Abstract

The present study investigates the effect of oil type on the formation, morphology and mechanical properties of phytosterol-based organogels. The formation of organogels can be satisfactorily predicted with a criterion based on Hansen Solubility Parameters (HSPs), provided that the sterol and sterol ester in these systems assemble as tubules. When structures other than tubules are formed, the predictability of the HSP-based criterion becomes void. In cases where organogelling occurred, the morphology and mechanical properties of the tubular network of the gels and water-in-oil emulsions were investigated. The findings revealed that the structure of the tubular network formed in oils with different compositions, could be grouped based on the dielectric constants of the oils. Curly and bundled tubules which formed networks, were observed in gels prepared with low dielectric constant oils (i.e. decane and limonene). For oils with a moderate dielectric constant (i.e. castor oil and sunflower oil), the tubules became less curly and straighter. Upon increasing the dielectric constant of the oil (eugenol), individual tubules were observed next to the bundled tubules. The results showed that straighter, bundled tubules are associated with firmer gels, whereas less straight (i.e. curly) tubules rendered weaker gels. The tubular network of the water-in-oil emulsions obtained for oils with a low dielectric constant appeared more open with straighter tubules. For oils with relatively high dielectric constant, the water-in-oil emulsions lost most of their tubular structure and only a few tubules could be observed. In the presence of emulsion droplets fewer tubules are formed, resulting in weaker networks.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Structuring of edible oils and oils in water-in-oil emulsions (w/o emulsions) is commonly accomplished through dissolution or dispersion of a structuring agent in the oil phase, before emulsification with an aqueous phase to form a w/o emulsion. Most of the commercially available formulations depend on highly saturated fats (i.e. triacylglycerols, TAGs) as structuring agents. A possible drawback of saturated fats is their contribution to an elevated blood cholesterol level, which is a risk factor for cardiovascular diseases [1, 2].

Structurants based on plant sterols [3], such as β-sitosterol and γ-oryzanol, show potential in structuring edible oils [4,5,6,7,8]. The use of the plant sterols appears rather promising as they do not contain saturated fatty acids, they lower the adsorption of cholesterol in the intestine and they enhance faecal extraction [1]. Structuring of edible triglyceride oil with mixtures of γ-oryzanol and β-sitosterol resulted in stable and translucent organogels, in which the two molecules self-assembled [9] into hollow tubules (~9.5 nm in diameter and with ~2.3 nm wall thickness [10, 11]). The resulting tubular network allows gelling of the oil phase and provides a good alternative to the crystalline fat network [12].

However, when oryzanol and sitosterol mixtures are used for structuring w/o emulsions (relevant for the production of w/o emulsions such as margarine and table spreads), the tubular network does not form at all, or it only forms partially with the tendency to disintegrate during prolonged storage [13,14,15]. The presence of water in the system leads to hydration of sitosterol and the formation of sitosterol monohydrates [16], which prevents hydrogen bonding between β-sitosterol and γ-oryzanol molecules. Consequently, the self-assembly of sitosterol and oryzanol into the tubular structure desired for structuring the continuous oil-phase in the emulsion, is inhibited. The self-assembly inhibition can be overcome by reducing the water activity through addition of salts or sugars in the emulsions, which suppresses the hydration of sitosterol and thereby allows the self-assembly with oryzanol into tubules [14]. Furthermore, the formation of sitosterol monohydrates can be avoided by replacing water with glycerol, which results in the formation of firm emulsion gels [17]. Another means of preventing the formation of sitosterol monohydrate is by adjusting the dielectric constant of the oil phase, such that the solubility of water in the oil phase is reduced. For instance, the use of oils with a low dielectric constant (i.e. non-edible long chain hydrocarbons such as decane) in the oil phase decreases the availability of water molecules in the oil phase substantially, thereby eliminating the formation of monohydrate sterol crystals and allowing the formation of tubules [14].

