Abstract

The objective of this research was to obtain a macerate with prebiotic potential from barley straw obtained after fermentation in solid-state. Fermentation process was carried out for 7 weeks at 30 °C using sterilized barley straw inoculated with Rhizopus oryzae JCP024. Spores number, changes in pH, and carbohydrates were monitored every 24 h. Deionized water was used to obtain the macerates of the fermented barley straw. The concentration of reducing carbohydrates and the total carbohydrates was determined by using DNS and Dubois technique, respectively. The effectiveness of the macerates as prebiotics was verified through a viability study with L. casei Shirota. Inulin was used as prebiotic control. Reducing carbohydrate content decreased until total carbohydrates increased due to the consumption of carbohydrates by the fungal biomass and hydrolysis of oligosaccharides at the same time. A constant viable count of the probiotic was observed, being comparable to that observed in the control (1 × 108 CFU/mL). With these results, it is demonstrated that the macerates of an agricultural waste obtained during fungal fermentation could be an alternative for obtaining carbon sources for probiotic growth.

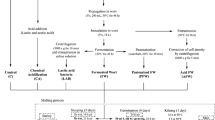

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Prebiotics are substances that are digestible only in the colon and positively affect the balance of the intestinal microbiota [1]. In addition, some natural prebiotics help to lower blood pressure, prevent platelet aggregation, and help in the absorption of some minerals such as calcium, iron, zinc, and magnesium [2].

Agricultural and food industry wastes are potential raw materials to obtain prebiotics. These productive sectors generate a large amount of organic waste that is only taken for animal feeding or is discharged without any treatment. Some of these wastes can be re-valued as raw materials for obtaining high commercial value metabolites [3]. This is the case of the sub-products of cereal processing, such as barley straw, whose nutrient content and mainly complex carbohydrates make it a potential source of prebiotics [4].

Prebiotics can be synthesized and obtained using different techniques: (1) extraction by physical methods, (2) enzymatic synthesis, and (3) enzymatic or microbiological hydrolysis. Extraction by physical methods has been used to obtain prebiotics from inulin since some of its oligosaccharides are soluble in water and they are easy to obtain [1]. Another technique is ultrasound, which has shown high efficiency and productivity [5]. This technique has recently been used for the extraction of oligosaccharides from industrial artichoke waste [6, 7].

The use of glycosyltransferases and galactosidases from lactic acid bacteria is used to obtain prebiotics synthesized through enzymatic reactions [8,9,10]. However, the most effective processes are those that involve the use of lipases and galactosidases [11]. The coupling of chemical compounds and enzymes improves the obtaining of structurally defined oligosaccharides, which enhances the biological functionality of these chains [10], although obtaining oligosaccharides by this method has some disadvantages, including its high cost and the need of purifying the final products.

Finally, the least used technique for the production of prebiotics is based on the hydrolysis of oligosaccharides and complex carbohydrates by fermentation due to microbial growth. This technique has its difficulties because the production performance of prebiotics is associated with the adaptation of the microorganism to the substrate, which in turn depends on the pH, temperature, and composition of the culture medium [12].

One of the great advantages of this type of method is the use of agro-industrial waste for both the production of functional oligosaccharides and enzymes for industrial use. According to Abdel-Sater and El-Said [13], rice and wheat straws and cane bagasse are materials from which microorganisms capable of producing xylanases can be isolated, which, in turn, are used by these microorganisms for the production of xylooligosaccharides. Fungi belonging to genus Penicillium, Aspergillus, and Fusarium are examples of xylanase-producing microorganisms.

According to Singh et al. [14], the limited aeration and the need for mechanical agitation in submerged fermentation, especially in block processes, are the main limitations in the performance of the process. On the other hand, one of the main advantages in solid fermentation processes is low humidity; this prevents both bacterial contamination and high-energy consumption [15]. That is why the objective of this work was to take advantage of solid fermentation with Rhizopus oryzae JCP024 in the fractionation of long-chain carbohydrates from barley straw to obtain macerates with prebiotic potential.

2 Material and methods

2.1 Sample

The barley straw was obtained from a farm located in the Municipality of Apan, Hidalgo, Mexico, until completing 3 kg. The straw was ground in a manual mill and sieved. Sections of 5 g were taken from particles less than 0.5 mm.

