Abstract

This study proposes a model-based evaluation of the effect of different operating conditions with and without pre-denitrification treatment and applying three different solids retention times on the fouling mechanisms involved in membrane bioreactors (MBRs). A total of 11 fouling models obtained from literature were used to fit the transmembrane pressure variations measured in a pilot-scale MBR treating real wastewater for more than 1 year. The results showed that all the models represent reasonable descriptions of the fouling processes in the MBR tested. The model-based analysis confirmed that membrane fouling started by pore blocking (complete blocking model) and by a reduction of the pore diameter (standard blocking) while cake filtration became the dominant fouling mechanism over long-term operation. However, the different fouling mechanisms occurred almost simultaneously making it rather difficult to identify each one. The membrane “history” (i.e. age, lifespan, etc.) seems the most important factor affecting the fouling mechanism more than the applied operating conditions. Nonlinear regression of the most complex models (combined models) evaluated in this study sometimes demonstrated unreliable parameter estimates suggesting that the four basic fouling models (complete, standard, intermediate blocking and cake filtration) contain enough details to represent a reasonable description of the main fouling processes occurring in MBRs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Membrane bioreactors (MBRs) represent promising technology for municipal and industrial wastewater treatment since they allow rapid start-up (Ferraris et al. 2009), small footprint, less sludge production and superior effluent quality if compared with conventional activated sludge processes (Wang et al. 2014). However, broader application of MBRs is still limited by membrane fouling which, by decreasing permeability, increases energy consumption due to the high aeration needed to promote membrane scouring, and also increases cleaning procedures and reduces the membrane lifespan (Janus et al. 2009; Meng et al. 2009; Xu et al. 2013; Eui-Jong et al. 2015).

Over the last decade, several studies have attempted to increase understanding of membrane filtration mechanisms in MBRs in order to optimise operating parameters for controlling and reducing membrane fouling. Although the effect of different operating conditions on sludge permeability and membrane fouling have already been studied (Pollice et al. 2007; Laera et al. 2009; Meng et al. 2009; Sabia et al. 2013, 2014; Eui-Jong et al. 2015; Lousada-Ferreira et al. 2015), no conclusive results have been achieved yet. With this in mind, models could represent essential and powerful tools for simulating fouling occurrence and predicting membrane filtration performance (Bolton et al. 2006; Liu and Kim 2008; Kim et al. 2013). However, owing to the great complexity of MBR systems due to the strictly linked interaction between filtration mechanisms, biological processes and hydrodynamic conditions, no general consensus has been achieved on the main causes triggering membrane fouling (Bolton et al. 2006; Pollice et al. 2007; Liu and Kim 2008; Laera et al. 2009; Drews 2010; Kim et al. 2013; Sabia et al. 2013; Eui-Jong et al. 2015) and, thus, different approaches have been applied for mathematical modelling of fouling processes (Broeckmann et al. 2006; Duclos-Orsello et al. 2006; Wu et al. 2011). Moreover, the models developed, generally classifiable as kinetic biomass models, membrane fouling models and integrated models, were based on different details describing all or part of the MBR complexity by taking into account different MBR system aspects (i.e. biology, physics, hydrodynamics) (Broeckmann et al. 2006; Ng et al. 2007; Zarragoitia-Gonzalez et al. 2008; Mannina et al. 2011; Lousada-Ferreira et al. 2015).

A widely adopted approach for describing membrane fouling has pinpointed four main mechanistic models known as complete blocking, standard blocking, intermediate blocking and cake filtration, which rely on empirically derived information (Hermia 1982; Iritani 2013). Briefly (Fig. 1), particles arriving on the membrane can completely block the pores (complete blocking), reduce the pore diameter (standard blocking) or have a specific probability of blocking a pore (intermediate blocking); in cake filtration, however, resistance increases due to the formation and growth of a cake layer on the membrane surface. The equations for the four fouling mechanisms have been described in several studies where the membranes were operated under constant pressure or flux, as well as applying dead-end and cross flow filtration (Bolton et al. 2006; Pollice et al. 2007; Liu and Kim 2008; Laera et al. 2009; Ng et al. 2007). Moreover, some researchers, considering the simultaneous and synergic occurrence of the fouling processes in MBRs, have developed two- to four-stage fouling models by combining single mechanistic equations (Bolton et al. 2006; Duclos-Orsello et al. 2006; Liu and Kim 2008; Wu et al. 2011).

Schematic representation of the four main fouling mechanisms: a complete blocking; b standard blocking; c intermediate blocking; d cake filtration (Wang et al. 2014)

Some authors have tried to identify the dominant fouling mechanisms in MBRs by analysing model performance (Bolton et al. 2006; Liu and Kim 2008; Drews et al. 2009; Charfi et al. 2012; Kim et al. 2013). However, the various models proposed have mostly been applied at laboratory scale with brief flux steps test, using a pilot scale in relatively short experimental time spans, or with synthetic feed, sometimes composed of just one chemical compound (e.g. proteins or carbohydrates) and under well-defined operating conditions (Bolton et al. 2006; Duclos-Orsello et al. 2006; Li and Wang 2006; Drews et al. 2009; Monclús et al. 2011; Charfi et al. 2012; Maere et al. 2012; Xu et al. 2013).

