Abstract

Microbial electrolysis cells (MECs) are considered as green technologies for H2 production with simultaneously wastewater treatment. Low H2 recovery and production rate are two key bottlenecks of MECs fed with real H2 fermentation effluent of biomass wastes. This work established a 1 L cylindrical single chamber MEC and enriched electroactive anodic biofilms from cow dung compost to overcome the bottlenecks. These MEC components (platinum-coated cylindrical titanium mesh cathode and cylindrical graphite felt anode) were arranged in a concentric configuration. A high H2 production rate of 6.26 ± 0.23 L L−1 day−1 with H2 yield of 5.75 ± 0.16 L H2 L−1 fermentation effluent was achieved at 0.8 V. The degradation of acetate and butyrate (main components of H2 fermentation effluent) could reach to 95.3 ± 2.1% and 78.4 ± 3.6%, respectively. The microbial community analysis for anode showed the abundance of Geobacter (22.6%), Syntrophomonas (8.7%), and Dysgonomonas (6.3%) which are responsible to complex substrate oxidation, electrical current generation, and H2 production. These results prove the feasibility of cylindrical single-chamber MEC for high H2 production rate and high acetate and butyrate removal from H2 fermentation effluent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

H2 as one promising green and clean energy carrier has attracted more attention in recent years (Song et al. 2014; Wang and Yin 2019). Meanwhile, the global interests in optimizing sustainable H2 production are growing. In particular, H2 production from agricultural wastes (e.g., corn stalk, wheat straw, and grass) by biological method exhibits great advantages due to the agricultural wastes that are abundant and renewable (Li et al. 2020; Tian et al. 2019; Wang and Yin 2019). Among all the biological methods for H2 generation, the coupling of dark-fermentation process and MEC has been considered as one of highly promising methods, due to its low costs and high H2 production yield (Desmond-Le Quemener et al. 2019; Gao et al. 2020; Khongkliang et al. 2019; Marone et al. 2017). In dark fermentation process, H2 production always accompanied with the generation of metabolic end products, such as acetate, butyrate, propionate, and alcohols, which can be used as substrates in MEC for additional H2 production (Rousseau et al. 2020; Zhang et al. 2019). The coupled process could significantly increase the overall production of H2 from agricultural wastes (Marone et al. 2017). For example, the overall H2 production yield of corn stalk in coupled process could be increased up to 4 times when compared to dark fermentation process alone (Li et al. 2014, 2017).

Numerous previous studies have reported different MEC structures to improve the performance of MEC and reduce the capital cost (Desmond-Le Quemener et al. 2019; Huang et al. 2019; Zhao et al. 2020; Priyadarshini et al. 2021). Normal MEC structures were divided into single-chamber and dual-chamber configurations. The use of double chambers with an ion exchange membrane or proton exchange membrane would increase the capital costs and limit MEC reactor scaling-up and commercialization application (Aiken et al. 2019; Pang et al. 2020). Single-chamber MECs without membrane are more attractive for scale-up due to high H2 production rate and low capital costs (Huang et al. 2019; Guo et al. 2022). Recently, some studies also demonstrated that the cylindrical configuration up-scaled MECs have more great potential for enhancing H2 production rate; this type of MEC has some advantages, such as simplified system design, low internal resistance, high current density, low operational costs, and easy maintenance and construction (Guo et al. 2017; Huang et al. 2019). However, high H2 recovery and production rate in up-scaled MECs were only obtained using acetate as substrate; H2 production from complex feedstocks (e.g., H2 fermentation effluent or hydrolysate of biomass wastes) still is challenged. For example, the H2 production rate could reach to 7.01 m3 m−3 day−1 in a 1-L up-scaled cylindrical configuration MECs using sodium acetate as substrate (Guo et al. 2017), while the highest H2 production rate only was 0.71 m3 m−3 day−1 feeding with lignocellulosic hydrolysate in a 10-L up-scaled single chamber MECs (Wang et al. 2021).

Moreover, the performance of MEC also is related to the enrichment strategy of electrogenic bacteria on the anode (Li et al. 2017; Ullery and Logan 2015); most of MEC anodes were enriched with electrogenic bacteria using sodium acetate as sole carbon source in MFC mode (Jatoi et al. 2021); acetate could be degraded completely in MECs. However, most of the butyrate could not be removed and produced H2 efficiently (Kadier et al. 2014; Yang et al. 2015). For example, the maximum H2 production rate could reach to 3.43 ± 0.12 m3 m−3 day−1 using corn stalk fermentation effluent as substrate; almost of all the acetate can be removed, while the butyrate degradation rate was only 4–6% (Li et al. 2014). When using complex substrate (e.g., fermentation effluent and butyrate) to acclimate the anode biofilm of MECs, the degradation of acetate and butyrate both could be improved efficiently (Yang et al. 2015; Li et al. 2017). For example, Popov et al. (2016) found that the butyrate-acclimated bioanode had obvious advantage for H2 production when using acetate and butyrate as mixture substrate. It is very important to enhance the conversion of butyrate to H2 by electrogenic bacteria in MEC, because many complex H2 fermentation effluents not only contain acetate, but also contain a large number of butyrate (Kumar et al. 2016; Marone et al. 2017).

