Abstract

One of the biggest problems the globe is currently experiencing is the availability of safe freshwater for drinking, especially in rural and dry regions. Drinking fresh water is among the basic requirements for surviving all life on Earth, along with food and energy. Rapid economic growth and poverty increase the demand for clean water. There are numerous approaches to getting clean water, and a current popular method is the solar distillation of brine water. Solar distillation converts brine water into fresh, usable water using solar radiation. It is a cheap, non-polluting, and greenhouse method. Various methods are used to enhance the distillate output, for instance, using nanoparticles, adding external devices, changing the design, and coupling the solar still. This paper reviews various research work and articles on different approaches used to enrich the distillate yield of solar still, increasing its efficiency and thermal energy, and decreasing the cost of desalination of brine water. Lastly, it contains challenges and the future scope.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the significant fundamentals in our everyday life is water. It is utilized in our daily life purposes, for example, drinking, washing, cooking, cleaning, etc. Seventy-one percent of the land is concealed with water, whereby 97% of the total H2O on Earth is salty for drinking or irrigation, and 3% is the un-salty water. Out of the 3% fresh water available, 2.997% is sealed in ice caps or glaciers, and just 0.003% is accessible for human utilization (Prajapati et al. 2021). This makes water extremely valuable. In 2017, World Health Organization (WHO) showed that approximately 71% of the world’s population is approx. 5.3 billion people—managed safe drinking water, free from pollution, unlike the 785 million people who could not manage, including 144 million people who depend on surface water. It is approximated that 2 billion people drink polluted water. Polluted water transmits diseases such as polio, diarrhea, cholera, etc., which can lead to death. In the least developed countries, 22% of healthcare facilities have no water service, 22% have no waste management service, and 21% have no sanitation service. Climate change, population growth, and changing consumption patterns are just a couple of factors putting freshwater systems gradually in danger (Sivaku and Jidhesh 2016).

As the population grows, the demand for freshwater increases as well simultaneously. Therefore, renewable energy is used to desalinate seawater. In the Kingdom of Saudi Arabia (KSA) 2200 kWh of thermal solar energy per square meter of the terrestrial area is utilized annually (Alawaji 2001; Danish et al. 2019). To improve potable water supply in the Kingdom of Saudi Arabia, a combination of two renewable energy sources, geothermal and solar energy, is used in distillation to improve supply by increasing vacuum pressure, which provides a higher ambient temperature and, as a result, increases the output productivity of the solar still (Danish et al. 2019). Another renewable energy is wind; as wind flow increases, it impacts the distillate productivity by accumulating the temperature difference between the inner surface of glass and water (El-Sebaii 2000; Sarkar et al. 2017).

Furthermore, Soliman found that when the ambient temperature is low, the wind speed increases, increasing the temperature gradient between the still glass cover and water. This increases heat transfer loss at a greater rate than increasing the degree of evaporation. This concluded that the still should be placed at places with high summertime and low wind during wintertime (Sarkar et al. 2017; Soliman 1972).

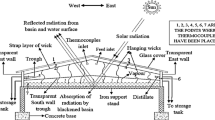

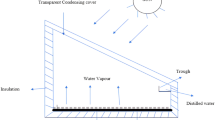

Solar energy is used to distillate sea water in coastal areas, islands, and salty wells in remote towns and villages. This is done by distillation, whereby the seawater evaporates as the sun’s rays heat the glass cover. The hot vapor rises and is collected on the glass surface due to condensation (Fig. 1). Consequently, salt and other impurities are removed. Pure water is collected (Gupta et al. 2013). It is a cheap portable water supply in small areas (Al-Hassan and Algarni 2013).

Simple solar water distillation process (Gupta et al. 2013)

Solar distillation is used to distill salty and underground H2O as potable water. The operating conditions can influence the output of the solar distillate, the design of the solar still, and the surrounding climate (Gupta et al. 2013). The device used for solar distillation is termed a solar still (Kalita et al. 2016) (Fig. 1). It is grouped as passive and active still. Passive still is a designed basin with no extra heating device such as a heater or boiler, and heated-up water from other sources is not flown. Active still has heating devices and uses heated-up water (Sarkar et al. 2017).

