Abstract

The interaction and synergetic effect of soy protein isolate (SPI) and its hydrolysates with different concentrations of monoglycerides were explored at the air-water/oil interfaces in recombined low-fat whipped cream (20%). The creams were made with 20% palm oil, 18% carbohydrate, 0.22% stabilizers, and 0.25–1.00% monoglycerides. The proteins used were native soy protein isolate (NSPI), commercial soy protein isolate (CSPI), soy protein hydrolysates by pepsin (SPHPe), soy protein hydrolysates by papain (SPHPa), and SC (sodium caseinate). Overrun, stability, rheological behavior, and texture of recombined low-fat whipped cream were studied. Results indicated that increasing concentration of monoglycerides was effective in improving the textural, whipping properties, and stability of recombined low-fat whipped cream. Increasing concentration of monoglycerides in the mix prompted the displacement of adsorbed protein from fat globules, built up a firmer structure of fat aggregates, and stabilized the trapped air bubbles in the structure of recombined low-fat whipped cream. At the same level of monoglycerides, SPHPa whipped cream produced a similar overrun, stability, and texture as SC. Due to the high proportion of β-conglycinin in SPHPe, a low degree of fat globule partial coalescence occurred and led to low overrun and weakened structure in recombined low-fat whipped cream.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Whipped cream is a traditional dairy product used with cakes, desserts, and pastries. It is a dispersion of gas bubbles surrounded by partially coalesced fat after air is incorporated by whipping into the oil/water emulsion with the fat content of 30–40% [1]. Whipped cream is a complex oil-in-water emulsion and structure in which aggregated fat globules absorb onto the surface of the air bubbles, creating a network and stabilizing its structure [2, 3]. Fat content and physical state, such as solid fat content and form of fat crystals, play critical roles in the physicochemical properties of whipped creams [4]. The interfacial membrane of fat globules after homogenization keeps the emulsion in a meta-stable state [5]. At the beginning of whipping, the giant gas bubbles beaten into the system are stabilized by protein from the serum phase [6]. As whipping continues, shearing promotes the rupture of the fat globule membrane between two colliding fat globules. The larger fat crystals in triglycerides and the presence of a liquid oil phase below 5 °C led to the formation of aggregated fat globules with some of their original identity [7]. The creation of aggregated fat globule networks helps to stabilize the air-water interface by adsorption and to immobilize air bubbles into the structure [8]. The interfacial strength is related to the development of partial coalescence and building the whipped cream structure. The fat globule membranes should be sufficiently thin to allow solid crystal penetration during aging and shearing [9]. Typically, in aerated emulsions, protein and small molecule emulsifiers (e.g., monoglycerides) are added into the system to ensure the appropriate membrane structure [7, 10]. According to Petrut, Danthine & Blecker (2016), the presence of low molecular weight monoglycerides displaces adsorbed protein molecules from the oil/water interface, weakens the strength of the membrane, and allows the occurrence of partial coalescence and air bubble entrapment in whipped cream [11]. Some studies about the interaction between protein molecules and emulsifiers have been conducted to form and stabilize aerated emulsions [11–13]. The composition of adsorbed protein can be optimized for better whipping properties. By manipulating protein composition, the partial coalescence of fat globules can be facilitated during the formation of whipped cream structure [14].

Milk protein such as sodium caseinate has been used extensively in whipped cream research and production [15–17]. Soy protein has also been considered as an alternative to or extension of milk proteins because of its excellent nutritional value and emulsifying properties [18]. Intact soy protein with hydrophobic and hydrophilic groups has been used as an emulsifier at oil/water interfaces. However, a less flexible structure of soy protein limits its emulsifying functionality. A few patents have applied soy protein isolate in whipped cream [19–21]. All those patents are related to the enzymatic modification of soy protein isolate so that the hydrolysates can be used as a whipping agent. However, the roles of soy protein hydrolysates in the formation of whipped cream and their interaction with small molecule emulsifiers are still unclear.

Moreover, the classic fat content of whipping cream is around 30–40%, which provides the desirable cream texture. The “creaminess” is from the fine globules dispersed in the aqueous phase [22]. However, low-fat products are becoming more popular in the market with increasing nutritional knowledge about the risk of cardiovascular disease with a higher intake of saturated fats. Thus, this study aimed to use pepsin and papain to produce differing soy protein hydrolysates with different interfacial and emulsifying properties and apply these soy protein hydrolysates to low-fat (20%) cream.