In this study, the anode biofilm was enriched successfully using H2 fermentation effluent of corn stalk as substrate in MEC mode; the potential of using volatile fatty acids (VFAs) and ethanol mixtures for H2 production was studied. The key operating parameters of MECs were optimized in batch experiments. The overall COD removal and degradation of different VFAs and ethanol also were studied for further improvement. Moreover, microbial community characteristics of anode biofilm were analyzed. Additional multiple cycles were also tested to investigate the stability of operation and to better understand how operating impacts performance for commercial applications.

Materials and methods

Seed microorganism of MECs

Cow dung compost was used as the inoculum of electrogenic bacteria, which was obtained from the biogas plant (Henan Agricultural University, Henan province, China). Firstly, the cow dung compost was pretreated by thermally treatment (100℃, 10 min) to inhibit the activity of methanogens. Thereafter, the pretreated cow dung compost was pre-incubated with medium in a 1-L batch-stirred anaerobic reactor at 36 ± 1℃ for 12 h, which was used as the inoculum of MEC anode biofilm; the medium contains the following: glucose, 10 g L−1; peptone, 2 g L−1; yeast, 2 g L−1; NH4HCO3, 1 g L−1; KH2PO4, 0.2 g L−1; and 10 mL mineral salt solution (contained NH4HCO3, 2 g L−1; KH2PO4, 1 g L−1; MgSO4·7H2O, 0.1 g L−1; NaCl, 0.01 g L−1; Na2MoO4·2H2O, 0.01 g L−1; CaCl2·2H2O, 0.01 g L−1; MnSO4·7H2O, 0.02 g L−1; FeCl2, 0.03 g L−1).

Characteristics of H2 fermentation effluent used in MECs

The H2 fermentation effluent was obtained from one 5-L anaerobic reactor; the reactor was operated as previous approach (Li et al. 2014). In order to remove fermentation residue and microorganisms, the fermentation effluent was pretreated by centrifuging at 13,000 rpm for 10 min before using as feedstock in MEC for H2 production. The centrifuged fermentation effluent was mainly including acetate 2550 ± 28 mg L−1, butyrate 2330 ± 25 mg L−1, propionate 137 ± 18 mg L−1, and ethanol 210 ± 19 mg L−1, the COD was 8740 ± 50 mg L−1.

MEC reactor construction

The cylindrical single-chamber MECs (10 cm outer diameter, 9.4 cm inner diameter, and 15 cm height) was constructed with working volume of 1 L using acryl glass (see Fig. 1). A total of 0.5 cm thick of cylindrical graphite felt (8 cm diameter and 10 cm length) was used for anode. The cathode was made of cylindrical Ti mesh (4 cm diameter and 10 cm length) coated with 0.5 mg Pt cm−2 (20 wt% Pt/C, JM). Titanium wires were used to connect the anode and cathode. The anode and cathode were connected to battery test system (Neware Battery Testing System TC53, China) that was used as power supply (PS) to supply the applied voltage and record the current of MECs.

MEC start-up and running

The anode was acclimated in MEC mode using the corn stalk fermentation effluent from the anaerobic bioreactor without centrifugation as inoculum; the MEC was inoculated with 1:1 (volume/volume) mixture of fermentation effluent and buffer solution, which contains the following: NH4Cl, 0.31 g L−1; KCl, 0.13 g L−1; NaH2PO4·2H2O, 2.27 g L−1; Na2HPO4·12H2O, 11.54 g L−1; trace mineral, 12.5 mL L−1; vitamin, 12.5 mL L−1. An applied voltage of 0.5 V was supplied to start up the MEC. When the electrogenic bacteria were acclimated on the anode surface, the inoculum was omitted. The MECs was feed with 1 L centrifuged H2 fermentation effluent, which added with trace mineral 12.5 mL L−1, vitamin 12.5 mL L−1, NH4Cl 0.62 g L−1, KCl 0.26 g L−1, NaH2PO4·2H2O 5.54 g L−1, and Na2HPO4·12H2O 23.08 g L−1 (equivalent to 100 mM phosphate buffer) to control the pH at 6.8 ± 0.1; the conductivity is 18.32 ms cm−1. The temperature of effluent in MEC was controlled at 36 ± 1℃. Meantime, the MECs was purged with N2 for 15 min to keep an anaerobic condition. The MECs was operated at least three times at the same condition, and the values of current density and H2 production rate in MEC were also consistent over triplicate cycles.

Analytical methods

The concentration of H2, CH4, and CO2 in MEC was detected using a gas chromatograph (GC, Agilent 5890), which was equipped with thermal conductivity detector (TCD) and stainless column packed with Porapak Q (80/100 mesh). The concentration of acetate, butyrate, propionate, and alcohols was detected using GC with a flame ionization detector (FID). The volume of H2 was calculated by the following Eq. (1):

where V is the total H2 volume at the time (i); Vi1 is the volume of headspace of the MECs and xi1 is the concentration of H2; Vi2 is the gas volume discharged from the MECs; and xi2 is the concentration of H2.

The H2 production rate was calculated by Eq. (2):

The t is the time of H2 production, and V0 is the working volume of the MECs.

