Abstract

Studies on the production of biogas of different organic materials in an anaerobic environment are being carried out all over the world. The most important parameters in these researches can be listed as raw material potential, production processes, economic analyses, and environmental effects. Chicken manure is one of the raw materials used in biogas production. In this study, in addition to the analysis of biogas and energy production potential from chicken manure, greenhouse gas emissions were analyzed to evaluate environmental effects. In Turkey, chicken manure is not adequately processed and causes environmental pollution. The model biogas plant and potential energy generation were researched in this field study. The pilot plant produces 8.58 million m3 of biogas per year by processing about 110 thousand tons of waste. It produces 17 GWh/year of electricity and 16 GWh/year of thermal energy, as well as reducing CO2 greenhouse gas emissions by 13.86 thousand tons/year.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In today’s energy-demanding lifestyle, the need for exploring and exploiting new sources of energy that are renewable and at the same time eco-friendly has become a mandate (Musa and Raji 2016). In this context, the conversion of underutilized organic wastes into renewable energy sources such as biogas in agricultural areas where they are produced can contribute to the recovery of waste as well as to the energy demands of the planet.

The use of renewable energy sources is often suggested as a possible solution to reducing a nation’s contribution to climate change and its dependency on fossil fuels. Biogas production by anaerobic fermentation is a promising method of producing an energy carrier from biomass resources while achieving multiple environmental benefits, e.g., fossil energy substitution, carbon emission reduction, and pollution abatement (Zhang et al. 2013). The biogas is generated through anaerobic digestion process (Kaur et al. 2017). Anaerobic digestion is a microbial-mediated process in which methanogenic microorganisms utilize organic matter, carbon dioxide, and hydrogen to produce methane, resulting in the creation of renewable energy and the reduction of greenhouse gas emissions, organic pollutants, pathogens, and foul odors (Klavon et al. 2013). Methane in biogas is the main component and it indicates the quality of biogas (Ilbas et al. 2016). Biogas contains about 60% methane (CH4) and 40% carbon dioxide (CO2) (Sefeedpari et al. 2012; Devi et al. 2016). Additionally, it could contribute to the suppression of fossil energy source use, to the neutralization of environmentally harmful toxic wastes, and to the reduction of greenhouse gas (GHG) emissions. Furthermore, a considerable amount of artificial fertilizers and irrigation water could be saved with the utilization of the digested bio manure (Szabó et al. 2014). In one study, the biogas energy potential was calculated using values for the amount of biogas energy produced per animal unit per day and the number of animal units in the USA. The 95 million animal units in the country were found to be capable of producing nearly 1 quad of renewable energy per year, amounting to approximately 1% of the US total energy consumption. Converting the biogas into electricity using standard micro turbines could produce 88 ± 20 billion kWh, or 2.4 ± 0.6% of the annual electricity consumption in the USA. Replacing coal and manure GHG emissions with the emissions from biogas would produce a net potential GHG emission reduction of 99 ± 59 million metric tons or 3.9 ± 2.3% of the annual GHG emissions from electricity generation in the USA (Cuéllar and Webber 2008). In another study, the authors concluded that manure digestion was the most efficient way to reduce GHG emissions, although not without other local environmental trade-offs. Biogas production from crops, while not providing environmental benefits per se, may be regarded as an option for facilitating the deployment of manure digestion (Agostini et al. 2015). By utilizing plant and animal wastes in the reduction of agricultural-based CO2, biogas conversion thus provides significant gains in the reduction of GHGs (Hou et al. 2017; Li et al. 2016).

The Paris Agreement, constituting the framework of the climate change regime after 2020, was adopted in Paris in 2015 and as of 5 October 2016 entered into force. On 4 November 2016, at least 55 parties accounting for 55% of global GHG emissions were required to ratify the agreement. Though some countries were against the treaty, most notably the USA, this treaty was an important step towards reducing GHGs worldwide. According to the greenhouse gas emission inventory results, the total GHG emissions in Turkey in 2015 amounted to a CO2 equivalent of 475.1 million tons. Again, the largest share of CO2 equivalent energy was 71.6% followed by industrial operations and product use by 12.8%, agricultural activities by 12.1%, and waste-based emissions by 3.5%. Moreover, 86.1% of all CO2 emissions were from energy, 13.7% from industry, and 0.2% from agriculture and waste; 54.3% of CH4 emissions were from agricultural activities, 25% from waste, 20.5% from energy, and 0.2% from industrial processes and product use; 75% of N2O emissions were from agricultural activities, 8.3% from energy, 8% from waste, and 7.8% from industrial processes and product use (TSI 2017).

