Abstract

The paper describes the formulation and simulative potential of a constitutive model for monotonic and cyclic shearing of sands. It is a SANISAND-type model that does not consider a (small) yield surface and employs the last stress reversal point for defining both the elastic and the plastic strain rates. Emphasis is put on the updating of the stress reversal point to avoid stress-strain overshooting. It incorporates a fabric evolution index that scales the plastic modulus targeting strain accumulation with cycles and a post-liquefaction formulation affecting the dilatancy function. The paper includes the calibration process of the 14 model parameters. Model performance is verified against a large database of monotonic and cyclic shearing tests on Toyoura and Ottawa-F65 sands. To complement sand-specific data, empirical relations are used for validating the shear modulus at small strains, its degradation with cyclic shear strain, the corresponding increase in hysteretic damping, the evolving rates of volumetric and shear strain accumulation with cycles and the effect of relative density and stress level on liquefaction resistance. Model verification shows that a single set of sand-specific parameters may be used for both monotonic and cyclic shearing of any strain level, irrespective of stress level and relative density.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Accurate numerical analyses of boundary value problems of geotechnical structures rely on the use of properly calibrated constitutive models that are appropriate for the geomaterial and the loading at hand. For coarse-grained geomaterials like sands, users often employ different constitutive models and/or different calibrations of the same model, depending on the target loading (e.g., monotonic versus cyclic, cyclic due to earthquakes versus cyclic due to wave action). Given its complexity, the issue of cyclic loading of sands has attracted a lot of attention in the literature, leading to multiple publications of constitutive models. Some of them incorporate the well-established mechanical framework of Critical State Soil Mechanics ([50]), while others are based on hypoplasticity theory (e.g., [5, 25, 41]). Nowadays, a large percentage of the pertinent Critical State models is of the SANISAND–type, i.e., bounding surface models ([11, 13]) in which the peak and the dilatancy deviatoric stress ratios depend on the state parameter ψ ([6]). Although the term SANISAND was coined in 2008 by Taiebat and Dafalias [56], the concept was first proposed by Manzari and Dafalias [34] in their two-surface model and adopted thereafter by many. The reason for its popularity is that it enables successful simulations for any relative density or stress level with the same set of model parameters.

In many cases, the papers that present models for cyclic loading of sands include accurate simulations of monotonic response, as well as of few cyclic loading tests leading to liquefaction. Such a presentation, although possibly sufficient for monotonic loading, may not be adequately complete for cyclic loading, whose characteristics are highly dependent on cyclic shear strain level ([66]). As such, a complete model verification for cyclic loading should focus distinctly on: a) small-strain response (“elastic” stiffness modulus and initial damping ratio), b) medium-strain response (shear modulus degradation and hysteretic damping ratio increase with cyclic strain amplitude; strain accumulation with number of cycles), c) large-strain response, mainly with emphasis on liquefaction resistance curves and post-liquefaction strain accumulation. The importance of these distinct cyclic shear strain regimes for proper simulations has started to attract attention in the literature lately. For example, McAllister et al. [37] showed that if “elastic” modulus stiffness of SANISAND models is calibrated on the basis of monotonic tests, it underestimates significantly the in situ shear wave velocity leading to erroneous prediction of seismic ground response. Similarly, specialized models are being formulated for proper simulation of strain accumulation with large number of (medium-strain) cycles (e.g., [27, 30]), an issue rarely studied in papers presenting cyclic models in the past. Finally, a multitude of recent papers deal specifically with post-liquefaction strain accumulation (e.g., [58, 74]), underlining its importance for accurate simulations of displacements of geostructures in a liquefaction regime. To the authors’ knowledge, there are few papers that present model verifications for all 3 distinct cyclic shear strain regimes (e.g., [1, 8, 10, 42]). Of course, this does not mean that sophisticated cyclic models that are not verified in this manner are inaccurate. It only means that their users should be cautious when using them outside their verified cyclic shear strain range.

Concurrently, some of the models that have exhibited a satisfactory performance for cyclic loading may not be as accurate when it comes to monotonic loading (e.g., the NTUA-SAND model ([1]) requires a change in the values of 2 model parameters in order to capture the monotonic response). In addition, some promising cyclic models were never implemented in numerical codes (e.g., [42]), while models that have been implemented in such codes have not been necessarily verified for the whole range of cyclic loading response (e.g., [77]). It goes without saying that targeted verification may also come from use in boundary value problems (e.g., [76]), which may even be preferable from mere comparison with element test data (e.g., [35]). In this respect, one should acknowledge models that have been widely used throughout the years, at least for liquefaction-related problems (e.g., [12]). Such models should be considered as equally accurate, at least for the problems that they have been repeatedly used in the past.

Based on the above, there is a need for a constitutive model for sands, which will be able to capture accurately both the monotonic response (until the critical state) and the cyclic response (for any shear strain level) with a single set of parameters for any relative density and stress level. This is the goal of the SANISAND-type model presented herein, which also incorporates stress reversal surfaces ([38, 68]) facilitating the simulation of cyclic loading without a (small) yield surface. In this respect, it is a SANISAND-R model, a term introduced recently by Papadimitriou et al. [44]. It builds on the NTUA-SAND model ([1]), from which it inherits concepts like the small- and medium-strain nonlinearity and the fabric evolution index for large strain response, albeit modified. Stress reversals are appropriately updated in order to avoid the stress–strain overshooting problem ([14]), but also to establish that strain accumulation does not appear at very small-strain cyclic loading in accordance to the literature ([66]). Post-liquefaction strains are in focus with an appropriate modification of the dilatancy function. It should be clarified in advance that the proposed is, by-design, a general-purpose constitutive model for sands. This means that its accuracy may not always be equal to that of dedicated models. For example, the accuracy of a fabric-based anisotropic model (e.g., [44]) may be superior for monotonic loading; however, such a model can only be used successfully for boundary value problems related to static loading (e.g., [9, 45]). On the contrary, the proposed model provides the user with a satisfactory performance without a need for recalibration regardless of whether the problem is static, cyclic or dynamic. In the sequel, this paper presents the model formulation in Sect. 2, which is followed by the thorough calibration of its 14 model parameters in Sect. 3. Then, Sect. 4 presents an elaborate verification against monotonic and cyclic test data, while the paper ends in Sect. 5 with notes regarding the applicability of the proposed model and its limitations.

2 Model formulation

2.1 Constitutive model platform

The formulation of the model is presented in the multiaxial stress space and the equations are given in tensorial form. Second-order tensors are written in bold characters, so as to be distinguished from scalars, while normal stress components are considered effective. A superposed dot over scalar or tensorial quantities implies material time derivative or rate. A symbol : between 2 tensors denotes their double inner product or equivalently the trace (tr) of their product. Specifically, the strain tensor is depicted as ε and can be decomposed into its (scalar) volumetric component εvol = trε and the (tensorial) deviatoric component e = ε–(εvol /3) I, with I standing for the second-order identity tensor. Superscripts e and p denote the elastic and plastic part of strains, respectively. The effective stress tensor is symbolized by σ and consists of its hydrostatic component p = (1/3)trσ (i.e., the mean effective stress) and its deviatoric component s = σ–pI. Of great importance is also the deviatoric stress ratio tensor r = s/p, which is instrumental in the constitutive equations of this model. Given the above definitions, the basic model equations are founded on elasto-plasticity theory and are summarized, for brevity, in Table 1.

Note that, in Eq. (4), the inclusion of scalar-valued loading index Λ is Macauley-bracketed implying that the plastic strain rate is zero when Λ < 0 (unloading) or Λ = 0 (neutral loading), and nonzero in cases of loading (Λ > 0). In Eq. (5), the plastic strain rate direction is defined, with unit-norm tensor n constituting its deviatoric part. The n adopts all the properties of unit-norm tensors (i.e., n = nT, trn = 0 and n: n = 1) and is determined according to the adopted mapping rule of the model. According to Eq. (6), loading takes place either with a combination of \({\varvec{n}}:\dot{\varvec{r}} > {0}\) (p is always nonnegative) and Kp > 0 (hardening response) or \({\varvec{n}}:\dot{\user2{r}} < {0}\) and Kp < 0 (softening response). Considering all the above, a nonzero deviatoric stress ratio rate serves as the necessary condition for nonzero plastic strain rates. This concept, while quite realistic during shearing, should be used with caution in problems where loading under constant stress ratio prevails (e.g., one-dimensional consolidation). Note also that a nonzero deviatoric stress ratio rate is not a sufficient condition for nonzero plastic strain rates. This is because the so-called neutral loading (Λ = 0) may appear for tangential loading paths, where both \({\varvec{n}} \ne {0}\) and \(\dot{\user2{r}} \ne {0}\) continuously, but \({\varvec{n}}:\dot{\user2{r}} = {0}\) throughout the loading. In this sense, the model does not have a truly zero elastic range in stress space, as was clarified for such models in Dafalias and Taiebat [14].

