Abstract

The potential use of Sporosarcina pasteurii in possible biotechnological applications on a large scale (ground improvement, consolidation of building structures and ornamental stone, or in developing bio-materials for the building industry), is based on its ability to produce high amounts of carbonate in a short period of time via urea hydrolysis. Industrial biomass production would have a low environmental impact and would be most economical if the standard growth media could be replaced with alternative nutrient sources, such as byproducts or wastes from other industries, or other low cost ingredients. The use of cost effective ingredients must guarantee ureolytic activities and growth conditions that are comparable to those resulting from the standard nutrient medium. In this work, three types of alternative media were tested for growing the ureolytic active bacteria S. pasteurii: (1) alternative nutrient sources such as industrial wastes resulting from the dairy and brewery industries, (2) fertilizer urea as an alternative urea substitute, and (3) different types of poultry manure based fertilizers as nutrient and urea substitutes. The comparison between the standard media, the nutrient alternatives and urea substitutes was possible by taking the protein concentration and nitrogen content into account. Bacterial activity was evaluated in terms of biomass changes over time (CFU, optical density, ATP measurements) and indirect estimation of the enzyme production (Nessler assay, conductivity measurement). The results revealed that some of the dairy wastes tested, such as whey and buttermilk, are potential alternative nutrients for bacterial development, while the urea fertilizer is perfectly suitable as an economical substitute for pure laboratory grade urea.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Potential applications of ureolytic microorganisms (Hammes et al. 2003; Chahal et al. 2011) in geotechnical engineering (Stocks-Fisher et al. 1999; Whiffin et al. 2007; Burbank et al. 2011), ground water and wastewater treatment (Fujita et al. 2008; Tobler et al. 2011), the construction field (de Muynck et al. 2008; Chunxiang et al. 2009; Kim et al. 2013) and carbon sequestration (Mitchell et al. 2010) have attracted a lot of attention in the last 10 years. This interest is due to the ability of these bacteria, which are naturally widespread in the environment (Fujita et al. 2000), to induce the precipitation of calcium carbonate via urea hydrolysis in a manner that is both efficient and easily controlled (Hammad et al. 2013). This process involves a series of complex biochemical reactions (Stocks-Fisher et al. 1999;Achal and Pan 2011; Li et al. 2011), in which urease and the recently discovered carbonic anhydrase (Achal and Pan 2011; Li et al. 2011) are key enzymes in the bio-induced calcification process. The hydrolysis of urea by the enzyme urease generates ammonia and carbonic acid, which subsequently form ammonium and bicarbonate ions. When this hydrolysis occurs in a calcium-rich environment, calcite precipitates from solution (Stocks-Fisher et al. 1999).

Ureolysis driven calcite precipitation shows great promise for biotechnological applications, in particular with the use of S. pasteurii. The ingredients of the growth medium in biotechnology processes are a major cost factor, ranging between 10 and 60 % of the total production costs (Whiffin 2004) when using the bio-cementation process. The costs of the growth medium increases proportionally with the scale of production. For this reason it is important to look for alternatives which stimulate and support bacterial growth and ureolytic activity which are more cost-effective than expensive commercial products.

There are many industrial wastes rich in proteins, especially from the production, preparation and consumption of food, that could be used as alternative nutrient sources in biotechnological processes. They could be hazardous to the environment if released in large quantities. However, if used effectively, they can be a valuable source of nutrients for different applications, providing a dual benefit through both cost reduction and environmental protection via waste recycling. Aside from the protein requirement (Whiffin 2004), urea is the other critical ingredient needed for S. pasteurii growth as well as for the ureolytic bio-induced calcite precipitation process. At present, the pure chemical form is used in most trials and laboratory work, but less costly alternatives need to be identified. In this paper different types of fertilizers (poultry manure based fertilizer and urea fertilizer) were tested for the first time for the development of S. pasteurii.

