Abstract

The construction industry plays a major role in Chinese economy, but associated with a disproportionately high number of injuries and fatalities. In this paper, we proposed a improved AHP-Grey Model which has 4 limitations before. A safety hierarchical framework was established and attributes were identified through reason analysis method of Accident Chain Reaction Theory and 4M Theory; attributes weights were determined by Interval Analytic Hierarchy Process instead of AHP, and the safety checklist was also improved; grey relative Euclid weighted correlation degrees were calculated for safety level ordering instead of Deng’s grey correlation degree. The improved model can better reflect the actual safety condition of the construction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The construction industry plays a major role in Chinese economy, accounting for around 6.8% of the gross domestic product [1], and the construction sector also employs approximately 38,930,000 workforce of China [2], contributing significantly to the social employment. Despite the considerable contributions, according to official statistics of the “Ministry of Housing and Urban–Rural Development of the People’s Republic of China (MOHURD)” (Fig. 1), the construction industry is associated with a disproportionately high number of injuries and fatalities, which equated to at least 0.42 construction fatality every ¥10 billion output, and it is notorious for being the second dangerous industrial sector only to the mining sector.

Construction work is dynamic and complex, the workers are often exposed to the inherent risks [3]. In China, the construction industry implement safety management system (SMS) based on the standards vested in government agencies. A questionnaire was designed to survey practitioners’ perception of the effectiveness of current safety management system. The questionnaires were sent to 300 randomly selected certified building contractors around China, and 261 responses were received. Past studies have discovered that the successful implementation of the SMS on construction sites may help to prevent accidents [4, 5].

2 Safety Evaluation Method for the Construction

Preliminary interviews were conducted with three safety auditors and five construction contractors to find out their evaluation practices. From the literature review and interview result, a AHP-Grey Model proposed by Zhongshan Lu [6] was found. The model is a combination of Analytic Hierarchy Process (AHP) and Grey Relational Degree Analysis, which considering the issue that factors influencing construction safety have some grey characteristic, and its’ evaluation results are much more practical. There are still four limitations which have not been solved in the application of the model as follows.

The first step of safety evaluation was hazard identification and to establish the construction safety hierarchical framework comprehensively. However, Carter and Smith [7] found that only 6.7% of method statements construction sites identified all of the relevant hazards. In China, the most typical and widely used hierarchical framework was proposed by Lan Lu and Lingdong Wang [8]. The framework consists of 5 main safety management elements as follows:

-

Safety production management,

-

Safety education,

-

Environment and health,

-

Occupational health protection,

-

Sub-contract management.

Secondly, different factors and attributes are of different importance with respect to construction site safety. It is therefore necessary to find out the degree of importance of each attribute by assigning them weights, and AHP is used to determine the weights. AHP is a multi-objective decision-making method with qualitative and quantitative combination, the data dealt with is “point” data or “rigid” data [9, 10]. However, research in construction operations has furthermore shown that familiarity with a task can in fact lead to decreased perception of a hazard, such as experts in the field of painting being “desensitized” to the risks associated with working on ladders (Zimolong and Elke 2006), and they may give a higher score than others. Interval Analytic Hierarchy Process (IAHP) was therefore proposed in this research.

Thirdly, Grey Relational Degree Analysis is used to calculate the grey relational degree, and obtain the construction safety management level. The traditional Deng’s grey correlation may not conform to the actual conditions. And Grey Relative Euclid Weighted Correlation Degree was proposed to solve the problem.

The final limitation is the large number of attributes and complex processes that must be evaluated on construction site. To further improve the user-friendliness of the model, a computer program should be designed to replace the paper-based model. The application interface can be designed to have various pull down menus and shorting functions, the low-educated mangers will only need to type in scores and the result can be obtained by pushing a few buttons.

Therefore, this paper builds the grey evaluation model based on the improved Analytic Hierarchy Process (AHP) to study the construction safety.

