Abstract

Water quality standard for nitrate becomes more and more strict, and the plant carbon source is widely used for denitrification by constructed wetland (CW) and bioreactor. However, the nitrate removal efficiency by different types of plant carbon source are not evaluated comprehensively. Denitrification performance of different plant carbon sources, and the influence of dosing method and pretreatment are thoroughly reviewed in this paper, which aims to investigate the accurate utilization of plant carbon source for nitrogen (as nitrate) removal. It is concluded that plant carbon source addition for all types of CWs and bioreactors can improve the nitrate removal efficiency to some extent, and the dosing method of plant carbon source for denitrification should be further studied and optimized in the future. The popular carbon sources for CW and bioreactor denitrification enhancement are woodchip, chopped macrophytes, crop plants, macrophytes litters, etc. The recommended optimum C:N ratios for CW and bioreactor are 4.0:5.0 and 1.8:3.0, respectively. The physical and biological pretreatments are selected to supply organic carbon for long-term denitrification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agricultural runoff and municipal wastewater treatment effluent always contain relatively high level of nitrate, which is the majority of the nitrogen in wastewater (Beutel et al. 2009; Lin et al. 2002). High nitrate causes excess algae growth in a waterbody (eutrophication), which degrades water quality, reduces biological diversity, and provokes deterioration of public health (Ballantine et al. 2014; Mirvish 1977; Sirivedhin and Gray 2006). Therefore, nitrate removal from agricultural runoff and effluent of treated municipal wastewater becomes more and more urgent (Bezbaruah and Zhang 2003).

A constructed wetland (CW) is an integrated system designed to take advantage of water, soil, plant, and microorganism reactions that occur in natural wetlands under controlled conditions (Davis 1995; Vymazal 2007; Vymazal and Kröpfelová 2011; Wu et al. 2014). CW technology, which is widely used as an alternative way for the treatment of nitrate from primary or secondary domestic sewage effluent, agricultural runoff (Brix and Arias 2005a, b; Vymazal and Kröpfelová 2011), storm water (Carleton et al. 2001), groundwater (Lin et al. 2002; Reilly et al. 1999), landfill leachate (Kozub and Liehr 1999; Liehr et al. 2000), drinking water (Reilly et al. 1999), etc., has developed rapidly over the last three decades.

CW has the advantages of sturdy, less expensive to build, low external energy consumption and minimal operational maintenance, which make them a cost-effective and technically feasible method for the treatment of agricultural runoff and decentralized sewage in rural and undeveloped areas (Brix 1999; IWA 2001; Vymazal 2009).

Nitrogen removal by CW is a complex and interrelated process, which depends on a variety of mechanisms as plant uptake, soil adsorption, microbial immobilization and denitrification, etc. and the persistent and dominating nitrate removal is caused by denitrificans, which account for 60–90 % of total nitrate reduction (Spieles and Mitsch 1999; Vymazal et al. 2006). Bioreactor treatment is also a popular technology for nitrate removal (Ovez 2006; Ovez et al. 2006; Park et al. 2008; Saliling et al. 2007).

Denitrification in CW and bioreactor is an anoxic process, in which nitrate is reduced to nitrite and subsequently to nitrogen gas by heterotrophic denitrifying bacteria as follows (Li et al. 2007):

However, the denitrification process is directly and/or indirectly influenced by several factors as carbon source, nitrate loading rate, oxygen availability, temperature, pH, species of wetland macrophytes, etc. (Aslan and Türkman 2004; Beauchamp et al. 1989; Cameron and Schipper 2010; Ingersoll and Baker 1998). The key influencing factor for nitrate removal in CW and bioreactor is carbon source, which can be oxidized as electron donors for biological denitrification (Bachand and Horne 1999; Matějů et al. 1992; Park et al. 2008; Shackle et al. 2000). Therefore, additional carbon source is necessary for the denitrification of relatively low COD/TN (C/N) ratio water such as agricultural runoff and treated municipal wastewater effluent (Lin et al. 2002; Wen et al. 2010). The characteristic of carbon source has a great influence on the major parameters as denitrification rate, COD demand and biomass composition of the denitrification systems (Lee and Welander 1996; Obaja et al. 2005). The factors that should be highlighted and considered for carbon source selection are cost, sludge production, denitrification rate, kinetics, utilization degree, handling and storage safety, the content of unfavorable/toxic compounds, the complete denitrification potential without microflora adaptation, etc. (ÆsØy et al. 1998). The cost of carbon source and waste management accounts for more than 50 % of the total cost of wastewater denitrification (Fernández-Nava et al. 2010; MacDonald 1990), and it is very important to find an economical carbon source for denitrification.

Methanol is the most commonly employed external organic carbon source for its easy assimilation by denitrificans and relatively low cost (Christensson et al. 1994; Clifford and Liu 1993; Rabah and Dahab 2004). Ethanol and acetic acid are also equivalent commercial carbon sources. Although the denitrification efficiency with the carbon sources mentioned above are very good, nitrite accumulation will occur for wastewater with high nitrate concentration (Glass and Silverstein 1998), which leads to the inhibition of bacteria growth. Moreover, the cost of these carbon sources is relatively high (Wang et al. 2016) and carbon residues may occur. CWs and bioreactors can be used to treat agricultural runoff, domestic sewage and industrial wastewater with plant addition as carbon source.

Plant carbon source application has been increased in the last decades due to its cost-effectiveness and high efficiency. The large amounts of organic compounds i.e., cellulose, hemicellulose and lignin contents contained in plant biomass can be released through complex decomposition and used for denitrification (Aerts and de Caluwe 1997; Chen et al. 2014a; Tian et al. 1992; Wardle et al. 2002).Considerable studies have been carried out to investigate the improvement of CW denitrification rate with carbon source plants as woodchip (Domingos et al. 2009), cattail litter (Bastviken et al. 2005; Chen et al. 2014b; Ingersoll and Baker 1998; Liu et al. 2010; Wen et al. 2010), wheat straw (Hamersley and Howes 2002), Elodea Canadensis (Bastviken et al. 2005), common reed (Bastviken et al. 2005; Zhang et al. 2014), Platanus acerifolia leaf (Zhang et al. 2014), bulrush (Gersberg et al. 1983), etc. Quite some carbon source plants as wheat straw (Aslan and Türkman 2004; Cameron and Schipper 2010; Soares and Abeliovich 1998; Warneke et al. 2011), G. verrucosa, liquorice (Ovez 2006), giant reed (Ovez et al. 2006), cotton wool (Della Rocca et al. 2007; Singer et al. 2008; Volokita et al. 1996), pine bark (Trois et al. 2010; Warneke et al. 2011), maize cobs, green waste (Cameron and Schipper 2010; Warneke et al. 2011), sawdust, eucalyptus (Warneke et al. 2011), tomato and cucumber leaves (Park et al. 2008), softwood, hardwood (Cameron and Schipper 2010), etc. have been tested in lab-scale bioreactors. Accordingly, the above-discussed studies provide a motivation to select an economically, effectively and ecologically alternative carbon source for improving denitrification in CWs and bioreactors.