2.2 Inoculum preparation

The microorganism was obtained from the Biotechnology Laboratory of the Universidad Autónoma del Estado de Hidalgo. The spore suspension of Rhizopus oryzae JCP024 was prepared from fully sporulated fungi cultivated for 7 days on potato and dextrose agar, using a 0.85% (w/v) NaCl solution. Through a platinum loop, the mycelium of the fungus was added to 10 mL of sterilized 1% (w/v) peptone water. Subsequently, 2 mL of this solution was added to a tube with 8 mL of water, so on until a concentration of 1 × 107 spores/mL was obtained. The spore count was performed by the Neubauer technique [16].

2.3 Solid-state fermentation

Solid-state fermentation was carried out according to the technique of Sandhu and Punia [17] with some modifications. In 250-mL Erlenmeyer flasks, 5 g (on a dry basis) of barley straw was added. The straw was mixed and autoclaved at 121 °C for 15 min. Under aseptic conditions, straw moisture was determined and adjusted to 60% (w/v) with citrate buffer pH 5. The study was carried out in independent units for each time. The sterilized solid substrate was inoculated with 1 × 107 spores/mL of the Rhizopus oryzae JCP024 preparation. The contents were mixed and incubated at 30 °C. Fermentation took place for 7 weeks and was monitored every 7 days. With this time, fungal growth was guaranteed until the deceleration stage. To determine the number of spores generated during fermentation, the Neubauer chamber count method was used, applying Equation 1 (Eq. 1):

2.4 Obtention of macerates

In order to obtain the soluble carbohydrates from the fermented barley, maceration was carried out. The Erlenmeyer flasks containing the sourdough were rinsed with 100 mL of previously sterilized deionized water. The flasks were heated for 90 min at 65 °C. The macerates obtained were vacuum filtered through a Büchner funnel with Whatman no. 1 filter paper of 90 mm of diameter. The filtrates were transferred to Eppendorf tubes which were centrifuged for 10 min at a speed of 8900×g and 4 °C. Soluble carbohydrates were determined from the centrifuged samples by the Dubois method and reducing carbohydrates by the DNS method.

2.5 Determination of total carbohydrates

Total carbohydrate was estimated using the phenol-sulfuric acid method described by Dubois et al. [18]. The process involved the successive addition of 1 mL 5% (w/v) phenol and 5 mL concentrated sulfuric acid (98% w/w) to 1 mL of samples. The mixture was then well shaken and cooled to 25 °C after a standing period of 10 min. The developed color was read at 490 nm, and the amount of total carbohydrate was determined using the calibration curve constructed with different working standards of glucose from 0 to 1000 mg/L.

2.6 Determination of reducing carbohydrates

Reducing carbohydrates were determined calorimetrically by the dinitrosalicylic acid (DNS) method [19]. To the properly diluted sample, DNS reagent was added followed by heating in a water bath and further addition of Rochelle salt solution (40% (w/v). The absorbance was taken at 510 nm after cooling the mixture under running water. Reducing carbohydrates were estimated from the standard curve of glucose prepared by plotting the absorbance of different known concentrations of working solutions against their concentration.

2.7 Prebiotic activity

To verify the prebiotic capacity of the macerates, an in vitro digestion study was carried out simulating the small intestine. The experiment was performed according to one described by Molly et al. [20] with modifications. Total carbohydrates were calculated to determine the amount of macerate to be used in each test. The medium was prepared by adding the volume of the filtrate obtained from each macerate necessary to provide 1 g/L of carbon source, and in the case of the control experiment, 1 g/L of inulin was added. The total volume of the medium was 35 mL containing 3 g of yeast extract, 1 g of proteose-peptone, 0.4 g of NaHCO3, 0.08 g of NaCl, 0.04 g of K2HPO4, 0.008 g of CaCl2, 0.008 g of MgSO4 • 7H2O, 0.04 g of bile salts, and 1 mL/L of Tween 80. The pH was adjusted to 7.2 with 0.1 N HCl or 0.1N NaOH depending on the initial pH level. The flasks were pasteurized at 90 °C for 10 min in an autoclave. The media were inoculated with 1 × 107 cfu/mL of Lactobacillus casei Shirota. The flasks were kept at 37 °C for 48 h with shaking at 150 rpm in an orbital shaker. Viable count of probiotics was determined by plating on MRS agar (DifcoTM). Subsequent dilutions of the fermented media were made to a final dilution of 1 × 10−6 and 100 μL of each dilution was taken and placed in Petri plates with MRS agar. Finally, they were incubated at 37 °C, under anaerobic conditions for 72 h. Plate count was performed for all macerates obtained and was carried out in duplicate. The carbon source consumption was determined by measuring total carbohydrates using the phenol-sulfuric acid method.