3 Model Construction

3.1 Construction Safety Hierarchical Framework

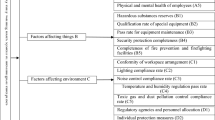

The hierarchical framework was established based on the research of Lan Lu and Lingdong Wang, and the attributes were identified through literature review, relative legislations and their relevance tested in an industry wide survey [11]. Reason analysis was carried out to ascertain if there is any missing attribute or further relationship among the many variables. Reason analysis method (see Fig. 2) adopted in this research was a combination of Accident Chain Reaction Theory and 4M Theory (Man Factors, Machine Factors, Media Factors, Management Factors) [12], which was motivated by the development sequence of accident, and the underlying correlation of man, machine, media and management.

As one of the five top construction accidents (fall from elevations, collapse, object striking, lifting injury and machine injury), take collapse for example, by the application of the reason analysis method, the attributes of construction form-work collapse can be obtained as Fig. 3 shows. By parity of reasoning, attributes of each accidents category can be obtained, and summarized into different factors which will be helpful in establishing the construction safety hierarchical framework.

Attributes obtained were organised into a hierarchy tree (see Fig. 4), with one goal, 2 levels, and 20 finalised attributes. Although the goal at the top was abstract, lower down on the tree, the attributes are more measurable, non-conflicting, and logical.

3.2 Importance Weights of Attributes Using IAHP

In this part, Interval Number Eigenvalue Method was adopted to determine interval weights from the various methods such as Iterative Method, Stochastic Simulation Method and Interval Number Eigenvalue Method [13]. There are two conventions to follow in assigning weights to attributes [14]: the final weight for each twig on the hierarchy tree is obtained by “multiplying through the tree”; normalise the weights to make weights sum to 1 at each level.

A questionnaire covering all the attributes was designed and sent to 40 experts who have more than 5 years of working experience in the construction industry. They were asked to compare each attribute against another to indicate their relative importance based on a 9-point scale where 1 = equal important, 3 = more important, 5 = obvious important, 7 = intensive important, 9 = extreme important and 2, 4, 6, 8 means their importance are between the two adjacent scales (Table 1).

The relative importance rating was put into the formula of consistency ratio (CR) for consistency testing, and the considered acceptable CR is 0.1 or less [15, 16]. 11 experts had CRs above 0.15, which was too high and their responses were abandoned. Only one expert had CRs between 0.1 and 0.15, and he changed his ratings to fulfill the CR target with sufficient reflection.

The interval matrix is operated in terms of digital matrix and vector computation. The interval matrix like Table 2 is marked as \({\text{B}} = \left[ {{\text{B}} - ,{\text{B}} + } \right]\), where, \({\text{B}} - = \left( {{\text{bij}} - } \right){\text{n}} \times {\text{n}},{\text{ B}} + = \left( {{\text{bij}} + } \right){\text{n}} \times {\text{n}}\), similarly, the vector is marked as \({\text{xi}} = \left[ {{\text{xi}} - ,{\text{xi}} + } \right]\), where, \({\text{x}} - = \left[ {{\text{x}}1 - ,{\text{ x}}2 - , \ldots ,{\text{ xn}} - } \right]{\text{T}},{\text{ x}} + = \left[ {{\text{x}}1 + ,{\text{ x}}2 + , \ldots ,{\text{ xn}} + } \right]{\text{T}}\). After constructing the interval judgment matrix, attribute weight is calculated using Eq. (1) below, and the total calculated results were shown in Table 2.

3.3 Scoring the Construction Site for Each Attribute Using Improved Safety Checklist

The improved checklist (see Table 3) divide experts into safety engineer A1, safety supervision A2, chief engineer A3, and project manager A4, and distribute reasonable weight to them by IAHP. Through calculation and verification, the weights of different inspectors are 0.12, 0.49, 0.23 and 0.16 respectively.

The final score is calculated using Eq. (2) below [17]:

where \(f_{i}\) is the final score for attribute i, \(e_{i}\) is the score by certain expert, and \(w_{i}\) is the relative importance of inspector i.

