Abstract

To treat high-salt urea wastewater by microbial hydrolysis, it is necessary to overcome the dual problems of incomplete removal of nitrogen (N) from mixed strains and inhibition of microbial activity by high salt (NaCl) concentrations. In this paper, the mechanism of NaCl tolerance of Halomonas sp. H36 was investigated. Using molecular biology and enzymatic methods, it was proven that the strain’s N-removal enzymes (urease; ammonia monooxygenase, AMO; nitrite reductase, NIR; nitrate reductase, NAR) played a key role in the removal of N, and the N-removal pathway was clarified. For the strain used to treat simulated ship domestic sewage, the urea nitrogen (CO(NH2)2-N)-removal rate was 88.52%, the ammonia nitrogen (NH4+-N)-removal rate was 91.16%, the total nitrogen (TN)-removal rate was 90.25%, and nitrite nitrogen (NO2−-N) and nitrate nitrogen (NO3−-N) did not accumulate. It was proven for the first time that Halomonas sp. H36 has the function of simultaneous urea hydrolysis-nitrification–denitrification with urea as the initial substrate and can simultaneously remove urea nitrogen and inorganic nitrogen from high-salt urea wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Urea (H2N-CO-NH2) is a simple nitrogen (N)-containing organic compound that is widely used in agricultural fertilizers, deicers, foaming agents, herbicide and pesticide production, automobile exhaust treatment, and other fields (Urbańczyk et al. 2016). Agricultural N fertilizer leaching, industrial production with urea as a raw material, and human life produce large amounts of urea wastewater (Li et al. 2015). Studies have shown that 80% of N pollution in domestic sewage comes from urea (Jimenez et al. 2012). The urea content in urine is as high as 25 g/L (Lee 1971). Urea-N (CO(NH2)2-N) easily leads to coastal eutrophication (Tzilkowski et al. 2018). According to the 2020 China Marine Ecological Environment Bulletin, a total of 31 red tides were found in China’s waters in 2020, with a cumulative area of 1,748 km2. Among them, there were two toxic red tides, with a cumulative area of 81 km2 (Ministry of Ecology and Environment, PRC 2020). Untreated urea wastewater poses a serious threat to biological survival, human health, and the ecological environment (Hu et al. 2020a, b; Vaneeckhaute and Fazli 2020). Therefore, there is an urgent need for the effective treatment of urea wastewater.

At present, microbial hydrolysis is one of the most economical and effective methods to remove urea from wastewater (Ilgrande et al. 2019; Jia et al. 2020). Traditionally, the complete removal of CO(NH2)2-N into gaseous N requires three steps: urea hydrolysis, nitrification, and denitrification (Garrido et al. 2001). However, the multistage urea treatment process has problems such as high cost and large space requirements. To overcome this drawback, researchers have used mixed strains for urea hydrolysis in a reactor. Hu et al. (2020a, b) treated urea-containing wastewater with mixed strains in a reactor. The results showed that urea-degrading bacteria, phylum Gemmatimonadetes, hydrolyzed urea to NH3, and then NH3 was oxidized to NO2− by ammonia-oxidizing bacteria. During this process, the high concentration of NH4+ inhibited the activity of nitrite-oxidizing bacteria, resulting in accumulation of NO2−, at a rate of 0.985 kg/(m3·d); Chen et al. (2022) used a mixed flora dominated by urea-degrading bacteria (Nitrosomonas) and anaerobic ammonia-oxidizing bacteria (Candidatus Brocadia) to undergo urea hydrolysis (CO(NH2)2-N → NH4+-N), part of the nitrification (PN) (NH4+-N → NO2−-N) and anammox (NH4+-N + NO2−-N → N2 + 2H2O) pathways to complete the removal of total nitrogen (TN). However, in the existing mixed-bacteria urea-removal process, the type, activity, and ratio of urea-hydrolyzing bacteria to N-removing bacteria in the biofilm are not easy to control, and the accumulation of NO2−-N and NO3−-N makes it difficult to convert CO(NH2)2-N to gaseous N and completely remove it (Rittstieg et al. 2001). It is necessary to develop a simple, reliable, and efficient technology for the complete removal of CO(NH2)2-N.

In addition, urea wastewater is often accompanied by high salt (NaCl > 10 g/L) problems. Urea containing azodicarbonamide foaming agent industrial sewage (NaCl = 56 g/L), toilet flushing wastewater in coastal cities (NaCl = 10–17 g/L), and domestic sewage from ships (NaCl = 10–20 g/L) have high salt contents (Jiang et al. 2019; Li 2018; Yang et al. 2015). The resulting high-salt urea wastewater also needs to be treated urgently. However, high salt concentrations can inhibit the respiration of microorganisms and decrease the urea removal rate. When the NaCl concentration was increased from 0.37 to 30.70 g/L, the respiratory inhibition rate of microorganisms increased from 4 to 84% (Pernetti and Palma 2005). When the NaCl concentration increased from 0.00 to 0.04 g/L, the removal rate of CO(NH2)2-N by mixed bacteria decreased from 94.2 to 67.0% (Wang et al. 2020a, b).

