Abstract

Purpose

Biogas slurry (BS) was known to influence soil–plant ecosystems when applied as a fertilizer, especially in combination with a chemical fertilizer (CF). Limited information was available regarding how this combination of BS–CF actually affected the soil–plant ecosystems. The purpose of this study was to evaluate the effects of BS–CF combinations on peanut yield, soil properties, and carbon (C) storage in a red soil (Ultisol) in southern China.

Materials and methods

The soil was fertilized with five treatments, including a control (T1), CF-only (T2) treatment, and three treatments with different BS–CF combinations (T3–T5). The final quantities of N/P2O5/K2O applied in T2–T5 were 120:90:135 kg ha−1. In T3–T5, 15 % (18 kg ha−1), 30 % (36 kg ha−1), and 45 % (54 kg ha−1) of total N (TN), respectively, were applied with BS and the remaining TN was applied with CF. Crop yield, soil nutrients, C storage, and microbial activity were determined through field and laboratory experiments.

Results and discussion

In the field experiment, peanut grain yields of T3–T5 were higher than those of T1 (44.5–55.7 %) and T2 (10.8–19.4 %), with the highest yield from T4 (3588 kg ha−1). The relationship between BS–TN inputs and peanut grain yield conformed to the linear-quadratic equation: y = −1.14x 2 + 59.1x + 2988 (R 2 = 0.98). The biomasses of peanut plants, at the flowering, pod production, and harvesting stages, were higher in T4 compared with those in T1 and T2. Moreover, T4 produced higher soil N and P (total and available) concentrations at the pod production and harvesting stages relative to other treatments, with increased soil microbial biomass C and N, and enhanced dehydrogenase and urease activities, at the flowering, pod production, and harvesting stages. Data from the incubation experiment were fitted to a first-order kinetic model, which showed that although the application of BS increased potentially mineralizable C, the additional C seemed to slowly degrade, and so would be retained in the soil for a longer period.

Conclusions

A BS–CF combination increased peanut grain yield and biomass, due to increases in soil N and P availability, microbial biomass C and N concentrations, and urease and dehydrogenase activities. Moreover, the organic C retention time in the red soil was extended. Combined application of BS–CF at a suitable ratio (36 kg BS–TN ha−1), together with proper management practices, could be effective to improve the quality and nutrient balance of amended soils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the increasing interest in using renewable energy, the production and subsequent use of biomass energy is seen as an important source. An established, robust technique for biomass energy production is the anaerobic digestion of organic matter (OM), which was shown to solve the environmental problem of excess raw materials and meanwhile contribute to climate change mitigation (Ragauskas et al. 2006). It was predicted that up to 25 % of all biomass energy in the future would comprise biogas (Nielsen and Oleskowicz-Popiel 2007).

Livestock residues provide one well-functioning substrate option for anaerobic digestion. In China, 9166 t of these residues was produced in 2002 (Li et al. 2002) and 10,666 t are predicted to be produced in 2020 (Galloway et al. 2008). However, the intensification of biogas production will produce substantial increases in the volumes of digestate, the disposal of which poses a problem (Galvez et al. 2012). The sustainability of the biogas chain would be greatly improved if a suitable method of utilizing the digestate was developed.

Biogas slurry (BS), the liquid fraction of the digestate, was found to contain substantial organic carbon (C) and crop nutrients that were attractive as fertilizers, to return nutrients to soil ecosystems (Svensson et al. 2004; Odlare et al. 2011). The soil application of BS may represent an effective way to tackle the widespread loss of soil organic C (SOC) (Galvez et al. 2012), which has, for example, occurred in regions of Jiangxi Province, southern China. This could benefit crop growth, if integrated with proper agricultural management (Holm-Nielsen et al. 2009).

Since the invention of the Haber–Bosch process, higher grain yields worldwide have relied on the intensive use of chemical fertilizers (CFs) in agriculture (Erisman et al. 2008; Abubaker et al. 2012). The majority of soil in the subtropical area of southern China has been subjected to the disorderly and massive use of CFs since the 1980s. As a consequence, regionally, the fertilizer uptake efficiency has been reduced, so the CFs applied are wasted, the SOC concentration has decreased, and water eutrophication has occurred (Zhang and Horn 2001; Huang et al. 2010). The application of BS has the potential to solve the above problems, as the BS containing high SOC and nutrient concentrations could partly substitute the overuse of CFs (Insam et al. 2015).

Soil application of BS has been shown to positively impact the soil–plant ecosystems. For instance, Tiwari et al. (2000) showed that a BS treatment resulted in substantially higher soil microbial biomass C (MBC) after wheat harvest in the field, and cumulative CO2 evolution after 20 days of laboratory incubation, compared with a non-amended control. Although Abubaker et al. (2012) found that soil fertilized with biogas residues had similar biomass yields, the treatment increased the N mineralization capacity and potential ammonium oxidation rates, in comparison with CF-only treatment.

