Abstract

Introduction

Terasi is a fermented shrimp paste unique to Indonesia and is used in dishes to add umami and saltiness. In a previous study, the controlled fermentation of terasi was optimized using starters containing three bacterial isolates: Staphylococcus saprophyticus, Bacillus subtilis, and Lactobacillus murinus. However, the influence of controlled fermentation using these starters on the metabolites in terasi has not yet been studied.

Objectives

Therefore, this study aimed to investigate the effect of controlled fermentation on taste-related metabolites in terasi using a metabolomics approach.

Results

Non-targeted analysis indicated that amino acids contributed to variations during fermentation. Subsequently, targeted analysis of amino acids revealed that terasi subjected to controlled fermentation using a starter with a 2:1:2 ratio of S. saprophyticus, B. subtilis, and L. murinus, respectively, resulted in a product containing d-amino acids, such as d-Asp, d-Gln, and d-Leu that was unique when compared to other terasi products prepared using controlled fermentation. Genetic analysis of isolates from the terasi produced using controlled fermentation was also carried out, and this is the first study to suggest that Staphylococcus spp. has the potential to produce d-amino acids.

Conclusion

In conclusion, the ratio of bacterial species in starter cultures used in controlled fermentation influenced the amino acid profile of the product and starters with a higher ratio of Staphylococcus spp. may result in the production of d-amino acids.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

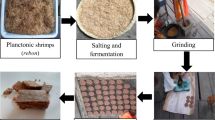

Terasi is a fermented shrimp paste prepared in Indonesia and is produced from the planktonic shrimp Schizopodes spp. or Mydes spp. The fermented shrimp paste is dark brown, gray, or red in color with a strong aroma and is usually mixed with chili, garlic, and salt to produce sambal-terasi (Hajeb & Jinap, 2012). In general, making terasi involves four processing steps: (a) salting, (b) drying, (c) kneading, and (d) fermenting. Approximately 10% (w/w) of salt is added to oceanic planktonic shrimps. Salt is added to enhance the flavor and extend the shelf life of the product (Hajeb & Jinap, 2012). Then, the mixture is dried to a final moisture content of 50%, which occurs either naturally, where the mixture is spread on straw mats and sun-dried, or mechanically (Ambarita, 2016). After the initial drying, extra salt may sometimes be added. The semi-dry mixture of shrimp is kneaded for homogenization and then pressed tightly into wooden tubs to remove excess air. The mixture is fermented in the tub for a length of time ranging from a few weeks to several months. The fermented product is dried again and thereafter packaged for the market (Hajeb & Jinap, 2012; Surono & Hosono, 1994).

Terasi is commonly produced in a cottage industry, and preparation methods are often based on family traditions. In the cottage industry, the process of natural fermentation is customary that can last from a few weeks to several months (Aryanta, 2000; Hajeb & Jinap, 2012; Waryono, 2002). and is considered to be complete when desired aromatic odors are obtained. However, this makes the fermentation process subjective, because the length of fermentation is solely dependent on the producer. Because the fermentation process is not uniform, the quality of the final product, including its nutritional content and aroma, varies greatly from region to region (Ambarita, 2016). Furthermore, the sole use of natural fermentation poses a higher risk for the entry of microbial pathogens (Cappozi, 2017). Therefore, controlled fermentation is recommended instead of natural fermentation to produce terasi products of uniform quality.

In this study, controlled fermentation was defined as the addition of a starter culture containing specific bacterial species at the beginning of the fermentation process. Starter cultures are used to promote the fermentation process, and the use of starter cultures to control fermentation has been demonstrated in several fermented products such as coffee (Pereira et al., 2015; Ribeiro et al., 2017), kimchi (Moon et al., 2018), kocho (Andeta et al., 2019), and owoh (Ezekiel et al., 2015). Starter culture for the controlled fermentation of terasi has already been isolated from the natural fermentation of Cirebon terasi, that and it includes a mixture of Staphyloccocus saprophyticus, Bacillus subtilis, and Lactobacillus murinus (Astuti et al., 2018). In addition, a previous study has shown that controlled fermentation with starter cultures containing S. saprophyticus, B. subtilis, and L. murinus suppressed the growth of unwanted microorganisms and resulted in different microbial compositions compared with natural fermentation (Sato et al., 2020). Changes in microbial composition can result in altered enzymatic reactions that can eventually affect food components produced during fermentation (Sharma et al., 2020). However, the effect of controlled fermentation on the food components in terasi has not yet been studied. Understanding changes in food components, especially those related to taste, is important for improving the sensory qualities of terasi.