Salt-tolerant or halophilic N-removal strains have attracted much attention in the field of high-salt nitrogenous wastewater treatment (Wang et al. 2019; Man et al. 2022). Most strains of Halomonas can synthesize ectoine without interfering with the normal life process of cells while balancing the osmotic pressure between the cytoplasm and the environment (Zhao et al. 2018). Halomonas meridiana SCSIO 43,005 can survive with urea as the sole N source (Zhou et al. 2020). Halomonas venusta TJPU05 has an obvious treatment effect on high-salt N-containing wastewater. Removal rates of 50.96%, 47.28%, and 43.19% were observed for NH4+-N, NO3—N, and TN, respectively (Man et al. 2022). Therefore, Halomonas has great application potential in the treatment of high-salt urea wastewater. To our knowledge, no one has carried out research on these issues in depth or systematically. (1) The process for removal of urea by Halomonas. (2) The removal effect of CO(NH2)2-N and inorganic N simultaneously by Halomonas in high-salinity environment.

In a previous study, Halomonas sp. H36 had the ability to hydrolyze urea (Li et al. 2020). In this paper, the mechanism of salt tolerance of Halomonas sp. H36 was investigated. We further evaluated the salt tolerance of N-removal enzymes of the strain. And the N-removal pathway of the strain with urea as the initial substrate was clarified. Finally, the strain was used for the treatment of simulating domestic sewage from ships. These findings provide a theoretical and methodological foundation for the bioremediation of high-salt urea wastewater in the future.

Materials and methods

Materials

Strain: Strain H36 was isolated from a salt-drying pond in a salt factory in Dalian City, Liaoning Province, China. This specimen was determined to be Halomonas sp. H36 (16S rRNA sequence GenBank No. ON935442) (Li et al. 2020).

LB medium (g/L): peptone 10, yeast powder 5, NaCl 30, pH 7.2. The medium was autoclaved at 121 °C for 20 min.

Growth medium (g/L): glucose 15, monosodium glutamate 15, (NH4)2SO4 10, urea 5, yeast powder 0.5, K2HPO4·3H2O 9, KH2PO4 3, MgSO4·7H2O 0.4, MnSO4·H2O 0.01. The NaCl concentration was determined by the experimental conditions (ectoine-induced synthesis experiment: 30, 60, 90, 120 g/L NaCl; effects of different NaCl concentrations in the enzymatic reaction system on the N-removal enzyme activities of Halomonas sp. H36: 30 g/L NaCl), pH 7.2. The medium was autoclaved at 121 °C for 20 min. The urea solution was sterilized by filtration (0.22 μm pore size, Millipore Express, USA).

Inducing medium (g/L): glucose 30, KNO3 0.4 (N element 50 mg/L), yeast extract 0.5, K2HPO4·3H2O 9, KH2PO4 3, MgSO4·7H2O 0.4, MnSO4·H2O 0.01, NaCl 60, pH 7.2. The medium was autoclaved at 121 °C for 20 min.

Trace mineral solution (g/L): EDTA-2Na 63.7, ZnSO4 2.2, CaCl2 5.5, MnCl2·4H2O 5.1, FeSO4·7H2O 5, Na2MO4·2H2O 1.1, CuSO4·5H2O 1.6, CoCl2·6H2O 1.6 (Vyrides and Stuckey 2009), pH 7.2. The trace mineral solution was sterilized by filtration (0.22 μm pore size, Millipore Express, USA).

N-removal medium (g/L): glucose 40, urea 6 (2,800 mg/L, CO(NH2)2-N), K2HPO4·3H2O 9, KH2PO4 3, MgSO4 ·7H2O 0.4, MnSO4·H2O 0.01, trace mineral solution 2 mL, NaCl 30. The N-removal medium was autoclaved at 121 °C for 20 min. The urea solution and the trace mineral solution were sterilized by filtration, respectively (0.22 μm pore size, Millipore Express, USA).

Simulated ship domestic sewage (mg/L): starch 100, glucose 800, urea 100, (NH4)2SO4 550, KH2PO4 31, K2HPO4·3H2O 9, trace mineral solution 0.1 mL, NaCl 30 g/L. The simulated ship domestic sewage was autoclaved at 121 °C for 20 min. The urea solution and the trace mineral solution were sterilized by filtration, respectively (0.22 μm pore size, Millipore Express, USA).

Induction of ectoine synthesis and estimation of ectoine content

Induction of ectoine synthesis: The strains were cultivated in 5 mL LB medium at 30 °C and 120 rpm in a rotary shaker for 24 h. Then, 1% aliquots of each these cultures were inoculated in shake flasks (300 mL) containing 30 mL growth medium, followed by the strains being grown and cultured in 30, 60, 90, and 120 g/L NaCl growth medium at 30 °C and 120 rpm for 48 h in a rotary shaker (Wang et al. 2017).

Ectoine concentration determination method. Extracellular ectoine estimation: The culture solution induced with ectoine synthesis was centrifuged at 14,000 × g, and the supernatant was diluted tenfold with distilled water for high-performance liquid chromatography (HPLC) measurement. The ectoine concentration obtained by HPLC analysis was defined as the concentration of extracellular ectoine. Intracellular ectoine estimation: Cells were collected by the centrifugation method described above, and the pellets were washed with 100 mM potassium phosphate (KPi) buffer (pH 7.2) containing NaCl at the same concentration as that of the medium. After centrifugation, the pellets were extracted with ethanol (80%, v/v) of the same volume as the culture medium, resuspended, and then stored at 25 °C overnight. The suspension was centrifuged again, and the supernatant was subsequently used for HPLC analysis. The ectoine concentration as estimated by HPLC analysis was defined as the concentration of intracellular ectoine. The total concentration of ectoine was the sum of the concentrations of intracellular and extracellular ectoine. The concentration of ectoine was measured by an HPLC setup with a C18 column, Hypersil ODS2 column (Elite, Dalian, China), and a UV detector (Elite, Dalian, China). A wavelength of 210 nm was used (Zhang et al. 2009).

