Abstract

Electrodialysis (ED) is a separation process based on the transport of ions through ion exchange membranes. Ion exchange membranes are the key factor of this system. In this research, PVC/HIPS/ABS blended heterogeneous cation exchange membranes were made by solution casting method using tetrahydrofuran as solvent and cation exchange resin. The blend of various ratios of these polymers was prepared, and the best ratio was selected as the polymeric matrix. Montmorillonite K10 nanoparticles (with cation exchange characteristics) were then added to the appropriate polymeric matrix to enhance the electrochemical properties of the membrane. All the electrochemical properties of the synthesized membranes (with and without additives) were investigated. Montmorillonite K10 particles enhanced the membrane properties due to their cation exchange capacity. The best results were obtained with PVC/ABS binder and 0.03 additive ratio, where the membrane electrical resistance was decreased 37% while the IEC and transport number were improved 75 and 6%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrodialysis (ED) is a separation process which is applied in the production of potable water for more than 50 years. In ED system, the cation and anion exchange membranes are arranged in an alternating pattern between the anode and the cathode. Ion exchange membranes are one of the advanced separation membranes and the key part in an ED system [1, 2]. According to their structure and preparation method, ion exchange membranes can be classified into two main categories: homogeneous and heterogeneous membranes. Homogeneous membranes have good electrochemical properties but low mechanical strength. On the other hand, heterogeneous membranes have good mechanical strength but weak electrochemical properties [3]. In general, in order to have a successful ion exchange membrane, the membrane must possess high permselectivity, low electrical resistance, and good mechanical and chemical stabilities [2, 4, 5]. However, optimizing these properties is very difficult, since the parameters that determine different properties have opposite effects on each other. The key elements that specify the membrane characteristics are membrane raw materials and the type and concentration of fixed ionic parts [3].

Preparation of heterogeneous ion exchange membranes with viable electrochemical and mechanical properties is achieveable by utilizing appropriate binders [3]. Using polymeric matrices and their blends of convenient properties is a feasible procedure. Blending provides a convenient way of combining the mechanical, physical, or thermal properties of more than one material and results in producing a new material with properties viable for specific applications. This procedure is also a viable method as an alternative for synthesizing new polymers or copolymerization. However, blends made from incompatible polymers are usually weak. The solution prepared from miscible polymers is homogeneous and clear and does not separate into discrete phases [6, 7]. Acrylonitrile-butadiene-styrene (ABS) and high impact polystyrene (HIPS) are common modifiers which are added to PVC to improve its properties [6]. Polyvinyl chloride (PVC) is a flexible and durable polymer with high chemical and biological resistances. This polymer is inexpensive, available, and feasible to work with. Many researchers have utilized PVC as a polymeric matrix in preparing heterogeneous cation exchange membranes. [8–15]. ABS is a mixture of styrene, butadiene, and acrylonitrile. This polymer provides suitable strength, rigidity, toughness, and chemical resistance while offers good workability, electrical insulation characteristic, and relatively low cost [6, 7, 16]. HIPS has great toughness and impact strength, while its tensile strength is not promising. Meanwhile, this polymer is hydrophobic and has a brittle nature [6]. Synthesizing heterogeneous cation exchange membranes by using (ABS) and (HIPS) at different ABS to HIPS ratios is reported. The membranes based on HIPS have better electrochemical properties but lower mechanical and chemical strengths in comparison with those based on ABS. The best electrochemical properties were obtained by using 20 wt% ABS and 80 wt% HIPS, while the mechanical stability was inadequate [17]. Since ABS/HIPS blend has good electrochemical properties but a poor mechanical stability; and also ABS and HIPS are introduced as common modifiers for PVC; in this research PVC was added to the ABS/HIPS blend in order to enhance its mechanical stability as well as electrochemical properties.

Heterogeneous ion exchange membranes can be prepared through incorporation of ion exchange resin particles within a polymeric matrix. The ion exchange particles perform as functional groups and play a very effective role on the membrane characteristics [18]. Amberlite IR120 is a strongly acidic cation exchange resin which was used as functional groups in this research for the synthesis of membranes. This resin has been also used in water and waste water treatment [19].