This study proposes a model-based evaluation of the fouling mechanisms involved in MBRs. The study was applied on an aerobic submerged pilot plant MBR fed by real municipal wastewater and operated over a long experimental period (450 days). In addition, the fouling models were evaluated under different operating conditions with and without pre-denitrification treatment, applying three different solids retention times (SRTs). The main purpose of the study was, thus, to evaluate the ways in which different operating conditions affect the fouling mechanisms and processes in MBR. Moreover, contrary to previous studies (Drews et al. 2009; Charfi et al. 2012), which tested only a few models of the main fouling mechanisms, a total of 11 models (i.e. most of the models that can be found in literature) were evaluated in the present work.

Experimental

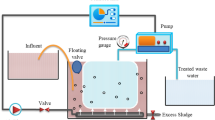

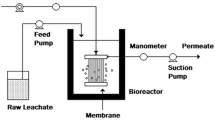

Pilot-scale MBR

The study was carried out using a pilot-scale MBR which was placed at the wastewater (WW) treatment plant (WWTP) of Bellavista in the city of Taranto, Southern Italy.

During the first 210 experimental days, the pilot plant consisted of an aerobic tank with a working volume of 120 L. Thereafter, a pre-denitrification tank of 60 L was added. The plant was continuously operated for approximately 450 days and fed by pre-settled municipal wastewater with a constant flow rate of 360 L day−1 resulting in an HRT of 8 h (when the pilot consisted of the oxic tank only) or 12 h (pilot with anoxic and aerobic processes).

The pilot-scale MBR was operated applying three different SRTs of 25 days (from day 0 to day 284), 50 days (284–380) and 75 days (380–end). The influent wastewater COD concentration of 300–520 mg O2 L−1 resulted in an applied organic loading rate in the range of 0.9–1.6 g COD L−1 aerobicreactor day−1 (Sabia et al. 2013).

Sludge biomass from the full-scale WWTP was used as inoculum at the initial total suspended solids (TSS) concentration of about 8 g L−1. Internal recycle (equal to 400 % of the influent flow) and sludge withdrawal were performed at constant flow using peristaltic pumps (Watson Marlow 620U).

A new hollow fibre microfiltration membrane module (GE-ZenonZeeWeed™ ZW-10) with 0.2 μm nominal pore size and filter area of 0.93 m2 (data from the supplier) was directly immersed in the aerobic tank. Membrane filtration was carried out by using a piston pump (FMI, Fluid Metering) under intermittent suction and backwash cycle of 6 (flux = 20 L m−2 h−1) and 0.5 min (flux = 30 L m−2 h−1), respectively; for the piston pump, a 2-s stop between forward/reverse mode operation was programmed in order to avoid water hammer phenomenon and to preserve the pump. The pump flow rate was controlled by an electronic DC speed device (Penta KB Power, KBIC-120) with adjustable acceleration start feature from 0 to full speed over a time period of 0.5–4 s, which was set at 2 s.

A blower (LA-120 Nitto Kohoki) assured the air flow for membrane scouring and the aeration of the oxic reactor; the dissolved oxygen (DO) in the aerobic tank was constantly maintained above 4 mg O2 L−1. An aeration flow rate of 0.057 m3 min−1 was applied resulting in a mean gas upflow velocity of approximately 0.8 m min−1.

The pilot was managed by means of a programmable relay (Omron Zen-10C1DR-D).

When the TMP values approached a value close to 0.2 bar, the membrane was physically cleaned by jet rinsing using tap water on days 126 and 312, and by chemical cleaning (as indicated by the membrane supplier) on days 228 and 380.

Further details on the wastewater characteristics, MBR setup and performances are reported elsewhere (Sabia et al. 2013).

Data measurement and acquisition

The pilot plant MBR was equipped with measuring instruments and probes for on-line monitoring of permeate flow, transmembrane pressure and water temperature. Permeate flow and TMP were measured by instruments typically employed in industrial applications. A differential pressure transmitter (Deltabar-S PMD70, Endress + Hauser) and a magnetic flow transmitter (Promag 23H DN 02 PFA, Endress + Hauser) were implemented on the permeate line and connected to a datalogger (CR1000, Campbell Scientific) for continuous data acquisition. The differential pressure transmitter was set with a span ranging from −500 to 500 mbar permitting measurements with a total error range of ±0.75 mbar and a reference accuracy of ±0.075 % of the span setting. The 63 % time response of the instrument was of 210 ms (data from the supplier).

The magnetic flow transmitter allowed for measurements with a total error percentage of under 2 % in the range 4.8–24 L h−1 with an adjustable response time of 1 to 100 s, set at 2 s in this study.