Method of PCR

The primer sequences of N-removal enzymes (urease; ammonia monooxygenase, AMO; nitrite reductase, NIR; nitrate reductase, NAR) were designed by a similar comparison method (Zhang et al. 2012). The sequence design information of the N-removal enzymes of Halomonas sp. H36 are shown in Table 1. Genomic DNA using TaKaRa DNAiso Reagent (Code: D305A). The PCR product was refined and recovered using the TaKaRa Agarose Gel DNA Purification Kit Ver. 2.0 (Code: DV805A) and was then sequenced by Takara Biotechnology (DALIAN) Co., Ltd.

Determination of N-removal enzyme activities

The strains were cultivated in 5 mL LB medium at 30 °C and 120 rpm in a rotary shaker for 24 h. Then, 1% of the cultures were inoculated in shake flasks (300 mL) containing 30 mL growth medium at 30 °C and 120 rpm in a rotary shaker for 36 h. The cells were collected by centrifugation (at 4 °C and 14,000 × g for 15 min) and transferred to the inducing medium at 30 °C and 120 rpm for 36 h.

Urease is a cytoplasmic enzyme (Mulrooney et al. 1989), AMO and NAR are cell membrane-bound enzymes (Hyman and Arp 1992; Blasco et al. 1992), and NIR is a periplasmic space enzyme (Blackmore et al. 1986).

Preparation of crude extracts of N-removal enzyme activities for enzyme activity determination: A crude extract of each enzyme prepared for this study was used for enzyme activity assays. The cytoplasmic enzyme (including the periplasmic enzyme) was prepared in 20 mL of the cell culture medium, which was also used to determine enzyme activity, centrifuged at 14,000 × g for 15 min at 4 °C, and the supernatant was discarded. Then, 100 mM phosphate buffer (pH 7.2) was added to the centrifuged pellet to resuspend it. A freeze–thaw cycle (at − 20 °C ≥ 2 h and at 30 °C for 30 min) was repeated 4 times. Ultrasound was used to disrupt cells in an ice bath (sonicated at 400 W for 3 s and stopped for 3 s) continuously through 30 cycles to obtain a solution of disrupted cells. The disrupted-cell solution was centrifuged at 14,000 × g for 15 min at 4 °C, the supernatant was collected, and the sample was used for cytoplasmic and periplasmic enzyme assays. The cell membrane debris was in the centrifuged pellet. The membrane-bound enzyme was prepared as follows: Dodecyl-β-D-maltoside is an alkylglycoside nonionic surfactant that promotes the disintegration of lipid membranes to release membrane proteins and provides a hydrophobic environment for membrane proteins in the state of membrane removal in solution. It maintains and protects the hydrophobic transmembrane structure of membrane proteins, thereby maintaining the structure and function of membrane proteins (Wang et al. 2020a). Therefore, decyl-β-D-maltoside is often used to extract proteins from cell membranes. In this paper, dodecyl-β-D-maltoside was used to dissolve the cytoplasmic membrane and release the membrane-bound proteins. The disrupted-cell centrifuge pellet, as described above, was resuspended in 100 mM phosphate buffer (pH 7.2) containing 1.0% dodecyl-β-D-maltoside, incubated for 1 h at 4 °C in the dark, and centrifuged at 14,000 × g for 15 min at 4 °C. Then, the supernatant was collected, and the sample was used for the cell membrane-bound enzyme assay. The total protein concentration of the enzyme solution to be determined was assayed as follows: Protein was determined using the BCA Protein Concentration Assay Kit (PC0020, Solarbio, Beijing, China). The amount of the enzyme solution to be determined was based on the total protein (mg) (Wang et al. 2020a).

Except for the enzyme reaction system (NaCl = 30 60 90 120 g/L in 3.3), NaCl = 0 g/L in the enzyme reaction system in other cases.

The urease activity was assayed as follows: Urease hydrolyzes CO(NH2)2-N to NH4+-N (Wang 2009). One unit of urease activity (U) is the amount of urease that hydrolyzes 1 mmol CO(NH2)2 per min at the reaction substrate of CO(NH2)2 (40 g/L), pH 7.2, and 37 °C under the specified reaction conditions.

The AMO activity was assayed as follows: AMO oxidizes NH4+-N to NH2OH (Ensign et al. 1993). One unit of AMO (U) is the amount of AMO that oxidizes 1 μmol NH4+ per min at the reaction substrate of NH4+-N (1,000 mg/L), pH 7.2, and 30 °C under the specified reaction conditions.

The NIR activity was assayed as follows: NIR reduces NO2− to NO (Rosa et al. 2001). One unit of NIR (U) is the amount of NIR that reduces that 1 μmol NO2− per min at the reaction substrate of NO2−-N (1,000 mg/L), pH 7.2, and 30 °C under the specified reaction conditions.