3.4 Aggregation Rule to Calculate the Grey Relative Euclid Weighted Correlation Degree

The traditional Deng’s grey correlation degree is calculated using Eq. (3) below.

where \(\xi_{0i} \left( k \right)\) is the correlation coefficient which was detailed below, as Deng’s grey correlation degree is the average of \(\xi_{0i} \left( k \right)\), as long as \(\sum\nolimits_{k = 1}^{n} {\xi_{0i} \left( k \right)}\) remain unchanged, \(\overline{{r_{0i} }}\) will not change regardless of correlation coefficient fluctuations [18, 19]. Therefore, the traditional aggregation rule cannot reflect the change of correlation degree caused by the correlation coefficient fluctuations. In this research, Grey Relative Euclid Weighted Correlation Degree was adopted to make up the deficiency.

3.4.1 Reference Series and Compare Series

Suppose the number of evaluation object is m, and the number of evaluation index is n, therefore the reference series \({\text{x}}0 = \{ {\text{x}}0\left( {\text{k}} \right) |\;{\text{k}} = 1, \, 2, \, 3 \ldots {\text{ n}}\}\), and the compare series \({\text{xi}} = \{ {\text{xi}}\left( {\text{k}} \right) |\;{\text{k}} = 1, \, 2, \, 3 \ldots {\text{ n}}\} \, \left( {{\text{i}} = 1, \, 2, \, 3 \ldots {\text{ M}}} \right)\). Adopt initial value transformation for non-dimensional quantities of original data:

Compare series were determined by the improved safety checklist.

3.4.2 Grey Correlation Coefficient

The grey correlation coefficient of compare series and reference series on each point is given in Eq. (5) below.

where ρ is the distinguish coefficient, 0 < ρ < 1, and ρ is usually evaluated to 0.5; however, the value of ρ should fully embrace the integrity of correlation degree with the anti-jamming capability, which can slack down the error repercussion of the entire correlation space caused by the anomaly value of the observational series [20]. The method for value assignment of ρ is shown as follows [21]:

where \(\Delta_{\nu }\) is the average of the absolute value of the difference, and \(\in_{\Delta } \le \rho \le 2 \in_{\Delta }\), \(\rho\) is evaluated between \(\in_{\Delta }\) and \(1.5 \in_{\Delta }\) when \(\Delta_{\hbox{max} } > 3\Delta_{\nu }\), while \(\rho\) is evaluated between \(1.5 \in_{\Delta }\) and \(2 \in_{\Delta }\) when \(\Delta_{\hbox{max} } \le 3\Delta_{\nu }\).

3.4.3 Grey Weighted Correlation Degree

where \(r_{0i}\) is the grey weighted correlation degree, \(w_{i} \left( k \right)\) is the synthetic weight corresponds to the correlation coefficient \(\xi_{0i} \left( k \right)\).

3.4.4 Grey Relative Euclid Weighted Correlation Degree

The grey Euclid closeness degree is given in Eq. (8) below [20, 21].

where \(A_{j}\) signals that \(x_{j}\) correlated with \(x_{l}\), \(A_{j} = \left\{ {\xi_{0j} \left( 1 \right),\xi_{0j} \left( 2 \right), \ldots ,\xi_{0j} \left( n \right)} \right\}\left( {j = 1,2, \ldots ,m} \right)\), and \(A_{l}\) signals that \(x_{j}\) and \(x_{l}\) are ideally correlated, \(A_{l} = \left( {1,1, \ldots ,1} \right)\left( {l = 1,2, \ldots ,m} \right)\).

Make a transfermation with Eq. (8) based on the case of \(A_{l}\), grey Euclid correlation degree is calculated using Eq. (9) below.

In this research, considering the attributes weights, grey relative Euclid weighted correlation degree is given in Eq. (10) by the transfermation with Eq. (9).

where \(\varepsilon_{0i}\) is the fluctuating value of correlation coefficient \(\xi_{0i}\) relative to grey weighted correlation degree \(r_{0i}\), and \(\varepsilon_{0i} \left( k \right) = \xi_{0i} \left( k \right) - r_{0i}\).

3.4.5 Correlation Degree Ordering

Sort evaluation objects based on the grey relative Euclid weighted correlation degree. Based on the Principle of grey correlation analysis, the higher the correlation degree is, the more satisfying the evaluation result will be.

