez I, Hidalgo-Hidalgo-de-Cisneros JL (2006) Modified carbon-paste electrodes as sensors for the determination of 1,4-benzodiazepines: application to the determination of diazepam and oxazepam in biological fluids. Sensors Actuators B 115:575–583

Kalcher K (1990) Chemically modified carbon paste in voltammetric analysis. Electroanalysis 2:419–433

Zhang L, Cheng G, Fu C, Liu X, Pang X (2003) Adsorption and regeneration properties of tyrosine imprinted polymeric beads. Adsorpt Sci Technol 21:775–785

Kia M, Islamnezhad A, Shariati S, Biparva P (2011) Preparation of voltammetric biosensor for tryptophan using multi-walled carbon nanotubes. Korean J Chem Eng 28:2064–2068

Chethana BK, Arthoba Naik Y (2012) Electrochemical oxidation and determination of ascorbic acid present in natural fruit juices using a methionine modified carbon paste electrode. Anal Methods 4:3754–3759

Bard AJ, Faulkner LR (2001) Electrochemical methods: fundamental and applications, Second addition edn. John Wiley & Sons, INC, New York

Zhang S, Wu K, Hu S (2002) Voltammetric determination of diethylstilbestrol at carbon paste electrode using cetylpyridine bromide as medium. Talanta 58:747–754

Boopathia M, Won MS, Shim YB (2004) A sensor for acetaminophen in a blood medium using a Cu(II)-conducting polymer complex modified electrode. Anal Chim Acta 512:191–197

Yang H, Liu B, Ding Y, Li L, Ouyang X (2015) Fabrication of cuprous oxide nanoparticles-graphene nanocomposite for determination of acetaminophen. J Electroanal Chem 757:88–93

Altınoz S, Suslu I (2005) Determination of pantoprazole in pharmaceutical formulations and human plasma by square-wave voltammetry. Anal Lett 38:1389–1404

Kalambate PK, Rawool CR, Srivastava AK (2016) Voltammetric determination of pyrazinamide at graphene-zinc oxide nanocomposite modified carbon paste electrode employing differential pulse voltammetry. Sensors Actuators B 237:196–205

Zhanga ML, Huang DK, Cao Z, Liu YQ, He JL, Xiong JF, Feng ZM, Yin YL (2015) Determination of trace nitrite in pickled food with a nano-composite electrode by electrodepositing ZnO and Pt nanoparticles on MWCNTs substrate. LWT–Food Sci Technol 64:663–670

Nair SS, John SA, Sagara T (2009) Simultaneous determination of paracetamol and ascorbic acid using tetraoctylammonium bromide capped gold nanoparticles immobilized on 1,6-hexanedithiol modified Au electrode. Electrochim Acta 54:6837–6843

Laviron E (1979) General expression of the linear potential sweep voltammogram in the case of diffusion less electrochemical systems. J Electroanal Chem Interfacial Electrochem 101:19–28

Shleev S, Tkac J, Christenson A, Alexander ITR, Yaropolov JW, Whittaker GL (2005) Direct electron transfer between copper-containing proteins and electrodes. Biosens Bioelectron 20:2517–2554

Yunhua XW, Shengshui JH (2004) Studies on electrochemical oxidation of azithromycin and its interaction with bovine serum albumin. Bioelectrochemistry 64:91–97

Compton RG, Banks CE (2007) Understanding voltammetry. World Scientific Publishing Co. Pte. Ltd., London, pp 341–352

Radi A (2003) Square-wave adsorptive cathodic stripping voltammetry of pantoprazole. J Pharm Biomed Anal 33:687–692

Devi OZ, Basavaiah K, Vinay KB (2010) Sensitive and selective spectrophotometric determination of pantoprazole sodium in pharmaceuticals using permanganate. Chem Ind Chem Eng Q 16:97–102

Acknowledgements

The authors are grateful to acknowledge the Department of Science and Technology (SERB), New Delhi, India, for providing instrumental facilities to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manjunatha, P., Arthoba Nayaka, Y., Purushothama, H.T. et al. Single-walled carbon nanotubes-based electrochemical sensor for the electrochemical investigation of pantoprazole in pharmaceuticals and biological samples. Ionics 25, 2297–2309 (2019). https://doi.org/10.1007/s11581-018-2624-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-018-2624-1