Metabolomics is an omics approach used to comprehensively analyze endogenous metabolites in biological systems (Cevallos-Cevallos et al., 2009). In food research, metabolomics techniques have been applied to differentiate samples based on origin or cultivar, evaluate the stress response, optimize the post-harvest process, monitor changes during growth or fermentation, and predict quality. More specifically, changes in metabolite profiles have been monitored during the fermentation of dough (Nakamura et al., 2018), crab paste (Chen et al., 2016), okara (Mok et al., 2019), fermented soybeans (Oh et al., 2016), and kimchi (Park et al., 2016). Therefore, metabolomics is an appropriate tool for investigating the changes in metabolite content during the terasi fermentation process.

The objective of this study was to use a metabolomics approach to investigate the effect of controlled fermentation with starter culture containing S. saprophyticus, B. subtilis, and L. murinus on taste-related metabolites in terasi. A Previous study on non-targeted metabolomics using gas chromatography/mass spectrometry (GC/MS) indicated that amino acids are one group of metabolites that change during terasi fermentation. Therefore, targeted analysis of amino acids was conducted using liquid chromatography/mass spectrometry (LC/MS) to determine the specific amino acids that distinguish terasi produced using natural fermentation from terasi produced using controlled fermentation. Based on the hypothesis that the ratio of the bacterial species in the starter culture influences the amino acid profile, bacteria were then isolated from terasi prepared using different starter culture ratios to determine which species were related to the production of which amino acids.

2 Materials and methods

2.1 Preparation of terasi samples

Starter culture inoculum containing three different ratios of Staphylococcus saprophyticus, Bacillus subtilis, and Lactobacillus murinus were prepared. Fermentation was then initiated by adding 10% (v/w) of inoculum to the shrimp mixture, as shown in Table 1. During the one-month fermentation period, time-course sampling was performed once every week. Detailed sample preparation of terasi can be found in a previous study (Sato et al., 2020).

2.2 Targeted analysis of amino acids using LC/MS to determine the influence of starter culture ratio of controlled fermentation

The purpose of the targeted analysis of amino acids using LC/MS analysis was to determine the specific amino acids that differentiate naturally fermented terasi from that produced using controlled fermentation. A list of targeted amino acids is shown in Table 2. This section discusses the pretreatment of the samples and the analysis conditions of LC/MS based on those described by Umakoshi et al. (2019).

2.2.1 Extraction of metabolites for LC/MS analysis

Metabolites were extracted based on the procedure shown in Fig. 1. The reagents used for pretreatment included high-performance liquid chromatography (HPLC)-grade acetonitrile (Kanto Chemical, Tokyo, Japan), HPLC-grade ethanol (Fujifilm Wako Pure Chemical, Osaka, Japan), chloroform (Kanto Chemical), trifluoroacetic acid (TFA) (Fujifilm Wako Pure Chemical), dl-Alanine-2,2,3,3,-d4 (Santa Cruz Biotechnology Inc., Dallas, Texas, United States), and ultrapure water. For LC/MS analysis, 10 g of the prepared powdered sample was weighed in a 1.5 mL Eppendorf tube. Thereafter, 500 μL of 1% TFA in water was added along with 20 μL of dl-Alanine-2,2,3,3,-d4 (internal standard; 40 μmol/mL). Acidic water was used to encourage the separation of amino acids from proteins. Samples were incubated in a shaker incubator (Thermomixer comfort, Eppendorf, Hamburg, Germany) at 1200 rpm and 4 °C for 30 min. To remove fat, 100 μL of chloroform was added to the mixed sample, which was then vortexed and centrifuged at 9170×g at 4 °C for 10 min. Next, 300 μL of the supernatant was transferred to 2.0 mL Eppendorf tubes, and 1400 μL of 70% acetonitrile was added to remove proteins. Samples were incubated in a shaker incubator at 1200 rpm at 4 °C for 15 min and then centrifuged at 9170×g at 4 °C for 10 min. Mixtures were concentrated using a centrifugal concentrator (VC-96R, Taitec, Saitama, Japan) at 150 rpm and 25 °C for approximately 120 min. Subsequently, 100 μL of the supernatant was diluted with 400 μL of 80% acetonitrile/20% ethanol solution. Afterward, 100 µL of each sample was transferred into LC–MS vials.

