Abstract

In this research, an amine-functionalized magnetic silica nanosorbent was prepared using the co-precipitation technique, and this nanosorbent can be effortlessly detached using an external magnetic field. FTIR and SEM analyses identified that the nanosorbent holds extraordinary adsorption characteristics for toxic metals’ (copper, cadmium, zinc, and nickel) removal. The adsorption-affecting parameters were optimized, and the thermodynamic studies assessed that the adsorption process seemed to be spontaneous, feasible, and exothermic. The pseudo-first-order and Freundlich models perfectly fit the kinetic and equilibrium data, respectively. Langmuir monolayer capacity of the nanosorbent was analyzed using nonlinear evaluation methods such as 419.9 mg/g for copper, 321.9 mg/g for nickel, 217.3 mg/g for cadmium, and 137.6 mg/g for zinc. The used adsorbent was simply rejuvenated using the 0.2 N HCl solution subsequently with intense agitation. The result of the present research confirms that the produced nanosorbent can be effectively utilized for industrial wastewater management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The progressive development of industries and technology over the decade has increased the extremity of pollution in our ecosystem. The contamination with substantial heavy metal ions is considered to be one of the most alarming threats because of their adverse characteristics such as high endurance, intense poison, and higher non-biodegradability (Cegłowskia et al. 2018). The human activities such as population explosion, urbanization, industrialization, automobiles, increased dumpsites, agricultural runoff, improper sewage system, and household wastes lead to the heavy metal pollution (Abhishek et al. 2018; Kobielska et al. 2018). Industrial sectors such as textiles, metal industry, fertilizer manufacturing, and electroplating industries which release wastewater are the major sources of heavy metal pollution (SenthilKumar et al. 2011; Rangabhashiyamm et al. 2016). Due to the improper monitoring of the industrial effluents, a noticeable amount of harmful heavy metal ions have crept into the nature inducing severe damage to the life of all kinds of living organisms; later, it also leads to a deficiency of fresh water and causes severe health impacts (Liu et al. 2019). The overdosage of heavy metals affects the most delicate organs such as the kidney, the liver, and the central nervous system of the human body (Kumar 2014; Siyal et al. 2018). Harmful heavy metals can apparently get bioaccumulated inside the human body through various mediums such as air, water, and majorly through the food chain, and also they get deeply deposited into the plants and animals (Neeraj et al. 2015). Even in low concentrations, some of the heavy metals such as copper, cadmium, zinc, lead, lithium, mercury, aluminum, nickel, arsenic, chromium, cobalt, and titanium are highly toxic whether it is in the mode of dissolved salts or metal ions, and they can cause serious damage to flora and fauna (Kumar et al. 2011; Al-Senani and Al-Fawzan 2018; Castro et al. 2018; Cegłowskia et al. 2018). The elimination of these heavy metals from the industrial effluent has turned into an essential issue on the grounds because of their deliberate negative impacts on the environment and progressively prohibitive enactments (Castro et al. 2018). Previously, diverse conventional methods such as filtration, chemical precipitation, flocculation, coagulation, dissolved air floatation, electrodialysis, ion exchange, reverse osmosis, electrochemical method, extraction, cementation, advanced oxidation process, membrane technology, spray drying, and microbial treatment have been used for eliminating the toxic metal ions from the aqueous solution (Basha et al. 2008; Castro et al. 2018; Cegłowskia et al. 2018; Saravannan et al. 2018; Siyal et al. 2018). Due to some of the adverse circumstances such as complexity, high expenditure, high energy demand, sophisticated instrumentation, and expertise labor, the above primitive techniques procrastinate in treating the effluents of lower metal ion concentration. Another main disadvantage of these traditional methods is that they produce secondary waste which is tedious to treat (Castro et al. 2018; Neeraj et al. 2015). Adsorption is one of the outstanding treatment technology used successfully for decontaminating the heavy metal–containing wastewaters, and this method is highly preferred for eliminating the industrial contaminants such as heavy metals, dyes, and organic pollutants. In addition, the adsorption is a simple, low-cost, efficient, and eco-friendly methodology which can be used both in the laboratory and industrial scale productively (Hemavathy et al. 2019). Another added advantage of utilization of adsorption technique is the ease in separation of the used adsorbent from the aqueous solution and uncomplicated regeneration of the spent adsorbent (Cegłowskia et al. 2018). Predominantly various economically feasible adsorbents such as saw dust, rice bran, Pinus kesia, biochar, cashew nut shell, bamboo, leaf biowaste, coffee waste, green macroalgae, polysaccharide, wild herbs, biopolymers, functional polymers, carbon spheres, hydrogel, and chitosan have been used in the adsorption of toxic heavy metal ions (Kumar et al. 2011; Anitha et al. 2015; Rangabhashiyamm et al. 2016; Cegłowskia et al. 2018; Kumar et al. 2018; Lee and Choi 2018; Lu et al. 2018; Rangabhashiyam and Balasubramanian 2019; Rathinam et al. 2018; Semerjian 2018; Shah et al. 2010; Song et al. 2018; Al-Senani and Al-Fawzan 2018; Suganya and Kumar 2018). The effectiveness of the adsorbent depends on the nature of the adsorbent and environmental conditions; moreover, during the utilization of the natural adsorbents, the regeneration of the adsorbent gets complicated and there arises a necessity for further purification (Neeraj et al. 2015). In order, to overcome the disadvantages of natural sorbents, the magnetic nanosorbents are employed in treating the heavy metal ions more specifically and effectively. Magnetic nanosorbents consolidate the attractive nanotechnology with biosorption paving way to effective removal of toxic metals from aqueous solution; further, they can also be effortlessly separated from the aqueous solution using an external magnetic field (Castro et al. 2018).

