Abstract

Many sectors of the food industry are interested in replacing synthetic or animal-based ingredients with plant-based alternatives to create products that are more natural, environmentally friendly, and sustainable. In this study, the ability of several plant protein concentrates to act as natural emulsifiers in oil-in-water emulsions fortified with omega-3 fatty acids was investigated. The impact of emulsifier type on the formation and stability of the emulsions was determined by measuring changes in droplet characteristics (size and charge) under different homogenization, pH, salt, and temperature conditions. Pea (Pisum sativum), lentil (Lens culinaris) and faba bean (Vicia faba) protein concentrates all proved to be effective emulsifiers for forming and stabilizing 10 wt% algae oil-in-water emulsions produced by high-pressure homogenization. The droplet size decreased with increasing emulsifier concentration, and relatively small oil droplets (d < 0.3 μm) could be formed at higher emulsifier levels (5% protein). Lentil protein-coated droplets were the most stable to environmental stresses such as pH, ionic strength and temperature changes. These results have important implications for the production of functional foods and beverages from natural plant-based ingredients.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Emulsifiers are surface active molecules that adsorb to the surfaces of oil droplets and form protective coatings around them [1]. Many proteins act as natural emulsifiers because they have an appropriate balance of hydrophilic and hydrophobic amino-acid groups, and adopt three-dimensional conformations where some of the hydrophobic groups are exposed at their surfaces [2]. Proteins therefore have the tendency to adsorb to oil droplet surfaces during homogenization and reduce the interfacial tension, which facilitates further droplet fragmentation by decreasing the Laplace pressure [3]. After adsorption, they may undergo conformational changes that increase the number of protein hydrophobic groups in contact with the oil phase, which may also lead to interfacial cross-linking of the proteins [4]. The protein coating formed around oil droplets also helps protects them against aggregation by generating electrostatic and steric repulsive forces [5]. Finally, the protein layer may also provide protection against chemical degradation by acting as a physical barrier, chelating agent, or antioxidant [6]. Compared to animal-based proteins, such as those from milk, eggs, meat or fish, the emulsification properties of plant-based proteins are much less well understood [1].

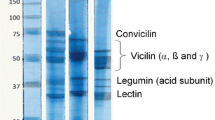

Proteins from legumes are of particular interest for use in the food industry due to their widespread abundance, low-cost, sustainability, low allergenicity, nutritional benefits, positive consumer perception, and good functional attributes [1, 7]. Pulses, which are the edible seeds of legumes, have been shown to contain amphiphilic proteins that form relatively thick layers around oil droplets, thereby enhancing emulsion formation and stability [8]. Legume proteins contain around 70% globulins and 10–20% albumins [9–11]. The main globulins found in legume proteins are vicilin and legumin [12]. Vicilin was found to be a better surface-active material than legumin, due to its low molecular weight and more flexible tertiary structure [13].

In this study, we investigated the ability of legume protein concentrates to act as plant-based emulsifiers in the development of emulsions fortified with omega-3 polyunsaturated fatty acids (PUFAs) from a non-animal source (algae). Two of the most biologically active sources of PUFAs currently utilized in the food industry are eicosapentaenoic acid (22:5 omega-3, EPA) and docosahexaenoic acid (22:6 omega-3, DHA). A diet rich in these omega-3 PUFAs may help prevent a variety of health problems, including cardiovascular disease, inflammation, diabetes, cancer, asthma, schizophrenia and depression [14–16]. Individuals can obtain nutritionally beneficial levels of these bioactive lipids by consuming sufficient quantities of fatty fish or isolated fish oils [14]. However, many individuals do not consume enough of these oil sources, including vegans, vegetarians, pregnant women (avoiding mercury), or people who dislike the taste of fish [14]. Consequently, there is considerable interest in identifying alternative sources of these long-chain omega-3 PUFAs, such as algae oil. In this case, it is necessary to incorporate the algae oil into a functional food or beverage product that consumers find desirable. There are a number of challenges associated with fortifying foods with omega-3 PUFAs due to their poor water solubility and high susceptibility to lipid oxidation [7]. These challenges can often be overcome by using well-designed emulsion-based delivery systems that can be used to conveniently incorporate these beneficial lipids into functional food and beverage products [17, 18].