3 Results

3.1 Compositional analysis of barley straw

The initial analysis of the barley straw revealed a humidity of 7.0% ± 0.16, total carbohydrates of 80.4%, and a concentration of reducing carbohydrates of 48%. The humidity value is comparable with that obtained by Contreras et al. [21] and Plazonic et al. [22]. Barley straw with a moisture content of less than 15% is known to be less susceptible to fungal contamination. On the other hand, Nasehi et al. [23] reported concentrations of total carbohydrates and fermentable carbohydrates (reducing) very similar to those obtained in this investigation (77.17% and 54.92%, respectively). From these analyses, the physicochemical changes in fermentation were observed.

3.2 Solid-state fermentation

3.2.1 Spore concentration of Rhizopus oryzae JCP024

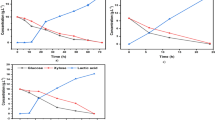

To carry out the solid-state fermentation study, the humidity was adjusted to 50%. Ezeilo et al. [24] showed that this adjusted humidity percentage is optimum for the growth of Rhizopus oryzae. The spore concentration of the starter solution was 40.5 ± 0.7 spores mL−1. After inoculating the straw with the starter solution, measurements were made once a week and the results are seen in Fig. 1.

From week 2, a significant increase was observed until week 4, compared to the concentration of spores in week 1. This concentration remained constant until week 7. The solid-state fermentation studies for the saccharification of barley straw have generally been made with macroscopic fungi. Nasehi et al. [25] determined that barley straw served as a means of containment for the growth and development of macroscopic fungi when the fermentation process was carried out for up to 34 days. On the other hand, the enzymatic activity of macroscopic fungi developed in barley straw undergoes an increase during solid-state fermentations up to 24 days [25]. However, in the case of the use of microscopic fungi such as Aspergillus oryzae to ferment barley straw, significant changes have been reported after 20 days [26] and after 7 days with Aspergillus fumigatus, when barley straw is pretreated with acids [27].

3.3 pH changes

Changes in pH during 7 weeks of fermentation are observed in Table 1. The final pH value was not significantly different compared to the initial, although some changes were observed during the process. These results are consistent with those informed by other authors [28, 29]. Wang et al. [28] reported that after 36 h of cereal fermentation by R. oryzae, pH changes observed were not significant. The changes were observable only during the first hours, and later, there was an increase over time. Blakeman et al. [29] have also reported this behavior; these authors observed a decrease in pH values during the first 36 h with a recovery of the initial pH value after 56 h in cereal fermentation at 22.5 °C.

3.4 Carbohydrate concentration changes (reducing and non-reducing)

Table 2 shows the changes found in the percentage of the remaining non-reducing carbohydrates and the concentration of reducing carbohydrates during the fermentation of barley straw for 7 weeks. The percentage of non-reducing remaining carbohydrates reached 28.49% after the 7 weeks of fermentation. The decrease was gradual during the fermentation time and no decrease in the metabolic activity of the fungus was observed. Likewise, an increase in the concentration of reducing carbohydrates was observed until week 3. This concentration remained stable until week 5, which increased again until week 6, and in week 7, no significant differences were found with the concentration. In general, the data on the decrease in the concentration of total carbohydrates corresponded to the increase in reducers.

In potato waste fermentation studies, R. oryzae is capable of breaking down complex carbohydrate chains by up to 44% during 36 h with the consequent accumulation of up to 2 g/L of reducing carbohydrates [30]. On the other hand, it is known that the saccharification of cellulose and hemicellulose of barley straw in biomass is due to the xylanase and cellulase capacity of microscopic fungi such as Aspergillus fumigatus, which is capable of accumulating up to 0.8 g/L of reducing carbohydrates in 140 h [27]. In the same sense, R. oryzae has been used for its lignocellulosic and cellulosic capacity for the production of glucose derived from the fractionation of complex carbohydrates from agro-industrial residues [31, 32].

3.5 Prebiotic capacity evaluation

Table 3 shows the results of carbohydrate consumption by L. casei Shirota. The results show the consumption of carbohydrates derived from the macerates of the different days of fermentation. Due to the high content of glucose chains (glucooligosaccharides), these macerates are used by probiotic for their development [33].