Moreover, different emulsifier concentrations were applied in the formula to determine if more fat globule destabilization occurred during whipping, contributing to the structure and texture of the whipped cream. Synergetic interfacial adsorption and displacement of soy protein hydrolysates and higher concentrations of emulsifiers were studied to find the most desirable structure of low-fat whipped cream.

Materials and Methods

Materials

Soybeans are purchased from the local market (Wuxi, China). Natural soy protein isolate (NSPI) was prepared with the method of Diftis & Kiosseoglou (2006) [23]. The protein content in the sample was determined by the Kjeldahl method (N × 6.25). Commercial soy protein isolate (CSPI) was obtained from Solae, USA. Sodium caseinate (SC) and lactose were obtained from Fonterra, New Zealand. Palm oil (Melting point: 33 °C) was obtained from Wilmar in China. Stabilizers (locust guar gum and guar gum) and monoglycerides (DIMODAN @ HP-C, from fully hydrogenated palm-based oil) were purchased from Danisco, China. Pepsin (3000 U/mg) was purchased from Sangon Biotech, Shanghai, China, and papain (2000 U/mg) was purchased from Regal, Shanghai, China. Corn syrup solids (36DE) was purchased from Cargill of China. Unless otherwise specified, deionized water was used as the component water, and all other chemicals used were of analytical grade.

NSPI was used to prepare pepsin-hydrolyzed soybean protein (SPHPe) by incubating with 0.3% pepsin at 40 °C for 2 h. NSPI was also used to prepare papain-hydrolyzed soybean protein (SPHPa) by incubating 0.5% papain at 50 °C for 30 min. After the enzyme treatment, the solution was freeze-dried to obtain powder for further use. Commercial soy protein isolate (CSPI) was reconstituted and centrifuged to remove the insoluble fraction (320×g, 5 min, 25 °C). The supernatant was freeze-dried into powder.

The Formulation of Whipping Cream and Processing

Whipping cream emulsions were prepared as follows: sugar (10%), corn syrup solids (DE36, 8%), palm oil (20%), protein (SPHPa, SPHPe, NSPI, CSPI or SC; 1.5% protein), stabilizer (0.1% guar gum, 0.1% locust bean gum, 0.02% k-carrageenan) and emulsifier (monoglyceride; 0.25%, 0.5% or 1.00%). Each mix went through pasteurization at 85 °C for 1 min and subsequently 2-stage homogenization (17.2/3.4 MPa; NANO Homogenizer Machine, Model AHBasic, ATS Engineering Inc., China). The mix was immediately cooled to 4 °C and aged for 24 h at 4 °C. Cream samples (500 mL) were whipped at room temperature with a KitchenAid (Bear Electric Appliance Co., Guangdong, China) at a speed of 1300 rpm for 5 min for further testing.

Composition of Soy Protein and its Hydrolysates

The peptide spectrum of the soybean protein isolate and its hydrolysates were determined by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) according to the method of Li et al. (2016) and Keerati-u-rai & Corredig (2009), with some modifications [24, 25]. The analysis was performed using a mini protein electrophoresis system (Bio-Rad Laboratories, Hercules, California, USA). For crude raw materials, soy protein isolate and its hydrolysates were dissolved in buffer (0.0625 M Tris-HCl, 10% glycerol, 2% SDS, and 0.0025% bromophenol blue) to 1 mg/mL protein solution. After heating in boiling water for 3 min and centrifuging at 5000×g for 10 min (TGL-16G 144, Shanghai Anting Scientific Instruments Co., Ltd., China), an aliquot (20 μL) of the prepared sample was loaded onto the protein gel. For the adsorbed protein, the mixture was centrifuged at 10,000×g for 45 min at 25 °C in a temperature-controlled centrifuge (SIGMA 3 K15, SIXMA, Germany). The gel was stained with Coomassie Brilliant Blue (G-250). All gels were scanned with a computational densitometer (Molecular Imager ChemiDocXRS +, Bio-Rad, USA). Image Lab software (Bio-Rad, USA) was applied to integrate the band intensity.

Particle Size Distribution

The particle size distribution of fresh emulsions and whipped creams were determined by Microtrac BlueWave S3500 laser diffraction particle size analyzer (Microtrac Inc., Montgomeryville, Pennsylvania, USA). The samples were diluted directly with MilliQ water at 16–18 °C by the ratio of 1: 1000 in the sample chamber. The refractive index of the emulsion was set at 1.33. Measurements were performed at ambient temperature and repeated three times. The volume-weighted average diameter (d4,3) was recorded.

