Abstract

The ubiquitous presence of brominated flame retardants (BFRs) in indoor air, dust, and even in human tissue could be attributed to their emissions from BFR-containing products. Nevertheless, the emission behavior of BFRs, especially novel BFRs from consumer materials, to the indoor environment has still not been well understood. To evaluate the effects of chemical content, temperature, and time on the emissions of BFRs, we used a batch of small glass chambers to conduct emission tests on carpet, computer casings, sound insulation, circuit boards, decorative laminate, and PVC floors at temperatures from 20 to 80 °C, as well as different emission times of up to 35 days. Seven BFRs were extracted from the tested materials with contents ranging from 50 to 35,803 μg g−1, and four BFRs were detected with emission rates between 5.9 and 418 pg g−1 h−1 at room temperature (20 °C); 1,2,5,6,9,10-hexabromocyclododecane (HBCD) was considered to be the dominant compound, which was found in and could be emitted from all of the tested materials. Emission rates are significantly and positively correlated with both the contents of tested materials and the elevated temperature. These results indicate that BFR-containing products have the potential to be a major source of indoor contamination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Strict bans, widespread restrictive regulations, and voluntary withdrawals on the manufacture and use of some common brominated flame retardants (BFRs), especially the Penta- and Octa-brominated diphenyl ether (BDE) formulations, have led to a growing number of alternative products (Geens et al. 2010; Li et al. 2016; Sun et al. 2013). With an increasing global market demand for alternative BFRs in polymeric materials in construction, electronics, and computer equipment, a fair estimate of annual production volumes of 21 novel BFRs is closer to 100,000 tons, assuming that the production volumes of BFRs have not changed much over the past few years (Covaci et al. 2011). Important representatives of alternate BFRs are decabromodiphenyl ethane or 1,2-bis(pentabromodiphenyl)ethane (DBDPE), 1,2-bis(2,4,6-tribromophenoxy)ethane (BTBPE),1,2-Dibromo-4-(1,2-dibromoethyl) cyclohexane (α-TBECH and β-TBECH), and hexachlorocyclopentadienyl-dibromocyclooctane (HCDBCO) (Covaci et al. 2011). Information regarding the persistent, bioaccumulative, and toxic characteristics of some BFRs has become available (Zhou et al. 2001; Birnbaum and Staskal 2004; Ezechiáš et al. 2014; Sun et al. 2018b). For example, studies on TBECH and BTBPE have shown that these compounds are persistent and have bioaccumulation potential (Covaci et al. 2011; Wu et al. 2011). There are indications that 1,2,5,6,9,10- hexabromocyclododecane (HBCD) exposure can affect the liver and thyroid hormone systems and may cause neurobehavioral alterations (Tang et al. 2015). Tetrabromobisphenol A (TBBPA) has also been shown to have effects on thyroid hormones, neurological function, and reproduction (Lilienthal et al. 2008; Ven et al. 2008).

Recently, a growing number of studies have reported on the ubiquitous presence of various BFRs, especially in indoor environments (Qi et al. 2014; Fan et al. 2016). BFRs have been detected at a wide range of concentrations in house dust and air samples in countries throughout the world (Covaci et al. 2011; Law et al. 2014; Sun et al. 2016; Xu et al. 2015). Biomonitoring studies have further documented the widespread presence of BFRs (e.g., HBCD) in human tissues and breast milk (Thomsen et al. 2010; Ezechiáš et al. 2014; Liang et al. 2016). Generally, BFRs have a much higher concentration in indoor air than in outdoor air, demonstrating that the indoor environment can be an important route by which contaminants accumulate in people via dust ingestion or respiratory inhalation (Kajiwara and Takigami 2013; Besis and Samara 2012; He et al. 2016; Newton et al. 2015). Due to the minimal air exchange rates and long exposure times spent indoors, people are more vulnerable to emissions from products and materials containing BFRs, such as polyurethane foam, plastics used in electric and electronic equipment, printed circuit boards, expanded and extruded styrofoam plastic, and textile back-coating in furniture (Stapleton et al. 2005; Covaci et al. 2011; He et al. 2018). Most BFRs are additives mixed directly into the product during manufacturing without reacting with raw materials, so they may easily be emitted from the products and migrate into the environment. Thus, more attention should be paid to the link between indoor contamination and the emissions from the main source to better understand the risks of longtime exposure in indoor environments (Zhang et al. 2011; Liagkouridis et al. 2016). Over the past few years, there has been a considerable amount of literature focusing on indoor levels and exposure to BFRs, but information on emissions is much scarcer, especially for novel BFRs (Stubbings and Harrad 2014; Rauert and Harrad 2015).