The main objective of this research work is to verify the effectiveness of amine-functionalized magnetic nanoparticles in the elimination of toxic metals from wastewater. This adsorbent utilized is eco-friendly and is also easily removed by using an external magnetic field. This research work primarily deals with the synthesis of an effective magnetic silica adsorbent followed by inducing amine functionalization to the adsorbent. The synthesized amine-functionalized magnetic silica nanoparticles were subjected to examine the biosorption of heavy metals such as copper, cadmium, zinc, and nickel. The various adsorption-influencing parameters such as pH, adsorbent dosage, initial metal ion concentration, contact time, and temperature have been experimented, and these parameters have been optimized for the effective removal of these heavy metal ions from the aqueous solution. The adsorption isotherms, kinetics, and thermodynamics were also studied from the batch adsorption process. The used adsorbent can be rejuvenated simply by using 0.2 N HCl several times without losing its metal sequestration capacity.

Materials and methods

Chemicals and materials

All the chemicals used during the synthesis procedure of the amine-functionalized magnetic silica adsorbent are of analytical grade, and it was acquired from Merck, India. The metal salts used in this study such as copper sulfate pentahydrate (CuSO4 · 5H2O), cadmium chloride (CdCl2), zinc sulfate heptahydrate (ZnSO4 · 7H2O), and nickel acetate tetrahydrate (Ni(OCOCH3)2 · 4H2O) were purchased from Merck, India, and they are used in the preparation of the heavy metal stock solution.

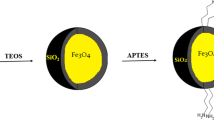

Synthesis of nanosorbent

Fe3O4 was synthesized according to the known procedure by co-precipitation method (Kumar et al. 2014a, b; Paripoorani et al. 2015). Eight milliliters of NH3.H2O was added dropwise into a mixed solution containing FeCl3.6H2O (1.351 g, 5 mmol), and FeSO4.7H2O (0.695 g, 5 mmol) was dissolved in 50 mL of deionized water under vigorous mechanical stirring at 70 °C until the magnetite particles precipitated out. After continuous agitation for 90 min, the magnetite precipitates were collected by a permanent magnet, and the pH of the black precipitates was adjusted to 7.0 by subjecting it to continuous wash using deionized water. The precipitate was then centrifuged and dried at 100 °C for a period of 2 h to attained Fe3O4 nanoparticles.

Synthesis of Fe3O4@SiO2

The procedure consisted of slow addition of 10 mL of Fe3O4 nanoparticles (4.85 mg/mL) which was first dispersed in 1 mL of freshly prepared APS solution and mixed with 25 mL of deionized water. The mixture was sonicated for 30 min and the solution was heated at 90 °C for 6 h with vigorous mechanical agitation. After that, 50 mL of ethanol and 5 mL of TEOS were successively added in the above solution and stirred for 24 h, during which the pH was controlled at 11.0 by the addition of NH3.H2O. Then the dark-brown precipitate was washed with water and methanol for four times in each case and separated with an external magnetic field several times and denoted as Fe3O4@SiO2. The separated particles were further dried in vacuum at 70 °C overnight to yield a fine powder.