The Coulombic efficiency (CE) was calculated based on the removal of the VFAs and alcohols; the cathodic H2 recovery (rcat), overall H2 recovery (RH2), and the energy efficiency (ηE) were calculated following previous report (Li et al. 2014). The volumetric current density (A m−3) was calculated based on the working volume of MEC; the projected current density (A m−2) was calculated based on surface area of cathode. The COD concentration of fermentation effluent was measured and calculated as the standard methods (American Public Health Association, AWWA 1998).

Anode microbial community analysis

The anode biofilm sample of MECs was collected when the MEC running stability for community characteristic analysis via high-throughput sequencing of 16S ribosomal RNA gene amplicons. The DNA was extracted in triplicate using a Soil DNA Kit (OMEGA, A/S). 16S sRNA gene was amplified with F968-GC (5′-GC-clamp-AACGCGAAGAACCTTAC-3′) and R1401 (5′-GCGTGTGTACAAGACCC-3′) and subjected to sequencing on an Illumina HiSeq2500 sequencer at Magigene Sequencing Lab. Bioanode community analysis was performed as previously described (Zhao et al. 2021).

Results and discussion

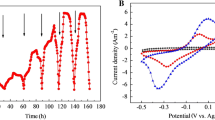

Bioanode pre-acclimation in MEC mode with applied voltage

Figure 2 shows the development of current of MEC during anode biofilm acclimating period. During the acclimating period, the anode was firstly pre-acclimated with fermentation effluent as inoculum and supplied 0.5 V applied voltage (cycle 1). The current starts to gradually increase at 18 h after inoculating; this demonstrated that the electrogenic bacteria have been effectively attached to the anode. From cycle 2 to 3, the current would directly increase to stable maximum value (16.3 ± 0.4 mA) after feeding centrifuged fermentation effluent (without lag phase); the corresponding H2 production rate was 0.73 ± 0.18 L L−1 day−1. When the fermentation effluent was switched to butyrate medium at cycle 4, the current firstly decreased to 4.6 ± 0.4 mA, and then increased smoothly peaking (11.1 ± 0.5 mA), thus demonstrating that the anode biofilm was adapting to the butyrate. In the three butyric medium-fed MEC batches (from cycle 4 to 6), the maximum current was kept at 11.1 ± 0.5 mA; the corresponding H2 production rate only was 0.46 ± 0.09 L L−1 day−1. The comparatively slower current to peak in the butyrate medium-fed MEC indicated that the electrogenic bacteria on the anode biofilm cannot degrade butyrate directly. Furthermore, acetate always was detected at the peak current period. These behaviors indicated that the butyrate was likely firstly degraded into acetate by the butyrate degrading acetogenic bacteria in MEC, and then the acetate was oxidized completely to CO2 and H+. The phenomenon is similar to previous several studies (Ullery and Logan 2015; Popov et al. 2016; Li et al. 2017). From cycle 7 to 9, the substrate was switched to fermentation effluent again; the current rapidly increased to a maximum of 20.4 ± 0.4 mA, and then stabled at the maximum value, which are higher than that of cycle 2 to cycle 6. Moreover, due to the higher current, the H2 production rate in cycle 8 and cycle 9 reached maximum of 2.61 ± 0.11 L L−1 day−1, which is higher than that of cycle 2 to 6. These results demonstrated that the current can be greatly improved by using butyrate as single substrate with applied voltage of 0.5 V to acclimate anode biofilm in MEC. Moreover, the pre-acclimation method of bioanode in MEC mode also is easy to operate in scaling up MEC reactor.

Effect of applied voltage on the MEC performance

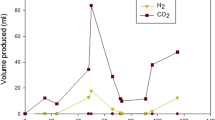

Applied voltage is an important factor of MECs for H2 production. As shown in Fig. 3, the H2 production rate almost linearly increased with the increasing of applied voltage from 0.5 to 0.8 V, which increased from 2.61 ± 0.11 to 6.26 ± 0.23 L L−1 day−1. Figure 3 depicts the current under different applied voltage; the corresponding stable current density was improved from 20.4 ± 0.4 (1.62 ± 0.03 A m−2) to 36.8 ± 0.4 A m−3 (2.93 ± 0.03 A m−2) with the increasing of voltage from 0.5 to 0.8 V. When the applied voltage was further increased to 0.9 V, both H2 production rate and current density were closed to plateau level (6.36 ± 0.21 L L−1 day−1 and 37.6 ± 0.4 A m−3). The higher current represents corresponding to the higher H2 production; this behavior also is similar with mostly previous MEC studies (Liu et al. 2012). However, compared to previous MECs, the higher H2 production rate was obtained in this MEC at same applied voltage. The maximum cumulative H2 volume also increased from 4.64 L H2 L−1 fermentation effluent to 5.75 ± 0.16 L H2 L−1 fermentation effluent with the applied voltage increasing from 0.5 to 0.8 V. When further increase the applied voltage from 0.8 to 0.9 V, the H2 volume was steady around 5.75 ± 0.16 L H2 L−1 fermentation effluent. The initial and final pH of fermentation effluent was kept at 6.8 ± 0.1; the lack of pH change due to the high buffering capacity of the phosphate buffer used for the fermentation effluent. The initial conductivity of fermentation effluent was 18.32 ms cm−1; the final conductivity under different applied voltage are shown in table S1. It has been reported that the H2 production is mainly by the oxidative degradation of substrate by the bioanode (Li et al. 2017; Zhang and Li 2020). The increasing of H2 production rate and cumulative H2 volume with the increasing of applied voltage, indicating the bioanode oxidating ability, was enhanced in the range of 0.5–0.8 V. However, the oxidative ability was not improved accordingly when the applied voltage increased to 0.9 V. Moreover, there only were H2 (91%) and CO2 (9%) were detected in gas phase; no CH4 was observed in the MECs. These results indicated that the MECs can produce addition H2 with high production rate from the H2 fermentation effluent. Cyclic voltammeter (CV) test was conducted to analyze the microbial activity of bioanode in the MECs (Fig. S1). Voltammograms showed that oxidation peaks were observed from − 200 to − 300 mV. Electrochemical impedance spectroscopy (EIS) spectrum was fitted to equivalent circuits (Fig. S2) to identify the inner resistances of the MECs; the calculated polarization resistance (Rpol) for anode is 84.94 Ω, the biofilm resistance (Rfilm) is 1.92 Ω, and the inner resistances of MECs contain solution (Rsol) is 3.02 Ω.