Overrun

Overrun was measured according to the method of Scurlock (1986), which was based on the mass of whipped cream after filling a tub to a set volume at 25 °C [26]. The overrun was calculated using equation below:

where M1 (g) is the weight of unwhipped cream with the set volume, and M2 (g) is the weight of whipped cream with the same volume.

Measurement of Partial Coalescence of Fat

The amount of free fat present in the whipped cream was determined according to the method described by Palanuwech et al. (2003) [27]. Oil Red O (0.1 mg/g) was stirred overnight in soybean oil using a magnetic stirrer (Meiyingpu Instrument Manufacturing Co., Shanghai, China). The solution absorbance at 520 nm was measured using a UV-visible spectrophotometer (Shanghai Jingke Industrial Co. Ltd), in which soybean oil was used as a blank. The principle of dilution technique was adopted: a dye solution in a non-polar solvent was poured onto the surface of the cream and then gently mixed. After gentle centrifugation, the colored oil was allowed to float on the cream surface, and free fat presented in the cream was dissolved in the colored oil, while other fat remained in the droplets. The diluted dye solution fraction was transferred from the surface, and its absorbance was then measured. The change in absorbance, which indicates the mass fraction that is not emulsified into fat (∅d), was calculated by the following Equation:

where ∅d is the mass fraction of fat in the cream, m0 is the weight of the added Oil Red O, me is the weight of the cream, ɑ is the ratio of absorbances of Oil Red O before and after centrifugation, and ∅ is the mass fraction of oil in the cream.

Serum Drainage

Analysis of serum drainage, defined as the percentage of serum loss from whipped cream, was performed after whipping for each sample. After whipping, a sample of 55 ± 5 g was transferred to a wire sieve with a mesh of 1 mm. Serum loss was collected over 2 h at 25 °C, and the weight percentage of serum loss from newly whipped cream was calculated.

Measurement of Rheological Behavior of Whipped Cream

Frequency sweep measurements were conducted using a Haake Mars Rheometer (Thermo Scientific, Germany) equipped with cone and plate (40 mm, 2°). Prior to the tests, the temperature of all samples was equilibrated to 25 °C for about 5 min (to ensure a uniform temperature). Frequency sweep measurements were then carried out at a frequency range of 1.0–100 Hz, with 0.5% strain being selected for tests. All measurements were conducted at 25 °C, using 40 mm diameter parallel plate geometry with a 1 mm gap, from which the storage (G′) and loss (G″) modulus of whipped cream were obtained.

Analysis of Textural Properties

Compression force measurements were performed using a TA-XT2i Texturometer (Stable Microsystems, Surry, UK) to determine the textural properties of the whipped cream. The probe (A/BE-d35, Back Extrusion, RiG 35 mm DISG) penetrated the sample to a depth of 25 mm at a speed of 2.0 mm/s, and the force exerted on the probe was automatically recorded. Four parameters (firmness, consistency, and cohesiveness) were recorded. Three aliquots of 150 mL from each trial were chosen for analysis at 10 °C.

Statistics Analysis

All experiments and measurements were repeated three times. Statistical analysies were performed using a two-way ANOVA (α < 0.05) by Statistix 9.0 (Statistix, Tallahassee, FL, USA).

Results and Discussion

Composition of Soy Protein Isolate and its Hydrolysates

The SDS-PAGE patterns of SPI with different degrees of hydrolysis as raw ingredients are shown for both non-reducing and reducing conditions in Fig.1A and 1B. The difference between the reducing condition and non-reducing condition is the larger protein aggregates on the top of the stacking gel (Fig.1A) and the absence of AB subunit in NSPI (Fig. 1B). Petruccelli and Anon (1995) reported that the main component of the aggregate was formed by trimers or dimers of α’, α, and acidic subunit of glycinin through ionic interaction and disulfide bonds [28]. The protein profile of NSPI showed intact β-conglycinin subunits (α, α’and β) and glycine (acidic and basic subunits), which is consistent with the results of previous studies [29]. Compared with NSPI, with CSPI the corresponding bands of basic and acid subunits gradually disappeared, while the AB subunits did not have corresponding bands (Fig. 1A), which was due to the loss by the heat treatment during production. The main subunits in SPHPe were α’-subunit, α-subunit, β-conglycinin, and acidic subunit. The SPHPa profile shows that all subunits of glycinin and β-conglycinin have been hydrolyzed, and only peptides with a molecular weight of less than 20 kDa were identified. (Fig. 1A and B). The polypeptide distribution of soy protein influenced its emulsifying function and surface properties because different subunits indicate different preferential adsorption. For example, β-subunit in β-conglycinin and basic subunit from glycinin show a greater extent of adsorption at the oil/water interface compared to α, α’, and acidic subunits [25].

