Abstract

Naphthalene (NAPH) and phenanthrene (PHEN) are two of the most abundant polycyclic aromatic hydrocarbons (PAHs) found in nature, and they are considered in the list of US EPA priority pollutants. The contribution of this research lies in the comprehensive analysis of a strategy for the coupling of electro-oxidation (EO) and biodegradation in a submerged membrane bioreactor (SMBR) with the objective to remove PAHs, using NAPH and PHEN as model compounds. The electrochemical degradation of NAPH and PHEN in aqueous synthetic solution has been carried out using two different anodes: Ti/IrO2 and Ti/SnO2. The effects of EO operating parameters (current density, reaction time, and pH) on the NAPH and PHEN removals were investigated applying 23 factorial design with both electrodes. Additionally, the EO effluents were analyzed for COD, NH4-N, and biodegradability (respirometry tests). The highest removals of both compounds were reached with Ti/IrO2 anode, at acidic conditions (pH of 2), current density of 50 mA cm−2, and electrolysis time of 60 min. However, the Ti/SnO2 anode allowed greater reduction of the biomass inhibition, which means that the enhancement of the EO effluent biodegradability was reached; therefore, this electrode was selected for the coupled EO–SMBR system, applying the operating conditions that improved the biodegradability of the effluent. The EO process allowed NAPH and PHEN removal efficiencies of 96 ± 5% and 94 ± 3%, respectively. The membrane bioreactor was operated with organic load of 0.6 ± 0.1 gCOD gVSS−1 d−1, hydraulic retention time of 6 h, and solid retention time of 30 d, obtaining average COD, NH4-N, NAPH, and PHEN removals of 98±0.5%, 91±6.4%, 99.1±0.96%, and 99.7±0.4% respectively. The sorption of phenanthrene onto the biomass had a low contribution, 0.9±0.2%, concluding that biodegradation was the main removal mechanism in the bioreactor. The coupled system EO–SMBR allowed high NAPH and PHEN removal efficiencies of 99.99±0.01 and 99.99±0.02%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The main input sources of polycyclic aromatic hydrocarbons (PAHs) in the environment are anthropogenic as they are by-products of deficient combustion of fossil fuels and organic matter, waste incineration, fuel-burning cookstove, petroleum refining and petrochemical processes, car exhausts, and in the production of coke, asphalt, coal tar, and black carbon (Forsgren 2015). PAHs may also be emitted directly to the receiving water bodies via municipal and industrial wastewater discharges, stormwater runoff, and road dust and through accidental spilling of hydrocarbons and oils and leaching from creosote-impregnated wood (Busetti et al. 2006; Fatone et al. 2011; Zhang et al. 2013).

Naphthalene (NAPH) and phenanthrene (PHEN) were selected as model compounds for this study as they are two of the most abundant PAHs found in nature, and therefore, they are frequently used as indicators for monitoring PAH-contaminated wastes (Tian et al. 2012). NAPH structure consists of a fused pair of benzene rings, which is a derivative of crude oil and coal tar, also used for the fabrication of insecticides, plastics, dyes, resins, wood preservatives, lubricants, and fuels (Sharma and Lee 2015). PHEN is an organic compound constituted by three benzene rings, employed in the synthesis of dyes, explosives, drugs, and phenantroquinone (Larrañaga et al. 2016). Since their toxicity and environmental persistence are known, both compounds are considered in the list of US EPA priority pollutants (Keith and Telliard 2005). Their occurrence and fate in aquatic environments are influenced by their physicochemical properties (Dabestani and Ivanov 1999). According to Mojiri et al. (2019), NAPH and PHEN have been found at levels ranging from 40 to 47,000 and 33 to 6,495,000 ng L−1, respectively, in water and wastewater. NAPH and PHEN physicochemical properties are shown in Table S1 of the supplementary material.

Advanced oxidation processes (AOPs) are characterized by the generation of highly reactive oxidant species that can mineralize the organic contaminants. These processes are useful as pre-treatment of biological process to oxidize toxic and hardly biodegradable pollutants or as a post-treatment for polishing before discharging to a receiving body (Urtiaga et al. 2018). Among these processes, there are electrochemical methods, which have gained interest in the last years for the treatment of wastewater contaminated with PAHs (Gargouri et al. 2014; Rajasekhar et al. 2021). Electro-oxidation (EO) is the most popular electrochemical process for the degradation of organic compounds in wastewater. This technology has become a promising method for the oxidation of toxic and bio-refractory compounds found in wastewater due to its high efficiency and mild operating conditions (ambient temperature and air pressure). The EO reactors are compact and easy to automate; the process does not produce waste streams and is relatively low-cost (Martínez-Huitle et al. 2015; Garcia-Segura et al. 2018), mainly when the reactors are powered by renewable energy sources (Ganiyu et al. 2020).

During the electrochemical treatment, organic compounds are oxidized by direct transfer of electrons on the surface of the anode or indirectly by the production of oxidants such as hydroxyl radical (·OH) or active chlorine species (Martínez-Huitle et al. 2015). According to the reaction mechanisms presented in the electro-oxidation process, the anode materials have been classified into two main groups: active and non-active (Martínez-Huitle and Ferro 2006). The active anodes (Ti/IrO2, Ti/RuO2, or Ti/Pt) can transform the pollutants to intermediate products. Nevertheless, the non-active ones [Ti/PbO2, Ti/SnO2, or boron-doped diamond (BDD)] can promote a complete oxidation of the organic compounds to CO2. The first reaction occurring in both kinds of anodes is the oxidation of water molecules (Eq. (1)) leading to the formation of adsorbed ·OH radicals on the anode surface (M) (Martínez-Huitle and Ferro 2006; De Battisti and Martínez-Huitle 2018):

Depending on the nature of the anode, an active anode surface interacts strongly with ·OH, and then a so-called oxide or superoxide (MO) may be formed (Eq. (2)), where the redox couple MO/M acts as a mediator in the oxidation of organic compounds (R) according to Eq. (3):

Contrarily, a non-active anode surface interacts weakly with ·OH, allowing a nonselective oxidation of organic contaminants, so a complete oxidation could be reached (Eq. (4)):

On the other hand, the oxidation of organic compounds by electrochemical methods may induce the formation of by-products more toxic and bio-recalcitrants than the original compounds, especially when active chlorine species are produced (Martínez-Huitle et al. 2015). For this reason, the determination of the optimal conditions of the process (electrodes material, current density, electrolysis time, pH of the medium, and ionic composition) must be supported by ecotoxicological assays (such as based on the growth inhibition of algae or plants, the mortality of crustaceans, and the inhibition mobility of Daphnia magna) (Mendonça et al. 2014) or biodegradability tests (aerobic or anaerobic systems) (Xiao et al. 2015).