Figure 4 shows the variation of energy efficiency (nE), Coulombic efficiency (CE), cathodic recovery (Rcat), and overall H2 recovery (RH2) of this MEC under different applied voltage. The CE ranged from 76 ± 3 (0.5 V) to 79 ± 2% (0.9 V), which were not significantly different. The ηE gradually decreased along with the increase of applied voltages, which were decreased from 285 ± 13 at 0.5 V to 163 ± 8% at 0.9 V. The ηE was higher than 100%, which demonstrated that the energy contained in the H2 produced by the MEC was higher than the electrical energy input. This trend of ηE was in agreement with most previous MEC studies (Wu et al. 2013; Guo et al. 2017; Li et al. 2017; Zhang et al. 2019). The Rcat showed a favorable increase with the increase in applied voltage, which increased from 73 ± 3% at 0.5 V to 81 ± 2% at 0.8 V. The RH2 increased from 61 ± 2 to 71 ± 3% with the increasing of applied voltage from 0.5 to 0.8 V, and then slightly increased to 72 ± 3% at 0.9 V. These results demonstrate that this single chamber MEC allows high H2 recovery with high H2 production rate at 0.8 V. Thus, considering to obtain high H2 production rate and H2 yield, 0.8 V was considered as the most promising applied voltage for this MEC. Furthermore, in order to better understand how operating impacts performance for commercial applications, more than 30 cycles were tested to investigate the stability of operation; the performance of MEC is very stable.

VFAs and COD removal of fermentation effluent in MECs

Figure 5a illustrates the removal of VFAs (e.g., acetate, butyrate, propionate), COD, and ethanol with different applied voltage. Seen from Fig. 5a, among all the applied voltages, the COD removal efficiency reached 69 ± 2%. The removal of acetate, propionate, butyrate, and ethanol could reach 95.3 ± 2.1%, 98.2 ± 1.3%, 78.4 ± 3.6%, and 100%, respectively. Even though the butyrate could not be removed completely, the butyrate removal has a great improvement, which is about 18.7–20 times higher than 4 ± 2% in previous study (Li et al. 2014), in which the MEC bioanodes were enriched using sodium acetate as sole carbon source in MFC. The butyrate removal also is higher than previous study using single-chamber MECs with square electrodes treating H2 fermentation effluent (mainly contains acetate and butyrate), generally ranging from 14 to 32% (Khongkliang et al. 2019). These results also show that acclimating MECs to H2 fermentation effluent provided a new strategy for H2 production simultaneously with treatment of fermentation effluent. In addition, the low COD removal is due to the fermentation effluent of corn stalk that contains some complex components, e.g., lignin cleavage fragment, pigment, and furfural generated due to the hydrolysis of corn stalk; they could not be efficiently degraded by the electrogenic bacteria.

It has been clearly studied that the current density and H2 production rate in MEC are proportional to the substrate utilization rate (Karthikeyan et al. 2017); the butyrate has been well known to difficulty utilized in MECs compared to acetate (Yang et al. 2015; Ullery and Logan 2015; Popov et al. 2016; Li et al. 2017). In order to provide greater insight on the relation of H2 production rate, VFA degradation, and current. One example of one cycle of H2 production rate, VFA degradation, and current of the MEC with 0.8 V applied voltage is shown in Fig. 5b. The current and H2 production rate decreased from maximum to 7.4 ± 0.5 mA and 0.76 ± 0.13 L L−1 day−1 after 24 h; the acetate concentration was stable at 123 ± 26 mg L−1. Moreover, when the current reached maximum, the acetate remove rate was 113 ± 12 mg L−1 h−1; the butyrate remove rate reached 88 ± 9 mg L−1 h−1. After 20 h, the current starts to decrease due to the acetate decreasing to 153 ± 26 mg L−1; the butyrate removal rate also decreased to 43 ± 7 mg L−1 h−1. When the H2 production stopped, the acetate has been degraded almost completely. The removing trend of acetate and butyrate in this MEC is similar with previous studies (Li et al. 2014, 2017); the acetate was firstly degraded quickly. The butyrate needed to be degraded firstly to acetate, H+, and CO2 by the electrogenic bacteria, and then the acetate was further degraded to H+ and CO2. The degradation process of butyrate to acetate is the rate-limiting step (Li et al. 2017), which resulting in butyrate could not be degraded completely when the H2 production stopped.