Results showed the effectiveness of the fermented barley straw macerates in the growth and maintenance of the probiotic. The survival test indicated that L. casei Shirota had growths comparable to those obtained with the inulin control. L. casei concentration was maintained at 11 logarithmic cycles (except for the macerate count of week 2, which presented a higher count), which means that in all the macerates, there were sufficient carbohydrates to keep the microorganism viable at these levels at the same way of inulin results. This carbon source has long been used due to its proven prebiotic capacity [34, 35] stimulating the growth and maintenance of probiotics mainly in dairy products. When comparing the results obtained between the macerates obtained and inulin, it is observed that this stimulating growth effect occurs in both cases. However, since the macerates are not purified carbon sources, they could have other compounds (e.g., mineral salts) that might influence the probiotic growth. Despite this, the results of carbohydrate consumption showed that the development of the microorganism is mainly due to the type of carbon source in the medium used. Escamilla-Lozano et al. [36] tested a medium similar to that used in our research, with and without a carbon source, to determine the influence of different sources of carbon on the growth of L. casei Shirota. These authors found that the medium without a carbon source was not able to stimulate the growth of the probiotic, although the initial concentration of inoculated probiotic remained constant. According to Huebner et al. [37], lactobacilli have the ability to ferment prebiotic carbohydrates, which is dependent on the substrate. Likewise, Makras et al. [38] demonstrated the production of both fructosidases and glucosidases in order to fractioned fructo- and glucooligosaccharides.

The present study has demonstrated the prebiotic capacity of macerates obtained after fermentation of barley straw whit Rhizopus oryzae JCP024. This study is the first to propose the use of agricultural waste to obtain a potentially prebiotic material. Many other studies done with barley have shown the ability of this germinated or fermented cereal to enhance the selective growth of probiotic bacteria [33, 39, 40].

The modulation of the human intestinal microbiota using prebiotics is one of the fields of application of this type of study. It is known that the intestinal microbiota plays a preponderant role in human health, which can be benefited by reducing the risk of colorectal cancer [41]. Based on the data obtained through this study, the prebiotic potential of barley straw, considered as agricultural waste, is determined by the activation that their fermented macerates exert over probiotic growth founding in the composition of the intestinal microbiota and for their use as a functional ingredient in symbiotic food.

4 Conclusion

Barley straw is a suitable substrate for the development of spores and growth of Rhizopus oryzae JCP024 due to its water activity and carbohydrate concentration. There is no direct relationship between pH changes and total carbohydrate degradation during the development of spores. On the contrary, there is a correlation between the production of reducing carbohydrates and the degradation of total carbohydrates measured as the remaining total carbohydrate concentration during the fermentation process. Barley straw macerates fermented with R. oryzae JCP024 stimulate the growth of L. casei Shirota in a minimal medium in a similar way to inulin, a prebiotic par excellence. The fractionation of cellulose by R. oryzae provoque leads to the formation of complex glucose chains that are being used by probiotics due to their glucosidase capacity. Further research is needed to demonstrate the endoglucanase activity due to the increase in the concentration of carbohydrates and its correlation with fungus growth. Macerates from solid fermentation of barley straw have potential as prebiotics for their use as raw material in the manufacture of symbiotic food.

References

Davani-Davari D, Negahdaripour M, Karimzadeh I, Seifan M, Mohkam M, Masoumi SJ, Berenjian A, Ghasemi Y (2019) Prebiotics: definition, types, sources, mechanisms, and clinical applications. Foods 8(3). https://doi.org/10.3390/foods8030092

Whisner CM, Castillo LF (2018) Prebiotics, bone and mineral metabolism. Calcif Tissue Int 102(4):443–479

Nayak A, Bhushan B (2019) An overview of the recent trends on the waste valorization techniques for food wastes. J Environ Manage 233:352–370

Xu J, Liu B, Wu L, Hu J, Hou H, Yang J (2019) A waste-minimized biorefinery scenario for the hierarchical conversion of agricultural straw into prebiotic xylooligosaccharides, fermentable sugars and lithium-sulfur batteries. Ind Crops Prod 129:269–280

Guo Z, Zhao B, Li H, Miao S, Zheng B (2019) Optimization of ultrasound-microwave synergistic extraction of prebiotic oligosaccharides from sweet potatoes (Ipomoea batatas L.). Innov Food Sci Emerg Technol 54:51–63

Li S, Wu Q, Yin F, Zhu Z, He J, Barba FJ (2018) Development of a combined trifluoroacetic acid hydrolysis and HPLC-ELSD method to identify and quantify inulin recovered from Jerusalem artichoke assisted by ultrasound extraction. Appl Sci 8(5):710