The main objective of this paper is to review the recent developments of plant carbon source used for denitrification in CWs and bioreactors, and several key factors as plant biomass, dosage, dosing position, pretreatment methods, etc. are thoroughly discussed. Moreover, the prospects of plant carbon source for CWs and bioreactors are put forward.

Plant carbon source for CW denitrification

Influence of plant biomass on CW denitrification

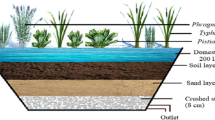

Denitrification in CWs can be slightly improved by supporting denitrificans with continuous input of labile organic carbon derived from decomposition of dead litter and root exudates of wetland plants such as bulrush (i.e., cattail) (Bachand and Horne 1999; Gersberg et al. 1986), common reed (Białowiec et al. 2011, 2012; Gersberg et al. 1986; Huett et al. 2005; Lin et al. 2002; Picek et al. 2007; Zhai et al. 2013), willow (Białowiec et al. 2012), Commelina communis, Penniserum purpureum, Ipomoea aquatic, Pistia stratiotes (Lin et al. 2002), Iris pseudacorus, Juncus effuses (Zhai et al. 2013), etc. Nevertheless, subsurface flow constructed wetlands (SFCWs) and vertical flow constructed wetlands (VFCWs) are marginally successful at removing nitrate from wastewater because the gravel layer prevents the aboveground plant litter from reaching the water and inhibits the carbon release from plant biomass (IWA 2001).

Various types of plant biomass have been employed as additional carbon source for CWs to enhance the denitrification efficiency, and the main aim of which is to find the optimal plant biomass as external carbon source for certain wastewater. CW denitrification potential is affected by the composition of the plant biomass, whose cellulose, hemicellulose and lignin content were greatly different (Cadisch and Giller 1997; Hume et al. 2002; Wen et al. 2010).

As shown in Table 1, when the influent nitrate is less than 50 mg · L−1, the addition of carbon source plants as cattail, common reed, wheat straw, rice straw, etc. can increase the denitrification rate. The nitrate removal efficiency is between 50 % and 100 % in various types of CWs (i.e., FWSCWs, SFCWs, and VFCWs), and it is above 90 % with plenty carbon source. The treatment efficiency varies with different plant biomass, e.g., the denitrification rate and nitrate removal efficiency of P. acerifolia leaf CW are 82.49 % and 3.36 g · m−3 · d−1, which are higher than those of P. austrails CW.(Zhang et al. 2014). The average nitrate removal of VFCW is 31 % without external carbon source, which increases to 84 % with 2140 g woodchip addition (Domingos et al. 2009). More than half of these studies were performed in lab-scale microcosms, which were economical and easy to test and repeat a large number of plant biomass. Furthermore, most of the studies were carried out in SFCWs.

One of the most frequently used plant carbon sources in CWs is cattail litter. The investigation of cattail carbon source application in lab-scale FWSCWs showed that the nitrate removal efficiency is higher than 90 % under the condition of 6 g dry weight (DW) plant · d−1 dosage and 10 cm · d−1 or even higher hydraulic loading rate, and the efficiency never exceed 40 % without dosing cattail biomass (Ingersoll and Baker 1998). Another study of SF indicated that the nitrate removal efficiency increased from 67.9 to 92.9 % with cattail litter addition, and the highest rate was 0.98 g · m−3 · d−1 higher than that of un-amended microcosm (3.46 g · m−3 · d−1) (Liu et al. 2010). A batch SFCW research found that the nitrate removal rate improved 2.4–3 times with cattail litter addition, which indicated that cattail litter can greatly enhance the nitrate removal ability (Wen et al. 2010).

The denitrification rate increased from 0.12 to 5.50 g · m−3 · d−1 with 1.4 g · L−1 particulate wheat straw addition in an aerated SFCW. After 7 weeks of operation, the NO x −-N in the tanks with wheat straw addition was 6.4 ± 1.9 mg · L−1, which was about 50 % lower than that of the tanks without wheat straw, i.e., 12.7 ± 2.7 mg · L−1 (Hamersley and Howes 2002). Ding et al. (2013) selected rice straw as the optimal plant carbon source, the average nitrate removal rate was 25.0 % when carbon source deficiency occurred in the influent, which increased 72.1 % for 4d HRTs with certain amount of rice straw addition (C:N ratio was 4.0). Likewise, Zhang et al. (2011) studied the influence of corncob on the treatment of secondary effluent from sewage treatment plant by lab-scale SFCWs, and the nitrate removal rate increased from 24.3–57.9 to 96.5–99.3 % after corncob addition for different influent and HRTs. The similar denitrification enhancement by adding cattail litter into SFCWs were also obtained by Chen et al. (2014b) and Gersberg et al. (1983). It can be concluded that cattail litter and corncob are optimal carbon sources for SFCW due to their high nitrate removal capacity.

The influence of different plant biomass on denitrification of partly nitrified wastewater by FWSCWs added with cattail, common reed or E. Canadensis (all plant biomass added were collected from planted wetland itself) was studied (Bastviken et al. 2005), the results showed that CW added with E. canadensis achieve about 3 times denitrification capacity as much as the CWs added with cattail litter or common reed. E. canadensis provides higher carbon availability and its surface maybe more suitable for bacterial growth, and thereby increased the bacterial population. For CWs planted and dosed with cattail litter and common reed, no significant denitrification difference was observed, which suggested that the submerged plants biomass can provide sufficient high quality organic substance for heterotrophic denitrificans.

A remarkable improvement of nitrate removal was obtained using P. acerifolia leaf and common reed as carbon source (Zhang et al. 2014). TOC released from the decomposition of P. acerifolia leaf was higher than that of common reed. The denitrification rate and nitrate removal efficiency of P. acerifolia leaf, i.e., 4.87 g · m−3 · d−1 and 100 %, were higher than those of P. austrails litters (3.36 g · m−3 · d−1 and 84.5 %) for denitrification enhancement in VFCWs.