The aim of the present study was to provide an understanding of the relative advantages and disadvantages of three different kinds of legume protein concentrate (pea, lentil, and faba bean) as natural emulsifiers for formulating emulsions enriched with omega-3 PUFAs. The influence of protein type, protein concentration, and processing conditions on emulsion formation and stability was investigated. This is the first part of a more comprehensive study using the same proteins, which also includes studies of their ability to inhibit lipid oxidation and their potential gastrointestinal fate to be published later. The information obtained from these studies may benefit the food industry by demonstrating the potential benefits of pulse protein concentrates as natural emulsifiers for formulating functional foods and beverages.

Materials and Methods

Materials

Pea, lentil, and faba bean protein concentrates (Vitessence Pulse 1550, 2550 and 3600, respectively) were kindly donated from Ingredion Inc. (Bridgewater, NJ). The composition of the legume protein concentrates is shown in Table 1. Glutamine and asparagine were the most abundant amino acids in the legume protein concentrates, making up to 17.8–19.5% and 11.6–12.8% of total amino acids, respectively. Whey protein isolate with 94% protein content (BiPro JE 011–4-420) was provided by Davisco Foods International Inc. (Le Sueur, MN). Algae oil (O55-O100 life’sOMEGA 60) was provided by DSM Nutritional products LLC (Parsippany, NJ). This product was reported to have a total omega-3 content of at least 550 mg/g, with 300 mg/g coming from DHA and 150 mg/g from EPA. All other chemicals were purchased from Sigma-Aldrich (St. Louis, MO, USA).

Methods

Protein Content of Plant Protein Concentrates

Information about the protein content of the plant protein concentrates was obtained using a modification of the method described by Joshi et al. (2011) [19]. Protein concentrates were dissolved in distilled water (20% w/w) and the mixture was adjusted to pH 8 using NaOH solutions. The dispersions were then stirred for an hour at room temperature. Any insoluble materials were then removed by centrifugation (Sorvall Lynx 4000 Centrifuge, Thermo Scientific, Agawam, MA) at 15,000 g for half an hour. The supernatants were collected and the solutions were adjusted to pH 4.5 using hydrochloric acid (HCl) solutions. The solutions were centrifuged as described above and the protein concentrates were collected in petri dishes and frozen by placing them into a − 80 °C freezer. The frozen protein concentrates were then freeze-dried overnight using a Virtis Freeze-dryer (Virtis Company, Gardiner, NY, USA). The dried protein concentrates were ground using a mortar and pestle.

The Lowry assay was used to quantify the protein content of the legume protein concentrate solutions [20]. The amount of protein present was calculated using a calibration curve prepared using bovine serum albumin as a standard.

The protein contents of the freeze-dried faba bean, lentil and pea protein concentrates were 74.5, 76.1 and 76.2%, respectively. This suggests that there must have been other components within the powders that co-precipitated with the proteins at pH 4.5, such as lipids, carbohydrates, or minerals.

Protein Solubility Assays

Protein solubility was determined following a modification of the method used by Aluko and Yada (1997) [21]. Protein concentrates were dispersed in sodium phosphate buffer (0.05% w/v) with sodium azide (0.02% w/v). For the pH-solubility assay, the pH values of the solutions were then adjusted to pH 2–9 using 1 N NaOH or HCl solutions. The solutions were then stirred overnight at room temperature and the pH values were re-adjusted to the appropriate values. To determine the total soluble protein content, a control group was carried by mixing the same concentration of the protein concentrates in 0.1 N NaOH solution. The protein solutions were centrifuged at 10,000 g for 20 min using a benchtop centrifuge (Sorvall ST8, Thermo Scientific, Tewksbury, MA, USA) and the protein concentrations of the supernatants were determined by the Lowry method [20]. Protein solubility (PS%) was calculated as:

Emulsion Formation

Emulsions were prepared using algae oil as the dispersed phase and a buffered protein solution as the continuous phase (10 mM sodium phosphate buffer, pH 7). These conditions were selected to simulate food and beverage products that have pH values around neutral. The powdered plant-protein concentrates were initially dissolved in sodium phosphate buffer overnight at 4 °C at concentrations ranging from 0.25 to 5% (w/w) based on the mass of the powder used. The pH values of the protein solutions were adjusted back to pH 7 after they were dissolved using sodium hydroxide (NaOH) solution. The manufacturer reported that these commercial ingredients contained 55–60% of protein, and therefore the actual protein contents were quantified using the Lowry method (Table 1). After dispersion in sodium phosphate buffer the protein concentrates tended to form cloudy dispersions. For this reason, the protein concentrate solutions were centrifuged (Sorvall Lynx 4000 Centrifuge, Thermo Scientific, Agawam, MA) at 15,000 g for 15 min to remove any insoluble particular matter. Emulsions were prepared using both centrifuged and non-centrifuged protein solutions, to determine the influence of this process on their functionality.