To date only a few alternative protein sources have been tested and proposed for developing S. pasteurii biomass. The alternative sources containing non-lysed cells (brewery waste yeast and sludge biomass from waste water treatment processing) were inaccessible for S. pasteurii, while within the pre-lysed protein sources tested, such as corn steep liquor, Torula yeast and Vegemite™, only the latter showed high levels of urease activity compared to standard nutrient media (Whiffin 2004). Another potential alternative nutrient source was found to be lactose mother liquor (LML), an industrial waste from the dairy industry, which was proposed as a substitute to the standard media (Achal et al. 2009). Blackstrap molasses, a by-product of the refining of sugar from raw sugar cane, was tested with good results regarding the stimulation of natural ureolytic groundwater communities, and their performance was compared to S. pasteurii (Fujita et al. 2008; Tobler et al. 2011).

This paper aims to compare and test a variety of alternative sources on S. pasteurii growth and its ureolytic performance. Nutrient substitutes (NS) came from the dairy and brewery industries (including wastewater from a dairy factory), a common urea fertilizer was tested to substitute the pure grade urea, while different poultry manure fertilizers were tested as nutrient-urea substitutes (NUS).

In order to evaluate the natural variance of the waste stream nutrients, we compared our results with the nutrients investigated and suggested by Whiffin (2004), Al-Thawadi (2008) and Achal et al. (2009). The efficiency of these media for S. pasteurii development has been evaluated in 100 ml of growing media using conductivity measurements, pH, optical density, total ammonia concentration evaluations, as well as by determining the vitality of the biomass through ATP measurements. A successful scale-up in a 5 l bioreactor was used to test the whey, using fertilizer urea (FU) as a substitute for pure laboratory grade urea.

Materials and methods

A variety of materials were used and a variety of test conditions were investigated. The alphabetical order of the recurrent abbreviations used in this paper are: Ba—Bakery yeast; Be1—Brewery yeasts (liquid); Be2—Brewery yeast (dry); CASO—casein peptone soybean flour peptone broth (Sigma Aldrich); EP1 and EP2 – commercial exsiccated organic fertilizers based on poultry manure (called Pollina or Pollina essicata); FU—mineral fertilizer (fertilizer urea); LML—lactose mother liquid; M—buttermilk; NAR—nutrient bullion (Carl Roth GmbH); NUS—nutrient-urea substitutes stands for one or more alternative nutrient-urea sources based on poultry manure fertilizers; NS—nutrient substitutes states for one or more alternative protein sources; PAV—a ripened and dried poultry manure with vegetable active principles; PHX—a commercial organic fertilizer (PHENIX); SNM—standard nutrient medium, which is CASO or NAR; SU—pure grade urea (Sigma Aldrich); V—Vegemite™/Marmite; W1, W2 and W3—three different types of whey; wW—wastewater from cleaning installation systems.

Biological material

Sporosarcina pasteurii, 33 type strain, was purchased from the DSMZ (German collection for microorganisms and cell cultures). It was grown aseptically under batch cultivation conditions according to the DSMZ instructions and stored on agar plates at 4 °C in the fridge, and used when necessary. All the experiments were performed in the same way, following a protocol defined as standard bacterial inoculum, starting from a stock culture not older than 1 month, in two revitalization (R) steps: R1—a loop containing bacterial biomass from stock culture inoculated in 20 mL SNM (standard nutrient medium) containing 20 g/l urea (incubated 8 h), and R2—0.5 ml of R1 in 100 ml of SNM with urea (incubated overnight) at 25–30 °C and 150 rpm. The R2 should be in the optimal condition for its experimental use—late exponential phase or in the early stationary phase, with values for the OD600 of about 1.900–2.000 rau and the ATP values at about 400,000 rlu/20 µl of R2 culture. For every type of experiment, the inoculum should be at about 4–5 ml of the R2 inoculum for 100 ml of new nutrient medium in order to have an initial OD600 of about 0.1000 rau.

Urea and nutrient substitutes

The SNM (standard nutrient medium) was prepared with a concentration of 8 g/l of protein and 20 g/l of SU (pure grade urea). The protein concentration of NS was adjusted to 8 g/l. The NS that were less rich in proteins were used without modification. The nitrogen content was considered for the preparation of NUS and urea substitute, in order to achieve the reference value (SU, 46.7 %). The characteristics of the NUS, FU, NS and SNM major ingredients that were used in this work are presented in Table 1. The elemental composition of poultry manure based fertilizers (Table 1) was determined using an elemental analyzer NA 1500 Series 2, Carlo Erba Instruments.

