Abstract

Functional and bioactive properties of crayfish meat convert their surpluses in an excellent alternative for the development of food products. Thus, protein dispersions were subjected to a thermal treatment, obtaining a protein-based gel. Rheological and antioxidant properties were studied at three different pH values (2.0, 6.5 and 8.0) when the TGase enzyme was used. The pH value exerted a strong influence on the gelation behaviour, as well as on the functional properties and the antioxidant activity of the final gels. The activity of the TGase enzyme is highly influenced by the pH of the protein dispersions. The highest antioxidant activity was obtained against ABTS and the lowest when FC reagent was used, whereas the activity against DPPH was also remarkable. TGase enzyme can be used during the thermal treatment to increase the mechanical properties, which were lost when hydrolysate systems were used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to population growth, there is a need for new protein sources. One way to introduce these new products into food products is in the development of protein gels. In order to do this, thorough studies of both the nutritive and the physiochemical properties of these proteins in food systems (or maybe just end after these proteins) is needed [1, 2]. The freshwater crayfish Procambarus clarkii can be an excellent protein source. It was introduced in the Guadalquivir marshlands (south of Spain), and as a result of abundant food, favourable weather conditions and lack of predators, the crayfish population had a fast growth, being now considered as an invasive species [3]. Currently, most of them are used as animal feed because a big amount of low-value surpluses is produced every year. An alternative may be the use of crayfish-meat to produce a techno-functional protein concentrate, which could be stored for later use. This protein concentrate may be used in different food products such as gels or emulsions [4, 5].

Over the last decade, there have been an increase in the interest of proteins and protein hydrolysates used in food products [6]. Hydrolysis of these protein systems may be an interesting alternative to improve their functional and bioactive properties [7, 8]. Many of these by-products exhibit bioactive properties such as antioxidant activity [9, 10]. This makes the food industry had a great interest in the use of by-products to develop food products with beneficial health effects. Antioxidant activity has been evaluated in numerous proteins and peptides from protein hydrolysates [11,12,13]. The exact mechanisms leading to exhibition of antioxidant activity are not completely known. However, the dominant antioxidative mechanism in food products is believed to be complex binding of metals leading to metal catalysed decomposition of lipid hydroperoxides [14].

Functional properties are also important for the texture and the appearance of food products [15, 16]. Rheological properties of fluid gels are essential features because gels behave in a solid-like at rest, but as a liquid above a critical value of stress [17]. Rheological behaviour can be modified to satisfy consumer requirements for desired applications by varying the composition, the crosslinking density and shape or particle size [18].

Functional properties of crayfish protein isolates such as gel and emulsifying properties of crayfish have been evaluated [19,20,21]. Moreover, the antioxidant activity of crayfish-based gels has been recently assessed [22]. These results indicated that this protein powder has an excellent antioxidant activity. However, it is strongly dependent on pH and the degree of hydrolysis. Unfortunately, the increase in the degree of hydrolysis gave a reduction in the water holding capacity, which is one of the most important features of gels. Transglutaminase (TGase) enzyme can be used to promote cross-linking between different kinds of proteins chains leading to gel formation. The crosslinking activity depends on the pH and temperature [23,24,25,26]. The use of TGase to promote cross-linking between crayfish proteins has not been yet evaluated.

The aim of this work was to evaluate the influence of TGase on gelling properties and bioactive potentials of gels made from crayfish protein hydrolysate, compared to gels from non-hydrolysate crayfish, at three different pH values (2.0, 6.5 and 8.0). Rheological measurements of aqueous protein dispersions were performed to simulate the gelation process by means of temperature ramp-test, as well as frequency sweep tests to obtain mechanical spectra. Functional and bioactive properties were assessed by means of the determination of water holding capacity and protein interactions. The antioxidant activity of the different gels was evaluated against three different compounds (ABTS, DPPH and Folin-Ciocalteu).

Material and Methods

Materials

Crayfish (CF) meat was separated from the shell by grinding and sieving and was kept frozen until use. This first stage was carried out by ALFOCAN (Isla Mayor, Sevilla, Spain). After thawing at 4 °C, CF2L protein system was obtained from the frozen CF-pulp as described by Felix et al. [21]. The protein content of the CF2L protein concentrate was ca. 80 wt.%.