On the other hand, according to the data of the year 2015, the electricity generation of the country was 262 TWh and according to these production sources, 29.1% was generated from coal, 0.9% from liquid fuels, 37.9% from natural gas, 25.6% from hydropower, and 6.5% from renewable energy and waste sources (TSI 2017).

In thisstudy, in addition to an analysis of the biogas and energy production potential of chicken manure, an analysis of GHG emissions was carried out by examining environmental effects.

Materials and methods

In Turkey, animal wastes are widely used as fertilizer after being kept to age for a year or more in the fields. However, during this waiting period, some serious problems may arise with chicken manure, such as high ammonia emissions and nitrate pollution. In addition, these accumulations of manure provide a breeding ground for flies and other parasites and are a source of bad odors. For this reason, in the last 20 years, some legal regulations have been enacted to regulate the chicken manure used on agricultural land, providing for it to be separated, composted, and then given to fertilizer processing plants, instead of being stored on farms. With both methods, however, the emergent methane gas and environmental pollution cannot be prevented during the fertilizer maturing process. Biogas production facilities using animal wastes have very recently entered the national agenda, and it is predicted that significant gains will be achieved in the environmental and energy arenas in the coming years.

In this field study, chicken manure was chosen as the raw material and the evaluation was based on the model of the Balikesir province pilot biogas production plant, which was the first to be established in Turkey.

Raw material potential and characterization

In the province of Balikesir in the Marmara region of Turkey, 98.5% of the total poultry production consists of broiler (meat) chickens and laying (egg) hens. The number of chickens and the amount of manure that can be obtained from them according to province, region, and country are given in Table 1, as reported by the Turkish Statistical Institute (TSI 2015). As seen in the table, the total manure production in the country in 2016 was about 7 million tons, which represents 564 million m3 of biogas potential. On the other hand, this amount also represents a serious potential for GHG emissions, as the manure cannot be utilized in agricultural areas because it is not sufficiently processed.

When the biogas potential of the chicken manure was calculated, the poultry production data for laying hens in the region was considered. The amount of daily manure for a laying hen is given in literature as 60–128 g (DBFZ 2011). In the study, 65 g was accepted because of the region where the study was conducted (Alibas 1996; EIE 2017), and the amount of biogas per ton of waste was accepted as 78 m3 (Akbulut and Dikici 2004; Kaya et al. 2009).

Technical data and capacity of biogas plant

The Balikesir plant is operated on a supply of local raw materials sourced from farm and agricultural waste, animal waste, maize silage, and especially from the poultry manure. Table 2 shows the characteristics details of the plant. Heat and electricity are obtained by a generator using biogas which is produced in the plant. The resulting organic wastes are passed through a separator and the solid part is used in greenhouse vegetable production operations and similar areas. Some of the liquid wastes are used again in the reactor, while the remainder is used by farmers in the region as agricultural fertilizer.

The analysis data of the raw material, mainly chicken manure, fed into the biogas plant are given in Table 3. The first six columns contain the analysis results of the raw materials from different sampling periods. The results are in accordance with those in the literature (Eleroglu et al. 2013).

Table 4 gives the results of the analyses carried out to assess the organic products as fertilizer. All analyses were made according to “Annex 18-Analysis Methods Regulations published on 29.03.2014 dated and 28956 numbered Offical Newspaper on Organic, Organomineral Fertilizers and Soil Regulators and Microbial, Enzyme Containing and Organic Based Other Products production, Export and Import to the Market” and “29.03.2014 dated and 28956 numbered Offical Newspaper on Market Surveillance and Inspection Regulations of Fertilizers.” The resulting organic matter was evaluated in three different forms, solid, liquid, and mixed, and then compared with the analyses made via anaerobic fermentation of chicken manure found in the literature. In addition, a comparison of the heavy metal content with legal criterion values was made and the results were found to be acceptable (Kivrak 2017; Eleroglu and Yildirim 2014). The heavy metal analyses of the solid, liquid, and mixed products are given in Table 5.

Results and discussion

Biogas energy potential

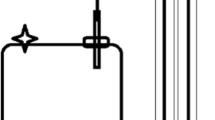

According to the measured values, it was seen that the raw material, in terms of gas production and productivity, reached ideal gas efficiency after a process time of approximately 45 days. Gas production according to the raw material input ratio and process time is given in Fig. 1.