SDS-PAGE patterns of the peptide profiles for soy protein isolates and its hydrolysates *Abbreviation: BS, basic subunits; AS, acidic subunits; AB, their aggregates. α, α’ and β are subunits from β-conglycinin; (A), Non reducing condition; (B), Reducing condition; NSPI, Native Soy Protein Isolate; CSPI, Commercial Soy Protein Isolate; SPHPe, Soy Proteins Isolate hydrolyzed by Pepsin; SPHPa, Soy Protein Isolate hydrolyzed by Papain

Particle Size Distribution of Fresh Emulsion and Whipped Cream

Oil-in-water emulsions are thermodynamically unstable systems. The change of fat globule particle size is an indicator of the shelf-life stability of the emulsion [30]. According to Dickinson (2009), the role of adsorbed emulsifiers at the oil-water interface in unwhipped emulsions is to prevent fat globule flocculation, aggregation, and coalescence [31]. Figure 2 shows the average particle size (d4,3) of the fresh emulsion prepared with different combinations of monoglycerides and SPI and its hydrolysates. With increasing concentration of monoglycerides, the particle size (d4,3) showed an increasing trend, which corresponded to less stable emulsions. This finding did not agree with the report given by Li et al. (2014) that the addition of a small amount of monoglycerides into protein-stabilized emulsions led to smaller particles size [32]. According to Sarker, Wilde & Clark (1995), the presence of a small concentration of surfactants weakened the elastic adsorbed protein layer by co-adsorption with protein molecules, which prevented inter-protein bonds from forming [33]. The weaker elastic layer may be the source of unstable foams and emulsion [34, 35]. At the same emulsifier concentration (0.25%), d4,3 of all samples did not demonstrate an apparent trend, ranging from 2.32 μm (CSPI) to 5.32 μm (NSPI). The result indicated that the type of protein did not significantly impact the particle size of the fresh emulsions. Compared to other samples, NSPI with larger molecules took a longer time to unfold at the oil-water interface. As a result, its fat globules size was slightly larger than the others. At the higher concentration of monoglycerides (above 0.5%), the size of the fat globules of all samples except CSPI increased. This trend indicated that the co-adsorption of monoglycerides and proteins impacted the particle size and emulsion stability at higher monoglyceride concentrations [2]. The remaining subunits in CSPI after thermal treatment and centrifugation were not sensitive to the concentration of monoglycerides during co-adsorption. In this study, the impact on the emulsion stabilized by SC and SPHPa was more remarkable than other samples. The possible cause may be from the relatively small molecular size of sodium caseinate and SPHPa in the interfacial layer, which may impact the system stability due to the formation of a thin film [34]. Those defects may weaken the layer by forcing the protein molecules into the aqueous phase with the presence of monoglycerides [36]. For NSPI, CSPI, and SPHPe, the interaction between neighboring molecules is relatively stronger than sodium caseinate and SPHPa.

Droplet size of fresh emulsion, as a function of protein and monoglycerides concentration *Abbreviation: NSPI, Native Soy Protein Isolate; CSPI, Commercial Soy Protein Isolate; SPHPe, Soy Proteins Isolate hydrolyzed by Pepsin; SPHPa, Soy protein Isolate hydrolyzed by Papain; SC, Sodium Caseinate, 0.25%, 0.50% and 1.00% represent the concentration of monoglycerides in the formulation. Values with different superscript letter are significantly different at P < 0.05

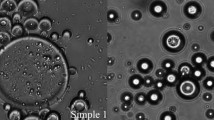

Figure 3 shows the synergetic effect of SPI and its hydrolysates and monoglycerides on the particle size distribution of whipped cream after 5 min whipping. The particle size distribution presented a shift to the right (i.e., larger) with increasing monoglycerides concentration, indicating more fat globule coalescence in the whipped cream except for SPHPe. Increasing the concentration of monoglycerides in the emulsion would likely displace more protein molecules from the oil-water interface and promoted more fat globules partial-coalescence, which compensated the effect of low-fat concentration in the mix by inducing a greater percentage of more structured fat globules. SPHPe has a higher percentage of β-subunits (Fig.1) that have preferential adsorption to fat globules surface and cannot be displaced by monoglycerides from oil/water interface during aging [25, 37]. The presence of a higher percentage of β-subunit played a critical role in emulsion stability and prevented fat globules coalescence. In this study, one peak with a larger molecular size (more than 100 um) was found in SPHPa whipped cream, which can be used to explain the higher overrun and stability of SPHPa whipped cream. The shifting trends of particle size of SPHPa and NSPI were similar to sodium caseinate. However, SPHPa had more big fat agglomerates compared to NSPI. The increasing droplet size in SPHPa was used to understand the improvement of partial coalescence [38], which was critical in building the structure of whipped cream.