CF2L was subjected to a hydrolysis process using pancreatic trypsin. The enzyme/substrate ratio (E/S) was set at 1:100 (w/w). The pH of the dispersion was kept constant at 8.0 over the entire period of hydrolysis (25 min) by the addition of 3 M NaOH. The resulting hydrolysates were heated in boiling water for 10 min to inactivate the enzyme, and centrifuged at 5000 x g for 15 min to separate any impurities. Finally, the supernatant was freeze-dried in order to obtain a protein powder. The degree of hydrolysis of the protein system obtained was 31% DH according to a previous work [27].

Transglutaminase (TGase), with activity between 80 and 140 U/g, was used as cross-linking agent, and was supplied by BDF Ingredients (PROBIND TX). Heat-induced gels were obtained from protein dispersions at 12 wt.%, using the CF2L protein concentrate (reference system), the hydrolysate from CF2L (for 25 min of hydrolysis, CF2LH25) and after adding 0.1 wt.% of TGase to the hydrolysate system. This TGase/protein ratio corresponds to the best rheological properties found in CF2L-based gels (lower TGase concentrations did not increase significantly the rheological properties of the gel, whereas higher TGase concentrations did not exhibit better rheological properties). This TGase concentration is similar to the one used by Lee et al. [28] for surimi-gels made from fish proteins. All gels were performed at three different pH values (2.0, 6.5 and 8.0).

All other reagents used were of analytical grade, purchased from Sigma–Aldrich Chemical Company (St. Louis, USA). Milli-Q ultrapure water was used for the preparation of all solutions.

Gel Characterisation

Viscoelastic Measurements of Gels

Small Amplitude Oscillatory Shear (SAOS) measurements were performed in a controlled-stress rheometer (Kinexus Ultra +) from Malvern Instruments (Malvern, Worcestershire, United Kingdom). Previously, the linear viscoelasticity ranges for different regions (temperatures and frequencies) were stablished by stress sweep. All tests were carried out at a stress clearly lower than the critical value for linear viscoelasticity. The geometry used was cone-plate geometry (50 mm, 2°).

12 wt.% protein/water dispersions were gelated through heating in situ in the rheometer with three different stages. (i) The first step consisted of a temperature ramp carried out at constant heating rate (5 °C/min) from 20 °C to 90 °C; (ii) After the first step, a isothermal oscillation was performed at 90 °C for 30 min; (iii) Subsequently, a temperature ramp was carried out at constant cooling rate (5 °C/min) from 90 °C to 20 °C. All stages were performed at constant frequency (6.28 rad/s). Finally, frequency sweep tests (0.06–64 s−1) at 20 °C were carried out in order to obtain mechanical spectra.

Protein Interactions

Solubility of CF2L gels in a number of selected solutions was carried out in order to determine the concentration of ionic bond, hydrogen bond, hydrophobic interaction and disulfide bond according to the method used by Gomez-Guillen et al. (1997). The selected solutions were as follows: 0.05 mol/L NaCl (SA), 0.6 mol/L NaCl (SB), 0.6 mol/L NaCl +1.5 mol/L urea (SC), 0.6 mol/L NaCl +8 mol/L urea (SD) and 0.6 mol/L NaCl +8 mol/L urea +0.5 mol/L β-mercaptoethanol (SE) solutions. Ionic interactions is given/determined as the difference between protein solubilized in SB and protein solubilized in SA; hydrogen bond was the difference between protein solubilized in SC and protein solubilized in SB; hydrophobic interaction was the difference between protein solubilized in SD and protein solubilized in SC and, finally, disulphide bond was the difference between protein solubilized in SE and protein solubilized in SD. The protein concentration was determined according to the modified Lowry method [29].

Water-Holding Capacity of Gels

Each gel (0.5–1.5 g) was equilibrated at room temperature and placed on a nylon plain membrane (5.0-mm pores, Micronsep, New York, N.Y., U.S.A.) maintained in the middle position of a centrifuge tube. Water loss was determined by weighing before and after centrifugation at 120×g for 5 min at 5 °C [30]. Water-holding capacity (WHC) was expressed as the percentage of the initial water remaining in the gel after centrifugation.