Concerning biological processes for wastewater treatment, a submerged membrane bioreactor is defined as a system integrated by an activated sludge process with a submerged membrane ultrafiltration or microfiltration module for the sludge separation (Judd 2016). The submerged membrane bioreactor (SMBR) has proven to be very effective in the treatment of municipal and industrial wastewater (Sabrina et al. 2013; Ma et al. 2018). Some advantages of this process are as follows: good control of the biological activity (high concentration of biomass and high solid retention time); a possibility to apply high organic rates; smaller plant size compared with conventional systems; effluent free of suspended solids, with low turbidity; and free of viruses and bacteria (Judd 2016). SMBR can provide an appropriate medium for the biodegradation of PAHs due to the high amount of biomass in the mixed liquor and to the high solid retention time. These conditions allow better acclimation of the microorganisms to toxic and bio-recalcitrant compounds, improving its capacity of degradation compared with conventional biological systems (Mohammad et al. 2015; Alkmim et al. 2017).

The combination of EO followed by a biological treatment is a strategy gaining interest for wastewater treatment (Carboneras et al. 2018; Trellu et al. 2016). According to Mousset et al. (2020), there are three main advantages of this combination: non-selectivity towards organic compound oxidation, allowing its application to almost any kind of wastewater; EO is able to avoid the accumulation of toxic by-products due to the high degradation rates; high current efficiencies can be reached when the wastewater contains high concentrations of organic compounds.

The present work focuses on the coupling of electro-oxidation and biodegradation in a submerged membrane bioreactor for the removal of polycyclic aromatic hydrocarbons, using NAPH and PHEN as model compounds. The electrochemical degradation of NAPH and PHEN in aqueous solution has been carried out by anodic oxidation using two different anodes (Ti/IrO2 and Ti/SnO2). The effect of the operating parameters’ current density, reaction time, and pH on the EO performance was investigated through 23 factorial design. Then, biodegradability levels before and after the electrochemical treatment (at different operating conditions) were determined by respirometric tests. Finally, the capacity of a combined EO–SMBR was evaluated for COD, NH4-N, NAPH, and PHEN removals.

Materials and methods

Experimental setup

A rectangular electrochemical reactor elaborated of acrylic was used, with an effective volume of 2.3 L. The tested anodes were plane electrodes of Ti/IrO2 or Ti/SnO2; the cathode was stainless steel (316 L) with plane configuration, vertically placed in front of the anode with an inter electrode gap of 1.3 cm. All electrodes had a geometric area of 110 cm2 (10 × 11 cm). The current input was supplied by a DC power source, Sorensen DLM40-15 (40 V–15 A). As turbulence promotor, the system was provided with a recirculation loop assembled with a digital Masterflex peristaltic pump. All assays were conducted in batch mode under galvanostatic conditions and at room temperature (25 °C).

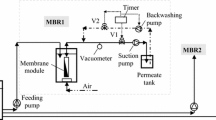

The SMBR was made of acrylic, and it had a cylindrical shape with an effective volume of 1.5 L. It had a submerged polysulfone ultrafiltration membrane module of hollow fiber (molecular weight cut-off of 100 kDa and surface area of 0.042 m2) General Electric®. The SMBR was constituted of a vacuometer to measure the transmembrane pressure, two Masterflex digital peristaltic pumps, and two solenoid valves for the cycle control. The cycles’ permeate backwashing was semiautomated by a control panel. The diagrams of the experimental setup of EO and SMBR are shown in Fig. 1 and Fig. 2, respectively.

Synthetic wastewater

Naphthalene (C10H8) and phenanthrene (C14H10), obtained from Sigma-Aldrich®, were dissolved in methanol (CH3OH) and diluted with tap water to have an initial concentration of NAPH and PHEN of 5 and 1 mg L−1, respectively. The organic fraction of the synthetic wastewater was mainly composed by methanol. For the maintenance of microbial metabolism, it was necessary to add macro- and micronutrients to ensure adequate performance of aerobic bacteria. Ammonium chloride (NH4Cl) and potassium hydrogen phosphate (K2HPO4) were added to get a C/N/P mass ratio of 100:5:1. The addition of micronutrients was based on Mijaylova and Esquivel (2016). Furthermore, 0.01 M sodium sulfate (Na2SO4) was added as supporting electrolyte to increase the water’s conductivity. All the reactives used were J.T. Baker® analytic grade. A characterization of synthetic wastewater is shown in Table 1.

COD, chemical oxygen demand; NH4-N, ammonia nitrogen; Cl−, chlorides; SO4−2, sulfates; TDS, total dissolved solids

Experimental procedure

Electro-oxidation assays

In order to determine the effect of the operational parameters on NAPH and PHEN removal efficiencies by electro-oxidation process, a 23 factorial design in duplicate (16 randomized experiments) was performed. Galvanostatic EO assays were conducted at initial pH of 2 and 8 (factor A), electrolysis time (te) of 20 and 60 min (factor B), and current density (j) of 10 and 50 mA cm−2 (factor C), maintaining a constant recirculation flow rate (Qr) of 4 L min−1, using both Ti/IrO2 and Ti/SnO2 anodes (coded factors are shown in Table S2 in supplementary material). The statistical analysis was carried out by using the software Design–Expert® v11. Before each experiment, the electrodes were washed with 5% (v/v) HNO3 and rinsed with tap water to remove the deposits from the surface that could decrease the process efficiency. The specific energy consumption (SEC), defined as the amount of energy consumed per unit mass of the removed organic pollutants during the electro-treatment, was calculated using Eq. (5) (Garcia-Segura et al. 2017):

where E is the cell potential (V); I is the current intensity (A); te is the treatment time (h); Vs is the volume of the electrolytic solution (L); R is the removal percentage of each pollutant (decimal); and C0 is the initial concentration of the pollutant (mg L−1). SEC units are kWh mg−1 pollutant.

