Abstract

Accelerated release of carbon dioxide (CO2) into the atmosphere has become a critical environmental issue, and therefore, efficient methods for capturing CO2 are in high demand. Graphene and graphene-based derivatives have demonstrated promising potential as adsorbents due to their unique properties. This review aims to provide an overview of the latest research on graphene and its derivatives fabricated from natural sources which have been utilized and may be explored for CO2 adsorption. The necessity of this review lies in the need to explore alternative, sustainable sources of graphene that can contribute to the development of viable environmentally benign CO2 capture technologies. The review will aim to highlight graphene as an excellent CO2 adsorbent and the possible avenues, advantages, and limitations of the processes involved in fabricating graphene and its derivatives sourced from both industrial resources and organic waste-based naturally occurring carbon precursors for CO2 adsorption. This review will also highlight the CO2 adsorption mechanisms focusing on density functional theory (DFT) and molecular dynamics (MD)–based studies over the last decade.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the inception of the industrial revolution, there has been a reliance on fossil fuels, which causes substantial amounts of carbon dioxide released into the atmosphere every second. With the progression of time, there has been an expansion of industrialization on a global scale, advances in technology such as genetically modified crops, and improved medicine, and greater distribution of such advancements across the entire globe due to improved connectivity and globalization has led to a population boom (The human population has amplified from two billion in 1930 to 7 billion in 2011. The human population currently stands at 8 billion at the end of 2022.). This has resulted in even greater quantities of carbon dioxide being released into the environment due to human civilization footprint (Fig. 1). The quantity of carbon dioxide being added to the atmosphere has displayed an exponential increase from 2010 to 2022, with a combined CO2 emission greater than that of all the years of the post-industrial revolution till 2009. In the year 1927, the total carbon dioxide emission from the burning of fossil fuels and industry was at 3.9 billion tons per year, while it was 31.51 billion tons at the end of 2006. Currently, it has escalated to 37.2 billion tons in 2021, with a projected growth of 1% for the year 2022. The current daily average reading for atmospheric CO2 on the planet is 417.46 ppm (parts per million), at Mauna Loa Observatory, Hawaii. This constant release of carbon dioxide has resulted in global warming (carbon dioxide resulting from the burning of fossil fuels contributes to nearly 60% of global warming), the phenomenon in which the average temperature of the Earth’s atmosphere rises due to the presence of greenhouse gases which prevent the incident solar radiation from being reflected by the earth back into space. With increasing carbon dioxide concentration in the atmosphere, the global surface temperature of the earth has ascended by 1.1–1.8 °C more than the nineteenth and twentieth century average. Since 1981, the rate of warming has doubled per decade (0.18 °C per decade). In 2022 earth’s surface temperature was 0.86 °C higher compared to the twentieth-century average of 13.9 °C and 1.06 °C higher than the pre-industrial period (1880–1900). This has resulted in the global average temperature rise of 1 °C in comparison to the pre-industrial period (1880–1900). The heat capacity of the earth is massive, considering the tremendous size and capacity of the oceans. This one-degree increase has resulted in extreme amounts of accumulated heat leading to seasonal temperature extremes, reduction of snow cover, increase in the amount of heavy rainfall, and noticeable change in the habitat of all living beings. The average increase in land and ocean temperature was 0.08 °C per decade from 1880; however, since 1981, the temperature increase rate has more than doubled to 0.18 °C per decade. The last decade (2014–2022) has witnessed the hottest 9 years in a row with the 10 warmest years on record having all occurred since 2010. Unless greenhouse gas emissions are restricted, climate models predict that global surface temperature will increase by an additional 4 °C during the twenty-first century. Predictions regarding the effect on climate range from, speeding up of the water cycle leading to increased precipitation by 7% with each degree rise in temperature (distribution will be uneven throughout the planet), a greater quantity of snow and ice will melt as compared to the precipitation during the winter causing a gradual reduction in the ice caps with the Arctic facing a greater reduction than the Antarctic (collapse of major ice caps in Greenland and Antarctica). By 2050, the global sea levels will rise by an additional 0.25 to 0.30 m, reaching 1.1 m by the end of 2100. Oceans that act as a buffer for absorbing CO2 will increase in pH (0.14 to 0.35), wreaking havoc on marine life; there will also be noticeable changes in ocean currents, severe weather, and cloud patterns, and disruption of thermohaline circulation. Studies reveal a possibility of a sudden release of methane gas trapped in the form of permafrost in the poles, endangering the livelihood of the whole planet. Initiatives, programs, conferences, and discussions on a global scale involving most nations across the globe have been undertaken to restrict the addition of carbon dioxide to the atmosphere, to reduce global warming and decelerate climate change, and various decisions have resulted from them. Stockholm hosted the first UN environmental conference in 1972. The agenda, which focused on concerns like chemical pollution, atomic bomb testing, and whaling, scarcely mentioned climate change. As a result, UN Environment Programme (UNEP) was created. The 1987 Montreal Protocol put restrictions on substances that harm the ozone layer. Despite not having been created with climate change in mind, it had a greater influence on greenhouse gas emissions than the Kyoto Protocol. The Intergovernmental Panel on Climate Change (IPCC) was founded in 1988 to bring together and evaluate climate change research. The IPCC released its First Assessment Report in 1990. It concluded that the increase in temperature by 0.3 to 0.6 °C during the past century was due to the increase in human emissions leading to an increased amount of greenhouse gases in the atmosphere. Governments ratified the United Framework Convention on Climate Change in 1992 during the Rio de Janeiro Earth Summit. Its main goal was “stabilization of atmospheric greenhouse gas occurrence at a point that would avoid harmful human intervention with the climate system.” Developed nations have consented unanimously to restrict their emissions to a level that was in 1990. The IPCC’s Second Assessment Report, published in 1995, indicated “a discernible human effect” on climate change. This has been referred to as the first unambiguous admission that people are the main cause of accelerating climate change. Kyoto Protocol was approved in 1997. From 2008 to 2012, developed countries agreed to cut emissions by an average of 5%, with widely divergent national targets. According to the IPCC’s Third Assessment Report issued in 2001, there was “new and stronger evidence” that greenhouse gas emissions from human activity are the primary reasons for the warming that transpired in the second half of the twentieth century. For those nations who are still party to it, the Kyoto Protocol became international law in 2005. In 2006, The Stern Review resolved that if left unchecked, climate change might reduce world GDP by up to 20%; however, reducing it would result in around 1% of global GDP. In 2007, the IPCC’s Fourth Assessment Report concluded a greater than 90% chance that greenhouse gas emissions from human activity were the main reason for the current state of the climate. Scientists are 95% positive that humans are the “primary cause” of global warming since the 1950s, according to the first section of the IPCC’s fifth assessment report in 2013. The Paris Agreement soon followed a landmark in the fight against climate change, embraced by 196 countries at COP21 in Paris on December 12, 2015, and implemented on November 4, 2016. The decision was taken to withhold global warming below 2 °C compared to the pre-industrial era. The main goal of this agreement is to reach the global peak of greenhouse gas emissions as soon as possible. One of the quantitative targets of this arrangement would be the establishment of zero-carbon discharge for the segments representing 70% of global emissions by 2030, to achieve a climate-neutral world by the mid-century period circa 2050. Fossil fuels will still be the major provider of energy (80%) in 2035, which will hinder the fulfillment of this objective. The additional route that may be undertaken to achieve the same goal would be the direct removal of carbon dioxide (CO2) from the atmosphere.

The first carbon capture plant was proposed in 1938 and became functional in 1972, and the first integrated capture and storage system was set up in Norway in 1996. There are over 43 large-scale setups that are slowly chipping away at the current CO2 stock in the atmosphere. Carbon capture for industrially produced CO2 comprises the following routes: the post-combustion method, the oxyfuel process, and the pre-combustion process (Markewitz et al. 2012; Wilberforce et al. 2019).