Antioxidant Activity

DPPH Assay

The 2,2-diphenyl-1-picrylhydrazyl (DPPH) assay was performed as described by Brand-Williams et al. [31] with some modifications [32,33,34]. Briefly, the day before analysis, 0.1 mM methanolic DPPH* working solution was prepared and kept on a magnetic stirrer overnight at 4 °C. A series of 0–750 μM methanolic working solutions of Propyl Gallate and gel solutions at 10 wt.% in methanol were prepared. An aliquot of DPPH* solution (2.9 mL) was well mixed with 0.1 mL of a sample or methanol (blank). After 20 min of incubation at room temperature, the absorbance at 515 nm was recorded. Water was used as a blank. Results were expressed as equivalent activity of the gel in contrast to the reference (Propyl Gallate).

ABTS Assay

The 2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS) assay was performed as described by Nenadis et al. [35] with a few modifications: ethanol was replaced with methanol and the amount of sample added to the ABTS•+ solution was 200 μL. For the analysis, a series of 0–55 μM working solutions of Propyl Gallate and gels at 1 wt.% were prepared from stock gels. To compare the antioxidant activities, the absolute values for each antioxidant and each assay were recalculated into Propyl Gallate equivalents.

Folin-Ciocalteu (FC) Assay

The FC assay was performed as described by Singleton et al. [36] with some modifications [35, 37]. Briefly, a series of 0–4 mM working solutions of Propyl Gallate and suitable gel solutions were prepared. Deionized water (10 mL), antioxidant solution (1 mL), and 2.0 M Folin-Ciocalteu phenol reagent (1 mL) were transferred to a 20 mL volumetric flask. The reaction mixture was mixed by shaking, and after 3 min, 2 mL of 20% Na2CO3 solution (20 g/L) was added. The volume was brought up with deionized water. The absorption at 725 nm was read after 1 h of incubation at room temperature. Water was used as a blank. Results were expressed as equivalent activity of the gel compared to the reference (Propyl Gallate).

Statistical Analysis

At least three replicates of each measurement were carried out. Statistical analyses were performed using t-test and one-way analysis of variance (ANOVA, p < 0.05) by means of the statistical package SPSS 18. Standard deviations from some selected parameters were calculated.

Results and Discussion

Gel Characterisation

Viscoelastic Characterisation

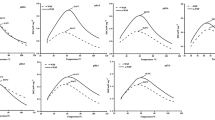

The viscoelastic profiles obtained over the gelation process were classified according to the effect hydrolysis and TGase at different pH values. Thus, Fig. 1a shows the gelation process for the CF2L system, Fig. 1b corresponds to the hydrolysate system (CF2LH25) and the Fig. 1c corresponds to the hydrolysated system treated with TGase (CF2LH25T). All of them were carried out at three different pH values (2.0, 6.5 and 8.0).

Temperature ramp tests performed at constant frequency, 0.63 rad/s for all studied systems (CF2L (a), CF2LH25 (b) and CF2LH25T(c)) at 12 wt.%. Three different pH values were evaluated (2.0, 6.5 and 8.0). An initial heating step (5 °C/min from 25 to 90 °C) was followed by an isothermal step (90 °C, 30 min) and a cooling step (rate: 5 °C/min from 90 to 25 °C)

The lowest viscoelastic response was obtained at pH 2.0 for all the protein-based gels studied. None of them exhibits any remarkable gelling potential under the processing conditions studied, since the highest G’ reached is around 1 Pa. No strong interactions among different protein chains were found and, consequently, weak gel-like products were obtained at pH 2.0. Neither the effect of hydrolysis, nor the use of TGase yields any thermal-induced reinforcing potential at this pH value. The lack of crosslinking potential observed at pH 2.0 seems to be related to non-adequate conditions for the enzyme employed. The hydrolysis seems to reduce the cross-linking and interaction potentials of CF2L-proteins systems. This is in accordance with earlier studies showing loss of functional properties of some proteins after hydrolysis [38, 39].