Comparison to other high-performance MECs

Several previous studies of MECs fed with various wastewater for H2 production were compared with this MEC, and the comparisons are summarized in the Table 1. As shown in Table 1, the H2 production rate and butyrate removal were much higher than that of other literatures (Liu et al. 2012; Li et al. 2014; Khongkliang et al. 2019). Especially, when comparing with previous MECs fed with fermentation effluent of biomass waste, this cylindrical single-chamber MEC has a higher H2 production rate. For example, Wu et al. reported one single-chamber MECs fed with fermentation effluent, which maximum H2 production rate was only 1.31 ± 0.04 L L−1 day−1 at 0.6 V applied voltage (Wu et al. 2013). Moreover, Nam et al. also reported H2 production from cellulose fermentation wastewater in one double-chamber MECs; the maximum H2 production rate was only 0.49 ± 0.05 L L−1 day−1 at 0.9 V (Nam et al. 2014). These results indicated that the cylindrical single-chamber MEC system has a higher H2 production efficiency and faster oxidation of the substrate.

The existence of methanogenic bacteria has been confirmed that is one of the limiting factors for MECs producing H2 (Kadier et al. 2018; Karthikeyan et al. 2017). Numerous researchers have studied single-chamber MECs for H2 production using fermentation effluent; the methanogenic activity would disturb the H2 production significantly by the methanogenic bacteria on the bioanode (Karthikeyan et al. 2017). Especially with the long-term operation of MECs, the competition would be dominant by the methanogenic bacteria over the electrogenic bacteria. Different methods of methanogenic bacteria inhibition have been studied in single MECs, e.g., 2-bromoethanesulfonate, chloroform, acetylene, UV radiation, and low temperature (Karthikeyan et al. 2017; Wang et al. 2019). Even though thermal treatment is known not be able to completely suppress methanogens, especially for long-term operation MEC (Hu et al. 2008), thermally treating (100 ℃) the mixed microorganism has been reported to inhibit the methanogenic bacteria during dark fermentation process for H2 production (Fu et al. 2020; Liao et al. 2021). No CH4 was observed in this MEC, indicating that the thermally treatment also might be an efficient method to inhibit the methanogenic bacteria when using the cow dung compost as inoculum. Furthermore, compared with several previous studies (see Table 1), the H2 production rate were improved in this study; it demonstrated that thermal treatment (100 ℃) could not inhibit the electrochemical performance of electrogenic bacteria when using cow dung compost as the seed of electrogenic bacteria.

The by-products of fermentation process mainly focus on the acetate, ethanol, and butyrate. The amounts and relative abundances of these by-products varied depending on the types of fermentation, substrates, and bacteria. Acetate and ethanol have been widely studied as promising substrates for H2 production in MEC; how to enhance the degradation of butyrate is one of the main challenges for H2 production using fermentation effluent. In this study, the butyrate removal could reach 78.4 ± 3.6%, which is higher than that of previous studies (details see Table 1). Moreover, compared to the previous MECs, the current density based on liquid volume was significantly lower in this study, possibly due to the use of H2 fermentation effluent as substrate in the MECs.

Numerous studies also have reported tubular and cylindrical MECs for boosting H2 production (Carmona-Martinez et al. 2015; Guo et al. 2017; Nguyen et al. 2020). For example, Guo et al. (2017) reported one tubular two-chamber MECs with anion exchange membrane, in which the maximum H2 production rate could reach 7.1 L L−1 day−1 using acetate as substrate. Although the maximum H2 production rate in here was lower than it, the cylindrical single-chamber MECs without membrane could reduce the capital cost of MEC and improve the MEC operating economics.

Analysis of microbial communities on bioanode

Microbial community information is another important information to explain the result. Currently, majority of the similar investigations would include data from high-throughput sequence or next-generation sequencing based on genomic DNA of samples. In this study, RNA-based sequencing was used to detect the metabolically active population (Fig. 6). The microbial samples were taken from bioanode at the end of the H2 production. A total of 15 phyla were detected, and 7 phyla are shown in Fig. 6a. The most abundant phylum was Proteobacteria (52.3%), followed by Bacteroidetes (18.2%), Firmicutes (14.3%), Actinobacteria (3.1%), and Synergistetes (2.7%) (Fig. 6a). Proteobacteria are well known playing important roles in extracellular electron transfer (Fykse et al. 2016). Bacteroidetes were related to methanogenesis (Cheng et al. 2021). The dominant genera in anodic communities were characterized as Geobacter (22.6%), Syntrophomonas (8.7%), Dysgonomonas (6.3%), Comamonas (4.3%), Pseudomonas (4.2%), and Clostridium (3.5%) (Fig. 6b). Geobacter as well-known electroactive bacteria using acetate as primary substrate has been researched widely (Zhu et al. 2020). Syntrophomonas as syntrophic bacteria has not been studied in previous MECs, which was able to oxidize acetate, butyrate, and more complex substrates (Guzman et al. 2019). Popov et al. (2016) also demonstrated that Syntrophomonas number increasing would enhance the H2 production performance and feedstock removal rate by using butyrate to acclimate anode. Dysgonomonas also has high ability to degrade different kinds of complex chemicals. Pseudomonas had critical functionalities in electrogenic biofilm by promoting acclimation biofilm and enhancing MEC performance for H2 production (Guzman et al. 2019; Zhao et al. 2021). Comamonas and Clostridium are classified as fermentative bacteria, and can participate in the degradation of complicated organics to degrade to more biodegradable substrates that can be metabolized by Geobactor for electricity generation and H2 production (Wang et al. 2021). Moreover, Comamonas also is a well-known exoelectrogens and has strong ability to degrade organics and generate electricity in MFC (Gao et al. 2020). Besides the high butyrate and acetate removal performance, such high current densities and H2 production rate for this MEC could also be attributed to the dominance of Geobacter and these co-cultures. Moreover, even though previous study has indicated that the methanogens could not be completely inhibited by heat treatment (Hu et al. 2008), no CH4 was detected in this study. It is possibly a result of inhibiting methanogens in the anode microbial community that compete with the exoelectrogens for feedstock and space (Wang et al. 2019; Zhao et al. 2021).