Nanoparticles can be used as additives to improve the properties of ion exchange membranes. Uniform dispersion of nanoparticles in the polymeric matrix enhances the interactions among the polymeric matrix and fillers. Therefore, the active sites, i.e., nanoparticles, act more effectively to improve the membrane properties [20]. Nanoparticles affect the permeability, selectivity, hydrophilicity, conductivity, mechanical, and thermal stabilities of the polymeric membranes and thus improve the membrane performance [21]. One of the nanoparticles with a wide range of applications is nanoclay. Unlimited resources in nature, low-cost, platelet structure bearing high aspect ratio, high efficiency, hydrophilicity, and cation exchange capacity are some interesting features of nanoclay. Content and dispersion state of clay layers in the polymeric matrix is a key factor that affects the membrane physical and mechanical properties. To improve the membrane properties, moderate dispersion of nanostructured particles is crucial. One of the advantages of using nanoclay particles as filler is the disklike structure of these particles. Thus, the polymer chains could penetrate through the gaps between the disks and disorganize nanoclay layered structure, making nanoparticles dispersed in the polymeric matrix uniformly [22, 23]. If the membrane matrix was hydrophobic and did not possess any hydrophilic agent, nanoclay particles would aggregate in the matrix. In the presence of hydrophilic reagents, intensive stirring and sonication might effectively reduce the aggregation and separate the silicate layers. The existence of polar groups would improve the dispersion of nanoclay particles, as the montmorillonite is rich of hydroxyl groups and thus polymers with hydrophilic agents can diffuse within its layers [22]. Incorporating nanoclay particles in direct methanol fuel cell membranes, such as Nafion, sPEEK, PVA, and PVDF membranes, is reported. These particles improved membrane mechanical and thermal stability, enhanced proton conductivity (due to clay cation exchange capacity), increased water absorption (as a result of clay hydrophilicity), and decreased the methanol permeability [23–28].

In this research a heterogeneous cation exchange membrane was synthesized via an easy procedure. The effect of polymeric binders and the addition of nanoparticles on the membrane electrochemical and mechanical properties were investigated. For this purpose, the blend of PVC/HIPS/ABS was used as the polymeric matrix and Amberlite IR-120, a strong acid cation exchange resin, was employed as the functional groups. In order to modify and enhance the membrane properties, incorporation of nanoclay particles due to their suitable properties, such as unlimited sources in nature, layered structure, hydrophilicity, and cation exchange capacity, was employed. Membranes were prepared via solution casting followed by dry phase inversion. According to the previous studies [18, 29, 30], the size of resin particles, resin to polymer ratio, and polymer to solvent ratio were considered constant at 39 μm, 1/1 (wt. ratio), and 1/17 (wt./v), respectively.

This article is presented in two parts. In the first part, the effect of the blend ratio on the membrane properties was investigated and the best polymeric matrix was chosen for the incorporation of nanoclay particles. In the second part, the effect of nanoclay particles on the membrane properties was studied. To the best knowledge of the authors, the combination of PVC/HIPS/ABS blend as the polymeric matrix, Amberlite IR120 as the functional groups, and nanoclay as an additive for the heterogeneous cation exchange membranes has not been reported so far.

Experimental

Materials

Polyvinylchloride (PVC; grade 7054, density 490 g/L, viscosity 105 cm3/g) was obtained from BIPC, Iran. High impact grade polystyrene (HIPS) and acrylonitrile-butadiene-styrene (ABS), were supplied by T.P.C., Iran. Chemical structures of polymers are shown in Table 1. Tetrahydrofuran (THF), which was used as solvent, was obtained from Royalex Company. The cation exchange resin, Amberlite IR120, used as functional group reagent (strongly acidic cation exchange resin) and nanoparticles of montmorillonite K(10) clay (100 nm, 220 m2/g, CEC = 0.92–0.1 meq/g [22, 28]) used as additive, were obtained from Sigma Aldrich. Other Chemicals such as NaCl (purity: ≥ 99%), NaOH, and HCl were obtained from Loba Chemie Co., India.

Membrane preparation

The heterogeneous cation exchange membranes were prepared by distributing resin and additive particles in the polymeric solution followed by dry phase inversion. Cation exchange resins were dried in an oven at 50 °C for 24 h, powdered in a ball mill, and sieved (mesh −300 + 400). The polymeric solution was prepared by dissolving 1 g of polymer binder in 17 mL of THF solvent at room temperature while stirring until a homogeneous solution was obtained. The homogeneity of the solution at room temperature while no stirring was applied ensured the compatibility of the blend polymers. Subsequently, 1 g of resin particles was added to the polymeric solution and was stirred vigorously by means of a mechanical stirrer. In the case of adding nanoparticles, the clay and resin particles were simultaneously added to the polymeric solution. For a better dispersion of particles and breaking up any aggregation, the mixture was sonicated (ultrasonic homogenizer, Bandeline) for 30 min. Prior to casting, the mixture was further stirred by the mechanical stirrer for another 15 min. The mixture was cast on a flat, clean, and dry glass and was dried at room temperature overnight (dry phase inversion). Afterwards, the membrane was immersed in deionized water (wet phase inversion). The synthesized cation exchange membranes were further treated with HCl (immersing in 0.1 M HCl solution for 12 h) and NaCl (0.5 M for 24 h) solutions. In all experiments, the ratios of resin to binder and THF to binder were kept constant at 1/1 (w/w) and 17/1 (v/w), respectively. Five membranes with different polymer ratios were initially prepared and their properties were investigated. The optimum polymer matrix was chosen to be modified by nanoclay. The name and composition of the prepared membranes are presented in Table 2.

