Abstract

Fipronil (C12H4Cl2F6N4OS) is a commonly used insecticide effective against numerous insects and pests. Its immense application poses harmful effects on various non-target organisms as well. Therefore, searching the effective methods for the degradation of fipronil is imperative and logical. In this study, fipronil-degrading bacterial species are isolated and characterized from diverse environments using a culture-dependent method followed by 16S rRNA gene sequencing. Phylogenetic analysis showed the homology of organisms with Acinetobacter sp., Streptomyces sp., Pseudomonas sp., Agrobacterium sp., Rhodococcus sp., Kocuria sp., Priestia sp., Bacillus sp., Aeromonas sp., and Pantoea sp. The bacterial degradation potential for fipronil was analyzed through high-performance liquid chromatography (HPLC). Incubation-based degradation studies revealed that Pseudomonas sp. and Rhodococcus sp. were found to be the most potent isolates that degraded fipronil at 100 mg L−1 concentration, with removal efficiencies of 85.9 and 83.6%, respectively. Kinetic parameter studies, following the Michaelis-Menten model, also revealed the high degradation efficiency of these isolates. Gas chromatography-mass spectrometry (GC-MS) analysis revealed fipronil sulfide, benzaldehyde, (phenyl methylene) hydrazone, isomenthone, etc., as major metabolites of fipronil degradation. Overall investigation suggests that native bacterial species isolated from the contaminated environments could be efficiently utilized for the biodegradation of fipronil. The outcome derived from this study has immense significance in formulating an approach for bioremediation of fipronil-contaminated surroundings.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fipronil [5-amino-1-[2,6-dichloro-4-(trifluoromethyl)phenyl]-4-[(trifluoromethyl)sulfinyl]-1H-pyrazole-3-carbonitrile] is a systemic insecticide grouped under the phenylpyrazole family (Tomlin 2000; Tingle et al. 2003). It is a broad-spectrum, among the most hazardous, lipophilic, and persistent pesticides used against rice stem borer, bollworm, ticks, aphids, locusts, termites, mosquitoes, ants, cockroaches, etc. (Mohapatra et al. 2010). In recent years, it was estimated that of the worldwide pesticide market, the combination of neonicotinoid and fipronil dominates ~ 30% (Casida and Durkin 2013; Pang et al. 2020). Fipronil is considered as a “next-generation insecticide” because its mechanism mode is different from the conventional biochemical routes of previously known insecticides which include pyrethroids (sodium channel blockers), carbamates, and organophosphates (cholinesterase inhibitors), to which many insects/pests have evolved resistance (Bobe et al. 1997; Aajoud et al. 2003; Bhatti et al. 2019). Fipronil induces its toxicity on gamma-aminobutyric acid (GABA) receptors which act as a nerve transmitter in insects. It blocks the passage of chloride ions through the GABA receptors which leads to the interruption in neuron signaling and finally closure of the central nervous system (CNS). It causes paralysis and eventually death of insects (Bhatti et al. 2019). The wide application, longer half-life (~ 3–7 months in field environment), and inappropriate management cause its augmentation in the environment that is detrimental to non-target biota (Bonmatin et al. 2015). WHO has also classified fipronil as a class II moderately hazardous pesticide. Therefore, the removal of fipronil from a contaminated environment is of utmost importance.

Bioremediation is considered a cost-effective mechanism for the removal of harmful compounds like fipronil as microbial organisms play a crucial role in achieving biodegradation pathways of fipronil from a contaminated habitat (Li et al. 2012; Paliwal et al. 2015). There are many studies have been documented that incorporated fungal and bacterial isolates for the degradation of fipronil some of which have been described here. Abraham and Gajendiran (2019) reported that Streptomyces rochei AJAG7 showed degradation efficiency of fipronil at 500 mg L−1 in mineral salt media (MSM) and soil in 6 and 7 days, respectively. Fungal species such as Trametes versicolor and Aspergillus glaucus have been reported for their degradation potential of fipronil (Wolfand et al. 2016; Gajendiran and Abraham 2017). Bhatt et al. (2020) reported that Bacillus sp. strain FA3 degraded ~ 77% fipronil after 15 days of incubation period in MSM media and ~ 77.5% fipronil in soil. Bhatt et al. (2021) conducted another study for the biodegradation of fipronil and identified a strain FA4 as Bacillus sp. that can degrade fipronil up to 75% in MSM broth and 77% in soil. Sayi et al. (2020) identified a bacterial strain SNCK-4 named Klebsiella pneumoniae that can grow on a medium containing 1% fipronil as a carbon source. Thirumalaiselvan et al. (2015) isolated bacterial strains from a freshwater environment belonging to Bacillus sp. and Comamonas aquatica and showed their potential to degrade 10.5 to 94.6% of the initial concentration fipronil of 10 and 20 mg L−1. do Prado et al. (2021) reported the highest degradation (94%) by Bacillus megaterium strain E1 for fipronil (600 mg L−1) utilizing it as a solitary nitrogen and main carbon source. In a recent study, Viana et al. (2022) reported a strain RFD1C as Bacillus amyloliquefaciens, which achieved 93% degradation of 10 mg L−1 of fipronil in a period of five days. Bacillus firmus, Burkholderia thailandensis, Acinetobacter calcoaceticus, Acinetobacter oleivorans, Paracoccus sp., and Gamma Proteobacteria are some of the known bacterial isolates, involved in the biodegradation of fipronil (Kumar et al. 2012; Mandal et al. 2014; Uniyal et al. 2016b; Cappelini et al. 2018). These studies reflected the considerable microbial potential for the degradation of fipronil.

In the contaminated surroundings, fipronil produces four major degradation products consisting of fipronil sulfide, fipronil sulfone, fipronil desulfinyl, and fipronil amide by the process of reduction, oxidation, photolysis, and hydrolysis, respectively (Gunasekara et al. 2007). These metabolites are also bioactive compounds and hazardous for many off-target organisms, which include butterflies, moths, pollinators (bees, bumblebees), and earthworms (Pisa et al. 2014; Bonmatin et al. 2015). However, few metabolites that are much more hazardous than the fipronil itself may be similarly degraded with the help of using microbes (Masutti and Mermut 2007; Tan et al. 2008). Fipronil sulfone, fipronil sulfide, fipronil amide, sulfurous acid, 2-ethylhexyl isohexyl ester, 1,2-benzene dicarboxylic acid, mono(2-ethylhexyl) ester, N-phenylmethacrylamide, and benzaldehyde (phenyl methylene) hydrazone have also been reported as biodegradation byproducts of fipronil (Mandal et al. 2013; Uniyal et al. 2016a; Abraham and Gajendiran 2019; At and Karthikeyan 2019; Bhatt et al. 2021).