Conclusion

The feasibility of using fermentation effluent of corn stalk for H2 production in a 1-L cylindrical single-chamber MEC was investigated in this work. The H2 production rate could reach to 6.26 ± 0.23 L L−1 day−1 and total H2 yield reach to 5.75 ± 0.16 L H2 L−1 fermentation effluent under applied voltage of 0.8 V. The corresponding COD and butyrate removal in MECs reached 69 ± 2% and 78.4 ± 3.6% separately. Analysis results of anodic microbial communities showed that the microbial culture acclimated to butyrate offered a significant advantage in H2 production and a role in the prevention of methanogenesis. Compared with other MECs, this study may provide an efficient MEC reactor and operating strategy for H2 production and simultaneous with H2 fermentation effluent treatment.

Data Availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Aiken DC, Curtis TP, Heidrich ES (2019) Avenues to the financial viability of microbial electrolysis cells MEC for domestic wastewater treatment and hydrogen production. Int J Hydrogen Energy 44(5):2426–2434. https://doi.org/10.1016/j.ijhydene.2018.12.029

American Public Health Association, AWWA (1998) Standard Methods for the Examination of Water and Wastewater, nineteenth. American Public Health Association, Washington, DC

Carmona-Martinez AA, Trably E, Milferstedt K, Lacroix R, Etcheverry L, Bernet N (2015) Long term continuous production of H2 in a microbial electrolysis cell (MEC) treating saline wastewater. Water Res 81:149–156. https://doi.org/10.1016/j.watres.2015.05.041

Cheng J, Li S, Yang X, Huang X, Lu Z, Xu J, He Y (2021) Regulating the dechlorination and methanogenesis synchronously to achieve a win-win remediation solution for gamma-hexachlorocyclohexane polluted anaerobic environment. Water Res 203:117542. https://doi.org/10.1016/j.watres.2021.117542

Desmond-Le Quemener E, Bridier A, Tian JH, Madigou C, Bureau C, Qi Y, Bouchez T (2019) Biorefinery for heterogeneous organic waste using microbial electrochemical technology. Bioresour Technol 292:121943. https://doi.org/10.1016/j.biortech.2019.121943

Fykse EM, Aarskaug T, Madslien EH, Dybwad M (2016) Microbial community structure in a full-scale anaerobic treatment plant during start-up and first year of operation revealed by high-throughput 16S rRNA gene amplicon sequencing. Bioresou Technol 222:380–387. https://doi.org/10.1016/j.biortech.2016.09.118

Fu SF, Liu R, Sun WX, Zhu R, Zou H, Zheng Y, Wang ZY (2020) Enhancing energy recovery from corn straw via two-stage anaerobic digestion with stepwise microaerobic hydrogen fermentation and methanogenesis. J Clean Prod 247:119651. https://doi.org/10.1016/j.jclepro.2019.119651

Gao Y, Kong X, Zhou A, Yue X, Luo Y, Defemur Z (2020) Enhanced degradation of quinoline by coupling microbial electrolysis cell with anaerobic digestion simultaneous. Bioresour Technol 306:123077. https://doi.org/10.1016/j.biortech.2020.123077

Guo K, Prévoteau A, Rabaey K (2017) A novel tubular microbial electrolysis cell for high rate hydrogen production. J Power Sources 356:484–490. https://doi.org/10.1016/j.jpowsour.2017.03.029

Guo ZB, Sun WL, Zuo XJ, Song HL, Liang H, Zhang S (2022) Increase of antibiotic resistance genes via horizontal transfer in single-and two-chamber microbial electrolysis cells. Environ Sci Pollut Res 29:36216–36224. https://doi.org/10.1007/s11356-022-18676-3

Guzman JJL, Sousa DZ, Angenent L (2019) Development of a bioelectrochemical system as a tool to enrich H2-producing syntrophic bacteria. Front Microbiol 10:110. https://doi.org/10.3389/fmicb.2019.00110

Huang L, Tian F, Pan Y, Shan L, Shi Y, Logan BE (2019) Mutual benefits of acetate and mixed tungsten and molybdenum for their efficient removal in 40 L microbial electrolysis cells. Water Res 162:358–368. https://doi.org/10.1016/j.watres.2019.07.003

Hu H, Fan Y, Liu H (2008) Hydrogen production using single-chamber membrane-free microbial electrolysis cells. Water Res 42:4172–4178. https://doi.org/10.1016/j.watres.2008.06.015