The dielectric constant of the oil affects the mutual interactions between oil and sterol compounds and, consequently, the thermodynamics of self-assembly of tubules in organogels, potentially changing the morphology of the tubular network as well as the thermal and mechanical properties of the organogels [18]. At the same time, it should be realised that interactions in organogels can be very complex and are not solely determined by a simple solvent characteristic like the dielectric constant. For example, next to the fatty acid composition, minor polar components in the oil greatly affect the organogel properties [19].

Two of our previous studies focused on the storage stability [14] and thermodynamics of assembly of organogels [20, 21] in different types of oil. The aim of the current study was to investigate the prerequisites for organogelling and the effect of the type of oil phase on the shape of the tubules in organogels, structured by γ-oryzanol and β-sitosterol mixtures. Hereto, two research questions were identified. Firstly, would an organogel form at all for a given combination of an oil and a structurant? This was addressed by a semi-empirical analysis based on the Hansen Solubility Parameters (HSPs) [22, 23]. Through this approach a slightly more complex quantification of the differences in interactions between solvent and structurant was introduced, which nevertheless still allowed the comparison of solvents with pronounced differences in molecular structure. Secondly, would the morphology and mechanical properties of the organogel and emulsions be affected by the type of oil? This question was addressed by an experimental study of γ-oryzanol and β-sitosterol organogel mixtures, prepared using various oil types and evaluated for the morphology of the tubular network (scanning electron microscopy) and firmness (large deformation measurements).

Materials and Methods

Materials

As structuring agents of the oil phase, γ-oryzanol powder purchased from Tsuno Rice Fine Chemicals (Wakayama, Japan) and tall oil sterol granules (78.5% β-sitosterol, 10.3% β-sitostanol, 8.7% campesterol and 3.8% of other minor sterols) obtained from Unilever (The Netherlands) were used. Various types of oils were used including: sunflower oil (Reddy, NV Vandemoortele, Breda, The Netherlands), castor oil (Sigma, The Netherlands), decane (> 99%, Sigma-Aldrich, The Netherlands), limonene (> 97%, Sigma-Aldrich, The Netherlands) and eugenol (> 99%, Aldrich, The Netherlands). For their role in organogel formation, all these solvents will be referred to as oils throughout this study, although technically e.g. decane could be considered to be too small to be called an oil. Table 1 shows the dielectric constant and chemical structures of these oils and sterols. All materials were used as received.

Methods

Preparation of the Organogels and W/O Emulsions

Structurant solutions were prepared by dissolving mixtures of oryzanol and sitosterol with a total concentration of 32% (w/w) in the oil phase, at a temperature of ~100 °C using a magnetic stirrer. Here it should be noted that these organogels can form at sterol and sterol ester concentrations above 3–4% (w/w) in triglyceride oils, although much higher concentrations were used in the present study (32% (w/w)) to achieve clear x-ray scattering patterns and SEM images. In a previous study it was demonstrated that the system does not show any phase transitions between 3 and 32% (w/w) structurant [24], and the qualitative features of the organogel structure are therefore not expected to be different as a result of the higher concentration. The oryzanol to sitosterol ratio was fixed (60 oryzanol:40 sitosterol w/w) in all experiments. Previously it was shown that these 1:1 molar mixtures give the strongest gels [25]. To form organogels, the structurant solution was cooled down to room temperature. In the case of w/o emulsions, the aqueous phase consisted of water at ~90 °C, which was added to the hot structurant solution at a fixed weight fraction of 10% (w/w). The two phases were mixed in a closed container at 1300 rpm for ~2 min using a magnetic stirrer. The formed emulsion was subsequently cooled to room temperature whilst stirring until a very weak organogel could be observed, which was left to solidify further without stirring. Most of the organogelling took place after the stirring was stopped. The solidified emulsions and the gels were stored after gel formation in the refrigerator at 5 °C for 1 week before further characterization. No additional emulsifiers were added to the system.