Accordingly, the primary objectives of our study were to (1) determine and compare the emissions of seven BFRs from six selected consumer materials using a simplified emission chamber, (2) link the emission behavior of BFRs in materials to their initial contents, and (3) assess the effects of temperature and time on the emissions.

Materials and methods

Chemicals and sample materials

Authentic standards of ally l 2,4,6-tribromophenyl ether (ATE), hexabromobenzene (HBBZ), bis (2-ethylhexyl) tetrabromophthalate (BEHTBP), HBCD, tetrabromobisphenol A (TBBPA), HCDBCO, and BTBPE were obtained from Wellington Laboratories Inc. (Guelph ON, Canada). Table S1 gives a complete list of seven BFRs included in this study with their abbreviations and molecular masses. 13C labeled standards of chlorinated biphenyl 141 and 202 (CB-141 and CB-202) and BDE-209 were purchased from Cambridge Isotope Laboratories (Andover, MA, USA). All organic solvents used, i.e., n-hexane, dichloromethane, and acetone, were of HPLC grade (Tedia Company, Shanghai, China). Polyurethane foam (PUF) plugs (with a diameter of 9 cm, thickness of 5 cm, and density of 0.0213 g cm−3) were purchased from Tisch Environmental, Inc. (Cleves, USA). PUF plugs were cleaned by the Soxhlet extraction process using acetone for 16 h, and the solvent was completely removed from the plugs by means of a vacuum drying system (> 12 h) before use.

The five investigated materials in this study (carpet, sound insulation, circuit board, decorative laminate, and PVC floor) were directly purchased from their manufacturers in 2015. All experiments were started immediately upon delivery of the samples. The computer casing sample was collected from a used personal computer in the lab, which was purchased in 2010.

Test chamber experiments

The investigations of BFRs emissions were carried out using 15 glass test chambers designed using published methods with some modifications (Rauert et al. 2014a; Rauert and Harrad 2015). Briefly, a round in-house-designed test chamber utilized for these investigations was constructed from glass cylinders with 8 cm diameter and 8 cm height to give an effective chamber volume of 328 cm3 and external surface area of 480 cm3 (Fig. S1). The air inflow into the chamber was 100 mL min−1. Three grams of samples cut in a round shape were transferred to the platform inside the chamber. A PUF plug on the exit air vent was used to collect compounds in both the gas and suspended particulate phases. Rinses of the chamber wall were included in the total emitted mass. After being sealed with Teflon tape, the chambers were maintained at the desired temperatures by immersion in hot water baths with the chamber internal temperature monitored using thermometers. Comparison of the emissions of the six materials was conducted at room temperature (20 °C) with a test duration of 7 days. To evaluate the effect of temperature, the internal temperatures of the chambers were set to 20, 35, 50, 65, and 80 °C for carpet and computer casing. The 80 °C maximum temperature was chosen to simulate the scenario of a high emission with a relatively high interior temperature in the case of an electronic item being heated during operation, and a car left under the sun in the summer (Kemmlein et al. 2003). Additionally, tests on the carpet with different durations, from 7 to 35 days, were designed to evaluate the effect of time.

Chemical analysis

The method for the treatment of PUF plug samples can be found in our previous studies (Sun et al. 2016, 2018a). Briefly, both the PUF plugs and material samples were extracted for 16 h in a Soxhlet apparatus using 120 ml of DCM (Kajiwara et al. 2009). Prior to extraction, the samples were spiked with known amounts of 13C-BDE-209 and 13C-CB-141 to monitor the recovery of the BFRs during treatment and analysis. The extracts were concentrated to 0.5 mL using a rotary evaporator, and then the solvent was exchanged with n-hexane under a gentle stream of nitrogen. Specifically, to collect the compounds sorbed to the chamber walls, chamber inner surface solvent rinses were combined with the extract. To measure the contents in each material, crude extracts were further cleaned using a chromatographic column containing, from the bottom up, 1 g of anhydrous sodium sulfate, 5 g of silica gel, 3 g of alumina, and 1 g of anhydrous sodium sulfate and were subsequently eluted with 70 mL of 70:30 (v/v) n-hexane/DCM. The elution was solvent-exchanged to n-hexane using a rotary evaporator, added with the internal standard (13C-CB 202), and blown down to 1 mL under a gentle high-purity nitrogen stream. The crude extract obtained from each type of material was diluted with n-hexane as appropriate before injection.