Coarse oil-in-water emulsions were prepared by blending the oil (10% w/w) and aqueous (90% w/w) phases together using a high-shear mixer (M133/1281–0, Biospec Products Inc., Bartlesville, OK) for 2 min at 10,000 rpm. This coarse emulsion was then passed three times through a high-pressure homogenizer (PureNano microfluidizer, Microfluidics, Newton, MA) operating at 10,000 psi. This system includes a Y- and a Z-type chamber to decrease the droplet size. The temperature of the emulsions was kept low (<15 °C) during homogenization by using an ice bath to cool the interaction chamber. This was done to prevent excessive heating of the emulsions at the high pressures used.

Emulsion Stability

A series of tests was carried out to establish the impact of environmental stresses on the stability of protein-coated oil droplets. These environmental stresses were selected to cover a range of representative conditions that emulsions may experience in commercial food products:

-

pH: Emulsions were prepared at pH 7 and then diluted 10-fold using 10 mM sodium phosphate buffer. A series of emulsions with different pH values (2 to 9) was then obtained by adjusting the diluted emulsions to the specified pH values using NaOH and HCl solutions.

-

Ionic strength: Emulsions were prepared at pH 7 and then they were diluted 10-fold using pH 7 sodium phosphate buffer containing a range of salt levels to achieve the final values of 0 to 500 mM sodium chloride (NaCl).

-

Temperature: Emulsions prepared at pH 7 were diluted 10-fold using pH 7 sodium phosphate buffer. They were then placed in glass test tubes (10 mL each), incubated in water baths set at different temperatures (20 to 90 °C) for 30 min, and then cooled down to room temperature.

After preparation, all of the emulsions were stored in the dark for 24 h at room temperature prior to analysis for particle size, particle charge, and emulsion appearance using the methods described in the following sections.

Droplet Characteristics

Droplet sizes were measured using a static light scattering instrument (MasterSizer 2000, Malvern Instruments, Westborough, MA). The resulting data is presented as particle size distributions or surface-weighted mean diameters (d 32). Droplet surface potentials (ζ-potentials) were measured by particle electrophoresis (Zetasizer Nano ZS Series, Malvern Instruments). Samples were diluted 1:100 with sodium phosphate buffer having the same pH and salt concentration as the sample prior to analysis to avoid multiple scattering effects.

Data Analysis

All data shown represents the mean values ± standard deviation of three repeated measurements from two replicates. Data results were analyzed by analysis of variance (ANOVA) using IBM SPSS Statistics 20 package program.

Results and Discussion

Emulsion Formation

The protein contents of the protein solutions were measured before and after centrifugation and are reported in Table 2. The percentages of proteins present were calculated from the ratio of the measured value to the amount of protein concentrate added to the solution. For the non-centrifuged samples, the protein contents were around 51.0%, 53.2%, and 63.5% for the pea, lentil, and faba bean proteins, respectively, which is in good agreement with the manufacturer’s specifications. For the centrifuged samples, the protein contents were around 43.1%, 43.3%, and 58.3% for the pea, lentil, and faba bean proteins, respectively. These results suggest that an appreciable amount of insoluble proteins were removed by centrifugation. Whey protein isolate was also used to compare the plant-based proteins with a widely-used animal-sourced protein for their potential to fabricate omega-3 emulsions.

The particle size distributions of emulsions stabilized using the centrifuged and non-centrifuged protein solutions were measured to determine the influence of this processing step on protein functionality (Fig. 1). The emulsions prepared from the non-centrifuged protein concentrates had a bimodal distribution, with a population of relatively small particles (peak around 0.2 μm) and another population of relatively large particles (peak around 20 μm). Optical microscopy images of the emulsions before centrifugation indicated that they did not contain any large individual oil droplets (data not shown), which suggests that the large particles in the bimodal distributions were probably insoluble protein particles. Conversely, the emulsions prepared from the centrifuged protein concentrates had a monomodal distribution, with a single peak around 0.5 μm. These results suggest that the non-centrifuged samples contained some relatively large insoluble particles that contributed to the light scattering signal measured by the instrument used to measure the particle size distribution. Interestingly, the population of small particles in the emulsions prepared from non-centrifuged solutions was smaller than those in the emulsions prepared from centrifuged solutions (Fig. 1). This suggests that there may have been some small particles that were also removed by centrifugation, or that there were some highly effective emulsifiers in the non-centrifuged samples that produced small lipid droplets during homogenization, but that were removed by centrifugation. Further work is clearly needed to determine the physicochemical origin of this interesting effect. Our results suggest that it may be advantageous for the manufacturers of the plant protein-based emulsifiers to include additional steps to remove any large insoluble aggregates from ingredients intended for applications in emulsions. Alternatively, it may be possible to dissolve the insoluble aggregates under certain pH, salt, or temperature conditions, but further work is needed to establish whether this is possible.