The post-combustion process involves washing the flue gas with chemical solvents to absorb CO2 from effluent streams from various industries. These solvents may be based on amines, ammonia, alkali, amino acid salt, aqueous carbonate, or even chilled ammonia (Fauth et al. 2012). Among the solvents MEA (methanol amine)-based liquid solvents are the most popular; however, the absorption has to be carried out at 40–60 °C, for which low-pressure steam has to be diverted from the electricity generation. As a result, an efficiency loss of 10 to 14% can occur (Nwaoha et al. 2017). Also, CO2 in the flue gas must have a partial pressure of 3–15 kPa to achieve a degree of separation of 80–95%. A few set-ups are already in operation with a plant in Oklahoma, USA (with a daily production of 20 MW and CO2 exhaust of 800 t CO2/day), which can capture 15% of the released CO2 (Kárászová et al. 2020). The plant in Sleipner, Norway, manages to capture over 1 million tons of CO2 per year. This method however has certain drawbacks, the main problem being the decomposition of solvents in air. This is mainly because SOx and NOx > 10 ppm will cause the salt formation of amines which will require a high temperature to precipitate out (IPCC, 2005). The energy expenditure on CO2 capture in this route varies around 4 GJ per ton of CO2 captured, a setup in Esbjerg (Denmark) with a 30% MEA solvent requiring 3.7 GJ per ton of CO2 captured, while similar energy requirements are required for the plant in NiederauƁem (Germany) which manages to capture 7.2 t of CO2 per day. Most upcoming and development power plants utilizing this technology have a restricted power output of less than 10 MW. Another innovation along this route has been the carbon looping method (calcium carbonate formed by carbonization of CaO at 600–700 °C followed by calcination at 900 °C). The efficiency loss of the power plant due to carbon capture modification has been less than 7.2%. In the most optimistic scenario, the efficiency loss of the plant due to the implementation of carbon capture technology will be 9.1% at the minimum (Scholes et al. 2020). The next process involves combustion in pure oxygen, which is named the Oxyfuel process; the key difference between conventional power plants and the post-combustion process is the composition of the flue gas, which has a CO2 composition of 89% volume for the oxyfuel process while only being 12–15% by volume in the post-combustion process (Markewitz et al. 2012). Here, O2, obtained from the air by cryogenic air separation units, is mixed with the fuel before combustion (Nemitallah et al. 2017). The current stoichiometric requirement of O2 for combustion in power plants is about 1.15 times the fuel, which is about 270,000 m3/h for a 500 MW plant; however, if the oxyfuel process is to be implemented, the required O2 would be 800,000 m3/h. The temperatures attained in such a set-up would also be higher, which will pose a threat of mechanical damage to the unit (Nikolopoulos et al. 2011; Wu et al. 2019). This would require a portion of the flue gas to be returned with the feed stream. If an excess amount of O2 required is compromised, burnout and corrosion can occur. Air-separation of O2, with a purity demand of 99.5% for the process, has a very high energy requirement; a lower degree of purity causes a rise in energy requirements downstream. Also, excess residual oxygen is available after combustion, and although the volume of the flue gas generated is low, NOx concentrations remain higher than accepted emission standards of coal-based power plants (365 ppm). A pilot plant setup in Germany of 30 MW capacity, utilizing the oxyfuel route, had to be fitted with denitrification units as the NOx formation exceeded emission norms. On completing 1200 operating hours, 1000 tons of 99.7% pure CO2 was captured with 90% carbon capture efficiency. An efficiency loss of 8–10% (6% loss from air separation unit, 7% from conventional cryogenic technology, and capture and processing of CO2 intended for transport costing 3% efficiency) is observed. Some improvements which are currently being explored are the utilization of a high temperature-air separation membrane, permeable to O2 only above a certain temperature, where adequate membrane material of sufficient mechanical strength has yet to be identified; another method would be chemical looping, where the fuel is oxidized by the metal oxide instead of molecular oxygen (which is then regenerated separately); this route prevents exposure of N2 to high temperature; the utilization of mixed ion–electron conducting membrane can reduce efficiency loss to 8% (Nemitallah et al. 2017). The final process, the pre-combustion process, involves the decarbonization of the combustion gas. This is achieved by the gasification of fuels to synthesis gas, by the CO-shift reaction. CO2 is captured using solvents before combustion from pressurized H2-enriched flue gas obtained after CO-shift, i.e., air separation unit placed before the gasification process. The fuel gas obtained through this process exclusively consists of CO2 and H2. Only 5 integrated gasification combined cycle (IGCC) power plants without CO2 capture have been fabricated across the world (2000), due to less credibility compared to conventional power plants (IPCC, 2005; Markewitz et al. 2012; Wilberforce et al. 2019; Olabi et al. 2022).

The implementation of carbon capture systems to reduce the global warming potential of conventional power plants has shown a noticeable effect, but the benefits are mostly of a reactive nature; these set-ups are reducing the carbon dioxide output of power plants, and the effects have been wide-ranging. They must not be restricted to capturing CO2 from effluent streams, but also be able to actively capture CO2 directly from the air thereby becoming effective at dealing with CO2 from anthropogenic activities ranging from respiration to CO2 developed due to intercontinental flights. The CO2 capture capacity has to be improved to reduce efficiency losses which show up when carbon capture setups are introduced to any system. Presently, 18 direct air capture plants are in operation worldwide, chipping away almost 0.01 metric tons of CO2 per year. Direct Air Capture Technology (DAC) includes both solid-sorbent–based systems and liquid-sorbent–based technologies. However, DAC is currently prohibitively expensive due to the excessive price of energy. Arguments for using reforestation to capture CO2 fall short due to the space requirement of plantations, with the scarcity of available space and the extensive time requirement to grow complete forest patches, and DAC can do the same with 99.7% less space.

Graphene as a CO2 capture material

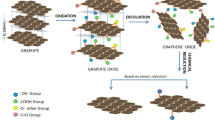

Among solid sorbent–based systems, the nanomaterial graphene, a two-dimensional allotrope of carbon that is formed primarily of sp2 hybridized carbon atoms (Fig. 2) (Armano and Agnello 2019), may be used as a molecular sieve to capture CO2 (Chuah et al. 2021; Sun et al. 2021). Nanographene layers (NGL) with etched holes and defects are efficient at CO2 capture (Huang et al. 2020). The cost requirements of graphene-based air adsorbents obtained from industrially sourced raw materials are very high, while the throughput of graphene obtained from naturally occurring carbon precursors is limited. Apart from pure graphene, reduced graphene oxide (RGO) may also be utilized as a CO2 capture material. In terms of the quantity of material that can be created, graphene oxide (GO), an intermediary produced in the process of producing graphene, is easier to get than pure graphene. RGO is also competitive with graphene in terms of CO2 adsorption performance due to the presence of greater defects in the structure. The functionalization of graphene and derivatives of graphene improves its CO2 adsorption ability (Fraga et al. 2019; Malekian et al. 2019). Mechanisms of graphene and GO formation are sensitive to process parameters and the choice of raw materials. Characterization techniques such as FTIR, SEM, TEM, BET, XPS, XRD, AFM, and Raman spectroscopy may be used to characterize graphene, RGO, their derivatives, and functionalized variants. The list of carbon sources for graphene and RGO is wide-ranging, with varying results in terms of CO2 capture performance in the final product (Tarcan et al. 2020; Jiříčková et al. 2022). The most common source material for obtaining graphene via the top-down route is industrial-grade graphite, which is chemically exfoliated by the modified Hummer’s method (Hummers and Offeman 1958) to obtain GO, which may be reduced to NGL or RGO. The bottom-up route involves the use of naturally available carbon sources, which are first carbonized and then graphitized utilizing chemical exfoliation (Viculis et al. 2003), catalytic oxidation (Lin et al. 2013), thermal treatments (Chowdhury and Balasubramanian 2016), and chemical treatments to yield graphene and RGO. More advanced methods for obtaining etched NGL involve bombarding the NGL with ozone in specialized reactors (Hsu et al. 2021), chemical vapor deposition (CVD) of high-quality graphene directly onto a template (Fujita et al. 2017), and the use of coordination compounds like ferrocene to treat carbonized precursors with ongoing thermal treatment to obtain GO (Zhao and Zhao 2013; Hashmi et al. 2020; Tamilselvi et al. 2020). As per the Web of Science Database, as of July 2023, there have been over 150,000 research papers published on graphene, over 10,000 research papers published on graphene-based adsorbent for CO2 capture. However, the number of papers that investigate graphene sourced from natural and waste-based carbon precursors as CO2 adsorbents only ranges in the hundreds. A similar scenario is observed from data obtained from the dimensions metric where the papers which investigate graphene sourced from natural and waste-based carbon precursors as CO2 adsorbents dramatically reduce the actual quantity of research work carried out on graphene as shown in the graph (Fig. 3). Graphene obtained from graphite and other industrial-grade sources limits graphene to be used as a CO2 adsorbent on a large scale due to the inhibitory costs of high-grade graphite and the chemicals involved in Hummer’s method. In the last few years, between 2014 and 2022, there has been a 200% growth in the number of publications related to graphene fabrication from natural carbon resources emphasizing environmentally benign routes of graphene preparation.