Solar energy is an emerging technology for the desalination of brine with great benefits, such as saving a high amount of energy as it is available in large quantities at zero energy cost and a small footprint. The main drawback is the high capital cost to capture the low-density solar radiation and convert it to poor-quality solar thermal energy, resulting in poor desalination efficiency. While designing a solar distillation system, it is necessary to ensure high energy efficiency to minimize thermal losses and irreversibility (Sethi and Dwivedi 2013).

This paper reviews various research work and review articles on different approaches used that can be implemented to enrich the distillate product of a tubular solar still. The following are the techniques used by various researchers to improve distillate output: heat exchanger (Alim and others 2013; Panchal et al. 2019; Panchal and Patel 2018; Panchal and Shah 2012), design, fabrication, and performance (Sethi and Dwivedi 2013), thermal modeling and efficiency (Gupta et al. 2013), pyramid solar still (Kalaivani et al. 2012), parabolic concentrator assisted solar desalting system (Arunkumar et al. 2016), single basin solar still coupled with evacuated tubes (Sampathkumar et al. 2011), climatic and design parameters effects on the productivity of solar stills (Ithape et al. 2017), investigation of a poly-energy multi-effect still (Abdessemed et al. 2019), flake graphite nanoparticles and phase change material (Rai and Sachan 2015), film cooling on solar still performance (Sharshir et al. 2017) and nanofluid (Balasubramanian and Esakki 2019). In addition, this paper will guide the reader to decide the correct parameters for optimal productivity and learn the future scope and challenges encountered while enlarging the still yield (Tables 1 and 2).

The remaining parts of this paper are structured as described as follows: the “Introduction to solar distillate” section covers the introduction to solar distillate, including ways to enhance the productivity output of solar still. The “Challenges and future scope” section gives future trends and challenges, whereas the “Conclusion” section concludes the paper.

Introduction to solar distillate

Solar distillation is categorized into two stills, i.e., the active and passive still (Sampathkumar et al. 2010). The difference between these two solar stills is that active solar still has a great distillate product yield than passive solar still, and active solar still uses the help of external heating devices such as a heater and boiler. In contrast, passive solar still does not use those devices.

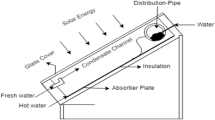

A tubular solar still (TSS) consists of a clear cylindrical cover that can be black in color and semicircular shaped. The salty water is fed into the basin for distillation. As the sun’s rays heat the water through the transparent cover, it is evaporated and condensed on the innermost external of the tubular cover, discharging latent heat of vaporization. Thanks to gravity, the condensed vapor goes to the bottom and is collected by a furnished pipe at the lower end of the tubular cover (Panchal et al. 2019).

It consists of an absorber plate that absorbs solar radiation rays passing over the glazing and transferring the heat to water by convection. It can be made of materials such as copper, aluminum, and steel. An insulator such as rice husk, glass wool, polystyrene, and foam prevents heat loss. Sealant material such as silicone rubber and M-seal is used to prevent leakage.

Ways to enhance the productivity output of solar still

Some of the ways that can be used to enhance the distillate output of tubular solar still are:

Material of construction

The glazing material commonly used is glass, as it can transmit ≥ 90% of the incident short wave radiation and heat radiation of wavelength range of 5–50 μm, which is emitted by absorber plate. Ismail researched the effect of plastic film as a glazing material. The plastic cover was a hemispherical dome in shape with an absorptivity of 0.9 and a transmissivity of 0.8. A glass cover of 3–4mm thickness is positioned at a slope of 15°. This acts as a dielectric material in order to reduce 50% of reflectivity (Kalita et al. 2016).

Varol and Yazar (1996) investigated on modification of glass cover by coating a layer of SnO2 on a glass composed of Fe2O3 of 4mm thickness with 1*1 m areas, inclined at 15° from the x-axis, and 96% transmissivity. The coated layer was observed to be trapped in infrared radiation and transmitted visible solar radiation. This increases the brackish water temperature and enhances productivity.