Experimental set-up

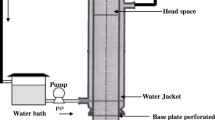

The bacterial behavior was tested at 24 °C in a 2 l bioreactor using CASO (casein peptone soybean flour peptone broth, 30 g/l) and SU (20 g/l), and the changes in pH level (Hamilton sensor), O2 (Oxysens 120 sensor) and conductivity were measured every 10 min for 25 h. The Nessler assay was conducted after inoculum (time 0) and after 2, 7 and 25 h. The biomass was evaluated by optical density (OD600) and ATP measurements, only immediately after inoculum and after 2, 4 and 7 h.

Different experimental sets were carried out for testing the alternative sources some in parallel by both ICVBC (Institute for the Conservation and Valorization of Cultural Heritage) and IFAM (Fraunhofer Institute for Manufacturing Technology and Advanced Materials) groups (supplementary material S1). The same protocol was always used, and similar results were obtained for the parallel experiments. The NS were used while in a fresh condition at 30 °C. The FU as an urea substitute and the NUS were tested at 24 °C. The FU was tested with SMN, while the NUS (nutrient-urea substitutes based on poultry manure fertilizers) were tested in two different sets, by mixing them with water only. The use of water instead of the standard nutrient medium for the NUS was chosen because the urease activity of S. pasteurii was very similar in both liquids with best results for PAV (supplementary material S2). Duplicates for each test condition were performed using 100 ml solutions.

In order to understand the influence of the indigenous microbial communities in NS or NUS, sterilized media were tested as well. The urea (SU or FU) was directly dissolved in the NM. When the nutrient media was sterilized, the urea was added after sterilization and after the media had cooled down, using urea stock solution (6.66 M) sterilized by filtration. The final urea concentration for all the tests was 0.33 M (20 g/l). The flasks were therefore inoculated with fresh bacterial inoculum, as described above in the Biological Materials section, and were continuously shaken at 150–160 rpm. In each experiment, changes in the aqueous nutrient media were determined at time zero, before and after bacterial inoculation, and monitored regularly using different parameters (pH level, conductivity, total ammonia, biomass) as described below, in order to evaluate bacterial development and urease activity.

Urease activity

The typical urease activity of S. pasteurii was calculated by conductivity measurements at 30 °C using 0.33 M urea (20 g/L), and compared with the pure enzymatic activity at 30 °C in the presence of 1 M urea. The urease TYPE IX from jack beans (Sigma Aldrich) was used as a standard at different concentration (0.03, 0.16 e 0.32 mg/ml), using 100 ml volumes of CASO (30 g/l) and SU (60 g/l).

The conductivity measurement is a suitable method for measuring urease activity, because urease turns the urea molecule (non-conductive) into two charged ions: ammonium (NH4 +, positively charged) and carbonate (CO3 2−, negatively charged). A conductivity meter Hanna DIST® Tester (ICVBC) or DIST 6 (IFAM) was used to record the conductivity changes over time. The urease activity was calculated (Whiffin 2004) using the linear relationship between the rate of conductivity (mS/cm/min/) changes and the rate of urea hydrolysis (mM urea hydrolysed/min) in the presence of pure urease TYPE IX from jack beans (supplementary material S3).

The Nessler assay was used to determine the nitrogen that was present in either free ammonia or ammonium ions in the aqueous solutions to test (Whiffin 2004). The samples were diluted at 1:1000 before running the assay. Two ml of the diluted sample were mixed with 100 µl of Nessler’s reagent and allowed to react for exactly 1 min before reading the absorbance at 425 nm with a Beckman DU 640 Spectrophotometer. Standards were made using a stock solution of 0.01 M of NH4Cl. The urease activity was calculated (Whiffin 2004) using the linear relationship between the rate of total ammonia (mM/min) formation, and the rate of urea hydrolysis (mM urea hydrolysed/min) in the presence of pure urease TYPE IX from jack beans (supplementary material S4).