In conclusion, plant application as carbon source in CWs for denitrification enhancement is extensively studied both in lab and pilot scale, and such methods are simple to perform, relatively low-cost and high nitrate removal. The popular carbon sources used to enhance CW denitrification are woodchip, chopped macrophytes (E. canadensis, common reed, cattail litter, etc.), wheat straw, rice straw, corncob, P. acerifolia leaf, etc. However, full-scale CW experiments should be carried out to test the results discussed above. What is more, plant biomass will release far less organic carbon after certain time, and then cannot provide enough electron donors for the denitrification in CWs. Therefore, the renewal cycle of plant substrates need to be investigated further. It is suggested that long-term and more slowly released organic carbon supply can be obtained for denitrificans in CWs if a mixture of labile (submergent, floating) and more unbiodegradable, grasses plants are used through a reasonable approach.

Influence of plant dosage on CW denitrification

Denitrification rates have strong positive correlations with the available organic carbon amount in CWs (Chen et al. 2011). Hume et al. (2002) suggested that acid soluble plant carbohydrates measurement is a good way to determine the denitrification ability of plant biomass. C:N ratio can be used as an indicator for organic carbon availability and quality of plant biomass. Low influent C:N ratio restricts the CW denitrification efficiency, and external plant carbon source addition can overcome the C:N ratio limitation, thus ensure the effluent meet the advanced treatment standards. As listed in Table 2, the influence of plant dosage on CW dentirification efficiency and effluent quality has been widely investigated, from which it can be concluded that nitrate is almost completely removed when C:N ratio ranges from 4:1 to 5:1, and no remarkable increase of removal efficiency can be achieved when C:N ratio is higher than 5:1. The optimal C:N ratio for denitrification varies with different plant biomass (Bremner and Shaw 1958). To assure carbon above the optimum requirement for denitrification in CWs, Gersberg et al. (1983) recommended 6 times dosage of the theoretical requirement based on carbon balance calculation. Most research about plant carbon dosage has been conducted in lab-scale, more pilot and even full-scale experiments are needed for better understanding of the dosage influence on nitrate removal.

The feasibility of supplying extracted carbon solution to improve denitrification in a lab-scale SFCW planted with cannas was thoroughly investigated. Sufficient carbon source solutions of different C:N ratio, which were extracted from the hydrolyzate of cattail, canna and rice straw mixture (Ding et al. 2013), can effectively promote half reaction and then improve NO2 −-N reduction, thus to keep comparatively high NO3 −-N removal efficiency (Chen et al. 2011; Virdis et al. 2010). At 0.0 and 1.0 influent C:N ratio, insufficient organic carbon source resulted in low nitrate removal in HSSF CWs for wastewater treatment. Carbon source was sufficient at 2.0 or higher influent C:N ratio, and high nitrate and TN removal efficiency could be obtained. The denitrification rate at 2.0 C:N ratio was two times higher than that at 1.0 and 0.0 C:N ratio.

It was indicated that extracted carbon solution act as electron donors that play an important role in nitrate reduction. According to the denitrification mechanism, denitrification processes include the initial NO3 −-N reduction to NO2 −-N, further NO2 − reduction to NO and N2O, and final reduction to N2, which are shown in Eqs. (2–5) (Wallenstein et al. 2006).

Denitrification capacity maybe depend on the quantity and quality of the organic carbon needed for bacterial growth, Ingersoll andBaker (1998) suggested that such dependence can be described as a proportional relationship between denitrification rate and carbon supply.

The effect of different biomass dosage was tested at 18 FWSCW microcosms with 30 mg · L−1 nitrate-contaminated influent, the nitrate removal efficiency varied from 8 % to above 95 %, and the maximum efficiency was attained at 5:1 C:N ratio (Ingersoll and Baker 1998). When C:N ratio was higher than 5:1, the nitrate removal efficiency kept higher than 90 % and appeared to be independent of the C:N ratio. While at very low C:N ratio, only slight denitrification occurred in CWs. The plant carbon source dosing position should be carefully designed to achieve preferable nitrate reduction by CWs. Up to present, the studies about dosing position is quite limited, and further research should be conducted to optimize the dosing position in CWs.

Influence of plant pretreatment on CW denitrification

Plant biomass is mainly composed of cellulose, hemicellulose, lignin, small amounts of pectin, protein, etc. (Kumar et al. 2009). The cellulose and hemicellulose are easier to be decomposed by microorganisms than lignin, which are likely the main carbon sources for denitrification (Wen et al. 2010). Pretreatment is critical for the cellulose and hemicellulose release from plant biomass, and thus provide more available organic carbon for denitrificans (McMillan 1994; Mosier et al. 2005). As illustrated in Tables 3 and 4, some researchers found that pretreated plant biomass can improve denitrification rate of CWs more effectively. Different pretreatment strategies have their specific effect on denitrification rate. Anaerobic, low DO, high DO, acids (usually H2SO4) and alkali (usually NaOH) pretreatment are often used to change the main plant carbon composition for CWs (Zhang et al. 2007), and such pretreatment can increase the content of cellulose and hemicelluloses. The change of main organic composition in plant biomass under different pretreatment methods are shown in Table 3.

Ding et al. (2013) used several carbon source extraction solutions, i.e., the hydrolyzate of selected wetland litters, in CWs for nitrogen removal enhancement. Cattail litter, canna and rice straw were cut into 1–2 cm sections. The mixture of each plant material (1 g) hydrolyzate (800 ml, deionized water, 2 % H2SO4 or 5 % H2SO4) was put into a 1000 ml beaker and heated by electromagnetic oven, and the reaction time ranged from 0 to 60 min at room temperature (25 °C). The optimal reaction condition was rice straw hydrolyzed in 5 % H2SO4 aqueous solution over 60 min, which yielded highest COD content, and the lignin reduced by 39.6 %, while the cellulose and hemicellulose increased by 23.0 and 29.6 % compared with the raw rice straw.

Both un-treated and NaOH-treated cattail litters were used to investigate the main composition variation and its influence on bioavailability and denitrification efficiency in lab-scale SFCWs (Wen et al. 2010). After NaOH pretreatment, the cellulose and hemicellulose increased 30.6 and 21.0 % while the lignin reduced 19.0 % compared with raw litters. Because of its solubilization in alkaline solution, certain lignin can be removed from raw material. What is more, the plant biomass C:N ratio increased from 60 to 669, which indicated that alkaline-pretreatment results in higher quantity C and then higher nitrate removal based on carbon balance.