2.2.2 Performing LC/MS analysis

After samples were transferred into their respective vials, they were placed in an autosampler. LC/MS analysis was performed using LCMS-8060 (Shimadzu, Kyoto, Japan), and the conditions are shown in Table 3. For the analysis, the automatic valve switching method described by Umakoshi et al. (2019) was performed using a high-pressure switching valve FCV-32AH (Shimadzu). Chromatogram and mass spectrum data were collected during the LC/MS analysis. For normalization, the peak area value of each compound was divided by the peak area of d-Alanine-2,2,3,3,-d4, the internal standard. Metabolites were then annotated using the amino acid standards in LabSolutions (Shimadzu). Similarly, principal component analysis (PCA) was performed to distinguish the differences between naturally fermented terasi samples and those produced using controlled fermentation.

2.3 Analysis of extracellular amino acids from terasi isolates

To validate the hypothesis that d-amino acid is produced from lactic acid bacteria, bacteria were isolated from terasi samples, and isolates were cultivated in vitro. Then, d-amino acid production was confirmed by measuring and identifying extracellular amino acids using LC/MS analysis.

2.3.1 Isolation of bacteria from terasi

The reagents used included peptone (BD Difco, Franklin Lakes, New Jersey, United States), De Man, Rogosa, Sharpe (MRS) broth (BD Difco), agar (BD Difco), glycerol (Tokyo Chemical, Tokyo, Japan), and pure water. Bacteria were isolated from samples of naturally fermented terasi and terasi C. Terasi C was selected because it produced the highest levels of d-amino acids. To isolate bacteria, 1.0 g of powdered sample (isolated from samples 28 days old as described in Sect. 2.2.1) were diluted with 9 mL of 0.1% peptone water. Then, 100 μL was plated on MRS agar and incubated at 37 °C for 48 h. Colonies with distinct characteristics were chosen as isolates, and the morphology of the bacterial colonies was described based on the characteristics discussed by Reynolds (2020).

The following cultivation conditions for bacteria were based on those described by Mutaguchi et al. (2018). For isolation, selected colonies were cultivated on MRS agar and incubated at 37 °C for 48 h. Then, isolates were pre-cultured in 10 mL of MRS medium at 37 °C and 200 rpm for 24 h. For the main culture, 1 mL of the pre-culture was transferred into 99 mL of MRS medium and cultivated at 37 °C and 125 rpm for 24 h. To ensure pure colonies of the isolates, 0.5 mL of main culture was inoculated in 0.5 mL of sterilized 50% glycerol solution in a screw top tube to prepare the glycerol stock, which was stored at − 80 °C.

2.3.2 Confirming d-amino acid production by the isolates

First, isolates were cultivated so that a medium containing extracellular d-amino acids could be obtained. For cultivation, the glycerol stock was streaked on MRS agar plates and incubated at 37 °C for 48 h. Then, isolates were pre-cultured in 10 mL of MRS medium at 37 °C and 200 rpm for 24 h. For the main culture, 1 mL of the pre-culture was transferred into 99 mL of MRS medium and cultivated at 37 °C at 125 rpm. Next, 1 mL of medium was sampled, centrifuged at 9170×g at 4 °C for 10 min, and 700 μL of the supernatant was transferred to a new 1.5 mL Eppendorf tube for use in LC/MS analysis. The medium was sampled based on the growth curve of individual isolates (Fig. S1), and Table 4 shows the sampling point.