All BFRs were analyzed using an Agilent 7890 GC coupled to an Agilent 5975 inter mass selective detector (GC/MSD) equipped with a DB-5MS capillary column (15 m × 0.25 μm × 0.10 μm film thickness, J&W Scientific, USA) in electron capture negative ionization (ECNI) mode using methane as the moderating gas. For TBBPA, derivatization was performed before analysis according to the previous work (Sun et al. 2018a). The initial oven temperature was set to 110 °C for 1 min, ramped at 5 °C min−1 to 220 °C, ramped at 20 °C min−1 to 310 °C, and held for 15 min. Two microliter extracts were injected in splitless mode and the selected-ion monitoring (SIM) mode was used for MS. Helium gas was used as a carrier with a flow rate of 1 mL min− 1. The injector and transfer lines were set isothermally to 250 and 280 °C, respectively. The following ions were used to quantify the various compounds: 290.8/79/81 for ATE, 551.6/79/81 for HBBZ, 607/609 for TBBPA derivative, 236.8/79/81 for HCDBCO, 159.9/79/81 for HBCD, 386.0/79/81 for BEHTBP, and 79/81 for BTBPE.

Quality assurance/quality control

Samples were analyzed using established laboratory QA/QC procedures. Each emission test, including the controls, consisted of three replicates. Method blanks for emission tests were conducted with each batch of samples, but without material samples in the chamber. A procedural blank for extraction was run with every batch of samples to ascertain potential contamination of solvents and glassware. To avoid dust deposition onto the PUF, the outlet of the device top was wrapped in foil with a few punctures.

To test the breakthrough and sampling efficiency of the PUF plugs and trace the distribution of compounds in the chamber wall and PUF plugs, a validation experiment was conducted by attaching two PUF plugs with a known amount of compounds on the sample platform. The results of mass balance and PUF efficiency were satisfied (“Method validation” section).

Recovery efficiencies of the analytical methods were checked with spiked PUF plugs and varied from 73.7 to 101.2% for all targets. The surrogate recoveries in all samples were within acceptable limits, ranging from 75 to 110%. The method detection limit (MDL) was calculated by multiplying the final extract volume by the concentration of the target compound that could produce a chromatographic peak with a signal-to-noise ratio of 10, and subsequently dividing by the sampling volume. The MDLs for seven compounds were between 0.005–0.072 pg m−3. Only a low concentration of HBCD was sometimes detected in the procedural blanks, which was at much lower concentrations (generally < 5%) than those in the PUF samples during emission tests. No other BFRs were detected in the procedural blanks.

Data analysis

Emission rates (pg·g−1·h−1) were calculated using the amount of compound adsorbed to the PUF and the chamber walls, the sample weight, and the sampling time (usually 144 h). The targets collected on the PUF plugs and chamber rinses were not analyzed separately, so the emission rates represent the total BFR emissions from the test materials, including the fraction of the emitted compounds adsorbed to the chamber walls. All reported data are the mean and standard deviation of three replicates. Statistical analysis of data was performed using Origin Pro (v.8.0; OriginLab, Northampton, MA).

Results and discussion

Method validation

The sampling efficiency of the PUFs to collect BFRs was uncertain, so we designed an experiment to validate PUF breakthrough, sink effect, and mass balance (Afshari et al. 2004). An aliquot with 100 ng of each compound was added to the sample platform inside the chamber. After the solution was dried, the system was conducted with the same parameters as the regular emission test. The extractions of the two PUF plugs, the rinse of the chamber inner wall surface, and the rinse of the sample platform were analyzed separately. Results of the distribution of each compound on the first chamber-side PUF (PUF1), second air-side PUF (PUF 2), chamber wall, and sample platform are shown in Table 1.

The chemical concentrations on PUF 2 ranged from below the detection limit (BDL) to 1.24 ng, indicating that there was no significant breakthrough on the chamber-side PUF and that the sampling method was reliable. In addition, every compound could strongly sorb onto the inner chamber surfaces with a range of 15.2–37.3%, which highlights the necessity of including the rinses of the chamber wall into the total emitted mass. These data are clear evidence that there is no significant loss in the designed chamber. This chamber could also be used as the emission test for specific consumer materials under different conditions. This validation experiment also indicates that every tested compound could potentially emit to air at room temperature, be trapped by PUF with a portion of 27.1–42.2% of the total spike. HBCD showed the highest emission potential in the dry mixture standard and the highest sink effect to the chamber wall. This is particularly relevant for its physical and chemical properties, such as a low value of vapor pressure and a high value of log Kow (Kemmlein et al. 2003). However, their emission characteristics in real materials are still unclear and need to be investigated in the following test.