In Bangladesh, Begum et al. (2018) covered the solar still with a 200-μm-thick transparent PVC sheet inclined at 13°. A black cotton towel was attached to the PVC sheet to ensure a large surface area for water evaporation. This is done by soaking the towel in saline water. The towel traps the heat and then increases the temperature. The production increased by 42%, but the results were very disappointing as the PVC gave less amount of distillate output when compared to the glass cover.

Angle of glass cover

Velmurugna et al. (2008) claimed that the distillation output could be enhanced if the latitude of the place where the experiment is equal to performing the glass cover inclination (Kalita et al. 2016; Velmurugan et al. 2008). When the solar intensity is high, maximum sun rays pass through the glass cover, evaporating more brine. This enhances the output with a glass of 99.64% efficiency. In Iraq, Azooz and Younis (2016) experimented with the effect of inkling the glass cover. They obtained maximum production at 20 and 25°; if the angle was increased, for instance, 30°, the production would immediately decrease. This setup was partially affected by temperature and wind (Azooz and Younis 2016).

Water depth

In Delhi, Sanjeev Kumar investigated the effect of water depth at different temperature conditions. It was observed that at noon, there was a supreme yield of 3.34 kg/(m2/h) from the lower basin due to the high temperature of the water, which was about 95 °C, unlike the upper basin where the water depth increased. The overall water temperature would be decreased. This results in a low evaporation rate, increasing the thermal efficiency and yield (Panchal and Patel 2018).

Yadav (1991) also found out that as the velocity of the flow rises, the thermal capacity of water mass being fed into the basin of the solar still increases. Due to this, the water temperature decreases, reducing the evaporation rate. The collector length and flow velocity rise, the distillate output increases and decreases, respectively (Panchal et al. 2019; Yadav 1991). Badran and Al-Tahaineh (2005) concluded that productivity decreased as the depth of the water increased, which was directly proportional to the sun’s rays on active solar still.

Addition of external devices

Kianifar and others (2012) experimented with the evaporation rate on an active system with a small fan and in a passive condition with no fan on different seasons and depths. It was concluded that the active system resulted in 15–20% productivity growth of pure water. In India, Bhaskar and Rai (2018) experimented with the effect of a fan inside the still. This was done during winter in both passive and active still. The passive still showed positive results with 133% exergy efficiency, while the active still had a 52% increase in output.

Arunkumar et al. (2012) investigated different solar still designs in India. The tubular solar coupled with a pyramid solar still provided maximum yield because of the concentrator effect. A parabolic-shaped concentrator can concentrate the incident radiation and focus it on the receiver. This increases the temperature and the evaporation rate, enhancing productivity by 18%. Rajesh et al. (2009) investigated the effect of a flat plate collector on basin solar still. The basin and the collector were connected, and the measurements were taken for 12 h in daylight. This combination resulted in a 25–50% increase in yield.

Hamdan et al. (1999) tried increasing the surface area of brine by keeping loofa cut into cubes in a basin solar still. This upturns the evaporation rate and productivity by 273% (Abeetha et al. 2017; Hamdan et al. 1999) Addition of fins (Kalita et al. 2016) increases the amount of area, exposing the saline water to the sun’s rays, and hence increases the output. Velmurugan et al. (2008) research enhance the output by using a sponge piece (an absorbing material) with fins of equal size in a wick-type solar still. The fins were placed at the bottom, and the purpose of the sponge was to provide more evaporation rate (Udhayabharathi and others 2015). Hence, the output increased by 45.5%.

Pramod et al. (2018) investigated the influence of using a solar still alone, attached with evacuated tubes, and still coupled with evacuated tubes and heat pipe, provided that the still is a pyramid type with a 1 m2 basin area. A solar still is painted with black paint. A graph of water temperature vs. time was plotted (Fig. 2). The still coupled with evacuated heat pipes showed the best result; it had an average solar radiation flux of 1335 W/m2 and 33.02% thermal efficiency. In order to attain maximum daily yield, ten evacuated tubes, if solar still can be used.

Water temperature with time (Pramod et al. 2018)

Tanaka and Nakatake (2009) researched the outcome of using a raised-wick solar still with a flat-plate external reflector. When the reflector was inclined, the productivity increased by 15–27%, unlike without inclination (Fig. 3) (Dhahad et al. 2017). Using internal and external reflectors can improve productivity by 125% (Khan et al. 2018).