2.2 Critical state behavior

The proposed model formulation incorporates the Critical State Theory of Soil Mechanics ([50]) by adopting a unique Critical State Surface (CSS) in the effective stress σ – void ratio e space. For its projection on the mean effective p – void ratio e space, i.e., for the Critical State Line (CSL), a power relation is adopted. Hence, for a given mean effective stress p, the corresponding critical value of void ratio ecs on the CSL is given by ([12, 28]):

where eref is the reference value of void ratio at p = 0 controlling the position of CSL (a model parameter), patm is the atmospheric pressure (e.g., patm = 101.3 kPa), and λ and ξ are nonnegative model parameters forming CSL’s curvature and shape in the (p – e) space.

The current state of the material is always identified with reference to the CSL through the state parameter ψ, which quantifies the difference between the current void ratio e and the corresponding critical state value ecs at the current mean effective stress p via ([6]):

Parameter ψ determines the state of the material as a combined function of its density (through void ratio e) and its effective mean stress (through ecs), expressing how far from critical is the current state. It is obvious that a state (e, p) above the CSL in the (p – e) space corresponds to ψ > 0 and consequently to contractive behavior, while, on the contrary, a state below the CSL in the (p – e) space corresponds to ψ < 0 and consequently to dilative behavior. The explicit incorporation of ψ in model equations, starting from the model surfaces in the next paragraph, is what gives the SANISAND character to this model.

2.3 Model surfaces

Being of the SANISAND-type, the proposed bounding surface model is stress ratio-driven. For the common case of loading in triaxial compression (TC), the critical state \({\it{\text{M}}}_{\text{ c}}^{\text{ c}}\), the bounding (or peak) \({\it{\text{M}}}_{\text{ c}}^{\text{ b}}\) and the dilatancy \({\it{\text{M}}}_{\text{ c}}^{\text{ d}}\) stress ratios (collectively \({\it{\text{M}}}_{\text{ c}}^{\text{ c,b,d}}\)) are related to each other via the state parameter ψ, as follows:

where \({\it{M}}_{\text{ c}}^{\text{ c}},\) nb and nd are nonnegative model parameters. Note that the subscript c depicts that loading is in triaxial compression, while superscripts c, b or d clarify which of the three stress ratios is of interest. These exponential equations are adopted from Li and Dafalias [26] and Dafalias and Manzari [12]. Note also that here Macauley brackets appear in Eq. (12) to make it qualitatively compatible with the linear form of this equation in Manzari and Dafalias [34]. Hence, based on Eqs. (12) and (13), for dilative states where ψ < 0, \({\it{\text{M}}}_{\text{ c}}^{\text{ d}}\text{ < }{\it{\text{M}}}_{\text{ c}}^{\text{ c}} \text{<}{\it{\text{M}}}_{\text{ c}}^{\text{ b}}\) holds. This implies that the peak stress ratio is higher than the critical state ratio, while the dilatancy stress ratio is lower than both of them. Similarly, for contractive states (ψ > 0) \({\it{\text{M}}}_{\text{ c}}^{\text{ d}}\text{ > }{\it{\text{M}}}_{\text{ c}}^{\text{ c}} ={\it{\text{M}}}_{\text{ c}}^{\text{ b}}\) holds, implying purely contractive response (since the \({\it{\text{M}}}_{\text{ c}}^{\text{ d}}\) is not reached) and attainment of the peak stress ratio at critical state.

The generalization of these three stress ratios in multiaxial stress space takes the form of surfaces, namely the critical state, the bounding and the dilatancy surface. All three surfaces have the shape of an open cone, with their apex on the origin of stress space, are homologous, and their apertures are defined by the stress ratio values \(M_{{\theta}}^{\text{c}}\), \(M_{\theta }^{\text{b}}\) and \(M_{\theta }^{\text{d}}\), respectively. The subscript θ in the foregoing stress ratio values depicts that this generalization is performed with the aid of the Lode angle θ, that is hereby defined in terms of the unit-deviatoric loading direction tensor n, according to:

where det is the determinant of a (second-order) tensor. Based on its definition, angle θ ranges between 0° and 60°, where 0° corresponds to loading in triaxial compression (TC) and 60° to triaxial extension (TE). All the intermediate values of θ correspond to non-triaxial loading conditions. Hence, the M stress ratio of the aforementioned surfaces can be defined as a continuous function of angle θ. In this model, this function is depicted by g and is used as follows:

where \({\it{\text{c}}}={\it{\text{M}}}_{\text{e}}^{\text{ c}}/{\it{\text{M}}}_{\text{c}}^{\text{ c}}\) is a nonnegative model parameter that is equal to the ratio of the critical stress ratio in triaxial extension (TE) over that in TC. In this paper, the adopted g(θ,c) function is borrowed from Loukidis and Salgado [33], although its more general form (involving 3 independent parameters) dates back to van Eekelen [18]. It reads:

where exponent μ controls the convexity of the surface on the π-plane of the deviatoric stress ratio space. This μ is set fixed to 0.16 here, which provides convexity for the usual cases of c > 0.67. Observe here that g = 1 for θ = 0ο and g = c for θ = 60ο, thus rendering the pertinent values for the stress ratios in TC and TE on the basis of Eq. (15). The procuring shape of the three model surfaces (for c = 0.712) on the foregoing π-plane is shown in Fig. 1 for an exemplary case where ψ < 0, which dictates their apertures as a function of Eqs. (12) and (13).

2.4 Mapping rule

The distance of the current stress ratio r from these surfaces on the π-plane of the deviatoric stress ratio space is a key component of the constitutive equations. The distance from each surface is defined with the aid of the image points rc, rb and rd (collectively rc,b,d) of r on the critical state, the bounding and the dilatancy surfaces, respectively. These image points are defined on the basis of the selected mapping rule, which is schematically illustrated in Fig. 1. This radial mapping rule has been repeatedly used in the past (e.g., [1, 68]).

The all-important tensor rini refers to the tensor r when the last load reversal took place, i.e., when the loading index Λ of Eq. (6) or Eq. (9) took a negative value last. For the first shearing path, it is, by default, equal to the value of tensor r at the initial state (e.g., end of consolidation). This correlation to the recent shear history via rini dates back to the concept of stress reversal surfaces by Mróz et al. [39] and Mróz and Zienkiewicz [38]. Having determined the image point rb on the bounding surface allows for the definition of the unit-norm deviatoric tensor n starting from the stress origin and depicting its direction as:

Given the unit-norm tensor n, the image points on all three model surfaces may be computed as:

where Mθc,b,d is defined in Eq. (15). Consequently, the scalar distance between the current stress ratio r and the model surfaces (collectively d c,b,d) is computed along the n direction, as:

According to Eq. (19), a positive dc,b,d value implies a current stress ratio r located inside the corresponding surface, while a negative value of the distance dc,b,d depicts that it is outside.

2.5 Elastic moduli

The maximum value of the shear modulus Gmax used herein follows a hypoelastic formulation, since it is a function of the current values of the mean effective stress p and the void ratio e. Specifically, based on Hardin [21], it holds:

where Go is a model parameter and patm is the atmospheric pressure. However, the tangential value of the shear modulus Gt entering the calculation of the elastic strain rate (see Eq. (3)) incorporates a Ramberg–Osgood-type ([48]) hysteretic behavior, which provides a nonlinear degradation with strain. This concept, originally proposed by Papadimitriou et al. [43] and then used slightly modified by Andrianopoulos et al. [1], Loukidis and Salgado [33] and Taborda et al. [55], allows for a smooth decrease in the tangential shear modulus Gt, from its maximum value (equal to Gmax from Eq. (20)) and a consequent smooth increase in hysteretic damping with increasing shear amplitude (e.g., [67]). In more detail, the nonlinear hysteretic form of Gt is given as:

where T is a positive scalar (≥ 1) variable, defined as:

Respectively, the tangential bulk modulus Kt entering Eq. (3) is interrelated to the tangential shear modulus Gt on the basis of a constant value ν of the Poisson’s ratio (a model parameter) according to:

Note that according to Eq. (22) variable T reduces the shear modulus Gt as the current deviatoric stress ratio r diverts from the stress ratio rini at the last stress reversal. In comparison with the Andrianopoulos et al. [1] version of variable T, the first difference is that in its denominator the current values of Gmax and p are used and not those at the last stress reversal (the same was also assumed in [33]). The second difference is the use of a1 (≤ 1) and γ1 (> 0) as fixed constants here, and not as model parameters that is the common choice in practically all pertinent formulations in the literature (e.g., [1, 33, 43, 55]). The hereby adopted fixed values are a1 = 0.85 and γ1 = 0.03%, i.e., they correspond to the upper bound of the range originally proposed by Papadimitriou et al. [43]. Fixing these parameters provides user-friendliness, but obviously reduces the flexibility of the model. However, extensive verification against data from multiple sands has shown that the plastic formulation of the model (described in the sequel) is flexible enough to provide the remainder of the measured nonlinearity.