Since stable C is the main constituent of humus, BS might be a potential source of SOC (Terhoeven-Urselmans et al. 2009). Limitations associated with BS and extensive use of CF must be immediately addressed (Zhang and Horn 2001; Huang et al. 2010; Abubaker et al. 2012; de la Fuente et al. 2013). However, most studies of BS application have been performed in laboratories, under controlled conditions (Abubaker et al. 2012; de la Fuente et al. 2013). The effects of BS on soil processes in field situations are relatively poorly understood. In particular, there has been little research into the soil fertilizing effect of P in BS–CF combinations, compared to CF only treatments (Li et al. 2014).

The objective of the present study was to evaluate and compare the fertilizing performance of BS–CF combinations against that of no CF or BS, and CF-only treatments, in terms of peanut grain yield, soil nutrients, C storage, and microbial activity. The optimal rate of BS application was determined for a regional soil (Ultisol) in Jiangxi Province, southern China.

2 Materials and methods

2.1 Field experiment

2.1.1 Study site and BS collection

The experiment was conducted during April–August 2013 in an experimental peanut field, located in the Luwang village of YuJiang County, Jiangxi Province, southern China (116° 5ʹ E, 28° 12ʹ N). This region has a typical subtropical monsoon climate with annual precipitation of 1795 mm, annual evaporation of 1318 mm, and a mean annual temperature of 17.6 °C. Regionally, the predominant soil, derived from the Quaternary red clay, is classified as red soil (Genetic Soil Classification of China (Zhou et al. 2013)), and Ultisol (Soil Taxonomy System of the USDA (Zhang and Peng 2006)). The physical and chemical properties of the field soil (0–20 cm depth) were as follows: pH 4.94 (H2O/soil = 2.5:1), clay 32.9 %, silt 61.0 %, sand 6.1 %, organic C (OC) 7.06 g kg−1, total nitrogen (TN) 0.83 g kg−1, total phosphorous (TP) 0.51 g kg−1, NH4 +-N 16.15 mg kg−1, and NO3 −-N 3.90 mg kg−1. Peanut crop and fallow had been alternated in the field during the previous 5 years.

The BS was collected directly from a middle-scale pig farm with a biogas plant that included a well-mixed BS storage facility. The main feedstock of the biogas plant reactor was a mixture of pig manure and urine. The operation temperature ranged from 35 to 40 °C, and the minimum retention time was 1 year. The main characteristics of the BS are shown in Table 1.

2.1.2 Experimental design

The field experiment was arranged in a single-factor randomized complete block design, with three replicates of each treatment. Each plot was 12.5 m × 4.8 m. Five treatments were applied, in which the BS was used as a substitute, to the CFs, of the source of TN, to varying degrees: T1, control (no CF or BS); T2, CF only; T3, 15 % BS–TN plus 85 % CF–TN; T4, 30 % BS–TN plus 70 % CF–TN; and T5: 45 % BS–TN plus 55 % CF–TN. Thus, the quantities of BS applied in each treatment were calculated based on its TN concentration, and the other macronutrients (phosphorous [P], potassium [K], and additional nitrogen [N]) were adjusted accordingly with CFs. Urea (46 % N), calcium magnesium phosphate (12 % P2O5), and potassium chloride (60 % K2O) were selected as the CF sources of inorganic N, P2O5, and K2O, respectively. For the CF treatment and the BS substitution treatments, the same final quantities of N, P2O5, and K2O were applied (N/P2O5/K2O, 120:90:135 kg ha−1). The actual quantities of the BS applied were 6.41, 12.81, and 19.22 × 104 L ha−1, respectively, for T3, T4, and T5. The organic C and nutrient input by the CFs and BS within each treatment are shown in Table 2.

The 0–20-cm soil layer was plowed before sowing on April 5, 2013, and then the appropriate quantities of BS for each treatment were manually spread using an open-head drum and ladle on April 6 and 7. After that, the CFs (urea, calcium magnesium phosphate, and potassium chloride) were mixed and then applied manually in sequence on April 8, before the soil layer was plowed for a second time on April 9. Thus, the BS and CFs were used as basal dressings. Two peanut seeds were planted in each hole to achieve a planting density of 140,000 plants per hectare (equivalent to 840 plants per treatment plot) on April 10. Line and row distances of 40 and 20 cm, respectively, were maintained between the holes. Field and crop management practices were conducted in accordance with local agricultural practices. The peanuts were harvested on August 10.

2.1.3 Soil and plant sampling

Five random soil subsamples (0–20 cm) were collected from each of the treatment plots and then mixed together to form a single sample, at the seedling, flowering, pod production, and harvesting stages of the peanut plants. At the same time points, five plant samples were collected (including the roots) from each plot. Once in the laboratory, all visible roots and crop residues were removed from the soil samples. Then, the composite soil samples were divided into two parts: One portion was air-dried at room temperature, ground, and passed through a 0.25-mm sieve, prior to analysis of the soil N and P concentrations, and the other portion was ground directly (without drying) and passed through a 2-mm sieve in preparation for the MBC, microbial biomass N (MBN), and enzyme activity analyses. The soil and plant sample portions were stored at 4 °C and room temperature, respectively, until analysis.