Biodegradability tests: respiration inhibition

The aim of these assays was to evaluate the biodegradability of synthetic wastewater with NAPH and PHEN before and after electrochemical treatment at different operating conditions. The biodegradability tests were based on the respiration rate of an activated sludge consortium, using the Organisation for Economic Co-operation and Development 209 method (OECD 2010). The tests were done by duplicating with non-acclimated activated sludge taken from the bioreactor of a domestic wastewater treatment plant (WWTP). The exposure of the activated sludge consortium to the test sample was performed in a vessel with an effective volume of 1.5 L, at room temperature, and ensuring a dissolved oxygen (DO) concentration of 6 mg L−1. The respiration rate was measured after 30 min of exposure. These measurements were done in 1 L plastic flask with cap, having immersed a Hach electrode model SensION Dissolved Oxygen Probe. During the DO measurements, the solution was mixed with a magnetic bar. Also, two blank controls (without test sample and only with mineral solution) were used at the beginning and the end of the assays to evaluate the biomass respiration without an inhibitor compound. Tests with cupric sulfate pentahydrate (CuSO4•5H2O) as a reference substance of inhibition of the total respiration and an abiotic control (determination of abiotic oxygen consumption by reducer compounds) were performed.

The inhibition percentage (I %) of the test sample can be calculated with Eqs. (6) to (8):

where SOURts is the specific oxygen uptake rate of the test sample (mgO2 gVSS−1 h−1) and SOURc1 and SOURc2 are the specific oxygen uptake rate of the two blank controls (mgO2 gVSS−1 h−1), respectively. OUR is the oxygen uptake rate (mgO2 h−1) and is defined as the slope of oxygen consumption profile. MLVSS is the concentration of mixed liquor volatile suspended solids in test.

Coupling electro-oxidation process and submerged membrane bioreactor

The coupled EO–SMBR system was operated during 29 days. The electrochemical experiments were conducted under galvanostatic conditions in batch regime, using Ti/SnO2 anode and stainless steel cathode. Daily, three batches of EO were carried out to ensure a continuous operation of the SMBR.

The SMBR was filled with acclimated activated sludge obtained from the WWTP. The biomass acclimatization was carried out in a batch bioreactor, containing 10 L of activated sludge (MLVSS of 2500 mg L−1), controlling a food to microorganism ratio (F/M) at 0.05–0.15 gCOD gVSS−1 d−1 and a hydraulic retention time (HRT) of 24 h. The performance of the process was stabilized at day 30, reaching a COD removal greater than 80%. The SMBR influent was adjusted to pH 7 with 0.5 M H2SO4 to guarantee a well metabolic activity and growthing of the biomass. The DO in the reactor was maintained at 4 mg L−1 to ensure the oxygen requirement of the microorganisms for both organic matter degradation and nitrification. In accordance with the results of previously performed hydraulic tests, the selected operational conditions were a permeate flux of 5.95 L m−2 h−1 (flow rate of 6 L d−1) and backwashing flux of 17.1 L m−2 h−1. Backwashing was applied to reduce clogging of the ultrafiltration membrane and maintain subcritical operational conditions. The permeation and backwashing times were 5 min and 15 s, respectively. As a fouling control strategy, every 2 weeks, chemical cleaning of the membrane module was performed submerging it in a 6.7-mM sodium hypochlorite solution for 30 min (Judd 2016). The operating conditions of the EO–SMBR are summarized in Table 2.

Analytical methods

A Hach® multi-parameter model SensION 156 was used for the measurement of pH, temperature, and DO in the samples. The COD were performed following Hach closed reflux/spectrophotometric method. The determination of the total suspended solids (TSS) and volatile suspended solids (VSS) in SMBR was based on standard methods (APHA 2005). The NAPH and PHEN concentrations were determined by gas chromatography coupled to a mass spectrometer detector (GC-MS), using CGVarian® CP-3800, with a HP-5ms column (0.25-mm diameter, 30-m long, and 0.25-μm film thickness), and MD Saturn 2200, based on the US EPA method 8270-D. The GC column temperature was programmed as follows: it was first maintained at 90 °C for 2 min, then heated at a rate of 10 °C min−1 up to 140 °C, then heated at a rate of 20 °C min−1 up to 250 °C (held for 1 min), and finally heated at a rate of 20 °C min−1 up to 300 °C. The temperature was maintained at 260 °C. The carrier gas was helium, and the injection flow was 1 mL min−1.

Results and discussion

Effect of operational conditions: NAPH and PHEN electro-oxidation assays

The results from the factorial design and the duplicates, as well as the predicted responses, and the SEC are shown in Table 3. Furthermore, the analysis of variance (ANOVA) and Pareto charts for NAPH and PHEN are presented in Tables S3 and S4 and Fig. S1, respectively (supplementary material).

According to the ANOVA (Table S3) and Pareto chart (Fig. S1a), pH and te were the most statistically significant factors which influenced NAPH removal (above the Bonferroni limit), followed by j and the interaction pH–j (between the Bonferroni and t-value limits). Furthermore, the coefficient of determination (R2) and the adjusted coefficient of determination (R2adj) were 0.9300 and 0.8775, respectively, indicating that the statistical model provides a good prediction for NAPH removal with Ti/IrO2 within the proposed experimental range.

From the ANOVA and Pareto chart for PHEN removal with Ti/IrO2 (Table S4 and Fig. S1b), pH, te, and j, as well as the triple interaction between them, had the major influence on PHEN removal (above the Bonferroni limit). The double interactions pH–te and pH–j were also significant but with moderate influence (between the Bonferroni and t-value limits). The coefficients R2 and R2adj were 0.9461 and 0.8922, showing the adequate fitting of the statistical model.