It has to be underlined here that without the additional nonlinearity offered by variable T it is impossible to attain accurate simulations across the whole range of shear strains, from small–strain dynamic loading to large-strain monotonic shearing using the same set of model parameters, with the Gmax being calibrated from truly small-strain measurements (e.g., bender elements, geophysical measurements). Another significant contribution of this formulation was highlighted in Loukidis and Salgado [33], where it was shown that without variable T it is impossible to obtain compatible drained and undrained stress–dilatancy response while retaining realistic values of Poisson’s ratio ν and Gmax irrespective of type of loading.

2.6 Plastic modulus

The plastic modulus Kp in Eq. (6) is given by:

where hθ, hf, hpp, hep are nonnegative model functions that will be discussed extensively in the sequel, and ho a nonnegative model parameter. Based on Eq. (24), the sign of plastic modulus Kp is controlled by the sign of the distance db. According to Eq. (6), when Λ > 0, hardening response occurs when the r lies inside the bounding surface (db>0), or, on the contrary, softening response occurs when the r lies outside the bounding surface (db<0). Moreover, the denominator (r – rini):n implies that at the initialization of a load reversal (where rini has just been updated to the value of r) the Kp takes an infinite value, thus leading to zero plastic strain at the beginning of every new shearing process.

Next, the effects of mean effective stress p and void ratio e on the Kp, that are introduced via functions hpp and hep respectively, will be discussed. Specifically, function hpp is given by:

which, in combination with p multiplying the right part of Eq. (24), results in a total effect of mean effective stress on Kp having an exponent of 0.5, in agreement with Eq. (20) for the elastic moduli. Note that in constitutive models for sands, the selected value of 0.5 for this exponent is the most common choice, although there are models in which this exponent reaches 1.5 (e.g., [55]). Similarly, the decreasing effect of void ratio e on the plastic modulus Kp is introduced via:

where ch is a nonnegative model parameter.

In the sequel, function hθ introduces an additional effect of Lode angle θ on the plastic modulus. This is related to the need to show more compliant response in loading with intermediate θ values (0ο < θ < 60ο), than what the g(θ,c) function of Eq. (16) provides in terms of the shape of model surfaces. For example, the comparison of resistance to liquefaction from cyclic triaxial tests (where angle θ jumps from 0° to 60°) versus that from cyclic simple shear tests (where angle θ takes intermediate values) shows that the former is larger than the latter (e.g., [40, 62]). Hence, here the function hθ (≤ 1) is introduced as a multiplier of the Kp which reads:

Function hθ actually utilizes function g of Eq. (16) to capture the foregoing effect, but for a modified Lode angle θ′ = θ + 30ο. In this way, for θ = 0ο (triaxial compression) and θ = 60ο (triaxial extension), the value of g entering Eq. (27) is the same and hθ attains its maximum value. For intermediate values of θ, g attains lower values, resulting in lower values also for hθ.

Finally, scalar-valued function hf is a macroscopic index of the effects of fabric evolution on the sand response. The use of such fabric-related functions emphasizing on cyclic shearing effects is common practice in constitutive modeling (e.g., [1, 8, 12]). In this model, this significant effect on plastic strains is described macroscopically by the function hf on Kp, which reads:

Specifically, the hf in Eq. (28) borrows elements of its formulation from the respective hf functions of Papadimitriou and Bouckovalas [42] and Andrianopoulos et al. [1]. Specifically, the numerator is a quadratic function of scalar-valued variable fp, while the denominator is a linear function of the inner product of an expression of a deviatoric fabric tensor f and the loading direction n. In addition, both fp and f initiate from zero at the initial state (leading to hf = 1) and evolve independently with plastic volumetric strain, the latter only in dilation. Apart from these qualitative similarities to the hf function in [42] and [1], in quantitative terms there are significant differences, since in the new model the evolution laws of fp and f are as follows:

where

is the common evolution rate parameter for both fp and f, that is calibrated via No a nonnegative model parameter, that is the only parameter requiring calibration for function hf. The above equations also include scaling functions that introduce effects of initial state on the evolution rate of both fp and f. Firstly, it is the effect of initial state parameter ψο, which appears in Macauley brackets that ensure a smooth transition between states where fabric evolution is important (when ψο < 0) and states where it is neglected (when ψο > 0), the latter mainly due to lack of pertinent experimental evidence. Then, the effects of the initial values of mean effective stress po and void ratio eo are included separately via:

Finally, note that parameters fmax and a that enter Eqs. (29) and (30) are variables that initiate from zero at the initial state and evolve during loading, as per:

where fmax is the maximum value that scalar fp has taken during loading from the initial state, while a is a variable that takes values between 0.0 and 1.0, on the basis of the absolute values of 2 strain integrals measured during loading from the initial state: that of the total volumetric strain and that of the plastic volumetric strain.

Equations (28–35) constitute a complete framework for describing the effects of fabric evolution on the sand response. Function hpost-liq entering Eq. (30) accounts for cyclic mobility and accumulation of strains after liquefaction is triggered, and its formulation is detailed in a special section below. For now, note that hpost-liq = 1 until initial liquefaction occurs, i.e., until the state when the current p becomes (for the first time) smaller or equal to a critical value pl, defined as pl = min (0.05 po; 10 kPa). In more detail, according to Eq. (29), function fp in the numerator of hf follows the whole shearing history of the sand, similarly to other models (e.g., [1, 42]). Model constant cf and the inclusion of the (fp–cf) difference into Macauley brackets in Eq. (28) imply that there is a threshold value of fp, beyond which stiffening starts to affect the plastic modulus. This prevents stiffening during the early stages of monotonic shear loading, when the stress point remains inside the dilatancy surface, without essentially affecting cyclic loading in which the fp surpasses quickly the value of cf. A value of cf = 1 is found appropriate for both monotonic and cyclic loading of various sands and is hereby adopted as a constant. Note that in existing similar models (e.g., [1, 42]), cf = 0 holds.

At the same time, and according to Eq. (30), deviatoric fabric tensor f evolves only during dilation and not during the whole shearing history of the sand, i.e., unlike the fp. During a dilative shear path, and due to the negative sign in the front of Eq. (30), the f develops in the opposite direction of the tensor quantity in brackets that is a function of the current values of the fabric tensor f and the loading direction n. As such, in dilative shear paths the f may stop developing only if the tensor quantity in brackets becomes zero, which appears when the f = –fmax(1+a)n, i.e., when the f takes its maximum norm, that is a nonnegative function (as fp initiates from zero) of the maximum value that the fp ever took during loading. However, it has to be underlined here that, unlike previous similar models (e.g., [1, 42]), it is not the value of fabric f that enters the hf in Eq. (28), but the value of fini, i.e., the value of fabric f at the last load reversal. In any case, based on Eq. (28), whenever the denominator of hf takes values greater than 1.0, this leads to a decrease of Kp and hence a softening response is predicted. Such a softening response does not appear during monotonic loading (since fini = 0), but only during unloading paths following loading outside the dilatancy surface.

Focusing on the common evolution rate parameter N for both fp and f, Eq. (31) incorporates its dependence on initial state. Particularly, function hef in Eq. (33), like its similar form included in the Kp equation (Eq. (26)), indicates a decreasing effect of (initial) void ratio on the rate of fabric evolution. Moreover, function hpf (Eq. (32)) that multiplies N in Eq. (29) for the fp evolution implies also a decreasing effect of (initial) mean effective stress on the rate of fabric evolution. Since the numerator of hf (via the fp evolution) mostly governs the stiffening response with cycles, the inclusion of functions hpf and hef in the evolution of fp in Eq. (29) ensures that the new model is in line with experimental results (e.g., [62]) and analytical relations (e.g., [22]) for the decreasing effect of overburden stress and relative density on the resistance to liquefaction via factor Κσ. This also explains the upper-bound value of 1.5 in hpf of Eq. (32) in order to disallow excessive increase in liquefaction resistance for very small po values.