The influence of protein type and concentration on the mean droplet diameter (d 32) of the emulsions was also investigated (Fig. 2). All the plant proteins used in this study led to a similar trend of decreasing mean particle size with increasing protein concentration. For both non-centrifuged (Fig. 2a) and centrifuged (Fig. 2b) protein solutions, the mean droplet diameter decreased with increasing protein content. This trend has been attributed to the fact that the droplet size that can be produced in a homogenizer is limited by the amount of emulsifier available to cover the surfaces of the droplets formed [22]. Commercially, it is important that fortified emulsions have relatively small droplet sizes (d < 0.5 μm) to reduce creaming and increase bioavailability [23]. In most previous studies using pea, bean, lentil, and chickpea protein concentrates to form oil-in-water emulsions it was reported that it was difficult to produce oil droplets with diameters below about 1 μm [24–26]. However, one study was able to produce smaller droplets by continuously passing pea protein stabilized emulsions through a high pressure homogenizer [12]. In the present study, we were able to fabricate emulsions with mean particle diameters below 0.35 μm for all plant protein concentrates. For example, for pea, lentil, and faba bean protein concentrates (5% w/w) the mean droplet diameters were 0.35, 0.35, and 0.28 μm for the centrifuged samples, respectively. The smaller size of the droplets produced in the current study may be due to the fact that a microfluidizer was used to produce the emulsions, which is known to be more efficient than high-pressure valve homogenizers at producing small droplets. It is also possible that the nature of the proteins used in this study was different from that used in previous studies due to differences in origin or isolation. Overall, our results suggest that the faba bean protein concentrates were able to produce the smallest droplets under standardized homogenization conditions.

For the remainder of this study, the centrifuged protein samples were utilized because they produced emulsions with a monomodal particle size distribution, which would be more suitable for most commercial applications.

Surface Load Calculations

The saturation surface load (Γ sat) is the mass of emulsifier adsorbed per unit surface area when an interface is completely covered with emulsifier, and it therefore provides a useful indication of the amount of emulsifier needed to prepare an emulsion [3]. The saturation surface load can be calculated from the following expression:

where C S is the emulsifier concentration in the emulsion, d 32 is the surface-weighted mean droplet diameter, and ∅ is the disperse phase volume fraction [3]. In our study, the initial emulsions were prepared with a disperse phase mass fraction of 0.1 (10% w/w), and so it is necessary to convert this value into a volume fraction [3]:

Here ρ 1 and ρ 2 are the densities of the continuous and dispersed phases, respectively. This equation was used to calculate the disperse phase volume fraction (∅ = 0.104) from the densities of the two phases and the mass fraction (∅ m = 0.100).

The lowest emulsifier concentration required to produce small droplets was obtained for the whey protein-stabilized emulsions (Fig. 2a) probably because they had the lowest surface load (Fig. 2a), i.e., whey protein was the most effective emulsifier among those tests in this study. Eq. 1 suggests that a plot of d 32 against 1/C S should be a linear line with a slope equal to 6Γ∅ (Fig. 3). This approach was therefore used to estimate the saturation surface loads of the different emulsifiers (Table 3). As expected from the particle size data, faba bean protein concentrate proved to be the most efficient plant-based emulsifier, i.e., it had the lowest surface load. Relatively small globular proteins (such as bovine serum albumin, α-lactalbumin, and β-lactoglobulin) typically have surface loads around 1 to 3 mg m−2 [27–32]. On the other hand, relatively large globular proteins (such as soy proteins) and some flexible proteins (such as casein) have been reported to have surface loads around 4 to 11 mg m−2 [33–35]. The higher values for these proteins may be due to their high molecular weights or their ability to form multilayers around oil droplets [32, 34]. It should be noted that the method used to calculate the surface load in our study is based on the assumptions that all of the proteins adsorb to the droplet surfaces, and that the surface load does not depend on initial protein concentration. In practice, these assumptions may not be valid, which would lead to some errors in the estimated values. Nevertheless, this approach does provide some valuable information about the effective surface load of emulsifiers under conditions that simulate those that would be used commercially to fabricate emulsions.