Limited studies were carried out to enquire into the influence of different pretreated biomass on bioavailability and denitrification performance in CWs (Table 4).

The three stage denitrification rates for alkali-pretreated cattail CW were 1.9, 0.7, and 0.9 times of those for un-pretreated cattail CW, which meant that pretreated plant addition is more efficient in the initial stage (1–25d) while un-pretreated plant addition is better in the middle (26–75d) and terminal (76–90d) stage (Wen et al. 2010). It can be concluded that alkali-pretreated plants cannot enhance denitrification for all the time, and this inadequacy should be considered when using pretreated plant carbon source for nitrate removal. Therefore, the un-pretreated plant was recommended as external carbon source for long-term steady carbon supply. Un-alkali pretreatment of the plants, i.e., physical pretreatment, can meet the basic requirements proposed by (Sun and Cheng 2002) as follows: (1) improve the formation of cellulose and hemicellulose, (2) avoid the degradation or loss of carbohydrate, (3) avoid the formation of byproducts that are inhibitory to organic carbon release, and (4) be cost-effective.

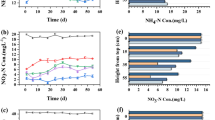

Chen et al. (2011) used cattail litter as external carbon source in SFCWs at anaerobic or aerobic conditions (low DO and high DO) to evaluate the improvement of denitrification rate. The denitrification rate declined over time and were enhanced greatly by anaerobic litter leachate, which had higher quantity and better quality of dissolved organic carbon (DOC) and available carbon source. The SFCW denitrification rate of anaerobic leachate was about 3.12–36.0 g · m−3 · d−1 higher than that of low DO leachate, i.e., 2.40–11.04 g · m−3 · d−1. Anaerobic condition was favorable for DOC accumulation from litter decomposition, which could promote denitrification in organic carbon-limited wetlands. Therefore, external litter carbon source was recommended to add in relatively anaerobic zones, e.g., the bottom of inlet.

According to the studies mentioned above, plant litter treated by acid or alkali can slightly improve the nitrate removal rate, and the plant biomass with chemical pretreatment cannot fulfill the long-term improvement of CW denitrification. Acid or alkaline pretreatment may break the lignin seal and disrupt the cellulose crystalline structure; thus, leading to a fast organic carbon release at the early stage and a far less release afterward. However, dosing chopped plant biomass directly in CWs could obtain sustainably effective enhancement of denitrification, which is probably resulted from the unchanged chemical properties of the plant biomass. Therefore, the chopped (physical treatment) plant biomass is recommended to add into relatively anaerobic zones, and it is an environmental-friendly pretreatment method to produce relatively high amount of organic carbon for enhancing long-term denitrification.

Plant carbon source for bioreactor denitrification

The influence of plant carbon source type, dosing and pretreatment method on the bioreactor denitrification has been studied all over the world (Aslan et al. 2004; Ovez 2006a; Ovez et al. 2006b; Singer et al. 2008; Trois et al. 2010; Warneke et al. 2011; Park et al. 2008).

Influence of plant biomass on bioreactor denitrification

Plant application in denitrification bioreactors was summarized in Table 5, from which it can be seen that plant biomass addition can increase the nitrate removal efficiency. Aslan andTürkman (2004) developed an up-flow denitrification bioreactor packed with wheat straw as carbon source and supporting particles to investigate the nitrate removal efficiency in both batch and continuous experiments. Since the DOC released from wheat straw was sufficient for biological denitrification, an almost-complete nitrate removal was obtained for 200 mg · L−1 nitrate influent when temperature was higher than 20 °C in the batch experiments, while for 22.6 mg · L−1 nitrate influent at 31 °C in the continuous experiments.

The influence of plant biomass on denitrification in batch bioreactors was studied in darkness at 20 °C, i.e., simulated natural denitrification condition, and the plant biomass (1 cm pieces of pine, poplar, cotton stem, thyme, carob, giant reed, liquorice, cinnamon, ginger, corn cob, laurel, C. barbata, C. sinuosa, D. dichotoma, U. lactuca, E. linza, and G. verrucosa, etc.) was placed into the reactor as carbon source and filler for anaerobic microbial community adhesion (Ovez 2006). G. verrucosa, liquorice and giant reed had positive effect on bioreactor denitrification, complete nitrate removal could be achieved in 13, 24, and 20 days, and the corresponding denitrification rates were 13.2, 6.24, and 3.36 g · m−3 · d−1, which maybe resulted from the different surface area of G. verrucosa, liquorice and giant reed, i.e., 12426, 962, and 1179 m2 · m−3, respectively. Also, the protein content on liquorice surface was higher than that on giant reed surface, which was consistent with the higher N2 production. In spite of its smaller surface area, liquorice reactor achieved better denitrification performance than giant reed.

Liquorice and giant reed carbon source were also investigated by batch, semi-batch, and continuous experiments for drinking water biological denitrification (Ovez et al. 2006). For batch experiments, complete denitrification was achieved for both liquorice and giant reed when the influent nitrate was 100 mg · L−1, while complete denitrification time for liquorice reactor was always shorter than that for giant reed reactor, i.e., liquorice provided higher denitrification velocity than giant reed. For semi-batch experiments, nitrate removal efficiency was lower in giant reed reactors (87 %) when compared to the liquorice reactors (98 %). Similar results were also obtained in continuous experiments. In general, Ovez (2006) and Ovez et al. (2006) found that liquorice reactor can achieve higher nitrate removal efficiency than giant reed reactor at all experimental conditions, and G. verrucosa reactor achieve the best performance.

A novel two-stage denitrification system, which comprised a small plastic degassing chamber and a denitrification biofilter, for wastewater treatment of high nitrate (higher than 200 mg · L−1) was developed by Singer et al. (2008). After 2 weeks of operation with cotton wools addition, the effluent nitrate of the denitrification biofilter reduced to less than 10 mg · L−1.

A series of static batch tests in 1.5 L anaerobic vessels were carried out to evaluate the influence of pine bark addition on nitrate removal from nitrified leachate (Trois et al. 2010). The denitrification rate for the pine bark packed column ranged from 152.64 to 203.04 g · m−3d−1. Filtration columns were also used to assess the denitrification efficiency of leachate, whose average nitrate concentration was 600 mg · L−1. Under the conditions mentioned above, the denitrification rate ranged from 12.48 to 60.0 g · m−3 · d−1. Therefore, the pine bark packed column was effective for the denitrification of nitrified leachate in fixed bed reactors.