X-Ray Scattering

Small- and wide-angle X-ray scattering (SAXS, WAXS) experiments were performed at the high-brilliance ID2 beamline of the European Synchrotron Radiation Facility (ESRF) in Grenoble, France [26]. SAXS/WAXS data were collected in the range of 0.0023 nm−1 < q < 5.20 nm−1, where q is the scattering vector defined by q = 4π·sinθ/λ (with θ the scattering angle and λ the wavelength of the incoming X-ray beam). Scattering data were corrected for scattering from the oil phase by subtraction of the pure oil signal. Details can be found elsewhere [12].

Scanning Electron Microscopy (SEM)

The morphology of the tubular structure of the gels and emulsions was visualized using a cryo- field emission scanning electron microscope (Magellan 400, FEI, Eindhoven, the Netherlands). Detailed information about the sample preparation and scanning procedure can be found elsewhere [14].

Firmness Measurements

For the measurements of the firmness (hardness) of the gels and emulsions, the samples were prepared and kept in glass cups with an internal diameter of 25 mm. A Texture Analyzer T2 (Stable Micro Systems Ltd., Surrey, UK) equipped with a probe of 2 mm (diameter) was used. The probe penetrated the sample to a maximum depth of 8 mm at a constant speed of 1 mm/s. The firmness was defined as the force (N) at the maximum penetration depth. The measurements were performed at least at three different locations in the same sample and the average was presented.

Results and Discussion

Empirical Identification of Potential Organo-Gelling Structurant and Solvent Combinations

Before discussing the experimental findings of the combinations of structurant and solvent forming organogels, we will first address the question on the necessary conditions for organogel formation. It has been stated that identifying organogel-forming combinations of a structurant and an oil depends on serendipity [27]. In recent years however, some progress has been made to narrow down the search area, by considering the so-called Hansen solubility parameters (HSPs) [22, 23] for the evaluation of organogelling potential.

The assumption behind the HSPs is that the total energy of vaporisation E can be written as the sum of three separate contributions: (i) (molecular) permanent dipole–dipole interactions, Ep; (ii) (molecular) hydrogen bond interactions (electron exchange), Eh; and (iii) (atomic) London dispersion interactions, Ed,

expressed in J/mol. The HSP can be obtained from the interaction energies by δi = (Ei/V)1/2, where V is the molar volume (in m3/mol), resulting in three separate characteristic HSPs: δp, δh and δd, having the unit (J/m3)1/2 or (Pa)1/2. The HSPs are calculated by adding functional group contributions to calculate the parameters for the molecule as a whole [28]. As an example the HSPs for decane can be calculated, which only has a dispersive contribution and no polar or hydrogen bonding components: Decane has two -CH3 and eight -CH2- groups which each contribute 4.7 and 4.9 kJ/mol to the polar interaction respectively [28], resulting in 48 kJ/mol in total. Using V = 196·10−6 m3/mol, a value of 15.7 (MPa)1/2 is obtained for δd ,(0.1 (MPa)1/2 different from the direct entry in the original table [28]) The geometric mean of the three interaction parameters, δtotal, is an estimate of the interaction between two unlike compounds in solution [23]. The concept of using the HSPs is that the difference between their values for structurant and solvent should be neither too small nor too large. If the difference is too small, there will be perfect solubility of the structurant, because the molecules are very similar. If the difference is too large, the structurant will precipitate and not contribute to the formation of an organogel. This requirement is often visualized in terms of a spherical surface in HSP space, where the three dimensions are defined by the three types of molecular-molecular interactions. In the following paragraphs this qualitative statement is quantified.

This approach has been evaluated for many single-component structurant systems and seems to give fair predictions of the potential of a system to form an organogel. It has not been applied yet to binary structuring systems like the sterol + oryzanol mixtures. A list of the HSPs (δd, δp and δh) for the ingredients considered in this study and which were obtained from various sources is shown in Table 2 [28, 29]. First we address how to define the HSPs for a binary structurant mixture. Here it was decided to take the molar average value for each of the contributions of the single components.

where i = p, h or d. We have chosen the molar average in the present analysis, as the sterol and sterol ester mixtures have a 1:1 molar ratio, but the exact choice for the average is inconsequential given the similarity of the HSPs for sterols and sterol esters. Most of the variation in HSPs in the present dataset originates from the variation in solvents, whereas the variation in the HSPs of the sterols and sterol esters is small in comparison. The gelling capability of sterols and sterol esters in various solvents was retrieved from the literature [14, 25, 30, 31]. The difference between the HSP for the solvent and structurant is defined by