Tilted solar still with external reflector (Dhahad et al. 2017)

In Bhopal, India, Verma and Varshney (2017) experimented with the effect of black cloth with an internal reflector. It was used to reflect sun rays onto the black cloth. The experiment was conducted with and without the absorber. It was concluded that the production with an absorber was 2.42 times that without an absorber at a temperature of 48–51 °C.

In India, Bidwaik et al. (2019) examined the impact of using a magnifying lens in distillation. The lens was placed at the bottom end of the still under atmospheric conditions. It was found that productivity increased by 43.67% (Bidwaik et al. 2019).

Addition of nanoparticles

Nanoparticles enhance the productivity of solar still. At night, there is low radiation; therefore, nanofluid is used, as it can absorb energy and releases it when needed by the system. Al2O3 nanofluid is kept in a water basin because of its heat storage capacity; the convective heat transfer rate improves, and productivity increases (Parikh 2018).

Sain and Kumawat (2015) investigated the effect of aluminum oxide nanoparticles with black paint in Jaipur, India. The use of the paint is to absorb solar radiation. The nanoparticle, with the size of 50–100 nm, was mixed with black paint and glazed at the basin. The depth of water was 0.01 m. The black paint absorbed the sun’s rays, increasing the thermal efficiency and distillate output by 38% (Sain and Kumawat 2015).

Kabeel et al. (2017) suggested mixing cuprous oxide (CuO) nanoparticles with black pai to enhance the heat transfer rate, increasing the saline water temperature. This mixture is kept on top of the absorber plate. The distillate was boosted by 16–25% (Kabeel et al. 2017). Gupta et al. (2017) inspected the effect of water sprinklers with nanoparticles in Jaipur, India. The still was kept facing toward the sun's direction, and the CuO nanoparticle was mixed with the salty water. The purpose of the sprinkler was to cool the glass surface at a certain time with 0.0001 kg/s. The increase in productivity was 54.54%, with 34% efficiency (Gupta et al. 2017).

Challenges and future scope

Solar still can be costly at the start of the setup, depending on the solar radiation (Kapnichor 2017). Different configurations of the still can help control and prevent pollution and produce clean water that society can use. With different techniques and configurations of the still, there are challenges faced. The major challenge is that some heat on the glass cover is transferred to the atmosphere when the wind blows. Hence, the still cools faster, and the productivity starts to decrease.

Nanofluid can enhance the distillate output because of its unique properties like high solar intensity absorptivity and thermal conductivity. It increases the efficiency by 29% if, for instance, a violet dye is used. The nanofluids that can be considered are aluminum oxide, tine oxide, and zinc oxide (Elango et al. 2015; Parikh 2018). It has unique properties and high efficiency, making it suitable for future use.

Ranjan et al. (2016) calculated the economic viability of solar distillation based on the equivalent cost of environmental deprivation. So far, the technologies used to distillate water are not polluting the environment; they save high energy and can be very reliable (Ranjan and Kaushik 2014). They estimated if the efficiency is 60%, then water desalination can cost approximately US $0.103–0.017/L, and if the equipment maintenance is high, it could last for more years.

Conclusion

Many factors affect the performance of the output, from construction to operation. In order to enhance the distillate output, there are various ways to do that. However, the best method is the one with high productivity and efficiency and a reasonable economic value. Some of the ways to enhance the distillate can be by using a suitable glazing material; the best glazing material from our observation is glass, ensuring that the glass cover is inclined at the best possible angle, using low water depth so that the evaporation rate can increase, using external devices such as a fan (the fan is used to raise the cooling rate of external surfaces of the glass cover in order to increase the condensation rate of vapors and, as a result, increase the amount of distilled water that is produced), which can improve the productivity by 15–20%. Different nanoparticles such as Al2O3 or CuO can be mixed with either black paint or kept in the basin without mixing it with any material to enhance the output. Making sure it has the right layout, including reflectors where needed and absorbing materials like black cloth or using a magnifying lens to focus the sun’s rays on a specific spot are all important aspects of effective design.