Due to wide applicability and longer persistence, the residual amount of fipronil reaches to various environmental components such as agricultural fields, sewage, and sewage treatment plant sludge. Over the course of time, the native bacterial species of these habitats get adapted to fipronil and develop the capability for degrading it. It would be worthwhile to isolate bacterial species from such habitats and investigate their fipronil degradation efficacy. In context with this, in the present work, bacterial species from various fipronil-contaminated environments have been isolated and characterized and their efficacy for fipronil degradation has been determined. The process of fipronil degradation kinetics has been evaluated, and their intermediate metabolites formed have also been detected.

Materials and methods

Chemicals and media

Technical grade fipronil (analytical standard), with a purity of 98.8% was bought from Sigma-Aldrich, USA. HPLC grade acetonitrile, dichloromethane, and, ultra-pure HPLC water were purchased from E. Merck Limited, Mumbai, India. Acetonitrile and water were filtered through a 0.5 µm and 0.45 µm nitrocellulose syringe filter (Merck Millipore Ltd.) respectively before use. A stock solution of fipronil (1 mg mL−1) was prepared in acetonitrile, filtered, and kept at 4 ℃ for further use (Gajendiran and Abraham 2017). For the fipronil biodegradation study, two different bacteriological grade media were used, i.e., mineral salt media (MSM) and Luria Bertani (LB) media. MSM was used for screening and isolation of fipronil-degrading bacterial strains with a composition of 9 g Na2HPO4, 1.5 g KH2PO4, 1 g NH4Cl, 0.2 g MgSO4·7H2O, 1.2 mg Fe(III) [NH4] citrate, 20 mg CaCl2, 0.5 g NaHCO3, and 1 mL trace element solution (in 100 mL stock solution) of 50 mg FeSO4·7H2O, 1 mg ZnSO4·7H2O, 0.3 mg MnCl2·4H2O, 3 mg H3BO3, 2 mg CaCl2·6H2O, 0.1 mg CuCl2·2H2O, 0.2 mg NiCl2·6H2O, and 0.3 mg Na2MoO4·H2O per liter in double distilled water, and pH was maintained between 6.8 and 7 (Maya et al. 2011; Singh et al. 2019). LB broth was used for the growth and sustenance of isolated bacterial strains. For preparing solidified media, 1.7% of bacteriological grade agar was added to the broth. For sterilization, both the media were autoclaved (121 ℃, 20 min).

Sample collection

Soil samples were collected from the Agricultural Field, Banaras Hindu University, Varanasi (25°15′19″N; 82°59′21″E), samples of sludge from drainage (25°26′N, 82°99′E), and activated sludge sample from Sewage Treatment Plant (STP) Bhagwanpur, Varanasi, India (25°17′N, 83°00′E) 83 meter above mean sea level (MSL). The topsoil layer samples (20 cm depth) were collected with the help of a sterile corer. Sludge samples were collected with the help of a sterile spatula. All the samples were placed in sterile poly bags and transported to the laboratory. The collected samples were dried, passed through a 2 mm mesh sieve to remove debris, and stored at 4 ℃ for further investigation.

Enrichment and isolation of fipronil-degrading bacterial species

Enrichment of bacterial strains from all three different samples was done in MSM in the presence of fipronil. Five grams of each of the samples was spiked with 50 mg L−1 of fipronil in three different 250 mL Erlenmeyer flasks containing 45 mL of MSM media. All three flasks were incubated on a shaker (120 rpm) at 28 ± 2 ℃ for 2 weeks. After the incubation period, 1 mL of suspension from each flask was put into their respective flasks containing 50 mL fresh MSM supplemented with 50 mg L−1 fipronil and incubated on a rotary shaker at 120 rpm at room temperature overnight. Serial dilution of overnight samples with microbial growth was made from 10−1 to 10−9 and incubated in vials containing MSM and fipronil (50 mg L−1). Lower dilutions were again transferred into vials having 10 mL MSM and fipronil (50 mg L−1) and were incubated on a shaker at 120 rpm (28 ± 2 ℃). The control included MSM and fipronil but absence of bacterial inoculum. Vials showed turbidity as an indicator of bacterial growth. Thus, 100 µL of enriched samples from vials showing the best bacterial growth was spread on MSM agar plates supplemented with 50 mg L−1 fipronil (Bhatt et al. 2021). Plates were incubated at 28 ℃ for 3–4 days. The morphologically distinct isolates were obtained by repetitive streaking on MSM agar plates with fipronil. Pure isolates were stored at 4 ℃ as well as stocked in glycerol at − 80 ℃.

Biochemical and molecular assessment of isolated fipronil degrading bacterial species

For the biochemical assessment of isolated bacterial strains, the methodology was used as discussed in Bergey’s Manual of Determinative Bacteriology (Holt et al. 1994). Furthermore, molecular characterization of bacterial strains was done through 16S rRNA nucleotide sequencing of genomic DNA. Overnight grown cultures of bacterial strains were used for the extraction of genomic DNA with the help of MasterPure™ complete DNA and RNA purification kit (Lucigen, Middleton, USA). After the extraction of DNA, quantification was done using a spectrophotometer (Nanodrop™ Technologies, Incorporated, Wilmington, DE, USA). Amplification of 16S rRNA gene (1.5 kb sized) was done in a Thermal cycler (My Cycler™, BioRad Laboratories, Inc., Australia) using universal primers 27 F′ 5′-AGAGTTTGATCMTGGCTCAG-3′ (forward) and 1492R’ 5′-TACGGYTACCTTGTACGACTT-3′ (reverse) in a reaction mixture including 10 × buffer, 10 mM dNTPs, 500 U Taq DNA polymerase, 100 ng of template DNA, and volume was maintained up to 50 µL with Milli-Q. The polymerase chain reaction (PCR) cycling parameters were initial denaturation at 94 ℃ for 5 min follows by 30 cycles of denaturation at 94 ℃ (1 min), further annealing at 55 ℃ (1 min), extension step at 72 ℃ (1.30 min), and the last extension step at 72 ℃ for 5 min, uphold at 4 ℃. DNA bands were observed on 1% agarose gel for PCR-amplified 16S rRNA amplicon size. Purification of amplified PCR products was done using MinElute® PCR Purification Kit (Qiagen), and sequencing was done by an automated sequencer at Centyle Biotech Pvt. Ltd., New Delhi, using Sangers dideoxy nucleotide chain termination method. Processing of obtained sequence was done by BioEdit Sequence Alignment Editor (Version 7.2.5). Further identification of sequences was done based on reference species present in National Center of Biotechnology Information (NCBI) using BLAST (Basic Local Alignment Search Tool). Finally, the sequences were submitted with NCBI database to get the GenBank Accession number. The phylogenetic tree was constructed for bacterial strains by the neighbor-joining method using MEGA X (Version 11.0.13) software (do Prado et al. 2021).