2.2 C mineralization experiment

The soil used in this laboratory incubation trial was sampled from the 0–20-cm soil layer of the control (no CF/BS) treatment plots. In the laboratory, the soil was air-dried and then passed through a 2-mm sieve before use. The incubation trial was performed using 100 g of soil (dry weight, DW) in 500-mL polypropylene jars. Empty polypropylene jars were used to obtain background air values. The relative quantities of BS applied for each treatment of the incubation trial were the same as those applied for the field experiment: T1, T2, T3, T4, and T5 treatments received 0, 0, 4, 8, and 12 mL BS 100 g−1 soil (DW) according to Table 2, respectively. The BS and CFs were thoroughly mixed with the soil prior to the experiment, and the soil was preconditioned to 60 % of its water-holding capacity with deionized water.

The treated soils were incubated under aerobic conditions in darkness at 26 ± 0.5 °C for 70 days. The moisture levels of the soils were checked three times every week, by weighing the soil, and deionized water was added when necessary to maintain constant moisture levels. CO2 evolution from the soil was measured at 2, 4, 7, 10, 14, 18, 21, 28, 35, 42, 49, 56, 63, and 70 days of incubation.

2.3 Analytical methods

The biomass (DW) of the peanut plants at the four growth stages (i.e., seedling, flowering, pod production, and harvesting) was determined by cutting the plants into small pieces (Abubaker et al. 2012) and subsequent drying at 105 °C for 30 min and 75 °C for 10 h. The overall biomass was derived by multiplying the individual plant biomass by the plant density. Grain yield (DW) was measured after harvest and standardized to tons per hectare. The DW of grain yield and biomass was determined by the standard baker oven method (Lu 1999). Each dried plant sample was ground and sieved with a 2-mm sieve. Then, the N concentration was measured colorimetrically, after Kjeldahl digestion (Nishikawa et al. 2012).

The electrical conductivity (EC) and pH of the BS were directly measured using a conductivity and pH meter, respectively. NH4 + and NO3 − were extracted from the soil by adding 1 mol L−1 KCl solution at a 1:10 (w/v) ratio. The extractable soil NH4 + was measured through a modified colorimetric method, based on the Berthelot reaction (Sommer et al. 1992). The concentrations of extractable NO3 − were determined by absorbance at 220 nm. The values obtained were subtracted from the corresponding values at 275 nm, which were attributed to OM (Galvez et al. 2012). The total magnesium (Mg), calcium (Ca), and metals in the BS were analyzed according to Lu (2000).

For soil analysis, MBC and MBN were determined using the fumigation–K2SO4 extraction method (Vance et al. 1987; Joergensen 1996), with an automatic analyzer used for liquid samples. Values were subsequently calculated according to the method of Wu et al. (1990). TP was determined through the colorimetric method (Van Veldhoven and Mannaerts 1987). OM concentration was calculated from loss on ignition at 500 °C for 24 h. Total organic C (TOC) was calculated by dividing the OM concentration by 1.72 (Nelson and Sommers 1982). TN and total K (TK) were determined using the potassium persulfate oxidation–ultraviolet spectrophotometer and flame photometer methods, respectively (Lu 1999). Available P (AP) was measured colorimetrically, after NaHCO3 extraction (Watanabe and Olsen 1965). Soil dehydrogenase and urease activities were determined using the methods of Le et al. (1964) and Perez-Mateos and Gonzalez-Carcedo (1988), respectively.

To determine the CO2 evolution from the amended soil in the incubation trial, NaOH solution was placed in a small beaker inside the 500-mL polypropylene jars. The NaOH solution was titrated with 0.05 M HCl and excess BaCl2, to precipitate the carbonates (de la Fuente et al. 2013).

2.4 Calculations and statistical analyses

The DW results are expressed on oven dry weight basis and represent the means of three replicates. The efficiency of the BS–CF treatments for plant N recovery was quantified by calculating the mean of the relative N fertilizer values (RNFVs), on the basis of the estimated functions previously reported (Sieling et al. 2013). The RNFVs were obtained as the ratio of the apparent N recovery (ANR, %) of each respective BS–CF treatment to that of the CF only treatment (Sieling et al. 2013); (Schröder et al. 2005).

Mineralization of the OC contained in the soil and BS was calculated as the difference between the CO2 evolved from the BS–CF treatments and the control (no CF/BS) treatment and expressed as the percentage of the TOC concentration (%TOC) contained in the soil and BS (natural and added) (de la Fuente et al. 2013).

The results of the C mineralization in soil were fitted to a first-order kinetic model, according to the following equation (de la Fuente et al. 2013):

where C m is the mineralized C obtained after t days of incubation; C 0 is the potentially mineralizable C; k is the decomposition rate constant for the TOC contained in the soil and BS (day−1); and t is the incubation time.

Statistical analyses were performed with SPSS 13.0 for Windows (SPSS Inc., Chicago, IL, USA). One-way analysis of variance (ANOVA), followed by least significant difference (LSD) pairwise comparisons, was performed to determine the significance of differences among treatments (a significance level of P < 0.05 was used). Linear regressions and coefficients of determination (R 2) were used to describe the relationship between the BS–TN input and peanut grain yield.