Temperature was monitored by using a multi-parameter probe (HydrolabDataSonde 5) which was directly immersed in the aerobic tank. The temperature probe had an accuracy of ±0.10 °C.

Data processing

The experimental set up allowed for the recording of TMP and flux values every 2 s for an overall data amount of 185 points for filtration and 15 for backwash periods.

A total amount of almost 100,000 cycles (filtration/backwash) were acquired over the entire experimental study, lasting approximately 450 days.

In structuring the dataset to be processed, raw data related to cycles when plant operational breaks occurred as well as when analytical procedures (e.g. evaluation of the critical flux (Sabia et al. 2013) or membrane cleanings implied that plant stoppages were discarded.

Moreover, taking into account the different response times of the instruments and their relative accuracy as well as the response delay of the equipment (e.g. pumps), the dataset was shortened in order to remove transient periods (i.e. backwash/filtration switch). Therefore, the first 20 s of each filtration and backwash phases were arbitrarily removed for further elaboration. As a result, the first 10 data (accounting for 20 s) of both filtration and backwash were discarded and the final dataset accounted for 61,401 cycles of 175 (350 s) and 5 (10 s) data during filtration and backwash, respectively.

TMP data acquired from the above dataset obtained were then normalised to the reference temperature of 20 °C in order to take into account the influence of permeate viscosity on the processes (Trussell et al. 2005) by applying the following equations:

where TMP20 and TMP T are the transmembrane pressure at 20 °C and at the experimental temperature (T).

The value of 0.025 for the temperature coefficient (Θ) was calculated taking into account water viscosity (assumed equal to permeate viscosity) in the T range (7 to 34 °C) measured during the study.

The mean value of TMP20 was, then, calculated for each filtration phase.

Dataset processing was performed by using the software Matlab 6.5 (Mathworks) and Excel 2010 (Microsoft). More details on the description of the instrumentation and data processing are reported in Sabia et al. (2013).

The values reported for the TMP in this work in the following sections always refer to the standardised value as described above (i.e. after correction for the temperature and as an average value of a filtration phase).

Fouling models

The models of fouling processes have been chosen according to their scientific basis theory (i.e. Darcy’s law), their common application in several studies on fouling phenomenon (Hlavacek and Bouchet 1993; Ognier et al. 2004; Bolton et al. 2006; Duclos-Orsello et al. 2006; Liu and Kim 2008; Drews et al. 2009; Charfi et al. 2012), the relative low number of parameters to be calibrated and their adaptability to different MBR configurations. As a result, a total of 11 models were evaluated.

The list (Table 1) includes models which consider single or combinations of single fouling mechanisms. The first four models consider the four basic fouling mechanisms (Fig. 1) while the following five models (N. 5 to 9 in Table 1) are combinations of them as described in Bolton et al. (2006). The subsequent equation (N. 10 in Table 1) describes a combined model which integrates all four single fouling processes of Fig. 1 (Kim et al. 2013).

The last model (here called local flux model) evaluated in the present study uses a different approach if compared with the previous ones. The model (Monclús et al. 2011) is, in fact, based on the notions of the “local flux” (Cho and Fane 2002) and the “critical flux” (Field et al. 1995). The model assumes that, during filtration below the critical flux, solute particles interact with the membrane reducing the number of pores involved in the filtration process; as the membrane flux is maintained constant, the local flux increases in the some regions of the membrane where the pores remained open. Thus, when the local flux exceeds the critical flux, a sudden rise in the TMP is observed (Ognier et al. 2004).

The 11 models were fitted on subsets of the experimental data selected according to experimental periods, which were identified on the basis of the applied operating conditions (i.e. SRT) and cleaning procedures as indicated in Fig. 2. Accordingly, a total of seven experimental periods, corresponding to the application of three SRTs (25, 50, 75 days) and, then, separated by cleaning procedures (indicated as 25a, 25b1, 25b2, 25c, 50a, 50b and 75a) were identified (Fig. 2).

Trend of the TMP over the entire experimental campaign. Vertical arrows indicate when cleaning procedures with tap water (tw) and chemicals (ch) were carried out. The graph also reports the applied operating conditions including the addition of the denitrification process and the SRT. The seven experimental periods (indicated as 25a, 25b1, 25b2, 25c, 50a, 50b and 75a) corresponding to the subsets of data used for the evaluation of the 11 fouling models (Table 1) are also reported

The equations of Table 1 were implemented in Matlab 6.5 (Mathworks) and fitted to the experimental TMP values. The constant flux applied during the study was assumed as J 0.