The statistical models for the removal of NAPH and PHEN with Ti/IrO2 anode are shown in the Eqs. (9) and (10). These linear equations can be used to predict the removal of NAPH and PHEN during the electro-oxidation process, as shown in Table 3:

The 3D surface response plots for the removal of NAPH and PHEN are shown on Fig. 3, and as it can be seen, the greatest NAPH and PHEN removals were obtained at pH 2 and 60 min of the reaction time, applying a current density of 50 mA cm−2. This can be attributed to the direct oxidation by ·OH radicals at the anode surface and also to the mediated oxidation trough strong oxidants electrogenerated from chloride (Cl−) ions added to the synthetic solution. The production of oxidants (·OH radicals and active chlorine species) with this anode was previously reported in our workgroup (García-Espinoza et al. 2018). At the anode surface, Cl− ions could be oxidized to produce active chlorine species, such as hypochlorous acid (HClO, E° = 1.49 V/SHE), species that predominates at pH between 2 and 6.5 in accordance with Eqs. (11) to (13) (Kraft 2008).

Regarding electrolysis at alkaline conditions (pH = 8), the removal of NAPH and PHEN was lower than the one obtained in the assays at acidic conditions, which may be mainly due to the generation of hypochlorite ion (OCl−, E° = 0.89 V/SHE ), which is a species that prevails at pH 8, and it has lower oxidation power compared to HClO:

In other study (Yaqub et al. 2014), a Ti/IrO2 anode was evaluated for the degradation of 16 PAHs at concentrations on the order of 10 μg L−1, 0.017 M NaCl as supporting electrolyte, applying a current density of 3.33 mA cm−2, pH of 3–9, and 4 h of electrolysis time. NAPH and PHEN were easily oxidized, reaching a complete removal. Herrada et al. (2018) reported removal efficiencies of 93 and 86% for NAPH and PHEN, respectively, in a synthetic solution with 2-μM NAPH or PHEN and 0.05 M Na2SO4, by using Ti/IrO2–Ta2O5 at 66.66 mA cm−2 and neutral conditions, attributing its degradation to the ·OH-mediated oxidation at the surface of the DSA® electrode.

Concerning the experiments with Ti/SnO2 anode, Table 4 shows the factorial matrix, experimental and predicted responses, and the SEC. Besides, Tables S5 and S6 and Fig. S2 added in the supplementary material show the ANOVA and Pareto charts for NAPH and PHEN, respectively.

Results of the ANOVA (Table S4) and Pareto chart (Fig. S2a) for NAPH removal with Ti/SnO2 anode indicated that the three factors (pH, te, and j) and the double interaction between them are statistically significant (p-value < 0.05), being the factors pH, te, and j, those that represent the greatest effect on the removal of the pollutant (above the Bonferroni limit). Contrarily, the ANOVA (Table S5) and Pareto chart (Fig. S2b) showed that only te, pH, and the interaction between pH–j were significant for PHEN removal with Ti/SnO2 anode. The statistical models were adequately fitted, showing the next linear Eqs. (14) and (15). As well, the coefficients R2 and R2adj were 0.9138 and 0.8491 for NAPH and 0.8702 and 0.7981 for PHEN, respectively, confirming the validity of the statistical models. The 3D surface response plots for the removal of NAPH and PHEN with Ti/SnO2 anode are shown in Fig. 4:

According to Fig. 4a, the highest removal efficiency for NAPH was obtained at acidic pH, 60 min electrolysis time, and applying the highest current density (50 mA cm−2). However, it can be noticed in Fig. 4b that the increase of current density did not allow an increment of PHEN removal, even at acidic conditions and 60 min of electrolysis. This behavior could be related to the applied current density (japp). If japp is higher than the limiting current density (jlim), the process is in a regime of mass transfer control. On the contrary, if japp is smaller than jlim, the process is in a regime of charge transfer control (Montiel et al. 2021). Therefore, it can be assumed that under these operational conditions, the electrochemical reaction was limited by the mass transport rate of pollutants towards the anode, explaining the restricted degradation rate. On the other hand, the oxygen evolution reaction (OER) as shown in Eq, (16) could also take place, competing with the ·OH radical production and decreasing the efficiency of the electrochemical process (Martínez-Huitle and Ferro 2006). Thus, the hydrodynamic and the electrode kinetic should be considered to enhance the performance of the electrochemical reactor. Similar behavior was reported by Tran et al. (2009), in the electro-oxidation of PAHs from a synthetic wastewater of the wood industry, applying current densities of 4 to 23 mA cm−2 and obtaining that there were no notable differences in the removal of PAHs at current densities greater than 15 mA cm−2. In addition, they also found that EO at alkaline conditions does not favor the removal of PAHs:

Comparing the performance of both kind of anodes (active and non-active), Ti/IrO2 anode showed the highest removal for both compounds, at acidic conditions (pH = 2), current density of 50 mA cm−2, and electrolysis time of 60 min, with an average removal of 92.0±2.8 and 96.5±2.1 % for NAPH and PHEN. IrO2 based dimensionally stable anodes are known to be good electro-catalysts for active chlorine production, even better than BDD anodes (Kraft 2008), possibly contributing to the higher NAPH and PHEN degradation. Furthermore, the specific energy consumption for NAPH and PHEN removal at the best operational conditions was slightly smaller with Ti/IrO2 anode (6.03 × 10−3 kWh mg−1 NAPH and 3.67 × 10−2 kWh mg−1 PHEN) than the values obtained with Ti/SnO2 anode (6.79 × 10−3 kWh mg−1 NAPH and 3.77 × 10−2 kWh mg−1 PHEN). CO2 emissions related to energy consumption for PAH removal (based on the equivalence reported by Levihn (2014), for natural gas as energy source used to generate electricity) are 2.4 g CO2 mg−1 NAPH and 14.7 g CO2 mg−1 PHEN for Ti/IrO2 anode. For Ti/SnO2, CO2 emissions are 2.7 g CO2 mg−1 NAPH and 15.1 g CO2 mg−1 PHEN.