The objective of the review would be to categorize and identify graphene and GO derivatives based on the carbon precursor, the synthesis route, the process parameters, and the CO2 capture performance. Although a lot of interesting and insightful review papers have been published in the last decade on CO2 capture by graphene and graphene derivatives (Lee and Park 2012; Tarcan et al. 2020; Bermeo et al. 2022; Castro-Muñoz et al. 2022; Gao et al. 2022; Gunawardene et al. 2022; Ramar and Balraj 2022; Wei et al. 2022; Zhu et al. 2022), this review will focus on graphene and its derivatives fabricated from natural and waste carbon sources, their properties, and specific possible uses for CO2 adsorption. Graphene from natural resources is still at its primitive stage of research as inferred from the number of publications; this review will give an insight into the efficacy of the processes involved in the fabrication of graphene from natural resources, the drawbacks of the processes involved, and a pathway to overcome the limitations.

Mechanism of CO2 capture by graphene

The CO2 capture mechanism is dictated by the chemical and physical characteristics of the adsorbent material. It has been observed that graphene can adsorb CO2 by both physisorption and chemisorption. The process by which gas molecules are drawn to and stick to the surface of a solid substance is known as adsorption. Due to the huge surface area of graphene, there are many adsorption sites for CO2 molecules. For CO2 adsorption, several graphene derivatives have also been investigated, including graphene oxide (GO) and reduced graphene oxide (rGO).

CO2 adsorption by graphene and its derivatives is predominantly physisorption, which is a van der Waals interaction, a weak connection between molecules of similar sizes without a net charge that does not require the creation of chemical bonds, the sharing of electrons, or changes to the chemical structure of interacting molecules. Weak van der Waals interactions between the CO2 molecules and the graphene surface power the physisorption process (Fig. 4). The pore size, surface area, and surface functions impact this interaction. GO has oxygen-containing functional groups on its surface, which can improve its physisorption of CO2. By the reduction process, GO can reduce to rGO adding more defects and increasing available sites for physisorption (Lee and Park 2012; Ali et al. 2019; Ramar and Balraj 2022).

It has also been observed that temperature, pressure, and the presence of other gases are a few variables that affect graphene’s ability to capture CO2. Because the van der Waals interactions between the CO2 molecules and the graphene surface diminish at higher temperatures, the adsorption capacity of graphene is reduced with temperature increase which also indicates an exothermic nature of physisorption. For physisorption, the binding energy lies between 20 and 40 kJ mol−1. At lower pressures, the ability of graphene to adsorb declines due to reduced quantities of CO2 molecules available for adsorption. Gases like N2, O2, CO, and CH4, with similar kinetic properties, can compete with CO2 molecules for adsorption sites, which can have an impact on the ability of graphene to selectively favor CO2. However, the adsorption capacity of graphene is reduced due to the presence of moisture in the gas stream as they can block the adsorption sites and inhibit CO2 facilitation on the adsorbent surface.

CO2 adsorption by graphene can also occur by chemisorption. Chemisorption is a stronger interaction between molecules than physisorption which involves sharing of electrons and the establishment of chemical bonds between two compounds. This kind of adsorption is reliant on the electronic configuration and both the chemical structure and composition of the adsorbent and adsorbate materials. Through the creation of chemical connections between the carbon atoms in the graphene lattice and the oxygen atoms in the CO2 molecule, graphene has demonstrated the chemisorption of CO2 by reconfiguring its lattice structure to accommodate the formation of carbonyl and carboxyl groups from the captured CO2 (Fig. 4). The binding energy for chemisorption is much greater than physisorption (80–40 kJ mol−1).

CO2 capture performance of graphene and its derivatives is also influenced by the introduction of functional groups, such as carboxyl, hydroxyl, and amine groups, on the adsorbent surface. Due to increased surface area and greater charge concentration exposed to the incoming CO2 molecule, functionalized graphene has a higher CO2 adsorption capacity than pristine graphene (Fraga et al. 2019) (Fig. 5). The introduction of hydroxyl and carboxyl groups on the surface of graphene improves its adsorption capacity of amoxicillin by up to 400% (Aguilar et al. 2021). Similarly, Fatihah et al. (2019) found that the introduction of amine groups on the surface of GO increased its CO2 adsorption capacity by up to 80%.

Adsorption of CO2 on graphene and its derivatives is predominantly physisorption. Dry conditions, low temperature, and high pressure are beneficial for the adsorption of CO2 molecules. By adding defects or functional groups to the surface of graphene, one can boost the material’s capacity for adsorption while also increasing the affinity of CO2 molecules for the graphene surface.

DFT is a quantum mechanics–based computational method that can be used to calculate the electronic structure of molecules and materials. DFT is based on the density of electrons rather than wave functions, which makes it computationally efficient for larger systems as compared to GCMC. DFT can be used to calculate various properties such as electronic structure, geometry, and thermodynamics of materials. In the context of CO2 capture, DFT in conjunction with molecular dynamic simulations can be used to investigate the adsorption mechanism, energy barriers, and the role of surface chemistry on CO2 capture (Chakraborti and Pal 2014; Mino et al. 2014; Balasubramanian and Chowdhury 2015; Liu et al. 2015; Sun et al. 2015; Coello-Fiallos et al. 2017; Gupta et al. 2017; Li et al. 2017; Kamel et al. 2020; Wang et al. 2020; Baachaoui et al. 2021).

The pioneering study employing DFT simulation was carried out to analyze the adsorption of CO2 on a single defective graphene sheet with a single vacancy defect by Pepa Cabrera. Demonstrating strong physisorption, the final configuration of a CO2 molecule with a vacancy defect results in an estimated molecule binding energy of around − 136 meV. This value is lower compared to the binding energy of − 151 meV obtained for the same simulation on pristine graphene sheets, which indicates that the presence of defects improves CO2 adsorption (Cabrera-Sanfelix 2009). This work has been built upon, by others since 2009, with variations including incorporation of dopants and functional groups on the adsorbent itself, gas mixtures instead of single species CO2 as the sole adsorbate, and external field variations.

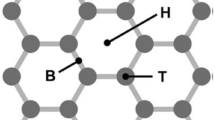

Investigating the selectivity trend of gas separation through nanoporous graphene (Liu et al. 2015), the authors used molecular dynamics simulations to study the separation of gases such as CO2, N2, and CH4 through nanoporous graphene membranes with varying surface characteristics. The results showed that the pore size and shape are the primary factors influencing gas separation and selectivity. In particular, the selectivity of CO2/N2 separation increased as the pore size decreased, whereas the selectivity of CO2/CH4 separation increased as the pore size increased. It was also illustrated that the pore shape also affects the selectivity, with zigzag-shaped pores showing higher selectivity than armchair-shaped pores. Building upon this work, a nitrogen and hydrogen atom–doped graphene adsorbent with 12 graphene rings has been investigated for its gas separation capability of species involved in natural gas processing; the selectivity of the gases CO2, H2S, and N2 is observed to be of the order 102 higher as compared to others.

The presence of dopants and functionalities has also been investigated by DFT and molecular dynamics simulation. Testing the effect of simultaneous doping of N, CO2 capture performance of graphene (Li et al. 2017) utilized a combination of experimental and computational techniques to study the effect of both dopants on the structural, electronic, and adsorption properties of graphene. The results showed that the CO2 adsorption capacity of graphene is improved due to doping of N and S, by creating additional adsorption sites and modifying the electronic structure of graphene. The authors also found that the optimal N/S doping ratio for maximizing the CO2 adsorption capacity was 2:1. Functionalized armchair graphene nano ribbons were tested as CO2 adsorbents using DFT while designing gas sensors (Salih and Ayesh 2020), which shows improvements in adsorption by almost 35 kJ mol−1 by incorporating O and OH functionalities on the surface of the adsorbent. Cooperative effects of metal-doped surface functional groups and the pore size effects have been investigated by use of both DFT and GCMC studies (Chen et al. 2021), which shows phosphorus doping is better for CO2 uptake.

DFT calculations have also been used to analyze the structural and electronic properties of graphene to attain further insights into its behavior; in one such study, graphene has been analyzed and compared to germanene in both single- and double-layer systems (Coello-Fiallos et al. 2017). The authors found that germanene exhibited stronger interlayer interaction than graphene in the bilayer system, resulting in a smaller interlayer distance and larger binding energy. The electronic properties of the two materials were found to be different, with germanene exhibiting a larger bandgap than graphene due to the buckling of its honeycomb lattice, which however reduces its capacity as a viable CO2 adsorbent.

The effect of an external force field has also been investigated; in one such study analyses, phosphorus-doped graphene has been tested as CO2 adsorbent in a controlled external electric field (Esrafili 2019), which indicates the change of adsorption energies from chemisorption to physisorption on removing the electric field. The difference in energies of 60 kJ mol−1 can also be applied to the same configuration for the CCS system. A similar study tested the potential of penta-graphene as a controllable carbon separation, capture, and storage material using a controlled electric field and utilized molecular dynamics simulations for studying CO2 adsorption on penta-graphene under different electric field strengths (Wang et al. 2020). The results showed that the adsorption of CO2 on penta-graphene was enhanced under an electric field (− 128.1 kJ mol−1), and the selectivity for CO2 over C2N (− 21.05 kJ mol−1) increased with increasing electric field strength. To test for CO2 under realistic conditions inside an electrode for electrochemical reduction of Fe–N-graphene was analyzed as a CO2 adsorbent using ab initio molecular dynamics simulation (Li et al. 2020a, 2020b), which provides adsorption energy of − 45.2704 kJ mol−1 in K-sol, indicating a strong affinity for CO2 for the intended catalyst.