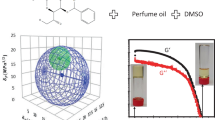

(where i = p, h or d). The values of the Δδi‘s are listed in Table 3. From Table 3 it is noted that the relative variation in the dispersion forces (Δδd) is much smaller than the relative variation in the dipole-dipole forces (Δδp) and hydrogen bonding forces (Δδh). Therefore Δδd can be safely neglected, which conveniently allows for a two-dimensional representation of the Hansen sphere, called the Hansen disc. The radius RHSP

defines the disc where gelling occurs. In Fig.1 the Hansen disc is plotted for sitosterol + oryzanol/solvent combinations (a subset of Table 3) in terms of Δδp and Δδh, which demonstrates that gelling and non-gelling systems can be segmented based on differences in HSP between solvent and structurant. Using a graphical method, the radius of the Hansen disc RHSP = 8.5 ± 0.6 MPa1/2 is obtained: two points in the graph determine the minimum and maximum radius, and their average value was used to estimate RHSP (note that the apparent ellipsoid shape is a consequence of the scale of the axes). A more complex approach to segmentation would have been possible if an ellipsoidal shape was used instead of a circle, but the current data does not justify such a step. We note that the Hansen criterion for gelling involving tubules is a necessary, but not sufficient criterion. It seems that the inner disk of complete solubility for these systems is extremely small, or perhaps even non-existent, because these systems are presently considered at ambient conditions, i.e. below the melting temperature of the structurant. At elevated temperatures an area may open up in the centre of the sphere in Hansen parameters space, where the effective attractive forces between the structurants are too small to form an organogel. For very dissimilar combinations of structurants and solvents, there seems to be a rather clear segmentation of gelling and non-gelling systems.

Segmentation in gelling and non-gelling sitosterol+oryzanol / solvent combinations. The open circles indicate non-gelling solvents, the filled symbols indicate gelling systems. The dashed line defines a disc around the average HSP for the sitosterol + oryzanol structurant mixture. The apparent outlier in the segmentation, a gelling system amongst non-gelling systems, is the sitosterol + oryzanol in propylene glycol system and is discussed later in the text

However, Fig. 1 reveals one outlier to this segmentation. This is the sitosterol + oryzanol in the propylene glycol system, despite the much higher polar and hydrogen bonding HSPs of the solvent. A sample of this system was prepared in order to verify gel formation, and the resulting gel was found to be much more turbid compared to the typical gels prepared with sunflower oil. X-ray scattering was further used to investigate whether a similar tubule structure as observed in sunflower oil is also present in propylene glycol-based gels as shown in Fig. 2. It was found that the molecular arrangement of the sitosterol + oryzanol structurant mixture in propylene glycol differed completely from the ~9.5 nm diameter tubules which were observed for the structurant mixture in solvents with a lower dielectric constant, such as triglyceride oil. The scattering data showed crystalline peaks at d = 2π/qi of 1.82 and 3.64 nm, reminiscent of regular crystallization of sitosterol in a very polar aqueous environment [16]. Specific crystalline structures in di-alcohol solvents have been observed before by Lan et al. [32]. Note that further criteria would have been required if additional binary structurant combinations were to be included in Fig. 1, such as requiring a sterol hydroxyl (which is missing in cholestane [25]) or requiring only modest solubility (in contrast to the high solubility of sitosteryl linoleate in triglyceride oil [31]) (cf. Table 3).