Gradual stiffening response with cycles is apparent both in drained and in early stages of undrained cyclic element tests. That is the reason why the accumulation of fabric-related components was conceptually chosen to develop with the plastic component of volumetric strain rate and not its total rate, similarly to all pertinent literature models (e.g., [1, 12]). However, this option creates an inherent quantitative differentiation of the fabric evolution under different drainage conditions. For example, if drainage occurs, the change of void ratio e directly affects the plastic modulus Kp via Eq. (26), and hence the value of the plastic volumetric strain rate entering fabric evolution via Eqs. (29) and (30). To counterbalance this effect, the intensity of fabric evolution during loading is set to depend on the correlation between the integral of the total volumetric strain and the integral of the plastic volumetric strain during loading via factor a that is introduced in Eq. (35) and takes values between 0.0 and 1.0. Based on its definition in Eq. (35), when the integral of total volumetric strain is equal to zero (e.g., in the extreme case of fully undrained conditions), then a = 1.0. On the other hand, when the ratio of the volumetric strain integrals is greater than 1.0, i.e., when volume change is significant (e.g., in the case of fully drained conditions), then a = 0.0. For all the intermediate states, factor a attains values between 0.0 and 1.0 according to Eq. (35). Given the above definitions, the term (2–a)N that acts as the scaling factor in Eq. (29) takes values between N and 2 N, while the maximum norm fmax(1+a) that fabric tensor f may take in the bracketed tensor term of Eq. (30) takes values between fmax and fmax2.

It is understood that making fabric evolution partially a function of the integral of total volumetric strain via factor a may seem inconsistent. However, based on all the above, this integral affects merely the scaling factor of fp evolution in Eq. (29) and the maximum norm of tensor f in Eq. (30). In other words, both fp and f continue to evolve as functions of the plastic volumetric strain rate in Eqs. (29) and (30), and the role of factor a is merely to enhance or reduce fabric evolution effects on the plastic modulus Kp depending on whether the loading induces volume change or not. Such a factor does not appear in any previous similar model (e.g., [1, 12, 42]) that focused mostly on undrained loading (and liquefaction) and an example of its necessity for other than undrained conditions is discussed below. Specifically, Fig. 2 presents the predicted shear stress–strain (τ–γSS) relation and volumetric strain (εvol–γSS) accumulation within 30 cycles of a strain-controlled drained cyclic simple shear test with single amplitude cyclic shear strain equal to γSS,cyc = 0.1%. Subplots c and d include the model prediction having factor a varying according to Eq. (35), while subplots a and b present the same predictions but with a factor a = 1.0 that leads to the lowest fp evolution rate equal to N and the highest maximum norm of f equal to fmax2. According to experimental evidence for drained cyclic loading (e.g., [51]), even for large cyclic shear strain amplitudes for which the shearing leads to dilation before the load reversal, the volumetric strain εvol accumulates with cycles, but at a steadily decreasing rate (e.g., see Fig. 2d), while the stress–strain relation becomes gradually stiffer (e.g., see Fig. 2c). In order to achieve this response, the new model (with variable a) employs fp evolution rates higher than N, thus enhancing the numerator of hf, concurrently with values of maximum norm of f lower than fmax2, thus reducing the importance of the denominator of hf. As a result, the predicted response is a gradual stiffening with cycles due to the effect of a gradually increasing hf.

Effect of factor a on the shear stress–strain (τ – γss) relation and the volumetric strain (εvol – γss) accumulation in 30 cycles of a strain-controlled drained cyclic simple shear test: a and b a = 1; c and d variable a, according to Eq. (35)

On the contrary, using a constant value of a = 1.0 leads to a milder increase in the numerator of hf concurrently with the potential for a more intense increase in its denominator. Such a choice may lead to the undesired response presented in Fig. 2a and b. Specifically, in the first cycles (phase A) the response becomes gradually stiffer, as it should. However, as the stress–strain loops become stiffer, the values of stress ratio r become higher and the stress point may shift outside the dilatancy surface. Due to the large maximum norm of fmax2, this partly dilative loading increases the f and thus the denominator of function hf. As cyclic loading continues (phase B), the hf gradually decreases, which leads to a softening response with cycles, i.e., an accelerated rate of εvol accumulation. This unrealistic softening leads to gradually larger εvol increments, which, in turn, allow for an intense evolution of the fp and of the numerator of hf. As a result, phase C of the loading appears, where the hf increases and reduces equally within each cycle, thus leading to a constant rate of εvol accumulation with cycles, which is again unrealistic.

2.7 Dilatancy

According to Eq. (5), the definition of plastic strain rate direction R in this model implies non-associativity, since the scalar-valued dilatancy function D is explicitly defined. Specifically, the dilatancy D is hereby defined with different equations for the contractive and the dilative phases of loading, a concept not uncommon in constitutive modeling literature (e.g., see [8]).

2.7.1 Contraction

Plastic volumetric strains during contraction (i.e., when dd > 0) are computed using the following expression for the dilatancy D:

where Ao is a nonnegative model parameter, while hpd,c is a nonnegative function related to the effect of mean effective stress p on the D for contractive states that will discussed in detail below. The correlation of D to the distance dd implies that Eq. (36) is founded on a generalization of Rowe’s dilatancy theory ([49]). However, the bracketed term in Eq. (36) includes the quantity (r – rini):n, which becomes zero at each load reversal. At the same time, this bracketed term includes a quantity in Macauley brackets, which is related to the value of distance dd at the last load reversal (depicted by \({\it{\text{d}}}_{\text{ ini}}^{\text{ d}}\)) and is nonzero only when the last load reversal occurred outside the dilatancy surface (\({\it{\text{d}}}_{\text{ ini}}^{\text{ d}}\) < 0). Hence, this bracketed term introduces the effect of the recent load reversal in the definition of D. This differentiation from Rowe’s dilatancy theory implies D = 0 and D ≠ 0 immediately after load reversal inside and outside the dilatancy surface, respectively. In all cases, as loading continues and the quantity (r–rini):n increases, the dilatancy D increases, before it eventually starts to decrease, as the effect of the decreasing dd prevails when approaching the dilatancy surface where the dd = 0, thus rendering D = 0, regardless of where the previous load reversal appeared.

Note here that the proposed Eq. (36) for D in contraction gives positive values of D close to zero for small values of quantity (r–rini):n. This means that for cyclic loading in which this quantity remains generally small (e.g., for low amplitude cyclic loading), the D remains close to zero. This constitutive trait proves very useful for predicting minimal volume change under drained conditions, or minimal excess pore-pressure build-up under undrained conditions, when low amplitude cyclic loading is at hand, thus leading to relatively “flat” liquefaction resistance curves. Similar formulations for dilatancy (in contraction), that deviate from Rowe’s dilatancy theory by introducing the distance from the last shear reversal rini, can also be found in recent literature (e.g., [8, 10]). Alternatively, but aiming at the same target, Tsaparli et al. [61] included in the dilatancy function the ratio of the distance from the dilatancy surface over the value of the respective distance at the last shear reversal. Note also here that a term of similar functionality to the term in Macauley brackets in Eq. (36) was used also by Boulanger and Ziotopoulou [8], while reduced and nonzero initial value of D upon shear reversal is also predicted in Tsaparli et al. [61].

The last term to be discussed is the function hpd,c of Eq. (36), given as:

with:

Function hpd,c acquires a double form, depending on whether or not initial liquefaction has occurred. In its default form (before initial liquefaction), function hpd,c = hpd,c*. This hpd,c* function decreases from 1.0 as p decreases from its initial value po, thus leading to gradual increase of D as per Eq. (36). Due to the exponent 0.5, the foregoing decrease of hpd,c* is notable only after a significant decrease of the p/po ratio (e.g., after significant excess pore-pressure build-up) and appears only for initially dilative initial states, i.e., only when the sign of –ψο is positive, and hence, the \(\left\langle {sign\left( { - \psi_{\text{o}} } \right)} \right\rangle = 1\). The inclusion of cpd,c = 0.1 (i.e., a small positive number) guarantees that hpd,c* remains positive and nonzero, when p = 0, while the Macauley brackets inside the bracketed term of Eq. (37b) make sure that for p/po > 1, the hpd,c* remains constant and does not affect the response. Once initial liquefaction occurs for the first time, the value of hpd,c* is stored as hpd,c,liq. Thereafter, the value of hpd,c is estimated as the minimum of 2 values: the hpd,c* on the basis of Eq. (37b) and the ratio of the aforementioned stored hpd,c,liq value over the function hpl,d of Eq. (37c) that introduces an effect of the p/pl ratio. As a whole, Eq. (37) ensures that in contractive paths after initial liquefaction, the hpd,c remains lower than what the hpd,c* prescribes and only when p/pl > 20, approximately, the hpd,c becomes equal to hpd,c* again, due to the operation of Eq. (37c).