Effect of Environmental Stresses on Emulsion Stability

For the stability studies, 10% (w/w) oil-in-water emulsions containing 3% (w/w) protein (centrifuged to remove insoluble matter) were prepared, because the droplet size appeared to reach a plateau region between 2 to 3% protein (Fig. 2b). The properties of the emulsions were measured after they had been exposed to the different pH, salt, and temperature conditions described earlier (Section 2.2.4).

Effect of pH

For commercial applications, it is often important that the emulsifier-coated oil droplets stay stable over the range of pH values typically found in emulsion-based food and beverage products. The aim of this study was therefore to evaluate the impact of storage pH on the properties of emulsions stabilized by the different legume protein concentrates. The electrical properties of the oil droplets were characterized by measuring their ζ-potential versus pH profiles (Fig. 4a). All of the emulsions exhibited a fairly similar behavior, with the ζ-potential moving from positive at low pH values to negative at high pH values, with an isoelectric point (pI) around pH 5. Legumes typically consist of a major fraction of globulins and a minor fraction of albumins [9–11]. The pI for globulins is around pH 4.5, whereas the pI of albumins is around pH 6, [13] and so the pH where the droplets have net zero charge would be expected to be between these values. Other researchers have also reported that pea, lentil, and soy protein concentrates have a low net charge around pH 5 [36].

Influence of pH on (a) droplet charge, (b) particle size, and (c) physical appearance of algae oil-in-water emulsions stabilized by different plant proteins. The protein-to-oil mass ratio in the emulsions was 0.27:1. The influence of pH on (d) the solubility of the protein in buffer solutions is also shown

The emulsions stabilized by lentil protein concentrate were the most stable to pH changes with the mean particle diameter being relatively low at all pH values except pH 5 (Fig. 4b), which is close to the pH where the droplets carry no charge. However, extensive phase separation due to creaming was observed from pH 4 to 6 in this system (Fig. 4c). The most likely reason for this observation is that the flocs were only held together by relatively weak attractive forces and so they were easily disrupted when the samples were diluted for the light scattering measurements. For the emulsions stabilized by pea protein concentrate, extensive droplet aggregation and creaming occurred in the range from pH 3 to 6. The emulsions stabilized by faba bean protein concentrate were the least stable to pH changes, with extensive aggregation and creaming occurring from pH 2 to 6. These results can be attributed to changes in the magnitude of the electrostatic repulsion between the droplets with pH [5, 37]. The protein-coated droplets have a high net charge at pH values well above or below their isoelectric point, which generates a strong electrostatic repulsion between them. Conversely, they have a low net charge at pH values around the pI, and so the electrostatic repulsion is not strong enough to overcome the van der Waals attraction, thereby leading to flocculation.

Interestingly, even though the electrical potential of the droplets was fairly similar for all the emulsions (Fig. 4a), the lentil protein-coated droplets were more stable to extreme pH values (Fig. 4c). This suggests that electrostatic interactions were not the only important colloidal interaction contributing to the overall aggregation stability of the emulsions. It is likely that those proteins that formed thick interfacial layers, such as the lentil proteins (high surface load), generated a longer-range steric repulsion between the droplets and therefore improved their aggregation stability.

It is interesting to compare the flocculation stability of the protein-coated emulsion droplets to the solubility of the protein molecules in solution, since both of these phenomena depend on electrostatic interactions, i.e. either between protein molecules or between protein-coated lipid droplets. For this reason, we measured the protein solubility as a function of pH (Fig. 4d). All of the plant proteins have a relatively high solubility at relatively high or low pH values because of the strong electrostatic repulsion between them, but they all aggregate around the isoelectric point because of the reduction in electrostatic repulsion. Thus, the solubility behavior of the protein molecules in solution follows a similar trend as the aggregation stability of the protein-coated droplets in emulsions.

Effect of Salt

Foods and beverages contain different levels of mineral ions and so it is important to understand the impact of salts on the properties of protein-coated oil droplets. For this reason, we examined the impact of NaCl on the stability of legume protein concentrate-stabilized emulsions at pH 7.