3 Results

3.1 Peanut yield, biomass, and soil nutrients

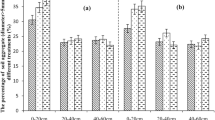

The effects of the different treatments on the yields of the peanut show that the BS–CF combination treatments (T3–T5) had higher yields than the treatment which only used CFs (T2) (Fig. 1a). Of the BC–CF combination treatments, T4 produced the largest yield, with significant difference from T3 and T5. The regression analysis indicated that the relationship between the input of TN by the BS and grain yield conformed to the linear-quadratic equation: y = −1.14x 2 + 59.1x + 2988 (R 2 = 0.98, P < 0.01). In other words, the yield (in terms of DW) was highest at a fertilization rate of 31.2 kg BS–TN ha−1, close to the fertilization rate of T4 (36 kg BS–TN ha−1). Likewise, the total biomass showed a significant response to BS–TN input (Fig. 1b). In T4, the total biomass reached 4.0, 10.6, and 11.9 t ha−1 at the flowering, pod production, and harvesting stages, respectively, which were higher than those in other treatments.

The NAAs of the plants in the BS–CF combination treatments (T3–T5; 224.5–248.7 kg ha−1) were higher than those subjected to the control treatment (T1; 153.4 kg ha−1) and CF-only treatment (T2; 200.5 kg ha−1) (Table 3). Additionally, T5 led to higher NAA than T3 (248.7 vs. 224.5 kg ha−1). With the promotion of plant N accumulation due to increased BS–TN input, T3 to T5 produced higher ANRs of the fertilizer applied (51.8–62.0 %) compared with those observed for T2 (38.7 %), and the difference was significant in terms of T4. The resultant RNFV of T3 to T5 ranged from 1.3 to 1.5.

At the seedling stage of the peanut plants, T2, T3, and T4 led to similar soil TN concentrations, which were higher than those produced by T1 and the highest BS–TN treatment T5 (Table 4). The BS–CF treatments (T3–T5) showed significant lower soil TN concentrations than those produced by T2, but were higher than T1 at the flowering stage. Higher soil TN concentrations occurred in T4 or T5 compared with the other treatments at the following two stages. In terms of soil NH4 +-N concentrations, T3 to T5 were lower than T2 at the seedling stage, whereas T4 was higher than other treatments at the harvesting stage. Additionally, T4 led to the highest soil NO3 −-N concentrations across all the four stages, although the differences were not necessarily significant. Overall, T4 and T5 had higher average mineral N (NO3 − + NH4 +) concentrations (24.64–25.91 mg kg−1) than T2 (21.28 mg kg−1) during the whole peanut growth period.

Additionally, soil C/N of ratio closest to the known optimum ratio (25:1) was observed at the flowering (31.6:1), pod production (33.3:1), and harvesting (23.7:1) growth stages, in T4 (36 kg BS–TN ha−1), compared to all other treatments (except T1; Table 7).

Soil TP and AP concentrations were generally highest in T4 (although not necessarily significantly), except the higher AP value in T5 at flowering. The soil in T3, T4, and T5 had higher TP concentrations than that in T2 at harvest, but not for AP (Table 5).

3.2 C mineralization

The amount of CO2-C (expressed as mg CO2-C kg−1 soil day−1) that evolved from the soil throughout the incubation experiment showed a similar pattern among all treatments (Fig. 2a). The amount of CO2-C that evolved from the soil of T3 to T5 was higher than that from T1, from the beginning to the end of the incubation period. After 14 days of incubation, the amount of CO2-C that evolved from T3 to T5 was higher than that from T2. The CO2-C production rates decreased rapidly after the first week of incubation and became fairly constant from day 18 until the end of the incubation period, as the easily mineralizable OM sources were exhausted.

The cumulative accumulation of total CO2-C that evolved from the soils during the 70-day incubation period was greatly affected by the different treatments (Fig. 2b), demonstrated by expressing the results as the %TOC of the OM mineralized that was originally from the BS and soil (added and natural, respectively). At the end of the incubation period, T4 showed the lowest percentage of mineralized C (36.10 % of the TOC from the BS and soil), followed by T3 (39.03 %), T5 (39.82 %), and T2 (39.96 %).

Data from the C mineralization in the soils were fitted to a first-order kinetic model, where the potentially mineralizable C (C 0) ranged from 52.45 to 82.37 % (Table 6). The C 0 in the soils of T2–T5 were 11.99–29.92 % higher than the control (T1). Moreover, the effect of BS increased the C 0 in T3 to T5 from 0.34 to 17.93 % compared with that in T2. However, the decomposition rate of OC (k) was lower when BS was added into in T3 to T5, compared with that in T2.

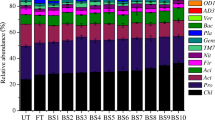

3.3 Soil microbial biomass and enzymatic activity

Both of the high BS treatments (T4 and T5) led to higher MBC and MBN levels in the soil than the CF only treatment (T2), across all four plant stages (Fig. 3a, b); the results were significantly different among all the treatments. The MBC and MBN of T4 increased at the flowering stage of the peanut plants and then sharply decreased at the pod production and harvesting stages, but the values were still higher than those observed in the other treatments. All the treatments conformed the trend that the MBC and MBN firstly increased before the flowering stage and subsequently decreased.

Similar to the results for the MBC and MBN, T4 resulted in a rapid increase in soil urease and dehydrogenase activities at the pod production and harvesting stages (Fig. 4a, b). The activities of the two enzymes firstly increased from the seedling to the pod production stages and then decreased thereafter. Both enzymes exhibited the highest activities in the soils of T4, showing significant difference from those in T2 at the pod production and harvesting stages (Fig. 4a, b).