However, the viscoelastic responses obtained over the gelling process at pH 6.5 and 8.0 were quite different. In these cases, the gelation profiles obtained for all the systems were more similar to other typical protein gelation processes [18, 40, 41]. In these cases, the SAOS responses were characterised by a first stage, in the first hundreds of seconds, where a smooth decrease in G’ and G” took place. Usually, this first stage occurs below 45 °C, and it has been related to the increase in mobility of the protein chains due to thermal agitation. Thus, the increase in temperature involves a reduction of physical interactions (i.e. hydrogen bonds) and, as a consequence, the viscosity of the dispersion decreases [42]. For meat proteins, the denaturation of myosin chains, which takes place around 30–40 °C [25, 43], seems to lead to some hydrophobic groups become exposed [44] Subsequently, above 50 °C, the increase in temperature involves a marked increase in both modulus (G’ and G”). This effect is a clear consequence of structural changes, which promotes an extended protein crosslinking with the resulting network formation, mainly through sulphide-bonds, as well as hydrophobic interactions [42, 45].

Note that it is in this heating stage where the most different behaviour is observed. Thus, systems at pH 6.5, whose pH corresponds to the isoelectric point (IEP) of this proteins (ca. pH 5) [21], seem to experience a fast increase in viscoelastic moduli whereas the increase observed in the isothermal stage was less pronounced. On the contrary, hydrolysate systems at pH 8.0 develop a real protein crosslinking during the isothermal stage. The addition of TGase to the protein dispersions at these pH values (6.5 and 8.0) gives an increase in both viscoelastic moduli, particularly relevant at pH 8.0. In addition, the growth of aggregates becomes slower for the hydrolysates at pH 8.0 without TGase, resulting in the delay in the gel development. In this sense, the optimal activity of the TGase was reported at a pH 5.0–8.0 and ca. 50 °C [46, 47], which indicates that the crosslinking reactions promoted by the TGase enzyme is favoured at pH 8.0.

Finally, at the cooling stage, a slight decrease in viscoelastic moduli was found, probably because of liquid volume contraction. This decrease was followed by an increase of both moduli (G’ and G”) (except for CF2L system). Interactions such as hydrogen bonds or hydrophobic interactions, among others, have been postulated to be responsible for the increase in both viscoelastic moduli and, consequently, an important stabilization of the protein system [48].

Fig. 2a, b and c show the mechanical spectra for the CF2L, CF2LH25 and CF2LH25T gels, at three pH values (2.0, 6.5 and 8.0), respectively. All the systems show a fairly weak gel-like behaviour, particularly at pH 2.0. These results are in accordance with the ones obtained from the rheological response over the gelation process, where the weakest gel (the lowest viscoelastic moduli) corresponded to systems at pH 2.0 (Fig. 1). Note that results at high frequencies were discharged since inertial effects takes place.

However, significant differences in the mechanical response were observed, not only on the effect of hydrolysis (Fig. 2b), but also on the use of the TGase (Fig. 2c), at different pH values. After these thermal treatments, gels exhibit higher values for both G’ and G” moduli that become nearly parallel, and also show low frequency-dependence, which are characteristic features of gel behaviour [49]. The increase in viscoelastic properties using hydrolysate would be related to the change of the protein conformation that would lead to the development to greater interactions at pH values 6.5 and 8.0. Beside the fact that a significant increase (p < 0.05) in viscoelastic moduli takes place at both pH values (pH 6.5 and 8.0) after either enzymatic treatment, this increase is more apparent at pH 8.0. Moreover, this increase is quite important since it has been related to the gel stability [49].

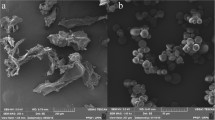

Physicochemical Characterisation

Protein solubility values obtained for all the gels studied at three different pH values (2.0, 6.5 and 8.0) in solutions with ability to disrupt different kinds of bonds are shown in CF2L (Fig. 3a), CF2LH25 (Fig. 3b) and CF2LH25T (Fig. 3c) according to Sano [50] and Gomez-Guillen [51].

All the specific interactions showed generally lower values at pH 2.0, while at pH 6.5 and 8.0 the interactions were stronger. These results are consistent with those obtained from rheological measurements that, as previously mentioned, reveal the formation of a weak gel at pH 2.0.

This figure also reveals that at pH 6.5 a high level of ionic interactions takes place, which indicates participation of ionic bonds in the gel obtained. These results must be related to lower surface charges found at this pH value, due to the closeness of the protein dispersion to the (IEP). Thus, the null net charge avoids electrostatic repulsions close to the IEP [51].