Extractable BFRs contents in materials

Information about the species and contents of additive flame retardants in the purchased materials included during their production are unavailable, so it is necessary to examine their content in the materials and to evaluate the effect of their emissions. A summary of the extractable BFRs contents in selected consumer materials is presented in Table 2. The samples of carpet, sound insulation cotton, circuit board, decorative laminate, and PVC floor were newly purchased for this study, but the computer casing was collected from an old PC purchased in 2008. Some materials, such as the carpet and sound insulation cotton, could not be completely dissolved in the solvent, so the extractable contents reported here may be lower than their actual content when they were produced (Kajiwara et al. 2009; Stapleton et al. 2009, 2011a, b). For computer casing samples, the values measured by Soxhlet extraction in this study may be considerably lower than those measured by the method of completely grinding and dissolving (Takigami et al. 2008) because the dissolution process (e.g., homogenized, blended, etc.) could extract the inside part of the full loading, which may not be emitted out from dense raw materials. The decorative laminate and sound insulation cotton contained four types of BFRs and the carpet and circuit board only contained two types. However, the highest total concentration of BFRs (∑BFRs) was found in sound insulation cotton (37 mg g−1), and the circuit board contains the lowest target compounds with a ∑NBFRs value of 0.9 mg g−1.

A total of seven BFRs were detected in the tested materials, while the HBCD was detected in all tested materials as the most abundant flame retardant observed, with contents ranging from 208 ± 63.0 μg g−1 in the decorative laminate to 35,803 ± 2598 μg g−1 in the sound insulation cotton. The content of HBCD in sound insulation cotton was comparable to a value of 2.2–5.5% from textile samples reported in Japan in 2008 (Kajiwara et al. 2009). HBCD was used as a principal alternative to PBDEs in foams and expanded polystyrene, as well as in the building industry (de Wit 2002). Although the HBCD has been added to the Stockholm convention Annex A in November 2015 with specific exemptions, and its production and sales have now been stopped, HBCD-containing materials will still be widely present in indoor environments for a long time before their elimination. The concentrations of TBBPA ranged from 50 to 500 μg g−1 in the computer casing, PVC floor, and sound insulation cotton, which were significantly lower by more than two orders of magnitude than that of a computer sample in Japan in 2006 (Takigami et al. 2008). Different from other additive BFRs, TBBPA was used both as a reactive FR in epoxy and polycarbonate resins for printed circuit boards and electronic equipment, and as an additive FR in HIPS or ABS resins (Abdallah et al. 2008). The TBBPA existing in computer casings may be the portion remaining from incomplete reactions in the polymerization process where TBBPA was used as a reactive additive (de Wit et al. 2010). HCDBCO and BEHTBP were only detected in one material at relatively low contents.

The contents of different compounds were varied by orders of magnitude. For instance, the computer casing was found to contain compounds at levels ranging from 50 to 1791 μg g−1. Additionally, the∑BFRs in sound insulation cotton was nearly 40 times the concentration in the circuit board. The highest content of HBCD, TBBPA, and HBBZ (35,803, 500, and 468 μg g−1 as the mean values, respectively) were all observed in the sound insulation cotton. A reported analytical result of TV components showed that the concentrations of TBBPA (19,000 μg g−1 as the mean values) were highest in the rear cabinets (Takigami et al. 2008). ATE was detected in two samples, sound insulation cotton and the circuit board. BTBPE content in the decorative laminate was higher than the others. Moreover, BEHTBP was detected at the lowest percentage among all measured BFRs. Owing to the substantial existence of flame retardants in the materials, it is essential to link their contents in the materials to their migration to indoor environments.

Comparison of emissions from different materials

The emission rates of 7 BFRs from 6 materials at 20 °C are summarized in Table 3. Four targeted BFRs (HBCD, TBBPA, BEHTBP, and HBBZ) were detected in the emission tests, suggesting their emission potential even at room temperature. HBCD was the main compound and detected in all of the six tested materials with considerable amounts, indicating its risk of widespread application in a variety of materials in indoor environments. It is probably a good explanation for an investigation that reported that HBCD was one of the dominating BFRs among 81 indoor dust samples across China in 2010 (Qi et al. 2014). The emission of HBBZ was measured in three materials but was relatively low. TBBPA was contained in the computer casing and sound insulation cotton but only emitted from the latter. These results suggested that the emission of these selected BFRs may be governed by several factors, including physical properties of chemicals, compositions, production processes, and materials technologies. For example, the fact that the HBCD is an additive BFR but the TBBPA is a reactive BFR allows easier migration of HBCD. The emission rates measured in this study are comparable with those of PBDEs in PUF and carpet, and HBCD in the insulating board (Zhang et al. 2009; Kajiwara and Takigami 2013).