4 Discussion

4.1 Effect of BS application on peanut yield and biomass

The present study has indicated that fertilization of soil with different ratios of BS and CF produces substantially higher grain yields in peanut, than by fertilizing with only CFs or no CF/BS (Fig. 1a). In particular, fertilization with 36 kg BS–TN ha−1 (T4) increased the grain yields in comparison with the other BS–CF combination treatments (T3 and T5), and a highly significant correlation was observed between BS–TN input and grain yield. A similar effect was observed in rice that a 10 % yield increase occurred with a BS–CF combination that contained 50 % BS–TN (Zuo 2008). Moreover, the combination of BS–CF improved the yields in rapeseed, compared to a CF-only treatment (Zhang et al. 2007). The yield increases in the present study may be attributed to the high biomass levels of the peanut plants at the four stages of growth (Fig. 1b). This hypothesis is supported by a positive correlation previously found between grain yield and biomass in summer maize, which indicates that biomass is the basis of yield formation (Zhao et al. 2006).

The differences in biomass between the treatments in the present study indicated that the accumulation of nutrients in the plants varied, because crop nutrient accumulation promotes biomass accumulation (Zhao et al. 2006). This was found true for the NAAs in this study (Table 3). The application of BS promoted N absorption (NAA) in the peanut plants, and a high ratio of NH4 +-N to TN (0.96) was observed (Table 1), thus resulting in a higher ANR of the fertilizer applied. Consequently, the N fertilizer value observed for the BS–CF treatments (T3–T5) was higher than that for the CF-only treatment (T2), even though the same amounts of TN were applied. Additionally, the extra micronutrients contained in the BS (e.g., S, Ca, and Mg; Table 1) may have promoted peanut growth. Ultimately, it is clear that the addition of BS enhanced the peanut grain yields.

4.2 Effect of BS application on soil nutrient availability

N is a critical nutrient in all plant-based systems. It is transformed by mineralization, nitrification, denitrification, and immobilization, as well as leaching and ammonia volatilization (Insam et al. 2015). The nature of N transformation mainly depends on the form of deposited N, the soil chemistry, and the land use strategy upon entering the soil (Bardgett and Wardle 2010; Insam et al. 2015). In regard of the introduction of N into the soil via the BS, the different amounts of BS added either promoted or suppressed N mineralization, compared to the CF only treatment (Table 4), dependent on the stage of growth of the peanut plants.

The dissolved OC present, and the corresponding OC/TN ratio (C/N) of the dissolved substances, can be considered as the most reliable indicators of biological activity (Alburquerque et al. 2012). Although the same amounts of N, P2O5, and K2O were added in each treatment, the application of 36–54 kg BS–TN ha−1 (T4, T5) led to the highest soil concentrations of TN (1.02–1.15 and 1.00–1.06 g kg−1) at the pod production and harvesting stages and average mineral N (NO3 − + NH4 +) concentrations (24.64–25.91 mg kg−1) during the whole peanut growth period, respectively. This result may be attributed to the organic N added by the BS (Table 2). The soil itself was another major source of N and promoted organic N mineralization after suitable BS–CF application, which likely increased the soil microbial activities (Möller and Müller 2012).

From another aspect, the different amounts of mineral N could have occurred because of different levels of the chemical composition in the BS–CF combination treatments (Diacono and Montemurro 2010). Thus, even if the amounts of TN input into the soil were the same among the treatments, the different levels of organic N mineralization led to variations in the soil TN and mineral N concentration. It seems that 36 kg BS–TN ha−1 (T4) comprised the most appropriate BS–CF combination, because this treatment promoted the concentrations of soil TN and mineral N most effectively. It favored the absorption of N by the peanut plant roots, promoting the growth and N accumulation of the plants. Corresponding to this, the ANR and RNFV (1.3–1.5) of the BS were higher in T4 (36 kg BS–TN ha−1). In fact, the RNFV of the T4 BS–CF combination was higher than pure digestate (0.87) and pig slurry (0.98) (Sieling et al. 2013).

P is an important plant macronutrient, as a constituent of adenylates, nucleic acids, and phospholipids (Insam et al. 2015). The 36 kg BS–TN ha−1 treatment (T4) promoted (not necessarily significantly) the TP and AP concentrations in the soils, across the four growth stages of the peanut plants. This positive effect of T4 may be attributed to the addition of BS affecting soil P availability and plant P nutrition. P can either be directly added by inorganic and organic P compounds, or indirectly, by influencing soil microbial activities (as a consequence of changes to the OC supply; Table 2), and enzyme activities related to P transformation (i.e., alkaline phosphatase) (Insam et al. 2015). The results from the present study were consistent with those obtained by Bachmann et al. that emphasize the potential of biogas residues as valuable and readily available P sources for crops (Bachmann et al. 2014).