Biodegradation of fipronil

To check the tolerance capacity of bacterial strains, a gradually increasing concentration range of fipronil was selected in which bacteria showed enormous growth in a short period. The inoculum for batch culture studies was prepared through LB overnight culture of bacterial strains. Cells were then centrifuged (5000 rpm, 15 min); pellets were washed with sterile saline (0.85%) and resuspended in sterile saline. A series of 100-mL flasks comprising 50 mL MSM were inoculated with 2 mL inoculum of individual isolates and supplemented with gradually increasing fipronil concentrations of 10, 25, 50, 100, 200, 300, and 400 mg L−1. Flasks in the absence of bacteria were considered as control for the comparison of bacterial growth. These were incubated at 28 ± 2 ℃ at 120 rpm for 13 days, and growth was monitored regularly with the help of a spectrophotometer (OD600). All these experiments were performed in replicates to minimize the chances of error. In order to determine the degradation potential of bacterial strains for fipronil, HPLC analysis was performed.

For the residue analysis of fipronil in samples, HPLC was performed through a method described by Abraham and Gajendiran (2019). For fipronil residue extraction, after 13 days of incubation period, 10 mL samples from each flask were withdrawn in a separate centrifuge tube and equal volume of 10 mL of dichloromethane was added to them. All the tubes were shaken vigorously for 5 min and kept aside in order to get a clean separation of phases. Five milliliters of dichloromethane layer was collected in a separate tube and evaporated in a vacuum evaporator, and it was resuspended in an equal volume of acetonitrile. Extracted fipronil concentration was analyzed by Waters (717 plus Autosampler) HPLC (Waters Corporation, Milford, USA) equipped with reverse phase C18 column (SunFire® 4.6 mm × 250 mm × 5 μm) and photodiode array (PDA) detector (Waters 2998). Acetonitrile and water (80:20 v/v) including 0.1% phosphoric acid were used as a mobile phase, and the flow rate was maintained at 1 mL min−1. Twenty-microliter samples were injected, and peaks were detected at a wavelength of 278 nm. All the samples were filtered through a 0.22 µm nylon syringe filter (Merck Millipore Ltd.) prior to their injection. For the quantification of fipronil concentration, a standard curve of peak area vs fipronil concentration was prepared. In order to know whether average degradation rate varied depending on concentration, the following formula (1) was used to obtain the average relative degradation rate of fipronil at different concentrations:

where ravg is average relative degradation rate, C0 is fipronil concentration at initial time, Ct is fipronil concentration at t time, and Δt is incubation period. Furthermore, the initial fipronil concentration which showed maximum degradation percent and average relative degradation rate (ravg) was chosen for the study of kinetic constants using the Michaelis-Menten model. MSM media containing individual isolates and amended with optimum fipronil concentration were incubated at 28 ± 2 ℃ at 100 rpm for 13 days. For analyzing residue fipronil concentration using HPLC, samples were collected regularly at time intervals of 24 h.

Metabolite analysis of fipronil degradation by FTIR and GC–MS

To determine the intermediates produced during the biodegradation of fipronil, FTIR and GC-MS analyses were performed. Two of the most efficient bacteria from the above study were selected for this experiment. One hundred-milliliter flasks containing 40 mL sterilized MSM were inoculated with 2 mL of both of the active bacterial strains individually and spiked with the 50 mg L−1 concentration of fipronil. These were incubated for seven days at 28 ± 2 ℃ at 100 rpm. After centrifugation (5000 rpm, 15 min) of bacterial culture, the supernatant was taken for further extraction of fipronil and its metabolites through liquid-liquid partitioning by adding an equal volume of dichloromethane and then evaporated on a rotary evaporator to concentrate the sample. Furthermore, it was resuspended in 4 mL MS-grade acetonitrile and analyzed on a triple quadrupole Gas Chromatography Tandem Mass Spectrometry (GC-MS/MS TQ-8050 NX, Shimadzu, Japan) with autosampler/injector AOC-20i + s. Rxi®-5 Sil MS Capillary column (5% diphenyl/95% dimethyl polysiloxane; 30 m, 0.25 mm, 0.25 µm) (Restek, USA) was used for separation. One-microliter sample was injected in a linear velocity, split mode with a ratio of 10, and the injector temperature was 260 ℃. Helium was used as the carrier gas, with a flow rate of 1.21 mL min−1. The oven temperature program was as follows: 100 ℃ (2 min hold) and increased up to 300 ℃ at a rate of 10 ℃ min−1 (18 min hold). Ion source temperature was 220 ℃, and the interface temperature was 270 ℃ with a solvent cut time of 4.50 min and operated in flame thermionic detector/barrier discharge ionization detector (FTD/BID) mode. MS has performed in multiple reaction monitoring (MRM) mode. Data were processed and integrated through Shimadzu Real-time analysis software. On the basis of retention time (RT) and molecular weight (m/z, 40–600), fipronil and its metabolites were identified using National Institute of Standards and Technology (NIST) library database.

For identification of functional group present in the parent chemical and its intermediate metabolites, FTIR analysis was performed through KBr pellet mode on Nicolet iS5 (THERMO Electron Scientific Instruments LLC). Spectra were recorded in the infrared region of 400–4000 cm−1 with a scan speed of 64 and resolution of 4 cm−1. For sample preparation, 20 mL sterilized MSM were enriched with fipronil (50 mg L−1) and 1 mL bacterial inoculum of both strains individually. A control sample was prepared without bacterial inoculum. After 7 days of the incubation period (28 ± 2 ℃, shaken at 100 rpm), the supernatant was collected by centrifugation (5000 rpm, 15 min), and extraction of compounds was done by adding an equal volume of dichloromethane. The organic layer was evaporated on a rotary evaporator and residues were reconstituted in acetonitrile for analysis of the functional groups and any bond stretching due to fipronil biodegradation.