The extraction method for LC/MS analysis was based on the procedure described by Konya et al. (2017) and metabolites were extracted based on the process shown in Fig. 2. The reagents used for pretreatment included HPLC-grade methanol (Kanto Chemical), HPLC-grade acetonitrile (Kanto Chemical), HPLC-grade ethanol (Fujifilm Wako Pure Chemical), chloroform (Kanto Chemical), trifluoroacetic acid (TFA) (Fujifilm Wako Pure Chemical), dl-Alanine-2,2,3,3,-d4 (Santa Cruz Biotechnology Inc.), and ultrapure water. For extraction, 50 μL of the medium was used as the sample. For the sample, 50 μL of ultrapure water, 100 μL of 50% methanol, 20 μL of dl-Alanine-2,2,3,3,-d4 (internal standard; 40 μmol/mL), and 300 μL of methanol were added. The sample was then vortexed and centrifuged at 9170×g at 4 °C for 10 min. Then, 360 μL of supernatant was transferred to a new tube, and 180 μL of water and 360 μL of chloroform were added. The sample was then vortexed and centrifuged at 9170×g at 4 °C for 10 min. Next, approximately 400 μL of the sample was syringe filtered using 0.25 μm filters (Kurabo, Osaka, Japan). Subsequently, 50 μL of the filtered sample was diluted with 200 μL of 80% acetonitrile/20% ethanol solution. The diluted sample (100 μL) was transferred to a vial, and LC/MS analysis was performed as described in Sect. 2.3.2.

Chromatogram and mass spectrum data were collected during the LC/MS analysis. For normalization, the peak area value of each compound was divided by that of d-Alanine-2,2,3,3,-d4, the internal standard. Metabolites were then annotated using the amino acid standards in LabSolutions (Shimadzu). Univariate analysis was performed by subtracting the original number of amino acids in the medium and Student’s t-test in Microsoft Excel.

2.4 Genetic analysis of isolates

Genetic analysis was conducted for isolates A and B. A total amount of 1.0 μg DNA per sample was used as input material for the DNA sample preparations. Sequencing libraries were generated using the NEBNext® DNA Library Prep Kit following the manufacturer's recommendations, and indices were added to each sample. The genomic DNA was randomly fragmented to a size of 350 bp by shearing, and then DNA fragments were end-polished, A-tailed, and ligated with the NEBNext adapter for Illumina sequencing. They were then PCR enriched using P5 and indexed P7 oligos. The PCR products were purified (AMPure XP system) and the resulting libraries were analyzed for size distribution using an Agilent 2100 Bioanalyzer and quantified using real-time PCR. Non-redundant protein annotation was conducted to determine the genus of the isolates.

3 Results and discussion

3.1 Amino acid profile is dependent on the starter culture ratio for controlled fermentation

A previous study indicated that amino acids are an important group of metabolites in the final terasi product (Sato et al., 2020). Therefore, targeted analysis of amino acids using LC/MS was conducted to further determine the specific amino acids that differentiate naturally fermented terasi from that produced using controlled fermentation. Amino acid analysis included both d- and l-forms, and a total of 33 compounds were detected, as shown in Fig. 3.

To determine the influence of controlled fermentation on the amino acid profile, PCA was conducted, and Fig. 4 shows the PCA score plot and results from each fermentation condition. When compared to naturally fermented terasi, terasi A had a similar profile and contained comparable l-amino acids. In contrast, terasi B demonstrated a distinct profile along PC1, however no specific amino acid distinguished terasi B from naturally fermented terasi. Lastly, terasi C showed a distinct profile along PC2, and many d-amino acids, such as d-asparagine, d-glutamine, and d-leucine, differentiated terasi C from naturally fermented terasi. Based on these results, the ratio of bacteria in the starter culture used in controlled fermentation influences the amino acid profile, and the presence of high levels of d-amino acids differentiated terasi C from naturally fermented terasi, terasi A, and terasi B. This study is the first to report the presence of d-amino acids in terasi.