Additionally, the C/N ratio is a crucial factor that influences short-term N and P availability and therefore is beneficial to crop growth (Möller et al. 2008; Fouda et al. 2013). In the present work, the C/N ratio closest to the known optimum ratio (25:1) was observed at the flowering, pod production, and harvesting (23.7:1) growth stages, in T4 (36 kg BS–TN ha−1), compared to that in all other treatments (except T1; Table 7). Such an optimum C/N ratio contributed to the highest N and P concentrations at these growth stages (Tables 4 and 5).

4.3 Effect of BS application on soil microbial activity

Beyond the N, P, and K added by the BS and CFs, the mineralization of OM, contained in the BS and naturally in the soil, was another important nutrient source. As an indicator of soil microbial activity and OM decomposition that occurred in each treatment, the CO2 efflux was measured through a 70-day laboratory incubation experiment. The data from the C mineralization experiment demonstrated that the BS input increased the amount of potentially mineralizable C (C 0) but decreased the mineralization rate (k) (Table 5). This implies that anaerobic digestion converted the labile organic C to CH4 and CO2, and the organic C in the BS was more stable and less readily decomposed by soil microorganisms (De Neve et al. 2003).

Thus, although the amount of potentially mineralizable C (%TOC present in the BS and soil) increased with the application of BS, it seems that the additional mineralized C from the BS slowly degraded and would have been retained in the soil for a long time. Therefore, from a practical point of view, the application of BS benefitted the long-term maintenance of soil fertility and crop growth. These results agree with the findings of Tao et al. (2003), which indicated that the soil OM increased by 58.4 % after 6 years of applying a dressing residue.

The 36 kg BS–TN ha−1 treatment (T4) also resulted in a significant increase of microbial biomass (MBC and MBN, Fig. 3) and enzymatic activities (urease and dehydrogenase, Fig. 4), compared to other treatments at the flowering, pod production, and harvesting stages. This result is in agreement with similar studies, which investigated the soil application of bio-fuel by-products (Alotaibi and Schoenau 2011; Abubaker et al. 2012; Galvez et al. 2012). Similar results were also reported by Ros et al. (2006), who attributed the significant increase in microbial biomass that they observed to the higher availability of C substrates, which stimulated microbial growth.

Previously, the microbial biomass was found to be a much more sensitive indicator of changes in soil conditions than the total soil OC and nutrient concentrations (Powlson et al. 1987). It also played an important role in guaranteeing the capacity of soils to develop important agronomical and environmental functions, such as the transformation of organic C and nutrient cycling (Galvez et al. 2012). Considering these studies, a significant increase in microbial biomass concentration at the flowering, pod production, and harvesting stages in T4 indicated an improvement in the soil’s ecosystem functioning due to combined application of BS–CF at a suitable ratio.

As a member of the hydrolase enzyme family, urease catalyzes the hydrolysis of organic N and urea, to form ammonia and carbamate. This enzyme can therefore be regarded as a sensitive indicator of changes in the N turnover in soil (Balasubramanian and Ponnuraj 2010). In the present study, the addition of BS, with available substrate and nutrients (especially in T4), may have either increased the activity of the microorganisms degrading the organic N, or increased the urease activity, by promoting the growth of microbial species, or by stimulating enzyme synthesis in the microbial cells, respectively (Dilly and Nannipieri 2001). The increase in urease activity recorded in this study was consistent with the findings in another field study (Chen et al. 2015).

Moreover, dehydrogenase plays an essential role in the oxidizing capacity of soil microorganisms. Since this enzyme only exists in live microbial cells, dehydrogenase activity is an important indication of soil microbial activity (Chen et al. 2009). Therefore, the significant increase in soil dehydrogenase activity resulting from 36 kg BS–TN ha−1 treatment (T4), at the flowering, pod production, and harvesting stages, demonstrated an enhancement of soil microbial activities, associated with OM transformation and nutrient cycling.

5 Conclusions

This study has clearly demonstrated that the combination of BS and CFs, at an appropriate ratio, was superior to no CF/BS and CF only, in terms of promoting peanut grain yields, soil nutrients, C storage, and microbial activities in the red soil. The application of 36 kg BS–TN ha−1 led to the highest plant biomass at the flowering, pod production, and harvesting stages, which corresponded to the highest grain yields and plant N uptake efficiency, as well as the maximum N accumulation and recovery. Additionally, soil microbial biomass (C and N), urease, and dehydrogenase activities markedly increased following the integrated use of 36 kg BS–TN ha−1, at the flowering stage, with their maximum values observed at the flowering, pod production, and harvesting stages. Although the application of BS increased the potentially mineralizable C, the additional C seemed to slowly degrade, and so would be retained in the soil for a long time. The combined application of BS and CFs (e.g., 36 kg BS–TN ha−1), together with proper management techniques, may represent an effective practical substitution of CF use, to improve the quality and nutrient balance of amended soils. These results help to establish the suitable agronomic use of BS, which could reduce the consumption of CFs and thereby alleviate environmental pollution. Further studies that focus on the performance of the long-term field application of BS–CF combination treatments need to be performed to verify the present findings.