Some advanced studies have also been made possible due to the rapid growth and accessibility of computational resources, enabling the testing of materials beyond graphene; one such material is germanene, which has already been discussed in the previous section. Another such advanced material is graphyne, which has been speculated as a CO2 adsorbent. Oxides of the same have been investigated as CO2 adsorbent using DFT and MD simulations which indicated physisorption behavior (− 22.73 kJ mol−1). Advanced studies have also been carried out to check changes in the adsorption behavior of CO2 over graphene influenced by CO2 clustering on adsorbent surfaces (Meconi and Zangi 2020; Zhang et al. 2022).

Functionalization of graphene with long-chain amines is a viable route to improve CO2 adsorption capabilities; one such analysis highlights the interaction between graphene and amino acids (Kamel et al. 2020) using DFT calculations and MD simulations, and the researchers found that graphene and functionalized graphene nanosheets can interact strongly with certain amino acids through hydrogen bonding and pi-stacking interactions. This study indicates that the nature and strength of interaction are dependent on functional groups present on the graphene surface with the possibility of potential applications of graphene-based materials in the field of biotechnology. In conclusion, density functional theory (DFT) is a reliable tool that has made possible calculations investigating the mechanism of air capture by graphene and its derivatives (Table 1). By modeling the interaction of graphene-based materials with various air molecules, one can identify key factors that influence the adsorption properties, such as the nature of the graphene surface and functionalities attached to it. DFT calculations have also been used to predict the thermodynamic and kinetic properties governing the air capture process and are an invaluable tool for the design and optimization of graphene-based air capture materials. Overall, the use of DFT calculations enables prospective investigators to attain insights into the fundamental processes underlying air capture by graphene and its derivatives, which has important implications for the development of sustainable and efficient air capture technologies.

Adsorption performance of graphene-based materials derived from industrial grade precursors

Owing to its distinctive blend of physical and chemical properties of graphene, it has been established as an innovative material for the adsorption of CO2. Its high mechanical and chemical stability makes it durable and able to withstand harsh conditions. Furthermore, graphene is a highly selective adsorbent, making it possible to target specific molecules such as CO2. This has the potential to lead to more efficient and targeted removal of CO2 from industrial processes or the atmosphere. Much research has already been done on obtaining varieties of graphene and related products to use as adsorbents. Graphene developed for air adsorption applications rely on industrial grade graphite as the carbon precursor, and this route is termed the top-down approach for synthesizing graphene and is summarized in Table 2. Mishra and Ramaprabhu (2012) utilized polyaniline-functionalized hydrogen exfoliated graphene (PANI-f-HEG) derived from pure graphite, demonstrating a high CO2 adsorption capacity. The PANI-f-HEG sample was found to show adsorption of about 21.6 mmol/g CO2 (at 25 °C and 11 bar pressure). However, using expensive graphite as a starting material stands out as one of the notable drawbacks.

In a study conducted by Chowdhury and Balasubramanian (2016) they investigated the use of graphene sheets derived from graphene powder through an enhanced version of the Hummer’s method and synthesis by hydrazine reduction of graphene oxide. The extremely hydrophobic graphene sheets interconnected by hierarchical pore networks exhibited an adsorption capacity of 2.894 mmol/g at 25 °C and 1 bar pressure. Politakos et al. (2020) put forward using graphene-based monolithic nanostructures obtained from GO nanoplatelets as adsorbent material. Under similar conditions of temperature and pressure, the material showed an adsorption capacity of 2.1 mmol/g. Hierarchical porous graphene-based carbons (HPGCs) obtained from analytical grade graphite have been used by Xia et al. (2014) as an adsorbing material. In this case, too, the GO is obtained using the modified Hummer’s method. At 0 °C and 1 bar pressure, the material has been found to adsorb 1.76 mmol/g of CO2. However, the reusability of this material remains a matter of question.

Reduced graphene oxide (RGO) has also been used as an adsorbent for CO2 in several instances. With industrial-grade GO as a precursor, Kumar et al. (2014) prepared rGO by NaBH4 reduction of graphene oxide. They subsequently employed the Sonogashira coupling strategy for synthesizing durable, porous, and robust graphene frameworks with organic linkers. Iodobezene functionalization of GO sheets was done using diazonium salt of 4-iodoaniline. This process resulted in the incorporation of iodobenzene functional groups on both sides of rGO, forming rGO-IBz. At 20 °C, 1 atm pressure, the material had a CO2 adsorption capacity of 1.24 mmol/g. The adsorption performance of nanocomposites of GO-doped stearate-intercalated layered double oxides (LDO) was studied by Wu et al. (2022), and their adsorption capacity at 200 °C indicated that a GO/LDO ratio of 6:1 had the best adsorption capacity. To activate the adsorbents before CO2 adsorption, they underwent a calcination process using a tube furnace. The calcination was carried out in a nitrogen flow of 50 ml/min at a temperature of 400 °C for a duration of 4 h.

Doping of GO with nitrogen is also one of the emerging adsorbents for CO2 capture. The process of synthesizing polypyrrole functionalized graphene sheets involved chemically polymerizing pyrrole in graphene oxide. This synthesis was achieved through the utilization of ammonium persulfate as an initiator, followed by subsequent reductions using hydrazine. Its CO2 adsorption capacity was observed to be 4.3 mmol/g at 25 °C, 1 bar pressure (Chandra et al. 2012). A variety of nitrogen-doped graphene oxide sheets (N-GOs) were tested by Alghamdi et al. (2018) which yielded interesting results. Monomers were mixed with a fixed quantity of desired dopant (HCl, H2SO4, C6H5-SO3-K), the mixture was stirred and added with ammonium persulfate dissolved in water. The prepared polymer was carbonized. Among the varied sample materials developed, a polymer to KOH ratio of 1:2 yielded a CO2 adsorption of 1.36 mmol/g at 50 °C and 1 atm pressure, while it decreased to 1.13 mmol/g for a polymer to KOH ratio of 1:4. Upon comparing the obtained adsorption values with those reported in previous studies, it was found that the adsorption capacities of N–GOs were marginally lower. This finding is a clear indication of the potential for improvement of these materials’ adsorption properties.

Zinc oxide-based N-doped reduced graphene oxide (N-rGO-ZnO) (Li et al. 2016) has been found to adsorb 3.55 mmol/g CO2 at 25 °C and 1 atm pressure. To synthesize N-rGO, a combination of GO and melamine was utilized. The inclusion of melamine served to create a charged layer that attracted the negatively charged GO via electrostatic interaction. Carbon materials doped with nitrogen or sulfur, developed by the Kwang Group, exhibited enhanced selectivity in capturing CO2 (Seema et al. 2014). S-doped microporous carbon materials formed by chemical activation of an rGO/PTh (thiophene) material (SG) on undergoing adsorption tests yielded a CO2 adsorption capacity of 4.5 mmol/g (Seema et al. 2014) under similar conditions. For synthesizing rGO, hydrazine reduction was employed. The necessary quantities of reduced graphene oxide and thiophene were dispersed in chloroform at room temperature using sonication. The synthesis of PTh was conducted using a comparable procedure, excluding the presence of reduced graphene oxide. Subsequently, the activation of SG was accomplished by utilizing a predetermined concentration of potassium hydroxide solution (Zhu et al., 2011; Raymundo-Piñero et al. 2005). Following 9 cycles, the material exhibited an initial decline of 10% in its adsorption capacity, which was subsequently recovered. This decline in adsorption capacity can be attributed to the instability of different oxidation states that sulfur can undergo during rigorous activation procedures. In a related study conducted by Ouyang et al. (2021), they focused on a material with some similarities. They utilized a unique nitrogen-doped porous carbon material derived from composites of melamine-resorcinol–formaldehyde resin and graphene oxide (MR/GO) as a precursor. To obtain a nanoporous carbon membrane (NPCM) derived from GO/MR, with a substantial surface area and abundant pores, the activation process was performed under an N2 stream using KOH as the activating agent. Final-stage carbon materials were obtained with activation temperatures of 500 °C. The developed sample adsorbed CO2 to an extent of 5.21 mmol/g at 25 °C and 500 kPa, while under similar conditions, NPCM activated at 600 °C showed CO2 adsorption of about 4.29 mmol/g. The exceptionally rapid kinetics observed in these materials indicate that the previously synthesized material offers the advantage of reducing the adsorption cycle time, which holds promising implications for practical applications.