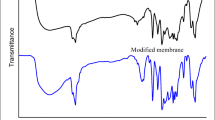

Membrane characterization

Membrane morphology

Scanning electron microscopy (SEM) was used to study the membrane structure as well as dispersion of functional groups and nanoclay particles. The membrane samples were cut into desired size and placed on a plate to be coated with gold. After coating the membrane surface, the images were taken at three magnifications of ×100, ×600, and ×1000.

Water content

In order to measure the membrane water content, it was immersed in deionized water for 24 h. The surface of the membrane was then wiped off by filter paper and weighed (W w ). The membrane was subsequently dried in an oven for 12 h at 50 °C until the membrane weight became constant (W d ). The difference between W w and W d represents the membrane water content as calculated by Eq. 1. Since the weight measurement of the wet and dry membranes is very sensitive, each measurement was repeated three times for every individual sample and the average value was then reported.

Ion exchange capacity and fixed ion concentration

Acid-base titration procedure was applied in order to measure the membrane ion exchange capacity (IEC). The membrane was initially immersed in 1 M HCl solution for 24 h to make sure that all of the exchangeable groups are converted to H+ form. The membrane was then washed and kept in deionized water overnight to remove any excess H+. After that, the membrane was placed in 1 M NaCl solution for 24 h. The content of liberated H+ ions in the solution was calculated through acid-base titration using 0.05 M NaOH solution and phenolphthalein as an indicator [17]:

where a is the volume (mL) of used NaOH and b is the normality of NaOH (meq/mL).

The fixed ion concentration (FIC) was then calculated through the following equation [17]:

Membrane potential and transport number

When two solutions of different concentrations are separated by a permselective membrane, a potential difference would be established between them. This potential difference is known as the membrane potential. The membrane potential is the result of Donnan and diffusion potentials. When both surfaces of an ion exchange membrane are in contact with electrolyte solutions of different concentrations, counter ions diffuse from the side of high concentration to that of low concentration, while the diffusion of co-ions is abundant. In the case that solutions are separated by a cation exchange membrane, the side of low concentration would be charged positively and the side of high concentration would be charged negatively. Thus the potential difference (membrane potential) will be generated which would hinder further diffusion of cations [31, 32].

Membrane potential can be directly measured in an electrolytic cell by standard electrodes (such as calomel electrodes). This potential was used for the calculation of membrane transport number and permselectivity. The cell that was used in this research is shown in Fig. 1. Two electrolyte solutions of different concentrations (C1 = 0.1 M and C2 = 0.01 M) were placed in two compartments and the concentrations were kept constant by circulating fresh solutions to both sides. The compartments were also stirred vigorously by means of mechanical stirrers to avoid any concentration polarization during the experiments. The potential which was developed across the membrane was measured by calomel electrodes (Azar electrode, Iran) and a digital multimeter (E m ). By using the measured potential and Eq. 4, the transport number of cation exchange membrane was calculated:

where t + , T (K), R (J/mol.K), F (J/V.geq.), z, and a 1 /a 2 are the transport number of cations, temperature, gas constant, Faraday constant, valence of cation, and the activity ratio of solutions in contact with both sides of the membrane, respectively.

The experiments were continued for 15 min and the potential was measured every 3 min until a constant value was achieved.

Permselectivity

Permselectivity or selectivity between co-ions/counter-ions was calculated by using the transport numbers of cation in the membrane and in the solution (Eq. 5) [18]:

In the above equation, t 0 is the cation transport number in the solution which is calculated through the cation mobility in the solution [18].

Donnan equilibrium

Donnan equilibrium which is established between the electrolyte solution and the ion exchange membrane is represented as the ratio of cation concentration in the membrane to that in the adjacent electrolyte solution [18, 30].

In Eq. 6 K ″, z i , and C i are Donnan equilibrium constant, the valence of the ion (absolute value), the cation concentration in the membrane and in the adjacent solution, respectively. Donnan equilibrium constant (K ″) can be calculated through the electroneutrality basis in the cation exchange membrane. The concentrations of cations and anions are calculated by Eqs. (7) and (8), respectively [18, 30]:

where C is the concentration of electrolyte solution. The ratio of cation/anion concentrations in the membrane phase determines the membrane selectivity between counter-ions and co-ions [18, 30].