Machado MTC, Eça KS, Vieira GS, Menegalli FC, Martínez J, Hubinger MD (2015) Prebiotic oligosaccharides from artichoke industrial waste: evaluation of different extraction methods. Ind Crops Prod 76(1):141–148

Lee S, Park J, Jang JK, Lee BH, Park YS (2019) Structural analysis of gluco-oligosaccharides produced by Leuconostoc lactis and their prebiotic effect. Molecules 24(1):3998

Black BA, Lee VSY, Zhao YY, Hu Y, Curtis JM, Gänzle MG (2012) Structural identification of novel oligosaccharides produced by Lactobacillus bulgaricus and Lactobacillus plantarum. J Agric Food Chem 60(18):4886–4894

Hanson S, Best M, Bryan MC, Wong CH (2004) Chemoenzymatic synthesis of oligosaccharides and glycoproteins. Trends Biochem Sci 29(12):656–663

Pérez-Escalante E, Alatorre-Santamaría S, Castañeda-Ovando A, Salazar-Pereda V, Bautista-Ávila M, Cruz-Guerrero AE, Flores-Aguilar JF, González-Olivares LG (2020) Human milk oligosaccharides as bioactive compounds in infant formula: recent advances and trends in synthetic methods. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2020.1813683

Sawangwan T, Saman P (2016) Prebiotic synthesis from rice using Aspergillus oryzae with solid-state fermentation. Agric Nat Resour 50(4):227–231

Abdel-Satera MA, El-Said AHM (2001) Xylan-decomposing fungi and xylanolytic activity in agricultural and industrial wastes. Int Biodeterior Biodegrad 47(1):15–21

Singh R, Kumar M, Mittal A, Mehta PK (2017) Microbial metabolites in nutrition, healthcare and agriculture. 3 Biotech 7(15). https://doi.org/10.1007/s13205-016-0586-4

Rodrigues THS, Dantas MAA, Pinto GAS, Alves, Goncalves LRB (2002) Tannase production by solid state fermentation of cashew apple bagasse. In: Mielenz JR, Klasson KT, Adney WS, McMillan JD (eds) Applied biochemistry and biotecnology. Springer, Heidelberg, pp 675–688

Gómez-Noguez F, Pérez-García B, Mehltreter K, Orozco-Segovia A, Rosas-Pérez I (2016) Spore mass and morphometry of some fern species. Flora 223:99–105

Sandhu KS, Punia S (2017) Enhancement of bioactive compounds in barley cultivars by solid substrate fermentation. J Food Meas Charact 11(3):1355–1361

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356

Miller GL (1959) Use of dinitrosalicylic acid for determination of sugars. Anal Chem 31:425–428

Molly K, Vande Woestyne M, Verstraete W (1993) Development of a S-step multi-chamber reactor as a simulation of the human intestinal microbial ecosystem. Appl Microbiol Biotechnol 39(2):254–258

Contreras LE, Jaimez OJ, Hernández MT, Añorve MJ, Beltran HR (2008) Composición química de cebadas cultivadas bajo diferentes condiciones de labranza en tres localidades del Estado de Hidalgo, México. Bioagro 20(3):201–208

Plazonic I, Zeljka Barbaricc-Mikoccevic Z, Antonovic A (2016) Chemical composition of straw as an alternative material to wood raw material in fibre isolation. DRVNA INDUSTRIJA 67(2):119–125

Nasehi M, Torbatinejad NM, Zerehdaran S, Safaei AR (2014) Effect of (Pleurotus florida) fungi on chemical composition and rumen degradability of wheat and barley straw. Iran J Appl Anim Sci 4(2):257–261

Ezeilo UR, Wahab RA, Mahat NA (2020) Optimization studies on cellulase and xylanase production by Rhizopus oryzae UC2 using raw oil palm frond leaves as substrate under solid state fermentation. Renew Energy 156:1301–1312

Nasehi M, Torbatinejad NM, Zerehdaran S, Safaie AR (2017) Effect of solid-state fermentation by oyster mushroom (Pleurotus florida) on nutritive value of some agro by-products. J Appl Anim Res 45(1):221–226

Saman P, Chaiongkarn A, Moonmangmee S, Artjariyasripong S (2012) Prebiotic isomalto-oligosaccharide production from economic crops of Thailand. KKU Res J 17(5):794–799

Lin C, Shen Z, Qin W (2017) Characterization of xylanase and cellulase produced by a newly isolated Aspergillus fumigatus N2 and its efficient saccharification of barley straw. Appl Biochem Biotechnol 182(2):559–569