Recently, a variety of experiments have been conducted to test the adsorption capacity of GO functionalized with different kinds of amines such as ethylenediamine (EDA), diethylenetriamine (DETA), and triethylenetetramine (TETA). Zhao et al. (2012) found the best performance with EDA. Synthesizing graphene with a modified Hummer’s method, the GO products were divided based on concentration in the aqueous solution. A pre-determined amount of EDA, DETA, or TETA was added to each solution, and finally, the modified GO was isolated by centrifugation. EDA functionalized GO adsorbed CO2 up to 1.1 mmol/g at 303 K temperature and 1 bar pressure. Tuning of operating conditions may lead to improved performance. Bhanja et al. (2016) explored an additional innovative material that revolves around amine functionalized graphene oxide. Their study focused on copper-grafted imine-functionalized graphene oxide (Cu-IFGO), which was obtained through post-synthetic modifications involving the co-condensation of 3-aminopropyltriethoxysilane (APTES). This material exhibited an adsorption capacity of 2.1 mmol/g at 298 K and 1 bar pressure. GO functionalized by a combination of a two-step process consisting of physical activation by ultrasound and chemical activation with TEPA to yield ultrasonic-TEPA activated GO, which has been found to have a CO2 adsorption capacity of 1.2 mmol/g (Liu et al. 2019) at 338 K temperature and 0.1 atm. One should bear in mind the criticality of regenerating an adsorbent both from an economic perspective and for prolonged utilization. In this specific instance, the cyclic adsorption/desorption data revealed the notable stability of TEPA-GO’s adsorption behavior, with a mere 1% reduction in adsorption capacity observed after 10 cycles. However, practical applications ask for a higher number of cyclical tests, which may lead to a reduction in adsorption capacity. DAC-GO-PEI formed by the impregnation and crosslink of polyethyleneimine (PEI) into a dialdehyde-cellulose/graphene oxide composite gel also acts as a good adsorbent (Qiu et al. 2022). On oxidation using NaIO4, thin cellulose nanofiber was found to gather into a strong dialdehyde cellulose network. To assess the impact of GO, the aldehyde group content of gels was measured using a titration method. At 25 °C, 4.25 mmol/g of CO2 was found to be captured by DAC-0.05GO-cPEI. But the dependency of the performance of the resultant product on GO being utilized is a problem.

Stankovic et al. (2022) used an industrially sourced aqueous dispersion of GO of 4 mg/mL to yield GO/polymer composites as adsorbents, where nanocomposites were functionalized with technical monomers; methyl methacrylate (MMA) and butyl acrylate (BA), sodium 4-vinyl benzenesulfonate (NaSS), glycidyl methacrylate (GMA), 2-hydroxyethyl methacrylate (HEMA), and 2-aminoethyl methacrylate hydrochloride (AEMH) were used as functional monomers. In the synthesis process, tert-butyl hydroperoxide solution (TBHP) and l-ascorbic acid (AsA) were employed as redox initiators, while sodium dodecyl sulfate (SDS) and hexadecyl trimethyl ammonium chloride (HAC) were used as demulsifiers. Sodium bicarbonate (NaHCO3) was used as a buffer. At 25 °C, the material exhibited an adsorption performance of 0.5–1 mmol/g. Politakos et al. (2020) used three-dimensional monolithic composite structures composed of reduced graphene oxide and polymer (NaSS and AMPS), copolymerized with the monomer MMA. This material also showed a similar CO2 adsorption of 1.01 mmol/g under similar temperatures and conditions.

Cu-BTC and its composites with graphite oxide forming MOF/GO-Urea stand out as good adsorbents. Testing was carried out on a variety of composites with increasing amounts of urea used for the synthesis of Cu-BTC as mentioned in the literature (Chui et al. 1999). Experiments conducted at 273 K and 295 K at 0.1 MPa, showed adsorption of 8.45 mmol/g CO2, which was the highest among all combinations of MOF/GO and urea. Just by a slight tweak in the conditions, Policicchio et al. (2014) put forward that the same composite can adsorb about 13.41 mmol/g CO2 at room temperature and 1.5 MPa pressure; this increase in the required operating pressure is a drawback for direct air capture applications. Garcia-Gallastegui et al. (2012) used layered double hydroxide (LDH) nanoparticles precipitated onto graphene oxide as CO2 adsorbent. By dispersing a fixed quantity of GO in an aqueous solution containing pre-determined concentrations of NaOH and Na2CO3, a colloidal dispersion of negatively charged GO nanosheets was achieved. This dispersion served as the basis for preparing four different LDH/GO hybrids, with varying weight percentages of GO. Upon conducting tests at a high temperature of 573 K, an adsorption capacity of 1.23 mmol/g was obtained. It is important to note that for applications involving synthesized LDHs in temperature swing processes like precombustion carbon capture and storage (CSS) and sorption-enhanced hydrogen production, the optimization of adsorption and regeneration temperatures is essential. While a low adsorption temperature and a high regeneration temperature can result in maximum adsorption capacity, it can lead to energy inefficiency and create thermal gradients Thus, lack of energy efficiency remains a notable limitation in this case.

Graphene and graphene derivatives sourced through the top-down route have demonstrated exceptional CO2 adsorption capability (up to 40 mmol/g). However, nearly all of the synthesized materials require very high-quality industrial grade precursors which inhibit the production of these adsorbents at a bulk scale due to economic constraints. Hummer’s method involved in the synthesis of GO from graphite and subsequent hydrazine reduction also relies on expensive chemicals which further drive up the process costs. For this material to be widely accepted and implemented at an industrial scale to combat pollution, the costs involved in the fabrication process need to be reduced.

Graphene from natural, organic, and plastic waste sources

Graphene, GO, and graphene derivatives of carbon obtained from the top-down route rely on industrially sourced precursors, with a dependence on harsh and non-environment friendly chemicals involved throughout the route of synthesis. This not only increases the cost but creates a negative environmental impact. An alternate procedure named the bottoms-up route is a viable alternative. This route involves sourcing the carbon from organic and natural materials (mostly organic wastes) and also from plastic wastes. This method allows for the valorization of wastes generated from daily life and also contributes to the removal of plastic wastes from the environment (Table 3).