Electrical resistance

In order to measure the membrane resistance, the membranes were immersed in 0.5 M NaCl solution for 24 h. Both compartments of the cell (Fig. 1) were filled with 0.5 M NaCl solution at room temperature and were fixed. An alternative current (frequency of 1500 Hz generated by an audio signal generator) was established across the cell. The cell resistance was measured with (R 1 ) and without (R 2 ) the membrane incorporation within the cell. Membrane electrical resistance (R m ) was calculated from the difference between R 1 and R 2 (R m = R 1 − R 2 ). The membrane total electrical resistance was calculated as follows [17]:

where A is the membrane surface area.

Membrane mechanical resistance

In order to study the mechanical stability of the prepared membranes, the tear resistance of the membranes was measured according to ASTM D1922–03 (Daventest, E 350/127, Wewlyn Garden City, England). To apply this measurement, all of the samples were cut into the standard shape and each test was repeated for five times for each and every individual sample. The average value of the measurement was then reported.

Results and discussion

Identification of the optimum blend ratio

The operational behavior of the prepared membranes depends on the membrane morphology; drying time (dry phase inversion time) has a great impact on the membrane morphology. By increasing the drying time, the membrane porosity is decreased. In other words, by increasing the solvent evaporation time, membrane pores become smaller and a dense membrane was obtained at a drying time of 24 h [18].

A heterogeneous cation exchange membrane composed of two different phases: continuous phase (polymer matrix) and dispersed phase (cation exchange resin particles). A membrane without the existence of resin particles although is completely homogeneous but would be incapable to transfer cations. Resin particles are the conductive regions and provide appropriate paths for cation exchange process; the polymeric matrix has no role in the ion exchange process [33]. The quality of dispersion of ion exchange resin particles has a great impact on the membrane behavior. When the cation exchange resin particles distribute uniformly in the polymeric matrix, adequate paths for the transfer of cations are formed, the accessibility to the resin particles would be enhanced and thus more conductive regions are developed. As such, the membrane transport number and permselectivity are enhanced and the membrane electrical resistance is reduced. The presence of more conductive regions in the membrane would intensify the uniform electrical field in the vicinity of the membrane and consequently decreases the concentration polarization [17, 18]. SEM images were taken in order to evaluate the membrane morphology and distribution of resin particles (Fig. 2). Both polymeric binder and resin particles are clearly specified in the images of this figure. As can be seen, by increasing the PVC to HIPS ratio, the membrane surface becomes more uniform and the distribution and dispersion of resin particles in the polymeric binder is enhanced. As it is also seen, the resin particles have been aggregated in the membrane containing almost no PVC.

By increasing the PVC to HIPS ratio, the amount of polar groups in the polymeric matrix increases, which is due to the polar group of chloride in PVC. The latter increases the interactions among the polymeric binder and resin particles and improves the distribution of charged particles, thus the accessibility to the particles is enhanced. In such a condition, the transfer of cations through the membrane is facilitated while the passage of anions is restricted and the membrane transport number and permselectivity are increased [18, 30]. The transport number and permselectivity of the prepared membranes at various blend ratios are shown in Fig. 3. By increasing the PVC content in the casting solution, dispersion of resin particles is improved, and as a result, the transport number and permselectivity of the membrane are increased.

Adequate dispersion of resin particles and hydrophilicity of the membrane surface would result in reducing the electrical resistance of the membrane, as well. In the synthesized membranes, where the content of ion exchange groups (resin particles) is similar, by improving the dispersion of resin particles, i.e., a more uniform and hydrophilic surface, the electrical resistance is decreased. By adequate distribution of particles, the ion exchange paths are improved and the ion mobility in the membrane is increased; therefore, the electrical resistance is decreased [18, 30, 34]. The obtained results are shown in Fig. 4. As it is seen, the increment of PVC in the membrane results in reduction of the electrical resistance.

The water content of the membranes versus the blend ratio is demonstrated in Fig. 5. By increasing the PVC percentage in the polymeric matrix from 0:80:20 to 20:60:20, (PVC:HIPS:ABS) the membrane water content is increased. This observation is attributed to the addition of polar group of chlorides to the matrix and thereby increasing the hydrophilicity of the membrane. On the other hand, by increasing the PVC content to 40%, the membrane water content is decreased. When the resin particles distribute more uniformly in the membrane, the membrane free spaces that can accommodate water are reduced and the total water content decreases. Meanwhile, by decreasing the amount of HIPS, the free volume which is due to the presence of HIPS phenyl rings is also reduced. However, by further increase in the PVC content, i.e., increase in the chloride polar groups, the membrane hydrophilicity enhances which subsequently increases the water content of the membrane.