2.7.2 Dilation

It has been made clear so far that in this model different dilatancy D functions are proposed for contraction (dd > 0 and dilation (dd < 0). However, it should be noted that during the transition from contractive to dilative stress state any discontinuity is prevented, as both D functions are proportional to dd and thus, at the crossing point with the dilatancy surface D = 0 holds, due to dd = 0.

During dilation, the dilatancy D takes the following form:

where Ao is the same model parameter as in Eq. (36), while hθ is the function incorporating the loading direction (Lode angle θ) that is identical to that in Eq. (27), i.e., identical to that incorporated in the plastic modulus Kp equation. It is noted here that while in contraction the inclusion of the effect of hθ only in Kp is proven sufficient, this effect is too subtle while in dilation, something that is especially true in monotonic loading. As also mentioned in the text explaining the Kp formulation, function hpost-liq accounts for accumulation of strains after liquefaction is triggered, and its formulation is detailed in a following dedicated section. It suffices here to note that hpost-liq = 1 unless liquefaction occurs. Focusing on the form of Eq. (38), it is deduced that unlike Eq. (36), it adopts directly the essence of Rowe’s dilatancy theory by defining a linear relation between D and dd.

What remains is the explanation of the effect of fabric evolution on D in dilation that is introduced via function hfd. Its inclusion in Eq. (38) stems from experimental observations in cyclic loading tests with very large cyclic shear amplitudes, in which net volume reduction is observed cycle after cycle, even if the stress state remains outside the dilatancy surface for significant portions of the loading (e.g., see drained cyclic experiments of [51]). This reduced tendency for dilation seems to appear gradually and is introduced via function hfd according to:

where cumulative index fpd initiates from fpd = 0 at initial state and has an evolution equation that reads:

Observe that scalar fpd evolves only when the integrals of total and plastic volumetric strains have a comparable measure and hence 0 ≤ a < 1 holds, as per Eq. (35), i.e., \(\dot{f}_{pd} = 0\) in fully undrained conditions. In addition, note that its evolution is solely increasing, due to the inclusion of the plastic volumetric rate in Macauley brackets in Eq. (40). On the other hand, for small intensity cyclic loading which retains the stress state inside the dilatancy surface and dilation does not occur, the term hpd plays no role. Finally, the inclusion of the (fpd–cfd) in Macauley brackets in Eq. (39), implies that a sufficiently large fpd quantity should be accumulated, before the hfd starts reducing the D in dilation. This essentially eliminates the hfd effect in monotonic loading, which does not require any fabric-related function acting on D (e.g., [65]). For this purpose, a constant value of cfd = 3 has been found suitable for all sands.

2.8 Post-liquefaction response and cyclic mobility

In recent years, within the framework of performance-based design, special research effort has been focused not only on liquefaction triggering, but also on the investigation of post-liquefaction deformations. There is a plethora of experimental evidence (e.g., [2, 4, 24, 71]) exhibiting significant shear strain accumulation after initial liquefaction, i.e., the state when the sand first reaches an excess pore pressure Δu that is at least 95% of the initial mean effective stress po, or equivalently when the mean effective stress p is smaller or equal to 5% of po. Capturing the response after initial liquefaction has proven a challenge for constitutive models. To this extent, a variety of constitutive schemes has been proposed first by Elgamal et al. [20], then by Zhang and Wang [77], Boulanger and Ziotopoulou [8] and Tasiopoulou and Gerolymos [57], and very recently by numerous publications targeting this issue (e.g., [3, 10, 31, 74]). In this model, the cyclic mobility response is captured with the aid of function hpost-liq, primarily in Eq. (38) for the dilatancy D in dilation and secondarily in Eq. (30) for the evolution equation of the deviatoric fabric tensor f that affects the plastic modulus Kp. Specifically, the role of function hpost-liq is to enable shear strain accumulation with cycles by (primarily) decreasing the dilation potential (via decreasing the D in dilation) after initial liquefaction in a progressive way, similarly to existing attempts in the literature (e.g., [8]). The target of this reduction of D is to avoid overlaid repeating stress strain loops during cyclic mobility. Here, this is achieved via a cumulative function varying continuously with mean effective stress p once initial liquefaction occurred, a concept originating from Barrero et al. [3]. This function, here, is given as:

where fl is a cumulative variable (initiating from fl = 0), whose evolution equation reads:

with:

being the rate of its evolution, calibrated via Lo a nonnegative model parameter and the void ratio eo at initial state. Equations (41) and (42) include hl and hpl, two nonnegative functions of p, given by:

Crucial for the evolution of fl in Eq. (42) is S, i.e., a flag function with a default value of zero. This S is set equal to 1 only when initial liquefaction is reached for the first-time during loading, i.e., when the current p becomes smaller or equal to the critical value pl. Based on the above, the fl starts to accumulate via Eq. (42) only when the p becomes lower than pl for the first time (due to switching to S = 1). The use of the absolute value of the plastic volumetric strain rate in Eq. (42) ensures that the fl after initial liquefaction does not decrease, regardless of whether the sand experiences contraction or dilation. Of major importance in this fl accumulation is the hpl function which scales the rate of evolution L in Eq. (42). According to Eq. (45), the hpl is a continuous nonlinear function of p/pl with an upper limit equal to 1.0 (when the p approaches zero) and a lower limit of 0.0 (when the p has increased sufficiently beyond pl). In essence, function hpl allows for fl accumulation only when the p is within a low effective stress regime and disallows it if the p becomes much larger, e.g., in the case of post-liquefaction re-consolidation. Such a p-dependence was recently introduced by Barrero et al. [3] and in the sequel by Yang et al. [74], who properly adjusted the plastic modulus and dilatancy functions when in this small p regime. Moreover, Cheng and Detournay [10] did the same for the adjustment of the plastic modulus. A p-dependence is also introduced on the hpost-liq itself in Eq. (41), via function hl in Eq. (44) that is very similar to the hpl function of Eq. (45). This means that the hpost-liq varies between 1.0 (when hl = 0.0) and (1 + fl) > 1 (when hl = 1.0).

The operation of function hpost-liq is discussed in Fig. 3 on the basis of the predicted response during cyclic mobility (following initial liquefaction) in undrained cyclic simple shear loading. The predictions are performed with the model parameters of Table 2 for Toyoura sand. Specifically, of interest is the response during the 3 overlaid effective stress path loops of this test shown in Fig. 3a, which correspond to the 3 non-overlaid stress–strain loops of increasing shear strain amplitude in Fig. 3b. Crucial in the successful simulation of this stress–strain response is the operation of hpost-liq, whose value during these 3 loading cycles is shown in Fig. 3c. Emphasis on the low mean effective stress p regime is provided via the shading, that depicts a range of p < 20 kPa and p/pl < 4 (since pl = 5 kPa for this example case). Observe in Fig. 3c that during the dilative phases of the loading cycles the hpost-liq initiates from a set value (equal to 1 + fl) at p → 0 (points a, c, e, g, i, k) and remains significantly larger than 1.0 only within the low stress regime, since the increase of p reduces the value of hl in Eq. (44), thus leading to hpost-liq = 1.0 asymptotically, and this is regardless of the value of fl in Eq. (41). However, the value of accumulated fl increases cycle after cycle (due to the accumulation of plastic volumetric strain in Eq. (42) and so does the value of (1 + fl) from which initiates the hpost-liq in each successive dilative phase (compare hpost-liq values in paths a–b, c–d, e–f, g–h, i–j, k–l in Fig. 3c). Based on Eq. (38), these increased values of hpost-liq lead to similarly decreased dilatancy D in successive dilative phases, which in turn lead to increased shear strains, especially in the low stress regime (compare range of γSS in paths a–b, c–d, e–f, g–h, i–j, k–l in Fig. 3b). Finally note that having the hpost-liq multiplying the \(\left\langle { - \dot{\varepsilon }_{\text{vol}}^{\text{p}} } \right\rangle\) term in the evolution of fabric tensor f in Eq. (30), essentially cancels out the post-liquefaction effect in the evolution of the fabric tensor f, and through it, on the fabric evolution index hf and the plastic modulus Kp. This ensures that during cyclic mobility the effective stress path loops remain essentially overlaid (see Fig. 3a), despite the shear strain accumulation exhibited by the stress–strain loops cycle after cycle (see Fig. 3b).

a Typical overlaid effective stress path loops during cyclic mobility following initial liquefaction in undrained simple shear loading; b corresponding stress–strain loops with progressive shear strain accumulation with cycles; c evolution of function hpost-liq as a function of p/pl and d effect of model parameter Lo on post-liquefaction shear strain accumulation rate with cycles

Moreover, Fig. 3d explores the effect of model parameter Lo that controls the rate of fl accumulation via L, as per Eqs. (42) and (43). Observe that as the Lo increases, so does the rate of fl accumulation, thus leading to larger hpost-liq values and more intense shear strain accumulation. The value of rate L in Eq. (43) is also made a function of the void ratio at the initial state eo, implying lower rates of post-liquefaction strain accumulation with an increase in relative density and the opposite, in accordance to data (e.g., [58]).