The model parameters were estimated by least squares fitting to the experimental data of TMP and using literature data (Bolton et al. 2006; Brookes et al. 2006; Liu and Kim 2008; Kim et al. 2013) as initial parameter values. The sum of squares (SSQ) of the residuals of the predicted values from the TMP data measured were minimised by nonlinear regression by using the nlinfit.m function included in MATLAB. In addition, nlinfit.m function returns the residuals, the Jacobian of model functions, the estimated variance-covariance matrix for the estimated coefficients, an estimate of the variance of the error term (i.e. the mean square error, MSE) and a structure containing details about the error model. Confidence intervals (95 %) for the parameters were calculated using the nlparci.m function, and the 95 % asymptotic prediction interval was calculated for the predicted experimental data (i.e. predicted TMP) using the nlpredci.m function (both functions included in Matlab 6.5).

Since the tested models contain different numbers of parameters, the goodness of the fits was finally evaluated by the root mean square error (RMSE) estimated using the following equation:

RMSE was preferred over MSE since the former returns results in the same unit (pressure, Pa) of the model (Bennett et al. 2013).

In order to compare the different parameters describing the different models, the values of the constants obtained for each separate model were normalised according to the min-max method as shown by the following equation:

where is the normalised value of the m-esim parameter (k m ), k max and k min are the maximum and minimum value of k m , respectively.

In addition, the Pearson Product Moment Correlation Distribution was used to test the correlation of the constant that describes the models by using Origin 6.5. In particular, correlations were considered statistically significant at 95 (p < 0.05), 99 (p < 0.01) and 99.9 % (p < 0.001) level.

Results and discussion

TMP monitoring

A slow but almost immediate and continuous TMP increase (TMP values reported are referred to the standardised value as described in “Data processing” section) was observed (Fig. 2) from plant start-up, although the membrane was operated at a flux of 20 L m−2 h−1 as indicated by the membrane supplier (Sabia et al. 2014). Therefore, despite the relatively low flux, significant fouling phenomena on the new membrane module still took place (Brookes et al. 2006; Guglielmi et al. 2007; Iritani 2013).

During the study, in spite of continuous maintenance operations (i.e. air scouring and backwash), the TMP trend showed the typical two-stage behaviour with a first part of slow pressure increase followed by a rapid rise with an exponential trend, according to the well-documented theory of the local critical flux concept (Cho and Fane 2002). Membrane cleaning by tap water rinsing helped to achieve significant improvement of the TMP measured but only chemical cleaning was able to restore the pressure close to the initial values (Fig. 2).

Performance evaluation of the fouling models

The seven experimental periods identified according to the operating conditions applied presented important differences in duration (from 6 to 128 days). Although the two shortest experimental periods fitted in this study (i.e. SRT25b2 and SRT50a) only lasted 6 days, other studies (Bolton et al. 2006; Charfi et al. 2012) stated that different fouling mechanisms can even be identified in membrane filtration of a few hours.

The findings achieved in this study demonstrated that all the models tested (and, thus, the proposed mechanisms) were capable of reasonably fitting the experimental data (see Supplementary Materials). Table 2 reports the RMSE obtained by the curve fitting (the graphs are reported in the Supplementary Material). These outcomes confirm the finding of Agustin Suarez and Veza (2000) who also found that all models (complete, standard and intermediate) they tested were able to reasonably describe the experimental data obtained filtering effluents of wastewater treatment plants using microfiltration hollow fibre membranes.

However, the models showed different effectiveness in describing the experimental data of various operating conditions (Table 2 and Supplementary Materials) suggesting that different fouling mechanisms prevailed during the applied operating conditions. However, while evident differences can clearly be observed among the models during the application of some operating conditions (e.g. during SRT25a and SRT25b1 operating conditions), over other conditions the models seemed to be equally capable of describing the TMP trend (e.g. SRT25b2 and SRT50a).

It should be pointed out that major differences in the effectiveness of the model in fitting the data were observed when a longer experimental phase was tested (e.g. 25a). Since the amount of data as well as the number of estimated parameters for each model do not affect the RMSE value, the largest RMSE observed over longer experimental phases suggest that several fouling mechanisms can occur simultaneously and, therefore, a single fouling model alone is not capable of describing the TMP trend.

In addition, the model proposed by Ognier et al. (2004) usually presented the highest RMSE, demonstrating that the mechanism proposed is the least effective in describing the fouling process in the treatment system studied. The graphs (see Supplementary Material) confirm its rather poor fitting ability, at least in some of the operating conditions tested. Poor fit of the model defined by Ognier et al. (2004) was also observed by Brookes et al. (2006) with TMP data obtained using a pilot-scale MBR equipped with a tubular membrane. Therefore, the results suggest that the models based on the main fouling mechanisms reported in Fig. 1 (Hermia 1982) usually better describe TMP behaviour in MBRs under operating conditions applied in this study than the model proposed by Ognier et al. (2004).