References

Abubaker J, Risberg K, Pell M (2012) Biogas residues as fertilisers—effects on wheat growth and soil microbial activities. Appl Energy 99:126–134

Alburquerque JA, de la Fuente C, Ferrer-Costa A, Carrasco L, Cegarra J, Abad M, Bernal MP (2012) Assessment of the fertiliser potential of digestates from farm and agroindustrial residues. Biomass Bioenergy 40:181–189

Alotaibi KD, Schoenau JJ (2011) Enzymatic activity and microbial biomass in soil amended with biofuel production byproducts. Appl Soil Ecol 48(2):227–235

Bachmann S, Gropp M, Eichler-Löbermann B (2014) Phosphorus availability and soil microbial activity in a 3 year field experiment amended with digested dairy slurry. Biomass Bioenergy 70:429–439

Balasubramanian A, Ponnuraj K (2010) Crystal structure of the first plant urease from jack bean: 83 years of journey from its first crystal to molecular structure. J Mol Biol 400(3):274–283

Bardgett RD, Wardle DA (2010) Aboveground-belowground linkages: biotic interactions, ecosystem processes, and global change. Oxford University Press, Oxford

Chen QL, Gu J, Gao H, Qin QJ, Zhen LS, Chen SN, Sun LN (2009) Effect of matching use of straw and fertilizer on the dynamic changes of soil dehydrogenase and polyphenoloxidase activities. Agric Res 27(4):146–151

Chen SL, Yu WW, ZHANG Z, Luo SR (2015) Soil properties and enzyme activities as affected by biogas slurry irrigation in the Three Gorges Reservoir areas of China. J Environ Biol 36(2):513–522

de la Fuente C, Alburquerque JA, Clemente R, Bernal MP (2013) Soil C and N mineralisation and agricultural value of the products of an anaerobic digestion system. Biol Fert Soils 49(3):313–322

De Neve S, Sleutel S, Hofman G (2003) Carbon mineralization from composts and food industry wastes added to soil. Nutr Cycl Agroecosyst 67(1):13–20

Diacono M, Montemurro F (2010) Long-term effects of organic amendments on soil fertility: a review. Agron Sustain Dev 30:401–422

Dilly O, Nannipieri P (2001) Response of ATP concent, respiration rate and enzyme activities in an arable and a forest soil to nutrient additions. Biol Fert Soils 34(1):64–72

Erisman JW, Sutton MA, Galloway J, Klimont Z, Winiwarter W (2008) How a century of ammonia synthesis changed the world. Nat Geosci 1(10):636–639

Fouda S, von Tucher S, Lichti F, Schmidhalter U (2013) Nitrogen availability of various biogas residues applied to ryegrass. J Plant Nutr Soil Sci 176(4):572–584

Galloway JN, Dentener FJ, Marmer E, Cai ZC, Abrol YP, Dadhwal VK, Vel Murugan A (2008) The environmental reach of Asia. Annu Rev Environ Resour 33:461–481

Galvez A, Sinicco T, Cayuela ML, Mingorance MD, Fornasier F, Mondini C (2012) Short term effects of bioenergy by-products on soil C and N dynamics, nutrient availability and biochemical properties. Agric Ecosyst Environ 160:3–14

Holm-Nielsen JB, Al Seadi T, Oleskowicz-Popiel P (2009) The future of anaerobic digestion and biogas utilization. Bioresour Technol 100(22):5478–5484

Huang S, Peng XX, Huang QR, Zhang WJ (2010) Soil aggregation and organic carbon fractions affected by long-term fertilization in a red soil of subtropical China. Geoderma 154(3):364–369

Insam H, Gómez-Brandón M, Ascher J (2015) Manure-based biogas fermentation residues–Friend or foe of soil fertility? Soil Biol Biochem 84:1–14

Joergensen RG (1996) The fumigation-extraction method to estimate soil microbial biomass: calibration of the k EC value. Soil Biol Biochem 28(1):25–31

Le C, Klein D (1964) Soil dehydrogenase activity. Soil Science 98(6):371–376

Li Y, Shan ZJ, Xu DH (2002) Preliminary of management of livestock pollution in China. Chin J Eco-Agric 10(2):136–138 (in Chinese)

Li Y, Sheng K, Peng S, Meng Z, Dong Z (2014) Effects of biogas slurry on wheat yield and the physical and chemical properties of soil. Chin Agric Sci Bull 30(12):181–186 (in Chinese)

Lu RK (2000) Analytical methods for soil and agricultural chemistry. Chinese Agricultural Scientech Press, Beijing (in Chinese)

Möller K, Müller T (2012) Effects of anaerobic digestion on digestate nutrient availability and crop growth: a review. Eng Life Sci 12(3):242–257

Möller K, Stinner W, Deuker A, Leithold G (2008) Effects of different manuring systems with and without biogas digestion on nitrogen cycle and crop yield in mixed organic dairy farming systems. Nutr Cycl Agroecosyst 82(3):209–232

Nelson DW, Sommers LE (1982) Total carbon, organic carbon, and organic matter. Methods of Soil Analysis. Part 2. Chemical and Microbiological Properties: 539-579

Nielsen JBH, Oleskowicz-Popiel P (2007) The future of biogas in Europe: visions and targets until 2020. The Future of Biogas in Europe III:101

Nishikawa T, Li KZ, Inoue H, Umeda M, Hirooka H, Inamura T (2012) Effects of the long-term application of anaerobically-digested cattle manure on growth, yield and nitrogen uptake of paddy rice (Oryza sativa L.), and soil fertility in warmer region of Japan. Plant Prod Sci 15(4):284–292