Macro-algae derived graphene adsorbent was obtained using KOH activation at a carbonization temperature of 400 °C, carbon and hydroxide ratio of 1:4, and activation of the blend at a temperature of 850 °C, which yielded porous graphene of about 1411 m2/g specific surface area and CO2 uptake capacity of 2.78 mmol/g at 30 °C and 1 bar pressure (Fig. 6). Characterization techniques undertaken for the samples (SEM, TEM, AFM, BET, XRD, Raman spectroscopy, XPS) show carbon-based graphene-like sheets, very similar to multi-layered graphene sheets. On carrying out CO2 adsorption tests, the exhibited CO2 uptake capacity is per the graphene sheet-like structure obtained. Though adsorption was not investigated by functionalizing the same, variations to pore structure and surface chemistry were investigated with changes in activation temperatures. This study has opened up the possibility of utilization of local macroalgae populations as an abundant and sustainable carbon precursor feedstock (Ai et al. 2021). Using the starting material wheat, few-layered graphene was fabricated by hydrothermally treating the precursor followed by carbonization and subsequent graphitization. Hydrothermal treatment was carried out inside a stainless-steel autoclave with Teflon lining at 150 °C for 6 h (Fig. 6). High-temperature pyrolysis was carried out at 800 °C for 3 h in a nitrogen atmosphere with KOH. The product was then dried inside a vacuum oven before thermally heating it inside a graphite furnace with Argon atmosphere blanketing at 2600 °C for 5. The yield was about 11.3 wt%, with a BET surface area of 35.5 m2/g; the nitrogen adsorption–desorption isotherm showed hysteresis at 0.8 to 0.95 relative pressure indicating mesopores (attributed to KOH activation). Besides, a very thin layer of carbon (1.2 nm) indicated a bi- and tri-layer, sheet thickness, and elementary analysis along with XRD, and XPS indicates the formation of almost pristine FLG with high-degree graphitization (Chen et al. 2016). This method does not involve harsh chemicals, but a graphite reactor with a temperature requirement of 2600 °C is highly cost sensitive. Disposable paper cups provide another route to produce high-quality graphene sheets in bulk. Chemical treatment of paper pulps includes blending with KOH followed by (NH4)2Fe(SO4)2 which will coordinate the pulp with Fe2+ ions. The pulp is then graphitized (Fig. 6). Dense Fe3C layers are formed due to the incorporation of a portion of carbon atoms into the iron phase. A rigid two-dimensional carbon atom layer (like graphite) manifests on the surface of iron layers due to the outward diffusion of carbon atoms upon lowering the temperature. The composite sheets are multi-layered, and treating the same with HCL removes the iron-producing high-quality graphene sheets. Compared to conventional routes, the yield of graphene sheets obtained per unit energy consumption is high. The sheets have low defects with high crystallinity and may be utilized as CO2 adsorbents (Zhao and Zhao 2013). Another route to high-quality graphene sheets involves one-step pyrolysis of dead camphor leaves (Cinnamomum camphora). The sample is mixed with d-tyrosine and trichloromethane, to precipitate amorphous carbon (Fig. 6). A few-layered graphene (FLG) remains suspended in chloroform confirmed by TEM images, which may be filtered to obtain FLG; a strong acid or base may be used to wash away the tyrosine. The graphitization reaction occurs directly on the carbon precursor surface. The graphene obtained is attributed to the morphology of the dead leaves which reveal a porous structure when investigated (due to the cleavage of hemicellulose under nitrogen), and the thin layers are a possible source of surface for graphene growth. The BET gives the surface area of the FLG to be about 296 m2/g, with a yield of 0.8%. The typical thickness obtained via AFM is about 2.37 nm corresponding to 7 layers of graphene. ID/IG ratio observed is 0.99 which is close to 0.845 of pristine graphene. The suspension obtained remains stable for 60 days (Shams et al. 2015). Plastic waste mix pyrolyzed with bentonite nano-clay as a reducing agent formed corrugated-edged graphene nanosheets (GN). GNs developed have been used in supercapacitors and dye-sensitized solar cells. The same substrate has favorable surface characteristics (about 0.91 ID/IG, and nearly 0.4-nm sheet thickness) for direct air CO2 adsorption operation (Pandey et al. 2021). Recently, Hibiscus sabdariffa sticks have been carbonized, KOH activated, and pyrolyzed to produce porous graphene-like carbon sheets with a high specific surface area of about 2300m2g−1 (BET), and a high pore volume of 1.3 cm3 g−1, with 2.2-nm average pore size (Nanaji et al. 2021). The sheets with high energy and power density (21.37 Wh kg−1 and 13,420 W kg−1) are suited for electrode development and can have CO2 capture potential. Cellulose filter paper engraved using laser produces laser-induced graphene (LIG) which has a sheet resistance of 71.6 Ω/square and nearly 1 ID/IG (Raman). LIG derived from laser induction exhibits strain and bending functionality (Kulyk et al. 2021), and LIG may be modified for carrying out CO2 adsorption studies.

A different route was investigated by Alkhavan, Bijanzad, and Mirsepah, making use of general wastes from day-to-day life, including natural waste like wood, leaf, bone, and cow dung, and also regular human activity-based waste, namely, bagasse, and newspaper. These were converted into GO and rGO suspensions. The route involved the production of industrial soot, by imperfect burning over a period of 5 days to obtain powdered soot which is carbonized by heating at 450 °C for 24 h; the as-prepared material was mixed with ferric chloride hexahydrate in distilled water along with continuous stirring. The graphitized material was then converted to GO using the modified Hummers’ method. The obtained GO was then reduced by hydrazine reduction to get graphene (Fig. 7). Although this method is extensive and makes use of Hummer’s method, it produces high-quality GO suspensions, which may be co-dispersed with polymer nanoparticles to yield graphene sheets. This method avoids the segregation of wastes and leads to a consistent final product. The properties of the obtained rGO sheets are independent of the carbon source and the properties observed, especially the ID/IG ratios are comparable to rGO sheets obtained from industrial graphite (Akhavan et al. 2014). Another production route of rGO utilizing waste dry cell batteries, a known persistent environmental hazard, involves utilization of graphite powder obtained from zinc-carbon dry cell electrodes. Improved Hummer’s method has been used to obtain GO, which undergoes hydrazine reduction to yield rGO (Fig. 7). A stable anionic ( Zeta potential of − 23.5 ± 0.41 mV) dispersion is obtained upon dispersing the rGO obtained in an aqueous medium, and the rGO has high conductivity due to restoration of sp2 hybridization indicated by the elimination of diffraction peak at 11.54° in XRD analysis and a reduction in the interlayer distance from 0.765 to 0.361 nm; the ID/IG ratios obtained are comparable to values observed for rGO obtained from industrially sourced graphite, so air/CO2 capture potential may be tested for graphene derivatives obtained via this route (Roy et al. 2016). Agricultural waste, namely, coconut shell and coconut choir, can also yield high-quality rGO by catalytic oxidation. This requires the carbonization of coconut shell and choir (crushed and ground to a fine powder), while mixed with ferrocene in a 1:5 ratio inside a muffle furnace for 15 min at 300 °C under atmospheric conditions. The mixture is then cooled to room temperature, which gives GO. This GO was thermally annealed for an additional 5 min, which is sufficient to get rGO from GO (Fig. 7). The final product obtained was a 2D rGO sheet with a well-graphitized structure, which was thin and consisted of a few layers indicated by SEM and AFM. Higher interlayer spacing for both choir and shell samples was attributed to minute quantities of residual functional groups mostly containing oxygen bonds. Zeta potential tests carried out indicated anionic dispersion stable in aqueous media (Tamilselvi et al. 2020). High-quality rGO may be synthesized efficiently, economically, and rapidly using this method. The CO2/air adsorption capability has not been tested; however, these rGO sheets were tested to be used as high-performance, flexible supercapacitors. Similarly, agro-wastes in both individual and tri composite forms, namely, rice bran, sugarcane bagasse, and orange peel were dried, crushed, and powdered to act as carbon precursors. They were mixed with ferrocene in a 1:3 ratio and introduced to the muffle furnace at 400 °C. The black solid residues were kept at ambient conditions for 30 min to obtain the final product. GO was effectively synthesized using relatively low temperatures (Hashmi et al. 2020). There were no tests carried out to air adoption capabilities, but it sheds light on a less arduous method to arrive at GO. Rice husk biomass may be used as a carbon precursor. Rice husk (after being washed) was treated inside a tube furnace for 2 h with N2 blanketing at 700 °C. The ash was treated with NaOH at 900 °C for 2 h under a protective atmosphere. The product, upon mixing with de-ionized (DI) water, yielded a mixture of carbon from rice husk (RHC) and silica. The carbon sourced from rice husk was obtained by vacuum filtration, and the same was treated with H2SO4, ultrasonicated for 5 h, and mixed with nitric acid. Then, it was vacuum filtered, thoroughly washed, pH adjusted, and autoclaved at 200 °C for 10 h. The sample was filtered to rice husk quantum dots (RHQD) (Wang et al. 2016). The intended product of graphene and graphene derivatives may be obtained by using KOH instead of NaOH and then using HCl to get GO. The same may be converted to rGO by suitable reduction methods. A readily available waste source, oil palm biomass, has been pulped, separated, and carbonized to derive lignin-derived graphene oxide powder (LGO). LGO obtained exhibits surface characteristics of 280.1 m2 g−1(BET) microporous area, 0.222 cm3 g−1 pore volume, and pore size of 3.15 nm (Yaqoob et al. 2021). High current density (15.65 mAm−2) and heavy metal removal (83.5% removal of cadmium) are observed in microbial fuel cells using lignin-based graphene oxide (LGO) anodes. The improved surface may be tested as CO2 adsorbent. Fairly abundant Miscanthus grass has been pyrolyzed, edge carboxylated, and ultrasonically exfoliated to yield graphene oxide and graphene quantum dots (Yan et al. 2021). The single-step method produces various graphene derivatives with controllable proportions.

A pathway to carbon sheets doped with nitrogen (known to improve gas-sieving characteristics (Li et al. 2017) without the GO intermediary incorporated the mixing of dried and crushed bagasse with melamine (an inexpensive chemical) in varying weight ratios inside a Teflon-lined autoclave. The product obtained was heated to 850 °C for 3 h in an argon atmosphere to facilitate N-doping. The result obtained is N-doped carbon sheets like graphene. The final product, the N-doped carbon sheets, from AFM established layered carbon structures similar to graphene. The N-doped carbon sheets were tested for sulfur retention in Li–S batteries. This route does not involve Hummers’ method (Babu and Ramesha 2019). Testing for the CO2 adsorption capacity may yield favorable results as a sheet-like structure is confirmed through SEM analysis. Coal tar pitch dispersed in ethyl acetate and carbonized with expanded vermiculite to yield carbon nanosheets (CNS) which show high specific surface area (280.1 m2 g−1(BET)) and high pore volume (0.222 cm3 g−1). CNSs demonstrate excellent performance as an anode in lithium-ion batteries (623 mAhg−1 (2 Ag−1)) reversible capacity with 99.7% capacity retention after 200 cycles) and may have good CO2 removal potential (Wang et al. 2021).