Basic fouling models

Considering the four basic fouling models (i.e. model 1 to 4 in Table 1), some general trends in their ability to fit the experimental data (according to the RMSE) can be observed. In fact, in the first experimental phase (SRT25a), the standard blocking model (RMSE of about 440 Pa) was the most effective in describing the experimental data, while, on the contrary, the cake filtration model (RMSE of about 1790 Pa) was the worst (among the four basic fouling models). This suggests that the mechanisms involving the reduction of pore volume during filtration (Zarragoitia-Gonzalez et al. 2008) dominated the fouling processes in the initial phase or when using a new membrane. It should be noted that the second most effective fouling mechanism was complete blocking indicating that pore blocking is the second most important mechanism when using a new membrane. On the contrary, after membrane cleaning by jet rinsing with tap water, the cake filtration model was the most effective in describing TMP behaviour (see phase SRT25b1 and SRT50b). This is in agreement with the hypothesis previously defined (Sabia et al. 2013, 2014), where membrane cleaning procedures with tap water were supposed to be only capable of removing the cake layer that had developed, while leaving almost intact the clogging materials deposited inside the pores or firmly attached to the membrane; therefore, after water cleaning, since the membrane was already partially clogged, TMP behaviour seems to be better described by the change in permeability due to the deposition of material that forms a cake layer on the membrane.

We should note that after the chemical cleaning procedures (see phases SRT25c and SRT75a) the four basic models had approximately the same capacity in describing TMP trends, since they showed comparable RMSE values suggesting that, in those cases, the four mechanisms occurred simultaneously and concurrently affected the fouling processes (at least at applied operating conditions). On the contrary, the models were not able to identify any effect of the applied condition (i.e. SRT and aerobic vs. anoxic/aerobic conditions) indicating that the membrane history is more important in affecting fouling mechanisms than applied operating conditions.

Single versus combined models

The use of the combined fouling mechanisms usually improved the curve fitting (Table 2) indicating that more than one mechanism is usually involved in the fouling process. Therefore, it is not surprising that the four stage model (i.e. the model which includes all four fouling mechanisms; Kim et al. 2013) usually produced the best fit to the experimental data. However, in some cases, the improvements when using models, including combined fouling mechanisms, was quite low suggesting that a single model can be used to describe the TMP trend.

In addition, the combined models usually confirmed the single fouling mechanisms identified as dominant by using single basic models. For instance, over the first experimental phase (i.e. SRT25a), RMSE values showed that the models combining standard blocking and complete blocking mechanisms (i.e. Complete Standard model) appeared to be the most effective in fitting the data pattern (among the models combining two basic mechanisms). It is worth highlighting that the predominance of these processes represent, during overall experimental time, a unique example since, within the following filtration periods, their actual relevance was overcome by other fouling mechanisms. These findings support the hypothesis described in “Basic fouling models” section that mechanisms involving pore volume reduction and pore blocking are the main fouling processes when using a new membrane module (Xiao et al. 2011; Kim et al. 2013; Wang et al. 2014).

In the second filtration period (SRTb1), the Cake-Complete and Intermediate-Standard models showed the lowest RMSE, whereas the other models were characterised by a fairly similar ability to fit the experimental data, with the exception of the local-flux model which, once again, showed the highest RMSE.

In the following filtration period SRTb2, after denitrification process activation, all the models showed similar RMSE values, confirming that operating conditions seem to be less important than membrane history in defining the fouling mechanisms.

After the first chemical cleaning (i.e. phase SRT25c), the models showed similar RMSE with the combined models in general and the four-stage one in particular, showing the lowest values. Although clear identification of the main fouling mechanisms after the first chemical cleaning cannot be observed, as the experiment proceeds (and moving on to the following phases, SRT50a and SRT50b), the fouling models, including cake filtration, became more relevant, showing low RMSE values. On the contrary, the last evaluation phase (i.e. SRT75a) showed that after further chemical cleaning the Intermediate-Standard model showed the lowest RMSE values (just after the four-stage model). These results confirm that chemical cleaning was, in this case, really effective in removing the fouling substances and, thus, after its execution pore blocking and the reduction of pore diameter were identifiable as the dominant fouling mechanisms (Xiao et al. 2011; Kim et al. 2013; Wang et al. 2014).

It is of note that combined models sometimes do not improve (on the basis of RMSE) the fit compared to the related single models, suggesting how one of the basic fouling processes included in the definition of the combined model seems to be able to completely describe the fouling mechanisms (Table 2).

Bolton et al. (2006) found that combined models greatly improved the effectiveness in simulating the fouling process filtering plasma IgG and protein (bovine serum albumin) solutions. In particular, among the models (Table 1) those authors tested, they found that the combined Cake-Complete and the Cake-Intermediate models were the most effective in describing the fouling processes. However, in this study, the most effective combined models were usually those which already included the most effective single fouling models confirming, once more, that single models are usually appropriate to reasonably describe the fouling process, at least in the operating conditions applied in this work.