However, while considerable amounts of ATE, HCDBCO, and BTBPE were contained in sound insulation cotton, decorative laminate, and/or computer casing, their emission was not detected at room temperature. Compared to the results of a nationwide survey across China, ATE was not detected in all indoor dust samples, and HCDBCO and BTBPE were detected at low frequency detection or low mean value (Qi et al. 2014).

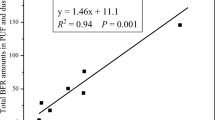

It has been confirmed that each of the BFR that exists in its corresponding material could be emitted out. Thus, the existence of BFRs in an actual material in consumer products could be a predictor of emission potential to indoor environments. Statistically, the regression analysis between measured emission rates and the initial contents in the 6 types of materials showed a positive correlation (R2 = 0.65, p = 0.03, an extremely high value of 35,803 μg g−1 was not counted in Fig. 1). In addition, a significant correlation between the emissions and the contents was found in HBCD in the five materials (Fig. S2, R2 = 0.70, p = 0.048). These results indicated that the emission potential of BFRs was heavily dependent on their content in materials. Theoretically, emission potential was also affected by physicochemical properties of BFRs such as vapor pressure (VP) and octanol-air partition coefficients (KOA) (Weschler and Nazaroff 2008). However, the linear regression between the physicochemical properties and emission rates was not observed in this work. This might be explained by the assumption that the content had a more profound effect on the emission than VP or KOA during the experimental period in this work.

Trends of emission over time

To evaluate the effect of time duration on emission, experiments were conducted with the new carpet as an emission source. The emitted amounts of BEHTBP and HBCD were measured in five groups with different periods up to 5 weeks. The time dependence of emission rates is illustrated in Fig. 2. The emission rates of both compounds significantly decreased with the prolonged weeks. The highest emission rate was observed in the first week. A previous study has concluded that emission rates of a material in a chamber should decrease continuously, and the highest emission rates usually occur at the beginning when the materials are introduced (Liang et al. 2015). Because the instantaneous rates of the targets in a specific time point could not be measured and the accurate real-time plot was unavailable, the emission rates under steady-state condition were not reported in the present work. There are actually a few experiments where a limited amount of time (e.g., less than 50 days) is sufficient to measure the timescale of release of SVOCs at room temperature, but longer measurements are often impractical (Rauert et al. 2014b). For example, Kemmlein et al. (2003) studied the emission trend of PBDEs from a printed circuit board at 23 °C over 105 days and found a rapid rise in the first 30 days and a tendency to finally stabilize. Time dependent emission rates of triphenylphosphate (TPP) flame retardants from plastic covers of video-display units over a 193-day period showed a significant reduction in air concentration of this pollutant after the first 50 days, which may be affected by sink effects and bulk diffusion (Carlsson et al. 2000).

Molecules of these additive BFRs are not chemically bonded to the resin chains but are attached through significantly weaker inter-molecular forces (Fujii et al. 2003). This means that over time, the molecules could be gradually released from the material body into the surrounding environment, and consequently, indoor air could be polluted with these emitted compounds (Fujii et al. 2003).

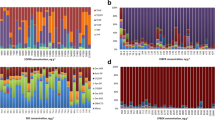

Effect of temperature

Temperature could be the most influential parameter because it directly affects vapor pressure and KOA, and hence gas−particle partitioning and all related fate processes (Liagkouridis et al. 2014). The emission rates of HBCD, HBBZ, BTBPE, TBBPA, and BEHTBP in 7 days from new carpet and computer casing under different temperatures are shown in Fig. 3. In general, five BFRs (except ATE and HCDBCO) contained in the materials were detected in the emission test at higher temperatures. Additionally, the emission rates of those compounds increased significantly with increasing temperature, and the absolute amounts of BFRs emitted from the tested materials were the highest at 80 °C. For example, the emission of HBCD from carpet at 80 °C (690 ± 91.0 pg g−1 h−1) was almost 10 times higher than the emission at 20 °C. Our results agreed with the studies of plasticizer phthalate and flame retardant PBDEs, which are semi-volatile organic compounds (SVOC) (Fujii et al. 2003; Kemmlein et al. 2003). Fujii et al. (2003) investigated temperature dependence of the emissions of various phthalate esters in a passive flux sampler and observed a 100-fold increase in the maximum emission rate with an increase in temperature from 20 to 80 °C. Kemmlein et al. (2003) studied the emission rate of PBDEs in printed circuit boards at high temperatures, and measured a 500-fold difference in the case of BDE47 at 60 and 23 °C.