The membranes based on HIPS have higher ion exchange capacities than the membranes based on PVC or ABS, due to the presence of phenyl rings in HIPS structure which act as steric hindrance and increase the free space among the polymeric chains. As such, in HIPS membranes the free volume is increased. In such a condition, the access to the ion exchange groups (resin particles) is enhanced and the membrane ion exchange capacity is improved. On the other hand, the presence of more polar groups such as chloride and nitrile in the membrane matrix enhances the interactions between the solution and the membrane surface which can facilitate the ion transfer through the membrane [17]. The results presented in Fig. 5 show that the membrane with the most HIPS content has the highest IEC. This observation is despite the fact that more polar groups are present in other membranes. By adding PVC to the membrane matrix, which results in a reduction in the free spaces, the IEC decreases. By further addition of PVC from 20 to 40%, the polar groups in the membrane increase and an increase in the IEC is observed. However, further increase in PVC (more decrease in HIPS) lowers the membrane ion exchange capacity.

The ratio of counter-ion (Na+) concentration to that of co-ions (Cl −) in the membrane matrix, is only a qualitative evaluation of the membrane selectivity. It is worth to mention that in the theory of Donnan equilibrium, the effects of concentration polarization, which can affect the membrane selectivity, have not been taken into account [34]. The fixed ion concentration is the ratio of IEC to water content (an independent parameter). The membrane with higher IEC and lower water content has a higher FIC. The variation of FIC versus the polymeric blend ratio is shown in Fig. 6. As it is shown, the highest FIC belongs to the membrane C, which has the lowest water content. The trend of variation of is very similar to that of FIC. By increasing FIC, the concentration of counter-ions in the membrane is increased while it is vice versa for the co-ions, i.e., electroneutrality. Thus, the concentration ratio of counter-ions to co-ions would be enhanced.

One of the advantages of polymeric blends is the improvement in the mechanical properties of the products [6]. The mechanical stability of the prepared membranes was investigated by tear resistance test. The obtained results which are presented in Table 3 demonstrate that by increasing the PVC content in the prepared membranes the mechanical stability is improved. HIPS has a more brittle structure than PVC and ABS, due to the presence of phenyl rings which have abundant mobility and rotation of the polymeric chains. Therefore, by reduction of HIPS content in the polymeric blend, the mechanical stability is increased. Moreover, by increasing the polar groups in the polymeric matrix, the interactions among the polymeric chains are enhanced and that would reinforce the membrane stability [17].

Incorporation of nanoclayparticles into the membrane

In this research, the membrane matrix with the most hydrophilic agents is membrane E (80 wt% PVC and 20 wt% ABS). Meanwhile, membrane E possesses the highest mechanical resistance and better electrochemical properties among all produced matrices. As such, various contents of nanoparticle (ratio of nanoparticle to total solid) (w/w) of 0.5/100, 1/100, 3/100, and 5/100 were added to the matrix.

Membrane morphology

In order to study the membrane morphology as well as dispersion of nanoclay, SEM images were taken from the surfaces of the prepared membranes (Fig. 7). The resin and nanoparticle regions are specified in the images. As can be seen, resin and nanoclay particles are very well distributed in the matrice, due to the presence of chloride and nitrile polar groups. Meanwhile, increasing the nanoclay ratio has led to a more uniform dispersion of resin particles. By increasing the additive ratio, the content of particles (nanoclay and resin) in the casting solution is increased, which leads to decrease of random distribution of the particles in the polymer solution and subsequently in the membrane matrix. Uniform dispersion of resin and nanoclay particles would result in a more uniform distribution of ionic sites on the membrane surface and thus more conducting regions are developed. The latter improves the electrochemical properties of the membranes [30, 35]. The SEM image of the membrane cross section is shown in Fig. 8 to emphasize the dense structure of synthesized membrane. As can be seen, a completely dense structure is obtained.

Water content

The amounts of water content of the membranes after adding nanoparticles are presented in Fig. 9. Since montmorillonite K10 is rich in hydroxyl groups and thus is very hydrophilic, by adding its particles to the membrane matrix the membrane hydrophilicity is enhanced, and the water content is increased.