Result and discussion

Biochemical and molecular assessment of isolated fipronil-degrading bacterial species

Identification of isolates were done on the basis of morphological, biochemical, and molecular characterization. Since each type of bacterial isolate holds unique enzymatic profiles, thus they help in the identification of particular ones. Eleven different bacterial isolates were obtained growing in the presence of fipronil, as identified on the basis of morphology. Out of eleven isolates, five (FIP_A1, FIP_A4, FIP_A8, FIP_C8, and FIP_C9) and six (FIP_A3, FIP_B3, FIP_B4, FIP_B10, FIP_C5, and FIP_C6) were Gram-negative and Gram-positive, respectively. All the isolates showed positive responses for catalase test, while in case of urease test, only three isolates (FIP_A3, FIP_A8, and FIP_B3) gave positive results. All the isolates except FIP_B3 and FIP_B4 showed positive results for citrate utilization test. For the oxidase test, FIP_A3, FIP_A4, FIP_A8, FIP_B4, and FIP_C8 were found positive except these all showed negative results. For the nitrate reduction test, only isolates FIP_A1, FIP_A3, FIP_A8, and FIP_C9 showed negative results. Biochemical test results of all isolates have been enlisted in Table S1. 16S rRNA nucleotide sequencing and phylogenetic tree analysis validated that the isolate belonged to ten different bacterial genera Acinetobacter sp. (FIP_A1), Streptomyces sp. (FIP_A3), Pseudomonas sp. (FIP_A4), Agrobacterium sp. (FIP_A8), Rhodococcus sp. (FIP_B3), Kocuria sp. (FIP_B4), Priestia sp. (FIP_B10), Bacillus sp. (FIP_C5, FIP_C6), Aeromonas sp. (Fip_C8), and Pantoea sp. (FIP_ C9) (Fig. 1).

Similar bacterial isolates have also been reported by other investigators for the biodegradation of fipronil. Abraham and Gajendiran (2019) reported Streptomyces sp. as a competent degrader of fipronil (500 mg L−1) by 50% within 2.8 and 4.3 days in aqueous media and soil, respectively. do Prado et al. (2021) showed the highest fipronil degradation using Bacillus megaterium. Acinetobacter calcoaceticus and Acinetobacter oleivorans also showed their efficacy of degrading fipronil in soils (Uniyal et al. 2016b). Various species of Bacillus have also been reported for the degradation of fipronil (Mandal et al. 2013, 2014; Bhatt et al. 2020, 2021; Gangola et al. 2021; Viana et al. 2022). Rhodococcus sp. was also reported for the degradation of many pesticides like endosulfan, cypermethrin, acetamiprid, and carbendazim (Verma et al. 2006; Phugare and Jadhav 2015; Abraham and Silambarasan 2018; He et al. 2022). Pseudomonas sp. was also found to be a degrader of pesticides like imidacloprid, sulfoxaflor, and chlorpyrifos (Pandey et al. 2009; Yadav et al. 2014; Jiang et al. 2022). Using omics-based approaches Gautam et al. (2023) reported Agrobacterium sp. InxBP2 as a potent degrader of insecticide imidacloprid. Biotransformation of insecticides is achieved by these bacterial populations as they are found in diverse habitats utilizing several chemicals as their source of energy and nutrients. Due to metabolic versatility, bacterial isolates develop the ability to survive in a range of environmental regimes and transform various hazardous chemicals (Liu et al. 2017; Yang et al. 2018; Gautam and Dubey 2023).

Processed 16S rRNA nucleotide sequences of eleven isolates were submitted to the NCBI gene database under accession numbers OP317323 to OP317332 and OP482264. Since Aeromonas sp. was found to be a pathogenic bacterium, it was not used for further study.

Biodegradation of fipronil

The results of the average degradation rate of fipronil by bacterial isolates are shown in Fig. 2. The relative average rate of fipronil degradation was increased up to 100 mg L−1 for bacterial isolates FIP_A1, FIP_A3, FIP_A4, and FIP_B3 and increased up to 50 mg L−1 for FIP_A8, FIP_B4, FIP_B10, FIP_C5, FIP_C6, and FIP_C9. There was a significant reduction in the biodegradation efficiency of bacterial isolates beyond these two optimum concentrations which could be due to the higher concentration of fipronil may be inhibitory to bacterial cells (Uniyal et al. 2016b). The variation in relative average degradation rates was followed in the range of 0.075 to 0.107 day−1. The highest value for the relative average degradation rate was observed in case of FIP_A4 (0.122 day−1), and FIP_B3 (0.114 day−1) at 100 mg L−1 while the lowest in case of FIP_C9 (0.075 day−1) at 50 mg L−1.

Growth of all the bacterial isolates and fipronil degradation studies are depicted in Fig. 3. Results obtained through batch culture studies showed that the growth curve followed an S-shaped graph for bacterial isolates FIP_A1, FIP_A3, FIP_A4, and FIP_B3 (100 mg L−1) and FIP_A8, FIP_B4, FIP_B10, FIP_C5, FIP_C6, and FIP_C9 (50 mg L−1) (Fig. 3). It was observed that the growth of bacteria increased up to the tenth day (for FIP_A1, FIP_A3, FIP_A4, FIP_A8, FIP_B3), the ninth day (for FIP_C5, FIP_C6, FIP_B10), and the eighth day (for FIP_B4, FIP_C9); then, growth became stationary and decreasing due to paucity of nutrients and accumulation of toxic intermediates during the incubation period. Similarly, a reduction in the concentration of fipronil was observed up to the ninth day for isolates FIP_A1, FIP_A3, FIP_A4, and FIP_B3, the eighth day for isolates FIP_A8 and FIP_B10, and seventh day for FIP_B4, FIP_C5, FIP_C6, and FIP_C9. The degradation rate decreased and finally stabilized after 9 days as bacterial isolates entered their stationery and death phases, respectively. Degradation percent for all the bacterial isolates was observed within the range of 61–86%. Maximum degradation percent found after 13 days’ time period were 85.9 and 83.6% at 100 mg L−1 of fipronil concentration, in the case of FIP_A4 and FIP_B3, respectively.

A bacterial strain Stenotrophomonas acidaminiphila was reported by Uniyal et al. (2016a), which was able to degrade 86.1% of 25 mg L−1 fipronil in 14 days as a carbon source. A study reported by At and Karthikeyan (2019) showed that Staphylococcus arlettae and Bacillus thuringiensis were able to degrade 76.4 and 65.9% of 10 mg L−1 of fipronil after 7 days. These results were obtained at relatively lower concentrations in contrast to the present study. While Gangola et al. (2021) performed a degradation study at a relatively higher concentration and obtained a bacterial isolate 2D named Bacillus cereus, 89% of fipronil (450 mg L−1) was degraded in 15 days of incubation period in MSM medium. The results obtained through the present investigation are in line with previous reports for fipronil biodegradation as these isolates have the potential to utilize it as a sole carbon source and energy. Many investigators also showed the ability of bacterial isolates to fulfill their nutritional requirements by consuming fipronil as a carbon and energy source (Mandal et al. 2013; Abraham and Gajendiran 2019; Bhatt et al. 2021).