With the advancement of analytical techniques, many reports on the presence of d-amino acids in various fermented products exist, including d-aspartate, d-glutamate, d-alanine, and d-leucine (Kobayashi, 2019; Marcone et al., 2020). Many of the d-amino acids that have been previously reported were also detected in terasi, especially in terasi C, and thus, the results were reasonable. In general, fermented products are known to contain d-amino acids because they contain microorganisms, specifically lactic acid bacteria, which can produce high amounts of D-amino acids. In particular, studies have shown that Lactobacillus species contain several types of racemases, which are enzymes responsible for catalyzing the reversible conversion of l-amino acids to d-amino acids. This includes racemases necessary for building the bacterial cell wall, such as alanine racemase, aspartate racemase, glutamate racemase, and branched-chain amino acid racemases, such as valine racemase and leucine racemase (Kobayashi, 2019; Mutaguchi et al., 2018). Because the presence of Lactobacillus species has previously been reported in terasi (Susiloningsih, 2008), it may also be the source of the d-amino acids detected in this study. In addition, as shown in Table 1, terasi C contains a greater ratio of Lactobacillus in its starter culture, which could be one of the reasons for the presence of d-amino acids. In summary, one possible source of d-amino acid production in terasi C is Lactobacillus.

3.2 Isolates from terasi can produce d-amino acids

To confirm the bacterial production of d-amino acids in terasi, bacteria were isolated from terasi C because it contained the highest levels of d-amino acids. Bacteria were also isolated from naturally fermented terasi as a control. A total of two bacterial isolates were found in terasi C, which are shown in Fig. 5. Isolate A, shown in Fig. 5A, was circular, with white colonies with raised elevation and a glistening surface. Isolate B, shown in Fig. 5B, was circular, with tan colonies with raised elevation and a dull surface. Two bacterial isolates were found in natural terasi as well. Isolate C, shown in Fig. 5C, was circular, with white colonies with raised elevation and a glistening surface. Isolate D, shown in Fig. 5D, was filamentous, with tan colonies, crateriform elevation, and filiform margins.

These isolates were individually cultivated, and extracellular d-amino acid levels were measured to determine whether the isolates could produce d-amino acids. As shown in Fig. 6, isolates A and B, originating from terasi C, showed increased levels of d-alanine, d-glutamate, and d-valine, indicating that these isolates have the potential to produce d-amino acids during the fermentation process. Contrarily, as shown in Fig. 6, isolates C and D, coming from naturally fermented terasi, only showed an increase in d-alanine and d-glutamate. In brief, both isolates have the potential to produce extracellular d-amino acids during fermentation. These results suggested that these isolates could be responsible for d-amino acid production in terasi. It is reasonable to detect an increase in levels of d-alanine, d-glutamate, and d-valine because bacteria contain racemase, the enzyme responsible for catalyzing the conversion of l-amino acids to d-amino acids. A previous study has shown that the gene for racemase is conserved throughout the bacterial kingdom (Mutaguchi et al., 2015).

Furthermore, the results indicated that isolates A and B, from terasi C, both produced extracellular d-glutamate and their presence could be the reason why terasi C contained more d-glutamate than those in natural terasi (Fig. 4). However, to confirm that isolates from terasi C demonstrated a higher potential for d-amino acid production, it would be best to compare the production titer between strains. Furthermore, extracellular d-amino acid production was measured in vitro in pure culture, which did not reflect the complex biological environment where the fermentation process took place. Therefore, in the future, measuring extracellular d-amino acid production in co-culture or with other, more natural substrates, such as raw shrimp, would also be desirable.