Graphene aerogel may be obtained from microcrystalline nanocellulose which involves the development of cellulose aerogel composited with a phenolic resin, and then subsequent carbonization in nitrogen at 600 °C to obtain graphene aerogel. This provided a high yield of products of about 48% with a specific porous network. BET analysis reveals a specific area of about 1426.11 m2/g, indicating a prospective candidate for adsorption applications (Li et al. 2020a, b). The use of phenol is a safety issue in this process, and microcrystalline cellulose, based on organic precursors, requires an extensive production route. Date syrup processed through heating, KCl treatment, sequential vacuum heating (N2), and HCl washing yields 3D networked graphene foam which exhibits a specific surface area of about 650m2g−1(BET), ~ 0.4 cm3 g−1 pore volume, and average particle size of 6 nm (Abed et al. 2023). Potential applications are yet to be investigated, with CO2 adsorption studies being one of them. Waxed cork has been treated with CO2 and Nd:YAG fiber lasers to create three-dimensional laser-induced graphene (LIG) network (Silvestre et al. 2022). Wax-based ink pre-treatment of cork eliminates the need for mechanical supports. Three-dimensional porous LIG has the potential for unsupported CO2 capture devices.

Waste chicken fat can be used to yield unified monolayer graphene film, utilizing low-pressure carbon vapor deposition (LPCVD) on Cu substrate. Chicken oil was obtained from waste chicken by the dry rendering process. Electrochemical delamination was used to transfer graphene onto a substrate polymethylmethacrylate (PMMA) to form PMMA/graphene composite, and finally, acetone was used to eliminate PMMA. The transferred graphene is continuous with no patches, Raman spectroscopy indicated a value of ID/IG < 0.1 and I2D/IG > 3, indicating uniform coverage of high-quality monolayer graphene. The hexagonal diffraction pattern indicated a mostly crystalline area (Rosmi et al. 2016). The requirement of a CVD setup restricts large-scale production potential at the moment. A similar method illustrated a route to directly obtain a single uniform layer of pristine graphene of high quality, with minimal defects and 97% transparency. The process involved spin coating of carbon source onto PMMA, and then subsequent CVD onto a Cu film, with an operating temperature of 800–1100 °C with reductive gas flow and low-pressure conditions. UV–Vis’s analysis points to typical π > π transition for aromatic C–C bonds in graphene film (peaks at 268 nm) and formation of monolayer graphene (peaks at 550 nm) (Ruan et al. 2011). A similar method involved CVD to obtain patterned graphene electrodes from quinone diluted coal tar pitch coated on a silica substrate, baked at 240 °C. Thermal annealing of the sample was carried out by CVD post deposition of nickel layer. Upon cooling, FeCl3 solution was used to etch away the Ni layer. UPS (ultraviolet photoelectron spectroscopy) to measure the work function of the prepared electrode showed a hole injection barrier of 0.43 eV. Extended characterization methods may be carried out to further analyze the morphological characteristics of prepared graphene samples (Seo et al. 2015). Gas adsorption experiments may also be carried out. The work of Cui et al. (2017) showed the production of high-quality graphene foil (GF) from regular plastic wastes on a large scale via a solid-state chemical vapor deposition method. The method claims to be safe, simple, and cheap. The GF demonstrates higher electrical conductivity (beyond 3500 Scm−1) than that of the conventional free-standing graphene films which require very high–temperature graphite reactors for synthesis. The GF demonstrates stable electrochemical duty as an electrode inside a foldable Li-ion battery demonstrating structural flexibility and consistent electrochemical performance. It is also able to generate beyond 300 °C against an applied potential difference of 5 V when operated as a heating element. Hence, the GF synthesized is extremely versatile and opens up numerous avenues for the implementation and application of waste-sourced graphene. Raman spectra indicate negligible structural defects and also establish exceptional degrees of graphitization and crystallinity (narrow and intense G-band), and crystallinity is also inferred from XRD analysis (26.7° sharp peak) while EDS reconfirms high graphitization. GFs prepared remain structurally consistent irrespective of the precursors utilized, and testing these versatile devices for CO2 adsorption may yield interesting insights.

Graphite rods from empty mosquito repellent refills, another common waste from households, were shown to be a viable source for obtaining graphene in an oxidation state, with carbon atoms in various functional groups. The method involves electrochemical exfoliation followed by treatment with sodium citrate to reduce the oxidation state. Before electrochemical exfoliation, the graphite rods have to be removed and washed with dilute HCL and also boiled to remove impurities. The product obtained remains untested for any real-life applications in this synthesis-focused work (Udhaya Sankar et al. 2018). Another common waste product similar to graphite rods from mosquito repellent refills is pencil cores, which tend to be discarded before complete utilization. The method utilized electrochemical exfoliation to turn the same pencil cores to high-quality graphene oxide flakes. The electrochemical approach was green, and cost effective, involving aqueous electrolytes H2SO4/H3PO4. TEM analysis indicated a few stacked layers with wrinkled morphology. SEM images showed GO flakes to be about 1–5 microns. FTIR results showed the presence of oxygen functionalization at the surface (Liu et al. 2013). This method is comparatively primitive, as compared to methods that form more stacked layers, and no tests were carried out to check gas adsorption performance. Both, waste dry cell battery and pencil cores, have undergone electrochemical exfoliation and thermal treatment to yield reduced graphene oxide modified with citric acid (CrGO) that has a crystallite size of about 17 nm and surface roughness of about 0.5 nm (Singh et al. 2023). CO2 adsorption applications may be investigated for CrGO.

A major waste material from the sugar and juice industry is pectin-rich mango peels. They have been used as raw material to synthesize graphene using a plasma-enhanced CVD technique. This enhanced CVD route has been able to synthesize both monolayer and multilayer graphene. The number of layers deposited on the substrate is controlled by the plasma exposure time, sheet thickness of graphene being inversely proportional to the time of plasma treatment (an hour of plasma treatment yields pristine single layer graphene). The etching effect of plasma, an apparent process drawback, may be harnessed to directly obtain graphene with vacancy defects, a very effective CO2 adsorbent (Shah et al. 2018). However, gas adsorption performance has not been investigated (Fig. 8).

The most abundant and easily available waste material is PET mineral water bottles. El Essawy et al. (2017) devised a way of synthesizing graphene by crushing and sieving waste PET bottles into desired size (1–3 mm) and then treating it in an autoclave reactor. XRD analysis of the sample displayed broad diffraction peaks corresponding to (002), (100), and (101) reflections. The broad (002) peak indicated inter-layer distances which were larger than crystalline graphite. The presence of a (101) peak suggests a stacking of layers in the resulting samples (Shen and Lua 2013). Though the prepared sample was not tested for CO2 adsorption, methylene blue (MB) and acid blue 25 (AB25) adsorptions were investigated to optimize adsorbent dosages and contact time using response surface methodology. A relatively cheap and simple utilization of waste plastic bottle carbon precursor has also been studied by Kamali et al. (2019) where they used a molten salt strategy for converting plastic bottles into a highly conductive nanostructured carbon. Small pieces of plastic waste and sodium chloride were heated to 1300 °C at a ramp of 10 °C/min and then quenched, in an alumina crucible inside a resistance furnace. The salt was dissolved out of the product to obtain synthesized amorphous carbon consisting of crystalline graphitic nanosheets of less than 10-nm thickness. Advincula et al. (2023) worked on using shredded consumer waste plastic and metallurgical coke as a precursor to yield turbostratic flash graphene (TFG). The product was achieved through flash joule heating (FJH), a pre-flashed blend of 5% carbon back and shredded high-density polyethylene (HDPE) at 120 V for 500 ms (Algozeeb et al. 2020). Metallurgical coke flash graphene (MCFG) was prepared by FJH pulse at varying duty cycles at 1 kHz frequency. The process yields of PFG and MCFG were about 40% and 95% respectively. After FJH, the average I2D/IG ratios for WPFG and MCFG indicated quality. The production process required 99% less water, 98% less energy, and 98.8% reduced gas emissions compared to the conventional production routes for graphene. FJH as a method for FG is an easy and affordable synthesis route that may be used on a large scale. Huang et al. (2021) have worked on developing carbon nanotubes (CNTs) from waste polyethylene by mixing it with a prescribed amount of ethanol, cobalt (II) hexahydrate under vigorous stirring with a protectant; and varying reactant precursors supported with varying amounts of cobalt nitrate at elevated temperatures. CNT yield using oleyl amine protectant was the highest (59%). A high yield of CNTs, with a length of 5–10 μm, and a diameter of less than 50 nm, was confirmed from SEM images. Similar to the study on waste PET bottles by Essawy et al., CNTs were tested for the adsorption of methylene blue, where it exhibited high adsorption capacity (up to 107.1 mg g−1). BET concluded a very high specific area of 195.7 m2 g−1 that may be tested as an effective CO2 adsorbent.