Instrumental analysis

The synthesized magnetic silica nanosorbent is characterized using the Fourier transform infrared spectroscopy (FTIR), energy dispersive X-ray spectroscopy, and scanning electron microscope (SEM) analyses. The functional groups responsible for the effective toxic metal sequestration which are existing in the surface of the magnetic silica adsorbent are examined using FTIR spectroscopy (4000–400 cm−1). The surface morphology of the magnetic silica adsorbent is explored using the scanning electron microscopy, and the EDX analysis is used to determine the elements poised in the magnetic silica adsorbent. The initial and final concentrations of heavy metals present in the exploratory solution were examined using the atomic adsorption spectroscopy (ELICO SL-176 Double beam AAS, India).

Adsorption-influencing parameter studies

The adsorption studies were performed by the amine-functionalized magnetic silica adsorbent for all the four heavy metals such as Cu(II), Zn(II), Ni(II), and Cd(II). The stock solutions of all the four metals are prepared by using their respective metal salts. The batch adsorption process was performed in the Erlenmeyer flask containing the magnetic silica adsorbent and the heavy metal solution. The adsorption experiments were performed by differing the various parameters such as pH, adsorbent dosage, temperature, contact time, and initial metal ion concentration; later, the adsorption kinetic, isotherm, and thermodynamic studies were determined using the conclusions of parameter studies. The batch adsorption studies were performed in the Erlenmeyer flasks (250 mL) containing stock solution of Cu(II), Ni(II), Zn(II), and Cd(II) ions of 100 mL with the nanosorbent with various dosage levels depending on the type of metal ion (Cu, 1 g/L; Ni, 1.5 g/L; Cd, 2 g/L; Zn, 3 g/L) and the flask containing adsorbent and adsorbate is subjected to agitation in the orbital shaker maintained at 130 rpm at 30 °C for an appropriate time interval. Then, the used adsorbent is easily segregated from the aqueous solution using an external magnet, and the supernatant is separated using the filtration process and examined under the AAS for determining the concentration of metal ions adsorbed. Subsequently, the pH profile was adjusted from 2 to 8 and maintained using the 0.1 N HCl or 0.1 N NaOH, and the optimum pH required for the maximum sequestration of metal ions is determined. Later, the initial metal ion concentration of the four toxic metals (Cu (II), Ni(II), Cd (II), and Zn (II)) are varied from 100 to 500 mg/L, and the adsorption experiment is conducted with the optimized level of adsorbent dosage (Cu, 1 g/L; Ni, 1.5 g/L; Cd, 2 g/L; Zn, 3 g/L). The contact time is one of the important parameters to be analyzed and it is performed by varying the incubation time in the shaker from 5 to 60 min, at every 5-min interval; the adsorbent-adsorbate mixture in the conical flask is subjected to filtration and heavy metal concentrations are analyzed using AAS. The impact of the temperature on the adsorption process was analyzed by performing the adsorption process at four various temperature profiles such as 30 °C, 40 °C, 50 °C, and 60 °C, respectively. Every parameter studies are conducted in triplets, and the concentration of all the four metal ions (Cu(II), Ni(II), Cd(II), and Zn(II)) adsorbed by amine-functionalized magnetic silica at varying process parameters was used in further studies such as adsorption isotherms, kinetic, and thermodynamics.

The effective heavy metal removal efficiency is calculated using Eq. (1) as follows:

Owing to the mass balance principle, the equilibrium concentration of the metal ions such as Cu(II), Ni(II), Cd(II), and Zn(II) adsorbed onto the magnetic silica adsorbent is examined using Eq. (2):

where Co and Ce are the initial and final concentrations (mg/L) of the metal ions present in the aqueous solution, V is the volume of metal ion solution (mL), and W is the mass of the adsorbent (g).

Thermodynamic study

The thermodynamic study is conducted to obtain the nature of the adsorption process, the feasibility, and also the thermodynamic parameters such as enthalpy change (ΔH°), entropy change (ΔS°), and free energy change (ΔG°). These parameters are calculated using the following equations:

where R is the universal gas constant (8.314 J/mol K), T is the optimum temperature, and K is the equilibrium constant. The entropy change and enthalpy change are determined using the following equation:

Adsorption isotherm studies

The Langmuir and Freundlich isotherms are the two adsorption models used in this adsorption process to explore about the amount of metal ions adsorbed onto the magnetic silica adsorbent. The adsorption isotherm models are utilized in examining whether the adsorption possess monolayer or multilayer adsorption types. The Langmuir model gives the affiliation between the metal ion equilibrium adsorption capacity (qe) and equilibrium concentration (Ce) (Flores Lopez et al. 2018). The Langmuir model in nonlinear form is expressed using the following equation:

where KL is the Langmuir constant, qe is the equilibrium concentration of the metal ions, qm is the maximum monolayer of toxic metal ion adsorption capacity of the adsorbent (mg/g), and Ce is the final concentration of the metal ions present in the aqueous solution after adsorption. The separation factor (RL) is an important parameter used to presume the effectiveness of the adsorption mechanism by determining the relationship between the adsorbent and adsorbate; also, it is calculated using the following equation:

The Freundlich isotherm in nonlinear form is indicated using the following equation:

where Freundlich constant is denoted by KF (mg/g)(L/mg)(1/n) and the intensity of adsorption is indicated by nF. The Freundlich adsorption isotherm parameters predict the concentration of the heavy metal ion adsorbed onto the magnetic silica adsorbent and the adsorption capacity of the adsorbent in terms of bonding energy (Neeraj et al. 2015). The adsorption equilibrium values of the abovementioned heavy metals and the magnetic silica nanoparticle were implied to the Langmuir and Freundlich adsorption isotherm models with the help of MATLAB 2009a software.

Adsorption kinetic studies

The adsorption kinetic studies are performed using two adsorption models such as pseudo-first-order model and pseudo-second-order model as described in Liu et al. (2019.) The pseudo-first-order kinetic model is expressed using the equation

where, kad = pseudo-first-order constant (min−1)

The pseudo-second-order kinetic model is expressed using the equation

where, k2 = pseudo-second-order rate constant

The adsorption equilibrium concentration values of the adsorption of heavy metals and the magnetic silica nanoparticles were implied to the pseudo-first-order and pseudo-second-order models with the help of MATLAB 2009a software.

Desorption studies

The reusability of magnetic silica adsorbent in the heavy metal adsorption has been determined using the desorption study. The sequential adsorption and desorption of heavy metals are performed repeatedly for around 5 cycles with the same magnetic silica adsorbent. Around 100 mg/L of the four heavy metal (Cu(II), Ni(II), Cd(II), and Zn(II)) solution are provided with the magnetic silica adsorbent at different optimum dosage levels based on the type of heavy metal, and the adsorbate-adsorbent mixture is subjected to vigorous agitation followed by magnetic separation. The obtained supernatant is analyzed under AAS for determining the concentration of heavy metal ion present in the solution. The spent magnetic silica adsorbent is dried and rejuvenated using 0.2 N HCl.

Results and discussions

Characterization studies

The magnetic silica adsorbent material is subjected to the FTIR analysis to determine the presence of surface active functional groups present in the nanosorbent. From the FTIR results, it is concluded that the effective surface active functional groups such as carboxyl, hydroxyl, and amine are present on the surface of this nanosorbent which are highly responsible for the enhancement of the toxic metal adsorption capacity. The scanning electron microscopy results inferred about the surface morphology of the adsorbent. This magnetic silica adsorbent possessed a good number of pores and cavities which strongly help in trapping the heavy metal ion.

Elimination of heavy metal under varied conditions

The adsorption of Cu(II), Ni(II), Cd(II), and Zn(II) ions onto amine-functionalized magnetic silica nanoparticles was at varied conditions of pH, temperature, initial metal ion concentration, adsorbent dosage, and contact time. The variation of pH in the adsorption of heavy metal ions affected the rate of adsorption in a similar way. From the experimental results, it is concluded that all the heavy metal ions followed a similar pattern, the extent of adsorption gets elevated gradually with the increase of pH, and the maximum metal recovery is attained at pH 5 which is considered to be the optimal pH. The rate of adsorption gets decreased gradually when the pH is raised above the optimal pH condition. At low pH conditions, the availability of the hydrogen ions is higher as compared with the metal ions’ availability and only low adsorption of metal ions is possible. pH of the adsorption solution was increased with an increase in adsorption due to lower availability of hydrogen ions as compared with metal ions and most of the metal ions get adsorbed onto the adsorbent. The adsorbent dosage is one of the significant parameters which decides the feasibility and compatibility of the adsorption process. When the adsorbent dosage is varied from 0.5 to 4 g/L, the removal efficiency of the adsorption process gets increased with the increase of the adsorbent dosage due to the maximum availability of active surface of the adsorbent, and the optimum adsorbent dosage level of each heavy metal seemed to be Cu(II) = 1 g/L; Ni(II) = 1.5 g/L; Cd(II) = 2 g/L; and Zn(II) = 3 g/L. After reaching the optimum dosage level, the rate of adsorption gets saturated and lowered. When the influence of contact time on the heavy metal adsorption is investigated, it is concluded that higher removal efficiency of metal ions was observed at 30 min, while exceeding the contact time after 30 min, there was no further increase in the rate of adsorption inferring that the incubation of 30 min is enough for the efficient removal of all heavy metal ion used in this experiment. The effect of contact time on the adsorption is depicted in Fig. 1. In addition, the batch adsorption experiments were performed by varying the initial metal ion concentration from 100 to 500 mg/L. The increase in metal ion concentration decreases the extent of adsorption due to the fluctuations in the availability of adsorption sites. The experimental investigation on the effect of temperature upon the removal of heavy metal ions is studied, the increase in the temperature simultaneously decreased the removal efficiency, and the optimum temperature was found to be at 303 K. The various parameters which enhance the effective elimination of heavy metal using amine-functionalized magnetic silica are successfully optimized using this optimization study.