The influence of salt concentration on the particle size, particle charge, and physical appearance of the emulsions was measured (Fig. 5). For all the protein concentrates, there was a decrease in the magnitude of the ζ-potential with increasing salt concentration (Fig. 5a), which can be attributed to electrostatic screening, i.e., the preferential accumulation of counter-ions (Na+) around the negatively charged droplet surfaces [3, 5]. Nevertheless, there were large differences in the stability of emulsions with different salt concentrations depending on the nature of the protein used. No increase in mean particle diameter or visible creaming was observed in the lentil protein-emulsions for all salt levels studied (Fig. 5b and c), which suggested that this protein concentrate produced droplets that were highly resistant to salt addition. Conversely, an increase in mean particle diameter and extensive creaming was observed in the faba bean-emulsions at 100 and 200 mM NaCl, and in the pea protein-emulsions at 100 mM (Fig. 5b and c). Surprisingly, these emulsions became stable to aggregation again at higher salt levels. Thus, it appeared that these emulsions were only unstable to salt at intermediate ionic strengths. This effect may be due to the ability of salt to alter various types of electrostatic interactions in the emulsions, both attractive and repulsive. The addition of salt will screen the electrostatic interactions between the droplets, which should decrease the electrostatic repulsion between the droplets and lead to flocculation [5]. On the other hand, addition of salt may also alter the conformation of the adsorbed protein molecules leading to a thicker interfacial layer that increases the steric repulsion between the droplets. Alternatively, the adsorption of salt ions to oppositely charged groups on droplet surfaces can increase the hydration repulsion between droplets due to the water of hydration associated with the salt ions [38, 39].

Other studies have also reported that emulsions stabilized by certain types of plant proteins are stable to aggregation at elevated salt levels, such as coconut or tomato seed proteins [40–42]. This effect can be partly attributed to the fact that the solubility of some proteins increases with increasing salt content due to the ability of the salts to weaken the attractive interactions between protein molecules (also known as the `salting in` effect) [43, 44].

Effect of Temperature

Foods and beverages may be exposed to elevated temperatures during their processing, transportation, storage, and handling, and so it is useful to study the impact of thermal processing on the stability of protein-coated oil droplets. For this reason, the influence of temperature on the stability of emulsions prepared using different plant protein concentrates was examined.

In the absence of added salt, the ζ-potential on the droplets changed appreciably after heat treatment depending on the holding temperature (Fig. 6a). The magnitude of the negative charge on the droplets was much higher at temperatures below 60 °C, than at higher temperatures. This result suggests that there was some change in the electrical characteristics of the droplets induced by heating. This change may have been brought about by a conformational change of the adsorbed proteins above their thermal denaturation temperature, which altered the exposure of charged groups or altered the number of counter-ions bound. The thermal denaturation temperatures of a number of plant proteins have been reported previously: faba bean protein, 88 °C [45]; pea protein, 80–86 °C [46, 47]; red bean globulin, 90 °C [48]; legume proteins, 84 °C [49]; and lentil proteins, 80 °C [50]. Typically, a protein will start to unfold considerably below its thermal denaturation temperature, and so it is possible that protein conformational changes may explain the observed effects on droplet charge with temperature (Fig. 6a). Alternatively, the solubility of any mineral ions in the system (such as calcium) may have changed with temperature, which could have altered their interactions with the adsorbed proteins, thereby modifying the surface potential.

Despite the observed decrease in droplet charge with heating in the absence of salt, the emulsions were still relatively stable to droplet aggregation (Fig. 6b) and creaming (data not shown). Presumably, the electrostatic and steric repulsions between the droplets were still strongly enough to prevent flocculation at low ionic strengths, as it was in other studies [51].

In the presence of salt (150 mM NaCl), the ζ-potential on all the coated droplets remained fairly constant (−9 to −16 mV) regardless of the temperature the emulsions were held at (Fig. 7a). This result suggests that there was little change in protein conformation or ion binding effects with temperature in the presence of relatively high salt levels. It has been reported that the denaturation temperature of oat globulin, [52] faba bean protein, [45] red bean globulin [48] and pea proteins [47] increase with NaCl addition. Consequently, it is possible that the unfolding of the proteins did not occur at the higher temperatures studied in the presence of salt. However, this effect is unlikely, because we did observe extensive droplet aggregation (Fig. 7b) and creaming (Fig. 7c) in some of the emulsions after they were exposed to the higher temperatures. This phenomenon may have occurred due to an increase in the hydrophobic attraction between the oil droplets when the protein molecules unfold and expose non-polar amino acids normally buried in their hydrophobic interiors [53]. Alternatively, the association of counter-ions with the charged groups on the protein surfaces may have changed with temperature, which would alter the magnitude and range of the repulsive electrostatic interactions [53]. Interestingly, the lentil protein-coated droplets appeared to be relatively stable to aggregation across the entire temperature range studied, since we observed little change in their mean particle diameter (Fig. 7b) or creaming stability (Fig. 7c) with storage temperature.