The NAR activity was assayed as follows: NAR reduced NO3− to NO2− in the presence of a reduced coenzyme (Kushner 1985). One unit of NAR activity (U) is the amount of NAR that reduces 1 μmol NO3− per min at the reaction substrate KNO3 (50.55 mg/L), pH 7.2, and 30 °C under the specified reaction conditions.

Determination method of N

The TN is the sum of cell total N (CN), CO(NH2)2-N, NH4+-N, NO2−-N, NO3−-N.

CO(NH2)2-N-removal rate (%) = (TUN0 − CN − TUNt) × 100%/(TUN0 − CN), where TUN0 is the initial CO(NH2)2-N, CN is the cell total N, and TUNt is the CO(NH2)2-N at a certain point in the N-removal process.

NH4+-N-removal rate (%) = (TAN0 − CN − TANt) × 100%/(TAN0 − CN), where TAN0 is the initial NH4+-N, CN is the total cellular N, and TANt is the NH4+-N at a certain point in the N-removal process.

TN-removal rate (%) = (TN0 − CN − TNt) × 100%/(TN0 − CN), where TN0 is the initial TN, CN is the total cellular N, and TNt is the TN at a certain point in the N-removal process.

CN was determined by the Kjeldahl method (Wang et al. 2020a). Cell growth was defined as the cell dry weight per liter of culture medium (CDW, g/L). The CDW of different qualities was taken to determine CN, and the relationship between CDW and CN was fitted. The urea concentration was determined by the p-dime-thylam inobenzaldehyde colorimetric method (Jiang and Bao 2005). NH4+-N was determined by Nessler’s reagent method (Wang et al. 2020a). NO2−-N was determined by the diazo-azo reaction method (Eaton et al. 1966). NO3−-N was determined by the zinc-cadmium reduction method (Sun et al. 2013).

Results and discussion

Effect of the medium NaCl concentration on the urease activity of Halomonas sp. H36

A previous study obtained a strain of Halomonas sp. H36 with high urease activity (Li et al. 2020). This experiment investigated the effect of NaCl concentration in the medium on the urease activity of Halomonas sp. H36. The results are shown in Fig. 1.

Under different NaCl concentrations, the cell growth and urease production of Halomonas sp. H36 had the same trend. When NaCl = 60 g/L, the strain growth amount was 10.26 g/L, and the urease activity was 75.28 U, both of which reached maximum values. When NaCl > 60 g/L, the urease activity of the strain decreased with increasing NaCl concentration. This shows that the excessive NaCl concentration in the medium affects the urease-producing ability of the strain. When NaCl = 120 g/L, the strain growth amount still reached 7.05 g/L, which was 68.71% of the maximum growth amount, the urease activity was 37.89 U, and 50.33% of the enzyme activity was still retained. Thus, Halomonas sp. H36 could still produce urease under high salinity.

The intracellular ectoine concentration increased with increasing NaCl concentration in the growth medium, which was similar to the ectoine synthesis in Halomonas sp. B01 (Wang et al. 2020a). In this experiment, the lowest intracellular ectoine concentration was 283.04 mg/L (30 g/L NaCl), and the highest intracellular ectoine concentration was 1179.89 mg/L (120 g/L NaCl). The extracellular ectoine concentration decreased with increasing NaCl concentration. The highest extracellular ectoine concentration was 1019.98 mg/L (30 g/L NaCl), and the lowest extracellular ectoine concentration was 123.13 mg/L (120 g/L NaCl). The highest secretion rate of ectoine was 78.28%, which was 1.28 times that of Halomonas organivorans D227 (Thuoc et al. 2019). The results indicated that Halomonas sp. H36 could initiate the protective mechanism of synthesizing ectoine in response to high-salt stress when NaCl = 30 g/L. Halomonas sp. H36 ectoine, which is used to regulate osmotic pressure, further protects the strain activity and allows the strain to produce urease.

In addition, it has been reported that nonsalt-tolerant strains in a hyperosmotic environment can maintain their own stability by ingesting external ectoine (Ono et al. 1999). In the future, the ectoine-secreting strain Halomonas sp. H36 may be used as a bioenhanced strain to hydrolyze urea and confer ectoine to other nonsalt-tolerant strains with additional function. This is of great significance for the comprehensive treatment of high-salt N-containing wastewater.

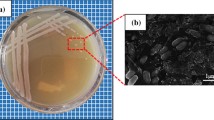

Halomonas sp. H36 N-removal enzyme gene cloning

At the molecular level, it has been proven that Halomonas sp. H36 N-removal enzymes exist, including urease, AMO, NIR, and NAR. The DNA of Halomonas sp. H36 was amplified by PCR to detect N-removal enzyme genes (ureA, amoA, nirS, narH) or fragments of Halomonas sp. H36. The agarose gel electrophoresis of the obtained amplification product is shown in Fig. 2. BLAST comparison was performed between the sequencing and translation results, and the results are shown in Table 2. Additional data are given in Online Resource 1.

In this study, the gene fragments (ureA, amoA, nirS, and narH) of urease, AMO, NIR, and NAR were successfully amplified from a strain of Halomonas for the first time. This provides a molecular theoretical basis for the simultaneous removal of CO(NH2)2-N and inorganic N from high-salt N-containing wastewater by Halomonas.