Particle size distribution of whipped cream, as a function of protein content and monoglycerides concentration *Abbreviation: N: native soy protein isolate; C: commercial soy protein isolate; Pe: Partial hydrolyzed Soy Protein Isolate; Pa: Soy protein Isolate hydrolyzed by Papain; SC: Sodium Caseinate. 0.25%, 0.50% and 1.00% represent the concentration of monoglycerides in the formulation as 25, 50 and 100

Measurement of Partial Coalescence of Fat

The partial coalescence of fat in whipped cream was determined to indicate the formation of a relatively rigid network of fat globules around air bubbles, which provides stability and texture to the whipping cream. Controlling the degree of partial coalescence of fat droplets was favorable to the stability of whipped cream [38]. According to Peng et al. (2018), the stability of whipped cream was positively related to the partial coalescence of fat [15]. From Fig. 4, the emulsion stabilized by sodium caseinate was the most susceptible to partial coalescence among all samples at the same concentration of monoglycerides, followed by SPHPa. SPHPe developed the lowest fat partial coalescence because the presence of SPHPe with a high percentage of β-subunits in the cream contributed to the higher stability of the fat globules. The higher concentration of emulsifiers promoted more partial coalescence (Fig.4). More protein molecules would be displaced from the interface at a higher concentration of emulsifiers. The addition of an emulsifier lowered the viscoelasticity by the displacement of protein [39, 40], which induced the fat globules to be more easily penetrated by one another and thereby facilitated the partial coalescence.

Partial coalescence of fat in whipped cream, as a function of protein content and monoglyceride concentration *Abbreviation: SC, Sodium Caseinate; NSPI, Native Soy Protein Isolate; CSPI, Commercial Soy Protein Isolate; SPHPe, Soy Proteins Isolate hydrolyzed by Pepsin; SPHPa, Soy Protein Isolate hydrolyzed by Papain. Values with different superscript letter are significantly different at P < 0.05. 0.25%, 0.50% and 1.00% represent the concentration of monoglycerides in the formulation

Rheological Behaviour of Whipped Cream

Frequency sweep test was conducted to further trace the synergetic effect of monoglycerides and soy protein and its hydrolysates (Fig. 5). Storage modulus (G’) values increased with increasing level of monoglycerides, which indicates that monoglycerides increase the rigidity of the whipped cream and contribute to a more robust fat globule network. In case of SC, when the monoglycerides concentration was 0.5% or 1.0%, the G’ increased significantly. There was no apparent difference between the sample with 0.5% and 1.0% monoglycerides for all protein samples in the low-frequency sweep range except for SPHPa. Increasing monoglycerides concentration from 0.5% to 1.0% helped build the solid SPHPa whipped cream structure. The G’ of SPHPa whipped cream at 0.25% monoglycerides was the highest in all samples, including the SC sample. At 0.25% monoglycerides, SPHPa whipped cream had the strongest molecular protein network and NSPI whipped cream had the weakest one. The reason could be that SPHPa with small peptides moved rapidly to the aqueous phase with the higher monoglycerides concentration [41].

Frequency sweeps of Elastic modulus (G’) for whipped creams, as a function of protein content and monoglyceride concentration. Abbreviation: SC, Sodium Caseinate; NSPI, Native Soy Protein Isolate; CSPI, Commercial Soy Protein Isolate; SPHPe, Soy Proteins Isolate hydrolyzed by Pepsin; SPHPa, Soy Protein Isolate hydrolyzed by Papain.0.25%, 0.50% and 1.00% represent the concentration of monoglycerides in the formulation