Immediate inhibition tests of electro-oxidation effluent

The results of inhibition tests using the different anodes, pH, and constant current density of 50 mA cm−2 are shown in Table 5. The blank controls showed an average SOUR of 9.14 mgO2 gVSS−1 h−1, when the typical SOUR for a conventional activated sludge process is in the range of 6–12 mgO2 gVSS−1 h−1 (Yoon 2015). This demonstrates a good activity of the biomass used for the tests. The test performed with the synthetic wastewater only, without any treatment, and after 30 min of exposure, indicated 49 ± 5% inhibition. It should be noted that the synthetic wastewater showed a greater inhibition even than the obtained with cupric sulfate (33.9%), which is widely known as an inhibitory compound of microorganism metabolism in biological wastewater treatment systems (Ochoa-Herrera et al. 2011). As it can be observed, the highest inhibitions in the solutions after EO were obtained at acid conditions (pH = 2) with Ti/IrO2 anode. This behavior can be attributed to the formation of highly toxic organic chlorinated by-products or other chlorine species like chlorate (ClO3−) and perchlorate (ClO4−), where chlorate can be formed electrochemically (Eq (17)) (Martínez-Huitle et al. 2015), chemically resulting in perchlorate (Eqs. (18) to (19)) (Zöllig et al. 2015):

At pH of 5, the average inhibitions obtained using Ti/IrO2 and Ti/SnO2 anodes were 45 ± 5 and 42 ± 5%, respectively, showing a non-significative improvement. At this pH value, HClO is in redox equilibrium with ClO− (Eq. (14)), which can be oxidized to produce ClO3− (Eq. (20)) (Lan et al. 2017), possibly contributing to the lower biodegradability:

In other study, the presence of highly toxic by-product hydrazine (N2H4) was reported in the electro-oxidation of artificial urine with NaCl as supporting electrolyte by IrO2 anode (Eq. (21)) (Li et al. 2015). Hence, the presence of chlorides and free ammonia in the synthetic wastewater could have promoted the electrochemical generation of N2H4:

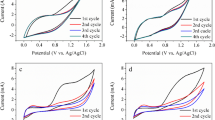

The lowest inhibition was obtained at pH of 8 and using Ti/SnO2 anode, accomplishing 31 ± 5 inhibition percentage. As it can be deduced, the non-active anode could have induced a deeper oxidation via ·OH radicals (E° = 2.8 V/SHE), reducing the toxicity of the treated water and increasing the activated sludge oxygen consumption as a physiological response of the microorganisms. The OD consumption profiles during the immediate inhibition tests of electrochemically treated at pH = 8 and Ti/SnO2 anode, synthetic wastewater (without electrochemical treatment), and a blank control are shown in Fig. 5. In this figure, the increase of the SOUR from 5.07 mgO2 gVSS−1 h−1 (in the synthetic wastewater) to 6.42 mgO2 gVSS-1 h-1 (after de EO treatment) can be observed, demonstrating an improvement in the biodegradability of the solution.

Coupled EO–SMBR process: organic matter and ammonia removal

The performance of the coupled EO–SMBR process is illustrated in Fig. 6. Accordingly to the results of the immediate inhibition tests, EO treatment step was carried out using Ti/SnO2 anode, applying the operating conditions that improved the biodegradability of the effluent (j = 50 mA cm−2, te = 60 min, pH = 8, and Qr = 4 L min−1). The EO’s influent COD and NH4-N concentrations were 865 ± 76 and 29.3 ± 2.9 mg L−1, respectively. For EO assessment, COD and NH4-N removals of 15 ± 4% and 8 ± 4% were reached, respectively, during the 29 days of operation, obtaining an effluent COD of 732 ± 68 mg L−1 and NH4-N of 27 ± 2.4. This results showed a non-significative removal of organic matter and ammonia, indicating that methanol was not oxidized efficiently using the Ti/SnO2 anode, which may be due to its low electrocatalytic activity for the oxidation of alcohols or to the deactivation of the SnO2 layer in the anode surface because of the formation of methanol by-products, as reported for Ti/IrO2 anode (Foti et al. 1999; Hu et al. 2008). However, the main objective of the electrochemical pre-treatment was not to decrease all the content of organic matter and ammonia but to degrade the highest percentage of PAHs (NAPH and PHEN), increasing the biodegradability of the synthetic solution. The improvement of the biodegradability of the synthetic solution could enhance the performance of the subsequent biological treatment, removing completely the residual PAHs.

Throughout the operation, SMBR conditions were maintained at F/M ratio of 0.6 ± 0.1 gCOD gVSS−1 d−1, ammonia loading rate of 0.45 ± 0.09 gNH4-N gTSS −1 h−1, HRT of 6 h, and solid retention time (SRT) of 30 d through an appropriate control of the influent flow rate and excess sludge. The biomass concentration measured as mixed liquor total suspended solids (MLTSS) and mixed liquor volatile suspended solids (MLVSS) in the bioreactor were 5810 ± 677 and 4907 ± 528 mg L−1, respectively, demonstrating a stable growth during the period of the experiment. As it can be seen in Fig. 6, since the first day of assessment, COD and NH4-N removals were above 95 and 80%, respectively, reaching an average of 98 ± 0.5% for COD and 91 ± 6.4% for NH4-N during the evaluation period. Although short HRT was applied, high COD and NH4-N eliminations were obtained. This fact can be linked to the electrochemical pre-treatment, which allowed a stable operation of the biological process.

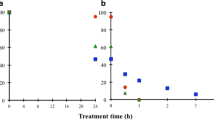

Coupled EO–SMBR process: NAPH and PHEN removal

Related to the PAH concentration in the synthetic wastewater, NAPH and PHEN were 5146 ± 3384 and 810±675 μg L−1, respectively. The coupled EO–SMBR process performance on PAH removal during the 29 days of operation is shown in Fig. 7. As it can be observed, EO NAPH and PHEN removal efficiencies were 96 ± 5 and 94 ± 3%, respectively (Fig. 7a). These results suggest that EO process was not efficient for the global removal of organic matter; however, the degradation of specific compounds such as NAPH and PHEN can be reached as a pre-treatment step. Besides, the SMBR process was fed with the effluent of EO containing 229 ± 299 and 49 ± 60 μg L−1 of NAPH and PHEN, respectively. After the biological treatment, PAHs in SMBR effluent were 0.43 ± 0.5 μg L−1 for NAPH and 0.06 ± 0.07 μg L−1 for PHEN, corresponding to the removals of 99.1 ± 0.96% for NAPH and 99.7 ± 0.4% for PHEN (Fig. 7b) for the period of the experiment. Hence, the coupled EO–SMBR process allowed obtaining NAPH and PHEN global removals of 99.99 ± 0.01 and 99.99 ± 0.02%, respectively.