The biogas and energy equivalents produced according to the raw material proportions of the sample are given in Table 6. During the calculations, the thermal value of the biogas was accepted as 22 MJ/m3 depending on the rate of methane and in accord with the reference value (Ulusoy et al. 2009; Eryasar and Kocar 2009). Its electricity energy equivalent was calculated as 1.9–2.2 kWh/m3 of biogas (Eryasar and Kocar 2009).

The greenhouse effect of electricity generation is reflected in the extent of the CO2 emissions, which amount to 0.4 kg/kWh when the electricity is generated from natural gas, 0.8 kg/kWh for electricity generated from petroleum, and 0.9–1 kg/kWh for that produced by coal (IEA 2016; Ministry of Energy 2017). The effect of heat generation is comparable to that of electricity production in terms of CO2. A biogas facility can eliminate 13.68 thousand tons of CO2 emissions per year from fossil fuel–based electricity generation. Moreover, when the thermal energy was obtained from biogas besides electric energy, heat energy was also produced.

Positive effects on environmental pollution

The pilot plant can produce 8 million m3 biogas per year by processing approximately 110 thousand tons of waste. In this way, the release of 4.4 million m3 of methane and 3.6 million m3 of CO2 per year is primarily controlled by waste. In addition, ~ 17.1 GWh/year of electricity and ~ 16 GWh/year of thermal energy are produced as renewable energy sources as opposed to electricity produced from petroleum-derived fuels. Therefore, 13.68 thousand tons/year of CO2 emissions from petroleum-based production are eliminated. Again, the methane gas in the processed and pathogen-free liquid fertilizer can be used without loss of the nitrogen needed for agricultural production. Therefore, it would not be wrong to say that the production of biogas from the chicken manure obtained in the region provides a three-way advantage in terms of environmental pollution.

It can be seen from Table 7 that, in general, 318 million tons/year of CO2 emissions can be eliminated in Turkey by utilizing chicken (laying hen) manure alone in this way.

Conclusion

In Turkey, up to 2015, 85.2% of greenhouse gas CO2 emissions resulted from energy production, with 54.3% of CH4 emissions from agricultural activities, 25% from waste, and 20.5% from energy production, while 75.9% of N2O came from agricultural activities. When all these are taken into account, Turkey has an energy potential of 156 million tons/year and 1.3 million tons of petroleum (oil) equivalent (TOE) energy potential per year. In addition, with 142 million tons/year of vegetative waste, it has an energy potential of 15.9 million TOE/year and with 29.6 million tons/year of urban organic waste, a potential of 2.2 million TOE/year. This adds up to a total of 19.4 million TOE/year of potential energy (BEPA 2017).

According to the results of the field study conducted in the province of Balikesir, only 110 thousand tons of fertilizer per year can be processed in the pilot facility to obtain 8 million m3/year of biogas. The energy value of this biogas is 17.1 GWh/year of electricity and 16 GWh/year of thermal energy production. Therefore, the release of 13.68 thousand tons/year of CO2 from petroleum is eliminated. When the energy potential of the country is calculated using the parameters employed in the study data, this model presents a structure that can produce 186 million m3/year of biogas processed from 2 million tons of chicken manure per year. The electrical energy value of this biogas is 198 million KWh/year and the emission gain is 317 thousand tons/year. This value clearly demonstrates the importance of biogas as a renewable energy source and an alternative to fossil-based fuels.

The waste management aspect of this evaluation also demonstrated very significant environmental benefits. Agricultural, animal, and urban organic wastes were appropriately utilized, resulting in the reduction of N2O and CH4. These two gasses arise from the unregulated and careless use of nitrogenous fertilizers and animal waste on agricultural lands. Direct GHG emissions resulting from electricity generation in the energy sector can be reduced by the generation of electrical energy from organic wastes.

It is important to note that the type of plant examined in this study has a strategic precaution in the name of the country under the Kyoto Protocol, not only in terms of waste disposal and electricity generation but also in the reduction of CO2, CH4, and N2O emissions. It is also clear that an incentive mechanism must also be established.

References

Agostini A, Battini F, Giuntoli J, Tabaglio V, Padella M, Baxter D, Marelli L, Amaducci S (2015) Environmentally sustainable biogas: the key role of manure co-digestion with energy crops. Energies 8(6):5234–5265

Akbulut A, Dikici A (2004) Biogas potential and cost analysis of Elazig Province. Dogu Anadolu Bölgesi Araştırmaları Dergisi 2(2):36–41

Alibas K (1996) Determination of biogas production and fermenter energy correlations of cattle manure, chicken manure and barley straw and silophilic, mesophilic and thermophilic fermentations. Uludag University, Faculty of Agriculture, Search and Investigation Notes, No 13, Bursa, 1996