Biodegradation kinetics of fipronil

The kinetics of fipronil biodegradation at the optimum concentration was investigated by selecting the Michaelis-Menten paradigm of the microbial kinetics model because substrate concentration and oxygen limitation did not serve as inhibitory factors in the biodegradation process. For the biodegradation process, kinetic parameters were resolved as described by Gautam and Dubey (2022). The non-linear kinetic model for the Michaelis-Menten equation is as follows (Eq. 2):

Kinetic parameters were calculated with the help of the Lineweaver-Burk equation, also known as the double reciprocal plot by linear regression plot (Eq. 3).

where t is time (day); Vmax is the maximum degradation rate of substrate (mg L−1 day−1); S0 and St are substrate (fipronil) concentrations (mg L−1) at time 0 and t, respectively; and Ks is Michaelis-Menten constant (mg L−1) (replaced Km from original equation) because biodegradation activity is accessed by virtue of intact bacterial cells instead of purified enzymes. Ks is the half-saturation concentration of substrate or the concentration of substrate at which reaction achieves half of its Vmax (maximum degradation rate). Values of Ks and Vmax/Ks were deduced through slope and intercept of the Lineweaver-Burk equation, respectively. The 1/t (ln S0/St) was plotted against (S0 − St)/t to obtain these kinetic parameters, Ks was calculated through the inverse of slope, and Vmax was obtained through intercept of the best fit straight line of experimental data. Vmax/Ks was calculated after getting the values of Ks and Vmax (Singh et al. 2019). The biodegradation kinetics of fipronil followed a first-order reaction (Bhatt et al. 2020, 2021) because, in the natural environment, bacterial inoculum (enzyme) was comparatively higher than the substrate (fipronil) concentration that is required to be degraded. Fipronil uptake efficiency of bacterial isolates can be demonstrated by lower values of Ks and higher values of Vmax, but Vmax/Ks (specific substrate affinity) can be considered as a better parameter instead of Vmax and Ks individually for measuring nutrient (fipronil) uptake efficiency and assimilation ability of bacterial isolates (Silambarasan and Vangnai 2016). The higher the values of Vmax/Ks, the higher will be the fipronil utilization or degradation potential and growth of bacterial strains. The degradation kinetics of fipronil by all the bacterial isolates unveiled conformity with the Lineweaver-Burk plot (linearized form) as depicted in Fig. 4, and the values of Vmax, Ks, and Vmax/Ks for all the bacterial isolates have been represented in Table 1.

Results obtained through our present study indicated that the value of Ks (mg L−1) was found between 135.13 to 166.67 mg L−1 for isolates FIP_A1, FIP_A3, FIP_A4, and FIP_B3 and between 61.73 and 76.33 mg L−1 for isolates FIP_A8, FIP_B4, FIP_B10, FIP_C5, FIP_C6, and FIP_C9. However, values of Vmax (mg L−1 day−1) were found highest for FIP_A4 (19.84) and FIP_B3 (19.13) followed by isolates FIP_A1 > A3 > A8 > C6 > B4 > C5 > C9 > B10 values that ranged between 2.83 and 15.01 mg L−1 day−1. The values of Vmax/Ks (day−1) were found highest for isolates FIP_A4 and FIP_B3, i.e., 0.125 and 0.115, respectively, whereas it was between 0.045 and 0.096 for the remaining strains with trend FIP_A1 > FIP_A3 > FIP_A8 = FIP_C6 > FIP_C5 > FIP_B4 > FIP_B10 = FIP_C9. The result obtained through the above kinetic study showed that the highest Vmax/Ks was observed in the case of FIP_A4 and FIP_B3, followed by other eight bacterial isolates. On that basis, it was concluded that Pseudomonas sp. FIP_A4 and Rhodococcus sp. FIP_B3 were the most efficient degrader of fipronil, while the isolate Pantoea sp. FIP_C9 was found to be the least efficient among all the ten bacterial isolates.

Bhatt et al. (2020) reported that Bacillus sp. FA3 followed first-order reaction kinetics for degradation of 50 mg L−1 of fipronil concentration with a degradation constant (k) of 0.0891 day−1, half-life (t1/2) of 7.7 days, determination coefficient (R2) of 0.921 day−1 and Ks of 65.096 mg L−1. Bhatt et al. (2021) conducted another study for understanding the biodegradation kinetics of fipronil (50 mg L−1) and reported that Bacillus sp. FA4 followed the kinetics of first-order reaction for fipronil biodegradation with k, t1/2, R2, and Ks of 0.0861 day−1, 8.04 days, 0.970 day−1, and 12.08 mg L−1. However, sufficient data for comparison was unavailable related to the kinetic parameters of the Lineweaver-Burk plot due to the lack of Michaelis-Menten kinetic study on fipronil biodegradation. Therefore, the comparison of all the kinetic parameters was not discussed here. Gautam and Dubey (2022) reported kinetic parameters for the biodegradation of imidacloprid, a neonicotinoid insecticide, i.e., Ks values ranged between 70.9 and 144.9 mg L−1, Vmax values ranged between 3.7 and 15.5 mg L−1 day−1, and Vmax/Ks (day−1) values that ranged from 0.051 to 0.107. Subsanguan et al. (2020) reported the kinetics results for the biodegradation of profenofos, an organophosphorus insecticide; the Ks, Vmax, and Vmax/Ks values were found 92.07, 13.07, and 0.14, respectively. Based on the above result, it was concluded that the result of the present study was in line and showed conformity with other previous results.

Metabolites analysis of fipronil

Since bacterial isolates FIP_A4 and FIP_B3 were identified as the most efficient degrader of fipronil as their specific substrate affinity (Vmax/Ks) was found highest, metabolites formed by them were analyzed. Metabolome analysis using GC-MS provided information regarding the compounds formed after the degradation of fipronil by FIP_A4 and FIP_B3 (Fig. S1). For FIP_A4, compound A1 was identified as fipronil sulfide at retention time (RT) 28.645 min with m/z of 417.51 and compound A2 as N-[2-(2,6-dichloro-4-trifluoromethyl-phenyl)-5-iminomethyl-4-trifluoromethanesulfonyl-2Hpyrazol-3-yl]-acetamide at RT 32.945 min with m/z of 495.45. The compound A3 was identified at RT 24.950 min with m/z of 467.40 as hydroxylated fipronil sulfone, and the compound A4 at RT 13.8 min with m/z of 154.10 was identified as isomenthone (Fig. 5), while samples inoculated with FIP_B3 revealed the production of three compounds, i.e., compounds B1, B2, and B3 that were characterized as benzaldehyde, (phenylmethylene) hydrazone (RT at 25.905 min), isomenthone (RT at 14.082 and 16.940 min), and hydroxylated fipronil sulfone (RT at 30.082 min) with m/z ratio of 207.05, 149.05, 154.10, and 467.45, respectively (Fig. 6). All metabolites have been enlisted in Table 2. In comparison to the chromatogram of control, fipronil peak area and concentration were found less in both the bacterial-treated samples; these were the result of bacterial degradation of fipronil. The concentration of produced intermediate metabolites was found less in comparison to the parent chemical.