Overrun of Whipped Cream

The overrun developed by the whipped cream provides information on the percentage of gas holdup within the structure, stabilized by a combination of adsorbed proteins and the network of fat globules [42], as influenced by the proteins and small molecule emulsifier. Figure 6 illustrates the overrun as a function of the level of monoglycerides and SPI and its hydrolysates. The overrun was found to increase with an increasing concentration of monoglycerides for the same protein. The maximum overrun was achieved when the concentration of monoglycerides was 1% in this study for all protein samples. When the concentrations of monoglycerides were the same for each sample, the sodium caseinate whipped cream achieved the highest overrun (95% at 1% monoglycerides), followed by SPHPa (85% at 1% monoglycerides). The results of overrun of whipped cream of SPHPa was in line with the partial coalescence of fat (Fig. 4). According to Zhao et al. (2013), the speed and extent of partial coalescence of fat determine the overrun of whipped cream [39]. With no emulsifier, lack of aggregation of fat globules would lead to less stabilization of air interfaces, thereby resulting in low overrun. With the presence of monoglycerides, the displacement of adsorbed protein on the surface of the fat globules promoted the formation of a sufficiently fat-aggregated structure. Eventually, a network of coalesced fat globules surrounded the air bubbles and prevented the collapse of the whipped cream [43].

Overrun of whipped cream, as a function of protein content and monoglyceride concentration *Abbreviation: SC, Sodium Caseinate; NSPI, Native Soy Protein Isolate; CSPI, Commercial Soy Protein Isolate; SPHPe, Soy Proteins Isolate hydrolyzed by Pepsin; SPHPa, Soy Protein Isolate hydrolyzed by Papain. Values with different superscript letter are significantly different at P < 0.05. 0.25%, 0.50% and 1.00% represent the concentration of monoglycerides in the formulation

Moreover, the presence of emulsifiers can control the speed and extent of partial coalescence of fat to stabilize the incorporated air bubbles. In this study, because the protein concentration and the speed and period of whipping are the same, the type of soy protein and concentration of emulsifier played a key role in developing overrun. According to Chen et al. (2019), monoglycerides displaced the small peptides, acidic and basic subunits from the interface and led to fat globule destabilization after 24 h aging [44]. In this study, NSPI, CSPI, and SPHPa contain the small peptides, acidic and basic subunits, which were displaced by monoglycerides. Therefore, 1% monoglycerides and SPHPa provided more opportunities for air to be incorporated into whipped cream amongst all soy protein samples and achieved comparable overrun as sodium caseinate (SC).

Stability of Whipped Cream

The drainage of serum from whipped cream during storage demonstrates partial coalescence of fat and development of structure, hence stability [15]. In this study, the whipped creams with sodium caseinate demonstrated the lowest loss of serum among all samples, followed by SPHPa (Fig. 7). Less partial-coalesced fat globules in the structure in NSPI, CSPI, and SPHPe samples resulted in higher serum loss. Moreover, a higher concentration of monoglycerides reduced the serum loss of the cream in all samples. These can be explained as follows: (i) higher level of monoglycerides may displace more protein molecules from the oil-water interface, causing more partial coalescence and contributing to a more orderly structure of fat and air in whipped cream, which can reduce or prevent serum loss during storage. (ii) For all soy protein samples, different surface properties determined its displacement by monoglycerides during aging. To explain the most stable whipped cream formed by SPHPa, the displacement of SPHPa, SPHPe, NSPI, and CSPI by monoglycerides as studied by Chen et al. (2018) [37] can be used. The displacement of small peptides, acidic and basic subunits from the interface led to fat globule destabilization after 24 h aging. Monoglycerides did not displace β-subunits during the aging. SPHPe has the highest percentage of β-subunits, hence a minor displacement by monoglycerides. Hence CSPI, NSPI, and SPHPe whipped cream indicated the highest loss of serum compared to SC and SPHPa.

Serum loss of all whipped creams, as a function of protein content and monoglyceride concentration *Abbreviation: SC, Sodium Caseinate; NSPI, Native Soy Protein Isolate; CSPI, Commercial Soy Protein Isolate; SPHPe, Soy Proteins Isolate hydrolyzed by Pepsin; SPHPa, Soy Protein Isolate hydrolyzed by Papain. Values with different superscript letter are significantly different at P < 0.05. 0.25%, 0.50% and 1.00% represent the concentration of monoglycerides in the formulation