Several denitrification beds filled with wood byproducts (pine woodchip, maize woodchip, wheat straw, green waste, sawdust, and eucalyptus woodchip) were designed to investigate the influence of different carbon sources on denitrification at 27.1 °C (Warneke et al. 2011). The influent nitrate was 17.2 mg · L−1, and the denitrification rate ranged from 2.4 g · m−3 · d−1 (pine woodchip barrel) to 6.24 g · m−3 · d−1 (maize cob). All the carbon sources could enhance the denitrification rate to some extent, and the best one was maize woodchip, followed by wheat straw, green waste, sawdust, eucalyptus woodchip and pine woodchip.

Denitrification walls filled with sawdust and soil mixture as sediment layer were used to remove nitrate from shallow groundwater (Schipper and Vojvodić-Vuković 2001). When nitrate ranged from 5 to 15 mg · L−1, more than 95 % nitrate removal was continuously obtained, and the corresponding denitrification rate ranged from 0.24 to 3.36 g · m−3 · d−1. The denitrification rates kept high enough to remove nitrate from groundwater, and the denitrification was limited by nitrate rather than available carbon source during five years.

Up-flow lab-scale bioreactors packed with wheat straw as the sole carbon source were used to treat nitrate-polluted drinking water (Soares andAbeliovich 1998). Complete nitrate reduction was obtained for 20 mg · L−1 nitrate influent, and the highest denitrification rate was 53 g · m−3 · d−1 during the first week. Then the denitrification rate declined with the decrease of available carbon source. It was demonstrated that the addition of fresh wheat straw can temporarily improve the denitrification rates.

In addition, long-term evaluation (over 23 months) of denitrification rate was conducted in denitrification beds with five different carbon substrates, i.e., maize cobs, green waste, wheat straw, softwood, and hardwood in 0.2 m3 barrels (Cameron andSchipper 2010). The best denitrification rate (i.e., 19.8 g · m−3 · d−1) was attained by maize cob bioreactors. At 14 °C, the highest denitrification rate of maize cob bioreactor was about 6.5, 2.5, and 3.4 times longer than that of wood media, green waste, and wheat straw, respectively.

Generally, the popular carbon sources used to enhance bioreactor denitrification are G. verrucosa, liquorice, giant reed, cotton wools, pine bark, maize woodchip, wheat straw, green waste, sawdust, eucalyptus woodchip, etc. The recommended plant biomass for bioreactor denitrification enhancement are maize cobs, cotton wool and pine bark.

Influence of dosage method on bioreactor denitrification

As shown in Table 6, nitrate removal efficiency usually changes with C:N ratio variation in the denitrification bioreactor with different dosage of plant carbon source. When the nitrate concentration of hydroponic wastewater was 353 mg · L−1, the best denitrification performance, i.e., 95.1–99.2 % nitrate removal and 0.58–0.62 g · m−3 · d−1 denitrification rate, was obtained at C:N ratio of 3:1 (Park et al. 2008). When the C:N ratio was 20:80 and influent nitrate concentration was 100 mg · L−1, complete nitrate removal could be achieved, and the denitrification rate was 9.12–61.92 g · m−3 · d−1 (Ovez 2006). When the C:N ratio was 1.83 ± 0.52 g cotton wool g−1-NO3 −-N, 95 % nitrate removal was attained by biofilter (Singer et al. 2008).

Park et al. (2008) investigated the feasibility of using pretreated plant liquor (the ratio of a mixture of tomato and cucumber leaves to wastewater was 1:1) as organic carbon source for the treatment of hydroponic wastewater with high nitrate (above 300 mg · L−1) in five identical lab-scale denitrification filters at 20 °C. The filters were operated with C:N ratio of 1.07 at stage 1, then the C:N ratio increased to 3.0 by plant liquor dosage (stage 2), and some filters were operated with C:N ratio of 2.0 at stage 3 to avoid excess effluent BOD5 while maintain high denitrification rate. The nitrate removal efficiency increased from 75.8 to 99.2 % following the change of stage 1 to stage 2, but relatively high effluent organic carbon were observed at stage 2, which meant that the organic carbon supply exceed the denitrification demand. During stage 3, the effluent organic carbon of all filters was below 25 mg · L−1, and the average volumetric denitrification rate was 0.46–0.62 g · m−3 · d−1.

The applied ratio of plant biomass to nitrate N can be theoretically calculated on the basis of the amount of carbon added and nitrogen to the system throughout the experiment. The average calculated ratio of cotton wool to nitrate was 0.82, which was below the theoretical ratio (1.36) reported as cellulose to nitrate (Singer et al. 2008). Della Rocca et al. (2007) found a C:N ratio of 2.9 g cotton wool · g-1 N in treatment of nitrate-dominated drinking water, which is higher than the above-mentioned ratio. The study of Volokita et al. (1996) showed that an optimal C:N ratio of 2.6 g cotton wool · g-1 N was needed to maintain low nitrate levels. Therefore, the recommended C:N ratio is therefore around 3.0 for bioreactors and the optimal C:N ratio (g:g) ranges from 0.82 to 2.9 with cotton wool as carbon source in different bioreactors.

Plant carbon source dosing position is also a key influencing factor for bioreactor denitrification. Saliling et al. (2007) evaluated woodchip and wheat straw as alternatives to expensive Kaldnes plastic media for denitrification by lab-scale biofilters, and the effects of dosing positions were taken into consideration. The up-flow biofilters were operated at least 4 weeks with 50, 120, and 200 mg · L−1 NO3 −-N influent, and the corresponding volumetric NO3 −-N + NO2 −-N loading rates were 340, 810, and 1380 g · m−3 · d−1, respectively. Samples were taken from port A (10 cm), B (20 cm), and C (30 cm) simultaneously at steady-state condition for each loading rate, and the nitrate removal for different plant dosing positions are shown in Table 7. The average denitrification rate for 10–20 cm (bottom-up, the same below) plant dosage, i.e., 768 ± 456 g · m−3 · d−1 for woodchip and 936 ± 216 g · m−3 · d−1 for wheat straw, were lower than those for 0–10 cm dosage, i.e., 2520 ± 780 and 2568 ± 564 g · m−3 · d−1, respectively. Generally speaking, the wheat straw and woodchip dosed at biofilter bottom can achieve higher nitrate removal rate than those dosed at biofilter top for almost all loading rates.