Biomass development

The biomass development was checked using a Beckman DU 640 Spectrophotometer for measuring the OD600 and a bioluminometer (3 M™ Clean-Ttrace™) for measuring the ATP level, while the CFU (Colonies Forming Unit) were estimated on agarized SNM, using serial dilution. The standard curves and the conversion factors between these analytical methods were elaborated and are shown in the supplementary material S5.

Results

Typical behavior of S. pasteurii

The typical behavior of a S. pasteurii bacterial culture at 24 °C (Fig. 1a, b) leads to significant changes in the initial nutrient medium during bacterial growth (2 % proteins, 0.33 M urea). The initial pH of the nutrient solution (7.3) increases towards an alkaline pH (9.2–9.4). The conductivity values and the total amount of ammonia ions also increase over time as a result of the enzymatic reaction, which hydrolyze between 0.5648 and 0.6138 mM urea/min in the exponential phase. The maximum pH is reached when the ionic equilibrium has been established. The medium acts as a buffer and the bacterial culture reaches an optimal condition. This is observed after about 6–7 h of development. During bacterial growth, the initial oxygen present in the nutrient medium decreases over time, until it has been completely consumed. After about 10 h, anaerobic conditions start to dominate the medium. At this time, the bacterial culture is in a stationary phase and is still enzymatically active, however all the urea has been depleted. If urea were to be added, the bacteria would hydrolyse it even under anaerobic conditions. The capacity of S. pasteurii to develop and hydrolyse urea under anoxic conditions was also observed by Stacy L. Parks (2009) and Tobler et al. (2011).

Typical behavior of the bio enzymatic reaction parameters inside the Bioreactor (2 l), such as, conductivity, oxygen, pH and ammonium (a); optical density and ATP (b), and the bacterial enzymatic activity compared with three different concentrations of pure urease (c). The initial biomass of S. pasteurii was 0.0079 for OD600 and 15,334 RLU/mL for ATP. The nutrient medium was CASO (30 g/L) with FU (0,3 M) at 24 °C (a, b) and 30 °C (c)

The urease activity of 1 ml S. pasteurii working culture (30 °C, 20 g/l urea and 2 % protein) corresponds to about 0.23 mg/ml urease TYPE IX from jack beans that hydrolyzes at about 2 mM urea/min. Assuming the turnover rate of urease TYPE IX this should correspond to 100–150 μmol NH3/min (Fig. 1c). Taking into account the conductivity change, the urease activity was found to be 1.6992 mM urea/min in the exponential phase.

Influence of the urea substitute and nutrient-urea substitutes

Compared with expensive pure grade urea (SU), the FU tested as an urea substitute, showed the same behavior in the presence of the commercial urease TYPE IX from jack beans (Fig. 2a). No significant difference was observed between the two types of urea in regard to enzymatic activity during bacterial development. The urease activity showed the same trend over time for both types of urea tested (Fig. 2b). The maximum urease activity was observed in the exponential phase for both types of urea tested (SU and FU). The conductivity and ammonium values increased over time in the same manner for both types of urea tested.

Rate of conductivity change for different urea concentrations (80, 160, 330 and 500) in the presence of urease type IX from jack beans, for pure grade urea—SU (continuous line) and fertilizer urea—FU (dashed lines) (a) and the urease activity in different phases of the bacterial development for the two types of urea (b)

Compared with expensive urea purchased from Sigma (SU), FU had no negative influence on the recorded growth curves of S. pasteurii. Therefore a substitution of SU with FU is recommended in order to reduce production costs.

As the synthesis of urea has a negative environmental impact due to the particular chemical conditions required (high temperatures and pressure), some alternative sources with a lower environmental impact were screened. Urea is found abundantly in urine and faeces, but the presence of pathogens in these make them difficult to use. For this reason, poultry manure organic fertilizers that contain nitrogen, carbon, and are free of pathogens were taken into consideration and investigated as possible NUS (Table 1).