Thermodynamic study

From the conclusions of the thermodynamic study, the parameters such as Gibbs free energy change (ΔG°), enthalpy change (ΔH°), and entropy change (ΔS°) have been evaluated. Negative values are obtained for all the three parameters such as ΔG°, ΔH°, and ΔS°. The thermodynamic study results concluded that the adsorption of Cu(II), Ni(II), Cd(II), and Zn(II) upon the magnetic silica adsorbent seemed to be spontaneous, feasible, and exothermic in nature.

Adsorption isotherms

The equilibrium data obtained from the above studies are fitted in the two-parameter models such as the Langmuir and Freundlich models using MATLAB 2009a software (Fig. 2). From the determined parameter values, the R2 values of the Langmuir and Freundlich isotherms of the entire four heavy metal ions are compared with one another and the best-fitted model is determined. The parameter obtained from the MATLAB through curve fitting is listed in Table 1. The isotherm study concluded that the R2 value of the Freundlich isotherm seemed to be higher than that of the Langmuir isotherm; thus, this adsorption process is said to possess multilayer adsorption capacity. The maximum adsorption capacity of all the metal ions listed as per Table 1 is as follows: Cu(II) = 419.9 mg/g; Ni(II) = 321.9 mg/g; Cd(II) = 217.3 mg/g; and Zn(II) = 137.6 mg/g. Among the four metal ions, the Cu(II) ions exhibit a Langmuir maximum adsorption capacity of about 419.9 mg/g. In the current adsorption study, the RL obtained is found between 0 and 1 which means that this adsorption of heavy metal upon magnetic silica implied that the process is feasible and reversible. From the Freundlich model, the nF values obtained seemed to be greater than 1, which means this heavy metal adsorption highly depends on physisorption. The comparison of monolayer adsorption capacities of several adsorbents used for heavy metal removal is listed in Table 2. Comparing with all other absorbents, this magnetic silica seemed to possess higher efficient monolayer adsorption capacity due to the nature and properties of the adsorbent.

Adsorption kinetics

The adsorption kinetics is studied using two models such as pseudo-first-order and pseudo-second-order models using the MATLAB software. The parameters obtained are listed in Table 3. The correlation coefficient obtained in the pseudo-first-order seemed to be higher than that in the pseudo-second-order model, so it is evident that this adsorption process seemed to be best fitted in pseudo-first-order model, and in addition, it is also inferred that this heavy metal adsorption is strongly supported by physisorption. These same kinetic features are obtained in some of the similar works done by Lee and Choi (2018). The kinetics’ equation curve fitting is represented in Fig. 3. The kinetic parameter values are listed in Table 3.

Desorption studies

The desorption study of this magnetic silica adsorbent concluded that this adsorbent retained its adsorption capacity even after 5 continuous adsorption and desorption cycles. The desorbed adsorbent can be easily regenerated and used again as a fresh adsorbent. Among all the four heavy metals used in this adsorption experiment, copper seemed to be highly effective even after 5 subsequent cycles of adsorption and desorption. This characteristic of this adsorbent results in its feasibility and compatibility during the heavy metal removal. Figure 4 depicts the metal recovery of the entire heavy metal ion after 5 cycles of adsorption and desorption.