The formation of the initial transformed product of fipronil, i.e., fipronil sulfone and fipronil sulfide, occurs via oxidation and reduction mechanisms, respectively (Uniyal et al. 2016b; Cappelini et al. 2018; Bhatti et al. 2019). Similar metabolites such as isomenthone, benzaldehyde, and (phenyl methylene) hydrazone were identified during the biodegradation of fipronil by a bacterium Streptomyces rochei strain AJAG7 and a fungus Aspergillus glaucus strain AJAG1, respectively (Gajendiran and Abraham 2017; Abraham and Gajendiran 2019). A compound named N-[2-(2,6-dichloro-4-trifluoromethyl-phenyl)-5-iminomethyl-4-trifluoromethanesulfonyl-2Hpyrazol-3-yl]-acetamide was detected in a microbial fuel cell in the process of degradation of fipronil (Zhang et al. 2019). For the fungal degradation of fipronil, an intermediate metabolite named hydroxylated fipronil sulfone was detected and reported by Wolfand et al. (2016). Based on the identified metabolites, it can be proposed that fipronil can be metabolized into fipronil sulfide and fipronil sulfone by reduction and oxidation reactions, respectively. Since fipronil sulfone is an unstable compound, a hydroxylation reaction occurs leading to the formation of hydroxylated fipronil sulfone. Furthermore, it may be converted into other simpler forms of metabolites which have been reported. Overall, from the above findings, it can be deduced that highly toxic fipronil can be metabolized into their simpler and less toxic intermediate compounds with the help of these bacterial species.

The biodegradation of fipronil is confirmed by correlating the numerous changes in FTIR spectra of bacterial strain-treated samples (MSM + Fipronil + bacterial inoculum) with control (MSM + Fipronil) (Fig. S2). A peak at 1735 cm−1 was observed in the samples treated with bacterial strains which correspond to ester groups indicating the formation of esters upon degradation of fipronil. Another band in treated samples at 1221 cm−1 also indicates the formation of an ester group in the samples. Peak formed around 1350 cm−1 showed the formation of sulfone derivatives of fipronil further proving the degradation of fipronil to its sulfone derivatives.

Gajendiran and Abraham (2017) in fipronil degradation by Aspergillus glaucus strain AJAG1 observed similar bands in FTIR spectra around 1737 and 1271 cm−1 indicating the formation of esters after degradation of fipronil. Control and bacterial-treated samples both include some similar peaks which could be due to the undegraded fipronil. Singh et al. (2021) reviewed the formation of various sulfone derivatives of fipronil after biodegradation and hence provide support to our analysis.

Conclusions

Bacterial strains isolated from fipronil-contaminated environments showed high potential for removal of fipronil (10–400 mg L−1 concentration) with degradation efficiency of ~ 61 to 86% in 13 days. Among all the isolated bacterial species tested for fipronil degradation, Pseudomonas sp. FIP_A4 and Rhodococcus sp. FIP_B3 were found to be the most promising for the biodegradation of fipronil. This conclusion is supported by the observation of their higher values for kinetic parameters such as Vmax and Vmax/Ks that eventually ratified the efficiency of these two isolates for the removal of higher concentrations of fipronil. Furthermore, this conclusion also finds support from identified intermediate metabolites of fipronil in our study during bacteria-mediated degradation. Thus, these isolates can aid in the degradation of fipronil and contribute to the reduction of its harmful effects on the environment and human health. Considering the extensive application of fipronil and its eventual release into the environment, outcomes of such type of studies would be properly utilized in the bioremediation of fipronil-contaminated soil and water. In addition, this study also opens the scope for understanding the mechanistic details of bacterial degradation of fipronil using genomic, proteomic, and metabolomic approaches.

Data availability

Accession numbers (OP317323 to OP317332, and OP482264) of 16S rRNA nucleotide sequences for eleven bacterial isolates used in this study are available in NCBI gene database.

References

Aajoud A, Ravanel P, Tissut M (2003) Fipronil metabolism and dissipation in a simplified aquatic ecosystem. J Agric Food Chem 51(5):1347–1352. https://doi.org/10.1021/jf025843j

Abraham J, Gajendiran A (2019) Biodegradation of fipronil and its metabolite fipronil sulfone by Streptomyces rochei strain AJAG7 and its use in bioremediation of contaminated soil. Pestic Biochem Phys 155:90–100. https://doi.org/10.1016/j.pestbp.2019.01.011

Abraham J, Silambarasan S (2018) Biodegradation of carbendazim by Rhodococcus erythropolis and its plant growth-promoting traits. Biol Environ Proc R Ir Acad 118(2):69–80 (https://muse.jhu.edu/article/809403)

At K, Karthikeyan S (2019) Occurrence and microbial degradation of fipronil residues in tropical highland rhizosphere soils of Kerala. India Soil Sediment Contam 28(4):360–379. https://doi.org/10.1080/15320383.2019.1578336

Bhatt P, Rene ER, Kumar AJ, Gangola S, Kumar G, Sharma A, Zhang W, Chen S (2021) Fipronil degradation kinetics and resource recovery potential of Bacillus sp. strain FA4 isolated from a contaminated agricultural field in Uttarakhand, India. Chemosphere 276:130156. https://doi.org/10.1016/j.chemosphere.2021.130156

Bhatt P, Sharma A, Rene ER, Kumar AJ, Zhang W, Chen S (2020) Bioremediation of fipronil using Bacillus sp. FA3: mechanism, kinetics and resource recovery potential from contaminated environments. J Water Process Eng 39:101712. https://doi.org/10.1016/j.jwpe.2020.101712

Bhatti S, Satyanarayana GNV, Patel DK, Satish A (2019) Bioaccumulation, biotransformation and toxic effect of fipronil in E. coli. Chemosphere 231:207–215. https://doi.org/10.1016/j.chemosphere.2019.05.124

Bobe A, Coste CM, Cooper JF (1997) Factors influencing the adsorption of fipronil on soils. J Agric Food Chem 45:4861–4865. https://doi.org/10.1021/jf970362

Bonmatin JM, Giorio C, Girolami V, Goulson D, Kreutzweiser DP, Krupke C, Liess M, Long E, Marzaro M, Mitchell EA, Noome DA, Simon-Delso N, Tapparo A (2015) Environmental fate and exposure; neonicotinoids and fipronil. Environ Sci Pollut Res 22:35–67. https://doi.org/10.1007/s11356-014-3332-7