Effects of different NaCl concentrations in the enzymatic reaction system on the N-removal enzyme activities of Halomonas sp. H36

At the enzymology level, under different NaCl concentrations (0, 30, 60, 90, and 120 g/L) in the enzyme reaction system, without adding exogenous ectoine, the activities of the N-removal enzymes of Halomonas sp. H36 were investigated and the results are shown in Fig. 3.

The N-removal enzymes of Halomonas sp. H36 still had good activity under high NaCl concentrations in the enzymatic reaction system. With the increase in NaCl concentration in the enzyme reaction system, the activities of the N-removal enzymes decreased to varying degrees. When NaCl = 120 g/L, the enzyme activities of urease, AMO, NIR, and NAR still retained 74.25%, 22.26%, 32.01%, and 26.82%, respectively. Compared with Halomonas sp. B01 NAR, there was no enzymatic activity under 120 g/L NaCl (Wang et al. 2020a, b). In this study, the N-removal enzymes (urease, AMO, NIR, and NAR) of Halomonas sp. H36 still had enzymatic activities under high-NaCl concentrations.

The effects of salinity on the activities of N-removal enzymes (urease, AMO, NIR, and NAR) in the enzymatic reaction system were investigated. N-removal enzyme activity is the key factor for the high-salt N-removal action of the strain (Baddam et al. 2016). Cortes-Lorenzo et al. (2012) found that high salinity affects the activity of denitrification-related enzymes, which is the same phenomenon observed in this study. Halomonas sp. H36 urease still had high activity under high-salt conditions, which was similar to Halomonas venusta TJPU05 AMO (Man et al. 2022). AMO, NIR, and NAR of Halomonas sp. H36 were still active under high-salt conditions. The results showed that the N-removal enzymes of Halomonas sp. H36 could still function in a high-salinity environment. These findings lay a theoretical foundation for Halomonas sp. H36 to treat high-salt noxious wastewater.

The N-removal process of Halomonas sp. H36 using urea as a substrate

We explored the N contents of various nitrogen species (CO(NH2)2-N; NH4+-N; NO2−-N; NO3−-N) and their relationship with each other in the N-removal process of Halomonas sp. H36 with urea as the sole N source. The results are shown in Fig. 4.

Halomonas sp. H36 cells were in the logarithmic growth stage from 0 to 48 h, and 219 mg/L N was used for cell growth. At this stage, the CO(NH2)2-N-removal rate was 73.11%, and the content of NH4+-N produced by the hydrolysis of CO(NH2)2-N gradually increased. This stage is dominated by the hydrolysis of urea by Halomonas sp. H36 (CO(NH2)2-N → NH4+-N).

Halomonas sp. H36 was in the quiescent growth stage from 48 to 192 h. At this stage, the CO(NH2)2-N-removal rate was 6.21%, the NH4+-N-removal rate was 73.44%, and the TN-removal rate was 53.62%. Very low levels of NO3−-N (≤ 40 mg/L) and NO2−-N (≤ 10 mg/L) were detected, and at 156 h, NO3−-N and NO2−-N were basically removed indicating that the removal of N by Halomonas sp. H36 was dominant at this stage. Cells in the resting state converted NH4+-N into gaseous N through simultaneous nitrification and denitrification (SND), avoiding the negative impact of the accumulation of NO2−-N and NO3−-N on the cells.

The results show that in the presence of only CO(NH2)2-N, the cells in the growing state first converted CO(NH2)2-N into NH4+-N under the catalysis of urease, and the removal of N was not obvious at this stage. In the resting state, under the catalysis of AMO, NIR, and NAR, cells converted NH4+-N into gaseous N, and the removal of N was mainly completed at this stage. During the whole process (0–192 h), the removal rate of CO(NH2)2-N was 74.77%, and the N-removal rate was 57.67%.

In this experiment, with 2,800 mg/L of initial CO(NH2)2-N, the CO(NH2)2-N degradation rate of Halomonas sp. H36 was 74.77%, and the TN-removal rate was 57.67%. This value was 1.62 times that of Pseudomonas mendocina sp. DM01, and with an initial CO(NH2)2-N concentration of 400 mg/L, the TN-removal rate was 35.50% (Chen 2018). Compared with mixed strains, it had stronger salt tolerance (Wang et al. 2020a, b).

The activity of N-removal enzymes was determined, and the N-removal enzymes of Halomonas sp. H36 were localized, as shown in Table 3. Most ureases are cytoplasmic enzymes (Mulrooney et al. 1989), and NIR is a periplasmic space enzyme (Blackmore et al. 1986). Therefore, it can be inferred that Halomonas sp. H36 urease is a cytoplasmic enzyme, AMO and NAR are cell membrane-bound enzymes, and NIR is a periplasmic space enzyme. Combined with the above experimental results, the N-removal pathway of Halomonas sp. H36 with urea as the substrate was obtained, as shown in Fig. 5.

With urea as the only N source, cells in the logarithmic growth phase mainly converted CO(NH2)2-N into NH4+-N under the catalysis of urease. Under the catalysis of AMO, NIR, and NAR, the cells in the resting state removed NH4+-N in the form of gaseous N and completed the SND. Halomonas sp. H36 completed simultaneous urea hydrolysis-nitrification–denitrification with urea as the initial substrate.