Parameter estimation of single and coupled models

Experimental data fitting provided estimates of the model parameters including their 95 % confidence intervals (Fig. 3). While in some experimental periods the different models showed similar values for the same model parameters (e.g. k b in the experimental phase SRT50a or k c in SRT25b2 and SRT50b), conversely, in some other experimental periods, the values obtained were very variable (Fig. 3). It should be pointed out that while the fit of the four basic fouling models and the local flux model (i.e. models 1 to 4 and 11 of Table 1) always demonstrated parameter values with small confidence intervals, the fit of the combined models sometimes provided parameter estimations with extremely large confidence intervals or, even, with negative values. For instance, k b estimation from the Cake-Complete model in SRT25b1 and k c of the Cake-Standard model in SRT50a demonstrated negative values suggesting a lack of meaning of the model in the specific operating conditions applied (since negative values should indicate that fouling decreases during filtration).

Trends of the parameter values of the models in the different experimental phases. The parameters are grouped according to the model that contains them: a k b (complete blocking constant) values estimated for the complete blocking, cake-complete and complete-standard models; b k s (standard blocking constant) values estimated for the standard blocking, complete-standard, cake-standard and intermediate-standard models; c k i (intermediate blocking constant) values estimated for the intermediate blocking, cake-intermediate and intermediate-standard models; d k c (cake filtration constant) values estimated for the cake filtration, cake-complete, cake-intermediate and cake-standard model; e k br, constant parameter of the local flux model. Bars for 95 % confidence intervals

Moreover, in the case of combined models, the model fit resulting in parameter values close to zero indicates that the combined model reduces to the one of the four basic fouling models (and in fact constants close to zero are only present with combined models).

Combined models also sometimes showed large confidence intervals suggesting, once more, low reliability of complex models in describing fouling mechanisms (at least with the operating conditions applied).

The fit of the four-stage fouling model showed several cases of values with scarce physical meaning (i.e. negative, close to zero or with very large confidence intervals) demonstrating the very low reliability of the model in spite of the fact that it usually showed the lowest RMSE (Table 2). Therefore, although combined models usually showed improved fits of the TMP trends (in terms of RMSE), the parameter estimations achieved might have low reliability in the understanding of the occurring fouling processes. It should be highlighted that in this study the pilot MBR was managed under low flow rates such as those commonly applied in full-scale plants (i.e. those from the membrane supplier) in order to reduce membrane fouling and, therefore, the prevailing fouling process could hardly be identified (Sabia et al. 2014).

Drews et al. (2009) have already observed that several models can yield good fits in simulating TMP trends. Therefore, they concluded that bounds for (the input) the parameters should be added in order to maintain their physical meaning. However, they used different models than those used in this study.

Preliminary results obtained in this study by the introduction of parameter bounds in the model fits (using the nlpredci.m function of Matlab) showed much worse fittings of the experimental data than the results obtained without bounds. Moreover, the application of the nlpredci.m function often resulted in estimations of parameter values that matched the upper or lower bounds confirming the limited suitability of using this optimisation function (data not shown). Liu and Kim (2008) found that the optimisation method they applied always returned one negative value for all models they evaluated (which were included in this study, Table 1) confirming that the fit of combined models can return parameters without physical meaning.

Parameter correlation

Table 3 reports the Pearson correlation coefficients evaluated on the basis of the estimated parameters included in the fouling models of Table 1. While the correlations of the same parameter in models which include the same fouling mechanisms were expected, the correlations matrix showed several further (highly) significant correlations. In particular, the parameters describing the four basic models were often (highly) significantly correlated confirming that the four basic fouling mechanisms give similar results and, thus, have similar capacity in identifying periods or operating conditions with variable fouling potential.

Moreover, parameters involved in the same model describing the combination of two fouling mechanisms were also sometimes correlated (i.e. k c and k b in the Cake-Complete and k c and k s in the Cake-Standard models): since these parameters were negative correlates, it suggests that one fouling mechanism tends to prevail over the other. However, the correlation could also suggest low parameter identifiability (Vanrolleghem et al. 1995) and, thus, low reliability of the values obtained.

The normalised values (according to Eq. 2) of the parameter estimates for the models characterised by a single parameter (i.e. models 1–4 and 11) during the different experimental periods show almost the same general behaviour (Fig. 4). It is of note that, with the exception of the first phase, all single models and, thus, their parameter values were able to identify the experimental phases with the highest fouling potential. In fact, all models showed the highest values of the fouling parameters during the experimental phases SRT25b2 and SRT50a. The trend of the fouling parameters identified can justify the several significant correlations of Table 3.

Figure 4 shows that low parameter values were usually observed just after the chemical cleaning procedures (i.e. phases SRT25c and SRT75a) confirming once more that the membrane history greatly affects the fouling propensity of the membrane. On the contrary, the parameters showed the highest values in the experimental phases when operating conditions were changed. In fact, the highest values were observed in the experimental phase when the denitrification process was added in the treatment line (i.e. phase SRT25b2) and when SRT was increased from 25 to 50 days (phase SRT50a). On the contrary, the further increase of SRT to 75 days (phase SRT75a) presented very low values for the fouling constants. These results suggest that changes in operating conditions (more than the specific operating condition itself) may be the second most important factor affecting fouling behaviour in MBR.