Texture of Whipped Cream

To determine the desirable texture of whipped cream, the synergetic effect of monoglycerides level and protein on the firmness, consistency, and cohesiveness of whipped cream are shown in Fig. 8. The gel strength of the whipped cream can be expressed as the results of the firmness and consistency. Consistency is one of the more important viscoelastic properties of whipped cream as it has a great effect on acceptability [45]. Cohesiveness represents the strength of internal structure within the body of the whipped cream and can be calculated as the ratio of positive force areas with the first and second compression in the test. By measuring the hardness and the consistency, the strength of whipped cream can be determined [46]. Both firmness and consistency increased with increasing concentration of monoglycerides for whipping cream with the same protein. The hardness and consistency of whipped cream with sodium caseinate were the largest amongst all samples when monoglycerides concentration is 1%, followed by the sample with SPHPa and 1% monoglycerides. This result agrees with the results that a high degree of partial coalescence of fat droplets contributed to whipping cream structure, as discussed in Section 3.4. The cohesiveness value was 9.09 g when 0.25% monoglycerides were used, which was significantly lower than 15.76 g when 1% monoglycerides were used in the sodium caseinate whipped cream. A similar trend was shown in all soy protein samples. SPHPa whipped cream has the highest increment in the cohesiveness in all soy protein samples. This can be explained as the result of more occurrence of fat globules destabilization. According to Peng et al. (2018), the merged fat globules and the rearrangement of whipped cream structure contributed to increased firmness and consistency of whipped cream [15]. According to Zhao et al. (2008), the adhesiveness of whipped cream is an important property, which can be used to indicate the flow capability and liquid state of materials [47]. There was an increasing tendency of adhesiveness of whipped cream with increasing monoglycerides concentration. From the results above, the overall improvement of firmness, cohesiveness and consistency indicated that SPHPa with the addition of 1% monoglycerides can achieve comparable properties as the sodium caseinate control sample.

Conclusion

This study demonstrated the interaction between soy protein molecules and monoglycerides at the oil-water interface in low-fat whipping creams and the impact on the properties of the whipped cream. For the low-fat whipped cream, it was clear that a higher concentration of monoglycerides added was effective at improving the textural and whipping properties of whipped cream for all soy protein samples. SPHPa whipped cream demonstrated similar properties as SC and can be considered as an alternative protein source in building a desirable whipped cream structure. Due to the high proportion of β-subunits in SPHPe, the lower degree of fat globules partial coalescence led to low overrun and weak structure of whipped cream.

References

K.E. Allen, E. Dickinson, B. Murray, LWT - Food Sci. Technol. 39, 225 (2006)

K. Ihara, M. Hirota, T. Akitsu, K. Urakawa, T. Abe, M. Sumi, T. Okawa, T. Fujii, J. Dairy Sci. 98, 2875 (2015)

M. Sajedi, A. Nasirpour, J. Keramat, S. Desobry, Food Hydrocoll. 36, 93 (2014)

A.K. Smith, H.D. Goff, Y. Kakuda, Int. Dairy J. 10, 295 (2000)

J. Maldonado-Valderrama, J.M.R. Patino, Curr. Opin. Colloid Interface Sci. 15, 271 (2010)

J. Zhang, L. Liu, Y. Jiang, S. Faisal, Q. Wang, J. Food Eng. 264, 109668 (2020)

H.D. Goff, Curr. Opin. Colloid Interface Sci. 7, 432 (2002)

H.J. Kim, A. Bot, I.C.M. de Vries, M. Golding, E.G. Pelan, Food Res. Int. 53, 342 (2013)

T.T.Q. Phan, K. Moens, T.T. Le, P. Van der Meeren, K. Dewettinck, Int. Dairy J. 39, 16 (2014)

P. Walstra, Chem. Eng. Sci. 48, 333 (1993)

R.F. Petrut, S. Danthine, C. Blecker, Adv. Colloid Interf. Sci. 229, 25 (2016)

M.B. Munk, H.R. Erichsen, M.L. Andersen, J. Colloid Interface Sci. 419, 134 (2014)

E. Fredrick, B. Heyman, K. Moens, S. Fischer, T. Verwijlen, P. Moldenaers, P. Van der Meeren, K. Dewettinck, Food Res. Int. 51, 936 (2013)

M.D. Eisner, H. Wildmoser, E.J. Windhab, Colloids Surfaces A Physicochem. Eng. Asp. 263, 390 (2005)

F. Peng, S. He, H. Yi, Q. Li, W. Xu, R. Wang, and Y. Ma, https://doi.org/10.1080/10942912.2018.146075521, 1190 (2018)

J. Jiang, Y. Jin, X. Liang, M. Piatko, S. Campbell, S.K. Lo, Y. Liu, Food Hydrocoll. 81, 15 (2018)

K. van Lent, C.T. Le, B. Vanlerberghe, P. Van der Meeren, Int. Dairy J. 18, 1003 (2008)

J.J. Anderson, M.S. Anthony, J.M. Cline, S.A. Washburn, S.C. Garner, Public Health Nutr. 2, 489 (1999)