The origin of the stability of the lentil protein-emulsions is currently unknown, but may be due to differences in the surface hydrophobicity or thickness of the adsorbed protein layer. The fact that the electrical characteristics of all the plant protein-coated droplets was similar (Fig. 7a), suggests that differences in hydrophobic or steric interactions are more likely to account for this effect than differences in electrostatic interactions.

Conclusions

This study has shown that omega-3 fortified emulsions can be produced using plant proteins as emulsifiers. These emulsions are completely free of synthetic or animal-based ingredients, and may therefore be suitable for consumers with particular dietary requirements, such as vegans and vegetarians. The initial droplet size decreased with increasing protein concentration, and relatively small droplets (d < 0.3 μm) could be produced using all plant protein types. The lentil protein-stabilized emulsions had better stability to environmental stresses (pH, salt, and temperature) than the faba bean- and pea protein-stabilized ones. The origin of the higher physical stability of the lentil protein-stabilized emulsions is currently unknown. However, the fact that the electrical characteristics of all the protein-coated droplets were very similar suggests that the higher stability of lentil protein-stabilized emulsions is due to differences in surface hydrophobicity or interfacial thickness. In summary, the results generated through this study may provide practical strategies for the food industry to formulate clean-label fortified foods and beverages, as well as other commercial emulsion-based products, such as personal care or cosmetic products.

References

N. Avramenko, Master’s thesis, University of Saskatchewan, (2013)

R.S.H. Lam, M.T. Nickerson, Food Chem. 141(2), 975–984 (2013)

B. Ozturk, S. Argin, M. Ozilgen, D.J. McClements, Food Chem. 187, 499–506 (2015)

H.J. Kim, E.A. Decker, D.J. McClements, J. Agric. Food Chem. 50(24), 7131–7137 (2002a)

E. Dickinson, Colloids Surf. B: Biointerfaces 81(1), 130–140 (2010)

M. Hu, D.J. McClements, E.A. Decker, J. Agric. Food Chem. 51(6), 1696–1700 (2003)

L. Aberkane, G. Roudaut, R. Saurel, Food Bioprocess Technol. 7(5), 1505–1517 (2014)

A.C. Karaca, N.H. Low, M.T. Nickerson, Trends Food Sci. Technol. 42(1), 5–12 (2015)

F. Roy, J.I. Boye, B.K. Simpson, Food Res. Int. 43(2), 432–442 (2010)

E.M. Papalamprou, G.I. Doxastakis, V. Kiosseoglou, J. Sci. Food Agric. 90(2), 304–313 (2010)

J.I. Boye, S. Aksay, S. Roufik, et al., Food Res. Int. 43(2), 537–546 (2010a)

F. Donsi, B. Senatore, Q. Huang, G. Ferrari, J. Agric. Food Chem. 58(19), 10653–10660 (2010)

B. Swanson, J. Am. Oil Chem. Soc. 67(5), 276–280 (1990)

S.M. Helmer, R.T. Mikolajczyk, J. McAlaney, et al., Prev. Med. 67, 204–209 (2014)

C.P. Chee, J.J. Gallaher, D. Djordjevic, et al., J. Dairy Res. 72(3), 311–316 (2005)

C.P. Chee, D. Djordjevic, H. Faraji, et al., Milchwissenschaft. Milk Sci. Int. 62(1), 66 (2007)

C. Jacobsen, Agro Food Ind. Hi-Tech 19(5), 9–12 (2008)

C. Jacobsen, Eur. J. Lipid Sci. Technol. 117(11), 1853–1866 (2015)

M. Joshi, B. Adhikari, P. Aldred, J.F. Panozzo, S. Kasapis, Food Chem. 129(4), 1513–1522 (2011)

O.H. Lowry, N.J. Rosebrough, A.L. Farr, R.J. Randall, J. Biol. Chem. 193(1), 265–275 (1951)

R.E. Aluko, R.Y. Yada, Int. J. Food Sci. Nutr. 48(1), 31–39 (1997)

S. Tcholakova, N.D. Denkov, T. Danner, Langmuir 20(18), 7444–7458 (2004)

R. Walker, E.A. Decker, D.J. McClements, Food Funct. 6(1), 42–55 (2015)

E. Makri, E. Papalamprou, G. Doxastakis, FOOHYD Food Hydrocoll. 19(3), 583–594 (2005)

A.C. Karaca, M.T. Nickerson, N.H. Low, J. Agric. Food Chem. 59(24), 13203–13211 (2011)