In addition, chemical interactions (disulphide bonds and crosslinking promoted by TGase) are also more relevant in systems where TGase has been added (Fig. 3c). This type of specific chemical interactions is a consequence of the thermal treatment [42] and, in systems with TGase, the crosslinking promoted by an enzymatic treatment. These interactions are the responsible for the higher values of both moduli (G’ and G”) found in viscoelastic measurements after the thermal gelation.

Water Holding Capacity (WHC)

Figure 4 shows WHC for all the gels studied: CF2L, CF2LH25 and CF2LH25T as a function of pH (2.0, 6.5 and 8.0). The results obtained from WHC tests are in agreement with those obtained from rheological properties and interactions measurements. Macroscopic properties of gels, rheological properties and WHC, are consequence of the balance between protein-protein and protein-water interactions in the gel and the amount of these interactions. In this sense, the gels obtained from the protein dispersions exhibit the highest WHC at pH 6.5, and it has been previously attributed to the absence of repulsive interactions [22]. However, the strengthening found in viscoelastic measurements for gels after the hydrolysis procedure does not result in an increase in WHC regardless of the pH used. This behaviour may be related to the fact that the gel structure is stronger, however is not able to hold water into protein clusters because the hydrolysis procedure applied reduces the yield strength of the gels. On the contrary, the higher values of WHC were found when the TGase enzyme took part in the gel formation, reaching higher values than the reference system and the hydrolysate at pH 6.5 and 8.0.

Antioxidant Activity

Figure 5 exhibits the antioxidant activity measured for all the gels studied at three different pH values (2.0, 6.5 and 8.0) with three different methods: DPPH (Fig. 5a), Folin-Ciocalteu (Fig. 5b) and ABTS (Fig. 5c). Results were expressed as mM Eq. of Propyl Gallate (PG). As may be deduced from the different scales of the Y-axis, the maximum antioxidant activity was obtained for ABTS, followed by DPPH and FC reagent. The antioxidant activity against DPPH does not seem to be influenced by the pH value (except for the system with TGase at pH 8.0, where this activity is reduced). However, the hydrolysis procedure leads to decrease this activity. The reinforcement of the gel-network after using TGase seems to promote a soft increase of this ability at pH 2.0 and 6.5. Note that the DPPH method is based on the reduction of DPPH which takes place when some substrate is able to donate a hydrogen group [52]. According to this premise, it seems that only at pH value 8.0 (when TGase enzyme plays a key role) the availability of hydrogen donator is reduced.

Fig. 5b shows antioxidant activity against ABTS, in this case both effects (pH and effect of hydrolysis) exert a strong influence on the antioxidant activity against ABTS. The antioxidant activity against ABTS is related to the ability of the protein to cation radical (ABTS•+) scavenging. An increase in pH leads to increase the antioxidant activity of protein-based gels against this reagent. The hydrolysis procedure leads to a noticeable increment of the antioxidant activity; however, the use of TGase as crosslinker agent reduces this potential. In any case, the antioxidant activity is higher than that one found for the reference system (CF2L).

Finally, the antioxidant activity found for the FC was the lowest. This protein behaviour may be explained because FC reagent is not capable to measure lipophilic antioxidants because of the high affinity of the FC chromophore toward water, as well as FC reagent is related to the presence of phenolic compounds [53]. As may be observed in Fig. 5c, this antioxidant activity slightly increases when the hydrolysis procedure was carried out. However, neither the use of TGase nor the pH value lead to no significant improvements on the antioxidant activity of crayfish-based gels against FC.

Conclusions

Surpluses from CF-processing industry can be used for manufacturing thermal gels, which exhibit antioxidant properties. Macroscopic evaluation of crayfish protein gels (SAOS measurements and WHC) reveals a strong dependence of gelation ability and gel strength on pH and the use of TGase enzyme as crosslinker agent. The lowest mechanical properties are always found at pH 2.0 where the protein interactions also exhibit the lowest values. On the other hand, near the IEP, the reduce electrostatic repulsion charges facilitates a proper development of gel network structures leading to fairly strong gel-like viscoelastic behaviour, with higher amount of disulphide bonds and enhanced WHC. Improvements in mechanical behaviour (rheological properties and WHC) of CF2L-based gels are found when TGase enzyme takes part in the gelation process, especially at pH 8.0.