The comparison between the sterile and non-sterile NUS organic fertilizers, by means of ATP, showed that other bacteria are present in the non-sterilized PAV—a ripened and dried poultry manure with vegetable active principles (38,850 rlu/ml), EP1—one type of commercial poultry manure fertilizer (28,755 rlu/ml), EP2—another type of commercial poultry manure fertilizer (49,800 rlu/ml) and PHX—a commercial organic fertilizer (16,900 rlu/ml). In absence of S. pasteurii, the NUS tested released very little amount of total ammonia in the water solution after 24 h, the lowest value, near to zero, being for EP2 (540 ppm), followed by PAV (1413 ppm), EP1 (1679 ppm) and PHX (8712 ppm). However, a little increase of ureolytic activity was detected especially in the unsterilized NUS media only after the S. pasteurii inoculation, which was attributed to the presence of this bacteria, and not the indigenous communities already present. In addition, when sterilized all the NUS suffered a change that rendered them less efficient for the urease activity of S. pasteurii being less efficient compared with the un-sterilized NUS (Fig. 3).

The urease activity (a) and the biomass development (b) in time of the S. pasteurii, in the presence of different urea substitutes sources, and the pH changing in time (c) in the presence (continuous) or absence of S. pasteurii (small dashed lines) for the urea substitutes (EP1, EP2, PAV, PHX and CASO reference). For the meaning of the abbreviations, see Table 1

The type of nitrogen (organic and/or ammonia) present in the dessicated poultry manures that were tested, induced only minor enzymatic activity of the S. pasteurii. It was higher for PAV (0.0804 mM after 6 h, and 0.1002 mM urea hydrolyzed/min after 24 h) and PHX (0.0536 mM after 6 h and 0.1807 mM urea hydrolyzed/min after 24 h) and lower for the others, with respect to the standard nutrient medium (Fig. 3a). The presence of the enzymatic activity is confirmed by the ATP measurements, but only for PAV, where the increasing biomass is observed (Fig. 3b). In the case of the PHX fertilizer, the ATP values were very low (Fig. 3b) even if the initial conductivity is very high (about 64 mS/cm, as itself dissolves many ions in the water solution with respect to the others NUS).

The bacterial biomass increased very slowly and had a lag phase of about 3 h for media containing the NUS when compared to the reference (CASO and SU). S. pasteurii had already passed the exponential phase during that time. In the media with PAV, the biomass reached a value corresponding to 4.21E + 08 CFU/ml in about 20 h, by maintaining an active growth phase. A similar value (4.33E + 08 CFU/ml) was obtained for the reference in only 4 h, while 20 h later the nutrients and urea were completely depleted and the bacteria was in the decline phase. This indicates that nutrients are present in the alternative media that were tested. The best results in terms of bacterial growth of the potential urea substitutes containing no additional urea was observed for PAV (Fig. 3b).

The initial pH level of the alternative media was a bit different from that of CASO (Fig. 3c), being more acidic for EP1st and PHX, and more alkaline for EP1 and EP2. Only in the case of the reference (CASO) did the pH level increase with the biomass uptake of S. pasteurii up until the most favorable pH level for this bacteria (about 9.4). The PAV and EP2 showed the maximum increase in pH level, followed by EP1 and PHX, among the poultry manure fertilizers tested. This could be explained by the influence of the initial pH level on bacterial growth and activity. An initial alkaline or neutral pH level favors bacterial development, as in the case of PAV, CASO and EP2, while an acidic pH level limits bacterial activity. However EP2, with the lowest initial pH level (6.4) was better digested by the bacteria than PHX (6.6), which means that PHX limits the bacterial development in other ways, such as a high ion content, as described above. The PHX seems to have a high ureolytic activity with little bacterial growth, but in fact its conductivity increase is due to the continuous ions dissociation of the original composition of PHX, and cannot be attributed to the bacterial activity.

Based on these results, it would appear that this material cannot be used as an urea substitute, although it was observed that some of the dehydrated poultry manures that were tested allowed the bacteria to remain vital, indicating that they might be at least partially appropriate as a nutrient source.