Conclusions

The results of this study demonstrated that in MBR systems implemented at pilot plant-scale treating real wastewater and operated under “sub-critical” flux (as those suggested by the membrane suppliers) as usually applied in order to maintain long-time membrane operation, many mechanisms concurred almost simultaneously to induce membrane fouling. Therefore, all the fouling models tested in this study were reasonably capable of describing the fouling processes. However, the local-flux model (model 11 in Table 1) was usually the lowest effective in fitting the experimental data.

The values of RMSE confirmed that membrane fouling started by pore blocking (complete blocking model) and pore diameter (standard blocking) reduction. Subsequently, cake filtration became the dominant fouling mechanism after long-time operation. However, since the fouling mechanisms occurred almost simultaneously, their specific identification can be rather difficult to obtain. The membrane “history” (i.e. age, lifespan, etc.) seems the most important factor affecting fouling occurrence. Moreover, changes in operating conditions may also affect the fouling processes more than the specific operating conditions. Among the 11 models evaluated in this study, although the combined models (models 5–10 in Table 1) usually achieved better fits of the experimental data than the basic fouling models (models 1–4 in Table 1), the estimates of the model parameters of the former were sometimes unreliable.

Abbreviations

- n :

-

Number of experimental data

- p :

-

Number of parameters to estimate

- J :

-

Flux (L m−2 h−1)

- J 0 :

-

Applied constant flux (L m−2 h−1)

- t :

-

Time

- TMP:

-

Transmembrane pressure (MPa). Note that the values reported for the TMP in this work always refer to the standardised value as described above (i.e. after correction for the temperature and as average value of a filtration phase; see “Data processing” section)

- TMP20 :

-

TMP normalised to the reference temperature of 20 °C

- TMPT :

-

TMP measured at the experimental temperature

- TMP i,measured :

-

Single TMP measure

- TMP i,estimated :

-

Single TMP estimated for each model fit

- k c :

-

Cake filtration constant (s m−2)

- k b :

-

Complete blocking constant (h−1)

- k i :

-

Intermediate blocking constant (m−1)

- k m :

-

Value of the m-esim parameter estimated

- \( {\overline{k}}_m \), k max, k min :

-

Normalised, maximum and minimum value of the m-esim parameter k m

- k s :

-

Standard blocking constant (m−1)

- k br :

-

Parameter incorporating membrane and suspension characteristics (m kg−1)

- SRT:

-

Solids retention time (day)

References

Bennett ND, Croke BFW, Guariso G et al (2013) Characterising performance of environmental models. Environ Model Softw 40:1–20

Bolton G, LaCasse D, Kuriyel R (2006) Combined model of membrane fouling: development and application to microfiltration and ultrafiltration membranes. J Membr Sci 277:75–84

Broeckmann A, Busch J, Wintgens T, Marquardt W (2006) Modeling of pore blocking and cake layer formation in membrane filtration for wastewater treatment. Desalination 189:97–109

Brookes A, Jefferson B, Guglielmi G, Judd SJ (2006) Sustainable flux fouling in a membrane bioreactor: impact of flux and MLSS. Sep Sci Technol 41:1279–1291

Charfi A, Ben Amar N, Harmand J (2012) Analysis of fouling mechanisms in anaerobic membrane bioreactors. Water Res 46(8):2637–2650

Cho BD, Fane AG (2002) Fouling transients in nominally sub-critical flux operation for a membrane bioreactor. J Membr Sci 209:391–403

Drews A (2010) Membrane fouling in membrane bioreactors: characterisation, contradictions, cause and cures. J Membr Sci 363:1–28

Drews A, Arellano-Garcia H, Schoneberger J et al (2009) Model-based recognition of fouling mechanisms in membrane bioreactors. Desalination 236:224–233

Duclos-Orsello C, Weiyi L, Chia-Chi H (2006) A three mechanism model to describe fouling of microfiltration membranes. J Membr Sci 280:856–866

Eui-Jong L, Young-Hoon K, Hyung-Soo K, Am J (2015) Influence of microbubble in physical cleaning of MF membrane process for wastewater reuse. Environ Sci Pollut Res 22(11):8451–8459

Ferraris M, Innella C, Spagni A (2009) Start-up of a pilot-scale membrane bioreactor to treat municipal wastewater. Desalination 237:190–213

Field RW, Wu D, Howell JA, Gupta BB (1995) Critical flux concept for microfiltration fouling. J Membr Sci 100:259–272

Guglielmi G, Chiarani D, Judd SJ, Andreottola G (2007) Flux criticality and sustainability in a hollow fibre submerged membrane bioreactor for municipal wastewater treatment. J Membr Sci 289:241–248

Hermia J (1982) Constant pressure blocking filtration laws—application to power-law non-Newtonian fluids. Trans I Chem E 60:183–187

Hlavacek M, Bouchet F (1993) Constant flowrate blocking laws and an example of their application to dead-end microfiltration of protein solutions. J Membr Sci 82(3):285–295