Cappelini LT, Alberice JV, Eugênio PF, Pozzi E, Urbaczek AC, Diniz LG, Carrilho EN, Carrilho E, Vieira EM (2018) Burkholderia thailandensis: the main bacteria biodegrading fipronil in fertilized soil with assessment by a QuEChERS/GC-MS method. J Braz Chem Soc 29:1934–1943. https://doi.org/10.21577/0103-5053.20180069

Casida JE, Durkin KA (2013) Neuroactive insecticides: targets, selectivity, resistance, and secondary effects. Annu Rev Entomol 58:99–117. https://doi.org/10.1146/annurev-ento-120811-153645

do Prado CCA, Pereira RM, Durrant LR, Scorza Junior RP, Bonfa MRL (2021) Fipronil biodegradation and metabolization by Bacillus megaterium strain E1. J Chem Technol Biotechnol 97(2):474–481. https://doi.org/10.1002/jctb.6758

Gajendiran A, Abraham J (2017) Biomineralisation of fipronil and its major metabolite, fipronil sulfone, by Aspergillus glaucus strain AJAG1 with enzymes studies and bioformulation. 3 Biotech 7:212. https://doi.org/10.1007/s13205-017-0820-8

Gangola S, Joshi S, Kumar S, Sharma A (2021) Differential analysis of pesticides biodegradation in soil using conventional and high-throughput technology. bioRxiv 2021–06 . https://doi.org/10.1101/2021.06.01.446544

Gautam P, Dubey SK (2022) Biodegradation of imidacloprid: molecular and kinetic analysis. Bioresour Technol 350:126915. https://doi.org/10.1016/j.biortech.2022.126915

Gautam P, Dubey SK (2023) Biodegradation of neonicotinoids: current trends and future prospects. Curr Pollut Rep 1–23. https://doi.org/10.1007/s40726-023-00265-8

Gautam P, Pandey AK, Dubey SK (2023) Multi-omics approach reveals elevated potential of bacteria for biodegradation of imidacloprid. Environ Res 221:115271. https://doi.org/10.1016/j.envres.2023.115271

Gunasekara AS, Truong T, Goh KS, Spurlock F, Tjeerdema RS (2007) Environmental fate and toxicology of fipronil. J Pestic Sci 32:189–199. https://doi.org/10.1584/jpestics.R07-02

He J, Zhang K, Wang L, Du Y, Yang Y, Yuan C (2022) Highly efficient degradation of cypermethrin by a co-culture of Rhodococcus sp. JQ-L and Comamonas sp. A-3. Front Microbiol 13. https://doi.org/10.3389/fmicb.2022.1003820

Holt JG, Krieg NR, Sneath PH, Staley JT, Williams ST (1994) Bergey’s manual of determinative bacteriology, 9th edn. Williams and Wilkins, Baltimore

Jiang HY, Wu HK, Yuan PP, Guo JJ, Wang L, Dai YJ (2022) Biodegradation of sulfoxaflor by Pseudomonas stutzeri CGMCC 22915 and characterization of the nitrile hydratase involved. Int Biodeterior Biodegrad 170:105403. https://doi.org/10.1016/j.ibiod.2022.105403

Kumar R, Singh B, Gupta VK (2012) Biodegradation of fipronil by Paracoccus sp. in different types of soil. Bull Environ Contam Toxicol 88(5):781–787. https://doi.org/10.1007/s00128-012-0578-y

Li C, Zhang J, Wu ZG, Cao L, Yan X, Li SP (2012) Biodegradation of buprofezin by Rhodococcus sp. strain YL-1 isolated from rice field soil. J Agric Food Chem 60(10):2531–2537. https://doi.org/10.1021/jf205185n

Liu X, Liang M, Liu Y, Fan X (2017) Directed evolution and secretory expression of a pyrethroid-hydrolyzing esterase with enhanced catalytic activity and thermostability. Microb Cell Fact 16:81. https://doi.org/10.1186/s12934-017-0698-5

Mandal K, Singh B, Jariyal M, Gupta VK (2013) Microbial degradation of fipronil by Bacillus thuringiensis. Ecotoxicol Environ Saf 93:87–92. https://doi.org/10.1016/j.ecoenv.2013.04.001

Mandal K, Singh B, Jariyal M, Gupta VK (2014) Bioremediation of fipronil by a Bacillus firmus isolate from soil. Chemosphere 101:55–60. https://doi.org/10.1016/j.chemosphere.2013.11.043

Masutti CS, Mermut AR (2007) Degradation of fipronil under laboratory conditions in a tropical soil from Sirinhaém Pernambuco. Brazil J Environ Sci Health B 42(1):33–43. https://doi.org/10.1080/03601230601017981

Maya K, Singh RS, Upadhyay SN, Dubey SK (2011) Kinetic analysis reveals bacterial efficacy for biodegradation of chlorpyrifos and its hydrolyzing metabolite TCP. Process Biochem 46(11):2130–2136. https://doi.org/10.1016/j.procbio.2011.08.012

Mohapatra S, Deepa M, Jagdish GK, Rashmi N, Kumar S, Prakash GS (2010) Fate of fipronil and its metabolites in/on grape leaves, berries and soil under semi arid tropical climatic conditions. Bull Environ Contam Toxicol 84(5):587–591. https://doi.org/10.1007/s00128-010-9965-4

Paliwal R, Uniyal S, Rai JPN (2015) Evaluating the potential of immobilized bacterial consortium for black liquor biodegradation. Environ Sci Pollut Res 22(9):6842–6853. https://doi.org/10.1007/s11356-014-3872-x

Pandey G, Dorrian SJ, Russell RJ, Oakeshott JG (2009) Biotransformation of the neonicotinoid insecticides imidacloprid and thiamethoxam by Pseudomonas sp. 1G. Biochem Biophys Res Commun 380(3):710–714. https://doi.org/10.1016/j.bbrc.2009.01.156

Pang S, Lin Z, Zhang W, Mishra S, Bhatt P, Chen S (2020) Insights into the microbial degradation and biochemical mechanisms of neonicotinoids. Front Microbiol 11:868. https://doi.org/10.3389/fmicb.2020.00868

Phugare SS, Jadhav JP (2015) Biodegradation of acetamiprid by isolated bacterial strain Rhodococcus sp. BCH2 and toxicological analysis of its metabolites in silkworm (Bombax mori). Clean-Soil Air Water 43(2):296–304. https://doi.org/10.3389/fmicb.2020.00868