Ion exchange capacity

The ion exchange capacity versus nanoclay ratio is demonstrated in Fig. 9. By adding nanoclay particles to the membrane matrix, due to the cation exchange capacity of montmorillonite K10, the IEC of the membrane is enhanced [22, 28, 36, 37]. As it can be seen, the membrane IEC is increased up to 3 wt% of nanoclay particles. Despite the well distribution of the nanoparticles in the membrane (see Table 2) due to the existence of polar groups, the IEC decreased at this ratio. This reduction is attributed to the coverage of the particles by polymeric chains and thus the accessibility to the particles and their cation exchange sites is decreased.

Fixed ion concentration and Donnan equilibrium

The variation of FIC versus additive ratio is presented in Fig. 10. As FIC is not an independent parameter, it shows a particular trend, according to the variations in the water content and IEC of the membrane. The variation in the concentration ratio of counter-ions/co-ions is similar to that of FIC. Higher FIC means higher concentrations of counter-ions and lower concentrations of co-ions in the membrane.

Transport number and permselectivity

The transport number and permselectivity of the membranes are shown in Fig. 11. Both transport number and permselectivity of the membranes are enhanced up to 3 wt% of nanoclay content and then decreased by further addition of nanoclay to the matrix.

Montmorillonite K10 has a high cation exchange capacity and could increment the ionic sites. Therefore, by uniform distribution of nanoclay particles in the membrane matrix, the content of ionic sites on the membrane surface is increased. So the interactions among the ions in the solution and the membrane surface are increased. Thus the ion transfer through the membrane is facilitated and the Donnan exclusion is improved where better conducting regions are provided. Moreover, since the clay particles are placed into the ion transfer channels, the functional groups (resin particles) can control the ion transfer. Therefore, the selectivity between co-ions and counter-ions is improved [18, 22, 30].

The transport number and permselectivity are increased upon addition of additive up to 3 wt% and then decreased by further addition of additive particles up to 5 wt%. Despite the uniform dispersion of additive particles at all ratios, at 5 wt%, the nanoclay particles are covered with the polymeric chains and the accessibility to the resin particles is decreased. So the interactions among the ions in the solution and the membrane surface are reduced and thus transport number and permselectivity are decreased.

Electrical resistance

Uniform distribution of the ion exchange groups and additive particles, and thus higher hydrophilicity of the membrane surface, lead to reduction of the membrane electrical resistance [18, 30, 34]. In the prepared membranes, by adding nanoclay particles to the membrane matrix, the electrical resistance is significantly decreased. The latter is due to increase in the amount of cation exchange groups, as well as improving the membrane hydrophilicity. The results of this part of investigation are shown in Fig. 10.

The properties of the prepared membrane in this research and some commercial membranes are given in Table 4. Results show that the ion exchange capacity and electrical resistance of the modified lab-made membrane in this study is comparable with that of commercial ones [4, 9, 13, 38, 39]. The IEC of the prepared membrane is better than those of commercial homogeneous and heterogeneous membranes, while its permselectivity (measured in NaCl solution) is lower. The electrochemical properties of an ion exchange membrane can oppose each other. Higher values of IEC result in increasing the water content and decreasing the electrical resistance. It also causes stronger swelling of the membrane due to hydrophilicity of the ion exchange groups. Water content has a strong effect on the membrane permselectivity, since the permselectivity depends on the ratio of IEC/water content [40]. In this research, the membrane IEC and electrical resistance were improved significantly, but as the ratio of IEC/water content decreased the membrane permselectivity was also decreased. Therefore, although the obtained results are very promising in terms of ion exchange capacity and electrical resistance, they still need further modifications to obtain better permselectivity.

Conclusions

The synthesis and characterization of heterogeneous cation exchange membranes were studied in this research. The effect of the blend ratio (PVC/HIPS/ABS) on the membrane properties was investigated. The results showed that by adding PVC to HIPS/ABS blend, the dispersion of resin particles in the membrane was improved and the membrane water content, transport number, permselectivity, and mechanical stability were increased. Membranes A (80/20: HIPS/ABS) and B (20/60:20 PVC/HIPS/ABS) are very brittle. Membrane C (40/40/20: PVC/HIPS/ABS) had the highest IEC, FIC, and the ratio of counter-ion/co-ion. In order to improve the membrane performance, nanoclay particles were chosen due to their appropriate properties (unlimited sources in nature, layered structure, and cation exchange capacity). As these particles are very hydrophilic, the matrix E, which had more polar groups and hydrophilic nature as well as the highest mechanical resistance and better electrochemical properties, was chosen to be modified by these particles. The results show a homogeneous dispersion of particles in the membrane matrix at all particle ratios. The best membrane in this research is \( {E}_3^C \) with a matrix composition of 20/80: ABS/PVC, and 3 wt% nanoclay (additive to total solid ratio). Ion exchange capacity, transport number, permselectivity, and electrical resistance of this membrane are 2.66 (meq/g), 0.8265, 0.7201, and 3.93 (Ω.cm2), respectively.