Jatoi AS, Akhter F, Mazari SA, Sabzoi N, Aziz S, Soomro SA, Mubarak NM, Baloch H, Memon AQ, Ahmed S (2021) Advanced microbial fuel cell for waste water treatment-a review. Environ Sci Pollut Res 28:5005–5019. https://doi.org/10.1007/s11356-020-11691-2

Kadier A, Kalil MS, Chandrasekhar K, Mohanakrishna G, Saratale GD, Saratale RG, Kumar G, Pugazhendhi A, Sivagurunathan P (2018) Surpassing the current limitations of high purity H2 production in microbial electrolysis cell (MECs): strategies for inhibiting growth of methanogens. Bioelectrochemistry 119:211–219. https://doi.org/10.1016/j.bioelechem.2017.09.014

Kadier A, Simayi Y, Kalil MS, Abdeshahian P, Hamid AA (2014) A review of the substrates used in microbial electrolysis cells (MECs) for producing sustainable and clean hydrogen gas. Renew Energ 71:466–472. https://doi.org/10.1016/j.renene.2014.05.052

Karthikeyan R, Cheng KY, Selvam A, Bose A, Wong JWC (2017) Bioelectrohydrogenesis and inhibition of methanogenic activity in microbial electrolysis cells a review. Biotechnol Adv 35(6):758–771. https://doi.org/10.1016/j.biotechadv.2017.07.004

Khongkliang P, Jehlee A, Kongjan P, Reungsang A, Thong S (2019) High efficient biohydrogen production from palm oil mill effluent by two-stage dark fermentation and microbial electrolysis under thermophilic condition. Int J Hydrogen Energy 44(60):31841–31852. https://doi.org/10.1016/j.ijhydene.2019.10.022

Kumar G, Mudhoo A, Sivagurunathan P, Nagarajan D, Ghimire A, Lay CH, Lin CY, Lee DJ, Chang JS (2016) Recent insights into the cell immobilization technology applied for dark fermentative hydrogen production. Bioresour Technol 219:725–737. https://doi.org/10.1016/j.biortech.2016.08.065

Li XH, Liang DW, Bai YX, Fan YT, Hou HW (2014) Enhanced H2 production from corn stalk by integrating dark fermentation and single chamber microbial electrolysis cells with double anode arrangement. Int J Hydrogen Energy 39(17):8977–8982. https://doi.org/10.1016/j.ijhydene.2014.03.065

Li X, Chen S, Liang D, Alvarado-Moralesa M (2020) Low-grade heat energy driven microbial electrosynthesis for ethanol and acetate production from CO2 reduction. J Power Sources 477:228990. https://doi.org/10.1016/j.watres.2018.06.013

Li X, Zhang R, Qian Y, Angelidaki I, Zhang Y (2017) The impact of anode acclimation strategy on microbial electrolysis cell treating hydrogen fermentation effluent. Bioresour Technol 236:37–43. https://doi.org/10.1016/j.biortech.2017.03.160

Liao Q, Sun C, Xia A, Fu Q, Huang Y, Zhu X, Feng D (2021) How can hydrothermal treatment impact the performance of continuous two-stage fermentation for hydrogen and methane co-generation? Int J Hydrogen Energy 46(27):14045–14062. https://doi.org/10.1016/j.ijhydene.2020.08.276

Liu W, Huang S, Zhou A, Zhou G, Ren N, Wang A, Zhuang G (2012) Hydrogen generation in microbial electrolysis cell feeding with fermentation liquid of waste activated sludge. Int J Hydrogen Energy 37(18):13859–13864. https://doi.org/10.1016/j.ijhydene.2012.04.090

Lu L, Ren N, Xing D, Logan BE (2009) Hydrogen production with effluent from an ethanol-H2-coproducing fermentation reactor using a single-chamber microbial electrolysis cell. Biosens Bioelectron 24(10):3055–3060. https://doi.org/10.1016/j.bios.2009.03.024

Marone A, Ayala-Campos OR, Trably E, Carmona-Martínez AA, Moscoviz R, Latrille E, Steyer JP, Alcaraz-Gonzalez V, Bernet N (2017) Coupling dark fermentation and microbial electrolysis to enhance bio-hydrogen production from agro-industrial wastewaters and by-products in a bio-refinery framework. Int J Hydrogen Energy 42(3):1609–1621. https://doi.org/10.1016/j.ijhydene.2016.09.166

Nam JY, Yates MD, Zaybak Z, Logan BE (2014) Examination of protein degradation in continuous flow, microbial electrolysis cells treating fermentation wastewater. Bioresour Technol 171:182–186. https://doi.org/10.1016/j.biortech.2014.08.065

Nguyen PKT, Das G, Kim J, Yoon HH (2020) Hydrogen production from macroalgae by simultaneous dark fermentation and microbial electrolysis cell. Bioresour Technol 315:123795. https://doi.org/10.1016/j.biortech.2020.123795

Pang Y, Gu T, Zhang G, Yu Z, Zhou Y, Zhu D, Zhang Y, Zhang T (2020) Experimental study on volatile sulfur compound inhibition using a single-chamber membrane-free microbial electrolysis cell. Environ Sci Pollut Res 27:30571–30582. https://doi.org/10.1007/s11356-020-09325-8