Pisa LW, Amaral-Rogers V, Belzunces LP, Bonmatin JM, Downs CA, Goulson D, Kreutzweiser DP, Krupke C, Liess M, Mcfield M, Morrissey CA, Noome DA, Settele J, Simon-Delso N, Stark JD, Van Der Sluijs JP, Van Dyck H, Wiemers M (2014) Effects of neonicotinoids and fipronil on non-target invertebrates. Environ Sci Pollut Res 22:68–102. https://doi.org/10.1007/s11356-014-3471-x

Sayi DS, Kumar V, Jijitha P, Sachithanandam V, Narayanan JK (2020) Isolation and molecular identification of pesticide (fipronil) degrading bacteria from mangrove soil. Res J Chem Environ 24:4

Silambarasan S, Vangnai AS (2016) Biodegradation of 4-nitroaniline by plant-growth promoting Acinetobacter sp. AVLB2 and toxicological analysis of its biodegradation metabolites. J Hazard Mater 302:426–436. https://doi.org/10.1016/j.jhazmat.2015.10.010

Singh A, Srivastava N, Dubey SK (2019) Molecular characterization and kinetics of isoprene degrading bacteria. Bioresour Technol 278:51–56. https://doi.org/10.1016/j.biortech.2019.01.057

Singh NS, Sharma R, Singh SK, Singh DK (2021) A comprehensive review of environmental fate and degradation of fipronil and its toxic metabolites. Environ Res 199:111316. https://doi.org/10.1016/j.envres.2021.111316

Subsanguan T, Vangnai AS, Siripattanakul-Ratpukdi S (2020) Aerobic and anoxic degradation and detoxification of profenofos insecticide by Pseudomonas plecoglossicida strain PF1. Ecotoxicol Environ Saf 190:110129. https://doi.org/10.1016/j.ecoenv.2019.110129

Tan H, Cao Y, Tang T, Qian K, Chen WL, Li J (2008) Biodegradation and chiral stability of fipronil in aerobic and flooded paddy soils. Sci Total Environ 407:428–437. https://doi.org/10.1016/j.scitotenv.2008.08.007

Thirumalaiselvan S, Pandey PK, Purushothaman CS (2015) Fipronil degrading bacteria from freshwater environment. J Inland Fish Soc India 47(2):13–19

Tingle CC, Rother JA, Dewhust CF, Lauer S, King WJ (2003) Fipronil: environmental fate, ecotoxicology, and human health concerns. Rev Environ Contam Toxicol 176:1–66. https://doi.org/10.1007/978-1-4899-7283-5_1

Tomlin CDS (2000) The pesticide manual. The British Crop Protection Council, Surrey, pp 413–415

Uniyal S, Paliwal R, Sharma RK, Rai JPN (2016a) Degradation of fipronil by Stenotrophomonas acidaminiphila isolated from rhizospheric soil of Zea mays. 3 Biotech 6(1):1–10. https://doi.org/10.1007/s13205-015-0354-x

Uniyal S, Paliwal R, Verma M, Sharma RK, Rai JPN (2016b) Isolation and characterization of fipronil degrading Acinetobacter calcoaceticus and Acinetobacter oleivorans from rhizospheric zone of Zea mays. Bull Environ Contam Toxicol 96(6):833–838. https://doi.org/10.1007/s00128-016-1795-6

Verma K, Agrawal N, Farooq M, Misra RB, Hans RK (2006) Endosulfan degradation by a Rhodococcus strain isolated from earthworm gut. Ecotoxicol Environ Saf 64(3):377–381. https://doi.org/10.1016/j.ecoenv.2005.05.014

Viana JG, Birolli WG, Porto ALM (2022) Biodegradation of the pesticides bifenthrin and fipronil by Bacillus isolated from orange leaves. Appl Biochem Biotechnol 1–16 . https://doi.org/10.1007/s12010-022-04294-9

Wolfand JM, LeFevre GH, Luthy RG (2016) Metabolization and degradation kinetics of the urban use pesticide fipronil by white rot fungus Trametes versicolor. Environ Sci Process Impacts 18(10):256–1265. https://doi.org/10.1039/C6EM00344C

Yadav M, Srivastva N, Singh RS, Upadhyay SN, Dubey SK (2014) Biodegradation of chlorpyrifos by Pseudomonas sp. in a continuous packed bed bioreactor. Bioresour Technol 165:265–269. https://doi.org/10.1016/j.biortech.2014.01.098

Yang J, Feng Y, Zhan H, Liu J, Yang F, Zhang K, Zhang L, Chen S (2018) Characterization of a pyrethroid-degrading Pseudomonas fulva strain P31 and biochemical degradation pathway of D-phenothrin. Front Microbiol 9:10. https://doi.org/10.3389/fmicb.2018.01003

Zhang Q, Zhang L, Li Z, Zhang L, Li D (2019) Enhancement of fipronil degradation with eliminating its toxicity in a microbial fuel cell and the catabolic versatility of anodic biofilm. Bioresour Technol 290:121723. https://doi.org/10.1016/j.biortech.2019.121723

Acknowledgements

We are thankful to the Advanced Instrumentation Research Facility (AIRF), JNU, New Delhi, India, for GC–MS analysis.

Funding

This research was financially supported by Banaras Hindu University, Varanasi, India, under Institutions of Eminence (IoE) Scheme No. 6031. The Department of Biotechnology (DBT), Government of India, provided financial assistance in the form of Junior Research Fellowship (Ref. DBTHRDPMU/JRF/BET-20/I/2020/AL/183).

Author information

Authors and Affiliations

Contributions

Anjali Jaiswal: experimentation, data collection and analysis, writing — original draft; Animesh Tripathi: data analysis; Suresh K. Dubey: supervision, conceptualization, writing — review and editing, funding acquisition (April 2022–March 2024).

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent for publication

All authors agreed to publish this research (including any individual details, images or videos) in Environmental Science and Pollution Research.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Gerald Thouand

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

11356_2023_29837_MOESM2_ESM.tif

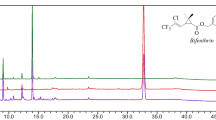

Supplementary file2. FIG S1: GC-MS spectra obtained for biodegradation of fipronil in (a) control sample (b) sample containing strain FIP_A4 and (c) sample containing strain FIP_B3. (TIF 4807 KB)

11356_2023_29837_MOESM3_ESM.tif

Supplementary file3. FIG S2: FTIR spectra obtained for biodegradation of fipronil in (a) control as fipronil (b) degraded sample by strain FIP_A4 (c) degraded sample by strain FIP_B3. (TIF 1739 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jaiswal, A., Tripathi, A. & Dubey, S.K. Biodegradation of fipronil: molecular characterization, degradation kinetics, and metabolites. Environ Sci Pollut Res 30, 106316–106329 (2023). https://doi.org/10.1007/s11356-023-29837-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-29837-3