In closing, the formulation described above eventually leads to hpost-liq = 1 when a future loading process leads to values of p much larger than the pl, i.e., outside the small p value regime related to liquefaction and cyclic mobility. In addition, if this future loading process leads to value of p ≥ po (e.g., re-consolidation after liquefaction), the model sets fl = 0, i.e., it erases the memory of the preceding liquefaction. This approach is simple, but has a limitation with respect to what happens if this future loading process increases the p, but to values lower than po or when this possible re-consolidation is followed by another liquefaction event in the future. The model unavoidably retains in memory the preceding liquefaction phase and hence the accumulated fl > 0, something that may be potentially erroneous. To address such issues, an additional constitutive mechanism to eliminate and readjust this effect for subsequent totally different loading conditions, like in Barrero et al. [3], should be included, but such a complication is beyond the scope of this model.

2.9 Mitigation of the overshooting problem

This model employs the deviatoric stress ratio tensor at the last load reversal rini for defining a number of constitutive aspects, namely the loading direction tensor n (Fig. 1), the small-strain nonlinearity (Eq. 22), the plastic modulus (Eq. 24) and the dilatancy in contraction (Eq. 36). One of the problems faced in models employing the last load reversal point, or in models employing reversal surfaces in general, is the overshooting upon unloading and immediate reloading due to the updating of rini in both instances, i.e., the prediction of a stress–strain curve that is unrealistic since it overshoots the expected continuation that this curve would have if this unloading–reloading cycle had not occurred. In their recent work, Duque et al. [17] underlined the sensitivity of both advanced plasticity (e.g., bounding surface) and hypoplasticity models to this issue. This problem has been satisfactorily studied in the literature leading to several approaches for overcoming it (e.g., [8, 10, 11, 14, 27, 76]). In this model, the problem is more complicated, since also the loading direction tensor n may be affected, while the dilatancy is updated as well. So, the issue here is not just an overshooting problem, and in terms of constitutive modeling, it boils down to what is the “accurate” value of rini for having a realistic response in any load path that may be encountered in boundary value problems, both static and dynamic.

As a first step, here the approach of Dafalias and Taiebat [14] is adopted, i.e., a robust methodology for “adjusting” the value of rini depending on the load path. In order to understand their methodology, the following terms are defined: r(m) is the current stress ratio tensor along the current load path (m) at the moment of load reversal (i.e., when Λ < 0 appears), \({\user2{r}}_{\text{ini}}^{\text{(m)}}\) refers to the rini adopted at the initiation of load path (m), \({\user2{r}}_{\text{ini}}^{\text{(m-1)}}\) is the rini of the previous load path (m-1) and \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) refers to the rini that is going to be adopted after the initiation of the upcoming (m + 1) load path. When Λ < 0 appears during load path (m), the r = r(m) and the quandary is whether \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) should be updated to r(m), thus increasing the stiffness of the stress–strain curve during the upcoming path (m + 1), or whether it should take another value. According to Dafalias and Taiebat [14] the answer depends on the “magnitude” of load path (m), that is quantified in terms of ep(m), the integral of plastic deviatoric strain quantity \(\sqrt {\left( {{2 \mathord{\left/ {\vphantom {2 3}} \right. \kern-\nulldelimiterspace} 3}} \right)\dot{\user2{e}}^{\text{p}} :\dot{\user2{e}}^{\text{p}} }\) during this path. For intermediate values of ep(m) an interpolation function for \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) should be used, which according to Dafalias and Taiebat [14] reads:

where k is the weighting parameter of Eq. (46) that quantifies the significance of load path (m) on the basis of the relative magnitude of plastic deviatoric strain ep(m) in comparison with \({\it{e}}_{1}^{\text{p}}\), a model constant serving as a shear strain threshold beyond which \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) = \({\user2{r}}^{\text{(m)}}\). In this model, \({\user2{e}}_{1}^{\text{p}}\) = 10–4, and n, the model constant controlling the non-linearity of Eq. (47), is set equal to 1, following the advice of Dafalias and Taiebat [14] for both. Based on the above, during any load path (m), both \({\user2{r}}_{\text{ini}}^{\text{(m-1)}}\) and \({\user2{r}}_{\text{ini}}^{\text{(m)}}\) should be kept into memory, the former for use in Eq. (46), while the latter as the rini entering all aspects of the constitutive model presented above.

According to Eqs. (46) and (47), if load path (m) is negligible in terms of ep(m), then \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) = \({\user2{r}}_{\text{ini}}^{\text{(m-1)}}\) (due to k = 1) and for loading path (m + 1), only \({\user2{r}}_{\text{ini}}^{\text{(m)}}\) and \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) are kept into memory, while the all-important \({\user2{r}}_{\text{ini}}^{\text{(m-1)}}\) is erased from memory. This is fine if loading path (m + 1) is significant. If it is not and k = 1 holds again, then, ideally, the \({\user2{r}}_{\text{ini}}^{\text{(m+2)}}\) should be again equal to \({\user2{r}}_{\text{ini}}^{\text{(m-1)}}\), only that this value has been erased from memory. This loss-of-memory problem does not only appear when k = 1, but also for 0 < k < 1, only that it requires a number of successive negligible load paths to erase from memory the effect of the all-important \({\user2{r}}_{\text{ini}}^{\text{(m-1)}}\). Such paths with successive negligible load paths are not uncommon in boundary value problems, especially of dynamic nature. This shortcoming is hereby remedied, by supplementing the foregoing methodology with a criterion on whether a load reversal (a state where Λ < 0) is “formal” or “informal.” Namely, as soon as a load reversal is detected for the initiation of load path (m + 1) at r = r(m), it is considered by default “informal” and no update of rini is performed (i.e., rini =\({\user2{r}}_{\text{ini}}^{\text{(m)}}\) remains). This holds until the accumulated stress ratio difference from the “informal” load reversal point is larger than a preset (small) tolerance level rtol. If this occurs, then the load reversal point is considered “formal” and the estimation of the \({\user2{r}}_{\text{ini}}^{\text{(m+1)}}\) is performed on the basis of Eqs. (46) and (47). In more detail, the condition that should be satisfied for considering the last load reversal as “formal” reads:

where rtol is a model constant selected equal to 0.01 here. During the (small) loading path following an “informal” load reversal that has not updated the rini, the loading index Λ usually continues to be negative, and thus, only elastic deformations are developed.

In Fig. 4, the effectiveness of this enhanced methodology for mitigating overshooting is presented for an exemplary case of an undrained triaxial test (for po = 1000 kPa and eo = 0.870) that is simulated with the model parameters of Table 2 for Toyoura sand. The test is not monotonic, since when the axial strain becomes equal to εa = 0.5% and 1%, three different cases of unloading–reloading are imposed, as depicted in subplots a, b and c. Specifically, in Fig. 4a, a single strain-controlled cycle with a large Δεa = 0.1% is applied at both levels of εa, while in Fig. 4b this single cycle has a much smaller strain amplitude of Δεa = 0.005%. Finally, in Fig. 4c, at both levels of εa, 10 successive cycles with Δεa = 0.005% are applied. In all subplots, the curve of the reference monotonic test is included, but this may only be considered relevant in Fig. 4b and 4c where the applied unload–reload cycles are of very small-strain amplitude. On top of this monotonic test curve, in all subplots, three stress–strain curves of the actual test are compared: one without mitigating overshooting, one that employs only Eqs. (46) and (47), and one that employs the whole methodology (including Eq. (48)). It is concluded that overshooting correction is not needed when the unload–reload cycles are of large amplitude (Fig. 4a). However, it is also shown that the overshooting correction of Dafalias and Taiebat [14], i.e., Eqs. (46) and (47), is required when the unload–reload cycles are of small amplitude (Fig. 4b), with the addition of Eq. (48) proving necessary for the more general case of multiple cycles of small amplitude (see Fig. 4c). In closing, note that the large differences in the stress–strain response with and without overshooting mitigation shown in Fig. 4 (e.g., increase of qTX by more than 100% for εa = 2% in Fig. 4b) should be viewed as an upper-bound estimate. For fully drained conditions and/or a more dilative initial state, the differences would be smaller, yet they would still vouch for the need of stress–strain overshooting mitigation.