References

Strathmann H (2010) Electrodialysis, a mature technology with a multitude of new applications. Desalination 264:268–288

Kariduraganavar MY, Nagarale RK, Kittur AA, Kulkarni SS (2006) Ion-exchange membranes: preparative methods for electrodialysis and fuel cell applications. Desalination 197:225–246

Kariduraganavar MY, Kittur AA, Kulkarni SS (2012) Ion exchange membranes: preparation, properties and applications. In: Inamuddin and Luqman (ed) ion exchange technology I: theory and material. Springer, Netherlands, pp 233–276

Xu T (2005) Ion exchange membranes: state of their development and perspective. J Membrane Sci 263:1–29

Vogel C, Meier-haack J (2014) Preparation of ion-exchange materials and membranes. Desalination 342:156–174

Chanda M, Roy SK (2009) Industrial polymers, specialty polymers, and their application, plastic engineering series. CRC Press, Taylor and Francis Group

Boricha AG, Murthy ZVP (2009) Acrylonitrile butadiene styrene/chitosan blend membranes: preparation, characterization, and performance for the separation of heavy metals. J Membrane Sci 339:239–249

Hosseini SM, Rafiei S, Hamidi AR, Moghadassi AR, Madaeni SS (2014) Preparation and electrochemical characterization of mixed matrix heterogeneous cation exchange membranes filled with zeolite nanoparticles: ionic transport property in desalination. Desalination 351:138–144

Hosseini SM, Gholami A, Koranian P, Nemati M, Madaeni SS, Moghadassi AR (2014) Electrochemical characterization of mixed matrix heterogeneous cation exchange membrane modified by aluminum oxide nanoparticles: mono/bivalent ionic transportation. J Taiwan Inst Chem Eng 45:1241–1248

Hosseini SM, Askari M, Koranian P, Madaeni SS, Moghadassi AR (2014) Fabrication and electrochemical characterization of PVC based electrodialysis heterogeneous ion exchange membranes filled with Fe3O4 nanoparticles. J Ind Eng Chem 20:2510–2520

Moghadassi AR, Koranian P, Hosseini SM, Askari M, Madaeni SS (2014) Surface modification of heterogeneous cation exchange membrane through simultaneous using polymerization of PAA and multi walled carbon nanotubes. J Ind Eng Chem 20:2710–21718

Zendehnam A, Mokhtari S, Hosseini SM, Rabieyan M (2014) Fabrication of novel heterogeneous cation exchange membrane by use of synthesized carbon nanotubes-co-copper nanolayer composite nanoparticles: characterization, performance in desalination. Desalination 347:86–93

Hosseini SM, Hamidi AR, Moghadassi AR, Koranian P, Madaeni SS (2015) Fabrication of novel mixed matrix electrodialysis heterogeneous ion-exchange membranes modified by ilmenite (FeTiO3): electrochemical and ionic transport characteristics. Ionics 21:437–447

Zarrinkhameh M, Zendehnam A, Hosseini SM (2014) Preparation and characterization of nanocomposite heterogeneous cation exchange membranes modified by silver nanoparticles. Korean J Chem Eng 31:1187–1193

Gizli N, Cinarli S, Demircioglu M (2012) Characterization of poly (vinylchloride) (PVC) based cation exchange membranes prepared with ionic liquid. Sep Purif Technol 97:96–107

Sanaeepur H, Ebadi-Amooghin A, Moghadassi A, Kargari A (2011) Preparation and characterization of acrylonitrile-butadiene-styrene/poly (vinyl acetate) membrane for CO2 removal. Sep Purif Technol 80:499–508

Hosseini SM, Madaeni SS, Khodabakhshi AR (2010) Preparation and characterization of ABS/HIPS heterogeneous cation exchange membranes with various blend ratios of polymer binder. J Membrane Sci 351:178–188

Kikhavani T, Ashrafizadeh SN, Van der Bruggen B (2014) Synthesis and characterization of a novel surfactant-enhanced chlorinated-polypropylene heterogeneous anion exchange membrane. Separ Sci Technol 49:1146–1155

Singare PU, Lokhande RS, Samant NG, Dhatrak MR (2010) Selectivity study of strongly acidic cation exchange resin Amberlite IR-120. Colloid J 72:538–543

Kim J, Van Der Bruggen B (2010) The use of nanoparticles in polymeric and ceramic membrane structures: review of manufacturing procedures and performance improvement for water treatment. Environ Pollut 158:2335–2349

Ng LY, Mohammad AW, Leo CP, Hilal N (2013) Polymeric membranes incorporated with metal/metal oxide nanoparticles: a comprehensive review. Desalination 308:15–33

Zhang X (2014) Novel approaches for nanocomposites preparation and characterization. Dissertation, University of Akron.