Popov AL, Michie IS, Kim JR, Dinsdale RM, Guwy AJ, Esteves SR, Premier GC (2016) Enrichment strategy for enhanced bioelectrochemical hydrogen production and the prevention of methanogenesis. Int J Hydrogen Energy 41(7):4120–4131. https://doi.org/10.1016/j.ijhydene.2016.01.014

Priyadarshini M, Ahmad A, Das S, Ghangrekar MM (2021) Application of microbial electrochemical technologies for the treatment of petrochemical wastewater with concomitant valuable recovery: a review. Environ Sci Pollut Res 06, July. https://doi.org/10.1007/s11356-021-14944-w

Rousseau R, Etcheverry L, Roubaud E, Basséguy R, Délia ML, Bergel A (2020) Microbial electrolysis cell (MEC): Strengths, weaknesses and research needs from electrochemical engineering standpoint. Appl Energy 257:113938. https://doi.org/10.1016/j.apenergy.2019.113938

Song ZX, Li XH, Li WW, Bai YX, Fan YT, Hou HW (2014) Direct bioconversion of raw corn stalk to hydrogen by a new strain Clostridium sp. FS3. Bioresour Technol 157:91–97. https://doi.org/10.1016/j.biortech.2014.01.084

Tian H, Li J, Yan M, Tong YW, Wang CH, Wang X (2019) Organic waste to biohydrogen: a critical review from technological development and environmental impact analysis perspective. Appl Energy 256:113961. https://doi.org/10.1016/j.apenergy.2019.113961

Ullery ML, Logan BE (2015) Anode acclimation methods and their impact on microbial electrolysis cells treating fermentation effluent. Int J Hydrogen Energy 40(21):6782–6791. https://doi.org/10.1016/j.ijhydene.2015.03.101

Wang J, Yin Y (2019) Progress in microbiology for fermentative hydrogen production from organic wastes. Crit Rev Environ Sci Technol 49(10):825–865. https://doi.org/10.1080/10643389.2018.1487226

Wang L, Trujillo S, Liu H (2019) Selective inhibition of methanogenesis by acetylene in single chamber microbial electrolysis cells. Bioresour Technol 274:557–560. https://doi.org/10.1016/j.biortech.2018.12.039

Wang L, Long F, Liang D, Xiao X, Liu H (2021) Hydrogen production from lignocellulosic hydrolysate in an up-scaled microbial electrolysis cell with stacked bio-electrodes. Bioresour Technol 320:124314. https://doi.org/10.1016/j.biortech.2020.124314

Wu T, Zhu G, Jha AK, Zou R, Liu L, Huang X, Liu C (2013) Hydrogen production with effluent from an anaerobic baffled reactor (ABR) using a single-chamber microbial electrolysis cell (MEC). Int J Hydrogen Energy 38(25):11117–11123. https://doi.org/10.1016/j.ijhydene.2013.03.029

Yang N, Hafez H, Nakhla G (2015) Impact of volatile fatty acids on microbial electrolysis cell performance. Bioresour Technol 193:449–455. https://doi.org/10.1016/j.biortech.2015.06.124

Zhang L, Wang YZ, Zhao T, Xu T (2019) Hydrogen production from simultaneous saccharification and fermentation of lignocellulosic materials in a dual-chamber microbial electrolysis cell. Int J Hydrogen Energy 44(57):30024–30030. https://doi.org/10.1016/j.ijhydene.2019.09.191

Zhang X, Li R (2020) Electrodes bioaugmentation promotes the removal of antibiotics from concentrated sludge in microbial electrolysis cells. Sci Total Environ 715:136997. https://doi.org/10.1016/j.scitotenv.2020.136997

Zhao N, Liang D, Meng S, Li X (2020) Bibliometric and content analysis on emerging technologies of hydrogen production using microbial electrolysis cells. Int J Hydrogen Energy 45(58):33310–33324. https://doi.org/10.1016/j.ijhydene.2020.09.104

Zhao N, Liang D, Li X, Meng S, Liu H (2021) Hydrophilic porous materials provide efficient gas-liquid separation to advance hydrogen production in microbial electrolysis cells. Bioresour Technol 337:125352. https://doi.org/10.1016/j.biortech.2021.125352

Zhu Q, Bu C, Yang C, Hu J, Liu B, Liang S, Xiao K, Yang J, Hou H (2020) Enhanced 2,4,6-trichlorophenol degradation and biogas production with a coupled microbial electrolysis cell and anaerobic granular sludge system. Bioresour Technol 303:122958. https://doi.org/10.1016/j.biortech.2020.122958

Funding

This work was supported by the grants from the National Natural Science Foundation of China (No. 22002006; 21706244; 52070008), Key Research Projects of the Science and Technology Department of Henan Province (No. 182102210162), and Beihang University Zhuo Yue 100 Talent Program (No. ZG 216S2192).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Jingnan Zhang, Hanghang Chang, and Xiaohu Li. The first draft of the manuscript was written by Jingnan Zhang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, J., Chang, H., Li, X. et al. Boosting hydrogen production from fermentation effluent of biomass wastes in cylindrical single-chamber microbial electrolysis cell. Environ Sci Pollut Res 29, 89727–89737 (2022). https://doi.org/10.1007/s11356-022-22095-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22095-9