Data availability

All relevant data and material are presented in the main paper.

References

Abdessemed A, Boubekeur I, Boublai N, Bougriou C (2019) Experimental investigation of a poly-energy multi-effect still in Algeria. Iwaponline.Com. https://doi.org/10.2166/ws.2018.143

Abeetha SM et al (2017) A review on distillate productivity enhancement techniques in the single basin solar still. J Adv Res Dynam Control Sys 9(2):898–924

Alawaji SH (2001) Evaluation of solar energy research and its applications in Saudi Arabia - 20 years of experience. Renew Sust Energ Rev 5(1):59–77. https://doi.org/10.1016/S1364-0321(00)00006-X

Al-hassan GA, Algarni SA (2013) Exploring of water distillation by single solar still basins. Am J Clim Chang 2:57–61. https://doi.org/10.4236/ajcc.2013.21006

Alim MA et al (2013) Analyses of entropy generation and pressure drop for a conventional flat plate solar collector using different types of metal oxide nanofluids. In. Energ Buildings 66, B. V:289–296. https://doi.org/10.1016/j.enbuild.2013.07.027

Arunkumar T, Velraj R et al (2016) Effect of parabolic solar energy collectors for water distillation. Desalin Water Treat 57(45):21234–21242. https://doi.org/10.1080/19443994.2015.1119746

Arunkumar T, Vinothkumar K et al (2012) Experimental study on various solar still designs. ISRN Renewable Energy 2012:1–10. https://doi.org/10.5402/2012/569381

Azooz AA, Younis GG (2016) Effect of glass inclination angle on solar still performance. J Renewable Sustain Energy 8:3. https://doi.org/10.1063/1.4948625

Badran OO, Al-Tahaineh HA (2005) The effect of coupling a flat-plate collector on the solar still productivity. Desalination 183(1):137–142. https://doi.org/10.1016/j.desal.2005.02.046

Balasubramanian M, Esakki B (2019) Investigational study on fresh water improvement in conventional solar still with PV submerged in nanofluid. Int J Mech Eng Technol 10(2):1331–1340

Begum HA et al (2018) Effect of top cover material on productivity of solar distillation unit. Bangladesh JMed Phys 9(1):11–16. https://doi.org/10.3329/bjmp.v9i1.37303

Bhaskar N, Rai AK (2018) Thermal investigation of a tubular solar still. Int J Mechl Eng Technol 9(1):356–362

Bidwaik AS, Pasi BN, Shaikh SB (2019) Design, modification and comparative study of a solar still to enhance its efficiency by using external active element. Int J Adv Eng Res Appl 5(01):34–40. https://doi.org/10.46593/ijaera.2019.v05i01.004

Danish SN, El-Leathy A, Alata M, Al-Ansary H (2019) Enhancing solar still performance using vacuum pump and geothermal energy. Energies 12(3):1–13. https://doi.org/10.3390/en12030539

Dhahad HA et al (2017) Review on the important methods used to enhance the productivity of the solar still. Int J Sci Eng Res 8(7):19–24

Elango T, Kannan A, Desalination KM (2015). Performance study on single basin single slope solar still with different water nanofluids. Elsevier. https://www.sciencedirect.com/science/article/pii/S0011916415000089. Accessed 9 Jan 2023

El-Sebaii AA (2000) Effect of wind speed on some designs of solar stills. Energy Convers Manag 41(6):523–538. https://doi.org/10.1016/S0196-8904(99)00119-3

Gupta B, Kumar A et al (2017) Experimental investigation on modified solar still using nanoparticles and water sprinkler attachment. Front Mater 4:1–7. https://doi.org/10.3389/fmats.2017.00023

Gupta B, Mandraha TK et al (2013) Thermal modeling and efficiency of solar water distillation: a review. Am J Eng Res (AJER) 2(12):203–213

Haddad Z, Chaker A, Desalination AR (2017). Improving the basin type solar still performances using a vertical rotating wick. Elsevier. https://www.sciencedirect.com/science/article/pii/S0011916416317702. Accessed 11 Jan 2023