Scattering data for 40% sitosterol + 60% oryzanol structurant mixture in two solvents, sunflower oil and propylene glycol: (grey line) 16% structurant in sunflower oil; (black line) 5% structurant in propylene glycol; Data obtained at ambient temperature. It has been shown previously that the qualitative features of the scattering pattern in sunflower oil do not depend on structurant concentration in this range [24]

The conclusion from this analysis is that HSPs may serve as a semi-empirical tool to predict whether a specific binary mixture of structurants will be capable of gelling various solvents. It should be stressed that Fig. 1 does not prove that HSPs are the only possible way to segment gelling and non-gelling combinations. In the present dataset there is considerable correlation between δp and δh (and little variation in δd), so this cannot be considered a test for all possible HSP combination – despite that most commonly used solvents are included in the dataset. Also, it is important, however, to compare similar modes of self-assembly, because two very different types of structuring may show a different dependence on HSPs, as is illustrated by the combination of oryzanol/sitosterol with propylene glycol. The type of change in molecular arrangement observed here, is more likely to occur for binary structurant mixtures, as opposed to single-component structurants. Thus, HSPs can be used as one exclusion criterion amongst others (a necessary, but not sufficient condition, and additional requirements could be formulated in terms of aspects of molecular structure, for example) that can restrict the number of potential candidates for gelling systems.

Effect of the Dielectric Constant of the Oil on Structure

The experimental assessment is restricted to systems that are expected to show organogelling according to the HSP analysis. In this group of systems, the effect of the type of oil on the tubular structure of the gels and emulsions was investigated. Although ideally this analysis would have been done in terms of the three HSPs too, the number of systems that could be investigated is too small to warrant an analysis in terms of three parameters. Therefore, the analysis in this section is performed in terms of the dielectric constant of the oils. In broad terms, however, the dielectric constant of the present solvents correlates well with δp and δh, but there is little correlation with δd.

Organogels

Figure 3 shows the SEM micrographs of organogel samples prepared with different types of oils. Tubular structures were observed with all types of oil, in agreement with earlier small angle X-ray scattering results [14]. Nonetheless, clear differences in the tubular morphology or super-tubular arrangement could be observed with respect to the type of oil. One could clearly observe that with oils with a low dielectric constant (i.e. decane and limonene), the tubular structure was rather curly and woven (see Fig. 3a and b). With increasing dielectric constant of the oils, the tubules became stretched, elongated and less curly (see images of sunflower oil and castor oil, Fig. 3c and d). With further increase of the dielectric constant of the oil (i.e. eugenol), the tubules appeared less aggregated and bundled, whilst individual tubules could also be observed as shown in Fig. 3e. This indicates that the tubular structure strongly depends on the dielectric constant of the oil. The presence of the polar groups in the oils with a relatively high dielectric constant seems to affect the tubule-tubule molecular interactions during formation of the tubular network at gelling, a finding which is also supported by recent work of Scharfe et al. [19]. The interaction between the polar groups of the oils and structuring agents interfere with the hydrogen bonding between oryzanol and sitosterol. This consequently affected the self-assembly of the tubular structure and disturbed the reorganization of the hydrophobic tail of oryzanol-sitosterol in the oil, thereby preventing the formation of a complex branched tubular network.

Emulsions

To further assess the effect of the dielectric constant of the system on the tubular structure, the morphology of emulsions prepared with various oils was studied. SEM micrographs of the emulsions prepared with decane, limonene and eugenol are shown in Fig. 4. In the case of oils with a low dielectric constant (i.e. decane and limonene), the curly and curved tubular structure observed in the gels (see Fig. 3a and b) became aligned and drawn-out tubules as shown in Fig. 4a and b. In addition, the tubular cluster in the emulsion seem to be less dense with tubules compared to that of the gels. For oils with a relatively high dielectric constant (eugenol), the number of tubules in the emulsion dramatically decreased and only a few tubules could be observed compared to the gel (see Fig. 4c).