At the end of the 29 days of assessment, the concentration of NAPH and PHEN in biomass was measured with the purpose of evaluating the influence of sorption of PAHs on its removal at the biological process. The GC-MS analysis showed that 0.00383 μg g−1 of NAPH and 0.01282 μg g−1 of PHEN were present on solids, which means that sorption contribution to the removal of PAHs was only 0.9 ± 0.2%, demonstrating that biodegradation was the main NAPH and PHEN removal mechanism.

It is interesting to compare these results with those obtained under different experimental conditions. Mijaylova and Esquivel (2016) evaluated the removal of NAPH and PHEN in synthetic wastewater with three submerged ultrafiltration membrane bioreactors. In this work, both PAHs were completely biodegraded at HRT and SRT of 8 h and 10 d, respectively, and a F/M ratio of 0.25 gCOD gVSS−1 d−1. Nevertheless, the increase of F/M ratio to 0.34 gCOD gVSS−1 d−1 and the decrease of HRT and SRT to 6 h and 21 d reduced PAH biodegradation till 72 and 60% for NAPH and PHEN, respectively. They concluded that the organic load, HRT, and STR were important factors for NAPH and PHEN removals. Furthermore, it was found that 0.19 μg g−1 of PHEN remained sorbed onto the biomass even at the best operating conditions. In other study accomplished by Fatone et al. (2011), the occurrence, removal, and fate of 16 PAHs, including NAPH and PHEN, were compared in full-scale activated sludge systems and membrane bioreactors. It was concluded that PAH removal in the membrane bioreactor systems was only 56–94% and 77–88% for NAPH and PHEN, respectively, at SRT from 200 to 500 d. Our results showed an SMBR stable operation and a consistent performance on the removal of organic matter, ammonia, and PAHs, inferring that EO was a good pre-treatment for the biological process. This behavior can be attributed to the ·OH-mediated electrochemical oxidation of PAHs and their transformation to less bio-recalcitrant by-products (indirectly proved in the biodegradability tests), additionally to the SRT in SMBR which provided an appropriate biomass acclimatization and biodegradation rates, in spite of relatively high F/M applied. Also, it is known that the long SRT allows an enrichment of slow-growing bacteria such as nitrifying bacteria, clearly presented in the SMBR due to the high ammonia removals, which could have contributed to the biotransformation of the aromatic compounds (Dawas et al. 2014).

Conclusions

This research has evidenced the effectiveness of coupling an electro-oxidation process and submerged membrane bioreactor for naphthalene and phenanthrene removal in a synthetic wastewater. Electro-oxidation allows effective simultaneous degradation of both polycyclic aromatic hydrocarbons. The naphthalene degradation showed a significant dependence of pH, electrolysis time, and current density using both anodes, Ti/IrO2 and Ti/SnO2. The tree factors were statistically significant for phenanthrene removal with the Ti/IrO2 anode; however, only pH and the treatment time were significant for the phenanthrene removal with Ti/SnO2 anode. Under optimal conditions (pH of 2, current density of 50 mA cm−2, and electrolysis time of 60 min), the active dimensionally stable anode Ti/IrO2 demonstrated better naphthalene and phenanthrene degradations compared with the ones obtained with the non-active Ti/SnO2 anode. However, the specific energy consumption for naphthalene and phenanthrene removal was slightly smaller with Ti/IrO2 anode than the values obtained with Ti/SnO2. The results of the performed immediate inhibition tests indicated that there was an enhancement of the biodegradability after the electro-oxidation using Ti/SnO2 anode at pH of 8, reaction time of 60 min, and current density of 50 mA cm−2. In contrast, the biomass respiration was lower when Ti/IrO2 anode was used, which can be attributed to the generation of toxic chlorinated by-products. Therefore, the coupled system electro-oxidation–membrane bioreactor was operated with the Ti/SnO2 anode, applying the operating conditions that improved the biodegradability of the effluent, and the electro-oxidation process allowed naphthalene and phenanthrene removal efficiencies of 96 ± 5% and 94 ± 3%, respectively. The membrane bioreactor was operated with an organic load of 0.6 ± 0.1 gCOD gVSS−1 d−1, HRT of 6 h, and solid retention time of 30 d, obtaining average COD, NH4-N, naphthalene, and phenanthrene removals of 98 ± 0.5%, 91 ± 6.4%, 99.1 ± 0.96%, and 99.7 ± 0.4%, respectively. The sorption of phenanthrene onto the biomass had a low contribution, 0.9 ± 0.2%, concluding that biodegradation was the main removal mechanism in the bioreactor. The integration of electro-oxidation process and submerged membrane bioreactor allowed global naphthalene and phenanthrene removals of 99.99 ± 0.01 and 99.99 ± 0.02%, respectively, and an important reduction on COD and ammonia of 98.3 ± 0.4 and 91.5 ± 5.8%, respectively. The contribution of this research lies in the comprehensive analysis of a strategy for the coupling of electro-oxidation and biodegradation in a submerged membrane bioreactor with the objective to remove naphthalene and phenanthrene.

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Alkmim AR, Paula R, Priscila C, Luzia BM (2017) Potential use of membrane bioreactor to treat petroleum refinery effluent: comprehension of dynamic of organic matter removal, fouling characteristics and membrane lifetime. Bioprocess Biosyst Eng 40(12):1839–1850. https://doi.org/10.1007/s00449-017-1837-4

APHA (2005) Standard methods for the examination of water and wastewater, 20th edn, American Public Health Association/American Water Works Association/Water Environment Federation (APHA-AWWA-WEF). USA, Washington DC

Busetti F, Heitz A, Cuomo M, Badoer S, Traverso P (2006) Determination of sixteen polycyclic aromatic hydrocarbons in aqueous and solid samples from an Italian wastewater treatment plant. J Chromatogr A 1102(1–2):104–115. https://doi.org/10.1016/j.chroma.2005.10.013

Carboneras MB, Cañizares P, Rodrigo MA, Villaseñor J, Fernandez-Morales FJ (2018) Improving biodegradability of soil washing effluents using anodic oxidation. Bioresour Technol 252:1–6. https://doi.org/10.1016/j.biortech.2017.12.060

Dabestani R, Ivanov IN (1999) A compilation of physical, spectroscopic and photophysical properties of polycyclic aromatic hydrocarbons. Photochem Photobiol 70(1):10–34. https://doi.org/10.1111/j.1751-1097.1999.tb01945.x