The highest antioxidant activity was obtained against ABTS and the lowest when FC was used, since this reagent is specific for phenol compounds. As for the activity against DPPH, it was also remarkable. The most remarkable effects observed were a dramatic increase on the activity against ABTS with increasing the pH value (around one decade) and an apparent maximum in this activity after hydrolysis. The use of TGase reduces this antioxidant activity, however is in any case higher than that one found for the reference system. After a hydrolytic treatment of the CF2L protein system, bioactive properties increase, however some mechanical properties (i.e. WHC) are reduced. To avoid this undesirable effect, TGase enzyme can be used during the thermal treatment, despite the fact that antioxidant properties are slightly reduced. Thus, protein-based gels can be obtained from crayfish surpluses, showing bioactive properties, that together to the structuration of gels, can be modulated by the hydrolysis and the use of TGase enzyme.

References

V. Urbonaite, H.H.J. de Jongh, E. van der Linden, L. Pouvreau, Food Hydrocoll. 46, 103 (2015)

S. David, Y. Zagury, Y.D. Livney, Food Biophys. 10, 195 (2015)

W. Geiger, P. Alcorlo, A. Baltanas, C. Montes, Biol. Invasions 7, 49 (2005)

C. Bengoechea, M.C. Puppo, A. Romero, F. Cordobes, A. Guerrero, J. Food Eng. 87, 124 (2008)

A. Romero, F. Cordobes, A. Guerrero, M. Cecilia Puppo, Food Hydrocoll. 25, 1490 (2011)

Y. Mine, E. Li-Chan, and B. Jiang, Bioactive Proteins And Peptides As Functional Foods And Nutraceuticals (Wiley-Blackwell, 2010).

E.C.Y. Li-Chan, Curr. Opin. Food Sci. 1, 28 (2015)

B.J.H. Kuipers, G.A. van Koningsveld, A.C. Alting, F. Driehuis, A.G.J. Voragen, H. Gruppen, Food Biophys. 1, 178 (2006)

R.H. Glew, R.S. Glew, L.T. Chuang, Y.S. Huang, M. Millson, D. Constans, D.J. Vanderjagt, Plant Foods Hum. Nutr. 61, 51 (2006)

L. Gwatidzo, B.M. Botha, R.I. McCrindle, Food Chem. 141, 2163 (2013)

R.J. Elias, S.S. Kellerby, E.A. Decker, Crit. Rev. Food Sci. Nutr. 48, 430 (2008)

B.H. Sarmadi, A. Ismail, Peptides 31, 1949 (2010)

M.C. Gomez-Guillen, B. Gimenez, M.E. Lopez-Caballero, M.P. Montero, Food Hydrocoll. 25, 1813 (2011)

D.J. McClements, E.A. Decker, J. Food Sci. 65, 1270 (2000)

S. Damodaran, K. L. Parkin, and O. R. Fennema, Fennema’s Food Chemistry, Fourth Edition (Taylor & Francis, 2007).

T.S. Leite, P.E.D. Augusto, M. Cristianini, Food Biophys. 10, 169 (2015)

I.T. Norton, D.A. Jarvis, T.J. Foster, Int. J. Biol. Macromol. 26, 255 (1999)

S. Ikeda, E.A. Foegeding, T. Hagiwara, Langmuir 15, 8584 (1999)

A. Romero, F. Cordobés, M.C. Puppo, A. Guerrero, C. Bengoechea, Food Hydrocoll. 22, 1033 (2008)

A. Romero, F. Cordobes, A. Guerrero, Food Hydrocoll. 23, 244 (2009)

M. Felix, A. Romero, A. Guerrero, Food Hydrocoll. 64, 9 (2017)

M. Felix, A. Romero, T. Rustad, A. Guerrero, Food Hydrocoll. 63, 429 (2017)

M. Motoki, K. Seguro, Trends Food Sci. Technol. 9, 204 (1998)

L. Kurth, P.J. Rogers, J. Food Sci. 49, 573 (1984)

Y.S. Kim, J. Yongsawatdigul, J.W. Park, S. Thawornchinsombut, J. Food Biochem. 29, 517 (2005)