Few studies were about the comparison of denitrification bioreactor performance under different C:N ratio conditions. C:N ratios of 1.83–3.0 were used to get about 95 % nitrate removal for bioreactors. Akunna et al. (1993) estimated that for a batch type reactor, the C:N ratio of 5.4, 4.8, 4.8, 5.0, and 3.7 is required for complete denitrificaion with glucose, glycerol, acetic acid, lactic acid, and methanol as carbon source, respectively. Generally, the optimal C:N ratio for bioreactor denitrification is not only strongly correlated with carbon source plant biomass, but also with environmental conditions. Further research about optimal C:N ratio selection and dosing position should be carried out for bioreactors in the future.

Influence of plant pretreatment method on bioreactor denitrification

Comparison of anoxic bioreactor denitrification with carbon sources pretreated by different methods are shown in Tables 8 and 9. Ovez (2006) compared the denitrification performance of raw liquorice material and extracted liquorice root carbon source. Liquorice roots were extracted with water at 50 °C, and the mass ratio of water and liquorice root was 40:1. The extracted liquorice root was much more effective than raw liquorice for denitrification, and nearly doubled the N2 production. Park et al. (2008) put the raw plant and hydroponic wastewater with 1:2 ratio into a tank, which produced the highest amount of organic carbon in terms of filtered biochemical oxygen demand (f-BOD5), i.e., 28.1 g f-BOD5 kg−1 plant material. It was indicated that the hydroponic wastewater contain lots of anaerobic microcosms and significantly assist the release of available organic carbon from the plant. The C:f-BOD5 of the extract produced by physical or biological pretreatment, which was used to assess the biodegradability, was ranged from 1.0 to 1.9. The results indicated that all the plant extract is readily biodegraded and suitable for heterotrophic denitrification as organic carbon source. The best denitrification performance was also achieved by denitrification filters with the ratio of plant to hydroponic wastewater was 1:2 under different C:N conditions.

As discussed above, physical (heating) and biological (anaerobic) pretreatment can enhance the production of easy-biodegradable carbon, which served as electron donors for denitrification. It is a prospective method for better nitrate removal performance in the case of avoiding secondary pollution.

Conclusions and prospects

Plant carbon sources are primarily used for the enhancement of nitrate removal from domestic wastewater and agricultural runoff. The nitrate removal enhancement in CWs and denitrification bioreactors by plant carbon source addition is influenced by many factors as plant biomass, dosage, dosing position and pretreatment strategy, which are reviewed and compared in this paper.

Plant biomass selection depends on the denitrification performance, CW and bioreactor type, wastewater characteristic and economic cost. The popular carbon sources used to enhance CW and bioreactor denitrification are woodchip (pine bark, maize woodchip, eucalyptus woodchip, etc.), chopped macrophytes (giant reed, E.canadensis, P. austrails, T. latifolia, etc.), crop plants (wheat straw, rice straw, corncob, liquorice, etc.), macrophytes litters (P. austrails, Commelina communis, Ipomoea, and Pistia stratiotes, etc.), and other plants as P. acerifolia leaf, G. verrucosa, cotton wools, sawdust, etc.

Moreover, for CWs plant dosage (C:N ratio), it can be concluded that nitrate is almost completely removed when C:N ratio ranges from 4 to 5, and no remarkable increase of removal efficiency can be achieved when C:N ratio is higher than 5 for CWs. The C:N ratios of 1.83–3.0 were used to get about 95 % nitrate removal for bioreactors. The optimal C:N ratio for denitrification vary with different plant biomass. The plant biomass dosing position also influenced the denitrification of the CW and bioreactor, and further study should be carried out in the future.

The physical (chopped, heating, etc.) and biological (anaerobic, etc.) plant biomass pretreatment are recommended to enhance the production of easy-biodegradable carbon, and it is an environmental-friendly pretreatment method to produce relatively high amount of organic carbon for enhancing long-term denitrification.

Although methanol, acetate and other commercialized low molecular weight organic compounds are widely used for denitrification enhancement in many full-scale wastewater treatment plants and CWs, they are gradually replaced by plant carbon sources in CWs and denitrification bioreactors recently. It is suggested that full-scale CW can be managed to favor denitrification by plant carbon sources derived from the wetland itself. The plant application as external carbon source, which is a cost-effective and environmental-friendly method for denitrification enhancement, might be industrialized in near future.

Integrated approaches should be carried out to investigate the plant carbon source performance in full-scale CWs and denitrification bioreactors, thus to promote the application and industrialization of such technologies.

References

Aerts R, de Caluwe H (1997) Nutritional and plant-mediated controls on leaf litter decomposition of Carex species. Ecology 78:244–260

ÆsØy A, Ødegaard H, Bach K, Pujol R, Hamon M (1998) Denitrification in a packed bed biofilm reactor (BIOFOR)—experiments with different carbon sources. Water Res 32:1463–1470

Akunna JC, Bizeau C, Moletta R (1993) Nitrate and nitrite reductions with anaerobic sludge using various carbon sources: glucose, glycerol, acetic acid, lactic acid and methanol. Water Res 27:1303–1312

Aslan Ş, Türkman A (2004) Simultaneous biological removal of endosulfan (α + β) and nitrates from drinking waters using wheat straw as substrate. Environ Int 30:449–455

Bachand PA, Horne AJ (1999) Denitrification in constructed free-water surface wetlands: II. Effects of vegetation and temperature. Ecol Eng 14:17–32

Ballantine KA, Groffman PM, Lehmann J, Schneider RL (2014) Stimulating nitrate removal processes of restored wetlands. Environ Sci Technol 48:7365–7373

Bastviken SK, Eriksson P, Premrov A, Tonderski K (2005) Potential denitrification in wetland sediments with different plant species detritus. Ecol Eng 25:183–190

Beauchamp E, Trevors J, Paul J (1989) Carbon sources for bacterial denitrification, advances in soil science. Springer, pp. 113-142

Beutel MW, Newton CD, Brouillard ES, Watts RJ (2009) Nitrate removal in surface-flow constructed wetlands treating dilute agricultural runoff in the lower Yakima Basin, Washington. Ecol Eng 35:1538–1546

Bezbaruah AN, Zhang TC (2003) Performance of a constructed wetland with a sulfur/limestone denitrification section for wastewater nitrogen removal. Environ Sci Technol 37:1690–1697

Białowiec A, Janczukowicz W, Randerson PF (2011) Nitrogen removal from wastewater in vertical flow constructed wetlands containing LWA/gravel layers and reed vegetation. Ecol Eng 37:897–902