Hamdan MA, Ali B, Toronto J, Hamdan MA, Musa AM, Jubran BA (1999) Performance of solar still under Jordanian climate. Elsevier. https://doi.org/10.1016/S0196-8904(98)00134-4

Ithape PK et al (2017) Climatic and design parameters effects on the productivity of solar stills: a review. Int J Curr Eng Sci Res, No 7:17–23. https://doi.org/10.21276/ijcesr

Kabeel AE et al (2017) Augmentation of a solar still distillate yield via absorber plate coated with black nanoparticles. Alex Eng J 56(4):433–438. https://doi.org/10.1016/j.aej.2017.08.014

Kalaivani S et al (2012) Experimental behaviour of a pyramid type solar still coupled and decoupled to an electrical temperature controller. Ijcrr 4:63–76

Kalita P et al (2016) A review on recent developments in solar distillation units. Sadhana - Acad Proc Eng Sci 41(2):203–223. https://doi.org/10.1007/s12046-015-0445-8

Kapnichor YS (2017) A review on solar still water purification. Int J Innov Res Sci Technol 3:59–63

Khan MA, Khan A et al (2018) Performance & analysis and optimization of stepped type solar still (a review). Int J Eng Sci Res Technol 7(3):69–74

Kianifar A et al. (2012) Exergy and economic analysis of a pyramid-shaped solar water purification system: active and passive cases. Energy, 38, 1, Ltd (31–36). https://doi.org/10.1016/j.energy.2011.12.046

Morad M, El-Maghawry H, Desalination KW (2015) Improving the double slope solar still performance by using flat-plate solar collector and cooling glass cover. Elsevier. https://www.sciencedirect.com/science/article/pii/S0011916415300011. Accessed 15 Jan 2023

Muraleedharan M, Singh H, Udayakumar M, Suresh S, Singh H, Muraleedharan MM (2019) Modified active solar distillation system employing directly absorbing Therminol 55–Al2O3 nano heat transfer fluid and Fresnel lens concentrator. Elsevier. https://www.sciencedirect.com/science/article/pii/S0011916418316369

Panchal H, Patel N et al (2017) Various techniques for improvement in distillate output from active solar still: a review. Int J Ambient Energy 38(2):209–222. https://doi.org/10.1080/01430750.2015.1076518

Panchal HN, Patel N (2018) ANSYS CFD and experimental comparison of various parameters of a solar still. Int J Ambient Energy 39(6):551–557. https://doi.org/10.1080/01430750.2017.1318785

Panchal H, Sadasivuni KK et al (2019) Various techniques to enhance distillate output of tubular solar still: a review. Groundw Sustain Dev 9, July, B. V:100268. https://doi.org/10.1016/j.gsd.2019.100268

Panchal HN, Shah PK (2012) Performance improvement of solar stills via experimental investigation. Int J Advanced Des Manuf Technol 5(5):19–23

Parikh R (2018) Solar distillation system with nano particle: a review. J Energy Manag 3:29–34

Prajapati M, Shah M, Soni B, Parikh S, Sircar A, Balchandani S, Thakore S, Tala M (2021) Geothermal-solar integrated groundwater desalination system: current status and future perspective. Groundw Sustain Dev 12:100506. https://doi.org/10.1016/J.GSD.2020.100506

Pramod BVN et al (2018) Performance analysis of a solar still coupled with evacuated heat pipes. IOP Conf Series: Mater Sci Eng 310:1. https://doi.org/10.1088/1757-899X/310/1/012149

Rajesh AM, Bharath KN (2009) Solar still coupled with solar collector and storage tank. Arxiv Org. https://arxiv.org/abs/1002.0049. Accessed 19 Jan 2023

Rai AK, Sachan V (2015) Experimental study of a single basin solar still with phase change material. IJMET 6(1):42–46

Ranjan KR et al (2016) Energy and exergy analysis of passive solar distillation systems. Int J Low-Carbon Technol 11(2):211–221. https://doi.org/10.1093/ijlct/ctt069

Ranjan KR, Kaushik SC (2014) Economic feasibility evaluation of solar distillation systems based on the equivalent cost of environmental degradation and high-grade energy savings. Int J Low-Carbon Technol 11(1):8–15. https://doi.org/10.1093/ijlct/ctt048