In addition to the results of the emissions from carpet and computer casing at room temperature, the HBCD remained the most abundant compound at higher temperatures. With the elevated temperatures, the increments of HBCD emission increased and the slope of emission rates also increased sharply, indicating a greater influence at higher temperatures. For carpet and computer casing materials, for example, each elevation of temperature by 15 °C could lead to an increase of emission between 12 and 135% for HBCD. On average, a 15 °C increase in temperature (ranging from 20 to 80 °C) resulted in more than a twofold increase in HBCD emission. This result could be a good explanation for our previous study, which found a positive correlation between the use of air-conditioners in the winter and PBDE levels in indoor air (Sun et al. 2016). Therefore, an elevated temperature by a heater in the winter, an electronic item heated during operation, or a car left in the sun in the summer could accelerate the emission of semi-volatile compounds from materials treated with flame retardants and consequently aggravate the risk for human health in indoor environments.

The influence of different temperatures was also compound-specific. Compared to BEHTB, HBBZ, and BTBPE, HBCD emissions were relatively more sensitive to temperature fluctuation. While the emissions trends of BEHTBP, HBBZ, and BTBPE remain at a relatively low level, HBCD had a growing tendency to migrate into the air at higher temperatures. The high sensitivity to temperature of HBCD could be attributed to its relatively higher vapor pressure (6.3 × 10−5 Pa at 21 °C) compared to those of BTBPE and BEHTBP (Rüdel et al. 2012). In particular, BTBPE and TBBPA were not measured at room temperature but only measured at the temperatures higher than 35 and 65 °C, respectively. It is interesting to note here that TBBPA has a higher vapor pressure than BTBPE, but it was detectable at a lower emission rate, most likely due to the difference in product contents or the mode of BFR incorporation, such as additive vs. reactive (Weschler and Nazaroff 2008). This result illustrates that higher temperatures may cause a compound to be emitted out from materials.

Conclusion

The present study reveals the link between the exposure risk through emission and commonly used BFR-containing materials in indoor environments. It was demonstrated that the combination of chamber emission tests under different temperatures and times, and materials analyses, enables a comprehensive understanding of the emission profiles of additive flame retardants. As the dominant detected pollutant in this investigation, HBCD could emit from several materials with relatively high levels at room temperature. Such results linking the BFR contents in materials and their emission potential could be an important factor when considering the addition of BFRs at an early stage of a material’s development. It is important to put this work in the context of human exposure and health implications. However, because the diversity, year of production, numbers, chemical compositions, and manufacturing processes of consumer materials are specific to each indoor environment, more chamber and modeling studies are needed to accurately estimate potential exposures under actual conditions.

References

Abdallah MAE, Harrad S, Covaci A (2008) Hexabromocyclododecanes and tetrabromobisphenol-a in indoor air and dust in Birmingham, UK: implications for human exposure. Environ Sci Technol 42:6855–6861

Afshari A, Gunnarsen L, Clausen PA, Hansen V (2004) Emission of phthalates from PVC and other materials. Indoor Air 14:120–128

Besis A, Samara C (2012) Polybrominated diphenyl ethers (PBDEs) in the indoor and outdoor environments—a review on occurrence and human exposure. Environ Pollut 169:217–229

Birnbaum LS, Staskal DF (2004) Brominated flame retardants: cause for concern? Environ Health Perspect 112:9–17

Carlsson H, Ulrika Nilsson A, Östman C (2000) Video display units: an emission source of the contact allergenic flame retardant triphenyl phosphate in the indoor environment. Environ Sci Technol 34:3885–3889

Covaci A, Harrad S, Abdallah MA, Ali N, Law RJ, Herzke D (2011) Novel brominated flame retardants: a review of their analysis, environmental fate and behaviour. Environ Int 37:532–556

de Wit CA (2002) An overview of brominated flame retardants in the environment. Chemosphere 46:583–624

de Wit CA, Herzke D, Vorkamp K (2010) Brominated flame retardants in the Arctic environment—trends and new candidates. Sci Total Environ 408:2885–2918

Ezechiáš M, Covino S, Cajthaml T (2014) Ecotoxicity and biodegradability of new brominated flame retardants: a review. Ecotoxicol Environ Saf 110:153–167

Fan X, Kubwabo C, Rasmussen PE, Wu F (2016) Non-PBDE halogenated flame retardants in Canadian indoor house dust: sampling, analysis, and occurrence. Environ Sci Pollut Res 23:7998–8007

Fujii M, Shinohara N, Lim A, Otake T, Kumagai K, Yanagisawa Y (2003) A study on emission of phthalate esters from plastic materials using a passive flux sampler. Atmos Environ 37:5495–5504

Geens T, Ali N, Roosens L, Neels H, Covaci A (2010) Analytical characteristics of several new brominated flame retardants. Talanta 81:1865–1869