T. Zhang, B. Jiang, W. Mu, Z. Wang, Food Hydrocoll. 23(1), 146–152 (2009)

M.M. Sakuno, S. Matsumoto, S. Kawai, K. Taihei, Y. Matsumura, Langmuir 24(20), 11483–11488 (2008)

E. Dickinson, J. Dairy Sci. 80(10), 2607–2619 (1997)

M. Jayasundera, B. Adhikari, P. Aldred, A. Ghandi, J. Food Eng. 93(3), 266–277 (2009)

K. Landström, B. Bergenstahl, J. Alsins, M. Almgren, Colloid Surf. B 12(3–6), 429–440 (1999)

D.J. McClements, Crit. Rev. Food Sci. Nutr. 47(7), 611–649 (2007)

S. Tcholakova, N.D. Denkov, D. Sidzhakova, I.B. Ivanov, B. Campbell, Langmuir 19(14), 5640–5649 (2003)

Z. Cui, Y. Chen, X. Kong, C. Zhang, Y. Hua, J. Agric. Food Chem. 62(7), 1634–1642 (2014)

M.C. Puppo, V. Beaumal, N. Chapleau, et al., Food Hydrocoll. 22(6), 1079–1089 (2008)

R. Waninge, P. Walstra, J. Bastiaans, et al., J. Agric. Food Chem. 53(3), 716–724 (2005)

C. Chang, S. Tu, S. Ghosh, M.T. Nickerson, Food Res. Int. 77, 360–367 (2015)

D.J. McClements, Curr. Opin. Colloid Interface Sci. 9(5), 305–313 (2004)

D.F. Parsons, A. Salis, J. Chem. Phys. 142(13) (2015)

W. Kunz, Curr. Opin. Colloid Interface Sci. 15(1–2), 34–39 (2010)

N. Tangsuphoom, J.N. Coupland, J. Food Sci. 73(6), E274–E280 (2008)

A. Sarkar, H. Kamaruddin, A. Bentley, S. Wang, Food Hydrocoll. 57, 160–168 (2016)

J.I. Boye, F. Zare, A. Pletch, Food Res. Int. 43(2), 414–431 (2010b)

S.M. Sun, T.C. Hall, J. Agric. Food Chem. 23(2), 184–189 (1975)

R.E. Aluko, R.Y. Yada, Food Chem. 53(3), 259–265 (1995)

S.D. Arntfield, E.D. Murray, M.A.H. Ismond, J. Food Sci. 51(2), 371–377 (1986)

S.D. Arntfield, E.D. Murray, Can I Food Sc. Tech. J. 14(4), 289–294 (1981)

J.L. Mession, N. Sok, A. Assifaoui, R. Saurel, J. Agric. Food Chem. 61(6), 1196–1204 (2013)

G.T. Meng, C.Y. Ma, Food Chem. 73(4), 453–460 (2001)

M.M. Il'in, M.G. Semenova, L.E. Belyakova, A.S. Antipova, Y.N. Polikarpov, J. Colloid Interface Sci. 278(1), 71–80 (2004)

V.L. Shnyrov, M.J. Marcos, E. Villar, Biochem. Mol. Biol. Int. 39(4), 647–656 (1996)

T.J. Wooster, M.A. Augustin, J. Colloid Interface Sci. 313(2), 665–675 (2007)

V.R. Harwalkar, C.Y. Ma, J. Food Sci. 52(2), 394–398 (1987)

H.J. Kim, E.A. Decker, D.J. McClements, Langmuir 18(20), 7577–7583 (2002b)

Acknowledgements

Cansu Ekin Gumus thanks the Ministry of National Education of Turkey for the International Graduate Fellowship provided for her ongoing doctoral degree. We also thank Jenny Tang and John Krill from DSM for useful advice and discussions.

This project was supported by Agriculture and Food Research Initiative Grant no. 2014-67017-21635 from the USDA National Institute of Food and Agriculture. It was also partly supported from funding provided by DSM.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Gumus, C.E., Decker, E.A. & McClements, D.J. Formation and Stability of ω-3 Oil Emulsion-Based Delivery Systems Using Plant Proteins as Emulsifiers: Lentil, Pea, and Faba Bean Proteins. Food Biophysics 12, 186–197 (2017). https://doi.org/10.1007/s11483-017-9475-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-017-9475-6