Performance of different schemes to treat overshooting for the stress–strain response of an undrained triaxial compression test, with three different cases of unloading–reloading cycles at εa = 0.5% and 1.0%: a single cycle with Δεa = 0.1%, b single cycle with Δεa = 0.005%, c 10 successive cycles with Δεa = 0.005%

3 Calibration procedure of model parameters

The proposed model requires the calibration of 14 parameters. Their values for Toyoura and Ottawa-F65 sand are summarized in Table 2.

They are divided in different groups according to the constitutive part they refer to. Of these 14 model parameters, 2 are related to elasticity, 5 to critical state, 3 to the plastic modulus, 2 to the dilatancy, 1 to fabric evolution and 1 to post-liquefaction response. The procedure of determining their values will be discussed here using Toyoura sand as merely an example case. As described in the previous section, the present model has similarities with the models proposed by Papadimitriou and Bouckovalas [42], Andrianopoulos et al. [1], Dafalias and Manzari [12] and Taiebat and Dafalias [56]. Their common constitutive ingredients include model parameters, whose calibration rationale is adopted unchanged and need not be repeated. This is the case for the first 12 out of the 14 model parameters in Table 2, i.e., the model parameters referring to elasticity, critical state, plastic modulus and dilatancy. It is merely mentioned here that out of these 12 model parameters, only 3 of them (ho, ch and Ao) require trial-and-error runs, while the remaining 9 parameters may be directly measured or estimated (e.g., for Toyoura sand: \({\it{M}}_{\text{ c}}^{\text{ c}}=\text{1.25}\), c = 0.712, as in [12]; ecs = 0.934, λ = 0.019, ξ = 0.70 as in [28]; ν = 0.15 in accordance with [52] and [59]).

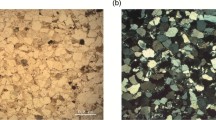

The exception to the foregoing rule is elastic parameter Go that quantifies the elastic shear modulus (Gmax), which must always be calibrated against small-strain tests (e.g., bender elements, resonant column tests), or wave propagation tests in the field or laboratory. According to McAllister et al. [37], the use of conventional triaxial data for this purpose (as is often performed in the literature) may lead to underestimation of its value. Here, the data of Wicaksono and Kuwano [70] for Toyoura sand are used for this purpose. As shear modulus was measured through different dynamic methods (trigger accelerometer, bender element, plate transducer), an average value is considered for the calibration of Go. In Fig. 5, the comparison between the measured and predicted (by Eq. (20)) elastic small-strain shear modulus Gmax is presented, for the selected value of Go = 650. The comparison is made in terms of Gmax versus mean effective stress p, for three different values of void ratio (e = 0.811-Dr ≈ 45%; e = 0.756-Dr ≈ 60%; e = 0.700-Dr ≈ 75%). Based on the good fitting of the data in Fig. 5, apart from the appropriate Go value, the calibrated Eq. (20) predicts quite well the correlation of Gmax with relative density and stress level.

Comparison of predicted Gmax values versus their measurements by Wicaksono and Kuwano [70] as a function of void ratio e and mean effective stress p, after calibration of parameter Go for Toyoura sand

The remaining 2 model parameters determine the cyclic response and are estimated on the basis of cyclic tests at the end of the calibration process, i.e., after the first 12 model parameters. The fabric evolution intensity constant No is calibrated by trial-and-error runs that target either the accumulated volumetric strains during cyclic drained tests, or the number of cycles to reach initial liquefaction during cyclic undrained tests. The selection of type of cyclic tests to be used depends on availability, or the task at hand, but both can be used equally well. Figure 6 illustrates the key role of No in controlling the intensity of fabric evolution function hf, Eq. (28), in 4 indicative loading conditions: 2 under cyclic (subplots a, c) and 2 under monotonic conditions (subplots b, d). In Fig. 6a, the effective stress path of a cyclic undrained triaxial test shows how the parameter No can be used to adjust the predicted rate of excess pore-pressure build-up and the number of cycles until initial liquefaction is triggered. Model predictions are compared with an undrained cyclic triaxial test performed by Toyota and Takada [60] (e = 0.756 (Dr ≈ 60%), po = 98.1 kPa). In the same way, in Fig. 6c the effect of No on the rate of accumulation of volumetric strains during a drained cyclic simple shear test-with the same initial conditions, but now with Ko = 0.50 instead of 1.0 - is explored. For this type of loading, experimental data for Toyoura sand are not available, but at least the accumulation of volumetric strains is validated against the empirical estimate of Duku et al. [16]. Moreover, Fig. 6b and 6d compares model predictions to monotonic triaxial compression tests of Verdugo and Ishihara [65] (Fig. 6b-undrained test with e = 0.833 (Dr ≈ 37%), po = 100 kPa; Fig. 6d-drained test with e = 0.831 (Dr ≈ 37%), po = 100 kPa). These comparisons with monotonic test data show that the fabric evolution function affects only marginally the monotonic response, but is crucial for a satisfactory cyclic loading prediction. Hence, the calibration for monotonic tests may be performed for No = 0, and then, the final value of No can be calibrated on the basis of trial-and-error simulations of cyclic tests, without essentially deteriorating the predicted monotonic response.

Effect of fabric evolution function and its scaling parameter No on: a effective stress path during an undrained cyclic triaxial test; b effective stress path during an undrained monotonic triaxial compression test; c rate of accumulation of volumetric strain during a drained cyclic simple shear test; d stress–strain response during a drained monotonic triaxial compression test

The last model parameter Lo requiring calibration is linked to the post-liquefaction shear strain accumulation and is quantified also by a trial-and-error procedure. It controls the intensity of the dilatancy decrease in dilation after initial liquefaction occurs, and thus the rate of strain accumulation, as depicted in Fig. 3d. Note that its value has no effect on the pre-liquefaction phase and this is why it is calibrated last. Its calibration requires good quality cyclic undrained tests reaching well beyond initial liquefaction, thus allowing the estimation of the rate of strain accumulation thereafter. In absence of specific experimental data, the semiempirical framework of post-liquefaction shear deformation accumulation in sands, recently proposed by Tasiopoulou et al. [58], can prove useful for this purpose.

4 Model performance

In this section, the performance of the new model is evaluated. The validation includes simulations of both monotonic and cyclic shearing tests on Toyoura and Ottawa-F65 sand that were performed with the values of model parameters shown in Table 2. In order to present a thorough evaluation of model performance that addresses all important aspects of monotonic and cyclic response, wherever sand-specific data are lacking, the model performance is validated against empirical relations from the literature, especially for cyclic loading. In the following, each subsection illustrates a different type of loading and comparisons are presented for at least one of the two sands, if not for both. All the information regarding the characteristics of the element tests employed in this section is summarized in table format in Appendix.

4.1 Drained and undrained monotonic loading

The new model is used to simulate drained triaxial compression tests (TC) on Toyoura sand, performed by Verdugo and Ishihara [65] on isotropically consolidated samples. Figure 7 compares numerical simulations to experimental data in terms of (triaxial) deviatoric stress qTX = σa-σr versus axial strain εa (subplots a, c) and volumetric strain εvol versus axial strain εa (subplots b, d). Subscripts a and r denote the axial and radial directions of the triaxial sample, respectively. Subplots a and b pertain to tests with po = 100 kPa, while subplots c and d to tests with po = 500 kPa, with po denoting the initial mean effective stress of the sample. The model simulates quite accurately the three distinct behaviors of the sand, as they emerge from the tests based on the initial value of void ratio eo of the samples after consolidation. More specifically, stress-strain response and volumetric strain are properly predicted both in the cases of the dilative response of the medium–dense (eo = 0.810-0.831, with Dr = 37-43%) samples, as well as the slightly (eo = 0.886-0.917, with Dr = 14-23%) or intensively (eo = 0.960-0.996, with Dr < 3%) contractive samples, for both stress levels.