Application of Halomonas sp. H36 in simulating domestic sewage from ships

Halomonas sp. H36 was transferred to simulated ship domestic sewage for treatment, and the results are shown in Fig. 6. In the whole process, the removal rate of CO(NH2)2-N was 88.52%, the removal rate of NH4+-N was 91.16%, and the TN-removal rate was 90.25%.

It was found that in 0–36 h, CO(NH2)2-N decreased from 48.52 to 18.80 mg/L, and 29.72 mg/L CO(NH2)2-N was converted into NH4+-N. The NH4+-N in the matrix only increased by 24.61 mg/L, and 5.11 mg/L NH4+-N was removed. In this process, the degradation rate of CO(NH2)2-N was 0.83 mg/(L·h), and the degradation rate of NH4+-N was 0.14 mg/(L·h). This process was dominated by the degradation of CO(NH2)2-N. It was shown that urease, AMO, NIR, and NAR in cells can play roles in the presence of CO(NH2)2-N and NH4+-N. However, urea degrades more rapidly. At 36–192 h, the CO(NH2)2-N decreased from 18.8 to 5.57 mg/L, the NH4+-N decreased from 137.84 to 10.01 mg/L, the CO(NH2)2-N-removal rate was 0.09 mg/(L·h), and the NH4+-N degradation rate was 0.82 mg/(L·h). The process was dominated by nitrification–denitrification. This may have been due to the low level of CO(NH2)2-N at this time, and NH4+-N accounted for 88.00% of the TN. This caused the enzymatic hydrolysis of urea to gradually weaken, and nitrification–denitrification became dominant.

NO2−-N (≤ 5 mg/L) and NO3−-N (≤ 10 mg/L) were detected. At 96 h, NO3−-N and NO2−-N were completely removed. It was proven that the strain avoided the negative impact of the accumulation of NO2−-N and NO3−-N on the cells and ensured effluent quality.

In this section, the results proved that Halomonas sp. H36 has the ability to simultaneously remove CO(NH2)2-N and inorganic N from ship domestic sewage. The CO(NH2)2-N-removal rate of Halomonas sp. H36 was 88.52%, the NH4+-N-removal rate was 91.16%, and the TN-removal rate was 90.25%. These results have obvious advantages compared with Pseudoalteromonas sp. SCSE709-6 (TN = 70 mg/L, with an TN-removal rate of approximately 50%) (Jiang et al. 2019).

Conclusions

In this paper, it was found for the first time that Halomonas sp. H36 has the function of simultaneous urea hydrolysis-nitrification–denitrification with urea as the initial substrate. It could simultaneously move CO(NH2)2-N and inorganic N in high-salt urea wastewater. Ectoine synthesized by Halomonas sp. H36, which is used to regulate osmotic pressure, protects the strain activity and allows urease production in a high-salt environment. The key roles of urease, AMO, NIR, and NAR in removing N were proven by molecular biology and enzymatic methods, and the simultaneous urea hydrolysis-nitrification–denitrification pathway was clarified by using urea as the initial substrate. The TN-removal rate of the strain in simulated ship sewage was 90.25%. In the future, Halomonas sp. H36 can be combined with an actual high-salt urea wastewater treatment process.

Data availability

All data are mentioned in the body of manuscript, tables, and figure.

References

Baddam R, Reddy GB, Raczkowski C, Cyrus JS (2016) Activity of soil enzymes in constructed wetlands treated with swine wastewater. Ecol Eng 91:24–30. https://doi.org/10.1016/j.ecoleng.2016.01.021

Blackmore R, Roberton AM, Brittain T (1986) The purification and some equilibrium properties of the nitrite reductase of the bacterium Wolinella succinogenes. Biochem J 233:547–552. https://doi.org/10.1042/bj2330547

Blasco F, Pommier J, Augier V, Chippaux M, Giordano G (1992) Involvement of the narJ or narW gene product in the formation of active nitrate reductase in Escherichia coli. Mol Microbiol 6:221–230. https://doi.org/10.1111/j.1365-2958.1992.tb02003.x

Chen H (2018) Heterotrophic nitrification-aerobic denitrification compound bacteria for enhanced denitrification and urea removal, Dissertation, Jinan University

Chen Y, Chen H, Chen Z, Zhu Z, Wang X (2022) The nitrogen removal performance and mechanisms for urea wastewater by simultaneous urea hydrolysis, partial nitritation and anammox in one reactor. J Clean Prod 332:130124. https://doi.org/10.1016/j.jclepro.2021.130124

Cortes-Lorenzo C, Rodriguez-Diaz M, Lopez-Lopez C, Sanchez-Peinado M, Rodelas B, Gonzalez-Lopez J (2012) Effect of salinity on enzymatic activities in a submerged fixed bed biofilm reactor for municipal sewage treatment. Biores Technol 121:312–319. https://doi.org/10.1016/j.biortech.2012.06.083

Eaton AD, Clesceri LS, Greenberg AE, Franson (1966) Standard methods for the examination of water and wastewater. Am J Public Health Nations Health 56: 387–388. https://doi.org/10.2105/AJPH.56.4.684-a

Ensign SA, Hyman MR, Arp DJ (1993) In vitro activation of ammonia monooxygenase from Nitrosomonas europaea by copper. J Bacteriol 175:1971–1890. https://doi.org/10.1128/JB.175.7.1971-1980.1993