Influence of protein content

The determination of bacterial enzymatic activity at 30 °C was done using the reference nutrient medium CASO with 2 % protein content (according to the supplier’s protocol), and two other lower concentrations (0.5 and 8 %), using an urea concentration of 20 g/l. The results showed that the expected conductivity increases for the 2 and 0.8 % protein concentration, while in the lowest one (0.5 %), the bacteria did not seem to be enzymatically active in the lag phase, starting to hydrolyze the majority of the urea with about 2 h delay when compared with the other two more concentrated media (Fig. 4). In fact, the bacterial enzymatic activity for the media with 2 and 0.8 % protein concentration is very similar in the exponential phase (between 2 and 4 h), with values for urease activity at 1.5364 mM urea hydrolyzed/min and 1.4945 mM urea hydrolyzed/min. For the same interval, bacterial urease activity in the 0.5 % protein concentration nutrient medium was only 25 % less, with a value of 1.1476 mM urea hydrolyzed/min. After 6 h, the beginning of the stationary phase had already started for bacterial biomass grown in the two highest protein concentrations, with a significant decrease in urease activity 0.2348 and 0.13340 mM urea hydrolyzed/min), while in the case of 0.5 % protein concentration, the bacteria still had good enzymatic activity (0.5282 mM urea hydrolyzed/min) because they were still in the exponential growth phase (Fig. 4). The total ammonia formation confirmed the ureolytic activity of S. pasteurii for all three cases of CASO protein concentrations (Fig. 4).

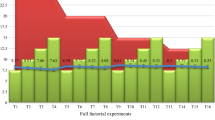

The bacterial activity in the alternative nutrient media showed an increase in conductivity over time for almost all NS tested (Fig. 5a). The dairy (buttermilk M, whey W1–W3 and waste water wW) and liquid brewery yeast products (Be1) were distinguished between sterile (st) and non-sterile in order to investigate the influence of competing bacteria or yeasts already present in the media. The pH level was adjusted in advance to 7 in case of acidic NS (LML, M and W1–W3). It was assumed that enzymes from the dairy nutrients were still active and competing with the urease of S. pasteurii. It was observed that once the alkaline conditions were reached, the ‘dairy enzymes’ could no longer compete with urease. The dairy product whey had higher urease activities than buttermilk, whether sterile or not, and even better than the yeast based sources. Within the three types of whey tested, the W3 was preferred by the S. pasteurii. The initial alkali pH level of the wW favored the growth of biomass (Fig. 5a) and therefore the amount of urease (Fig. 5a), meaning that the wW also gave satisfactory results. The bacteria displayed a quite constant enzymatic activity in the presence of LML, with a maximum of 0.2743 mM urea hydrolyzed/min after 6 h, similar to V and NAR.

The bacterial enzymatic activity of S. pasteurii in low protein content nutrient media (a) and the biomass growth over time expressed by ATP (rlu/ml) in the presence of different alternative nutrient sources (b). (for legend, see Table 1)

S. pasteurii showed the typical growth curve only in the presence of the standard nutrient medium. The potential nutrient sources had an influence on bacterial vitality (Fig. 5b). The behavior of S. pasteurii in the CASO nutrient medium (0.5 %) was similar to the ones of the dairy alternative nutrient media with a protein content <1 % (Table 1). The main difference was the longer lasting lag phase of bacterial growth for all the NS tested. The lowest enzymatic activity was observed for brewery based alternative nutrients. But a high number of vital cells was attributed to the brewery yeasts as well. In this case it seems that the presence of the competitors (brewery yeast) and, potentially, traces of ethanol, inhibited ureolytic bacterial growth.

Discussion

Biotechnology grade qualities and sterile conditions are cost drivers, which should be replaced by substitutes that are economical and production conditions that are ‘easy to handle’ in order to achieve the affordable biotechnological use of S. pasteurii. For large scale production it is necessary to find an inexpensive substrate for the bacteria to grow on that still produces a good level of urease activity. The cost for 1 l of standard nutrient medium (biotechnology grade) used in this work was about €2, including the pure grade urea. There were additional costs for water, oxygen, depreciation, personal costs, storage of the backup culture and energy. Low cost substrates are generally subject to a lower level of quality control and reproducibility. The effects of variable feedstock and the additional processing required (e.g. for the presence of insoluble particles when dissolved in water) should be considered in relation to the application of the enzyme produced.

Within the possible alternative nutrient sources tested for the growth of S. pasteurii ureolytic bacteria, the byproducts originating from the dairy industry tested in non-sterile conditions gave the best results when compared with yeast-based products originating from the brewery or bakery industry. Whey, also called permeate, induced a bacterial enzymatic activity of about 80 % when compared to the reference nutrient medium, with a longer lag phase in the bacterial growth.