Rashidi S, Rahbar N, Valipour MS, Esfahani JA (2018) Enhancement of solar still by reticular porous media: experimental investigation with exergy and economic analysis. Elsevier. https://www.sciencedirect.com/science/article/pii/S1359431117332957. Accessed 20 Jan 2023

Sain MK, Kumawat G (2015) Performance enhancement of single slope solar still using nano- particles mixed black paint in one hour and initial temperature of water of two continues observations in one hour ( o C) E evap energy used to evaporate water (MJ) E i energy input, in MJ E. An Int J (ANTJ) Adv Nanosci Technol An Int J (ANTJ) 11(11):55–65

Sampathkumar K, Arjunan T, v, Pitchandi, P., & others. (2010) Active solar distillation-a detailed review. Renew Sust Energ Rev 14(6):1503–1526. https://doi.org/10.1016/j.rser.2010.01.023

Sampathkumar K, Arjunan T, v, & Senthilkumar, P. (2011) Single basin solar still coupled with evacuated tubes - thermal modeling and experimental validation. Int Energy J 12(1):53–66

Sarkar Md NI et al. (2017) A review of optimum parameter values of a passive solar still and a design for Southern Bangladesh. In Renewables: Wind, Water, and Solar, 4, 1, Singapore (1–13). https://doi.org/10.1186/s40807-017-0038-8

Sethi AK, Dwivedi VK (2013) Design , fabrication and performance evaluation of active solar still under forced circulation mode. Res J Eng Sci 2(6):6–12. https://doi.org/10.5383/ijtee.06.01.005

Sharshir SW et al (2017) The effects of flake graphite nanoparticles, phase change material, and film cooling on the solar still performance. In. Appl Energy 191, Ltd:358–366. https://doi.org/10.1016/j.apenergy.2017.01.067

Sivaku R, Jidhesh P (2016) Improvement techniques in performance and productivity of solar stills. International Journal of Engineering Science and Computing 6(9):2441–2450

Soliman SH (1972) Effect of wind on solar distillation. Sol Energy 13(4):403–415. https://doi.org/10.1016/0038-092X(72)90006-0

Tanaka H, Nakatake Y (2009) Increase in distillate productivity by inclining the flat plate external reflector of a tilted-wick solar still in winter. Sol Energy 83(6):785–789 https://doi.org/10.1016/j.solener.2008.12.001

Udhayabharathi K et al (2015) Performance analysis of wick type solar stills. Int J Chem Sci 13(3):1109–1122

Varol HS, Yazar A (1996) A hybrid high efficiency single-basin solar still. Int J Energy Res 20(6):541–546. https://doi.org/10.1002/(SICI)1099-114X(199606)20:6<541::AID-ER172>3.0.CO;2-0

Velmurugan V et al (2008) Single basin solar still with fin for enhancing productivity. Energy Convers Manag 49(10):2602–2608. https://doi.org/10.1016/j.enconman.2008.05.010

Verma S, Varshney R (2017) Experimental evaluation of a solar still with absorber material. International Journal of Research and Scientific Innovation (IJRSI) 4(5):30–33

Yadav YP (1991) Performance analysis of a solar still coupled to a heat exchanger. Desalination 82:1–3. https://doi.org/10.1016/0011-9164(91)85188-Z

Acknowledgements

The authors are grateful to Sahyadri School and the Department of Chemical Engineering, School of Technology, Pandit Deendayal Petroleum University for the permission to publish this research.

Author information

Authors and Affiliations

Contributions

All the authors make a substantial contribution to this manuscript. MAG, MS, KY, MP, and MAS participated in drafting the manuscript. MAG and MAS wrote the main manuscript. All the authors discussed the results and implications of the manuscript at all stages.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gulamhussein, M.A., Shah, M., Yadav, K. et al. A comprehensive and systematic study on the techniques used for augmenting the performance of a solar still distillate yield. Environ Sci Pollut Res 30, 57271–57278 (2023). https://doi.org/10.1007/s11356-023-26751-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-26751-6