Dawas A, Gur-Reznik S, Lerman S, Sabbah I, Desoretz C (2014) Co-metabolic oxidation of pharmaceutical compounds by a nitrifying bacterial enrichment. Bioresour Technol 167:336–342. https://doi.org/10.1016/j.biortech.2014.06.003

De Battisti A, Martínez-Huitle CA (2018) Electrocatalysis in wastewater treatment. In: Martínez-Huitle CA, Rodrigo MA, Scialdone O (eds) Electrochemical water and wastewater treatment, 1st edn. Elsevier Incorporated, Oxford, United Kingdom, pp 119–131. https://doi.org/10.1016/B978-0-12-813160-2.00005-5

Fatone F, Di Fabio S, Bolzonella D, Cecchi F (2011) Fate of aromatic hydrocarbons in Italian municipal wastewater systems: an overview of wastewater treatment using conventional activated-sludge processes (CASP) and membrane bioreactors (MBRs). Water Res 45(1):93–104. https://doi.org/10.1016/j.watres.2010.08.011

Forsgren AJ (2015) Wastewater treatment: occurrence and fate of polycyclic aromatic hydrocarbons (PAHs), 1st edn. CRC Press, Boca Raton, USA

Foti G, Gandini D, Comninellis C, Perret A, Haenni W (1999) Oxidation of organics by intermediates of water discharge on IrO2 and synthetic diamond anode. Electrochem Solid-State Lett 2:228–230

Ganiyu SO, Martínez-Huitle CA, Rodrigo MA (2020) Renewable energies driven electrochemical wastewater/soil decontamination technologies: a critical review of fundamental concepts and applications. Appl Catal B Environ 270:118857. https://doi.org/10.1016/j.apcatb.2020.118857

García-Espinoza JD, Mijaylova-Nacheva P, Avilés-Flores M (2018) Electrochemical carbamazepine degradation: effect of the generated active chlorine, transformation pathways and toxicity. Chemosphere 192:142–151. https://doi.org/10.1016/j.chemosphere.2017.10.147

Garcia-Segura S, Eiband MMSG, de Melo JV, Martínez-Huitle CA (2017) Electrocoagulation and advanced electrocoagulation processes: a general review about the fundamentals, emerging applications and its association with other technologies. J Electroanal Chem 801:267–299. https://doi.org/10.1016/j.jelechem.2017.07.047

Garcia-Segura S, Ocon JD, Chong MN (2018) Electrochemical oxidation remediation of real wastewater effluents - a review. Process Saf Environ 113:48–67. https://doi.org/10.1016/j.psep.2017.09.014

Gargouri B, Dridi O, Gargouri B, Kallel S, Abdelhedi R (2014) Application of electrochemical technology for removing petroleum hydrocarbons from produced water using lead dioxide and boron-doped diamond electrodes. Chemosphere 117:309–315. https://doi.org/10.1016/j.chemosphere.2014.07.067

Herrada RA, Acosta-Santoyo G, Sepúlveda-Guzmán S, Brillas E, Sirés I, Bustos E (2018) IrO2-Ta2O5|Ti electrodes prepared by electrodeposition from different Ir:Ta ratios for the degradation of polycyclic aromatic hydrocarbons. Electrochim Acta 263:353–361. https://doi.org/10.1016/j.electacta.2018.01.056

Hu J, Sun X, Hou Y, Zhang J, Cao C (2008) Degradation characteristics of IrO2 -type DSA ® in methanol aqueous solutions. Electrochim Acta 53:3127–3138. https://doi.org/10.1016/j.electacta.2007.11.045

Judd S (2016) Principles and applications of membrane bioreactors for water and wastewater treatment, 1st edn. Elsevier Science, Oxford, United Kingdom

Keith L, Telliard W (2005) ES&T Special report: priority pollutants: I-a perspective view. Environ Sci Technol 13(4):416–423. https://doi.org/10.1021/es60152a601

Kraft BA (2008) Electrochemical water disinfection: a short review. Platin Met Rev 52(3):177–185. https://doi.org/10.1595/147106708X329273

Lan Y, Coetsier C, Causserand C, Serrano KG (2017) On the role of salts for the treatment of wastewaters containing pharmaceuticals by electrochemical oxidation using a boron doped diamond anode. Electrochim Acta 231:309–318. https://doi.org/10.1016/j.electacta.2017.01.160

Levihn F (2014) CO2 emissions accounting: whether, how, and when different allocation methods should be used. Energy 68:811–818. https://doi.org/10.1016/j.energy.2014.01.098

Li H, Yu Q, Yang B, Li Z, Lei L (2015) Electro-catalytic oxidation of artificial human urine by using BDD and IrO2 electrodes. J Electroanal Chem 738:14–19. https://doi.org/10.1016/j.jelechem.2014.11.018

Ma J, Dai R, Chen M, Khan SJ, Wang Z (2018) Applications of membrane bioreactors for water reclamation: micropollutant removal, mechanisms and perspectives. Bioresour Technol 269:532–543. https://doi.org/10.1016/j.biortech.2018.08.121

Martínez-Huitle CA, Ferro S (2006) Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chem Soc Rev 35:1324–1340. https://doi.org/10.1039/b517632h

Martínez-Huitle CA, Rodrigo MA, Sirés I, Scialdone O (2015) Single and coupled electrochemical processes and reactors for the abatement of organic water pollutants: a critical review. Chem Rev 115(24):13362–13407. https://doi.org/10.1021/acs.chemrev.5b00361

Mendonça E, Picado A, Paixão SM, Silva L, Barbosa M, Cuhna MA (2014) Treatment ecotoxicological evaluation of wastewater in a municipal WWTP in Lisbon area (Portugal). Desalin Water Treat 51:4162–4170. https://doi.org/10.1080/19443994.2013.768021

Mijaylova P, Esquivel A (2016) Removal of naphthalene and phenanthrene using aerobic membrane bioreactor. Biodegradation 27(2–3):83–93. https://doi.org/10.1007/s10532-016-9757-6

Mohammad S, Razavi R, Miri T (2015) Engineering a real petroleum refinery wastewater treatment using hollow fiber membrane bioreactor (HF-MBR). J Water Process Eng 8:136–141. https://doi.org/10.1016/j.jwpe.2015.09.011