Garrido JM, Méndez R, Lema JMJWR (2001) Simultaneous urea hydrolysis formaldehyde removal and denitrification in a multifed upflow filter under anoxic and anaerobic conditions. Water Res 35:691–698. https://doi.org/10.1016/S0043-1354(00)00311-0

Hu XR, Zhu JY, Li JF, Wu QS (2020a) Urea electrooxidation: current development and understanding of Ni-based catalysts. ChemElectroChem 7:3211–3228. https://doi.org/10.1002/celc.202000404

Hu H, Deng C, Wang X, Chen Z, Wang RJC (2020b) Performance and mechanism of urea hydrolysis in partial nitritation system based on SBR. Chemosphere 258:127228. https://doi.org/10.1016/j.chemosphere.2020.127228

Hyman MR, Arp DJ (1992) 14C2H2- and 14CO2-labeling studies of the de novo synthesis of polypeptides by Nitrosomonas europaea during recovery from acetylene and light inactivation of ammonia monooxygenase. J Biol Chem 267:1534–1545. https://doi.org/10.1016/S0021-9258(18)45979-0

Ilgrande C, Defoirdt T, Vlaeminck SE, Boon N, Clauwaert PJA (2019) Media optimization, strain compatibility, and low-shear modeled microgravity exposure of synthetic microbial communities for urine nitrification in regenerative life-support systems. Astrobiology 19:1353–1362. https://doi.org/10.1089/ast.2018.1981

Jia F, Liu Y, Yu X, Cai W, Xing W, Yao J (2020) Research progress on the principle and process of biological treatment of urea wastewater. Chinese Environ Sci 12:5270–5279. https://doi.org/10.19674/j.cnki.issn1000-6923.2020.0583

Jiang M, Bao M (2005) Application of p-dimethylamino-benzaldehyde colorimetric method in the determination of constant urea. Chemical Industry Bao J 36:4. https://doi.org/10.3969/j.issn.1006-4184.2005.03.019

Jiang L, Chen X, Qin M, Cheng S, Wang Y, Zhou W (2019) On-board saline black water treatment by bioaugmentation original marine bacteria with Pseudoalteromonas sp. SCSE709-6 and the associated microbial community. Biores Technol 273:496–505. https://doi.org/10.1016/j.biortec-h.2018.11.043

Jimenez J, Bott C, Love N, Bratby JJPotWEF, (2012) Source separation of urine as an alternative solution to nutrient management in wastewater treatment plants: a model-based analysis. Proc Water Environ Fed 10:5308–5323. https://doi.org/10.2175/193864712811709724

Kushner DJJA (1985) Chapter 3—the halo-bacteriaceae. 171–214. https://doi.org/10.1016/B978-0-12-307208-5.50009-X

Lee AJJ (1971) Forms of organic nitrogen in domestic wastewater. J Water Pollut Control Fed 43:2271–2279. https://doi.org/10.2307/25037233

Li P (2018) Research on ADC industrial wastewater resource recovery and treatment technology. Dissertation, Harbin Engineering University. CNKI:CDMD:2.1018.286066

Li Z, Shi X, Zhang J (2015) Distribution characteristics of urea and composition of dissolved nitrogen in seawater of the Yellow Sea and Bohai Sea in spring. Environ Sci 6. https://doi.org/10.13227/j.hjkx.2015.11.008

Li YJ, Liang XY, Zhang LH, Iop (2020) Study on the properties of Halomonas urease and optimization of its production conditions, 6th International Conference on Advances in Energy Resources and Environment Engineering (ICAESEE). IOP Conference Series-Earth and Environmental Science, Chongqing, PR China. https://doi.org/10.1088/1755-1315/647/1/012099

Ma L, Pang AP, Luo YS, Lu XL, Lin FM (2020) Beneficial factors for biomineralization by ureolytic bacterium Sporosarcina pasteurii. Microb Cell Fact 19:12. https://doi.org/10.1186/s12934-020-1281-z

Man QL, Zhang PL, Huang WQ, Zhu Q, He XL, Wei DS (2022) A heterotrophic nitrification-aerobic denitrification bacterium Halomonas venusta TJPU05 suitable for nitrogen removal from high-salinity wastewater. Front Environ Sci Eng 16. https://doi.org/10.1007/s11783-021-1503-6

Martı́nez-Espinosa RM, Marhuenda-Egea FC, Bonete MJ (2001) Purification and characterisation of a possible assimilatory nitrite reductase from the halophile archaeon Haloferax mediterranei. Fems Microbiol Lett 196:133–138. https://doi.org/10.1111/j.1574-6968.2001.tb10550.x

Ministry of Ecology and Environment of the People’s Republic of China (2020) Bulletin on the state of China’s marine ecological environment in 2020. https://www.mee.gov.cn/hjzl/sthjzk/jagb/. Accessed 26 May 2021

Mulrooney SB, Pankratz HS, Hausinger RP (1989) Regulation of gene expression and cellular localization of cloned Klebsiella aerogenes (K. pneumoniae) urease. J Gen Microbiol 135:1769–1776. https://doi.org/10.1099/00221287-135-6-1769