SEM micrographs of emulsions prepared with 32% total sterols (60:40 mixture of oryzanol:sitosterol) in various types of oils: a) decane, b) limonene and c) eugenol. The amount of water phase in the emulsion samples was fixed at 10% w/w. The particle in panel (a) is a dust particle that should be ignored

The results obtained for the emulsions confirmed the findings on the effect of the dielectric constant of the oil on the tubular network observed with gels using various oils (Fig. 3). The amount of water dissolved in the oil phase is dependent on the dielectric constant of the oil. For oils with a relatively low dielectric constant (decane and limonene), the solubility of water in the oil phase is very low. Consequently, the amount of water that could be present in the oil phase is relatively small, but enough to enhance the dielectric constant of the system which leads to aligned and elongated tubules, as observed in the gels prepared with oils with a relatively high dielectric constant such as eugenol. On the other hand, eugenol absorbs more water compared to the oils with a low dielectric constant (i.e. water solubility in eugenol is 19.6 mg/g compared to 0.23 mg/g and 0.62 mg/g in decane and limonene, respectively [14]), which is enough to form sitosterol monohydrate crystals. This reduces the amount of sitosterol molecules available for the self-assembly with oryzanol considerably and consequently depletes the tubular network in the emulsion as observed in Fig. 4c. The results suggest that the transition from curly to straight is related to the dielectric constant of the system which increases with increasing water uptake from the surroundings. At low water content (i.e. low with a relatively low dielectric constant) curly tubules are formed. At increasing water content and consequently dielectric constant of the system, the tubules straighten and at sufficiently high water content they become unstable and fall apart due to the formation of sterol monohydrates. There seem to be a transition from curly tubules towards straight ones as a function of the dielectric constant of the oil phase, either by the polar groups present in the oil phase itself or from the availability of water, which is possibly taken up from the surrounding continuous phase. This might lead to the formation of a water layer around the tubules, which could be due to the interaction of the ferulic acid moiety with the water. This is in line with the observation that with a low dielectric constant of the oil phase, curly tubules are observed, which could be due to interaction between different ferulic acid moieties of either the same tubule or different tubules. At increasing dielectric constant, the tubules straighten as the ferulic acid moieties are possibly blocked by water.

Mechanical Properties

Organogels

The effect of the oil on the firmness of the organogels is shown in Fig. 5. The firmness of the gels with straighter tubules (i.e. prepared with sunflower oil and castor oil) was higher than those with curly tubules prepared with decane and limonene. The straighter tubules appear to be stiffer compared to curly ones, thereby, the gels prepared with castor oil and sunflower oil showed higher resistance against deformation. Besides, the tubular network of organogels prepared with sunflower and castor oil seem to remain more intact, making the system more robust and resistant to the applied stresses.

Firmness of organogel and emulsions samples prepared with 32% total sterols (60:40 mixture of oryzanol:sitosterol). The amount of water phase in the emulsion samples was fixed at 10% w/w. The firmness data of the emulsions were obtained from [14]

Emulsions

A 90 to 95% decrease in firmness was observed for the emulsions compared to the organogels for systems prepared with either eugenol or castor oil (see Fig. 5). For the limonene-based systems, this decrease in the firmness of the emulsions was less extreme (~50%). The breakdown of the tubules in the oil phase of the w/o emulsions prepared with oils with a relatively high dielectric constant (eugenol and castor oil) is ascribed to the sitosterol depletion of the tubular network (see Fig. 4c), caused by the formation of sitosterol monohydrates. In the case of oils with a low dielectric constant (limonene), the hydration of the sitosterol is less pronounced due to the reduced availability of water and the tubular structure remaining practically intact (see Fig. 4b).

Conclusions

This paper documents the effect of the type of oil phase on the properties of organogels structured by γ-oryzanol and β-sitosterol mixtures. The observations indicated that HSPs are a suitable tool to predict the gelling behaviour of binary phytosterol structurants in various organic phases, provided that the mode of assembly remains the same (in this case the mode of assembly is tubule formation).

Increasing the dielectric constant of the oil leads to straighter tubules and less bundling of the tubules in the organogels. The straighter tubules result in firmer gels, whereas less bundling leads to weaker gels. In case of emulsions, a modest increase of dielectric constant of the oil, leads to a more open tubular network with straighter tubules than the organogel. It is interesting to observe that subtle morphological changes occur in organogels depending on the solvent used, even if the solvent as such meets the criteria to allow organogelling. At this stage it is not possible to determine whether the relation between the firmness and the morphology of the tubules and the firmness of organogels and emulsions is causal or the result of a common underlaying cause. With the oils with a relatively high dielectric constant, most of the tubules in the emulsions disintegrated and, consequently, the gels weakened.