Y. Kim, J.I. Kee, S. Lee, S.-H. Yoo, Food Chem. 145, 409 (2014)

M. Felix, A. Romero, T. Rustad, A. Guerrero, Food Bioprod. Process. 102, 167 (2017)

H.G. Lee, T.C. Lanier, D.D. Hamann, J.A. Knopp, J. Food Sci. 62, 20 (1997)

M.A.K. Markwell, S.M. Haas, L.L. Bieber, N.E. Tolbert, Anal. Biochem. 87, 206 (1978)

C. Queguiner, E. Dumay, C. Cavalier, J.C. Cheftel, Int. J. Food Sci. Technol. 24, 601 (1989)

W. Brand-Williams, M.E. Cuvelier, C. Berset, Food Sci. Technol. 28, 25 (1995)

H. Kikuzaki, M. Hisamoto, K. Hirose, K. Akiyama, H. Taniguchi, J. Agric. Food Chem. 50, 2161 (2002)

P. Stratil, B. Klejdus, V. Kuban, J. Agric. Food Chem. 54, 607 (2006)

N. Nenadis, O. Lazaridou, M.Z. Tsimidou, J. Agric. Food Chem. 55, 5452 (2007)

N. Nenadis, L.F. Wang, M. Tsimidou, H.Y. Zhang, J. Agric. Food Chem. 52, 4669 (2004)

V.L. Singleton, R. Orthofer, R.M. Lamuela-Raventos, Oxid. Antioxidants, Pt A 299, 152–1999

G. Miliauskas, P.R. Venskutonis, T.A. van Beek, Food Chem. 85, 231 (2004)

L. Wang, Y.J. Wang, Starch/Staerke 53, 570 (2001)

A. Surendra Babu, R. Parimalavalli, S.G. Rudra, Int. J. Biol. Macromol. 80, 557 (2015)

F. Cordobes, P. Partal, A. Guerrero, Rheol. Acta 43, 184 (2004)

A. Romero, F. Cordobes, M.C. Puppo, A. Villanueva, J. Pedroche, A. Guerrero, Food Hydrocoll. 23, 964 (2009)

J.C. Acton, R.L. Dick, J. Am. Oil Chem. Soc. 65, 497 (1988)

W.B. Yoon, S. Gunasekaran, J.W. Park, J. Food Sci. 69, E338 (2004)

A.H. Clark, G.M. Kavanagh, S.B. Ross-Murphy, Food Hydrocoll. 15, 383 (2001)

T. C. Lanier, P. Carvajal, and J. Yongsawatdigul, Surimi Gelation Chemistry, Surimi and SurimiSeafood, 2nd ed. (Boca Raton, 2004).

H. Ando, M. Adachi, K. Umeda, A. Matsuura, M. Nonaka, R. Uchio, H. Tanaka, M. Motoki, Agric. Biol. Chem. 53, 2613 (1989)

K. Yokoyama, N. Nio, Y. Kikuchi, Appl. Microbiol. Biotechnol. 64, 447 (2004)

T.C. Lanier, P. Carvajal, J. Yongsawatdigul, Food Sci. Technol. (Boca Raton, FL, U. S.) 142, 435 (2005)

S. Damodaran, Food Proteins and Their Applications (Taylor & Francis, 1997).

T. Sano, S.F. Noguchi, J.J. Matsumoto, T. Tsuchiya, J. Food Sci. 55, 55 (1990)

M. C. Gomez-Guillen, A. J. Borderias, and P. Montero, Food Sci. Technol., 602 (1997).

M.S. Blois, Nature 181, 1199 (1958)

K.I. Berker, F.A.O. Olgun, D. Ozyurt, B. Demirata, R. Apak, J. Agric. Food Chem. 61, 4783 (2013)

Acknowledgements

Authors were sponsored by Andalousian Government, (Spain) (project TEP-6134). The authors gratefully acknowledge their financial support. The authors also acknowledge to the. The authors were also supported by a grant from Iceland, Liechtenstein and Norway through the EEA Financial Mechanism. Operated by Universidad Complutense de Madrid.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Felix, M., Romero, A., Rustad, T. et al. Influence of Transglutaminase (TGase) Enzyme on Mechanical and Bioactive Properties of Crayfish Protein Gels. Food Biophysics 12, 348–355 (2017). https://doi.org/10.1007/s11483-017-9490-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-017-9490-7