Conclusion

The experimental investigation, on the whole, concludes that this amine-functionalized magnetic silica is a highly potential adsorbent which can be used in the removal of toxic heavy metal ions released from the industrial effluents. The magnetic silica adsorbent is prepared using the co-precipitation technique in an eco-friendly approach, and it is effectively used in the sequestration of some of the toxic metal ions such as Cu(II), Ni(II), Cd(II), and Zn(II). Based on the characterization results of the prepared adsorbent using FTIR and SEM, the following outcome can be inferred: The prepared magnetic silica adsorbent possesses the ionizable functional groups such as carboxyl, hydroxyl, and amine groups which are highly helpful in active sequestration of all the four metal ions mentioned above. In addition, the surface of the magnetic silica adsorbent seemed to acquire pretty good number of pores and cavities in the exterior which makes the adsorbent more available for trapping the metal ions. The adsorption-influencing parameters such as pH, adsorbent dosage, initial metal ion concentration, temperature, and contact time markedly influenced and enhanced the metal recovery capacity of all the four heavy metal ions such as Cu(II), Ni(II), Cd(II), and Zn(II). Based on the optimization studies, it is concluded that pH 5 seemed to be the optimum pH for the adsorption of all the four metal ions onto the magnetic silica adsorbent; when the pH is increased above the optimum level, then the removal efficiency of the adsorbent gets lowered or saturated. The optimum initial metal ion concentration of all the four metal ions such as Cu(II), Ni(II), Cd(II), and Zn(II) is intend to be at 1 g/L, 1.5 g/L, 2 g/L, and 3 g/L, respectively. Further, the optimum contact time was found to be at 30 min at 30 °C for all the four metal ions. The thermodynamic study revealed that this adsorption process is feasible, spontaneous, and exothermic in nature. In addition, it follows the Freundlich isotherm resulting in a multilayer adsorption, and the kinetic studies also resulted that this adsorption followed pseudo-first-order model. From the conclusions of the desorption study, it is evident that the adsorbent retained the higher adsorption capacity even after several cycles. The simple rejuvenation of the absorbent used is an outstanding feature in this adsorption process using 0.2 N HCl. This adsorption study concluded that the prepared adsorbent is an efficient, economically feasible, and eco-friendly adsorbent which can be effectively utilized for the sequestration of metal ions present in the aqueous system.

References

Abhishek A, Saranya N, Chandi P, Selvaraju N (2018) Studies on the remediation of chromium(VI) from simulated wastewater using novel biomass of Pinus kesiya cone. Desalin Water Treat 114:192–204 http://www.deswater.com/DWT_abstracts/vol_114/114_2018_192.pdf

Al-Senani GM, Al-Fawzan FF (2018) Adsorption study of heavy metal ions from aqueous solution by nanoparticle of wild herbs. Egypt J Aquat Res 44:187–194. https://doi.org/10.1016/j.ejar.2018.07.006

Anitha P, Kumar PS, Kumar KS, Ramkumar B, Ramalingam S (2015) Adsorptive removal of Pb(II) ions from polluted water by newly synthesized chitosan–polyacrylonitrile blend: Equilibrium, kinetic, mechanism and thermodynamic approach. Process Saf Environ 98:187–197. https://doi.org/10.1016/j.psep.2015.07.012

Basha CA, Ramanathan K, Rajkumar R, Mahalakshmi M, Kumar PS (2008) Management of chromium plating rinsewater using electrochemical ion exchange. Ind Eng Chem Res 47:2279–2286. https://doi.org/10.1021/ie070163x?journalCode=iecred

Castro L, Blazquez LM, Gonzalez F, Munoz JA, Ballester A (2018) Heavy metal adsorption using biogenic iron compounds. Hydrometallurgy 179:44–51. https://doi.org/10.1016/j.hydromet.2018.05.029

Cegłowskia M, Gierczyka B, Frankowskia M, Popendab L (2018) A new low-cost polymeric adsorbents with polyamine chelating groups for efficient removal of heavy metal ions from water solutions. React Funct Polym 131:64–74. https://doi.org/10.1016/j.reactfunctpolym.2018.07.006

Chen H, Qu X, Liu N, Wang S, Chen X, Liu S (2018) Study of the adsorption process of heavy metals cations on Kraft lignin. Chem Eng Res Des 139:248–258. https://doi.org/10.1016/j.cherd.2018.09.028