In addition, genetic analysis was conducted for isolates A and B. Non-protein redundant annotation revealed that isolate A shares 1188 genes with Staphylococcus carnosus, and other possible candidates included different species of Staphylococcus (Fig. 7A). For isolate B, 1165 genes matched with Staphylococcus carnosus, and similarly, other possible candidates included different species of Staphylococcus (Fig. 7B). However, based on their morphological characteristics and biochemical properties (Table S2), isolates A and B are most likely two different strains of bacteria. In this study, it was feasible to find Staphylococcus species as isolates because terasi C was inoculated with a starter containing a higher ratio of Staphylococcus species than the starters used for either terasi A or terasi B (Table 1). This finding suggests that a higher ratio of Staphylococcus in the starter results in d-amino acid production that distinguishes the amino acid profile of terasi C from those of naturally fermented terasi, terasi A, and terasi B (Fig. 4). Furthermore, this is the first study to suggest that Staphylococcus spp. has the potential to produce d-amino acids and could possibly be used as a d-amino acid producer in the industry.

4 Conclusion

The objective of this study was to investigate the effect of controlled fermentation on taste-related metabolites in terasi using a metabolomics approach. In previous study, non-targeted analysis indicated a general trend toward increasing essential amino acid levels throughout the fermentation of terasi. Then, targeted analysis revealed that the amino acid profile of terasi was dependent on the starter culture ratio of the controlled fermentation. More specifically, terasi subjected to controlled fermentation with S. saprophyticus, B. subtilis, and L. murinus at a ratio of 1:1:1, respectively, showed a similar amino acid profile to naturally fermented terasi, whereas terasi subjected to controlled fermentation with a starter containing S. saprophyticus, B. subtilis, and L. murinus in a ratio of 2:1:2, respectively, showed a unique amino acid profile that included d-amino acids. Furthermore, a study revealed that Staphylococcus spp. have the potential to produce d-amino acids in vitro, and a higher ratio of Staphylococcus in the starter culture for controlled fermentation may account for the unique amino acid profile of some terasi products.

Further studies should be conducted to confirm d-amino acid production in isolated strains. For example, the enzymatic activity and gene expression of enzymes involved in this process should be validated. In addition, because the amino acid profile greatly differed between naturally fermented terasi and terasi made using controlled fermentation, sensory evaluations should be carried out to determine whether there is a significant difference in the sensory attributes of these two products. Based on previous reports, the taste properties of d-amino acids and their counter l-forms are different (Mutaguchi et al., 2015), and it would be interesting to investigate whether panelists could detect the difference in taste properties as well.

References

Andeta, A. F., et al. (2019). Development and validation of lactic acid starter cultures for enset (Ensete ventricosum) fermentation. LWT—Food Science and Technology, 115, 108462.

Ambarita, M. T. D. (2016). Considering the nutrional value of terasi and incorporating into the Indonesian diet. International Indonesia Forum.

Aryanta, W. R. (2000). Traditional fermented foods in Indonesia. Japanese Journal of Lactic Acid Bacteria, 10, 90–102.

Astuti, D. I., Taufik, I., Achnafani, D., & Priscila, E. S. (2018). Physiological profiling and microorganism community analysis of cirebon shrimp paste fermentation “terasi” using BIOLOGTM EcoPlate. Microbiology Indonesia, 12(1), 3.

Cappozi, V. (2017). Spontaneous food fermentations and potential risks. Fermentation, 3(49), 1–19.

Cevallos-Cevallos, J. M., et al. (2009). Metabolomic analysis in food science: A review. Trends in Food Science & Technology, 20, 557–566.

Chen, D., Ye, Y., Chen, J., & Yan, X. (2016). Evolution of metabolomics profile of crab paste during fermentation. Food Chemistry, 192, 886–892.

Ezekiel, O. O., Ogunshe, A., & Jegede, D. (2015). Controlled fermentation of cotton seeds (Gossypium hirsutum) for Owoh production using bacteria starter cultures. Nigerian Food Journal, 33, 54–60.

Hajeb, P., & Jinap, S. (2012). Fermented shrimp products as source of umami in Southeast Asia. Nutrition and Food Sciences, 10, 1–5.

Kobayashi, J. (2019). D-amino acids and lactic acid bacteria. Microorganisms, 7(12), 690.