Odlare M, Arthurson V, Pell M, Svensson K, Nehrenheim E, Abubaker J (2011) Land application of organic waste–effects on the soil ecosystem. Appl Energy 88(6):2210–2218

Perez-Mateos M, Gonzalez-Carcedo S (1988) Assay of urease activity in soil columns. Soil Biol Biochem 20(4):567–572

Powlson DS, Prookes PC, Christensen BT (1987) Measurement of soil microbial biomass provides an early indication of changes in total soil organic matter due to straw incorporation. Soil Biol Biochem 19(2):159–164

Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, Eckert CA, Frederick WJ, Hallett JP, Leak DJ, Liotta HL (2006) The path forward for biofuels and biomaterials. Science 311(5760):484–489

Ros M, Pascual JA, Garcia C, Hernandez MT, Insam H (2006) Hydrolase activities, microbial biomass and bacterial community in a soil after long-term amendment with different composts. Soil Biol Biochem 38(12):3443–3452

Schröder JJ, Jansen AG, Hilhorst GJ (2005) Long-term nitrogen supply from cattle slurry. Soil Use Manag 21(2):196–204

Sieling K, Herrmann A, Wienforth B, Taube F, Ohl S, Hartung E, Kage H (2013) Biogas cropping systems: short term response of yield performance and N use efficiency to biogas residue application. Eur J Agron 47:44–54

Sommer SG, Kjellerup V, Kristjansen O (1992) Determination of total ammonium nitrogen in pig and cattle slurry: sample preparation and analysis. Acta Agric Scand Sect B Soil Plant Sci 42(3):146–151

Svensson K, Odlare M, Pell M (2004) The fertilizing effect of compost and biogas residues from source separated household waste. J Agric Sci 142(04):461–467

Tao HG, Li XB, Zhao TL (2003) Bioliquid & biosolid and eco-agriculture. Renew Energy 2:37–38

Terhoeven-Urselmans T, Scheller E, Raubuch M, Ludwig B, Re J (2009) CO2 evolution and N mineralization after biogas slurry application in the field and its yield effects on spring barley. Appl Soil Ecol 42(3):297–302

Tiwari VN, Tiwari KN, Upadhyay RM (2000) Effect of crop residues and biogas slurry incorporation in wheat on yield and soil fertility. J Indian Soc Soil Sci 48(3):515–520

Van Veldhoven PP, Mannaerts GP (1987) Inorganic and organic phosphate measurements in the nanomolar range. Anal Biochem 161(1):45–48

Vance ED, Brookes PC, Jenkinson DS (1987) An extraction method for measuring soil microbial biomass C. Soil Biol Biochem 19(6):703–707

Watanabe FS, Olsen SR (1965) Test of an ascorbic acid method for determining phosphorus in water and NaHCO3 extracts from soil. Soil Sci Soc Am J 29(6):677–678

Wu JS, Joergensen RG, Pommerening B, Chaussod R, Brookes PC (1990) Measurement of soil microbial biomass C by fumigation-extraction—an automated procedure. Soil Biol Biochem 22(8):1167–1169

Zhang B, Horn R (2001) Mechanisms of aggregate stabilization in Ultisols from subtropical China. Geoderma 99(1):123–145

Zhang B, Peng X (2006) Organic matter enrichment and aggregate stabilization in a severely degraded Ultisol after reforestation. Pedosphere 16(6):699–706

Zhang Y, Hong JP, Ren JX, Zhao ST (2007) Research on biogas slurry impact on the output and quality of oil seed rapes. J Shanxi Agric Sci 35(5):54–57 (in Chinese)

Zhao Y, Tong Y, Zhao H (2006) Effects of different N rates on nutrients accumulation, transformation and yield of summer maize. Plant Nutri Fertil Sci 12(5):622–627 (in Chinese)

Zhou H, Peng X, Perfect E, Xiao T, Peng G (2013) Effects of organic and inorganic fertilization on soil aggregation in an Ultisol as characterized by synchrotron based X-ray micro-computed tomography. Geoderma 195:23–30

Zuo X (2008) Preliminary investigation on the biogas slurry used in rice production in cold region. Hei Long Jiang Agric Sci 2:61–62, in Chinese

Acknowledgments

The authors sincerely thank Haihong Zong for his help in the progress of samples analyzing and Xinhua Peng for his help in paper revision in Institute of Soil Science, Chinese Academy of Sciences. This work was financially supported by grants from the Commonweal Project of the Ministry of Agriculture of China (No.201203050), National Natural Science Foundation of China (Nos. 31201690, 41401254, and 41401347), National Science and technology support plan (No. 2015BAD05B01 and 2014BAC04B02), and Jiangsu Municipal Natural Science Foundation (BK20140723 and BK20141050).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Hailong Wang

Rights and permissions

About this article

Cite this article

Zheng, X., Fan, J., Cui, J. et al. Effects of biogas slurry application on peanut yield, soil nutrients, carbon storage, and microbial activity in an Ultisol soil in southern China. J Soils Sediments 16, 449–460 (2016). https://doi.org/10.1007/s11368-015-1254-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11368-015-1254-8