References

M.B. Katan, S.M. Grundy, P. Jones, M. Law, T. Miettinen, R. Paoletti, Efficacy and safety of plant stanols and sterols in the management of blood cholesterol levels. Mayo Clin. Proc. 78(8), 965–978 (2003)

A. Matheson, G. Dalkas, P.S. Clegg, S.R. Euston, Phytosterol-based edible oleogels: A novel way of replacing saturated fat in food. Nutr. Bull. 43(2), 189–194 (2018)

A. Bot, Phytosterols. In: Encyclopedia of Food Chemistry, Reference Module in Foods Science (Elsevier, 2018), pp. 225–228

M. Pernetti, K.F. van Malssen, E. Flöter, A. Bot, Structuring of edible oils by alternatives to crystalline fat. Curr. Opin. Colloid Interface Sci. 12(4-5), 221–231 (2007)

A. G. Marangoni, N. Garti (eds.), Edible Oleogels: Structure and Health Implications (Elsevier/Academic Press, London, 2018)

A.R. Patel (Ed). Edible Oil Structuring: Concepts, Methods and Applications. (Royal Society of Chemistry, 2018)

S. Calligaris, G. Mirolo, S. Da Pieve, G. Arrighetti, M.C. Nicoli, Effect of oil type on formation, structure and thermal properties of γ-oryzanol and β-sitosterol-based organogels. Food Biophysics 9(1), 69–75 (2014)

M.A. Rogers, Novel structuring strategies for unsaturated fats – Meeting the zero-trans, zero-saturated fat challenge: A review. Food Res. Int. 42(7), 747–753 (2009)

G. Dalkas, A.B. Matheson, H. Vass, A. Gromov, G.O. Lloyd, V. Koutsos, P.S. Clegg, S.R. Euston, Molecular interactions behind the self-assembly and microstructure of mixed sterol organogels. Langmuir 34(29), 8629–8638 (2018)

A. Bot, E.P. Gilbert, W.G. Bouwman, H. Sawalha, R. den Adel, V.M. Garamus, P. Venema, E. van der Linden, E. Flöter, Elucidation of density profile of self-assembled sitosterol + oryzanol tubules with small-angle neutron scattering. Faraday Discuss. 158, 223–238 (2012)

A.B. Matheson, V. Koutsos, G. Dalkas, S.R. Euston, P.S. Clegg, Microstructure of β-sitosterol:γ-oryzanol edible organogels. Langmuir 33(18), 4537–4542 (2017)

A. Bot, R. den Adel, E.C. Roijers, Fibrils of γ-oryzanol + β-sitosterol in edible oil organogels. Journal American Oil Chemist Society 85(12), 1127–1134 (2008)

A. Bot, R. den Adel, C. Regkos, H. Sawalha, P. Venema, E. Flöter, Structuring in β-sitosterol + γ-oryzanol-based emulsion gels during various stages of a temperature cycle. Food Hydrocoll. 25(4), 639–646 (2011)

H. Sawalha, R. den Adel, P. Venema, A. Bot, E. Flöter, E. van der Linden, Organogel-emulsions with mixtures of β-sitosterol and γ-oryzanol: Influence of water activity and type of oil phase on gelling capability. J. Agric. Food Chem. 60(13), 3462–3470 (2012)

T. Moschakis, E. Panagiotopoulou, E. Katsanidis, Sunflower oil organogels and organogel-in-water emulsions (part I): Microstructure and mechanical properties. LWT 73, 153–161 (2016)

R. den Adel, P.C. Heussen, A. Bot, Effect of water on self-assembled tubules in β-sitosterol+ γ-oryzanol-based organogels. J. Phys. Conf. Ser. 274, 012025 (2010)