Whey, followed by the alkaline water resulting from cleaning the installed systems of dairy factories, and LML, are potential candidates for use as a less expensive and low environmental impact nutrient source for biotechnological applications.

The most effective alternative urea substitute is FU. The poultry manure could not replace the urea as the available ammoniacal nitrogen is too little with respect to the reference (Table 2). However, the experimental data suggested that this material contains high amounts of organic substances that could be suitable as NS. The bacterial growth with poultry manure and FU water solution seems to progress with similar enzymatic activity as the standard nutrient medium.

The FU used was available on the market for a cost of about 1 €/kg. The most promising alternative nutrient sources tested in this work (whey, alkaline waste-water from dairy industries, LML) were sourced at no cost, but in small quantities. If the biotechnological development of S. pasteurii uses these at scale then there is almost certainly going to be a cost involved in sourcing these in the volumes required for commercial production. This cost is most likely still going to be less than that of pure grade ingredients. The price calculated for 1 liter of this alternative medium was €0.02 which is a 200-fold reduction in the cost of the medium and ten times lower than the one obtained by Whiffin (2004) for the use of ‘Vegemite™’ mixed with acetate.

Another solution for affordable alternative nutrient sources proposed in this work is the use of commercial poultry manure based fertilizers, containing high amounts of organic substances, mixed with FU. The cost of this substitute is about €0.20/l. It was observed (supplementary material S6) that if the FU is added to these media, even in small amounts (5 g/l), the enzymatic activity is significantly increased, reaching an enzymatic activity of 76 % for PAV and of 62 % for EP1 compared with the typical one observed for reference, where S. pasteurii was developed in the presence of CASO and pure grade urea.

A successful scale up of the unsterilized whey alternative nutrient medium and 20 g/l of urea fertilizer was performed in a 5 liter bioreactor (supplementary material S7), where the temperature (set at 24 °C), pH level and conductivity were continuously measured during bacterial development. In addition, the initial pH level was not adjusted. The urea was dissolved in the whey medium and agitated for 15 min and then the medium was inoculated with the ureolytic bacteria. The urease activity of the S. pasteurii was 0.4675 mM urea hydrolyzed/min after 240 min and 0.5888 mM urea hydrolyzed/min after 360 min. Satisfactory enzymatic activity is obtained at 24 °C using little amounts of proteins and urea. An increasing of temperature of 6 °C (30 °C) will improve the urease activity about three times more (1.6992 mM urea/min, with respect to 0.6138 mM urea/min), at the same concentration of urea and proteins. When little protein concentration (0.5 %) is used, the bacteria were growing more slowly, but with a good enzymatic activity at 30 °C (0.5282 mM urea/min), comparable with the one obtained at 24 °C by S. pasteurii. The use of dairy by-products and/or wastes (whey, alkaline waste water) and the cheap FU are suitable and affordable ingredients for large scale production of S. pasteurii for biotechnological uses.

References

Achal V, Pan X (2011) Characterization of urease and carbonic anhydrase producing bacteria and their role in calcite precipitation. Curr Microbiol 62:894–902. doi:10.1007/s00284-010-9801-4

Achal V, Mukherjee A, Basau PC, Reddy MS (2009) Lactose mother liquor as an alternative nutrient source for microbial concrete production by Sporosarcina pasteurii. J Ind Microbiol Biotechnol 36:433–438. doi:10.1007/s10295-008-0514-7

Al-Thawadi SM (2008) High strength in situ biocementation of soil by calcite precipitating locally isolated ureolytic bacteria. PhD Dissertation. Murdoch University Australia

Burbank MB, Weaver TJ, Green TL, Williams BC, Crawford RL (2011) Precipitation of calcite by indigenous microorganisms to strengthen liquefiable soils. Geomicrobiol J 28:301–312. doi:10.1080/01490451.2010.499929

Chahal N, Rajor A, Siddique R (2011) Calcium carbonate precipitation by different bacterial strains. Afr J Biotechnol 10:8359–8372. doi:10.5897/AJB11.345