Ono H, Sawada K, Khunajakr N, Tao T, Murooka Y (1999) Characterization of biosynthetic enzymes for ectoine as a compatible solute in a moderately halophilic eubacterium Halomonas elongata. J Bacteriol 181:91–99. https://doi.org/10.1109/EPTC.2003.1271569

Pernetti M, Palma LDJET (2005) Experimental evaluation of inhibition effects of saline wastewater on activated sludge. Environ Technol 26:695–704. https://doi.org/10.1080/09593330.2001.9619509

Rittstieg K, Robra KH, Somitsch WJAM (2001) Aerobic treatment of a concentrated urea wastewater with simultaneous stripping of ammonia. Appl Microbiol Biotechnol 56:820–825. https://doi.org/10.1007/s002530100696

Sun HF, Wang HW, Yuan CY (2013) Optimization of zinc-cadmium reduction method for determination of nitrate in seawater, 3rd International Conference on Energy, Environment and Sustainable Development (EESD 2013). Advanced Materials Research, Shanghai, PR CHINA, pp. 1004–1007. https://doi.org/10.4028/www.scientific.net/AMR.864-867.1004

Thuoc DV, Hien TT, Sudesh K (2019) Identification and characterization of ectoine-producing bacteria isolated from Can Gio mangrove soil in Vietnam. Ann Microbiol 69:819–828. https://doi.org/10.1007/s13213-019-01474-7

Tzilkowski SS, Buda AR, Boyer EW (2018) Urea fluctuations in stream baseflow across land cover gradients and seasons in a coastal plain river system. J Am Water Resour Assoc 55:228–246. https://doi.org/10.1111/1752-1688.12716

Urbańczyk E, Sowa M, Simka W (2016) Urea removal from aqueous solutions—a review. J Appl Electrochem 46:1011–1029. https://doi.org/10.1007/s10800-016-0993-6

Vaneeckhaute C, Fazli A (2020) Management of ship-generated food waste and sewage on the Baltic Sea: a review. Waste Manage 102:12–20. https://doi.org/10.1016/j.wasman.2019.10.030

Vyrides I, Stuckey DC (2009) Adaptation of anaerobic biomass to saline conditions: role of compatible solutes and extracellular polysaccharides. Enzyme Microb Technol 44:46–51. https://doi.org/10.1016/j.enzmictec.2008.09.008

Wang R (2009) Microbial regulation of calcium carbonate formation and its application in defect repair of cement-based materials. Dissertation, Southeast University. https://doi.org/10.7666/d.y1847540

Wang T, Li J, Zhang LH, Yu Y, Zhu YM (2017) Simultaneous heterotrophic nitrification and aerobic denitrification at high concentrations of NaCl and ammonia nitrogen by Halomonas bacteria. Water Sci Technol 76:386–395. https://doi.org/10.2166/wst.2017.214

Wang X, Zhu H, Shutes B, Fu B, Yan B, Yu X, Wen H, Chen X (2019) Identifcation and denitrifcation characteristics of a salt-tolerant denitrifying bacterium Pannonibacter phragmitetus F1. AMB Express 193: 193–204. https://doi.org/10.1186/s13568-019-0918-y

Wang T, Li YJ, Zhang LH, Liu WF, Zhu YM (2020a) Salt tolerance of nitrate reductase in Halomonas sp. B01. Folia Microbiol 65:909–916. https://doi.org/10.1007/s12223-020-00801-9

Wang M-M, Cao G, Zhang D, Feng N-X, Pan Y-Z (2020b) Removal of urea by heterotrophic nitrification-aerobic denitrification mixed strains and effects of heavy metals and salinity. Huan jing ke xue= Huanjing kexue 41:2787–2795. https://doi.org/10.13227/j.hjkx.201911116

Yang M, Liu J, Zhang X, Richardson SD (2015) Comparative toxicity of chlorinated saline and freshwater wastewater effluents to marine organisms. Environ Sci Technol 49:14475–14483. https://doi.org/10.1021/acs.est.5b03796

Zhang LH, Lang YJ, Nagata S (2009) Efficient production of ectoine using ectoine-excreting strain. Extremophiles 13:717–724. https://doi.org/10.1007/s00792-009-0262-2

Zhang D, Zhong W, Zhang C, Lu F, Bie X, Lu J (2012) Optimization of lipoxygenase production conditions of recombinant Bacillus subtilis by response surface methodology. J Nucl Agron 26: 324-329. CNKI:SUN:HNXB.0.2012-02-024

Zhao Q, Meng Y, Li S, Lv P, Xu P, Yang C (2018) Genome sequence of Halomonas hydrothermalis Y2 an efficient ectoine-producer isolated from pulp mill wastewater. J Biotechnol 285:38–41. https://doi.org/10.1016/j.jbiotec.2018.08.017

Zhou Y, Tang K, Wang P, Wang W, Wang X (2020) Identification of bacteria-derived urease in the coral gastric cavity. Sci China Earth Sci 63:1553–1563. https://doi.org/10.1007/s11430-020-9647-x

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by YL, LZ, WL, and ZZ. The first draft of the manuscript was written by YL. And all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Gerald Thouand

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Zhang, L., Liu, W. et al. Simultaneous removal of urea nitrogen and inorganic nitrogen from high-salinity wastewater by Halomonas sp. H36. Environ Sci Pollut Res 30, 2544–2554 (2023). https://doi.org/10.1007/s11356-022-22018-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22018-8