He RW, Li YZ, Xiang P, Li C, Zhou C, Zhang S, Cui XY, Ma LQ (2016) Organophosphorus flame retardants and phthalate esters in indoor dust from different microenvironments: bioaccessibility and risk assessment. Chemosphere 150:528–535

He RW, Li YZ, Xiang P, Li C, Cui XY, Ma LQ (2018) Impact of particle size on distribution and human exposure of flame retardants in indoor dust. Environ Res 162:166–172

Kajiwara N, Sueoka M, Ohiwa T, Takigami H (2009) Determination of flame-retardant hexabromocyclododecane diastereomers in textiles. Chemosphere 74:1485–1489

Kajiwara N, Takigami H (2013) Emission behavior of hexabromocyclododecanes and polybrominated diphenyl ethers from flame-retardant-treated textiles. Environ Sci Process Impacts 15:1957–1963

Kemmlein S, Hahn O, Jann O (2003) Emissions of organophosphate and brominated flame retardants from selected consumer products and building materials. Atmos Environ 37:5485–5493

Law RJ, Covaci A, Harrad S, Herzke D, Abdallah MA, Fernie K, Toms LM, Takigami H (2014) Levels and trends of PBDEs and HBCDs in the global environment: status at the end of 2012. Environ Int 65:147–158

Liagkouridis I, Cequier E, Lazarov B, Cousins AP, Thomsen C, Stranger M (2016) Relationships between estimated flame retardant emissions and levels in indoor air and house dust. Indoor Air 27:650

Liagkouridis I, Cousins IT, Cousins AP (2014) Emissions and fate of brominated flame retardants in the indoor environment: a critical review of modelling approaches. Sci Total Environ 491–492:87–99

Liang S, Xu F, Tang W, Zhang Z, Zhang W, Liu L (2016) Brominated flame retardants in the hair and serum samples from an e-waste recycling area in southeastern China: the possibility of using hair for biomonitoring. Environ Sci Pollut Res 23:1–9

Liang W, Yang S, Yang X (2015) Long-term formaldehyde emissions from medium-density fiberboard in a full-scale experimental room: emission characteristics and the effects of temperature and humidity. Environ Sci Technol 49:10349–10356

Lilienthal H, Verwer CM, Lt VDV, Piersma AH, Vos JG (2008) Exposure to tetrabromobisphenol A (TBBPA) in Wistar rats: neurobehavioral effects in offspring from a one-generation reproduction study. Toxicology 246:45–54

Li B, Sun SJ, Huo CY, Li WL, Zhu NZ, Qi H (2016) Occurrence and fate of PBDEs and novel brominated flame retardants in a wastewater treatment plant in Harbin, China. Environ Sci Pollut Res 23:19246–19256

Newton S, Sellström U, de WCA (2015) Emerging flame retardants, PBDEs, and HBCDDs in indoor and outdoor media in Stockholm, Sweden. Environ Sci Technol 49:2912–2920

Qi H, Li WL, Liu LY, Zhang ZF, Zhu NZ, Song WW, Ma WL, Li YF (2014) Levels, distribution and human exposure of new non-BDE brominated flame retardants in the indoor dust of China. Environ Pollut 195C:1–8

Rauert C, Harrad S (2015) Mass transfer of PBDEs from plastic TV casing to indoor dust via three migration pathways—a test chamber investigation. Sci Total Environ 536:568–574

Rauert C, Harrad S, Stranger M, Lazarov B (2014a) Test chamber investigation of the volatilisation from source materials of brominated flame retardants and their subsequent deposition to indoor dust. Indoor Air 25:393–404

Rauert C, Lazarov B, Harrad S, Covaci A, Stranger M (2014b) A review of chamber experiments for determining specific emission rates and investigating migration pathways of flame retardants. Atmos Environ 82:44–55

Rüdel H, Müller J, Quack M, Klein R (2012) Monitoring of hexabromocyclododecane diastereomers in fish from European freshwaters and estuaries. Environ Sci Pollut Res 19:772–783

Stapleton HM, Dodder NG, Offenberg JH, Schantz MM, Wise SA (2005) Polybrominated diphenyl ethers in house dust and clothes dryer lint. Environ Sci Technol 39:925–931

Stapleton HM, Klosterhaus S, Eagle S, Fuh J, Meeker JD, Blum A, Webster TF (2009) Detection of organophosphate flame retardants in furniture foam and U.S. house dust. Environ Sci Technol 43:7490–7495

Stapleton HM, Klosterhaus S, Keller A, Ferguson PL, Bergen SV, Cooper E, Webster TF, Blum A (2011a) Identification of flame retardants in polyurethane foam collected from baby products. Environ Sci Technol 45:5323–5331