Iritani E (2013) A review on modelling of pore-blocking behaviours of membrane during pressurized membrane filtration. Dry Technol 31:146–162

Janus T, Paul P, Ulanicki B (2009) Modelling and simulation of short and long term membrane filtration experiments. Desalin Water Treat 8:37–47

Kim M, Sankararao B, Seungchul L, ChangKyoo Y (2013) Prediction and identification of membrane fouling mechanism in a membrane bioreactor using a combined mechanistic model. Ind Eng Chem Res 52(48):17198–17205

Laera G, Pollice A, Saturno D et al (2009) Influence of sludge retention time on biomass characteristics and clearing requirements in a membrane bioreactor for municipal wastewater treatment. Desalination 236:104–110

Li X, Wang X (2006) Modelling of membrane fouling in a submerged membrane bioreactor. J Membr Sci 278:151–161

Liu QF, Kim SH (2008) Evaluation of membrane fouling models based on bench scale experiments: a comparison between constant flowrate blocking laws and artificial neural network (ANNs) model. J Membr Sci 310 (1–2):393–401

Lousada-Ferreira M, van Lier JB, van der Graaf JHJM (2015) Impact of suspended solids concentration on sludge filterability in full-scale membrane bioreactors. J Membr Sci 476:68–75

Maere T, Villez K, Marsili-Libelli S et al (2012) Membrane bioreactor fouling behaviour assessment through principal component analysis and fuzzy clustering. Water Res 46:6132–6142

Mannina G, Di Bella G, Viviani G (2011) An integrated model for biological and physical process simulation in membrane bioreactors (MBR). J Membrane Sci 376(1–2):56–69

Meng F, Chae SR, Drews A et al (2009) Recent advances in membrane bioreactors (MBRs): membrane fouling and membrane material. Water Res 43:1489–1512

Monclús E, Ferrer G, Buttiglieri G et al (2011) Online monitoring of membrane fouling in submerged MBRs. Desalination 277:414–419

Ng A, Albert NL, Kim S (2007) A mini-review of modeling studies on membrane bioreactor (MBR) treatment for municipal wastewaters. Desalination 212:261–281

Ognier S, Wisniewski C, Grasmick A (2004) Membrane bioreactor fouling in sub-critical filtration conditions: a local critical flux concept. J Membr Sci 229(1–2):171–177

Pollice A, Giordano C, Laera G et al (2007) Physical characteristics of the sludge in a complete retention membrane bioreactor. Water Res 41:1832–1840

Sabia G, Ferraris M, Spagni A (2013) Effect of solid retention time on sludge filterability and activity: long-term experiment on a pilot-scale membrane bioreactor treating municipal wastewater. Chem Eng J 221:176–184

Sabia G, Ferraris M, Spagni A (2014) Online monitoring of MBR fouling by transmembrane pressure and permeability over a long-term experiment. Sep Purif Technol 122:297–305

Suarez JA, Veza JM (2000) Dead-end microfiltration as advanced treatment for wastewater. Desalination 127:47–58

Trussell RS, Adham S, Trussell RR (2005) Process limits of municipal wastewater treatment with the submerged membrane bioreactor. J Environ Eng 131:410–416

Vanrolleghem PA, Van Daele M, Dochain D (1995) Practical identifiability of a biokinetic model of activated sludge respiration. Water Res 29(11):2561–2570

Wang Z, Ma J, Tang CY et al (2014) Membrane cleaning in membrane bioreactors: a review. J Membr Sci 468:276–307

Wu J, He C, Jiang X, Zhang M (2011) Modeling of the submerged membrane bioreactor fouling by the combined pore constriction, pore blockage and cake formation mechanisms. Desalination 279:127–134

Xiao K, Wang X, Huang X et al (2011) Combined effect of membrane and foulant hydrophobicity and surface charge on adsorptive fouling during microfiltration. J Membr Sci 373(1–2):140–151

Xu K, Ren H, Ding L et al (2013) A review of membrane fouling in municipal secondary effluent reclamation. Environ Sci Pollut Res 20:771–777

Zarragoitia-Gonzalez A, Schetrite S, Alliet M et al (2008) Modelling of submerged membrane bioreactor: conceptual study about link between activated sludge biokinetics, aeration and fouling process. J Membr Sci 325:612–624

Acknowledgments

This study was conducted as part of a research and development project named SIRPAR “Integrated Strategies for Urban Wastewater Reclamation in the Apulia Region” financed by Regional authorities of Apulia. Gianpaolo Sabia has been partly supported by the Regional Technological Project funded by the Emilia-Romagna Region

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Bingcai Pan

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 8567 kb)

Rights and permissions

About this article

Cite this article

Sabia, G., Ferraris, M. & Spagni, A. Model-based analysis of the effect of different operating conditions on fouling mechanisms in a membrane bioreactor. Environ Sci Pollut Res 23, 1598–1609 (2016). https://doi.org/10.1007/s11356-015-5372-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5372-z