Konya, Y., Taniguchi, M., & Fukusaki, E. (2017). Novel high-throughput and widely-targeted liquid chromatography-time of flight mass spectrometry method for d-amino acids in foods. Journal of Bioscience and Bioengineering, 123(1), 126–133.

Marcone, G. L., Rosini, E., Crespi, E., & Pollegioni, L. (2020). D-amino acids in foods. Applied Microbiology and Biotechnology, 104, 555–574.

Mok, W. K., et al. (2019). A metabolomic approach to understand the solid-state fermentation of okara using Bacillus subtilis WX-17 for enhanced nutritional profile. AMB Express, 9(1), 60.

Moon, S., Kim, C., & Chang, H. (2018). Heterofermentative lactic acid bacteria as a starter culture to control kimchi fermentation. LWT—Food Science and Technology, 88, 181–188.

Mutaguchi, Y., Kasuga, K., & Kojima, I. (2018). Production of d-branched-chain amino acids by lactic acid bacteria carrying homologs to isoleucine 2-epimerase of Lactobacillus buchneri. Frontiers in Microbiology, 9, 1540.

Mutaguchi, Y., Ohmori, T., & Oshima, T. (2015). 乳酸発酵とD-アミノ酸生産 [Lactic Fermentation and D-Amino Acid Production]. 化学と生物 [Chemistry and Biology] 53(1).

Nakamura, T., Tomita, S., & Saito, K. (2018). Metabolite profiling in dough during fermentation. Food Science and Technology Research, 24(3), 509–517.

Oh, D.-G., Jang, Y. K., Kim, J.-S., & Lee, C. H. (2016). Metabolomics reveals the effect of garlic on antioxidant- and protease-activities during Cheonggukjang (fermented soybean paste) fermentation. Food Research International, 82, 86–94.

Park, S.-E., et al. (2016). GCeMS based metabolomics approach of Kimchi for the understanding of Lactobacillus plantarum fermentation characteristics. LWT—Food Science and Technology, 68, 313–321.

Pereira, G. V. D. M., et al. (2015). Conducting starter culture-controlled fermentations of coffee beans during on-farm wet processing: Growth, metabolic analyses and sensorial effects. Food Research International, 75, 348–356.

Reynolds, J. (2020). 8: Bacterial Colony Morphology. Retrieved December 31, 2020, from https://bio.libretexts.org/Bookshelves/Ancillary_Materials/Laboratory_Experiments/Microbiology_Labs/Microbiology_Labs_I/08%3A_Bacterial_Colony_Morphology.

Ribeiro, L. S., et al. (2017). Controlled fermentation of semi-dry coffee (Coffea arabica) using starter cultures: A sensory perspective. LWT—Food Science and Technology, 82, 32–38.

Sato, A., Astuti, D. I., Putri, S. P., & Fukusaki, E. (2020). Quality improvement of semi-wet terasi by optimizing the starter culture ratio of controlled fermentation. Hayati Journal of Biosciences, 27(4), 320–329.

Sharma, R., et al. (2020). Microbial fermentation and its role in quality. Fermentation, 6, 106.

Surono, I. S., & Hosono, A. (1994). Chemical and aerobic bacterial composition of “terasi”, a traditional fermented product from Indonesia. Journal of the Food Hygienic Society of Japan, 35(3), 299–304.

Susiloningsih, R. (2008). The effect of starter (Lactobaccilus plantarum) concentration and fermentation time on the quality dan deterioration of terasi product. Jurnal PROTEIN, 15(2), 72–76.

Umakoshi, Y., et al. (2019). Automatic switching valve system to minimize variation of liquid chromatography-tandem mass spectrometry-based chiral amino acid profiling. Journal of Bioscience and Bioengineering, 128(6), 773–779.

Waryono, T. (2002). The history and social value characteristics of kampung laut segara anakan cilacap community. Kumpulan Makalah periode (pp. 1–17).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sato, A., Putri, S.P., Astuti, D.I. et al. Metabolome analysis to investigate the effect of controlled fermentation on taste-related metabolites in terasi. Metabolomics 18, 44 (2022). https://doi.org/10.1007/s11306-022-01902-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11306-022-01902-x