Białowiec A, Davies L, Albuquerque A, Randerson PF (2012) Nitrogen removal from landfill leachate in constructed wetlands with reed and willow: redox potential in the root zone. J Environ Manag 97:22–27

Bremner J, Shaw K (1958) Denitrification in soil II factors affecting denitrification. J Agric Sci 51:40–52

Brix H (1999) How “green” are aquaculture, constructed wetlands and conventional wastewater treatment systems? Water Sci Technol 40:45–50

Brix H, Arias CA (2005a) Danish guidelines for small-scale constructed wetland systems for onsite treatment of domestic sewage. Water Sci Technol 51:1–9

Brix H, Arias CA (2005b) The use of vertical flow constructed wetlands for on-site treatment of domestic wastewater: new Danish guidelines. Ecol Eng 25:491–500

Cadisch G, Giller KE (1997) Driven by nature: plant litter quality and decomposition. CAB international

Cameron SG, Schipper LA (2010) Nitrate removal and hydraulic performance of organic carbon for use in denitrification beds. Ecol Eng 36:1588–1595

Carleton J, Grizzard T, Godrej A, Post H (2001) Factors affecting the performance of stormwater treatment wetlands. Water Res 35:1552–1562

Chen Y, Wen Y, Cheng J, Xue C, Yang D, Zhou Q (2011) Effects of dissolved oxygen on extracellular enzymes activities and transformation of carbon sources from plant biomass: implications for denitrification in constructed wetlands. Bioresour Technol 102:2433–2440

Chen Y, Wen Y, Zhou Q, Vymazal J (2014a) Effects of plant biomass on denitrifying genes in subsurface-flow constructed wetlands. Bioresour Technol 157:341–345

Chen Y, Wen Y, Zhou Q, Vymazal J (2014b) Effects of plant biomass on nitrogen transformation in subsurface-batch constructed wetlands: a stable isotope and mass balance assessment. Water Res 63:158–167

Christensson M, Lie E, Welander T (1994) A comparison between ethanol and methanol as carbon sources for denitrification. Water Sci Technol 30:83–90

Clifford D, Liu X (1993) Biological denitrification of spent regenerant brine using a sequencing batch reactor. Water Res 27:1477–1484

Davis L (1995) A handbook of constructed wetlands: a guide to creating wetlands for: agricultural wastewater, domestic wastewater, coal mine drainage, stormwater in the Mid-Atlantic Region

Della Rocca C, Belgiorno V, Meriç S (2007) Cotton-supported heterotrophic denitrification of nitrate-rich drinking water with a sand filtration post-treatment. Water SA 31:229–236

Ding Y, Song X, Wang Y, Yan D (2013) Effect of supplying a carbon extracting solution on denitrification in horizontal subsurface flow constructed wetlands. Korean J Chem Eng 30:379–384

Domingos S, Boehler K, Felstead S, Dallas S, Ho G (2009) Effect of external carbon sources on nitrate removal in constructed wetlands treating industrial wastewater: woodchips and ethanol addition

Fernández-Nava Y, Marañón E, Soons J, Castrillón L (2010) Denitrification of high nitrate concentration wastewater using alternative carbon sources. J Hazard Mater 173:682–688

Gersberg R, Elkins B, Goldman C (1983) Nitrogen removal in artificial wetlands. Water Res 17:1009–1014

Gersberg R, Elkins B, Lyon S, Goldman C (1986) Role of aquatic plants in wastewater treatment by artificial wetlands. Water Res 20:363–368

Glass C, Silverstein J (1998) Denitrification kinetics of high nitrate concentration water: pH effect on inhibition and nitrite accumulation. Water Res 32:831–839

Hamersley MR, Howes BL (2002) Control of denitrification in a septage-treating artificial wetland: the dual role of particulate organic carbon. Water Res 36:4415–4427

Huett D, Morris S, Smith G, Hunt N (2005) Nitrogen and phosphorus removal from plant nursery runoff in vegetated and unvegetated subsurface flow wetlands. Water Res 39:3259–3272

Hume NP, Fleming MS, Horne AJ (2002) Denitrification potential and carbon quality of four aquatic plants in wetland microcosms. Soil Sci Soc Am J 66:1706–1712

Ingersoll TL, Baker LA (1998) Nitratfe removal in wetland microcosms. Water Res 32:677–684

IWA (2001) Constructed wetlands for pollution control: processes, performance, design and operation. Iwa Publishing

Kozub D, Liehr S (1999) Assessing denitrification rate limiting factors in a constructed wetland receiving landfill leachate. Water Sci Technol 40:75–82

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Lee NM, Welander T (1996) The effect of different carbon sources on respiratory denitrification in biological wastewater treatment. J Ferment Bioeng 82:277–285

Li B, Irvin S, Baker K (2007) The variation of nitrifying bacterial population sizes in a sequencing batch reactor (SBR) treating low, mid, high concentrated synthetic wastewater. J Environ Eng Sci 6:651–663

Liehr SK, Kozub D, Rash J, Sloop G, Doll B, Rubin A, House C, Hawes S, Burks D (2000) Constructed wetlands treatment of high nitrogen landfill leachate. Water Environment Research Foundation

Lin Y-F, Jing S-R, Wang T-W, Lee D-Y (2002) Effects of macrophytes and external carbon sources on nitrate removal from groundwater in constructed wetlands. Environ Pollut 119:413–420

Liu G, Wen Y, Zhou Q (2010) Nitrate removal in horizontal subsurface constructed wetland with cattail litter addition, bioinformatics and biomedical engineering (iCBBE), 2010 4th international conference on. IEEE pp 1-4

MacDonald DV (1990) Denitrification by fluidized biofilm reactor. Water Sci Technol 22:451–461

Matějů V, Čižinská S, Krejčí J, Janoch T (1992) Biological water denitrification—a review. Enzym Microb Technol 14:170–183

McMillan JD (1994) Pretreatment of lignocellulosic biomass, ACS symposium series (USA)

Mirvish SS (1977) N-nitroso compounds, nitrite and nitrate: possible implications for the causation of human cancer. Prog Water Technol 8:195

Mosier N, Wyman C, Dale B, Elander R, Lee Y, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Obaja D, Mace S, Mata-Alvarez J (2005) Biological nutrient removal by a sequencing batch reactor (SBR) using an internal organic carbon source in digested piggery wastewater. Bioresour Technol 96:7–14

Ovez B (2006) Batch biological denitrification using Arundo donax, Glycyrrhiza glabra, and Gracilaria verrucosa as carbon source. Process Biochem 41:1289–1295