4 Conclusion

-

1.

A improved safety assessment model of construction based on the AHP-Grey Model was proposed in this research, which dealt with the difficult to quantify attributes reasonably.

-

2.

The improved model not only minimise the influence of subjective and the probability of having two or more inspectors getting vastly different results on the same issue, but also considering the influence of correlation coefficient fluctuating value on the correlation degree.

-

3.

Furthermore, the improved AHP-Grey Model was developed into a software with rectification measures corresponding to the evaluation result, which was user-friendly for the relative low-educated contractors.

References

The prediction report of competition situation and investment perspective in China construction industry during 2013–2018. Creative industries reporting network, <http://www.chinairr.org/view/V05/201312/17-146422.html>.

Hu, J., & Gu, Y. (2013). China construction industry is the decisive source of new job. Construction Times, 4(4).

Raheem, A. A., & Hinze, J. W. (2014). Disparity between construction safety standards: A global analysis. Safety Science, 70, 276–287.

Teo, E. A. L., & Ling, F. Y. Y. (2006). Developing a model to measure the effectiveness of safety management systems of construction sites. Building and Environment, 41, 1584–1592.

Cox, S., & Cox, T. (1996). Safety systems and people. London: Reed Educational and Professional Publishing.

Zhongshan, L., Yang, S., & Yang, S. (2008). Safety assessment model of construction based on grey correlation theory. Journal of Hefei University of Technology (Natural Science Edition), 2, 262–266.

Perlman, A., Sacks, R., & Barak, R. (2014). Hazard recognition and risk perception in construction. Safety Science, 64, 22–31.

Lan, L., & Wang, L. (2003). Research on fuzzy comprehensive Evaluation model of construction. Journal of Industrial Engineering, 11, 49–53.

Wang, Z., & Liu, M. (2006). On fire-safety of high-rises with IAHP-based method. Journal of Safety and Environment, 6(1), 12–15.

Li, J. (2012). Determination the weights in adjusting formula based on IAHP method. Science & Technology Vision, 34, 97–98.

Teo, E. A. L., Ling, F. Y. Y., & Chong, A. F. W. (2005). Framework for project managers to manage construction safety. International Journal of Project Management, 23, 329–341.

Yang, L. (2014). Construction engineering accident reason analysis based on the set theory. Beijing: Capital University of Economics and Business.

Xiao, J., Luo, F., Wang, C., & Guo, T. (2004). Weight solving methods of Interval Analytic Hierarchy Process. Electricity System Engineering Journal, 3, 12–16.

Keeney, R. L., & Rafiffa, H. (1976). Decisions with multiple objectives: Preferences and value trade offs. New York: Wiley.

Gaili, X., & Xie, X. (2013). Research on consistency and priority of interval number complementary judgment matrix. Fuzzy Systems and Mathematics, 4, 162–168.

Xu, Z. (2007). Safety system engineering (p. 9). Beijing: China Machine Press.

Zhang, J. (2007). Methods of construction safety hazard evaluation and management. Dalian: Dalian Technology University.

Wang, C., & Zhou, P. (2004). Euclid approach degree-grey relational model application in environmental assessment. Environmental Science and Technology, 27, 25–27.

Zhang, Y., & He, J. (2008). Euclid gray relational model and application of safety assessments in rise building fire evacuation. Fire Science, 17(2), 105–110.

Fan, K., & Haoying, W. (2002). A new method of determining the coefficient resolution. Wuhan Technology University, 24(7), 86–88.

Lv, F. (1997). Research on discrimination coefficient of gray correlation degrees. System Engineering Theory and Practice, 6, 49–54.

Acknowledgements

This work was supported by the experts from China Construction Third Building (group) Co. Ltd and Beijing Shuang Yuan Engineering Consultation and Supervision Co. Ltd. Special thanks should be given to the authors of references. Any errors or shortcoming in the paper are the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, G., Sun, S. & Zhang, D. Safety Evaluation of Construction Based on the Improved AHP-Grey Model. Wireless Pers Commun 103, 209–219 (2018). https://doi.org/10.1007/s11277-018-5436-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11277-018-5436-8