Stubbings WA, Harrad S (2014) Extent and mechanisms of brominated flame retardant emissions from waste soft furnishings and fabrics: a critical review. Environ Int 71:164–175

Sun J, Zhang A, Li F, Wang J, Liu W (2013) Levels and distribution of dechlorane plus and related compounds in surficial sediments of the Qian tang river in eastern China: the results of urbanization and tide. Sci Total Environ 443:194–199

Sun J, Xu Y, Zhou H, Zhang A, Qi H (2018a) Levels, occurrence and human exposure to novel brominated flame retardants (NBFRs) and dechlorane plus (DP) in dust from different indoor environments in HangZhou, China. Sci Total Environ 631-632:1212–1220

Sun J, Chen Q, Qian Z, Zheng Y, Yu S, Zhang A (2018b) Plant uptake and metabolism of 2,4-dibromophenol in carrot: in vitro enzymatic direct conjugation. J Agric Food Chem 66:4328–4335

Sun J, Wang Q, Zhuang S, Zhang A (2016) Occurrence of polybrominated diphenyl ethers in indoor air and dust in Hangzhou, China: level, role of electric appliances, and human exposure. Environ Pollut 218:942–949

Takigami H, Suzuki G, Hirai Y, Sakai S (2008) Transfer of brominated flame retardants from components into dust inside television cabinets. Chemosphere 73:161–169

Tang B, Zeng YH, Luo XJ, Zheng XB, Mai BX (2015) Bioaccumulative characteristics of tetrabromobisphenol A and hexabromocyclododecanes in multi-tissues of prey and predator fish from an e-waste site, South China. Environ Sci Pollut Res 22:12011–12017

Thomsen C, Stigum H, Frøshaug M, Broadwell SL, Becher G, Eggesbø M (2010) Determinants of brominated flame retardants in breast milk from a large scale Norwegian study. Environ Int 36:68–74

Ven LTMVD, Kuil TVD, Verhoef A, Verwer CM, Lilienthal H, Leonards PEG, Schauer U, Cantón RF, Litens S, Jong FHD (2008) Endocrine effects of tetrabromobisphenol-A (TBBPA) in Wistar rats as tested in a one-generation reproduction study and a subacute toxicity study. Toxicology 245:76

Viberg H, Fredriksson A, Eriksson P (2004) Neonatal exposure to the brominated flame-retardant, 2,2',4,4',5-pentabromodiphenyl ether, decreases cholinergic nicotinic receptors in hippocampus and affects spontaneous behaviour in the adult mouse. Environ Toxicol Pharmacol 17:61–65

Weschler CJ, Nazaroff WW (2008) Semivolatile organic compounds in indoor environments. Atmos Environ 42:9018–9040

Wu JP, Guan YT, Zhang Y, Luo XJ, Zhi H, Chen SJ, Mai BX (2011) Several current-use, non-PBDE brominated flame retardants are highly bioaccumulative: evidence from field determined bioaccumulation factors. Environ Int 37:210–215

Xu F, Liu Y, Wang J, Zhang G, Zhang W, Liu L (2015) Characterization of heavy metals and brominated flame retardants in the indoor and outdoor dust of e-waste workshops: implication for on-site human exposure. Environ Sci Pollut Res Int 22:5469–5480

Zhang X, Diamond ML, Ibarra C, Harrad S (2009) Multimedia modeling of polybrominated diphenyl ether emissions and fate indoors. Environ Sci Technol 43:2845–2850

Zhang X, Diamond ML, Robson M, Harrad S (2011) Sources, emissions, and fate of polybrominated diphenyl ethers and polychlorinated biphenyls indoors in Toronto, Canada. Environ Sci Technol 45:3268–3274

Zhou T, Ross DG, Devito MJ, Crofton KM (2001) Effects of short-term in vivo exposure to polybrominated diphenyl ethers on thyroid hormones and hepatic enzyme activities in weanling rats. Toxicol Sci 61:76–82

Acknowledgements

This study was supported by the National Natural Science Foundation of China (21577127, 21307111), the Natural Science Foundation of Zhejiang Province (LY17B070006, LY13B070009), and the State Key Laboratory of Urban Water Resource and Environment, Harbin Institute of Technology (No. QAK201715).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Constantini Samara

Electronic supplementary material

ESM 1

(DOC 89 kb)

Rights and permissions

About this article

Cite this article

Sun, J., Chen, Q., Han, Y. et al. Emissions of selected brominated flame retardants from consumer materials: the effects of content, temperature, and timescale. Environ Sci Pollut Res 25, 24201–24209 (2018). https://doi.org/10.1007/s11356-018-2494-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2494-0