Ovez B, Ozgen S, Yuksel M (2006) Biological denitrification in drinking water using Glycyrrhiza glabra and Arunda donax as the carbon source. Process Biochem 41:1539–1544

Park JBK, Craggs RJ, Sukias JPS (2008) Treatment of hydroponic wastewater by denitrification filters using plant prunings as the organic carbon source. Bioresour Technol 99:2711–2716

Picek T, Čížková H, Dušek J (2007) Greenhouse gas emissions from a constructed wetland—plants as important sources of carbon. Ecol Eng 31:98–106

Rabah FK, Dahab MF (2004) Nitrate removal characteristics of high performance fluidized-bed biofilm reactors. Water Res 38:3719–3728

Reilly JF, Horne AJ, Miller CD (1999) Nitrate removal from a drinking water supply with large free-surface constructed wetlands prior to groundwater recharge. Ecol Eng 14:33–47

Saliling WJB, Westerman PW, Losordo TM (2007) Wood chips and wheat straw as alternative biofilter media for denitrification reactors treating aquaculture and other wastewaters with high nitrate concentrations. Aquac Eng 37:222–233

Schipper LA, Vojvodić-Vuković M (2001) Five years of nitrate removal, denitrification and carbon dynamics in a denitrification wall. Water Res 35:3473–3477

Shackle V, Freeman C, Reynolds B (2000) Carbon supply and the regulation of enzyme activity in constructed wetlands. Soil Biol Biochem 32:1935–1940

Singer A, Parnes S, Gross A, Sagi A, Brenner A (2008) A novel approach to denitrification processes in a zero-discharge recirculating system for small-scale urban aquaculture. Aquac Eng 39:72–77

Sirivedhin T, Gray KA (2006) Factors affecting denitrification rates in experimental wetlands: field and laboratory studies. Ecol Eng 26:167–181

Soares MIM, Abeliovich A (1998) Wheat straw as substrate for water denitrification. Water Res 32:3790–3794

Spieles DJ, Mitsch WJ (1999) The effects of season and hydrologic and chemical loading on nitrate retention in constructed wetlands: a comparison of low-and high-nutrient riverine systems. Ecol Eng 14:77–91

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Tian G, Kang B, Brussaard L (1992) Biological effects of plant residues with contrasting chemical compositions under humid tropical conditions—decomposition and nutrient release. Soil Biol Biochem 24:1051–1060

Trois C, Pisano G, Oxarango L (2010) Alternative solutions for the bio-denitrification of landfill leachates using pine bark and compost. J Hazard Mater 178:1100–1105

Virdis B, Rabaey K, Rozendal RA, Yuan Z, Keller J (2010) Simultaneous nitrification, denitrification and carbon removal in microbial fuel cells. Water Res 44:2970–2980

Volokita M, Abehovich A, Soares MIM (1996) Denitrification of groundwater using cotton as energy source. Water Sci Technol 34:379–385

Vymazal J (2007) Removal of nutrients in various types of constructed wetlands. Sci Total Environ 380:48–65

Vymazal J (2009) The use constructed wetlands with horizontal sub-surface flow for various types of wastewater. Ecol Eng 35:1–17

Vymazal J, Kröpfelová L (2011) A three-stage experimental constructed wetland for treatment of domestic sewage: first 2 years of operation. Ecol Eng 37:90–98

Vymazal J, Greenway M, Tonderski K, Brix H, Mander Ü (2006) Constructed wetlands for wastewater treatment, Wetlands and natural resource management. Springer, pp. 69-96

Wallenstein MD, Myrold DD, Firestone M, Voytek M (2006) Environmental controls on denitrifying communities and denitrification rates: insights from molecular methods. Ecol Appl 16:2143–2152

Wang HY, Hang QY, Crittenden J, Zhou YX, Yuan Q, Liu HT (2016) Combined autotrophic nitritation and bioelectrochemical-sulfur denitrification for treatment of ammonium rich wastewater with low C/N ratio. Environ Sci Pollut Res 23(3):2329–2340

Wardle D, Bonner K, Barker G (2002) Linkages between plant litter decomposition, litter quality, and vegetation responses to herbivores. Funct Ecol 16:585–595

Warneke S, Schipper LA, Matiasek MG, Scow KM, Cameron S, Bruesewitz DA, McDonald IR (2011) Nitrate removal, communities of denitrifiers and adverse effects in different carbon substrates for use in denitrification beds. Water Res 45:5463–5475

Wen Y, Chen Y, Zheng N, Yang D, Zhou Q (2010) Effects of plant biomass on nitrate removal and transformation of carbon sources in subsurface-flow constructed wetlands. Bioresour Technol 101:7286–7292

Wu S, Kuschk P, Brix H, Vymazal J, Dong R (2014) Development of constructed wetlands in performance intensifications for wastewater treatment: a nitrogen and organic matter targeted review. Water Res 57:40–55

Zhai X, Piwpuan N, Arias CA, Headley T, Brix H (2013) Can root exudates from emergent wetland plants fuel denitrification in subsurface flow constructed wetland systems? Ecol Eng 61:555–563

Zhang Y-HP, Ding S-Y, Mielenz JR, Cui J-B, Elander RT, Laser M, Himmel ME, McMillan JR, Lynd LR (2007) Fractionating recalcitrant lignocellulose at modest reaction conditions. Biotechnol Bioeng 97:214–223

Zhang L, Chen Y, Wu J, Tie J, Li Z, Jiang S (2011) Effects of natural solid carbon source on advanced treatment of secondary effluent in subsurface-flow constructed wetland, 2011 5th International Conference on Bioinformatics and Biomedical Engineering

Zhang M, Zhao L, Mei C, Yi L, Hua G (2014) Effects of plant material as carbon sources on TN removal efficiency and N2O flux in vertical-flow-constructed wetlands. Water Air Soil Pollut 225:1–11

Acknowledgments

This study was supported by National Major Science and Technology Program for Water Pollution Control and Treatment (2012ZX07105-002). The authors also appreciate support from Research Center for Water Pollution Control Technology at Chinese Research Academy of Environmental Sciences.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Kenneth Mei Yee Leung

Rights and permissions

About this article

Cite this article

Hang, Q., Wang, H., Chu, Z. et al. Application of plant carbon source for denitrification by constructed wetland and bioreactor: review of recent development. Environ Sci Pollut Res 23, 8260–8274 (2016). https://doi.org/10.1007/s11356-016-6324-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-6324-y