Bahavan Palani P, Kannan R, Rajashabala S, Rajendran S, Velraj G (2014) Effect of nano-composite on polyvinyl alcohol-based proton conducting membrane for direct methanol fuel cell applications. Ionics 21:507–513

Sasikala S, Meenakshi S, Bhat SD, Sahu AK (2014) Functionalized bentonite clay-sPEEK based composite membranes for direct methanol fuel cells. Electrochim Acta 135:232–241

Kakati N, Maiti J, Das G, Lee SH, Yoon YS (2015) An approach of balancing the ionic conductivity and mechanical properties of PVA based nanocomposite membrane for DMFC by various crosslinking agents with ionic iquid. Int J Hydrogen Energ 40:7114–7123

Jana KK, Charan C, Shahi VK, Mitra K, Ray B, Rana D, Maiti P (2015) Functionalized poly (vinylidene fluoride) nanohybrid for superior fuel cell membrane. J Membrane Sci 481:124–136

Wu XW, Wu N, Shi CQ, Zheng ZY, Qi HB, Wang YF (2016) Proton conductive montmorillonite-nafion composite membranes for direct ethanol fuel cells. Appl Surf Sci 388:239–244

Hu Z, He G, Gu S, Liu Y, Wu X (2014) Montmorillonite-reinforced sulfonated poly (phthalazinone ether sulfone ketone) nanocomposite proton exchange membranes for direct methanol fuel cells. J Appl Polym Sci 131:39852–39857

Kikhavani T, Ashrafizadeh SN, Van der Bruggen B (2014) Identification of optimum synthesis conditions for a novel anion exchange membrane by response surface methodology. J Appl Polym Sci 131:1–16

Kikhavani T, Ashrafizadeh SN, Van der Bruggen B (2014) Nitrate selectivity and transport properties of a novel anion exchange membrane in electrodialysis. Electrochim Acta 144:341–351

Strathmann H (2004) Electrochemical and thermodynamic fundamentals. In: Strathmann H (ed) Ion-Exchange membrane separation processes, Elsevir, pp 23–88.

Tanaka Y (2007) Membrane characteristics and transport phenomena. In: Membrane science and technology: ion exchange membranes — fundamentals and applications. Elsevier, Netherlands, pp 37–57

Khodabakhshi AR, Madaeni SS, Hosseini SM (2011) Investigation of electrochemical and morphological properties of S-PVC based heterogeneous cation exchange membranes modified by sodium dodecyl sulfate. Sep Purif Technol 77:220–229

Hosseini SM, Madaeni SS, Khodabakhshi AR (2011) Preparation and characterization of heterogeneous cation exchange membranes based on S-poly vinyl chloride and polycarbonate. Separ Sci Technol 46:794–808

Hosseini SM, Madaeni SS, Khodabakhshi AR (2010) Preparation and characterization of PC/SBR heterogeneous cation exchange membrane filled with carbon nano-tubes. J Membrane Sci 362:550–559

Gopinath S, Sugunan S (2007) Enzymes immobilized on montmorillonite K 10: effect of adsorption and grafting on the surface properties and the enzyme activity. Appl Clay Sci 35:67–75

Urbano BF, Rivas BL, Martinez F, Alexandratos SD (2012) Equilibrium and kinetic study of arsenic sorption by water-insoluble nanocomposite resin of poly [N-(4-vinylbenzyl)-N-methyl-d-glucamine]-montmorillonite. Chem Eng J 194:21–30

Dlugolecki P, Nymeijer K, Metz S, Wessling M (2008) Current status of ion exchange membranes for power generation from salinity gradients. J Membrane Sci 319:214–222

Nagarale RK, Gohil GS, Shahi Vinod K (2006) Recent developments on ion-exchange membranes and electro-membrane processes. Adv Colloid Interfac 119:97–130

Stranska E (2015) Relationships between transport and physical-mechanical properties of ion exchange membranes. Desal Water Treat 56:3220–3227

CMI-7000 Cation Exchange Membranes Technical Specification, Membrane International Inc., www.membranesinternational.com.

Product specification Risingsun Membrane Technology, www.risingsunmem.com.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Namdari, M., Kikhavani, T. & Ashrafizadeh, S.N. Synthesis and characterization of an enhanced heterogeneous cation exchange membrane via nanoclay. Ionics 23, 1745–1758 (2017). https://doi.org/10.1007/s11581-017-2009-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2009-x