Flores Lopez SL, Moreno Virgen MR, Montoya VH, Montes Moran MA, Gomez RT, Rangel Vazquez NA, Perez Cruz MA, Esparza Gonzalez MS (2018) Effect of an external magnetic field applied in batch adsorption systems: removal of dyes and heavy metals in binary solutions. J Mol Liq 269:450–460. https://doi.org/10.1016/j.molliq.2018.08.063

Hemavathy, Kumar PS, Suganya S, Swetha V, Varjani SJ (2019) Modelling on the removal of toxic metal ions from aquatic system by different surface modified Cassia fistula seeds. Bioresour Technol 281:1–9. https://doi.org/10.1016/j.biortech.2019.02.070

Kobielska PA, Howarth AJ, Farha OK, Nayak S (2018) Metal–organic frameworks for heavy metal removal from water. Coord Chem Rev 358:92–107. https://doi.org/10.1016/j.ccr.2017.12.010

Kumar PS (2014) Adsorption of lead(II) ions from simulated wastewater using natural waste: A kinetic, thermodynamic and equilibrium study. Environ Prog Sustain Energy 33:55–64. https://doi.org/10.1002/ep.11750

Kumar PS, Ramalingam S, Abhinaya RV, Thiruvengadaravi KV, Baskaralingam P, Sivanesan S (2011) Lead(II) adsorption onto sulphuric acid treated cashew nut shell. Sep Sci Technol 46:2436–2449. https://doi.org/10.1080/01496395.2011.590174

Kumar PS, Senthamarai C, Durgadevi A (2014a) Adsorption kinetics, mechanism, isotherm, and thermodynamic analysis of copper ions onto the surface modified agricultural waste. Environ Prog Sustain Energy 33:28–37 https://onlinelibrary.wiley.com/doi/abs/10.1002/ep.11741

Kumar VV, Sivanesan S, Cabana H (2014b) Magnetic cross-linked laccase aggregates—bioremediation tool for decolorization of distinct classes of recalcitrant dyes. Sci Total Environ 487:830–839. https://doi.org/10.1016/j.scitotenv.2014.04.009

Kumar PS, Sivaranjanee R, Rajan PS, Saravanan A (2018) Carbon sphere: synthesis, characterization and elimination of toxic Cr(VI) ions from aquatic system. J Ind Eng Chem Res 60:307–320. https://doi.org/10.1016/j.jiec.2017.11.017

Lee SY, Choi HJ (2018) Persimmon leaf bio-waste for adsorptive removal of heavy metals from aqueous solution. J Environ Manag 209:382–392. https://doi.org/10.1016/j.jenvman.2017.12.080

Liu J, Hu C, Huang Q (2019) Adsorption of Cu2+, Pb2+, and Cd2+ onto oil tea shell from water. Bioresour Technol 271:487–491. https://doi.org/10.1016/j.biortech.2018.09.040

Lu L, Lin Y, Chai Q, He S, Yang S (2018) Removal of acenaphthene by biochar and raw biomass with coexisting heavy metal and phenanthrene. Colloids Surf A Physicochem Eng Asp 558:103–109. https://doi.org/10.1016/j.colsurfa.2018.08.057

Manirethan V, Rava K, Rajan R, Thaira H, Balakrishnan RM (2018) Kinetic and thermodynamic studies on the adsorption of heavy metals from aqueous solution by melanin nanopigment obtained from marine source: Pseudomonas stutzeri. J Environ Manag 214:315–324. https://doi.org/10.1016/j.jenvman.2018.02.084

Neeraj G, Krishnan S, Kumar PS, Shriaishvarya KV, Kumar VV (2015) Performance study on sequestration of copper ions from contaminated water using newly synthesized high effective chitosan coated magnetic nanoparticles. J Mol Liq 214:335–346. https://doi.org/10.1016/j.molliq.2015.11.051

Paripoorani KS, Ashwin G, Vengatpriya P, Ranjitha V, Rupasree S, Kumar VV, Kumar VV (2015) Insolubilisation of inulinase on magnetite chitosan micro-particles, an easily recoverable and reusable support. J Mol Catal B Enzym 113:47–55. https://doi.org/10.1016/j.molcatb.2015.01.004

Rangabhashiyam S, Balasubramanian P (2019) Characteristics, performances, equilibrium and kinetic modelling aspects of heavy metal removal using algae. Bioresour Technol 5:261–279. https://doi.org/10.1016/j.biteb.2018.07.009