Wang K, Niu M, Song D, Liu Y, Wu Y, Zhao J, Li S, Lu B (2020) Evaluation of biochemical and antioxidant dynamics during the co-fermentation of dehusked barley with Rhizopus oryzae and Lactobacillus plantarum. J Food Biochem 44(2):e13106. https://doi.org/10.1111/jfbc.13106

Blakernan JP, McCracken AR, Seaby DA (1988) Changes brought about in solid substrates after fermentations of mixtures of cereals and pulses with Rhizopus oryzae. J Sci Food Agric 45(2):109–118

Huang LP, Jin B, Lant P, Zhou J (2005) Simultaneous saccharification and fermentation of potato starch wastewater to lactic acid by Rhizopus oryzae and Rhizopus arrhizus. Biochem Eng J 23(3):265–276

Zhang L, Li X, Yong Q, Yang ST, Ouyang J, Yu S (2015) Simultaneous saccharification and fermentation of xylo-oligosaccharides manufacturing waste residue for l-lactic acid production by Rhizopus oryzae. Biochem Eng J 94:92–99

Zhang L, Li X, Yong Q, Yang ST, Ouyang J, Yu S (2016) Impacts of lignocellulose-derived inhibitors on L-lactic acid fermentation by Rhizopus oryzae. Bioresour Technol 203:173–180

Bamba T, Kanauchi O, Andoh A, Fujiyama Y (2002) A new prebiotic from germinated barley for nutraceutical treatment of ulcerative colitis. J Gastroenterol Hepatol 17:818–824

Collins MD, Gibson GR (1999) Probiotics, prebiotics, and synbiotics: approaches for modulating the microbial ecology of the gut. Am J Clin Nutr 69:1052S–1057S

Kolida S, Gibson GR (2007) Prebiotic capacity of inulin-type fructans. J Nutr 137:2503S–2506S

Escamilla-Lozano Y, García-Garibay M, López-Munguía-Canales A, Gómez-Ruiz L, Rodríguez-Serrano G, Cruz-Guerrero A (2015) Shyntesis of a-L-fucosidase in different strains of lactic acid bacteria. Rev Mex Ing Quím 14(3):623–629

Huebner J, Wehling RL, Hutkins RW (2007) Functional activity of commercial prebiotics. Int Dairy J 17(7):770–775

Makras L, Van Acker G, De Vuyst L (2005) Lactobacillus paracasei subsp. paracasei 8700:2 degrades inulin-type fructans exhibiting different degrees of polymerization. Appl Environ Microbiol 71(11):6531–6537

Salmeron I (2017) Fermented cereal beverages: from probiotic, prebiotic and synbiotic towards nanoscience designed healthy drinks. Lett Appl Microbiol 65:114–124

Kanauchi O, Serizawa I, Araki Y, Suzuki A, Andoh A, Fujiyama Y, Mitsuyama K, Takaki K, Toyonaga A, Sata M, Bamba T (2003) Germinated barley foodstuff, a prebiotic product, ameliorates inflammation of colitis through modulation of the enteric environment. J Gastroenterol 38(2):134–141

Wong SH, Yu J (2019) Gut microbiota in colorectal cancer: mechanisms of action and clinical applications. Nat Rev Gastroenterol Hepatol 16:690–704

Acknowledgements

The authors thank David Juarez Balderas for their excellent technical support and to “Productores de cebada de Apan” for providing the substrate.

Funding

This work was part of a project based on valorization of barley straw with any financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of novelty

Barley straw is an agro-industrial waste with high technological value. Its chemical composition includes a high content of oligosaccharides especially cellulose and hemicellulose. In spite of that, it is used almost exclusively for animal feeding. The relevance of this work is the use of barley straw as a source of potential prebiotic after saccharification by R. oryzae JCP024 during a solid-state fermentation. The recovery of agricultural residue as part of waste management is a relevant issue in the implementation of biorefineries. This research is the beginning in a process of valorization of barley straw and it is the first study to demonstrate the activation of probiotic growth by macerates derived from barley straw saccharified.

Rights and permissions

About this article

Cite this article

Jaimez-Ordaz, J., Contreras-López, E., Ramírez-Godínez, J. et al. Prebiotic potential of macerates derived from solid-state fermentation of barley straw by Rhizopus oryzae JCP024: preliminary evaluation. Biomass Conv. Bioref. 13, 4797–4802 (2023). https://doi.org/10.1007/s13399-021-01395-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01395-z