Mojiri A, Zhou JL, Ohashi A, Ozaki N, Kindaichi T (2019) Comprehensive review of polycyclic aromatic hydrocarbons in water sources, their effects and treatments. Sci Total Environ 696:133971. https://doi.org/10.1016/j.scitotenv.2019.133971

Montiel H, Pechaud Y, Oturan N, Trellu C, Oturan MA (2021) Pilot scale continuous reactor for water treatment by electrochemical advanced oxidation processes: development of a new hydrodynamic/reactive combined model. Chem Eng J 404:127048. https://doi.org/10.1016/j.cej.2020.127048

Mousset E, Trellu C, Olvera-Vargas H, Pechaud Y, Oturan MA (2020) Electrochemical technologies coupled with biological treatments. Curr Opin Electrochem 26:100668. https://doi.org/10.1016/j.coelec.2020.100668

Ochoa-Herrera V, León G, Banihani Q, Field JA, Sierra-Alvarez R (2011) Toxicity of copper(II) ions to microorganisms in biological wastewater treatment systems. Sci Total Environ 412–413:380–385. https://doi.org/10.1016/j.scitotenv.2011.09.072

OECD (2010) Test No. 209: Activated sludge, respiration inhibition test (carbon and ammonium oxidation), OECD guidelines for the testing of chemicals, Section 2. OECD Publishing, Paris. https://doi.org/10.1787/9789264070080-en

Rajasekhar B, Nambi IM, Kumar S (2021) Investigating the degradation of nC12 to nC23 alkanes and PAHs in petroleum-contaminated water by electrochemical advanced oxidation process using an inexpensive Ti/Sb-SnO2/PbO2 anode. Chem Eng J 404:125268. https://doi.org/10.1016/j.cej.2020.125268

Sabrina N, Mutamim A, Zainon Z, Ariffin M, Hassan A, Yuniarto A, Olsson G (2013) Membrane bioreactor: applications and limitations in treating high strength industrial wastewater. Chem Eng J 225:109–119. https://doi.org/10.1016/j.cej.2013.02.131

Sharma A, Lee B (2015) Adsorptive/photo-catalytic process for naphthalene removal from aqueous media using in-situ nickel doped titanium nanocomposite. J Environ Manag 155:114–122. https://doi.org/10.1016/j.jenvman.2015.03.008

Larrañaga MD, Sax NI, Lewis RJ (2016) Hawley’s condensed chemical dictionary, 16th edn. Wiley, New York, USA

Tian W, Bai J, Liu K, Sun H, Zhao Y (2012) Occurrence and removal of polycyclic aromatic hydrocarbons in the wastewater treatment process. Ecotox Environ Safe 82:1–7. https://doi.org/10.1016/j.ecoenv.2012.04.020

Tran L, Drogui P, Mercier G (2009) Electrochemical degradation of polycyclic aromatic hydrocarbons in creosote solution using ruthenium oxide on titanium expanded mesh anode. J Hazard Mater 164(2-3):1118–1129. https://doi.org/10.1016/j.jhazmat.2008.09.012

Trellu C, Ganzenko O, Papirio S, Pechaud Y, Oturan N, Huguenot D, Van Hullebusch ED, Esposito G, Oturan MA (2016) Combination of anodic oxidation and biological treatment for the removal of phenanthrene and Tween 80 from soil washing solution. Chem Eng J 306:588–596. https://doi.org/10.1016/j.cej.2016.07.108

Urtiaga AM, Iban R, Rivero MJ, Ortiz I (2018) Integration of electrochemical advanced oxidation with membrane separation and biodegradation. In: Martínez-Huitle CA, Rodrigo MA, Scialdone O (eds) Electrochemical water and wastewater treatment, 1st edn. Elsevier Incorporated, Oxford, United Kingdom. https://doi.org/10.1016/B978-0-12-813160-2.00018-3

Xiao Y, Araujo CD, Chau C, Stuckey DC (2015) Toxicity measurement in biological wastewater treatment processes: A review. J Hazard Mater 286:15–29. https://doi.org/10.1016/j.jhazmat.2014.12.033

Yaqub A, Isa MH, Rahman S, Kutty M, Ajab H (2014) Surface characteristics of Ti/IrO2 anode material and its electrocatalytic properties for polycyclic aromatic hydrocarbons (PAHs) degradation in aqueous solution. J New Mat of Electr Sys 44(17):39–44. https://doi.org/10.14447/jnmes.v17i1.442

Yoon SH (2015) Membrane bioreactor processes: principles and applications, 1st edn. CRC Press, Boca Raton, USA

Zhang W, Wei C, Yan B, Feng C, Zhao G, Lin C, Yuan M, Wu C, Hu Y (2013) Identification and removal of polycyclic aromatic hydrocarbons in wastewater treatment processes from coke production plants. Environ Sci Pollut R 20(9):6418–6432. https://doi.org/10.1007/s11356-013-1697-7

Zöllig H, Remmele A, Fritzsche C, Morgenroth E, Udert KM (2015) Formation of chlorination byproducts and their emission pathways in chlorine mediated electro-oxidation of urine on active and nonactive type anodes. Environ Sci Technol 49(18):11062–11069. https://doi.org/10.1021/acs.est.5b01675

Acknowledgements

The authors acknowledge the master’s degree scholarship from the Consejo Nacional de Ciencia y Tecnología de los Estados Unidos Mexicanos (CONACYT, Mexico).

Funding

The research was funded by an internal source of the Mexican Institute of Water Technology.

Author information

Authors and Affiliations

Contributions

JTR performed and interpreted EO assays and part of the EO–SMBR coupling. PMN installed the experimental setup and performed and analyzed the biodegradability tests and part of the coupling. JTR and PMN wrote the manuscript. JTR and PMN have equal contribution for this research; they approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philipp Gariguess

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 278 kb)

Rights and permissions

About this article

Cite this article

Treviño-Reséndez, J., Nacheva, P.M. Removal of naphthalene and phenanthrene in synthetic solutions by electro-oxidation coupled with membrane bioreactor. Environ Sci Pollut Res 28, 48543–48555 (2021). https://doi.org/10.1007/s11356-021-13787-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13787-9