Experimental results and model predictions of drained monotonic triaxial compression tests. Data on Toyoura sand after Verdugo and Ishihara [65]

In the sequel, the model performance is evaluated against the drained torsional shear tests (TS) of Pradhan et al. [47]. These torsional shear tests were performed after Ko-consolidation of the samples to an initial axial stress σa,o, and then, shear deformation is applied producing shear stress τ in the torsional shear apparatus, while retaining the effective axial stress constant (σa = σa,o). At the same time, radial and circumferential strain increments were kept equal to zero throughout the test, ensuring simple shear loading conditions. Three different combinations of initial axial stress σa,o and initial void ratios eo are presented. Based on Pradhan et al. [47], the Ko value in these samples is estimated by the empirical relation Ko = 0.52eo and the thus procuring values were considered in the simulations. In Fig. 8, the comparison of data to simulations is presented in terms of the stress ratio τ/σa versus shear strain γ = ε1–ε3 (subplot a) and εvol versus γ (subplot b), where subscripts 1 and 3 denote the maximum and minimum principal values of the tensor, irrespective of its direction. The overall response is simulated with fair accuracy, besides the slight stiffer stress–strain response, mainly for the very dense sample with eo = 0.674 (Dr = 81%).

Experimental results and model predictions of drained monotonic torsional shear tests. Data on Toyoura sand after Pradhan et al. [47]

Figure 9 shows the model performance for drained TC tests on Ottawa-F65 sand conducted by Vasko [63] and Vasko et al. [64] for medium–dense (eo = 0.604, Dr ≈ 55%) and dense (eo = 0.585, Dr ≈ 62%) isotropically consolidated samples. The comparison is presented in the format of Fig. 7. Three stress levels (100 kPa-300 kPa) are examined for each density. The comparison for eo = 0.604 is quite satisfactory, while that for eo = 0.585 is considered fair, with a slight under-prediction of the peak strength of these denser samples. For both relative densities, the volumetric response is predicted satisfactorily.

Subsequently, in Fig. 10, the model is evaluated against the undrained TC tests of Verdugo and Ishihara [65] on isotropically consolidated samples of Toyoura sand. The comparison of data versus simulations is shown in the spaces of qTX versus εa (subplots a, c) and qTX versus p (subplots b, d). The simulations concern two relative densities (e = 0.735 and 0.833, with Dr ≈ 63%-37%) and a great range of initial mean effective stresses, from po = 100 kPa to the extremely high value of po = 2000 kPa. Hence, the versatility of the model to predict both contractive or dilative response for this wide range of initial conditions, depending on the combination of e-po, is depicted.

Experimental results and model predictions of undrained monotonic triaxial compression tests. Data on Toyoura sand after Verdugo and Ishihara [65]

Then, Fig. 11 compares experimental data to numerical simulations for undrained simple shear tests (SS), performed by Yoshimine et al. [75], on isotropically consolidated samples of Toyoura sand. The initial mean effective stress po has a common value of 100 kPa for all samples, and the examined relative densities cover a range between loose and medium–dense conditions (e = 0.804–0.888, with Dr ≈ 22–45%). In all cases, the comparison is made in terms of effective stress paths q = σ1–σ3 versus p (subplot a) and stress–strain relations q vs γ (subplot b). The simulations are fair for the most dilative of the examined densities and show a gradually increasing contractive response as the void ratio e increases. However, an under-prediction of the effect of void ratio e may be observed. This should not be considered as a shortcoming of the model, since it has been calibrated to provide satisfactory accuracy for a huge range of void ratio values of Toyoura sand, from e = 0.674 (Dr ≈ 81% in Fig. 8) to e = 0.996 (Dr < 0% in Fig. 7).

Experimental results and model predictions of undrained monotonic simple shear tests (Ko = 1). Data on Toyoura sand after Yoshimine et al. [75]

4.2 Undrained cyclic loading

With the same set of parameters (listed in Table 2), undrained cyclic loading tests are simulated in this paragraph. Figure 12 shows the model capability in simulating an undrained cyclic torsional shear test conducted by Zhang [78] on Toyoura sand and presented by Zhang and Wang [77]. It was isotropically consolidated at po = 100 kPa and a relative density Dr = 70%, which according to the given values of emax = 0.973 and emin = 0.635 corresponds to a void ratio e equal to 0.736. The single amplitude of the cyclically applied shear stress for this test is τcyc = 33 kPa. The comparison is made in the spaces of shear stress τ versus mean effective stress p (subplots a, c) and τ vs shear strain γSS (subplots b, d). The comparison is quite satisfactory as the model successfully captures the cyclic mobility between loading–unloading paths and illustrates “banana-shaped” stress–strain (τ versus γSS) loops when approaching p = 0 (initial liquefaction). Moreover, shear strain continuously increases during the cyclic shearing after liquefaction triggering in good agreement with the experimental data.

Experimental results and model predictions of undrained cyclic torsional shear test. Data on Toyoura sand after Zhang [78]

Then, in Fig. 13, the model is evaluated against an undrained cyclic triaxial test on Ottawa-F65 sand, performed by El Ghoraiby et al. [19]. The test is performed for e = 0.585, and the sample was initially consolidated at a mean effective stress of 100 kPa. The comparison is made in the spaces of qTX versus radial effective stress σr (effective stress path in subplots a, c) and qTX vs axial strain εa (stress–strain relation in subplots b, d). The test is performed as stress controlled with a single amplitude of cyclic stress qTX,cyc = 34 kPa. Both the effective stress path and the stress–strain relation are captured quite well by the model. Observe how the model predicts well the initially decreasing rate of excess pore-pressure build-up with cycles and then how this rate increases to bring the sand to initial liquefaction. This non-constant rate of excess pore-pressure build-up is typical of sand response; however, it is rarely commented on in the literature of constitutive models for liquefaction, despite its importance for accurate simulations of boundary value problems. On the other hand, the model shows small bias in strain accumulation in the stress–strain relation (qTX versus εa) toward the extension side. This is attributed to the different shear strengths in triaxial compression and extension, which lead to different strain accumulation rates. This bias is a common shortcoming of constitutive models aiming at liquefaction response (e.g., [17]) and has been hereby reduced, yet not alleviated, due to the introduction of the post-liquefaction constitutive ingredient hpost-liq of Eq. (41). Note also here that this bias is not evidenced in cyclic loading in simple shear or torsional shear (e.g., in Fig. 12) where the Lode angle θ change within a loading cycle is very small in comparison with the “jump” between θ = 0ο and θ = 60ο in cyclic triaxial loadings. This is why any model aiming at successful liquefaction predictions should always be verified in both triaxial and simple shear or torsional cyclic loading.

Experimental results and model predictions of undrained cyclic triaxial test. Data on Ottawa-F65 sand after El Ghoraiby et al. [19]

4.2.1 Liquefaction resistance curves for different relative densities

Liquefaction resistance curves are a practical tool for assessing the simulation success for undrained cyclic loading, since they provide a grouping of many element tests for different cyclic stress ratio amplitudes, relative densities and stress levels and even different loading conditions. Toyoura sand is one of the most widely used sands for the study of liquefaction, so there is a plethora of experimental liquefaction resistance curves published by different researchers worldwide. Given the use of different Toyoura sand batches, there is significant scatter in the pertinent data, even when referring to the same values of relative density, initial stress level, as well as the same preparation method or loading type. Hence, it was deemed fairer to evaluate the model's accuracy in predicting liquefaction resistance through comparison with a group of liquefaction resistance curves of Toyoura sand from the literature ([23, 32, 60, 69, 73]) instead of a single set of curves.

In this perspective, in Fig. 14 a wide range of liquefaction resistance curves from cyclic triaxial tests is presented. The grouping of the experimental data was based on the relative density Dr of the sand, in groups of test data with Dr = 45% (subplot a), 60% (subplot b) and 75-80% (subplot c). Notice that there is a large deviation between the referenced values of emin (0.597–0.635) and emax (0.970–0.990) in the employed studies. Hence, since the model requires values of void ratio e and not Dr, their calculation is based on the average values of emin = 0.609 and emax = 0.976 that were estimated on the basis of the employed studies. So, the simulated void ratio for Dr = 45% is 0.811, for Dr = 60% is 0.756 and for Dr = 77.5% (a mean value between 75 and 80%) is 0.691. To reduce the scatter of the experimental results, all selected literature liquefaction resistance curves refer to isotropically consolidated samples at initial mean effective stress po = 100 kPa which are prepared with the method of air pluviation, except for the data of Yamashita and Toki [73] at Dr = 80%, where the vibration method was used. The comparison is made in terms of cyclic stress ratio CSR (= qTX,cyc /2po) versus Nl, the number of cycles required for a double amplitude axial strain equal to 5% to be developed. Observe that the liquefaction resistance curves procuring from the simulations generally plot within the range of the experimental data, albeit showing a slightly steeper inclination. However, it should be acknowledged that the typical experimental observation of no-liquefaction (Nl → ∞) at small CSR values is well captured by the model, i.e., the model remedies a common shortcoming of liquefaction models (e.g., [1]). Moreover, the model simulates well the experimentally established increase in liquefaction resistance with relative density.