Z. Wang, B.L. Dekkers, A. Jan, V. Der Goot, J. Food Eng. 275, 109866 (2020)

J. Zhang, L. Liu, Y. Jiang, F. Shah, Y. Xu, Q. Wang, Food Hydrocoll. 99, 105311 (2020)

Z. Wang, B.L. Dekkers, R. Boom, A.J. van der Goot, Food Hydrocoll. 95, 143 (2019)

W. Hoffmann and W. Buchheim, (n.d.)

N. Diftis, V. Kiosseoglou, Food Hydrocoll. 20, 787 (2006)

W. Li, Y. Wang, H. Zhao, Z. He, M. Zeng, F. Qin, J. Chen, Food Hydrocoll. 60, 453 (2016)

M. Keerati-u-rai, M. Corredig, Food Hydrocoll. 23, 2141 (2009)

P.G. Scurlock, J. Dairy Res. 53, 431 (1986)

J. Palanuwech, R. Potineni, R.F. Roberts, J.N. Coupland, Food Hydrocoll. 17, 55 (2003)

S. Petruccelli, M.C. Anon, J. Agric. Food Chem. 43, 1762 (1995)

K. Nishinari, Y. Fang, S. Guo, G.O. Phillips, Food Hydrocoll. 39, 301 (2014)

S.R. Euston, S.R. Finnigan, R.L. Hirst, Food Hydrocoll. 15, 253 (2001)

E. Dickinson, Food Hydrocoll. 23, 1473 (2009)

L. Day, M. Golding, M. Xu, J. Keogh, P. Clifton, T.J. Wooster, Food Hydrocoll. 36, 151 (2014)

D.K. Sarker, P.J. Wilde, D.C. Clark, Colloids Surfaces B Biointerfaces 3, 349 (1995)

M. Coke, P.J. Wilde, E.J. Russell, D.C. Clark, J. Colloid Interface Sci. 138, 489 (1990)

M. Cornec, A.R. Mackie, P.J. Wilde, D.C. Clark, Colloids Surfaces A Physicochem. Eng. Asp. 114, 237 (1996)

*,† Alan R. Mackie, † A. Patrick Gunning, ‡ Luis A. Pugnaloni, ‡ Eric Dickinson, † and Peter J. Wilde, and V. J. Morris†, Langmuir 19, 6032 (2003)

C.H. Tang, LWT - Food Sci. Technol. 41, 1380 (2008)

Q. Zhao, M. Zhao, B. Yang, C. Cui, Food Chem. 116, 624 (2009)

Q. Zhao, W. Kuang, Z. Long, M. Fang, D. Liu, B. Yang, M. Zhao, Food Chem. 141, 1834 (2013)

Z. Wang, B. Tian, S. Karleen, A. Jan, V. Der Goot, J. Chen, Food Struct. 28, 100171 (2021)

W. Chen, G. Liang, X. Li, Z. He, M. Zeng, D. Gao, F. Qin, H.D. Goff, J. Chen, Food Hydrocoll. 94, 279 (2019)

W. Chen, G. Liang, X. Li, Z. He, M. Zen, D. Gao, F. Qin, H.D. Goff, J. Chen, Colloids Surfaces B Biointerfaces 177, 550 (2019)

S. Damodaran, Anal. Biochem. 145, 200 (1985)

M. Li, T.C. Lee, J. Agric. Food Chem. 44, 1871 (1996)

Q. Zhao, M. Zhao, J. Li, B. Yang, G. Su, C. Cui, Y. Jiang, Food Hydrocoll. 23, 2168 (2009)

V. Nguyen, C.T.M. Duong, V. Vu, J. Food Eng. 163, 32 (2015)

Q. Zhao, M. Zhao, J. Wang, C. Wang, B. Yang, J. Food Process Eng. 31, 671 (2008)

Acknowledgements

This work was supported by the independent research project program of the State Key Laboratory of Food Science and Technology, Jiangnan University (SKLF-ZZB-202012) and the Fundamental Research Funds for the Central Universities (JUSRP12052).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval

We affirm that all work here has been conducted in an ethical manner and that it is original work for publication that has not been shared elsewhere. The patient consent and permission to reproduce do not apply to this work.

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Z., Liang, G., Chen, W. et al. Effects of Soy Proteins and Hydrolysates on Fat Globule Coalescence and Whipping Properties of Recombined Low-Fat Whipped Cream. Food Biophysics 17, 324–334 (2022). https://doi.org/10.1007/s11483-021-09714-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-021-09714-7