Investigation of works that have employed the bottoms-up route indicates that bulk production of graphene and its derivatives is viable and can be categorized broadly into 4 categories as depicted in Fig. 9. Most notably, abundantly available carbon precursors in the form of self-sustaining biomass, organic wastes, and domestic plastic waste have the potential to reduce the price involving industrial grade precursors. Work involving the production of rGO from sources such as agricultural wastes (rice husk, coconut husk, bagasse) has the least temperature requirement during synthesis; however, ferrocene used during carbonization might increase the overall cost. A major advantage of using ferrocene not only reduces the temperature requirement but also reduces the required time which in turn compensates for the cost of ferrocene. The produced rGO has also exhibited comparable properties to derivatives obtained from industrial graphite. Further investigation will help to identify better precursors for this route. The produced rGO can be tested for its CO2 capture capacity, with a promising potential for developing sustainable CO2 adsorbents with high surface area. Although the precursor cost goes down when using natural sources, certain raw materials, namely, waste dry cell batteries, require the Hummer’s method to obtain GO as an intermediary step and later hydrazine reduction to get rGO, increasing overall process cost.

CVD has also been demonstrated as a pathway to very high–quality, pristine graphene sheets from various natural resources (Fig. 8), which may be impinged (to introduce defects) and doped (with metals) to obtain high-performing CO2 adsorbents. The price reduction achieved by sourcing an easily available raw material is offset by the cost and low yield involved in the CVD process. Production in bulk is still a major challenge in this route. This route is however just a breakthrough in the CVD process away from becoming an extremely efficient route to high-quality graphene.

Among all the processes considered, a few layers of graphene obtained via the chemical treatment of carbonized products of natural and waste-based carbon precursors is the most interesting process. The utilization of macro-algae highlights a pathway to graphene-based CO2 adsorbents with minimal cost requirements. Wheat straw, paper cups, and camphor leaves indicate obstacles to economic feasibility due to the necessity of graphite reactor, ammonium iron(II) sulfate, and D-tyrosine, respectively. However, graphene obtained from macro-algae using KOH activation followed by pyrolysis not only reduces the cost of the source but also energy decreases the energy requirement of the process. It has demonstrated notable CO2 adsorption capacity and may be improved further by incorporating functional groups on the prepared adsorbents. It may also be viable to treat other carbon precursors in the same manner and analyze the final products obtained for their CO2 capture performance. The pyrolysis temperature requirement of 850 °C is a minor trade-off for the results demonstrated.

Conclusion

Multiple instances of investigations, i.e., experimental work, have been carried out to test the CO2 adsorption capacity of graphene and its derivatives. Graphene and its derivatives sourced from the top-down route involving industrial grade precursors have shown exceptional CO2 adsorption performance due to favorable surface characteristics as an adsorbent. Functionalization has been accomplished to improve the capability of graphene as an adsorbent. Certain innovations have also been achieved, notably the establishment of free-standing graphene-based membranes eliminating the need for a template. However, irrespective of the advancements, the requirement of highly pure precursors and an extensive list of chemicals involved in this route pose a major demerit on the aspect of utilizing graphene as a universally accepted direct air capture adsorbent for CO2. The environmental consequences from a life cycle assessment approach create doubt about the viability and environmental compatibility of graphene and graphene-based derivatives. But this hurdle may be overcome by synthesizing such adsorbents from naturally sourced and waste-based carbon precursors. Certain works have already highlighted the use of naturally sourced graphene as an effective air adsorbent. More investigations must be carried out to test for the viability of graphene from an increased pool of carbon precursors. Graphene development from waste plastics and naturally occurring sources have seen a large volume of work, yet very few of such developed graphene and derivatives have been tested for CO2 adsorption behavior. Graphene has a wide range of applications including its capability as a viable supercapacitor, an excellent pollutant capture capability, and even geo-sensor properties, and it is necessary to test all its capabilities. Yet, the need to devote a substantial number of resources and time to develop and test direct air capture systems for CO2 adsorption based on graphene and graphene derivatives from natural and waste carbon precursors is urgent and global.

References

Abed M et al (2023) From date syrup to three-dimensional graphene network. Phys Scr 98(8). https://doi.org/10.1088/1402-4896/ace3fe

Advincula PA et al (2023) Waste plastic- and coke-derived flash graphene as lubricant additives. Carbon 203(October 2022):876–885. https://doi.org/10.1016/j.carbon.2022.12.035

Aguilar JCS et al (2021) Hydroxyl-functionalized graphene from spent batteries as efficient adsorbent for amoxicillin. Chem Eng Trans 86:331–336. https://doi.org/10.3303/CET2186056

Ai N et al (2021) Facile synthesis of macroalgae-derived graphene adsorbents for efficient CO2 capture. Process Saf Environ Prot 148:1048–1059. https://doi.org/10.1016/j.psep.2021.02.014

Akhavan O et al (2014) Synthesis of graphene from natural and industrial carbonaceous wastes. RSC Adv 4(39):20441–20448. https://doi.org/10.1039/c4ra01550a

Alghamdi AA et al (2018) Enhanced CO2 adsorption by nitrogen-doped graphene oxide sheets (N-GOs) prepared by employing polymeric precursors. Materials 11(4). https://doi.org/10.3390/ma11040578

Algozeeb WA et al (2020) Flash graphene from plastic waste. ACS Nano 14(11):15595–15604. https://doi.org/10.1021/acsnano.0c06328

Ali A et al (2019) Graphene-based membranes for CO2 separation. Materials Science for Energy Technologies. KeAi Communications Co., 83–88. https://doi.org/10.1016/j.mset.2018.11.002

Armano A, Agnello S (2019) Two-dimensional carbon: a review of synthesis methods, and electronic, optical, and vibrational properties of single-layer graphene. C — J Carbon Res 5(4):67. https://doi.org/10.3390/c5040067

Baachaoui S et al (2021) Density functional theory investigation of graphene functionalization with activated carbenes and its application in the sensing of heavy metallic cations. J Phys Chem C 125(48):26418–26428. https://doi.org/10.1021/acs.jpcc.1c07247

Babu DB, Ramesha K (2019) Melamine assisted liquid exfoliation approach for the synthesis of nitrogen doped graphene-like carbon nano sheets from bio-waste bagasse material and its application signi high areal density Li-S batteries. Carbon 144:582–590. https://doi.org/10.1016/j.carbon.2018.12.101

Balasubramanian R, Chowdhury S (2015) Recent advances and progress in the development of graphene-based adsorbents for CO2 capture. J Mater Chem A. Royal Soc Chem 21968–21989. https://doi.org/10.1039/c5ta04822b

Bermeo M et al (2022) Critical assessment of the performance of next-generation carbon-based adsorbents for CO2 capture focused on their structural properties. Sci Total Environ 810:151720. https://doi.org/10.1016/j.scitotenv.2021.151720

Bhanja P et al (2016) Functionalized graphene oxide as an efficient adsorbent for CO2 capture and support for heterogeneous catalysis. RSC Adv 6(76):72055–72068. https://doi.org/10.1039/c6ra13590k

Cabrera-Sanfelix P (2009) Adsorption and reactivity of CO2 on defective graphene sheets. J Phys Chem A 113(2):493–498. https://doi.org/10.1021/jp807087y

IPCC (2005) IPCC Special Report on Carbon Dioxide Capture and Storage. Prepared by Working Group III of the Intergovernmental Panel on Climate Change. In: Metz B, Davidson O, de Coninck HC, Loos M, Meyer LA (eds) Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, p 442

Castro-Muñoz R et al (2022) A new relevant membrane application: CO2 direct air capture (DAC). Chem Eng J 446(March). https://doi.org/10.1016/j.cej.2022.137047

Chakraborti H, Pal SK (2014) Assessment of amine functionalized graphene nanoflakes for anode materials in Li-ion batteries: an ab initio study. Chem Phys Lett 600:118–122. https://doi.org/10.1016/j.cplett.2014.03.065

Chandra V et al (2012) Highly selective CO2 capture on N-doped carbon produced by chemical activation of polypyrrole functionalized graphene sheets. Chem Commun 48(5):735–737. https://doi.org/10.1039/c1cc15599g

Chen F et al (2016) Facile synthesis of few-layer graphene from biomass waste and its application in lithium ion batteries. J Electroanal Chem 768:18–26. https://doi.org/10.1016/j.jelechem.2016.02.035

Chen H et al (2021) The synergistic effects of surface functional groups and pore sizes on CO2 adsorption by GCMC and DFT simulations. Chem Eng J 415(February):128824. https://doi.org/10.1016/j.cej.2021.128824