A. Matheson, G. Dalkas, R. Mears, S.R. Euston, P.S. Clegg, Stable emulsions of droplets in a solid edible organogel matrix. Soft Matter 14(11), 2044–2051 (2018)

Y. Lan, M.G. Corradini, X. Liu, T.E. May, F. Borondics, R.G. Weiss, M.A. Rogers, Comparing and correlating solubility parameters governing the self-assembly of molecular gels using 1,3:2,4-dibenzylidene sorbitol as the gelator. Langmuir 30(47), 14128–14142 (2014)

M. Scharfe, Y. Ahmane, J. Seilert, J. Keim, E. Flöter, On the effect of minor oil components on β-sitosterol/γ-oryzanol oleogels. Eur. J. Lipid Sci. Technol. 121(8), 1800487 (2019)

H. Sawalha, G. Margry, R. den Adel, P. Venema, A. Bot, E. Flöter, E. van der Linden, The influence of the type of oil phase on the self-assembly process of γ-oryzanol + β-sitosterol tubules in organogel systems. Eur. J. Lipid Sci. Technol. 115(3), 295–300 (2013)

H. Sawalha, P. Venema, A. Bot, E. Flöter, E. van der Linden, The influence of concentration and temperature on the formation of γ-oryzanol + β-sitosterol tubules in edible oil organogels. Food Biophysics 6(1), 20–25 (2011)

Y. Lan, M.G. Corradini, M.A. Rogers, Do molecular gelators cluster in Hansen space? Cryst. Growth Des. 14(9), 4811–4818 (2014)

M.A. Rogers, Hansen solubility parameters as a tool in the quest for new edible oleogels. Journal American Oil Chemist Society 95(4), 393–405 (2018)

H. Sawalha, P. Venema, A. Bot, E. Flöter, R. den Adel, E. van der Linden, The phase behavior of γ-oryzanol and β-sitosterol in edible oil. Journal American Oil Chemist Society 92(11-12), 1651–1659 (2015)

A. Bot, W.G.M. Agterof, Structuring of edible oils by mixtures of γ-oryzanol with β-sitosterol or related phytosterols. Journal American Oil Chemist Society 83(6), 513–521 (2006)

T. Narayanan, O. Diat, P. Bösecke, SAXS and USAXS on the high brilliance beamline at the ESRF. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment 467–468 Part 2, 1005–1009 (2001)

R.G. Weiss, The past, present, and future of molecular gels. What is the status of the field, and where is it going? Journal of the American Chemical Society 136, 7519–7530 (2014)

C.M. Hansen, Hansen Solubility Parameters: A users’s Handbook, second edn. (CRC Press, Boca Raton, 2007)

S. Abbott, C. Hansen, Hansen Solubility Parameters (HSP) Application Notes: Hansen Solubility Parameters in practice, Hansen-Solubility.com (2013)

H. Ritter, R.L. van de Sande, V. Muller, Liquid fatty component containing composition. Patent application WO 97(42830) (1997)

A. Bot, R. den Adel, E.C. Roijers, C. Regkos, Effect of sterol type on structure of tubules in sterol + γ-oryzanol-based organogels. Food Biophysics 4(4), 266–272 (2009)

Y. Lan, M.A. Rogers, 12-Hydroxystearic acid SAFiNs in aliphatic diols–a molecular oddity. CrystEngComm 17(42), 8031–8038 (2015)

Acknowledgements

The research described in this paper is financially supported by Food and Nutrition Delta. The authors thank Ruud den Adel for performing a measurement on the ID02 beamline in Grenoble, and T. Narayanan and M. Sztucki (European Synchrotron Radiation Facility) for support during these measurements. The authors also thank Adriaan Van Aelst, Wageningen University for preparing the SEM images. Claudine Diedericks is thanked for detailed feedback on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration

The authors have no conflict of interest to declare concerning the present manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sawalha, H., Venema, P., Bot, A. et al. Effects of Oil Type on Sterol-Based Organogels and Emulsions. Food Biophysics 16, 109–118 (2021). https://doi.org/10.1007/s11483-020-09654-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-020-09654-8