Rangabhashiyamm S, Suganya E, Lity AV, Selvaraju N (2016) Equilibrium and kinetics studies of hexavalent chromium biosorption on a novel green macroalgae Enteromorpha sp. Res Chem Intermed 42:1275–1294 https://springerlink.bibliotecabuap.elogim.com/article/10.1007/s11164-015-2085-3

Rathinam K, Singh SP, Arnusch CJ, Kasher R (2018) An environmentally-friendly chitosan-lysozyme biocomposite for the effective removal of dyes and heavy metals from aqueous solutions. Carbohydr Polym 199:506–515. https://doi.org/10.1016/j.carbpol.2018.07.055

Saravannan A, Kumar PS, Renita AA (2018) Hybrid synthesis of novel material through acid modification followed ultrasonication to improve adsorption capacity for zinc removal. J Clean Prod 172:92–105. https://doi.org/10.1016/j.jclepro.2017.10.109

Semerjian L (2018) Removal of heavy metals (Cu, Pb) from aqueous solutions using pine (Pinus halepensis) sawdust: equilibrium, kinetic, and thermodynamic studies. Environ Technol Innov 12:91–103. https://doi.org/10.1016/j.eti.2018.08.005

SenthilKumar P, Ramalingam S, Abhinaya RV, Kirupha SD, Vidhyadevi T, Sivanesan S (2011) Adsorption equilibrium, thermodynamics, kinetics, mechanism and process design of zinc(II) ions onto cashew nut shell. Can J Chem Eng 90:973–982. https://doi.org/10.1002/cjce.20588

Shah LA, Khan M, Javed R, Sayed M, Khan MS, Khan A, Ullah M (2010) Superabsorbent polymer hydrogels with good thermal and mechanical properties for removal of selected heavy metal ions. J Clean Prod 201:78–87. https://doi.org/10.1016/j.jclepro.2018.08.035

Siyal AA, Shamsuddin RS, Khan MI, Rabat NE, Zulfiqar M, Man Z, Siame J, Azizli KA (2018) A review on geopolymers as emerging materials for the adsorption of heavy metals and dyes. J Environ Manag 224:327–339. https://doi.org/10.1016/j.jenvman.2018.07.046

Song X, Li L, Zhou L, Chen P (2018) Magnetic thiolated/quaternized-chitosan composites design and application for various heavy metal ions removal, including cation and anion. Chem Eng Res Des 136:581–592. https://doi.org/10.1016/j.cherd.2018.06.025

Suganya S, Kumar PS (2018) Influence of ultrasonic waves on preparation of active carbon from coffee waste for the reclamation of effluents containing Cr(VI) ions. J Ind Eng Chem Res 60:418–430. https://doi.org/10.1016/j.jiec.2017.11.029

Wang B, Bai Z, Jiang H, Prinsen P, Luque R, Zhao S, Xuan J (2019a) Selective heavy metal removal and water purification by micro fluidically-generated chitosan microspheres: characteristics, modeling and application. J Hazard Mater 364:192–205. https://doi.org/10.1016/j.jhazmat.2018.10.024

Wang Z, Tan K, Cai J, Hou S, Wang Y, Jiang P, Lian M (2019b) Silica oxide encapsulated natural zeolite for high efficiency removal of low concentration heavy metals in water. Colloids Surf A Physicochem Eng Aspects 561:388–394. https://doi.org/10.1016/j.colsurfa.2018.10.065

Xiao F, Cheng J, Cao W, Yang C, Chen J, Luo Z (2019) Removal of heavy metals from aqueous solution using chitosan-combined magnetic biochars. J Colloid Interface Sci 540:579–584. https://doi.org/10.1016/j.jcis.2019.01.068

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Tito Roberto Cadaval Jr

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Research highlights

1. Synthesis of effective novel nanosorbent for toxic metals.

2. Higher adsorption capacity of nanosorbent for Cu(II) ions was 419.9 mg/g.

3. Adsorption is exothermic and obeyed with Freundlich and pseudo-first-order models.

4. Adsorbent regeneration was done by using 0.2 N HCl and many adsorption/desorption cycles were carried out.

5. Scale up of the system is widely advised for industrial wastewater treatment.

Rights and permissions

About this article

Cite this article

Joshiba, G.J., Kumar, P.S., Christopher, F.C. et al. Fabrication of novel amine-functionalized magnetic silica nanoparticles for toxic metals: kinetic and isotherm modeling. Environ Sci Pollut Res 27, 27202–27210 (2020). https://doi.org/10.1007/s11356-019-05186-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-05186-y