Chunxiang Q, Jianyun W, Ruixing W, Liang C (2009) Corrosion protection of cement-based building materials by surface deposition of CaCO3 by Bacillus pasteurii. Mater Sci Eng C 29:1273–1280. doi:10.1016/j.msec.2008.10.025

de Muynck W, Debrouwer D, de Belie N, Verstraete W (2008) Bacterial carbonate precipitation improves the durability of cementitious materials. Cem Concr Res 38:1005–1014. doi:10.1016/j.cemconres.2008.03.005

Fujita Y, Ferris FG, Lawson RD, Colwell FS, Smith RW (2000) Calcium carbonate precipitation by ureolytic subsurface bacteria. Geomicrobiol J 17:305–318. doi:10.1080/01490450050193360

Fujita Y, Taylor JL, Gresham TLT, Delwiche ME, Colwell FS, McLing TL, Petzke LM, Smith RW (2008) Stimulation of microbial urea hydrolysis in groundwater to enhance calcite precipitation. Environ Sci Technol 42:3025–3032. doi:10.1021/es702643g

Hammad IA, Talkhan FN, Zoheir AE (2013) Urease activity and induction of calcium carbonate precipitation by Sporosarcina pasteurii NCIMB 8841. J Appl Sci Res 9:1525–1533. ISSN 1819-544X

Hammes F, Boon N, de Villiers J, Verstraete W, Siciliano SD (2003) Strain-specific ureolytic microbial calcium carbonate precipitation. Appl Environ Microbiol 69:4901–4909. doi:10.1128/AEM.69.8.4901-4909.2003

Kim HK, Park SJ, Han JI, Lee HK (2013) Microbially mediated calcium carbonate precipitation on normal and lightweight concrete. Constr Build Mater 38:1073–1082. doi:10.1016/j.conbuildmat.2012.07.040

Li W, Liu L-P, Zhou P-P, Cao L, Yu L-J, Jiang S-Y (2011) Calcite precipitation induced by bacteria and bacterially produced carbonic anhydrase. Curr Sci 100:502–508

Mitchell AC, Dideriksen K, Spangler LH, Cunningham AB, Gerlach R (2010) Microbially enhanced carbon capture and storage by mineral-trapping and solubility-trapping. Environ Sci Technol 44:5270–5276. doi:10.1021/es903270w

Parks SL (2009) Kinetics of calcite precipitation by ureolytic bacteria under aerobic and anaerobic conditions. Master thesis. Montana State University, USA

Stocks-Fisher S, Galiant GK, Bang SS (1999) Microbiological precipitation of CaCO3. Soil Biol Biochem 31:1563–1571. doi: 10.1016/S0038-0717(99)00082-6

Tobler DJ, Cuthbert MO, Greswell RB, Riley MS, Renshaw JC, Handley-Sidhu S, Phoenix VR (2011) Comparison of rates of ureolysis between Sporosarcina pasteurii and an indigenous groundwater community under conditions required to precipitate large volumes of calcite. Geochim Cosmochim Acta 75:3290–3301. doi:10.1016/j.gca.2011.03.023

Whiffin VS (2004) Microbial CaCO3 precipitation for the production of biocement. PhD Dissertation. Murdoch University Australia

Whiffin VS, van Paassen LA, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423. doi:10.1080/01490450701436505

Acknowledgments

This work is made under the framework of the ECO-CEMENT project (FP7- Grant 282922). The authors would like to thank Giuliano Tazzari (Amek srl, Italy), Gianfranco Betti (Mukki Latte, Italy), Mr. Roberto (I Marzoli, Italy), Juergen Harves (a farm in Oyten, Germany) and Javier Arroyo Abancéns (Solintel) for their kindness in supplying the alternative sources to test, to Jay Stuart (DWEcoCo) for his precious assistance in improving the paper and to Laura Sánchez Alonso (Essentium) for the exemplary coordination of the project.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cuzman, O.A., Richter, K., Wittig, L. et al. Alternative nutrient sources for biotechnological use of Sporosarcina pasteurii . World J Microbiol Biotechnol 31, 897–906 (2015). https://doi.org/10.1007/s11274-015-1844-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-015-1844-z