BEPA (2017) Biomass Energy Potential Atlas, General Directorate of Renewable Energy (YEGM), 2017 http://bepa.yegm.gov.tr/

Cuéllar AD, Webber ME (2008) Cow power: the energy and emissions benefits of converting manure to biogas. Environ Res Lett 3(3):1–8

DBFZ (2011) Deutsches Biomasse Forschungs Zentrum gemeinnützige GmbH, Assessing the conditions and potentials for biogas investments in Turkey: 125. http://www.biyogaz.web.tr/files/docs/dbfz_turkiye_biyogaz_ potansiyel_raporu.pdf, Accessed June, 2017

Devi R, Kumar A, Kumar S (2016) Use of pine needles as substrate for biogas production. Int J Renew Energ Res 6(4):1242–1247

EIE (2017) http://www.eie.gov.tr/yenilenebilir/biyogaz.aspx, Accessed July 2017

Eleroglu H, Yildirim A (2014) Microbiological and chemical investigation of chicken manure in a new drying technology. J Poultry Res 11(1):28–34

Eleroglu H, Yildiz S, Yildirim A (2013) Methods of removing environmentally problematic chicken manure. Gaziosmanpasa Journal of Scientific Research 2:14–24

Eryasar A, Kocar G (2009) Effect of pressure on biogas production. Pamukkale Univ J Eng Sci 15(2):181–186

Hou J, Zhang W, Wang P, Dou Z, Gao L, Styles D (2017) Greenhouse gas mitigation of rural household biogas systems in China: a life cycle assessment. Energies 10(2):1–14

IEA (2016) Paris. CO2 emissions from fuel combustion highlights (2016 edition) World energy outlook special report: energy and climate change, OECD/IEA, https://www.iea.org/.../CO2EmissionsfromFuelCombustion_Highlights_2016.pdf

Ilbas M, Sahin M, Karyeyen S (2016) Combustion behaviors of different biogases in an existing conventional natural gas burner: an experimental study. Int J Renew Energy Res 6(3):1178–1188

Kaur H, Sohpal VK, Kumar S (2017) Designing of small scale fixed dome biogas digester for paddy straw. Int J Renew Energy Res 7(1):422–431

Kaya D, Cagman S, Eyidogan M, Aydoner C, Coban V, Tiris M (2009) Turkey’s animal waste biogas potential and economy. Atık Teknolojileri Dergisi (Waste Technology Journal) 1:48–51

Kivrak M (2017) www.mucahitkivrak.com.tr Accessed July 2017

Klavon KH, Lansing SA, Mulbry W, Moss AR, Felton G (2013) Economic analysis of small-scale agricultural digesters in the United States. Biomass Bioenergy 54:36–45. https://doi.org/10.1016/j.biombioe.2013.03.009

Li F, Cheng S, Yu H, Yang D (2016) Waste from livestock and poultry breeding and its potential assessment of biogas energy in rural China. J Clean Prod 126:451–460

Ministry of Energy (2017) CO2 emission values of some sources in electric energy generation http://www.enerji.gov.tr/tr-TR/Sayfalar/Temiz-Enerji (2017)

Musa B, Raji HM (2016) Quantitative and qualitative analysis of biogas produces from three organic wastes. Int J Renew Energy Res 6(1):299–305

Sefeedpari P, Rafiee A, Akram A (2012) Providing electricity requirements by biogas production and its environmental benefit in sample dairy farms of Iran. Int J Renew Energ Res 2(3):384–387

Szabó G, Fazekas I, Szabó S, Szabó G, Buday T, Paládi M, Kisari K, Kerényi A (2014) The carbon footprint of a biogas power plant. Environ Eng Manag J 13(11):2867–2874

TSI (2017) Turkish Statistical Institute (TUIK) press release, No: 24588, Accessed 17 April

TSI, Turkish Statistical Institute (TUIK) (2015) http://www.tuik.gov.tr/. Accessed July 2017

Ulusoy Y, Ulukardesler AH, Ünal H, Alibaş K (2009) Analysis of biogas production in Turkey utilising three different materials and two scenarios. Afr J Agr Res 4(10):996

Zhang LZ, Wang CB, Song B (2013) Carbon emission reduction potential of a typical household biogas system in rural China. J Clean Prod 47:415–421

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Ulusoy, Y., Ulukardesler, A.H., Arslan, R. et al. Energy and emission benefits of chicken manure biogas production: a case study. Environ Sci Pollut Res 28, 12351–12356 (2021). https://doi.org/10.1007/s11356-018-3466-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-3466-0